Characterization of Alginate–Gelatin–Cholesteryl Ester Liquid Crystals Bioinks for Extrusion Bioprinting of Tissue Engineering Scaffolds

Abstract

:1. Introduction

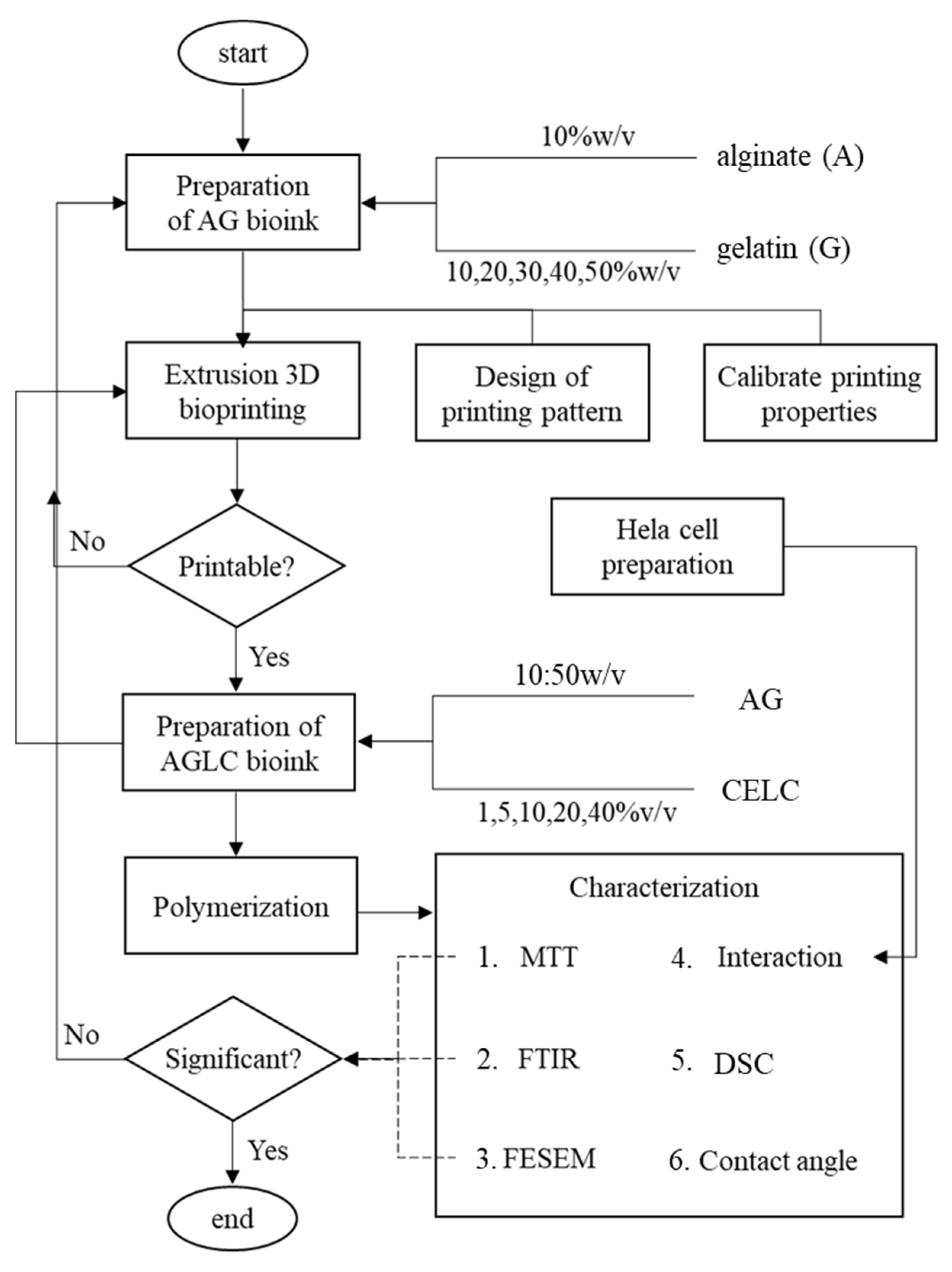

2. Materials and Methods

2.1. Preparation of Materials

2.1.1. Preparation of Alginate–Gelatin (AG) Hydrogels

2.1.2. Preparation of Cholesteryl Ester Liquid Crystals Biomaterial

2.1.3. Preparation of Alginate–Gelatin–CELC

2.1.4. Preparation of Crosslinking Solution Calcium Chloride

2.1.5. Cell Preparation and Subculture

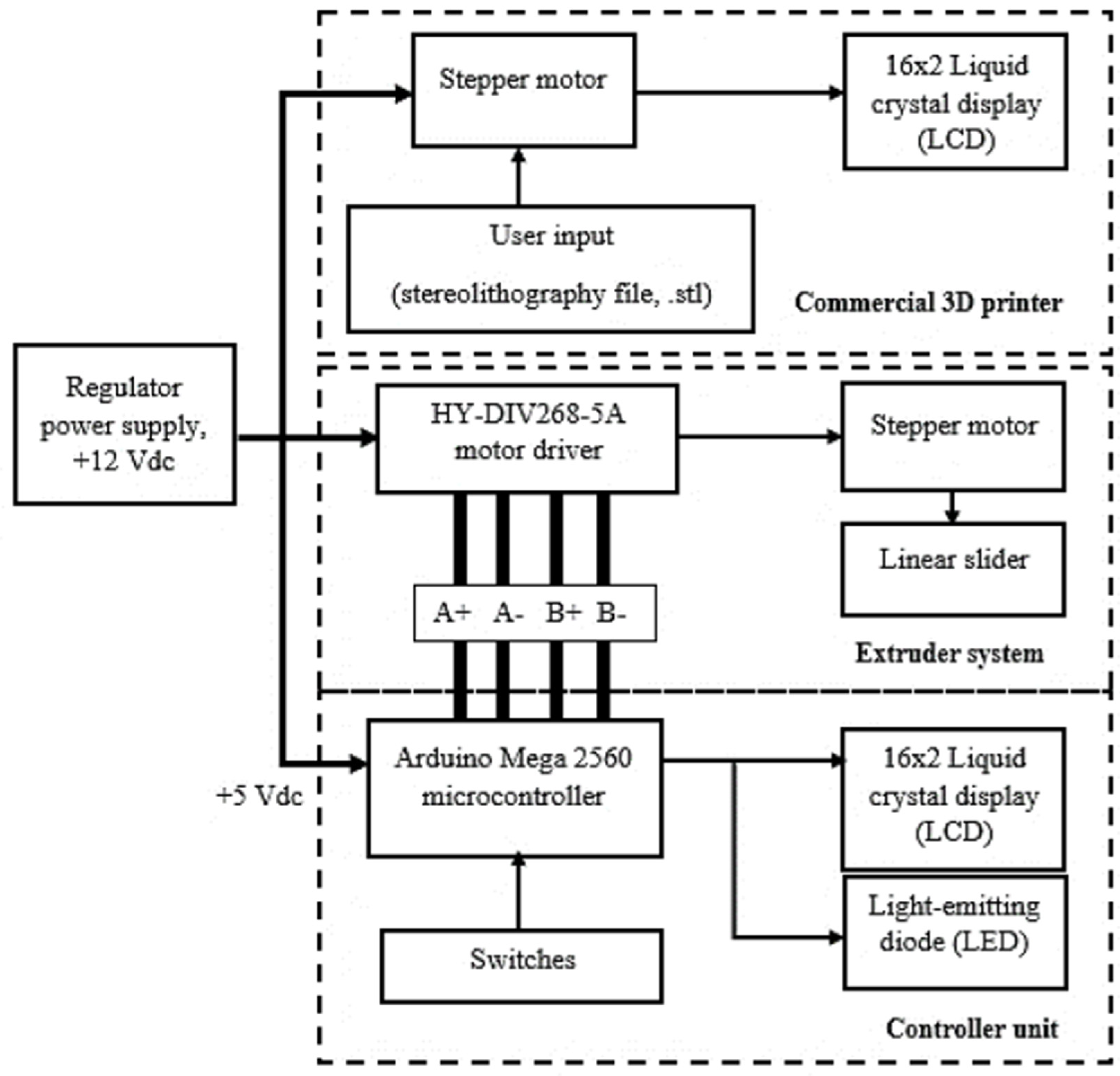

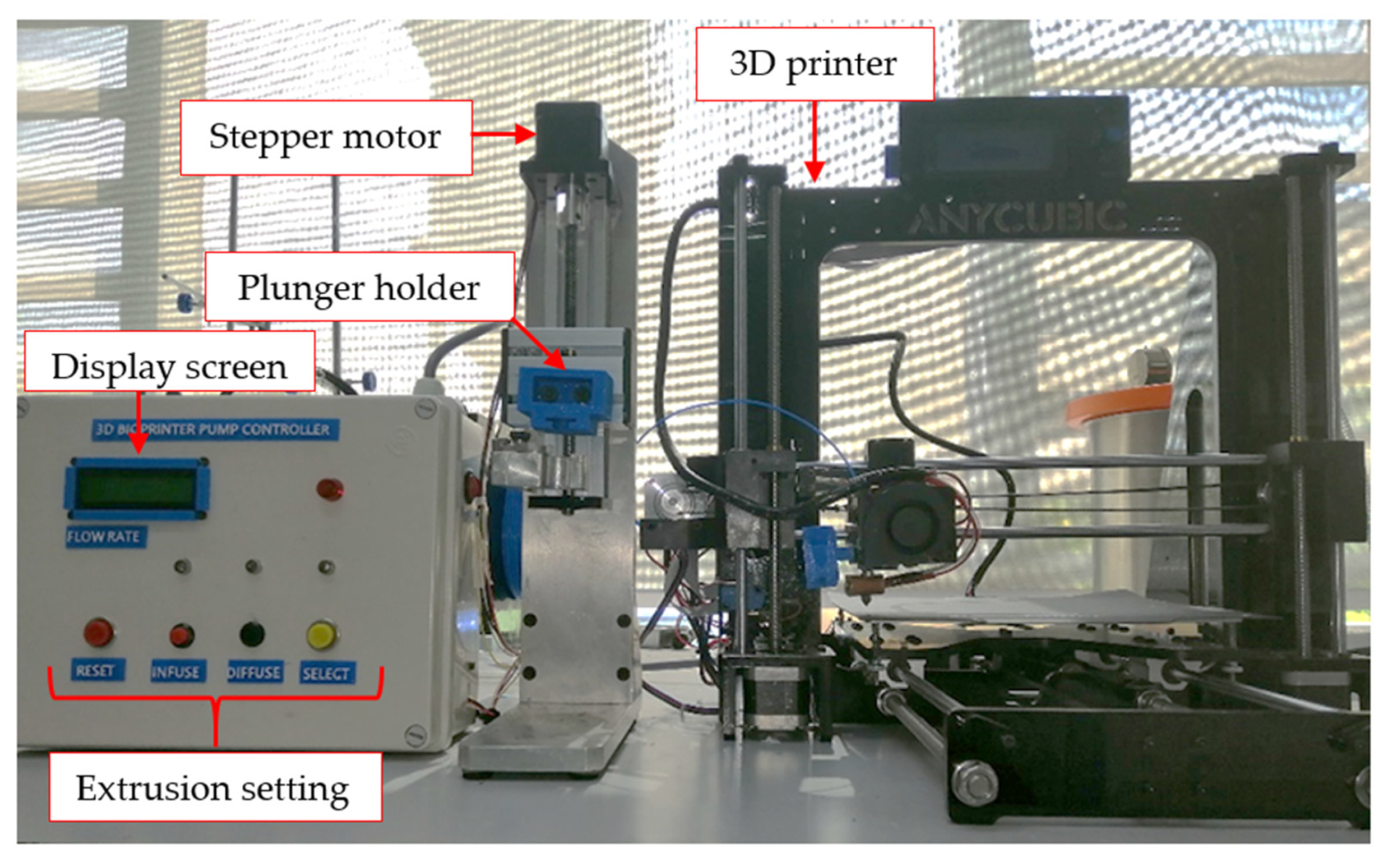

2.2. 3D Printing System

3. Experiments

3.1. Printability Experiments

3.1.1. Printability Experiments of Alginate–Gelatin Hydrogels

3.1.2. Printability Experiments of AGLC Bioinks

3.2. Characterization Experiments

3.2.1. Polymerization

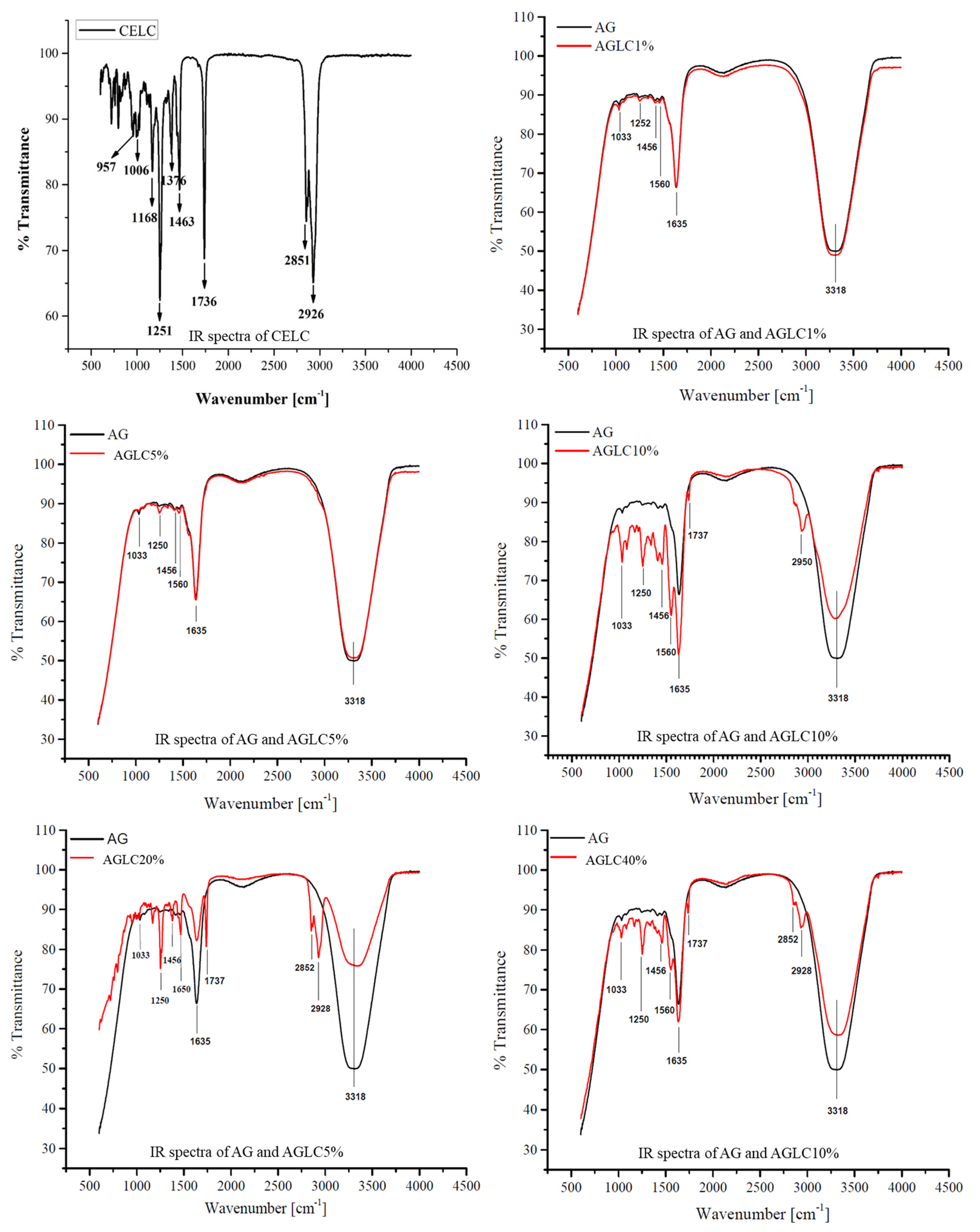

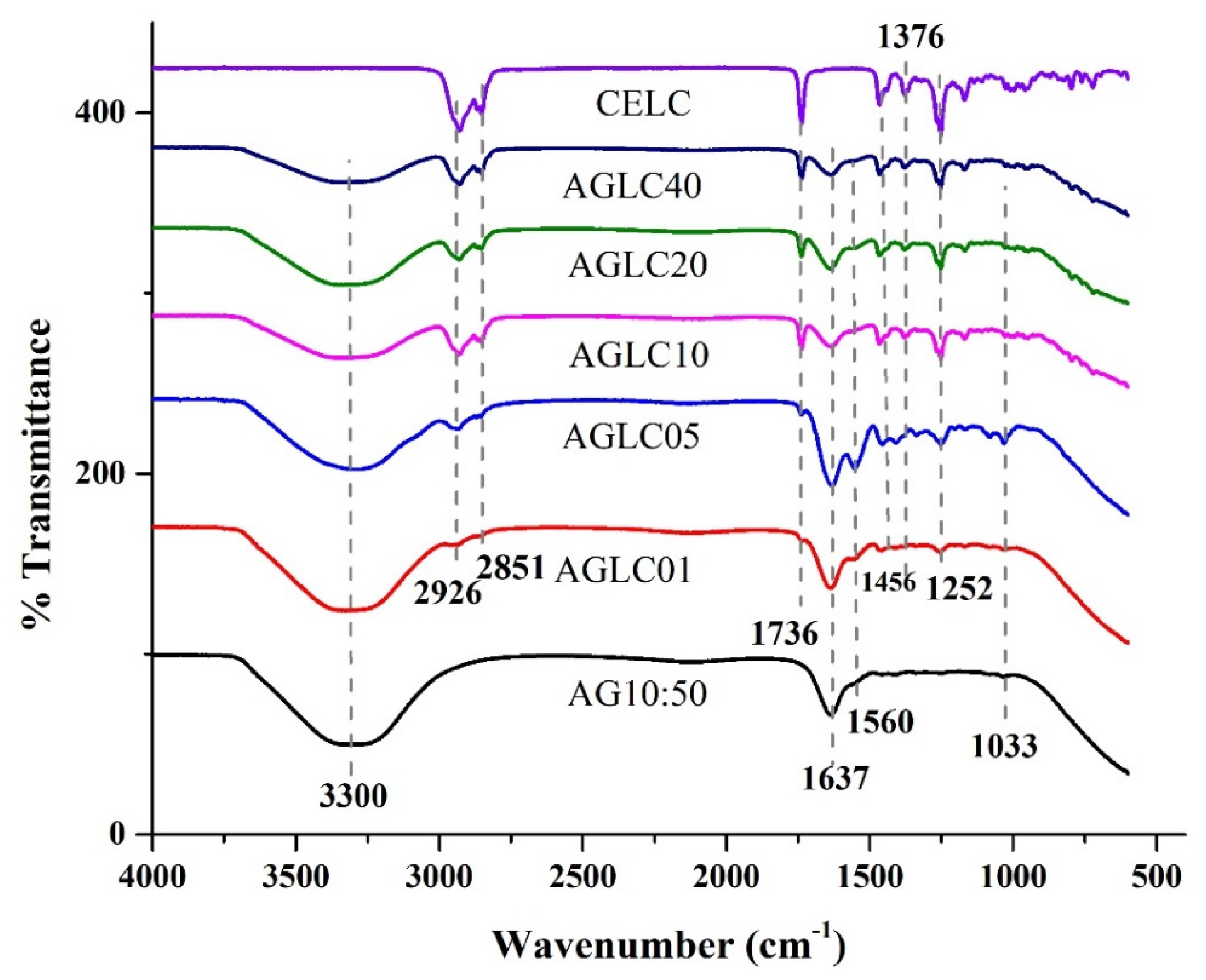

3.2.2. Fourier Transform Infrared Spectroscopy

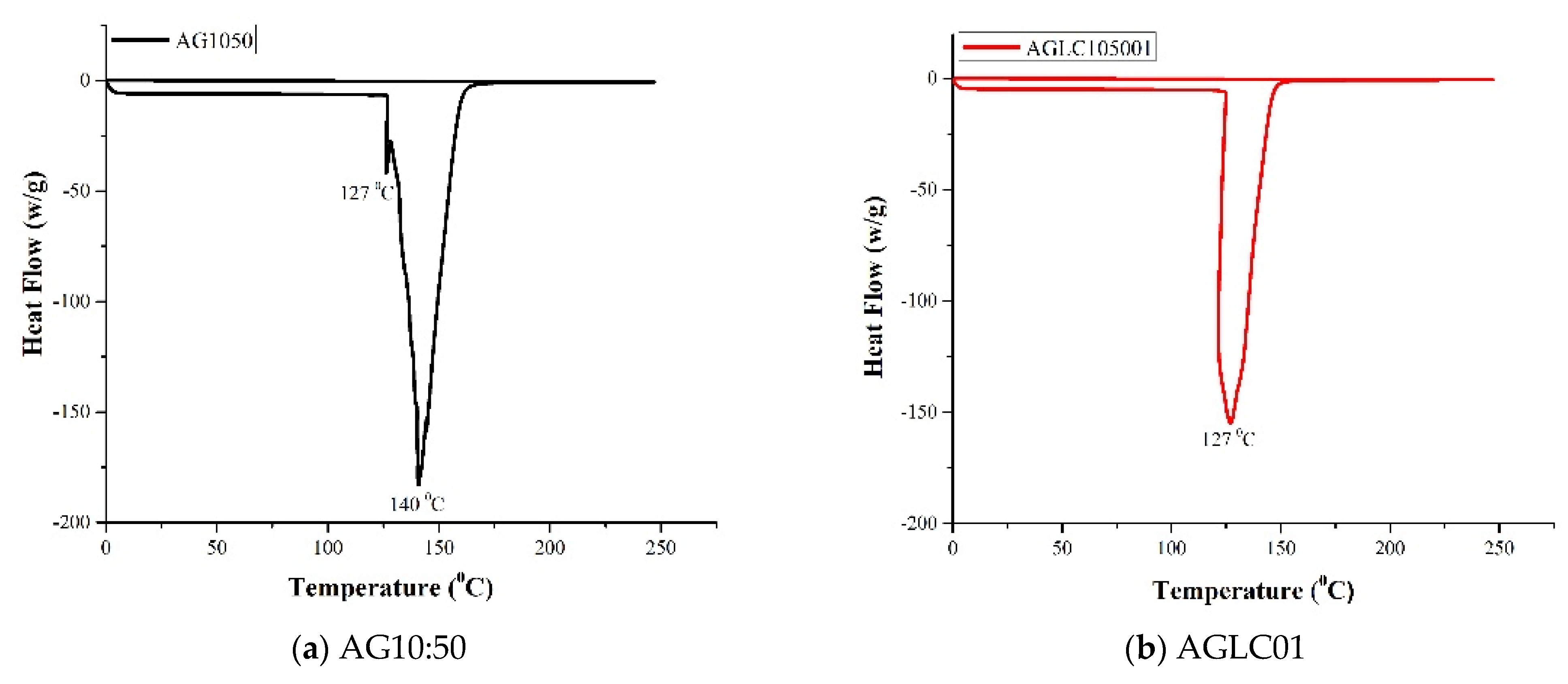

3.2.3. Differential Scanning Calorimetric

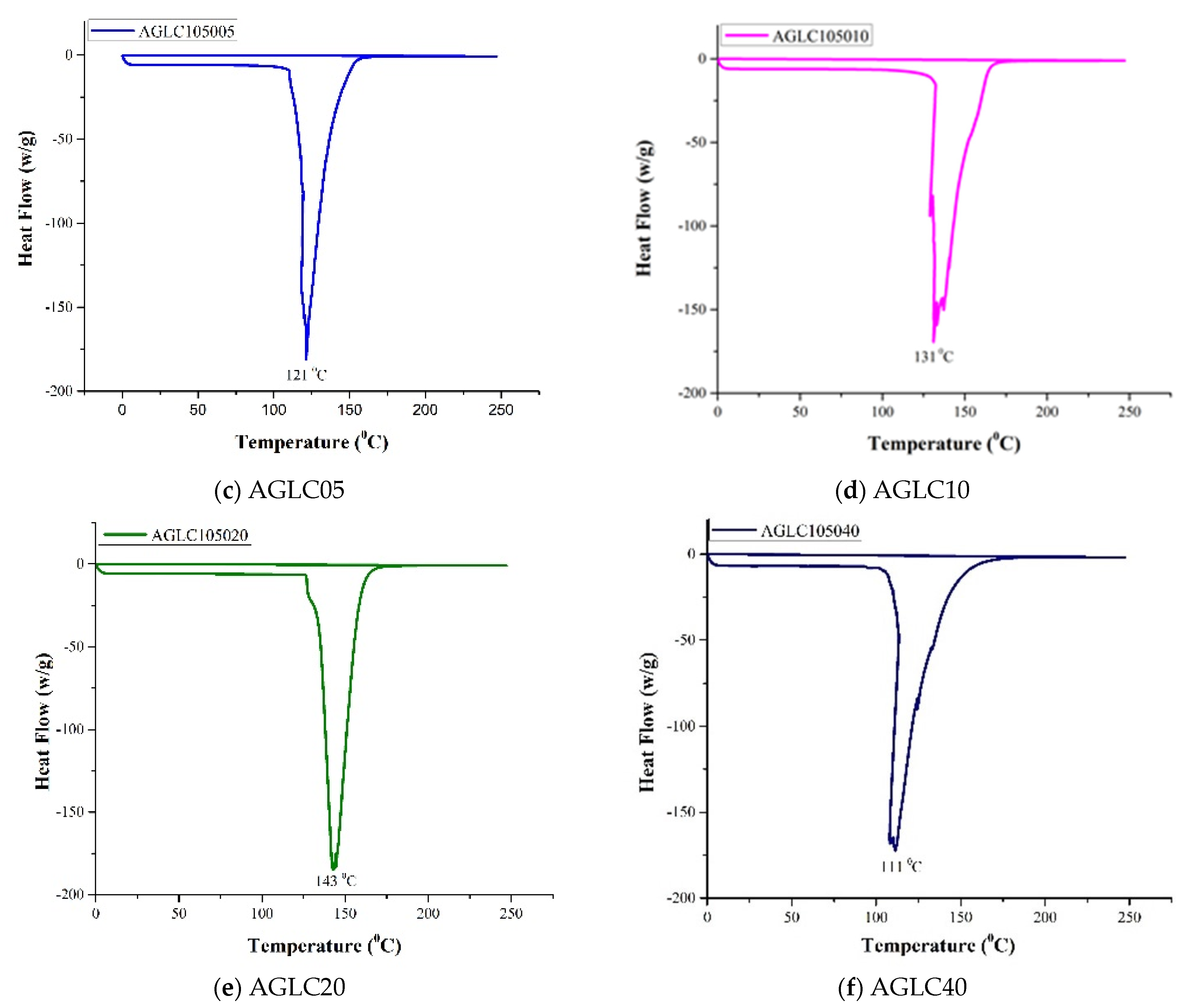

3.2.4. Contact Angle Measurement

3.2.5. Field Emission Scanning Electron Microscopy

3.2.6. In Vitro Cytotoxicity of AGLC Bioinks

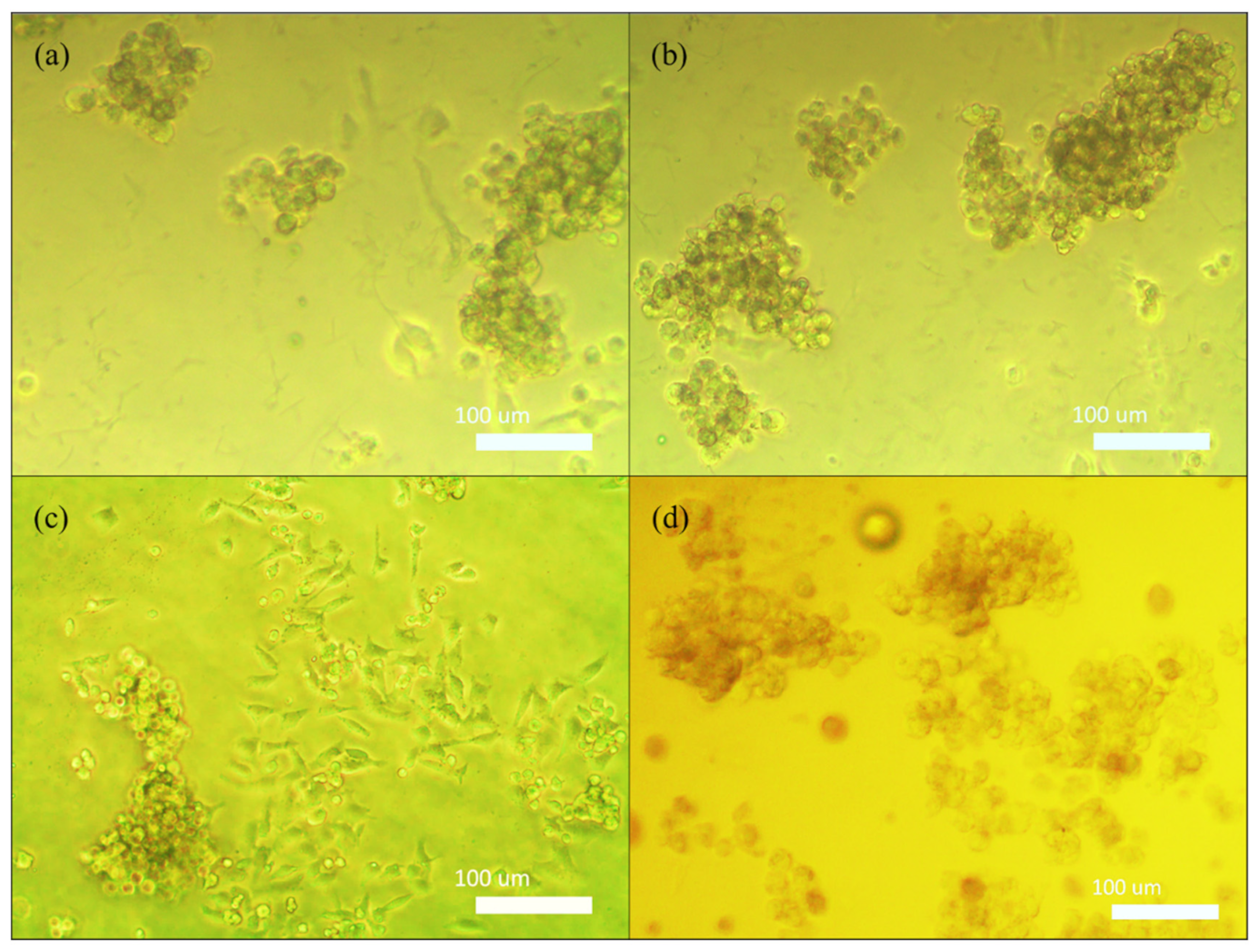

3.2.7. Cell Interaction

4. Results

4.1. Printability Results

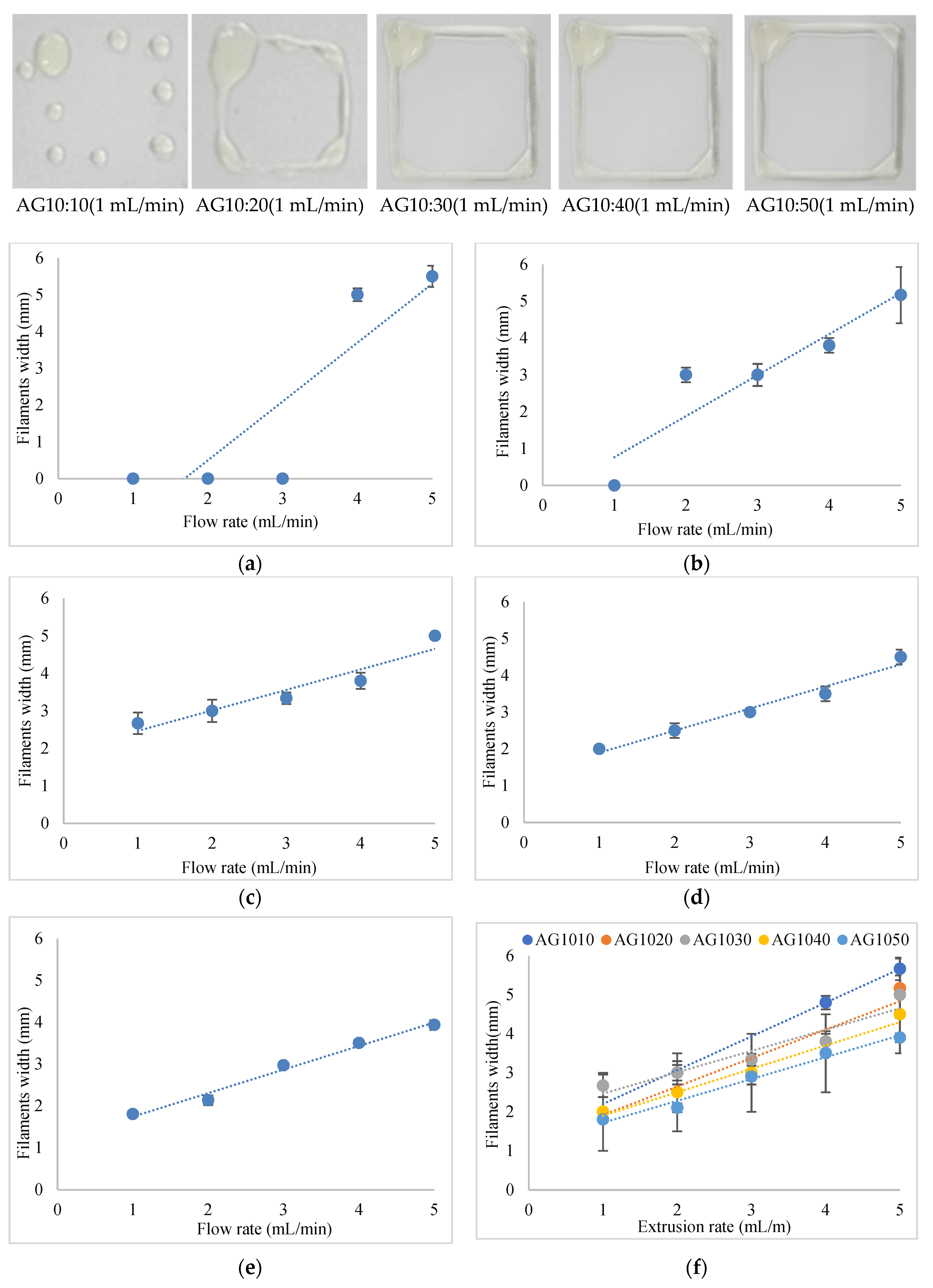

4.1.1. Printability of AG Hydrogels

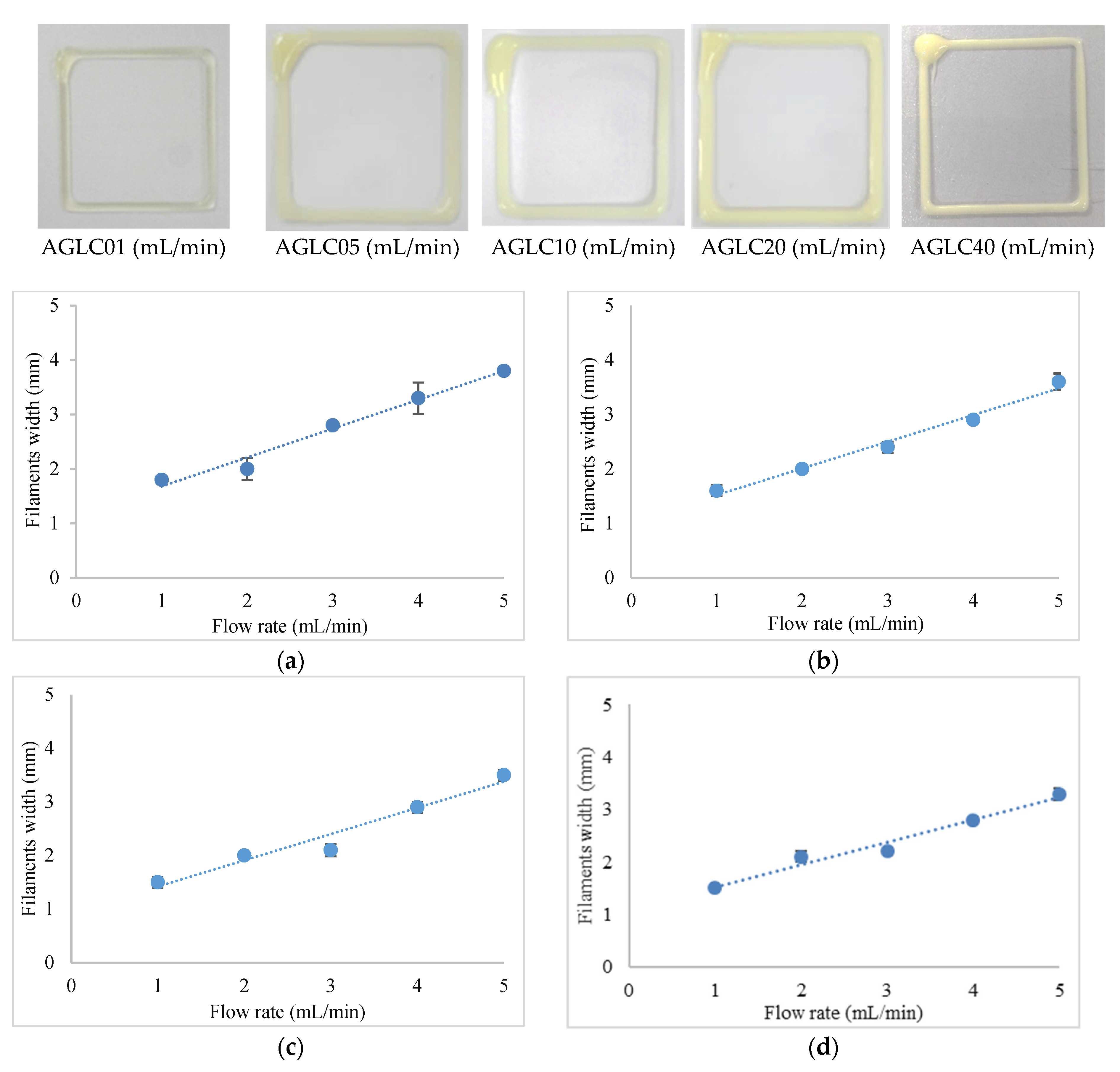

4.1.2. Printability of AGLC Bioinks

4.2. Characterization Results

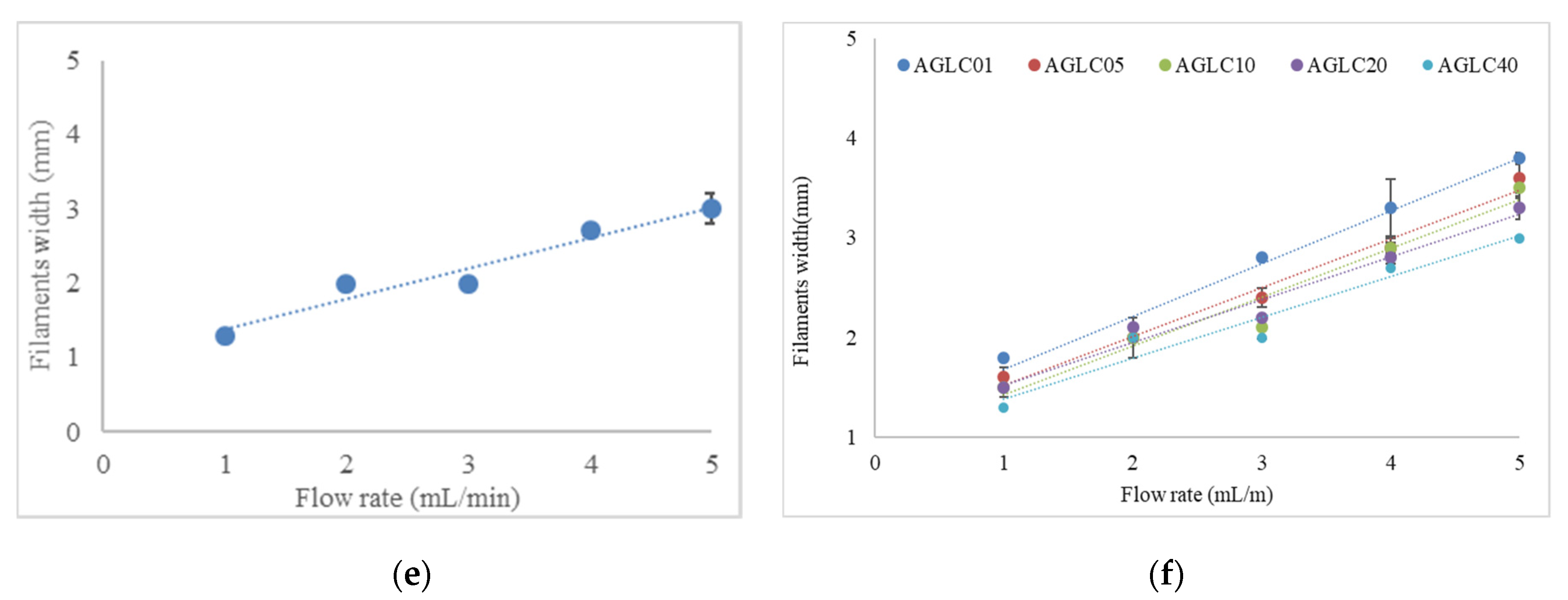

4.2.1. Polymerization

4.2.2. Chemical Properties

4.2.3. Thermal Properties

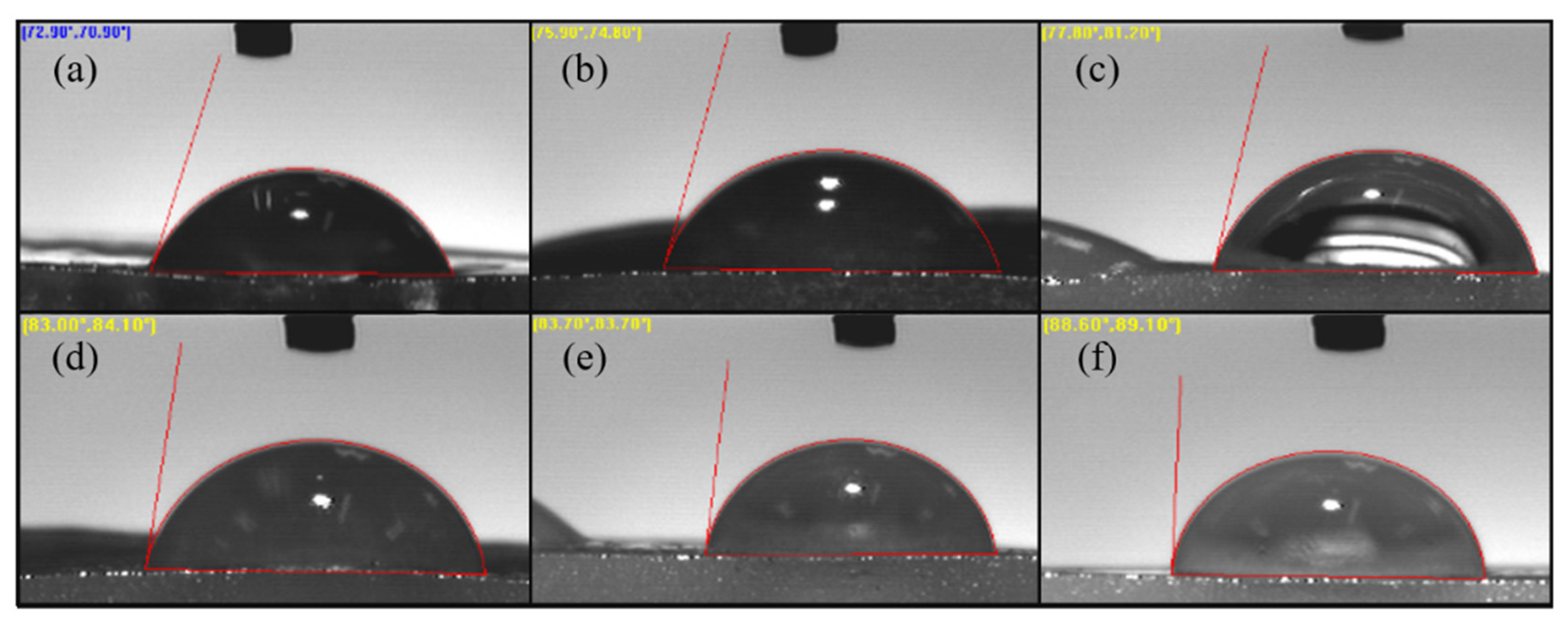

4.2.4. Contact Angle Properties

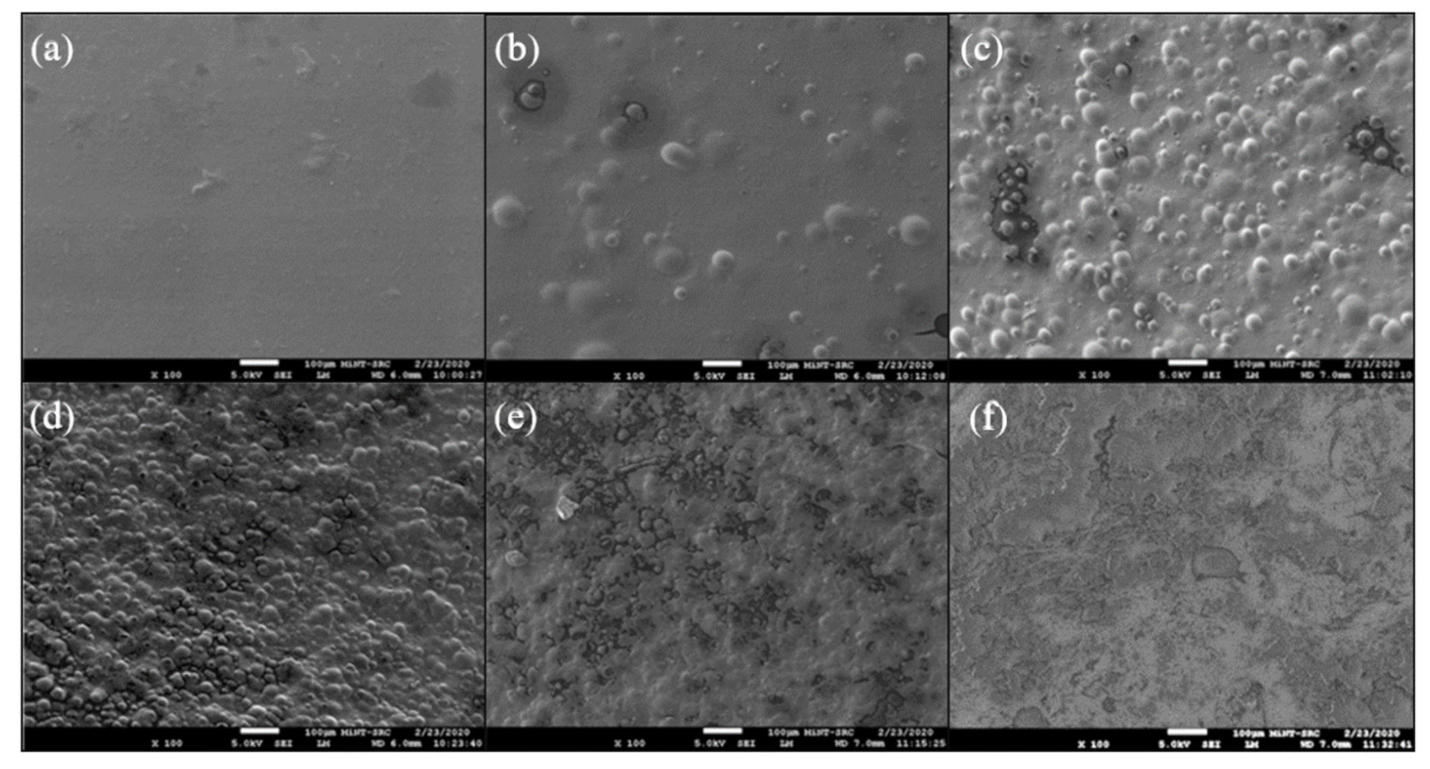

4.2.5. Surface Morphology Analysis

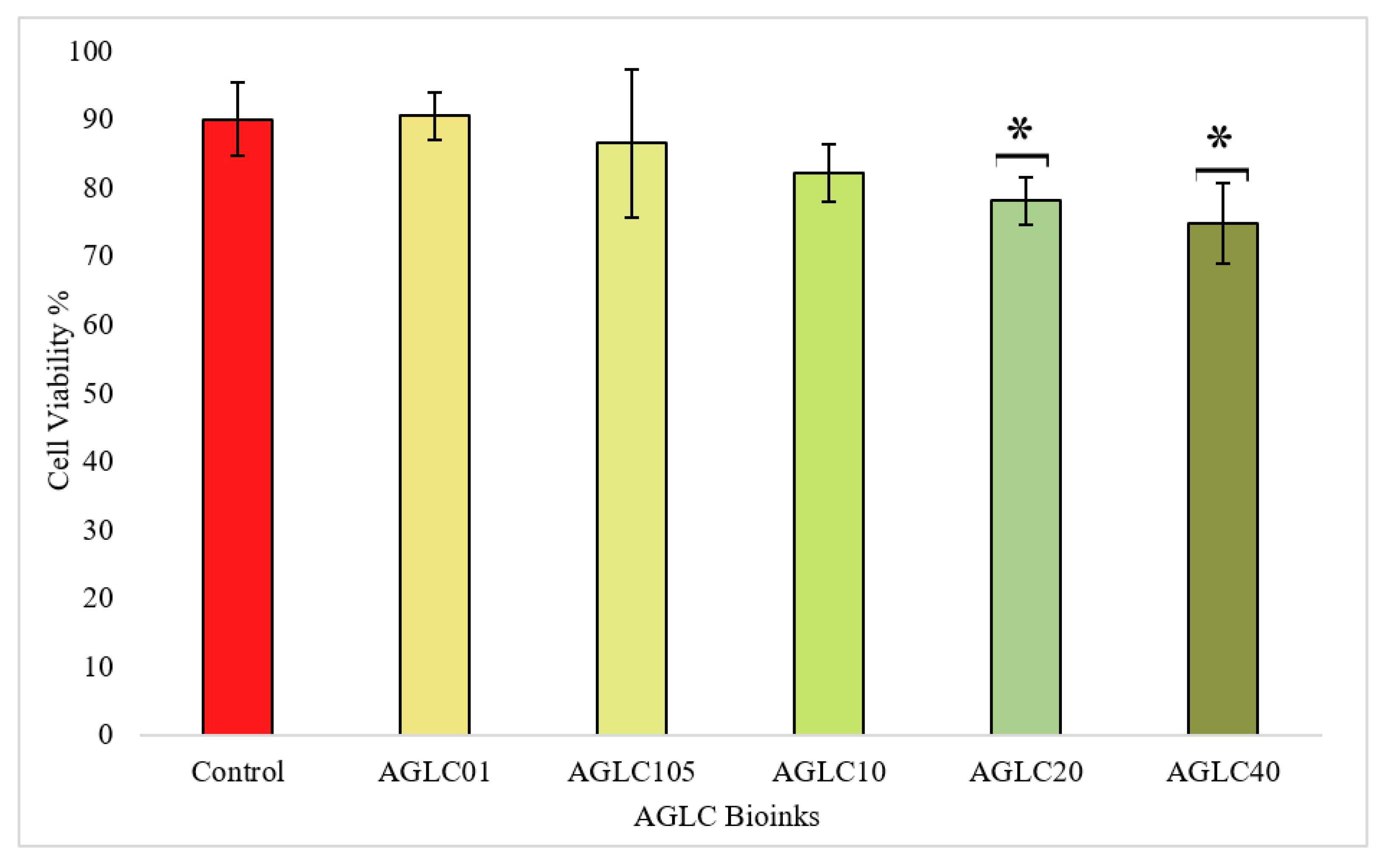

4.2.6. In Vitro Cytotoxicity Properties

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Algorithm A1: The designed algorithm for the 3D printed shape | |

| 00 | begin |

| 01 | Header |

| 02 | Setup basic information of the 3D printer including: program name, programmer, date, bioprinter name; |

| 03 | Header-end |

| 04 | Tooling |

| 05 | Set default tool Set a Programming unit in milimeters; |

| 06 | Set a Programming unit in milimeters; |

| 07 | Set a path id; |

| 08 | Tooling-end |

| 09 | Start cutting path id |

| 10 | Perform rapid movement to the nozzle according to X, Y, Z geometric shape; |

| 11 | Perform linear interpolation to the nozzle according to X, Y, Z geometric shape; |

| 12 | end cutting path id |

| 13 | Footer |

| 14 | Turns the spindle off; |

| 15 | Move the nozzle to the initial location; |

| 16 | Ends the program; |

| 17 | Footer-end |

| 18 | end. |

Appendix B

References

- Lewis, A.; Koukoura, A.; Tsianos, G.-I.; Gargavanis, A.A.; Nielsen, A.A.; Vassiliadis, E. Organ donation in the US and Europe: The supply vs demand imbalance. Transplant. Rev. 2020, 35, 100585. [Google Scholar] [CrossRef] [PubMed]

- Becker, G.S.; Elías, J.J. Introducing Incentives in the Market for Live and Cadaveric Organ Donations. J. Econ. Perspect. 2007, 21, 3–24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, B.; Luo, Y.; Ma, L.; Gao, L.; Li, Y.; Xue, Q.; Yang, H.; Cui, Z. 3D bioprinting: An emerging technology full of opportunities and challenges. Bio-Design Manuf. 2018, 1, 2–13. [Google Scholar] [CrossRef]

- Hoffman, T.; Antovski, P.; Tebon, P.; Xu, C.; Ashammakhi, N.; Ahadian, S.; Morsut, L.; Khademhosseini, A. Synthetic biology and tissue engineering: Toward fabrication of complex and smart cellular constructs. Adv. Funct. Mater. 2020, 30, 1909882. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Yue, K.; Aleman, J.; Mollazadeh-Moghaddam, K.; Bakht, S.M.; Yang, J.; Jia, W.; Dell’Erba, V.; Assawes, P.; Shin, S.R.; et al. 3D Bioprinting for Tissue and Organ Fabrication. Ann. Biomed. Eng. 2016, 45, 148–163. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rutz, A.; Hyland, K.E.; Jakus, A.E.; Burghardt, W.R.; Shah, R.N. A Multimaterial Bioink Method for 3D Printing Tunable, Cell-Compatible Hydrogels. Adv. Mater. 2015, 27, 1607–1614. [Google Scholar] [CrossRef] [Green Version]

- Sefat, F.; Youseffi, M.; Khaghani, S.A.; Soon, C.F.; Javid, F. Effect of transforming growth factor-β3 on mono and multilayer chondrocytes. Cytokine 2016, 83, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Ma, X.; Gou, M.; Mei, D.; Zhang, K.; Chen, S. 3D printing of functional biomaterials for tissue engineering. Curr. Opin. Biotechnol. 2016, 40, 103–112. [Google Scholar] [CrossRef] [Green Version]

- Ashammakhi, N.; Ahadian, S.; Xu, C.; Montazerian, H.; Ko, H.; Nasiri, R.; Barros, N.; Khademhosseini, A. Bioinks and bioprinting technologies to make heterogeneous and biomimetic tissue constructs. Mater. Today Bio. 2019, 1, 100008. [Google Scholar] [CrossRef]

- Jiang, T.; Munguia-Lopez, J.; Flores-Torres, S.; Kort-Mascort, J.; Kinsella, J.M. Extrusion bioprinting of soft materials: An emerging technique for biological model fabrication. Appl. Phys. Rev. 2019, 6, 011310. [Google Scholar] [CrossRef]

- Jang, T.-S.; Jung, H.-D.; Pan, M.; Han, W.T.; Chen, S.; Song, J. 3D printing of hydrogel composite systems: Recent advances in technology for tissue engineering. Int. J. Bioprinting 2018, 4, 126. [Google Scholar] [CrossRef] [PubMed]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Tabriz, A.G.; A Hermida, M.; Leslie, N.; Shu, W. Three-dimensional bioprinting of complex cell laden alginate hydrogel structures. Biofabrication 2015, 7, 045012. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, H.; Hu, Q.; Shen, Z.; Rana, D.; Ramalingam, M. Designing vascular supportive albumen-rich composite bioink for organ 3D printing. J. Mech. Behav. Biomed. Mater. 2020, 104, 103642. [Google Scholar] [CrossRef] [PubMed]

- Berg, J.; Hiller, T.; Kissner, M.S.; Qazi, T.H.; Duda, G.N.; Hocke, A.C.; Hippenstiel, S.; Elomaa, L.; Weinhart, M.; Fahrenson, C.; et al. Optimization of cell-laden bioinks for 3D bioprinting and efficient infection with influenza A virus. Sci. Rep. 2018, 8, 13877. [Google Scholar] [CrossRef]

- Sun, W.; Starly, B.; Daly, A.C.; Burdick, J.A.; Groll, J.; Skeldon, G.; Shu, W.; Sakai, Y.; Shinohara, M.; Nishikawa, M.; et al. The bioprinting roadmap. Biofabrication 2020, 12, 022002. [Google Scholar] [CrossRef]

- Skardal, A.; Atala, A. Biomaterials for Integration with 3-D Bioprinting. Ann. Biomed. Eng. 2014, 43, 730–746. [Google Scholar] [CrossRef]

- Chimene, D.; Lennox, K.K.; Kaunas, R.R.; Gaharwar, A.K. Advanced Bioinks for 3D Printing: A Materials Science Perspective. Ann. Biomed. Eng. 2016, 44, 2090–2102. [Google Scholar] [CrossRef]

- Axpe, E.; Oyen, M.L. Applications of Alginate-Based Bioinks in 3D Bioprinting. Int. J. Mol. Sci. 2016, 17, 1976. [Google Scholar] [CrossRef] [Green Version]

- Andersen, T.; Auk-Emblem, P.; Dornish, M. 3D Cell Culture in Alginate Hydrogels. Microarrays 2015, 4, 133–161. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.J.; Chung, S.; Lee, J.H.; Kim, W.D.; Lee, J.Y.; A Park, S. Cell-laden 3D bioprinting hydrogel matrix depending on different compositions for soft tissue engineering: Characterization and evaluation. Mater. Sci. Eng. C 2017, 71, 678–684. [Google Scholar] [CrossRef] [PubMed]

- Valot, L.; Martinez, J.; Mehdi, A.; Subra, G. Chemical insights into bioinks for 3D printing. Chem. Soc. Rev. 2019, 48, 4049–4086. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jia, J.; Richards, D.J.; Pollard, S.; Tan, Y.; Rodriguez, J.; Visconti, R.P.; Trusk, T.C.; Yost, M.J.; Yao, H.; Markwald, R.R.; et al. Engineering alginate as bioink for bioprinting. Acta Biomater. 2014, 10, 4323–4331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panwar, A.; Tan, L.P. Current Status of Bioinks for Micro-Extrusion-Based 3D Bioprinting. Molecules 2016, 21, 685. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Li, Q.; Xie, S.; Shan, X.; Cai, Z. In vitro and in vivo biocompatibility evaluation of a 3D bioprinted gelatin-sodium alginate/rat Schwann-cell scaffold. Mater. Sci. Eng. C 2019, 109, 110530. [Google Scholar] [CrossRef] [PubMed]

- Kajave, N.S.; Schmitt, T.; Nguyen, T.-U.; Kishore, V. Dual crosslinking strategy to generate mechanically viable cell-laden printable constructs using methacrylated collagen bioinks. Mater. Sci. Eng. C 2019, 107, 110290. [Google Scholar] [CrossRef]

- Chung, J.H.Y.; Naficy, S.; Yue, Z.; Kapsa, R.; Quigley, A.; Moulton, S.E.; Wallace, G.G. Bio-ink properties and printability for extrusion printing living cells. Biomater. Sci. 2013, 1, 763–773. [Google Scholar] [CrossRef] [Green Version]

- Shaw, G.S.; Uvanesh, K.; Gautham, S.; Singh, V.; Pramanik, K.; Banerjee, I.; Kumar, N.; Pal, K. Development and characterization of gelatin-tamarind gum/carboxymethyl tamarind gum based phase-separated hydrogels: A comparative study. Des. Monomers Polym. 2015, 18, 434–450. [Google Scholar] [CrossRef] [Green Version]

- Di Giuseppe, M.; Law, N.; Webb, B.A.; Macrae, R.A.; Liew, L.J.; Sercombe, T.B.; Dilley, R.J.; Doyle, B.J. Mechanical behaviour of alginate-gelatin hydrogels for 3D bioprinting. J. Mech. Behav. Biomed. Mater. 2018, 79, 150–157. [Google Scholar] [CrossRef]

- Duan, B.; Hockaday, L.A.; Kang, K.H.; Butcher, J.T. 3D Bioprinting of heterogeneous aortic valve conduits with alginate/gelatin hydrogels. J. Biomed. Mater. Res. Part A 2012, 101A, 1255–1264. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdulmaged, A.I.; Soon, C.F.; Talip, B.A.; Othman, S.A.; Lim, G.P.; Tee, K.S. Investigation on the printability of bioink based on alginate-gelatin hydrogel and liquid crystals. Bull. Electr. Eng. Informatics 2020, 9, 1718–1725. [Google Scholar] [CrossRef]

- Soule, E.R.; Rey, A.D. Modelling complex liquid crystal mixtures: From polymer dispersed mesophase to nematic nanocolloids. Mol. Simul. 2012, 38, 735–750. [Google Scholar] [CrossRef]

- Urbanski, M.; Reyes, C.G.; Noh, J.; Sharma, A.; Geng, Y.; Jampani, V.S.R.; Lagerwall, J.P.F. Liquid crystals in micron-scale droplets, shells and fibers. J. Phys. Condens. Matter 2017, 29, 133003. [Google Scholar] [CrossRef] [Green Version]

- Acharya, B.R. Applications of liquid crystals in chemical and biological detection. SPIE Newsroom 2011. [Google Scholar] [CrossRef]

- Prévôt, M.E.; Ustunel, S.; Hegmann, E. Liquid Crystal Elastomers—A Path to Biocompatible and Biodegradable 3D-LCE Scaffolds for Tissue Regeneration. Materials 2018, 11, 377. [Google Scholar] [CrossRef] [Green Version]

- Sidiq, S.; Pal, S.K. Liquid Crystal Biosensors: New Approaches. Proc. Indian Natl. Sci. Acad. 2016, 82, 75–98. [Google Scholar] [CrossRef]

- Traugutt, N.A.; Mistry, D.; Luo, C.; Yu, K.; Ge, Q.; Yakacki, C.M. Liquid-Crystal-Elastomer-Based Dissipative Structures by Digital Light Processing 3D Printing. Adv. Mater. 2020, 32, 2000797. [Google Scholar] [CrossRef]

- Sung, B.; Kim, M.-H. Liquid-crystalline nanoarchitectures for tissue engineering. Beilstein J. Nanotechnol. 2018, 9, 205–215. [Google Scholar] [CrossRef] [Green Version]

- Mitov, M. Cholesteric liquid crystals in living matter. Soft Matter 2017, 13, 4176–4209. [Google Scholar] [CrossRef]

- Du, L.; Yang, X.; Li, W.; Luo, X.; Wu, H.; Zhang, J.; Tu, M. Construction of physical crosslink-based chitosan/liquid crystal composite hydrogel and evaluation on their cytocompatibility. Regen. Biomater. 2016, 4, 39–45. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, H.; Shang, Y.; Zhang, J.; Cheang, L.H.; Zeng, X.; Tu, M. The effects of liquid crystal-based composite substrates on cell functional responses of human umbilical cord-derived mesenchymal stem cells by mechano-regulatory process. J. Biomater. Appl. 2017, 32, 492–503. [Google Scholar] [CrossRef]

- Othman, S.A.; Soon, C.F.; Ma, N.L.; Tee, K.S.; Lim, G.P.; Morsin, M.; Ahmad, M.K.; Abdulmaged, A.I.; Cheong, S.C. Alginate-gelatin bioink for bioprinting of hela spheroids in alginate-gelatin hexagon shaped scaffolds. Polym. Bull. 2020, 78, 6115–6135. [Google Scholar] [CrossRef]

- Nasajpour, A.; Mostafavi, A.; Chlanda, A.; Rinoldi, C.; Sharifi, S.; Ji, M.S.; Ye, M.; Jonas, S.J.; Swieszkowski, W.; Weiss, P.S.; et al. Cholesteryl Ester Liquid Crystal Nanofibers for Tissue Engineering Applications. ACS Mater. Lett. 2020, 2, 1067–1073. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, Y.; Yang, S.; Wu, S.; Zeng, R.; Wu, H.; Zhang, J.; Zha, Z.; Tu, M. Improving blood-compatibility via surface heparin-immobilization based on a liquid crystalline matrix. Mater. Sci. Eng. C 2016, 58, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Li, Q.; Xu, S.; Zheng, Q.; Cao, X. Preparation and Properties of 3D Printed Alginate–Chitosan Polyion Complex Hydrogels for Tissue Engineering. Polymers 2018, 10, 664. [Google Scholar] [CrossRef] [Green Version]

- Soon, C.F.; Omar, W.I.W.; Berends, R.F.; Nayan, N.; Basri, H.; Tee, K.S.; Youseffi, M.; Blagden, N.; Denyer, M.C.T. Biophysical characteristics of cells cultured on cholesteryl ester liquid crystals. Micron 2014, 56, 73–79. [Google Scholar] [CrossRef] [Green Version]

- Soon, C.F. Development of a Novel Cell Traction Force Transducer Based on Cholesteryl Ester Liquid Crystals. Ph.D. Thesis, University of Bradford, West Yorkshire, UK, 2011. [Google Scholar]

- Hernández-González, A.C.; Téllez-Jurado, L.; Rodríguez-Lorenzo, L.M. Alginate hydrogels for bone tissue engineering, from injectables to bioprinting: A review. Carbohydr. Polym. 2019, 229, 115514. [Google Scholar] [CrossRef]

- Xiao, C.; Liu, H.; Lu, Y.; Zhang, L. Blend films from sodium alginate and gelatin solutions. J. Macromol. Sci. Part A 2001, 38, 317–328. [Google Scholar] [CrossRef]

- Soon, C.F.; Tee, K.S.; Wong, S.C.; Nayan, N.; Sundra, S.; Ahmad, M.K.; Sefat, F.; Sultana, N.; Youseffi, M. Comparison of biophysical properties characterized for microtissues cultured using microencapsulation and liquid crystal based 3D cell culture techniques. Cytotechnology 2017, 70, 13–29. [Google Scholar] [CrossRef]

- Aroguz, A.Z.; Baysal, K.; Adiguzel, Z.; Baysal, B.M. Alginate/Polyoxyethylene and Alginate/Gelatin Hydrogels: Preparation, Characterization, and Application in Tissue Engineering. Appl. Biochem. Biotechnol. 2014, 173, 433–448. [Google Scholar] [CrossRef] [PubMed]

- Lopes, S.; Bueno, L.; Júnior, F.D.A.; Finkler, C. Preparation and characterization of alginate and gelatin microcapsules containing Lactobacillus rhamnosus. An. Acad. Bras. Ciencias 2017, 89, 1601–1613. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.J.; Iyer, S.N.; Li, L.-S.; Claussen, R.; Harrington, D.; Stupp, S.I. Self-assembling biomaterials: Liquid crystal phases of cholesteryl oligo(L-lactic acid) and their interactions with cells. Proc. Natl. Acad. Sci. USA 2002, 99, 9662–9667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarker, B.; Papageorgiou, D.G.; Silva, R.; Zehnder, T.; Gul-E-Noor, F.; Bertmer, M.; Kaschta, J.; Chrissafis, K.; Detsch, R.; Boccaccini, A.R. Fabrication of alginate–gelatin crosslinked hydrogel microcapsules and evaluation of the microstructure and physico-chemical properties. J. Mater. Chem. B 2013, 2, 1470–1482. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Z.L.; Gong, J.P. Hydrogels with self-assembling ordered structures and their functions. NPG Asia Mater. 2011, 3, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Lai, J.-Y.; Ma, D.H.-K.; Lai, M.-H.; Li, Y.-T.; Chang, R.-J.; Chen, L.-M. Characterization of Cross-Linked Porous Gelatin Carriers and Their Interaction with Corneal Endothelium: Biopolymer Concentration Effect. PLoS ONE 2013, 8, e54058. [Google Scholar] [CrossRef] [Green Version]

- Gilarska, A.; Lewandowska-Łańcucka, J.; Horak, W.; Nowakowska, M. Collagen/chitosan/hyaluronic acid–based injectable hydrogels for tissue engineering applications–design, physicochemical and biological characterization. Colloids Surf. B Biointerfaces 2018, 170, 152–162. [Google Scholar] [CrossRef]

- Ferrari, M.; Cirisano, F.; Morán, M.C. Mammalian cell behavior on hydrophobic substrates: Influence of surface properties. Colloids Interfaces 2019, 3, 48. [Google Scholar] [CrossRef] [Green Version]

- Gun’Ko, V.M.; Savina, I.N.; Mikhalovsky, S.V. Properties of Water Bound in Hydrogels. Gels 2017, 3, 37. [Google Scholar] [CrossRef]

- Ma, Z.; Mao, Z.; Gao, C. Surface modification and property analysis of biomedical polymers used for tissue engineering. Colloids Surf. B Biointerfaces 2007, 60, 137–157. [Google Scholar] [CrossRef]

| No | Gel Name | AG (w/v:w/v%) |

|---|---|---|

| 1 | AG10:10 | 10%A:10%G |

| 2 | AG10:20 | 10%A:20%G |

| 3 | AG10:30 | 10%A:30%G |

| 4 | AG10:40 | 10%A:40%G |

| 5 | AG10:50 | 10%A:50%G |

| No | Bioink Name | AG-CELC |

|---|---|---|

| 1 | AGLC01 | AG10:50-1% |

| 2 | AGLC05 | AG10:50-5% |

| 3 | AGLC10 | AG10:50-10% |

| 4 | AGLC20 | AG10:50-20% |

| 5 | AGLC40 | AG10:50-40% |

| Sample | Tm (°C) | ΔH (°C) |

|---|---|---|

| AG1050 | 126.9, 140 | 29.6 |

| AGLC01 | 126.9 | 37.8 |

| AGLC05 | 121.2 | 39.4 |

| AGLC10 | 131, 137 | 44.3 |

| AGLC20 | 142.8 | 49.1 |

| AGLC40 | 111 | 42.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulmaged, A.I.; Soon, C.F.; Talip, B.A.; Zamhuri, S.A.A.; Mostafa, S.A.; Zhou, W. Characterization of Alginate–Gelatin–Cholesteryl Ester Liquid Crystals Bioinks for Extrusion Bioprinting of Tissue Engineering Scaffolds. Polymers 2022, 14, 1021. https://doi.org/10.3390/polym14051021

Abdulmaged AI, Soon CF, Talip BA, Zamhuri SAA, Mostafa SA, Zhou W. Characterization of Alginate–Gelatin–Cholesteryl Ester Liquid Crystals Bioinks for Extrusion Bioprinting of Tissue Engineering Scaffolds. Polymers. 2022; 14(5):1021. https://doi.org/10.3390/polym14051021

Chicago/Turabian StyleAbdulmaged, Alyaa Idrees, Chin Fhong Soon, Balkis A. Talip, Siti Adibah Ahmad Zamhuri, Salama A. Mostafa, and Wenbin Zhou. 2022. "Characterization of Alginate–Gelatin–Cholesteryl Ester Liquid Crystals Bioinks for Extrusion Bioprinting of Tissue Engineering Scaffolds" Polymers 14, no. 5: 1021. https://doi.org/10.3390/polym14051021

APA StyleAbdulmaged, A. I., Soon, C. F., Talip, B. A., Zamhuri, S. A. A., Mostafa, S. A., & Zhou, W. (2022). Characterization of Alginate–Gelatin–Cholesteryl Ester Liquid Crystals Bioinks for Extrusion Bioprinting of Tissue Engineering Scaffolds. Polymers, 14(5), 1021. https://doi.org/10.3390/polym14051021