Developing Microbial Co-Culture System for Enhanced Polyhydroxyalkanoates (PHA) Production Using Acid Pretreated Lignocellulosic Biomass

Abstract

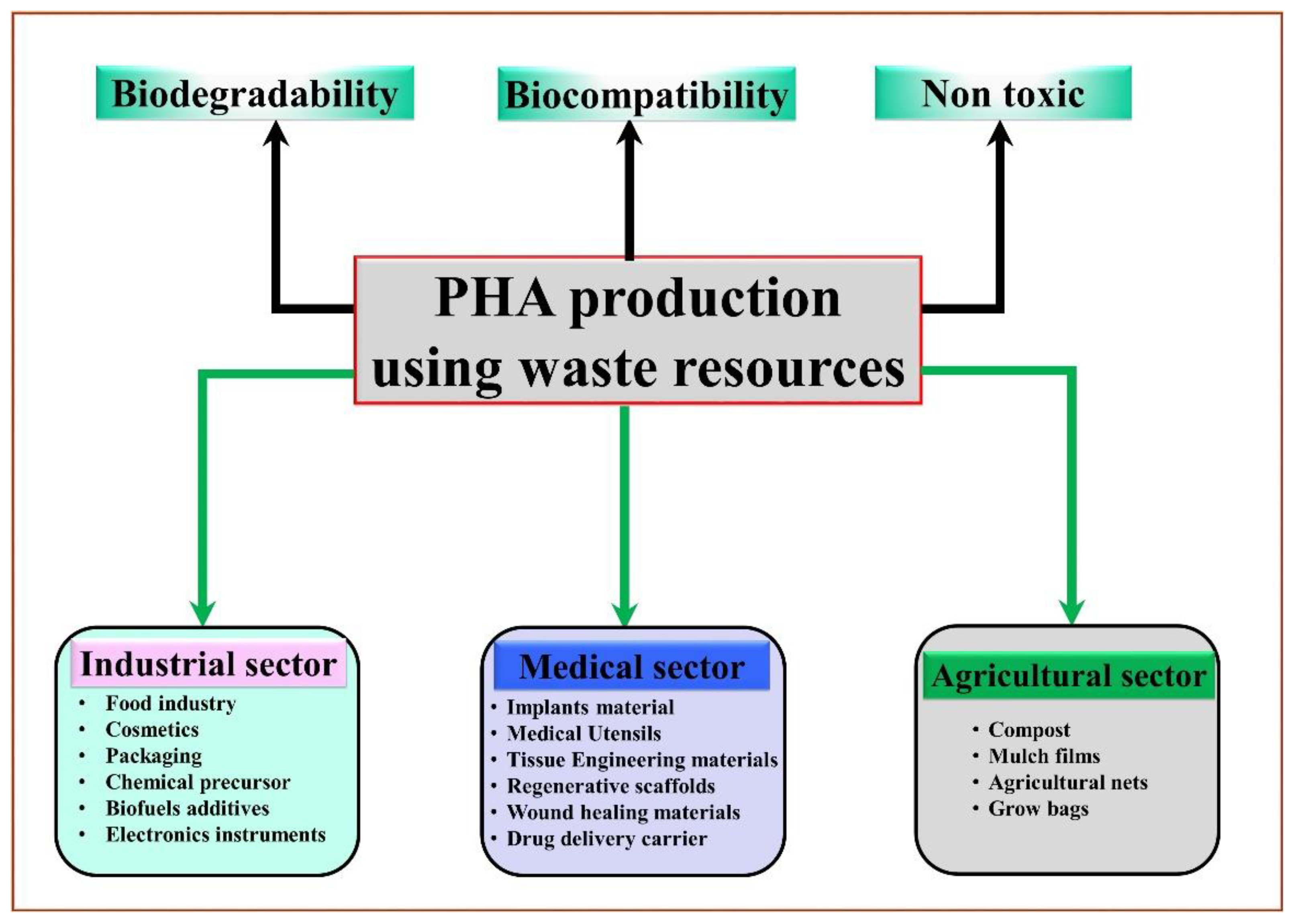

:1. Introduction

2. Materials and Methods

2.1. Biomass and Chemicals

2.2. Chemical Pretreatment of SCB and Enzymatic Hydrolysis

2.3. Enzymatic Hydrolysis of Pretreated SCB

2.4. Development of Microbial Co-Culture of Lysinibacillus sp. and Ralstonia eutropha

2.5. PHA Production Using Chemically Pretreated SCB Hydrolysates by Individual and Co-Culture Microbial System

2.6. Statistical Analysis

3. Results and Discussion

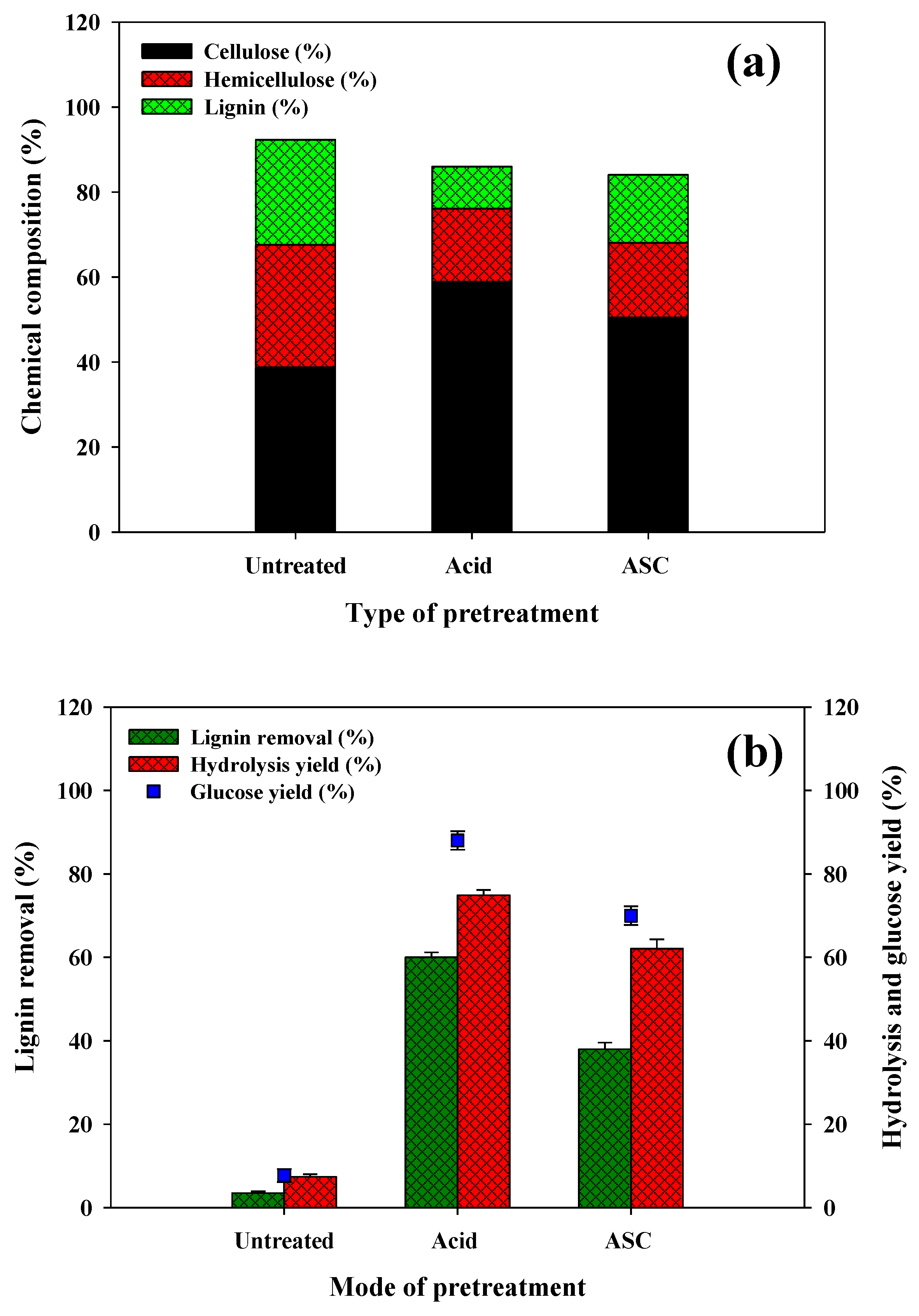

3.1. Preparation of Sugarcane Bagasse Feedstock for PHA Production

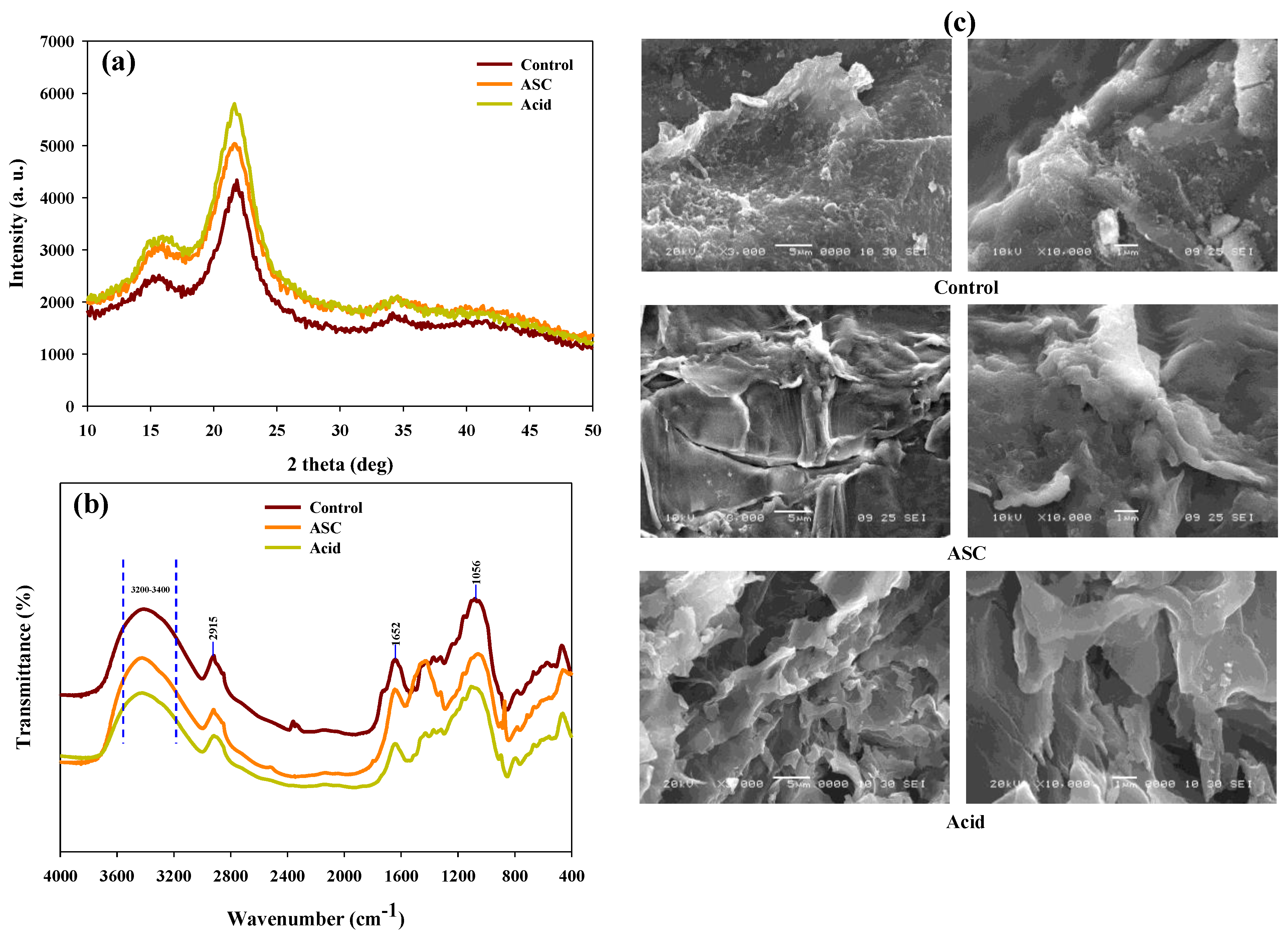

3.2. Analytical Characterization of Chemically Pretreated SCB Biomass

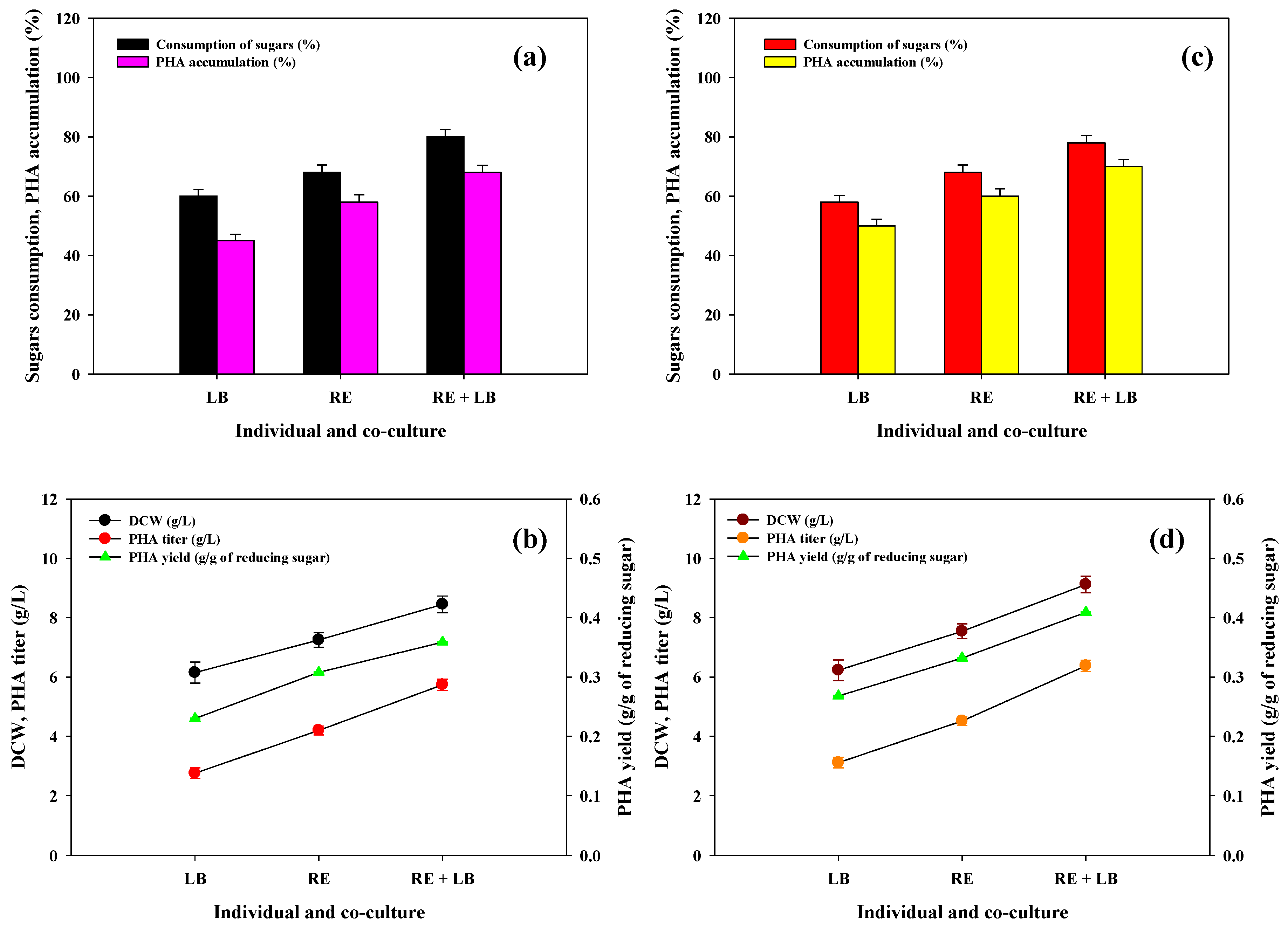

3.3. PHA Production Studies

3.3.1. Effects of Substrate Concentration

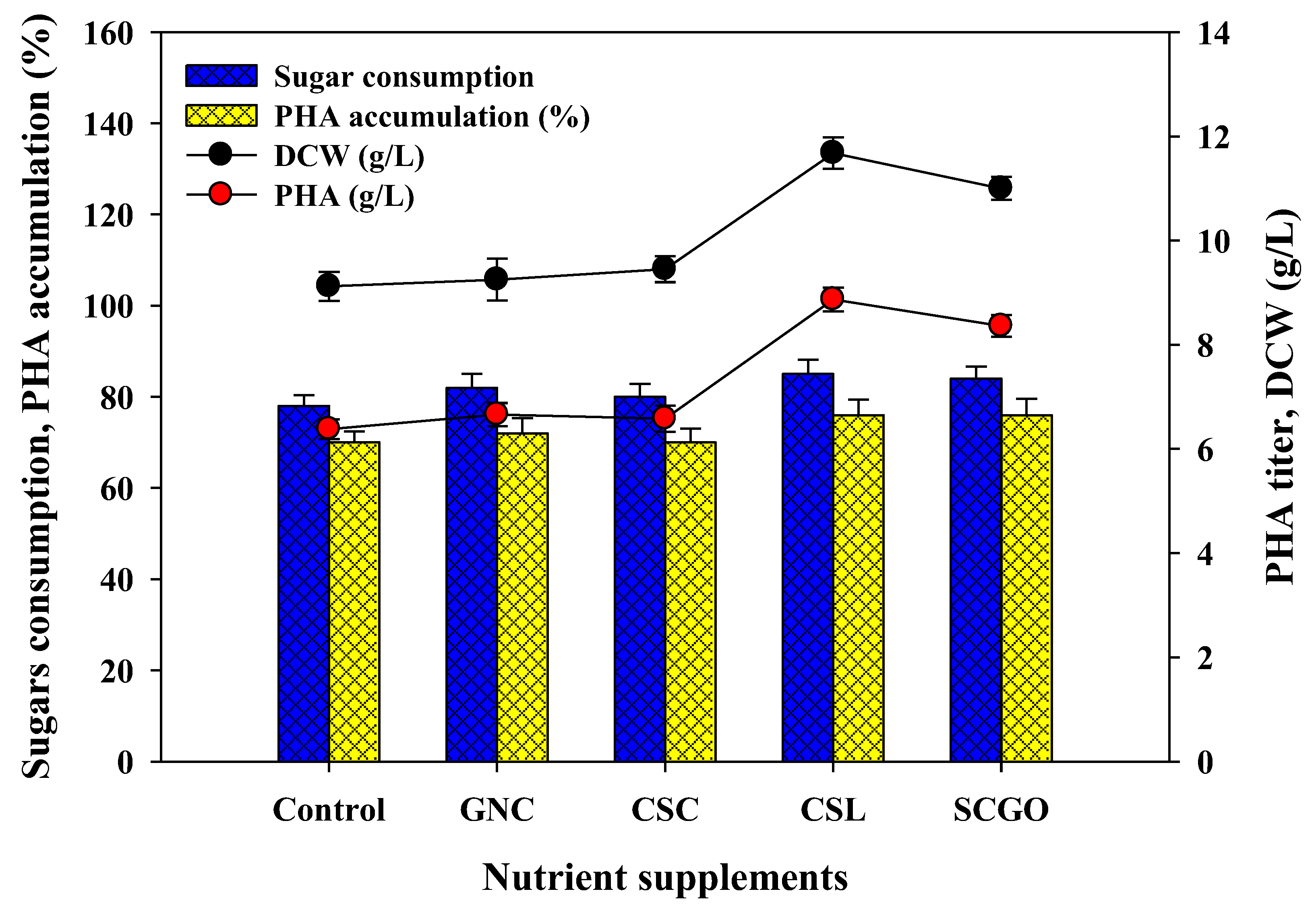

3.3.2. Effects of Cost-Effective Nutrients Supplementation in PHA Production Media

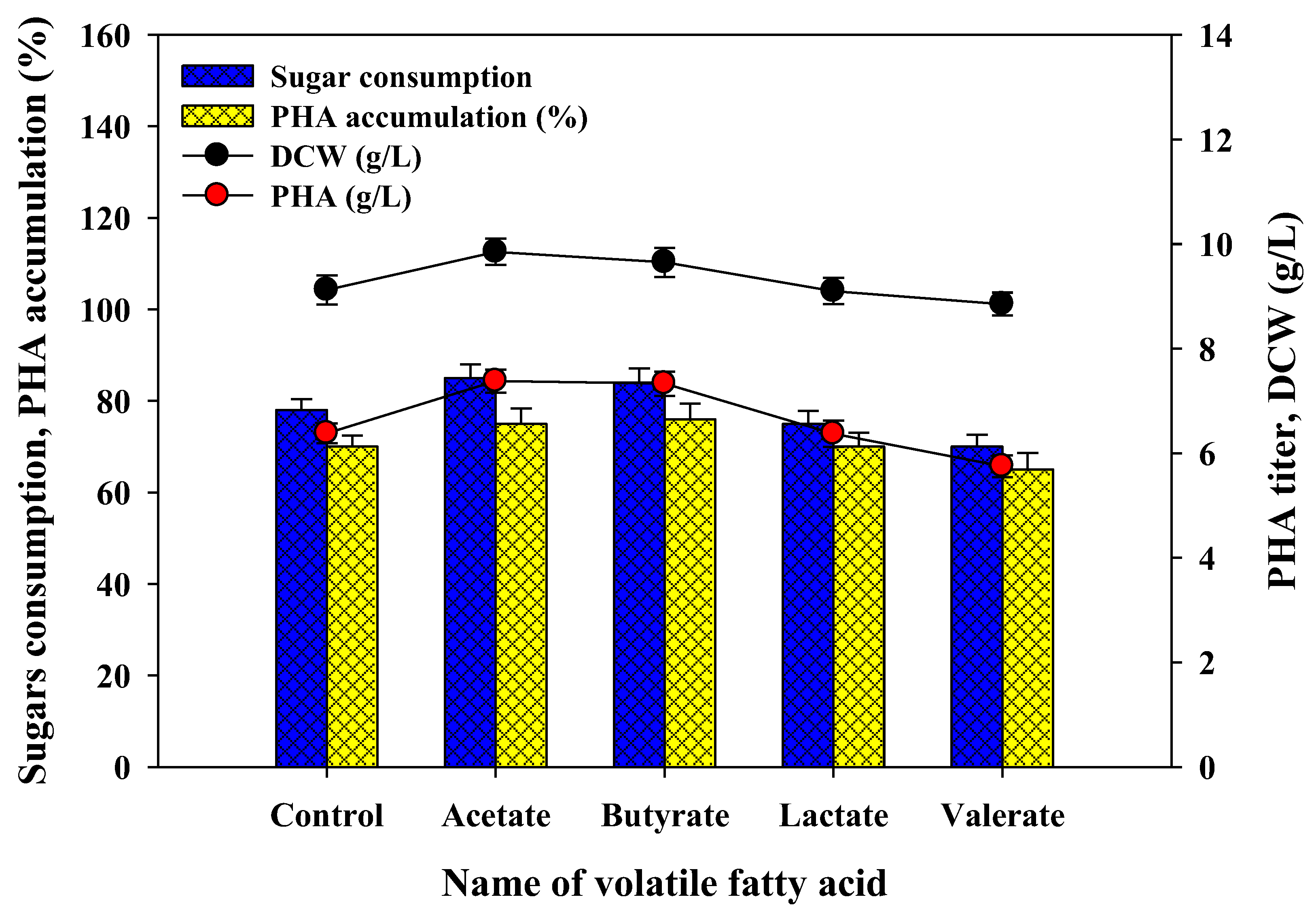

3.3.3. Effects of Individual Volatile Fatty Acid Supplementation in PHA Production Media

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Volova, T.G.; Kiselev, E.G.; Demidenko, A.V.; Zhila, N.O.; Nemtsev, I.V.; Lukyanenko, A.V. Production and Properties of Microbial Polyhydroxyalkanoates Synthesized from Hydrolysates of Jerusalem Artichoke Tubers and Vegetative Biomass. Polymers 2022, 14, 132. [Google Scholar] [CrossRef] [PubMed]

- Chae, Y.; An, Y.J. Current research trends on plastic pollution and ecological impacts on the soil ecosystem: A review. Environ. Pollut. 2018, 240, 387–395. [Google Scholar] [CrossRef] [PubMed]

- Windsor, F.M.; Durance, I.; Horton, A.A.; Thompson, R.C.; Tyler, C.R.; Ormerod, S.J. A catchment-scale perspective of plastic pollution. Glob. Chang. Biol. 2019, 25, 1207–1221. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Harding, K.G.; Dennis, J.S.; von Blottnitz, H.; Harrison, S.T. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically based poly-beta-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Sirohi, R.; Pandey, J.P.; Tarafdar, A.; Sindhu, R.; Parameswaran, B.; Pandey, A. Applications of poly-3-hydroxybutyrate based composite in advanced applications of polysaccharides and their composites. Mater. Res. Found. 2020, 68, 45–59. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.-K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Kumar, G.; Kim, D.S.; Mulla, S.I. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef]

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Prog. Polym. Sci. 2013, 38, 536–583. [Google Scholar] [CrossRef]

- Koller, M. Biodegradable and biocompatible polyhydroxy-alkanoates (PHA): Auspicious microbial macromolecules for pharmaceutical and therapeutic applications. Molecules 2018, 23, 362. [Google Scholar] [CrossRef] [Green Version]

- Alcântara, J.M.G.; Distante, F.; Storti, G.; Moscatelli, D.; Morbidelli, M.; Sponchioni, M. Current trends in the production of biodegradable bioplastics: The case of polyhydroxyalkanoates. Biotechnol. Adv. 2020, 42, 107582. [Google Scholar] [CrossRef]

- Saratale, G.D.; Saratale, R.G.; Varjani, S.; Cho, S.K.; Ghodake, G.S.; Kadam, A.; Mulla, S.I.; Bharagava, R.N.; Kim, D.S.; Shin, H.S. Development of ultrasound aided chemical pretreatment methods to enrich saccharification of wheat waste biomass for polyhydroxybutyrate production and its characterization. Ind. Crop. Prod. 2020, 150, 112425. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Huang, J.; Qu, Z. A review on polyhydroxyalkanoate production from agricultural waste Biomass: Development, Advances, circular Approach, and challenges. Bioresour. Technol. 2021, 342, 126008. [Google Scholar] [CrossRef] [PubMed]

- Sagong, H.Y.; Son, H.F.; Choi, S.Y.; Lee, S.Y.; Kim, K.J. Structural Insights into Polyhydroxyalkanoates Biosynthesis. Trends Biochem. Sci. 2018, 43, 790–805. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Perez, S.; Serrano, A.; Pantión, A.A.; Alonso-Fariñas, B. Challenges of scaling-up PHA production from waste streams. A review. J. Environ. Manag. 2018, 205, 215–230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saratale, R.G.; Cho, S.-K.; Saratale, G.D.; Kumar, M.; Bharagava, R.N.; Varjani, S.; Kadam, A.A.; Ghodake, G.S.; Palem, R.R.; Mulla, S.I.; et al. An Overview of Recent Advancements in Microbial Polyhydroxyalkanoates (PHA) Production from Dark Fermentation Acidogenic Effluents: A Path to an Integrated Bio-Refinery. Polymers 2021, 13, 4297. [Google Scholar] [CrossRef]

- Bezerra, T.L.; Ragauskas, A.J. A review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels Bioprod. Biorefin. 2016, 10, 634–647. [Google Scholar] [CrossRef]

- Kumar, G.; Dharmaraja, J.; Arvindnarayan, S.; Shoban, S.; Bakonyi, P.; Saratale, G.D.; Nemestóthy, N.; Bélafi-Bakó, K.; Yoon, J.J.; Kim, S.H. A comprehensive review on thermochemical, biological, biochemical and hybrid conversion methods of bio-derived lignocellulosic molecules into renewable fuels. Fuel 2019, 251, 352–367. [Google Scholar] [CrossRef]

- van Osch, D.J.G.P.; Kollau, L.J.B.M.; van den Bruinhorst, A.; Asikainen, S.; Rocha, M.A.A.; Kroon, M.C. Ionic liquids and deep eutectic solvents for lignocellulosic biomass fractionation. Phys. Chem. Chem. Phys. 2017, 19, 2636–2665. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.; Laaksonen, A.; Liu, C.; Lu, X.; Ji, X. The peculiar effect of water on ionic liquids and deep eutectic solvents. Chem. Soc. Rev. 2018, 47, 8685–8720. [Google Scholar] [CrossRef] [Green Version]

- Saratale, R.G.; Cho, S.K.; Saratale, G.D.; Ghodake, G.S.; Bharagava, R.N.; Kim, D.S.; Nair, S.; Shin, H.S. Efficient bioconversion of sugarcane bagasse into polyhydroxybutyrate (PHB) by Lysinibacillus sp. and its characterization. Bioresour. Technol. 2021, 324, 124673. [Google Scholar] [CrossRef]

- Hubbell, C.A.; Ragauskas, A.J. Effect of acid-chlorite delignification on cellulose degree of polymerization. Bioresour. Technol. 2010, 101, 7410–7415. [Google Scholar] [CrossRef]

- Goering, H.D.; Van Soest, J.P. Forage for fiber analysis. In USDA Agricultural Handbook; USDA: Washington, DC, USA, 1970; No. 379; pp. 1–20. [Google Scholar]

- Kim, S.; Holtzapple, M.T. Effect of structural features on enzyme digestibility of corn stover. Bioresour. Technol. 2006, 97, 583–591. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Govil, T.; Wang, J.; Samanta, D.; David, A.; Tripathi, A.; Rauniyar, S.; Salem, D.R.; Sani, R.K. Lignocellulosic feedstock: A review of a sustainable platform for cleaner production of nature’s plastics. J. Clean. Prod. 2020, 270, 122521. [Google Scholar] [CrossRef]

- Nan, Y.; Jia, L.; Yang, M.; Xin, D.; Qin, Y.; Zhang, J. Simplified sodium chlorite pretreatment for carbohydrates retention andefficient enzymatic saccharification of silvergrass. Bioresour. Technol. 2018, 261, 223–231. [Google Scholar] [CrossRef] [PubMed]

- Rezende, C.A.; De Lima, M.; Maziero, P.; Deazevedo, E.; Garcia, W.; Polikarpov, I. Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnol. Biofuels 2011, 4, 54. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, J.; Stahl, H. Microbial utilization and biopolyester synthesis of bagasse hydrolysates. Bioresour. Technol. 2008, 99, 8042–8048. [Google Scholar] [CrossRef]

- Grimaldi, M.P.; Marques, M.P.; Laluce, C.; Cilli, E.M.; Sponchiado, S.R.P. Evaluation of lime and hydrothermal pretreatments for efficient enzymatic hydrolysis of raw sugarcane bagasse. Biotechnol. Biofuels 2015, 8, 205. [Google Scholar] [CrossRef] [Green Version]

- Ishizawa, C.I.; Davis, M.F.; Schell, D.F.; Johnson, D.K. Porosity and its effect on the digestibility of dilute sulfuric acid pretreated corn stover. J. Agric. Food. Chem. 2007, 55, 2575–2581. [Google Scholar] [CrossRef]

- Mittal, A.; Katahira, R.; Himmel, M.E.; Johnson, D.K. Effects of alkaline or liquid-ammonia treatment on crystalline cellulose: Changes in crystalline structure and effects on enzymatic digestibility. Biotechnol. Biofuels 2011, 4, 41–55. [Google Scholar] [CrossRef] [Green Version]

- de Paula, C.B.C.; de Paula-Elias, F.C.; Rodrigues, M.N.; Coelho, L.F.; de Oliveira, N.M.L.; de Almeida, A.F.; Contiero, J. Polyhydroxyalkanoate Synthesis by Burkholderia glumae into a Sustainable Sugarcane Biorefinery Concept. Front. Bioeng. Biotechnol. 2021, 8, 631284. [Google Scholar] [CrossRef]

- Olsson, L.; Hahn-Hägerdal, B. Fermentation of lignocellulosic hydrolysates for ethanol production. Enzym. Microb. Technol. 1996, 18, 312–331. [Google Scholar] [CrossRef]

- Lopes, M.S.; Gomez, J.G.; Taciro, M.K.; Mendonca, T.T.; Silva, L.F. Polyhydroxyalkanoate biosynthesis and simultaneous remotion of organic inhibitors from sugarcane bagasse hydrolysate by Burkholderia sp. J. Ind. Microbiol. Biotechnol. 2014, 41, 1353–1363. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.F.; Taciro, M.K.; Michelin Ramos, M.E.; Carter, J.M.; Pradella, J.G.C.; Gomez, J.G.C. Poly-3-hydroxybutyrate (P3HB) production by bacteria from xylose, glucose and sugarcane bagasse hydrolysate. J. Ind. Microbiol. Biotechnol. 2004, 31, 245–254. [Google Scholar] [CrossRef]

- de Souza, L.; Manasa, Y.; Shivakumar, S. Bioconversion of lignocellulosic substrates for the production of polyhydroxyalkanoates. Biocatal. Agric. Biotechnol. 2020, 28, 101754. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, H.J.; Kim, S.H.; Suh, M.J.; Cho, J.Y.; Ham, S.; Jeon, J.M.; Yoon, J.J.; Bhatia, S.K.; Gurav, R.; et al. Screening of the strictly xylose-utilizing Bacillus sp. SM01 for polyhydroxybutyrate and its co-culture with Cupriavidus necator NCIMB 11599 for enhanced production of PHB. Int. J. Biol. Macromol. 2021, 181, 410–417. [Google Scholar] [CrossRef]

- Rosero-Chasoy, G.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Buitrón, G.; Chairez, I.; Ruiz, H.A. Microbial co-culturing strategies for the production high value compounds, a reliable framework towards sustainable biorefinery implementation—An overview. Bioresour. Technol. 2021, 321, 124458. [Google Scholar] [CrossRef]

- Jones, J.A.; Wang, X. Use of bacterial co-cultures for the efficient production of chemicals. Curr. Opin. Biotechnol. 2018, 53, 33–38. [Google Scholar] [CrossRef]

- Khatami, K.; Perez-Zabaleta, M.; Cetecioglu, Z. Pure cultures for synthetic culture development: Next level municipal waste treatment for polyhydroxyalkanoates production. J. Environ. Manag. 2022, 305, 114337. [Google Scholar] [CrossRef]

- Anburajan, P.; Naresh Kumar, A.; Sabapathy, P.C.; Kim, G.B.; Cayetano, R.D.; Yoon, J.J.; Kumar, G.; Kim, S.H.; Kumar, A.N.; Chandrika, P.; et al. Polyhydroxy butyrate production by Acinetobacter junii BP25, Aeromonas hydrophila ATCC 7966, and their co-culture using a feast and famine strategy. Bioresour. Technol. 2019, 293, 122062. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Yoon, J.-J.; Kim, H.-J.; Hong, J.W.; Hong, Y.G.; Song, H.-S.; Moon, Y.-M.; Jeon, J.-M.; Kim, Y.-G.; Yang, Y.-H. Engineering of artificial microbial consortia of Ralstonia eutropha and Bacillus subtilis for poly (3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer production from sugarcane sugar without precursor feeding. Bioresour. Technol. 2018, 257, 92–101. [Google Scholar] [CrossRef]

- Nikodinovic, J.; Kenny, S.T.; Babu, R.P.; Woods, T. The conversion of BTEX compounds by single and defined mixed cultures to medium-chain-length polyhydroxyalkanoate. Appl. Microbiol. Biotechnol. 2008, 80, 665–673. [Google Scholar] [CrossRef] [PubMed]

- Munir, S.; Jamil, N. Polyhydroxyalkanoates (PHA) production in bacterial co-culture using glucose and volatile fatty acids as carbon source. J. Basic Microbiol. 2018, 58, 247–254. [Google Scholar] [CrossRef] [PubMed]

- Gouda, M.K.; Swellam, A.E.; Omar, S.H. Production of PHB by a Bacillus megaterium strain using sugarcane molasses and corn steep liquor as sole carbon and nitrogen sources. Microbiol. Res. 2001, 156, 201–207. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.M.; Geng, A.L.; Yao, C.Y.; Lu, L.H.; Li, Q.B. Xylitol production from D-xylose and horticultural waste hemicellulosic hydrolysate by a new isolate of Candida athensensis SB18. Bioresour. Technol. 2012, 105, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Sawant, S.S.; Salunke, B.K.; Kim, B.S. Degradation of corn Stover by fungal cellulase cocktail for production of polyhydroxyalkanoates by moderate halophile Paracoccus sp. LL1. Bioresour. Technol. 2015, 194, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Salgaonkar, B.B.; Bragança, J.M. Utilization of Sugarcane Bagasse by Halogeometricum borinquense Strain E3 for Biosynthesis of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Bioengineering 2017, 4, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Atabani, A.E.; Al-Muhtaseb, A.H.; Kumar, G.; Saratale, G.D.; Aslam, M.; Khan, H.A.; Said, Z.; Mahmoud, E. Valorization of spent coffee grounds into biofuels and value-added products: Pathway towards integrated bio-refinery. Fuel 2019, 254, 115640. [Google Scholar] [CrossRef]

- Obruca, S.; Benesova, P.; Petrik, S.; Oborna, J.; Prikryl, R.; Marova, I. Production of polyhydroxyalkanoates using hydrolysate of spent coffee grounds. Process Biochem. 2014, 49, 1409–1414. [Google Scholar] [CrossRef]

- Dalsasso, R.R.; Pavan, F.A.; Bordignon, S.E.; de Aragao, G.M.F.; Poletto, P. Polyhydroxybutyrate (PHB) production by Cupriavidus necator from sugarcane vinasse and molasses as mixed substrate. Process Biochem. 2019, 85, 12–18. [Google Scholar] [CrossRef]

- Rajesh Banu, J.; Ginni, G.; Kavitha, S.; Yukesh Kannah, R.; Adish Kumar, S.; Bhatia, S.K.; Kumar, G. Integrated biorefinery routes of biohydrogen: Possible utilization of acidogenic fermentative effluent. Bioresour. Technol. 2021, 319, 124241. [Google Scholar] [CrossRef]

- de Souza, L.; Shivakumar, S.; Das, A. Dual phase statistical optimization of biological pretreatment of sugarcane bagasse with Pycnoporus coccineus MScMS1 for polyhydroxyalkanoates production. J. Environ. Manag. 2022, 302, 113948. [Google Scholar] [CrossRef] [PubMed]

- Gowda, V.; Shivakumar, S. Agrowaste-based Polyhydroxyalkanoate (PHA) production using hydrolytic potential of Bacillus thuringiensis IAM 12077. Braz. Arch. Biol. Technol. 2014, 57, 55–61. [Google Scholar] [CrossRef] [Green Version]

| Pretreatment | Biochemical Components (%) | On Enzymatic Hydrolysis | |||

|---|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | Enzymatic Hydrolysis Yield (%) | Total Reducing Sugar | |

| No pretreatment | 38.80 ± 0.85 | 28.82 ± 0.68 | 24.70 ± 0.68 | 7.44 ± 0.32 | 50.0 ± 1.38 |

| Acid (1% H2SO4) | 58.91 ± 1.28 | 17.22 ± 0.42 | 9.82 ± 0.32 | 74.90 ± 1.65 | 569.0 ± 5.65 |

| ASC | 50.50 ± 0.88 | 17.54 ± 0.41 | 16.02 ± 0.44 | 62.10 ± 1.58 | 422.2 ± 4.98 |

| Parameters | Acid Pretreated SCB Enzymatic Hydrolysates Concentration (g/L) | ||

|---|---|---|---|

| 20 | 30 | 40 | |

| Fermentation period (h) | 48 | 48 | 48 |

| Total Sugar assimilation (%) | 78.0 ± 1.54 | 84.0 ± 1.65 | 80.0 ± 1.72 |

| Dry cell weight (DCW, g/L) | 9.12 ± 0.38 | 14.24 ± 0.65 | 16.32 ± 0.71 |

| Residual biomass (g/L) | 2.74 ± 0.28 | 3.99 ± 0.32 | 5.23 ± 0.26 |

| PHA accumulation (%) | 70.0 ± 2.50 | 72.1 ± 2.15 | 68.2 ± 1.98 |

| PHA titer (g/L) | 6.38 ± 0.25 | 10.25 ± 0.42 | 11.09 ± 0.52 |

| Qp g PHA/L/h | 0.132 ± 0.001 | 0.213 ± 0.001 | 0.231 ± 0.001 |

| PHA yield (g/g) | 0.409 ± 0.001 | 0.406 ± 0.001 | 0.346 ± 0.001 |

| Name of Substrate | Type of Pretreatment | Microorganism | Operation Mode | PHA Accumulation (%) | PHA Concentration (g/L) | Reference |

|---|---|---|---|---|---|---|

| Sugarcane bagasse | Ultrasound + alkaline pretreatment | Lysinibacillus sp. RGS | Batch | 61.5 | 5.31 | [19] |

| Sugarcane bagasse | Acid pretreatment | Ralstonia eutropha | Batch 50:50 | 56.7 | 6.06 | [27] |

| Sugarcane bagasse | Acid pretreatment | Burkholderia glumae MA13 | Batch | 14.95 | 0.09 | [31] |

| Sugarcane bagasse | Acid pretreatment | Burkholderia sp. F24 | Fed-Batch | 49.31 | 12.25 | [33] |

| Sugarcane bagasse | Acid pretreatment Detoxified | Burkholderia cepacia IPT 048 | Fed-batch | 53 | 2.3 | [34] |

| Sugarcane bagasse | Acid pretreatment + Detoxified | Burkholderia sacchari IPT 101 | Fed batch | 62 | 2.7 | [34] |

| Sugarcane bagasse | Acid pretreatment | Halogeometricum borinquense strain E3 | Batch | 50.4 | 1.6 | [47] |

| Sugarcane bagasse | Biological pre-treatment with Pycnoporus coccineus MScMS1 | Bacillus megaterium Ti3 | Batch | 65 | 0.58 | [52] |

| Sugarcane bagasse | Acid pretreatment | Bacillus thuringiensis | Batch | 39.6 | 4.2 | [53] |

| Sugarcane bagasse | Acid pretreatment | R. eutropha +Lysinibacillus sp. Co-culture | Batch | 70.0 | 6.38 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saratale, R.G.; Cho, S.-K.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Varjani, S.; Nair, S.; Kim, D.-S.; Shin, H.-S.; et al. Developing Microbial Co-Culture System for Enhanced Polyhydroxyalkanoates (PHA) Production Using Acid Pretreated Lignocellulosic Biomass. Polymers 2022, 14, 726. https://doi.org/10.3390/polym14040726

Saratale RG, Cho S-K, Kadam AA, Ghodake GS, Kumar M, Bharagava RN, Varjani S, Nair S, Kim D-S, Shin H-S, et al. Developing Microbial Co-Culture System for Enhanced Polyhydroxyalkanoates (PHA) Production Using Acid Pretreated Lignocellulosic Biomass. Polymers. 2022; 14(4):726. https://doi.org/10.3390/polym14040726

Chicago/Turabian StyleSaratale, Rijuta Ganesh, Si-Kyung Cho, Avinash Ashok Kadam, Gajanan Sampatrao Ghodake, Manu Kumar, Ram Naresh Bharagava, Sunita Varjani, Supriya Nair, Dong-Su Kim, Han-Seung Shin, and et al. 2022. "Developing Microbial Co-Culture System for Enhanced Polyhydroxyalkanoates (PHA) Production Using Acid Pretreated Lignocellulosic Biomass" Polymers 14, no. 4: 726. https://doi.org/10.3390/polym14040726

APA StyleSaratale, R. G., Cho, S.-K., Kadam, A. A., Ghodake, G. S., Kumar, M., Bharagava, R. N., Varjani, S., Nair, S., Kim, D.-S., Shin, H.-S., & Saratale, G. D. (2022). Developing Microbial Co-Culture System for Enhanced Polyhydroxyalkanoates (PHA) Production Using Acid Pretreated Lignocellulosic Biomass. Polymers, 14(4), 726. https://doi.org/10.3390/polym14040726