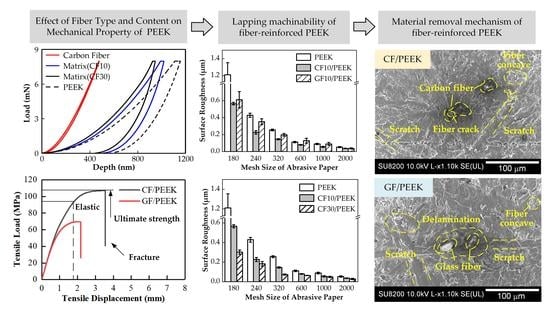

Effect of Fiber Type and Content on Mechanical Property and Lapping Machinability of Fiber-Reinforced Polyetheretherketone

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Material Property Tests

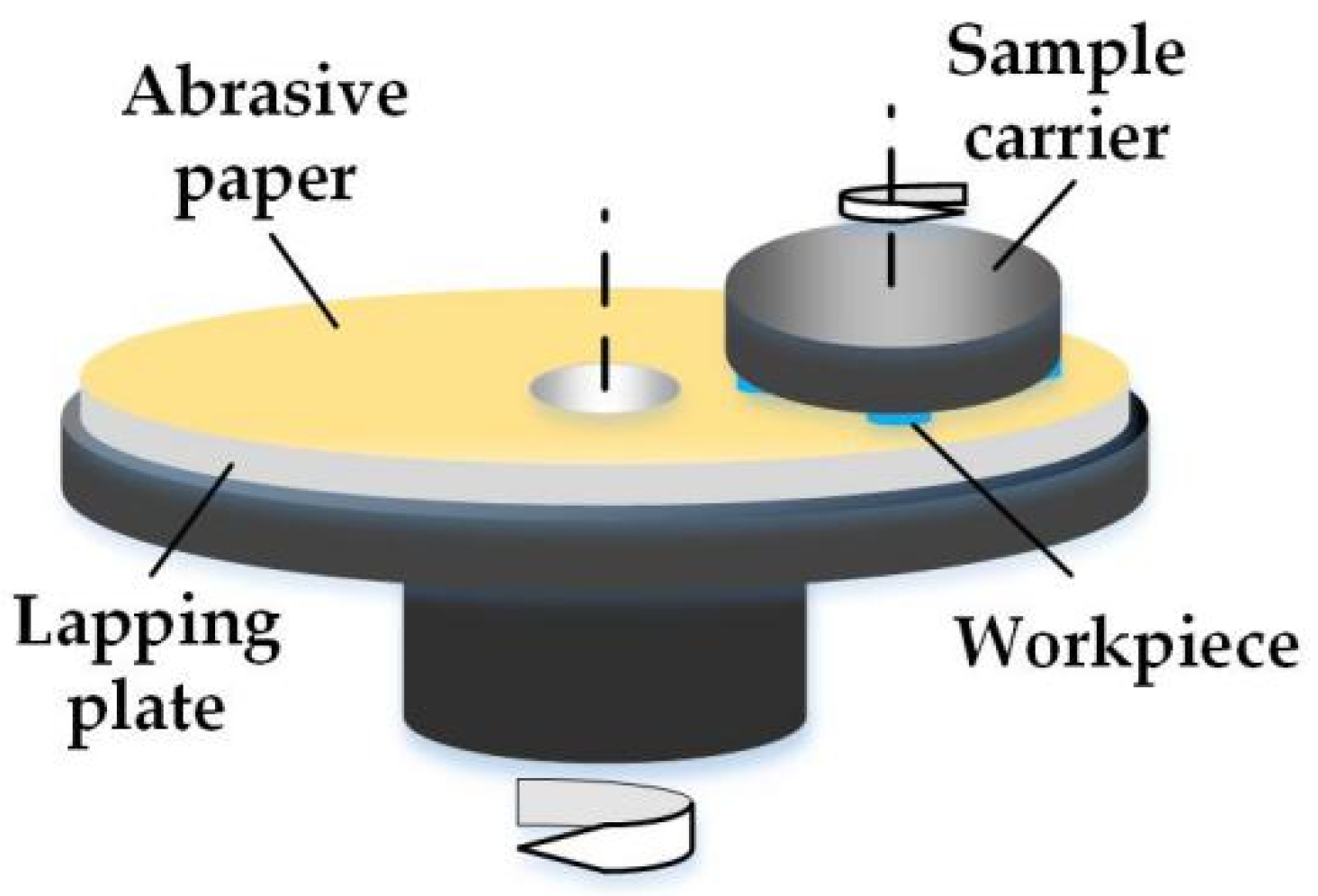

2.2.2. Lapping Experiment Details

3. Results

3.1. Material Properties of Fiber-Reinforced PEEK

3.1.1. Nanomechanical Properties of Fiber-Reinforced PEEK

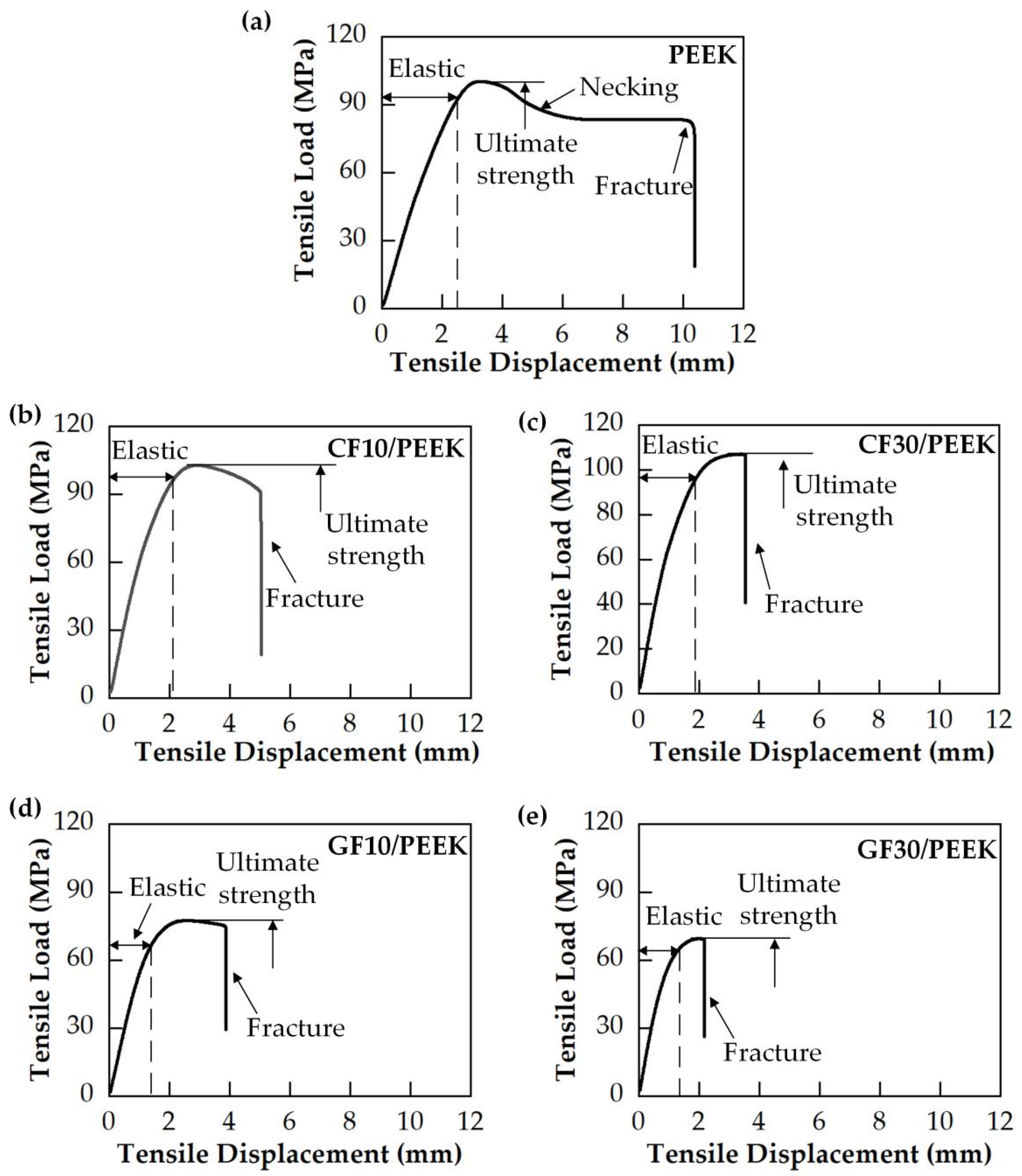

3.1.2. Tensile Mechanical Properties of Fiber-Reinforced PEEK

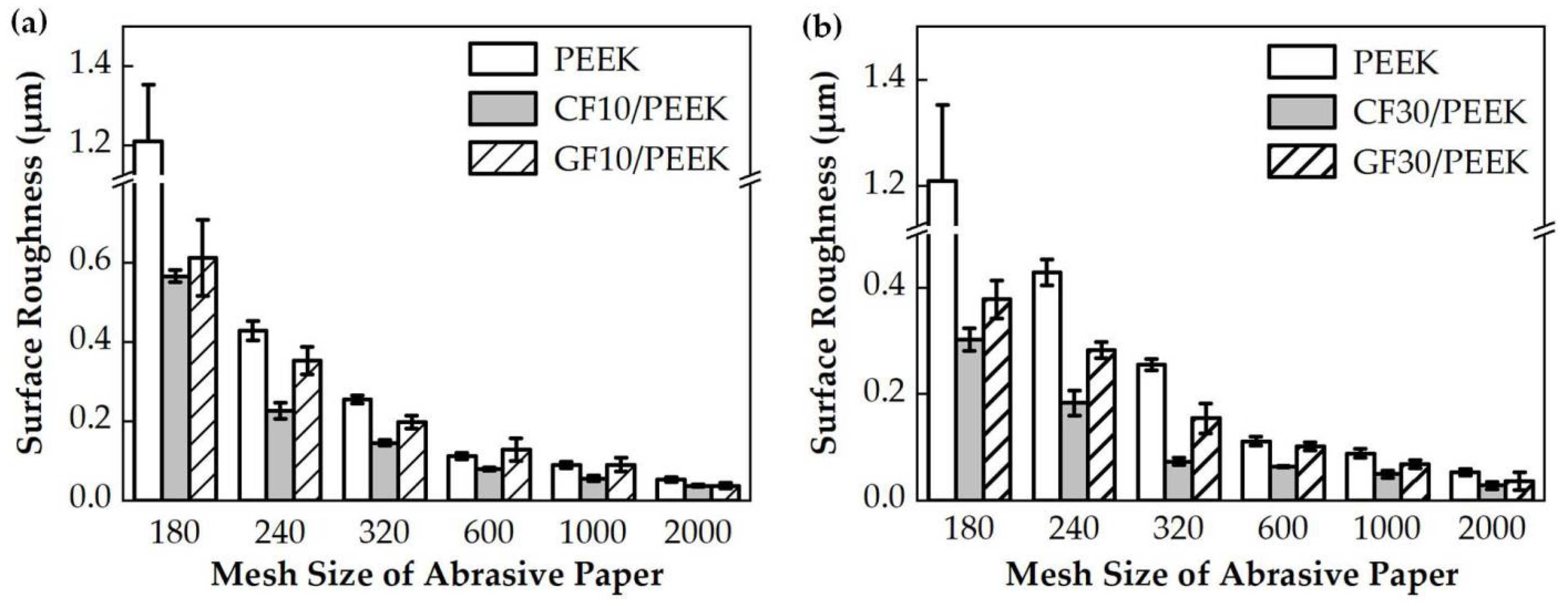

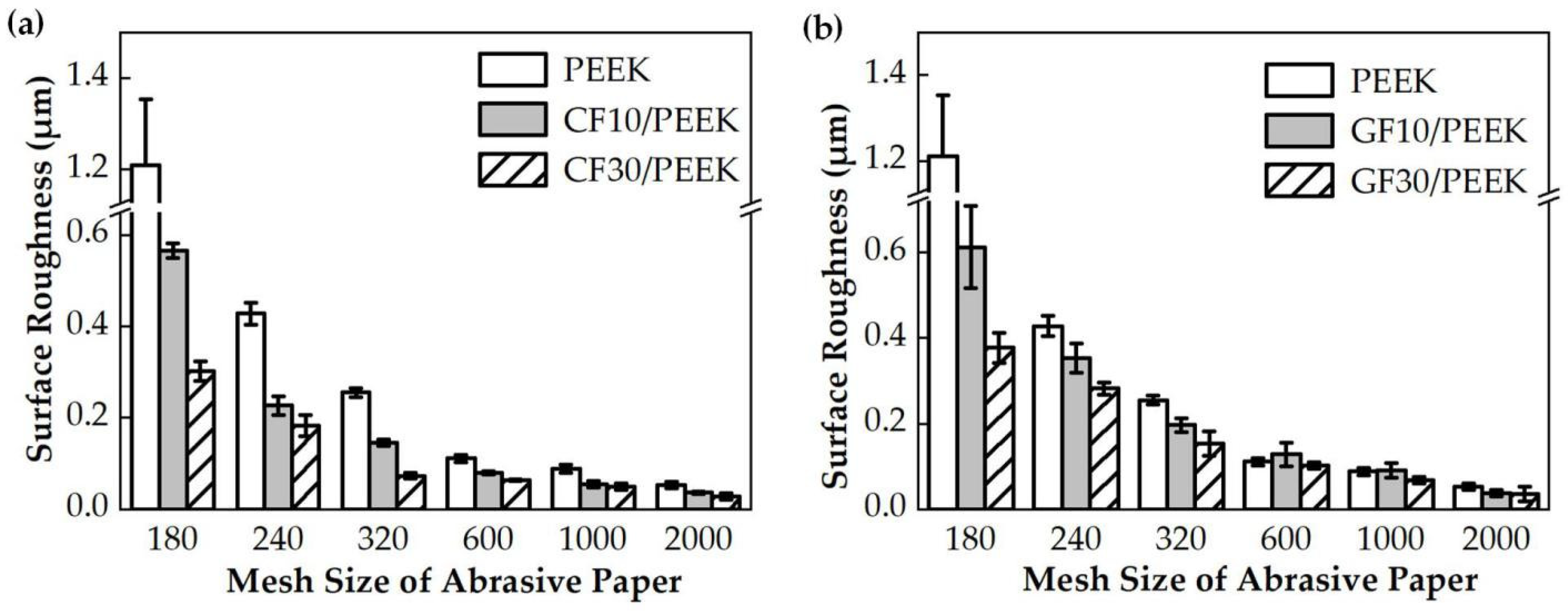

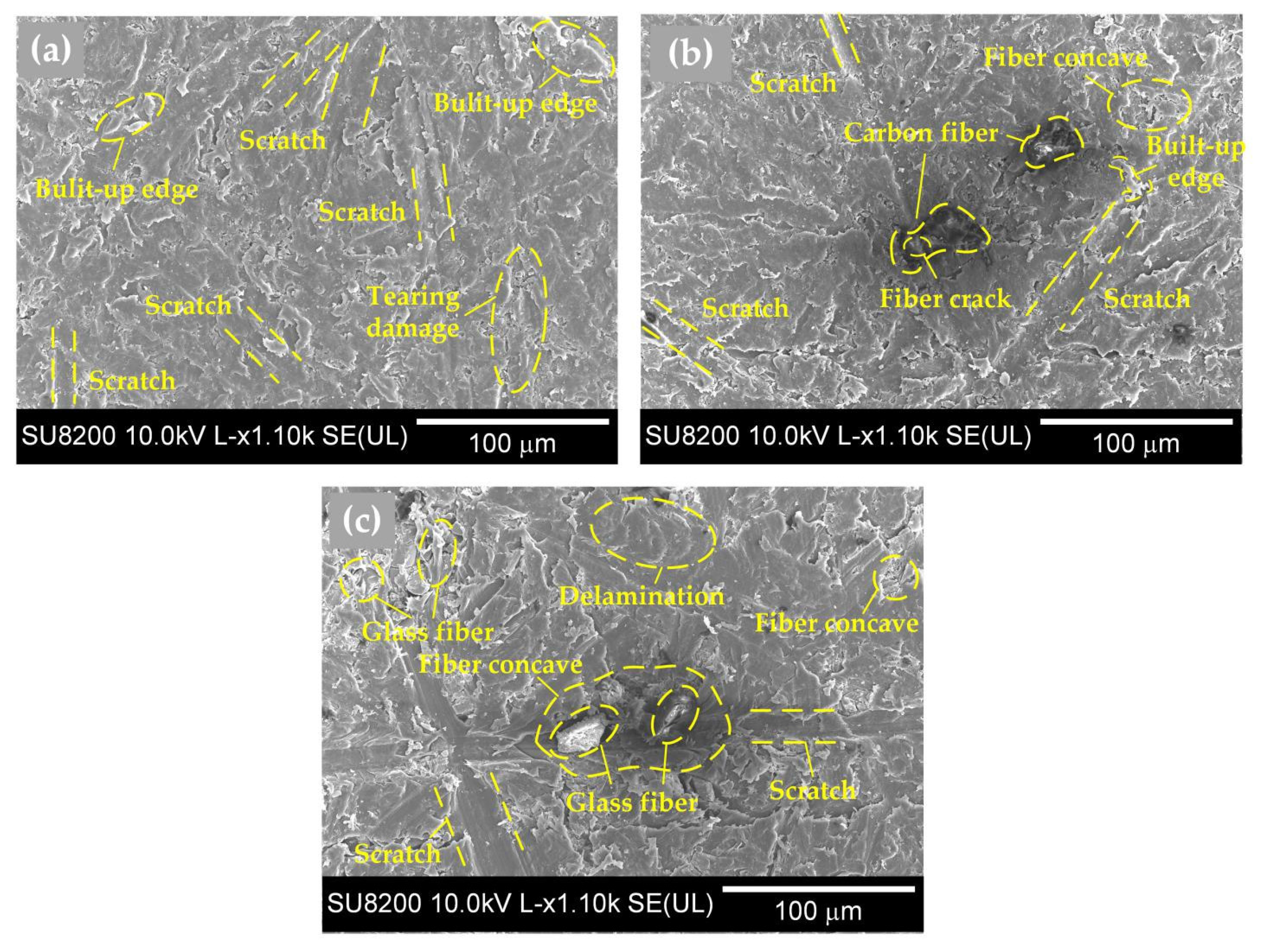

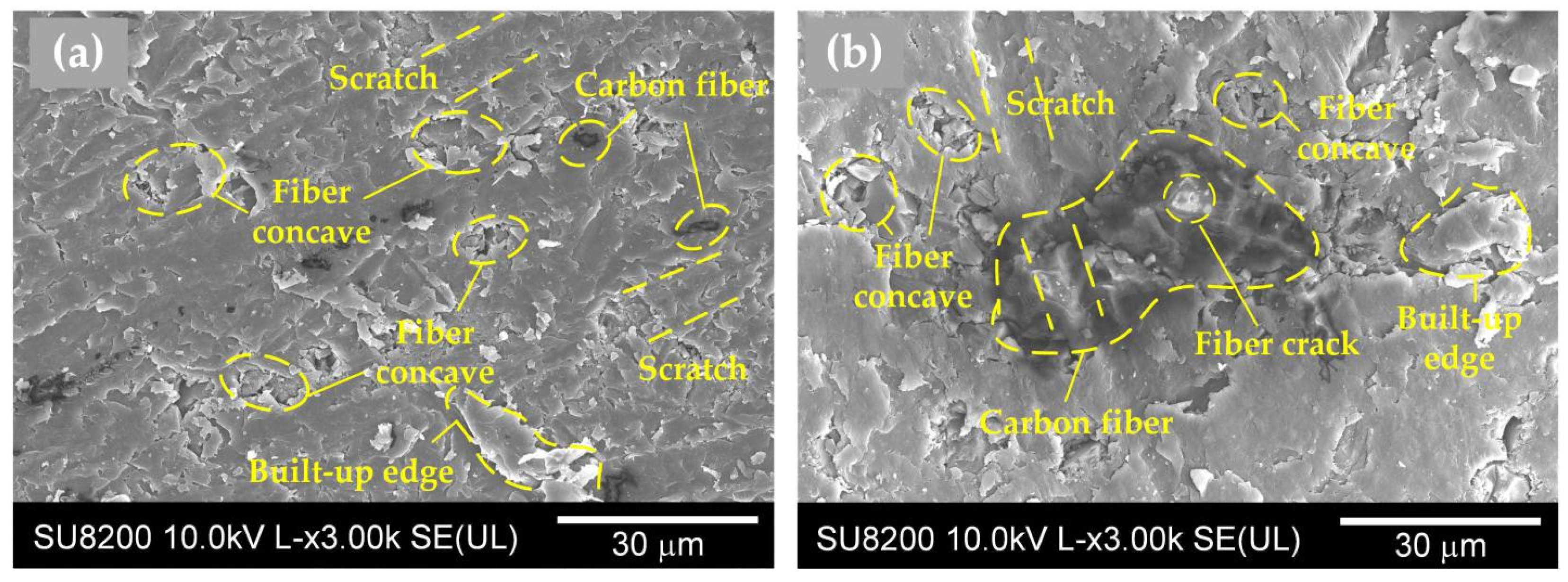

3.2. Lapping Processing Properties of Fiber-Reinforced PEEK

4. Discussion

4.1. The Influence of Fiber Types on Lapping Machinability of Fiber-Reinforced PEEK Materials

4.2. The Influence of Fiber Mass Fraction on Lapping Machinability of Fiber-Reinforced PEEK Materials

5. Conclusions

- (1)

- In terms of material properties for CF/PEEK, carbon fiber has high hardness and modulus and is evenly distributed inside the material. Thus, the tensile strength, hardness, and modulus are improved. For GF/PEEK, the glass fiber is easy to concentrate and form defects inside the material due to its high hardness, modulus, and brittleness. This, in turn, decreases the tensile strength and improves the hardness and modulus. The influences on tensile strength and nanomechanical properties are more significant as the fiber mass fraction increases.

- (2)

- In the lapping process, fiber-reinforced PEEK has better surface quality, and the MRR is lower than the pure PEEK due to the superior mechanical properties of the fiber. The lapped surface quality of CF/PEEK is better than GF/PEEK. Because the carbon fiber has higher hardness and modulus than the glass fiber, this results in a weaker deformation on the PEEK matrix surface.

- (3)

- The higher the mass fraction is, the more the mechanical properties of fiber-reinforced PEEK are improved. As the fiber reinforcing can improve the lapped surface quality and hardness of the PEEK matrix, the fiber-reinforced PEEK with a higher fiber mass fraction has a better lapped surface quality and lower MRR.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mate, F.; Gaitonde, V.N.; Karnik, S.R.; Davim, J.P. Influence of cutting conditions on machinability aspects of PEEK, PEEK CF 30 and PEEK GF 30 composites using PCD tools. J. Mater. Process. Technol. 2009, 209, 1980–1987. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Arevalo, S.E.; Pruitt, L.A. Nanomechanical analysis of medical grade PEEK and carbon fiber-reinforced PEEK composites. J. Mech. Behav. Biomed. Mater. 2020, 111, 104008. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Qi, L.; Dang, H.; Jin, K.; Thomson, D.; Cui, H.; Li, Y. Biaxial tensile failure of short carbon-fibre-reinforced PEEK composites. Compos. Sci. Technol. 2021, 208, 108764. [Google Scholar] [CrossRef]

- Davim, J.P.; Mata, F.; Gaitonde, V.N.; Karnik, S.R. Machinability evaluation in unreinforced and reinforced PEEK composites using response surface models. J. Thermoplast. Compos. Mater. 2010, 23, 5–18. [Google Scholar] [CrossRef]

- Talbott, M.F.; Springer, G.S.; Berglund, L.A. The effects of crystallinity on the mechanical properties of PEEK polymer and graphite fiber reinforced PEEK. J. Compos. Mater. 1987, 21, 1056–1081. [Google Scholar] [CrossRef]

- Frick, A.; Sich, D.; Heinrich, G.; Lehmann, D.; Gohs, U.; Stern, C. Properties of melt processable PTFE/PEEK blends: The effect of reactive compatibilization using electron beam irradiated melt processable. J. Appl. Polym. Sci. 2013, 128, 1815–1827. [Google Scholar] [CrossRef]

- Qin, W.; Ma, J.; Liang, Q.; Li, J.; Tang, B. Tribological, cytotoxicity and antibacterial properties of graphene oxide/carbon fibers/polyetheretherketone composite coatings on Ti–6Al–4V alloy as orthopedic/dental implants. J. Mech. Behav. Biomed. Mater. 2021, 122, 104659. [Google Scholar] [CrossRef]

- Li, F.; Hu, Y.; Hou, X.; Hu, X.; Jiang, D. Thermal, mechanical, and tribological properties of short carbon fibers/PEEK composites. High Perform. Polym. 2018, 30, 657–666. [Google Scholar] [CrossRef]

- Najim, A.S.; Adwaa, M. Studying mechanical properties specially fatigue behavior of (polyether ether ketone)/glass fiber composites in aerospace applications. Appl. Mech. Mater. 2014, 666, 8–16. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.; Yang, C.; Spintzyk, S.; Scheideler, L.; Li, P.; Li, D.; Geis-Gerstorfer, J.; Rupp, F. Carbon fiber reinforced PEEK composites based on 3D-printing technology for orthopedic and dental applications. J. Clin. Med. 2019, 8, 240. [Google Scholar] [CrossRef] [PubMed]

- Zheng, B.; Deng, T.; Li, M.; Huang, Z.; Zhou, H.; Li, D. Flexural behavior and fracture mechanisms of short carbon fiber reinforced polyether-ether-ketone composites at various ambient temperatures. Polymers 2019, 11, 18. [Google Scholar] [CrossRef] [PubMed]

- Díez-Pascual, A.M.; Ashrafi, B.; Naffakh, M.; González-Domínguez, J.M.; Johnston, A.; Simard, B.; Martínez, M.T.; Gómez-Fatou, M.A. Influence of carbon nanotubes on the thermal, electrical and mechanical properties of poly(ether ether ketone)/glass fiber laminates. Carbon 2011, 49, 2817–2833. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P.; Lapa, V.; Antonio, C.C. Machinability study on polyetheretherketone (PEEK) unreinforced and reinforced (GF30) for applications in structural components. Compos. Struct. 2003, 62, 67–73. [Google Scholar] [CrossRef]

- Zhang, L.Z.; Li, M.; Hui, H. Study on mechanical properties of PEEK composites. In Proceedings of the 3rd International Conference on Manufacturing Science and Engineering, Xiamen, China, 27–29 March 2012. [Google Scholar] [CrossRef]

- Ji, S.; Sun, C.; Zhao, J.; Liang, F. Comparison and analysis on mechanical property and machinability about polyetheretherketone and carbon-Fibers reinforced polyetheretherketone. Materials 2015, 8, 4118–4130. [Google Scholar] [CrossRef]

- Ji, S.; Yu, H.; Zhao, J.; Liang, F. Comparison of mechanical property and machinability for polyetheretherketone and glass fiber-reinforced polyetheretherketone. Adv. Mech. Eng. 2015, 7, 1–7. [Google Scholar] [CrossRef]

- Khoran, M.; Amirabadi, H.; Azarhoushang, B. The effects of cryogenic cooling on the grinding process of polyether ether ketone (PEEK). J. Manuf. Process. 2020, 56, 1075–1087. [Google Scholar] [CrossRef]

- Ahn, Y.; Park, S.S. Surface roughness and material removal rate of lapping process on ceramics. KSME Int. J. 1997, 11, 494–504. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hou, L.; Qu, M.; He, J.; Sun, Y.; Wu, L.; Na, F. Study on properties of glass fiber reinforced PEEK composites with different length and diameter ratio. Plast. Sci. Technol. 2018, 46, 41–46. [Google Scholar] [CrossRef]

- Quan, Y.; Yan, Y. Machined surface texture and roughness of composites. Acta Mater. Compos. Sin. 2001, 5, 128–132. [Google Scholar] [CrossRef]

- Kobayashi, A.; Saito, K. On the cutting mechanism of high polymers. J. Polym. Sci. 1962, 58, 1377–1396. [Google Scholar] [CrossRef]

- Rentsch, R.; Inasaki, I. Molecular dynamics simulation for abrasive process. CIRP Ann. 1994, 43, 327–330. [Google Scholar] [CrossRef]

- Mionru, A.; Kazuo, N.; Wang, X.D. Study on the surface intergrity in aluminum reinforced by short fibre. J. Jpn. Soc. Precis. Eng. 1991, 57, 172–177. [Google Scholar] [CrossRef][Green Version]

| Lapping Condition | Value |

|---|---|

| Abrasive | Silicon carbide abrasive paper |

| Mesh size | 180, 240, 320, 600, 1000, 2000 |

| Lapping plate speed (r/min) | 40 |

| Workpiece speed (r/min) | 63 |

| Lapping time (min) | 40 |

| Lapping pressure (KPa) | 11 |

| Sample | PEEK | Carbon Fiber | Glass Fiber |

|---|---|---|---|

| Hardness (GPa) | 0.3 | 3.3 | 2.9 |

| Modulus (GPa) | 5.06 | 16.52 | 26.71 |

| Materials | PEEK | CF10/PEEK | CF30/PEEK | GF10/PEEK | GF30/PEEK |

|---|---|---|---|---|---|

| Ultimate tensile strength (MPa) | 98.1 | 99.5 | 102.6 | 78.6 | 61.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Qu, J.; Li, H.; Kang, R. Effect of Fiber Type and Content on Mechanical Property and Lapping Machinability of Fiber-Reinforced Polyetheretherketone. Polymers 2022, 14, 1079. https://doi.org/10.3390/polym14061079

Gao S, Qu J, Li H, Kang R. Effect of Fiber Type and Content on Mechanical Property and Lapping Machinability of Fiber-Reinforced Polyetheretherketone. Polymers. 2022; 14(6):1079. https://doi.org/10.3390/polym14061079

Chicago/Turabian StyleGao, Shang, Jialu Qu, Honggang Li, and Renke Kang. 2022. "Effect of Fiber Type and Content on Mechanical Property and Lapping Machinability of Fiber-Reinforced Polyetheretherketone" Polymers 14, no. 6: 1079. https://doi.org/10.3390/polym14061079

APA StyleGao, S., Qu, J., Li, H., & Kang, R. (2022). Effect of Fiber Type and Content on Mechanical Property and Lapping Machinability of Fiber-Reinforced Polyetheretherketone. Polymers, 14(6), 1079. https://doi.org/10.3390/polym14061079