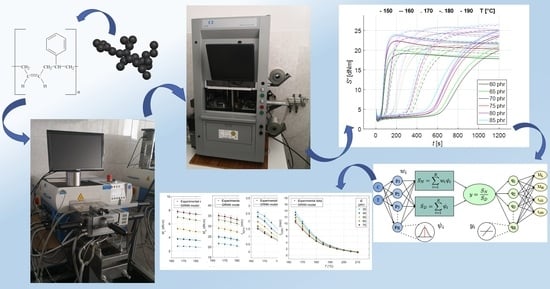

A Generalized Regression Neural Network Model for Predicting the Curing Characteristics of Carbon Black-Filled Rubber Blends

Abstract

1. Introduction

1.1. Curing Characteristics

1.2. Curing Process Modelling

1.3. Artificial Neural Networks

1.4. Generalized Regression Neural Networks

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

2.3. Rheological Analysis

2.4. Artificial Neural Network Modelling

3. Results and Discussion

3.1. Experimental Results

3.2. Pre-Processing of Experimental Data for ANN Analysis

3.3. GRNN Training Algorithm

3.4. Evaluation of the Goodness of the GRNN Model

3.5. Evaluation of the Predictive Performance and Generalization Capability of the GRNN Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vayyaprontavida Kaliyathan, A.; Varghese, K.M.; Nair, A.S.; Thomas, S. Rubber–rubber blends: A critical review. Prog. Rubber Plast. Recycl. Technol. 2020, 36, 196–242. [Google Scholar] [CrossRef]

- Nakanishi, Y.; Mita, K.; Yamamoto, K.; Ichino, K.; Takenaka, M. Effects of mixing process on spatial distribution and coexistence of sulfur and zinc in vulcanized EPDM rubber. Polymer 2021, 218, 123486. [Google Scholar] [CrossRef]

- Kruželák, J.; Kvasničáková, A.; Hudec, I. Peroxide curing systems applied for cross-linking of rubber compounds based on SBR. Adv. Ind. Eng. Polym. Res. 2020, 3, 120–128. [Google Scholar] [CrossRef]

- Hansupalak, N.; Srisuk, S.; Wiroonpochit, P.; Chisti, Y. Sulfur-Free Prevulcanization of Natural Rubber Latex by Ultraviolet Irradiation. Ind. Eng. Chem. Res. 2016, 55, 3974–3981. [Google Scholar] [CrossRef]

- Haque, M.E.; Makuuchi, K.; Mitomo, H.; Yoshii, F.; Ikeda, K. New Trend in Radiation Vulcanization of Natural Rubber Latex with a Low Energy Electron Beam. Polym. J. 2005, 37, 333–339. [Google Scholar] [CrossRef][Green Version]

- Kopal, I.; Vršková, J.; Bakošová, A.; Harničárová, M.; Labaj, I.; Ondrušová, D.; Valíček, J.; Krmela, J. Modelling the Stiffness-Temperature Dependence of Resin-Rubber Blends Cured by High-Energy Electron Beam Radiation Using Global Search Genetic Algorithm. Polymers 2020, 12, 2652. [Google Scholar] [CrossRef]

- Martin, D.; Ighigeanu, D.; Mateescu, E.; Craciun, G.; Ighigeanu, A. Vulcanization of rubber mixtures by simultaneous electron beam and microwave irradiation. Radiat. Phys. Chem. 2002, 65, 63–65. [Google Scholar] [CrossRef]

- Mutar, M. A study in vulcanization of neoprene rubber (wrt) by polymethylol resin (resol). J. Al-Nahrain Univ. Sci. 2010, 13, 1–6. [Google Scholar] [CrossRef]

- Karpeles, R.; Grossi, A.G. EPDM Rubber Technology. In Handbook of Elastomers, 2nd ed.; Bhowmick, A.K., Stephens, H.L., Eds.; Marcel Decker, Inc.: New York, NY, USA, 2001; pp. 845–876. [Google Scholar]

- Hopmann, C.H.; Schmitz, M. Data Acquisition and Process Monitoring as Enabler for Industry 4.0. In Plastic Industry 4.0; Carl Hanser Verlag GmbH & Co.: München, Germany, 2020; pp. 11–73. [Google Scholar]

- Chang, B.P.P.; Gupta, A.; Muthuraj, R.; Mekonnen, T. Bioresourced fillers for rubber composite sustainability: Current development and future opportunities. Green Chem. 2021, 23, 5337–5378. [Google Scholar] [CrossRef]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Large amplitude oscillatory rheology of silica and cellulose nanocrystals filled natural rubber compounds. J. Colloid Interface Sci. 2021, 588, 602–610. [Google Scholar] [CrossRef]

- Labaj, I.; Skalková, P.; Dubec, A.; Janík, R.; Papučová, I.; Ondrušová, D. Study of properties of elastomer blends based on natural rubber and chitosan. In Proceedings of the 24th International Conference on Composite Structures, Porto, Portugal, 14–18 June 2021. [Google Scholar]

- Dick, J.S. Rubber Technology—Compounding and Testing for Performance, 2nd ed.; Hanser Publishers: Munich, Germany, 2009. [Google Scholar]

- Abdelsalam, A.A.; Araby, S.; El-Sabbagh, S.H.; Abdelmoneim, A.; Hassan, M.A. Effect of carbon black loading on mechanical and rheological properties of natural rubber/styrene-butadiene rubber/nitrile butadiene rubber blends. J. Thermoplast. Compos. Mater. 2021, 34, 490–507. [Google Scholar] [CrossRef]

- Hossain, M. Modelling and Computation of Polymer Curing. Ph.D. Thesis, Der Technischen Fakultät der Universitat Erlangen-Nurnberg, Erlangen, Germany, 2010. [Google Scholar]

- Devi, K.G.; Rath, M.; Linh, N.T.D. Artificial Intelligence Trends for Data Analytics Using Machine Learning and Deep Learning Approaches, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- ArulRaj, K.; Karthikeyan, M.; Narmatha, D. A View of Artificial Neural Network Models in Different Application Areas. E3S Web Conf. 2021, 287, 03001. [Google Scholar] [CrossRef]

- Karaağaç, B.; İnal, M.; Deniz, V. Artificial neural network approach for predicting optimum cure time of rubber compounds. Mater. Des. 2009, 30, 1685–1690. [Google Scholar]

- Karaağaç, B.; İnal, M.; Deniz, V. Predicting optimum cure time of rubber compounds by means of ANFIS. Mater. Des. 2012, 35, 833–838. [Google Scholar] [CrossRef]

- Lubura, J.D.; Kojić, P.; Pavličević, J.; Ikonić, B.; Omorjan, R.; Bera, O. Prediction of rubber vulcanization using an artificial neural network. Hem. Ind. 2021, 75, 277–283. [Google Scholar] [CrossRef]

- Du, K.L.; Swamy, M.N.S. Neural Networks and Statistical Learning; Springer Science & Business Media: London, UK, 2013. [Google Scholar]

- Rao, M.A.; Srinivas, J. Neural Networks: Algorithms and Applications, 1st ed.; Alpha Science International: Oxford, UK, 2003. [Google Scholar]

- Paliwal, M.; Kumar, U.A. Neural networks and statistical techniques: A review of applications. Expert Syst. Appl. 2009, 36, 2–17. [Google Scholar] [CrossRef]

- Gambella, C.; Ghaddar, B.; Naoum-Sawaya, J. Optimization problems for machine learning: A survey. Eur. J. Oper. Res. 2021, 290, 807–828. [Google Scholar] [CrossRef]

- Hagan, M.T.; Demuth, H.B.; Beale, M.H.; De Jesús, O. Neural Network Design, 2nd ed.; Martin Hagan: Oklahoma, OK, USA, 2014. [Google Scholar]

- Liu, X.; Tian, S.; Tao, F.; Yu, W. A review of artificial neural networks in the constitutive modeling of composite materials. Compos. B. Eng. 2021, 224, 109152. [Google Scholar] [CrossRef]

- Kopal, I.; Harničárová, H.; Valíček, J.; Kušnerová, M. Modelling the temperature dependence of dynamic mechanical properties and visco-elastic behavior of thermoplastic polyurethane using artificial neural network. Polymers 2017, 9, 519. [Google Scholar] [CrossRef]

- Kopal, I.; Labaj, I.; Harničárová, M.; Valíček, J.; Hrubý, D. Prediction of the tensile response of carbon black filled rubber blends by artificial neural network. Polymers 2018, 10, 644. [Google Scholar] [CrossRef]

- Kopal, I.; Harničárová, M.; Valíček, J.; Krmela, J.; Lukáč, O. Radial basis function neural network-based modeling of the dynamic thermo-mechanical response and damping behavior of thermoplastic elastomer systems. Polymers 2019, 11, 1074. [Google Scholar] [CrossRef]

- Dreyfus, G. Neural Networks Methodology and Applications; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Al-Mahasneh, A.J.; Anavatti, S.; Garratt, M.; Pratama, M. Applications of General Regression Neural Networks in Dynamic Systems. In Digital Systems, Asadpour, V., Ed.; Intech Open: London, UK, 2018. [Google Scholar]

- Farokhi, F. Deconvoluting kernel density estimation and regression for locally differentially private data. Sci. Rep. 2020, 10, 21361. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kun, I. Fundamentals of Probability and Stochastic Processes with Applications to Communications; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Pernot, P.; Savin, A. Probabilistic performance estimators for computational chemistry methods: Systematic improvement probability and ranking probability matrix. I. Theory. J. Chem. Phys. 2020, 152, 164108. [Google Scholar] [CrossRef]

- O’Neill, B. Elementary Differential Geometry, 2nd ed.; Elsevier Academic Press: San Diego, CA, USA, 2006. [Google Scholar]

- Wen, H.; Yan, T.; Liu, Z.; Chen, D. Integrated neural network model with pre-RBF kernels. Sci. Prog. 2021, 104, 00368504211026111. [Google Scholar] [CrossRef] [PubMed]

- Specht, D.F. A general regression neural network. IEEE Trans. Neural Netw. 1991, 2, 568–576. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Liu, J.; Zhu, K.; Hu, J.; Jiang, X.; Liu, Y. Generalized regression neural network association with terahertz spectroscopy for quantitative analysis of benzoic acid additive in wheat flour. R. Soc. Open Sci. 2019, 6, 190485. [Google Scholar] [CrossRef]

- Sharkawy, A.N. Principle of neural network and its main types. J. Adv. Appl. Comput. Math. 2020, 7, 8–19. [Google Scholar] [CrossRef]

- Rajasekaran, S.; Pai, G.V. Neural Networks, Fuzzy Logic and Genetic Algorithms, 1st ed.; Prentice Hall of India: New Delhi, India, 2004. [Google Scholar]

- Huang, Y.C.; Liao, H.S. Building prediction model for a machine tool with genetic algorithm optimization on a general regression neural network. J. Intell. Fuzzy Syst. 2020, 38, 2347–2357. [Google Scholar] [CrossRef]

- Al-Nesrawy, S.H.; Al-Maamori, M.H.; Japor, H. Effect of temperature on rheological properties of sbr compounds reinforced by some industrial scraps as a filler. Int. J. Chem. Sci. 2016, 14, 1285–1295. [Google Scholar]

- Arayapranee, W.; Rempel, G.L. Effects of polarity on the filler-rubber interaction and properties of silica filled grafted natural rubber composites. J. Polym. 2013, 2013, 279529. [Google Scholar] [CrossRef]

- Chalid, M.; Husnil, Y.A.; Puspitasari, S.; Cifriadi, A. Experimental and Modelling Study of the Effect of Adding Starch-Modified Natural Rubber Hybrid to the Vulcanization of Sorghum Fibers-Filled Natural Rubber. Polymers 2020, 12, 3017. [Google Scholar] [CrossRef] [PubMed]

- Sattayanurak, S.; Sahakaro, K.; Kaewsakul, W.; Dierkes, W.K.; Reuvekamp, L.A.; Blume, A.; Noordermeer, J.W. Synergistic effect by high specific surface area carbon black as secondary filler in silica reinforced natural rubber tire tread compounds. Polym. Test. 2020, 81, 106173. [Google Scholar] [CrossRef]

- Ghosh, J.; Ghorai, S.; Jalan, A.K.; Roy, M.; De, D. Manifestation of Accelerator Type and Vulcanization System on the Properties of Silica-reinforced SBR/devulcanize SBR blend Vulcanizates. Adv. Polym. Technol. 2018, 37, 2636–2650. [Google Scholar] [CrossRef]

- Hussain, M.; Yasin, S.; Akram, M.A.; Xu, H.; Song, Y.; Zheng, Q. Influence of Ionic Liquids on Structure and Rheological Behaviors of Silica-Filled Butadiene Rubber. Ind. Eng. Chem. Res. 2019, 58, 18205–18212. [Google Scholar] [CrossRef]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Effects of ionic liquid on cellulosic nanofiller filled natural rubber bionanocomposites. J. Colloid Interface Sci. 2021, 591, 409–417. [Google Scholar] [CrossRef]

- Shanks, R.A.; Kong, I. General Purpose Elastomers: Structure, Chemistry, Physics and Performance. In Advances in Elastomers I. Advanced Structured Materials; Visakh, P., Thomas, S., Chandra, A., Mathew, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 11, pp. 11–45. [Google Scholar]

- Kurian, T.; George, K.E.; Francis, D.J. Effect of vulcanization temperature on the cure characteristics and vulcanizate properties of natural rubber and styrene-butadiene rubber. Angew. Makromolek. Chem. 1988, 162, 123–134. [Google Scholar] [CrossRef]

- Ramesan, M.T. The effects of filler content on cure and mechanical properties of dichlorocarbene modified styrene butadiene rubber/carbon black composites. J. Polym. Res. 2005, 11, 333–340. [Google Scholar] [CrossRef]

- Joseph, A.M.; George, B.; Madhusoodanan, K.N.; Alex, R. Cure characteristics of devulcanized rubber: The issue of low scorch. Rubber Chem. Technol. 2017, 90, 536–549. [Google Scholar] [CrossRef]

- Sadequl, A.M.; Ishiaku, U.S.; Ismail, H.; Poh, B.T. The effect of accelerator/sulfur ratio on the scorch time of epoxidized natural rubber. Eur. Polym. J. 1998, 34, 51–57. [Google Scholar] [CrossRef]

- Khimi, S.R.; Pickering, K.L. A new method to predict optimum cure time of rubber compound using dynamic mechanical analysis. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Maciejewska, M.; Siwek, M. The Influence of Curing Systems on the Cure Characteristics and Physical Properties of Styrene–Butadiene Elastomer. Materials 2020, 13, 5329. [Google Scholar] [CrossRef] [PubMed]

- Ploskas, N.; Samaras, N. GPU Programming in MATLAB; Morgan Kaufmann: Cambridge, UK, 2016. [Google Scholar]

- de Bragança Pereira, B.; Rao, C.R.; de Oliveira, F.B. Statistical Learning Using Neural Networks: A Guide for Statisticians and Data Scientists with Python; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopal, I.; Labaj, I.; Vršková, J.; Harničárová, M.; Valíček, J.; Ondrušová, D.; Krmela, J.; Palková, Z. A Generalized Regression Neural Network Model for Predicting the Curing Characteristics of Carbon Black-Filled Rubber Blends. Polymers 2022, 14, 653. https://doi.org/10.3390/polym14040653

Kopal I, Labaj I, Vršková J, Harničárová M, Valíček J, Ondrušová D, Krmela J, Palková Z. A Generalized Regression Neural Network Model for Predicting the Curing Characteristics of Carbon Black-Filled Rubber Blends. Polymers. 2022; 14(4):653. https://doi.org/10.3390/polym14040653

Chicago/Turabian StyleKopal, Ivan, Ivan Labaj, Juliána Vršková, Marta Harničárová, Jan Valíček, Darina Ondrušová, Jan Krmela, and Zuzana Palková. 2022. "A Generalized Regression Neural Network Model for Predicting the Curing Characteristics of Carbon Black-Filled Rubber Blends" Polymers 14, no. 4: 653. https://doi.org/10.3390/polym14040653

APA StyleKopal, I., Labaj, I., Vršková, J., Harničárová, M., Valíček, J., Ondrušová, D., Krmela, J., & Palková, Z. (2022). A Generalized Regression Neural Network Model for Predicting the Curing Characteristics of Carbon Black-Filled Rubber Blends. Polymers, 14(4), 653. https://doi.org/10.3390/polym14040653