Improved Performance of Solid Polymer Electrolyte for Lithium-Metal Batteries via Hot Press Rolling

Abstract

:1. Introduction

2. Materials and Methods

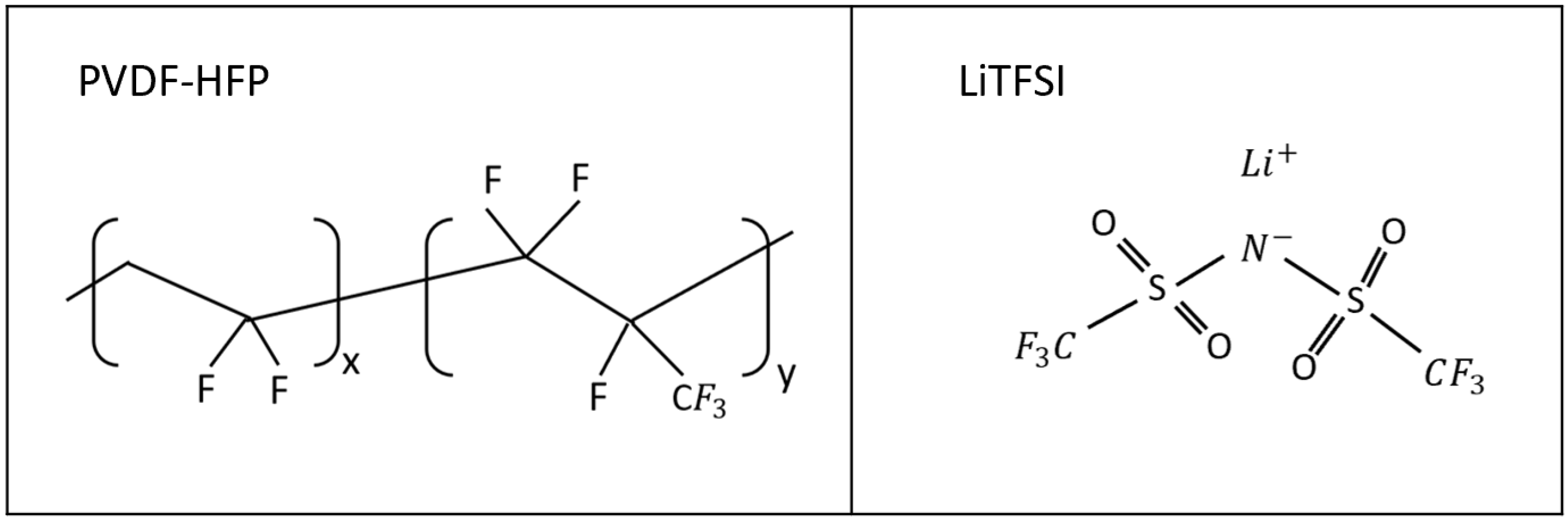

2.1. Materials Used

2.2. Methods

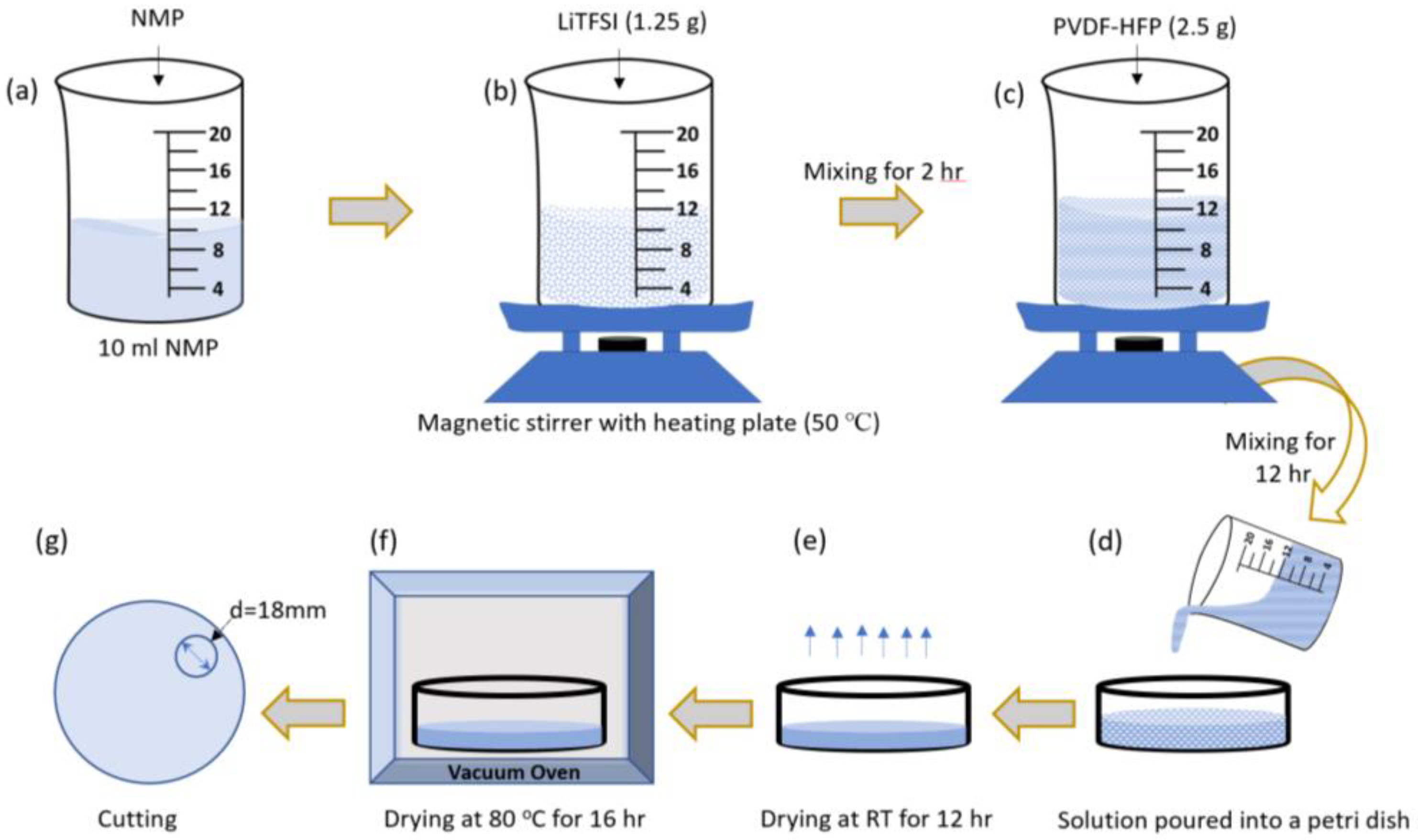

2.2.1. Preparation of Solid Polymer Electrolyte Membranes

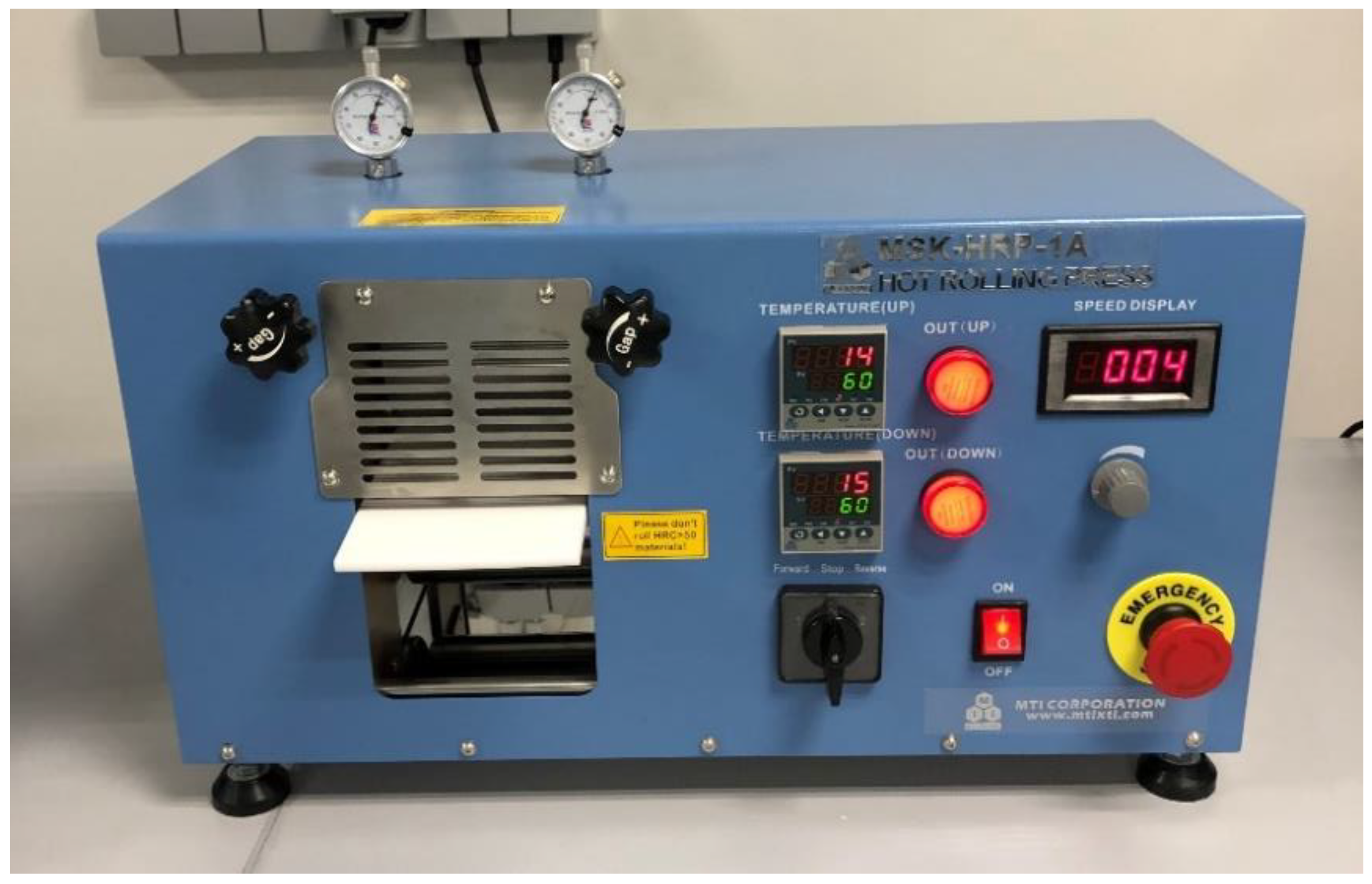

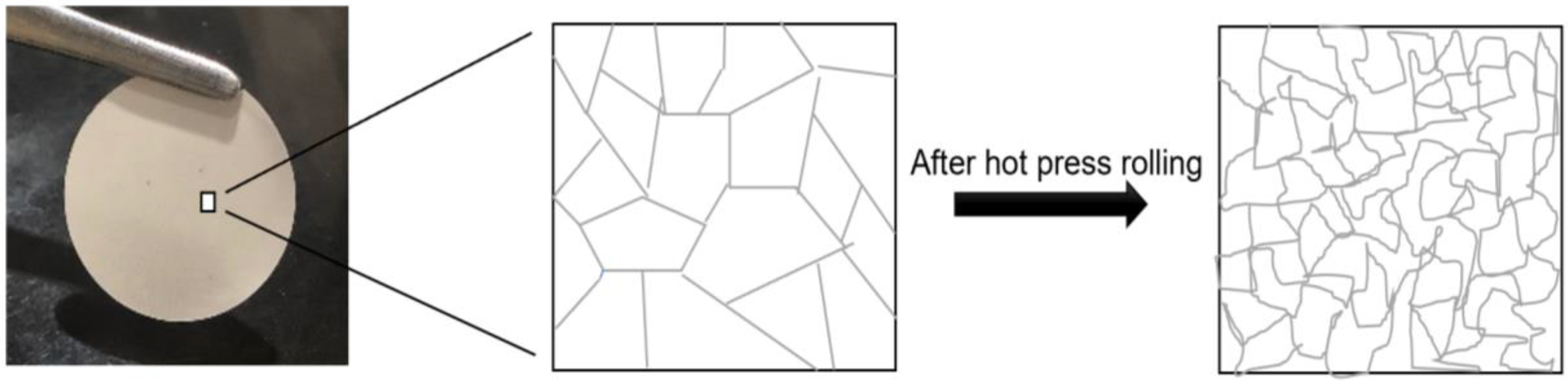

2.2.2. Hot Press Rolling Treatment of Solid Polymer Electrolytes

2.2.3. Catholyte Preparation

2.3. Characterization Methods

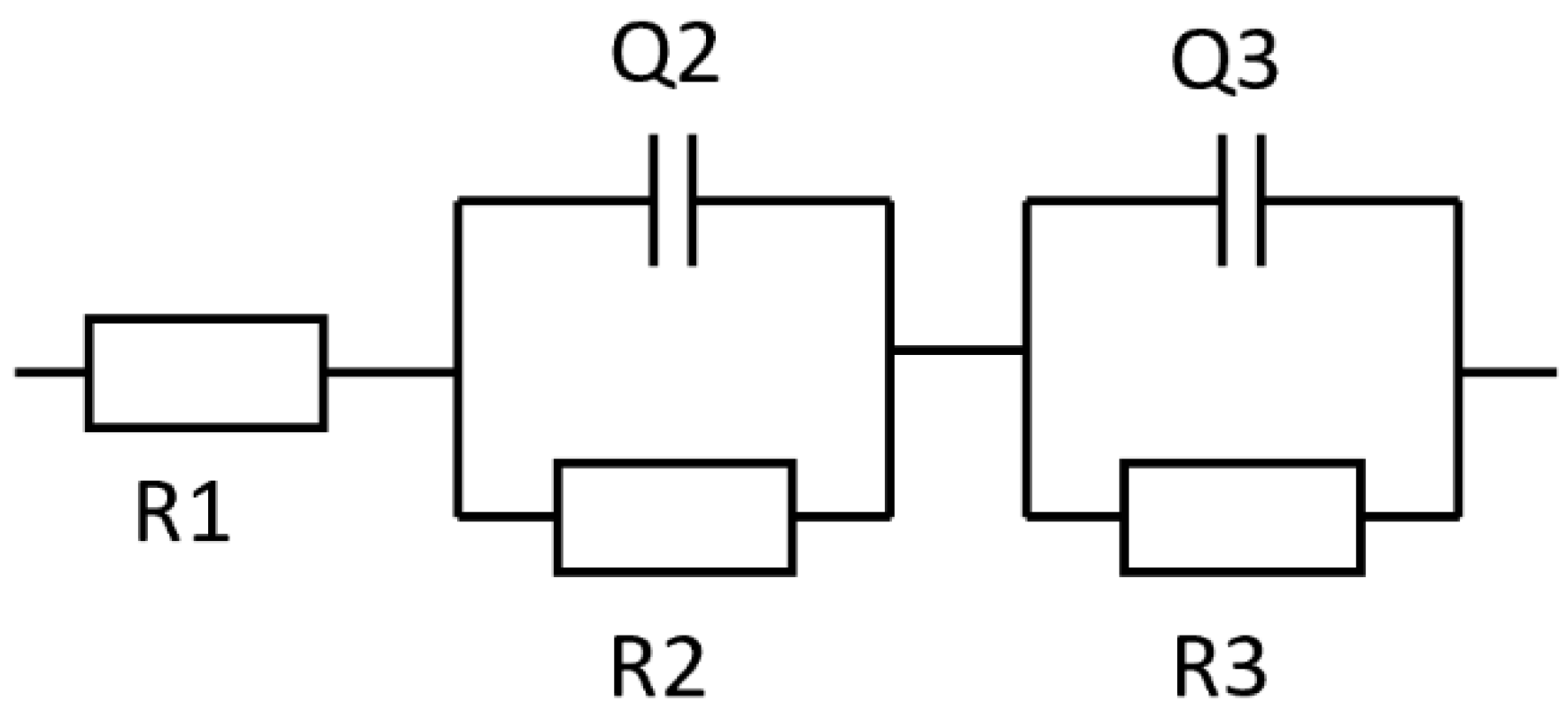

2.3.1. Electrochemical Impedance Spectroscopy (EIS)

2.3.2. Direct Current (DC) Polarization

2.3.3. Linear Sweep Voltammetry (LSV)

2.3.4. Symmetrical Cell Cycling

2.3.5. Galvano-Static Charge–Discharge Cycling

3. Results and Discussion

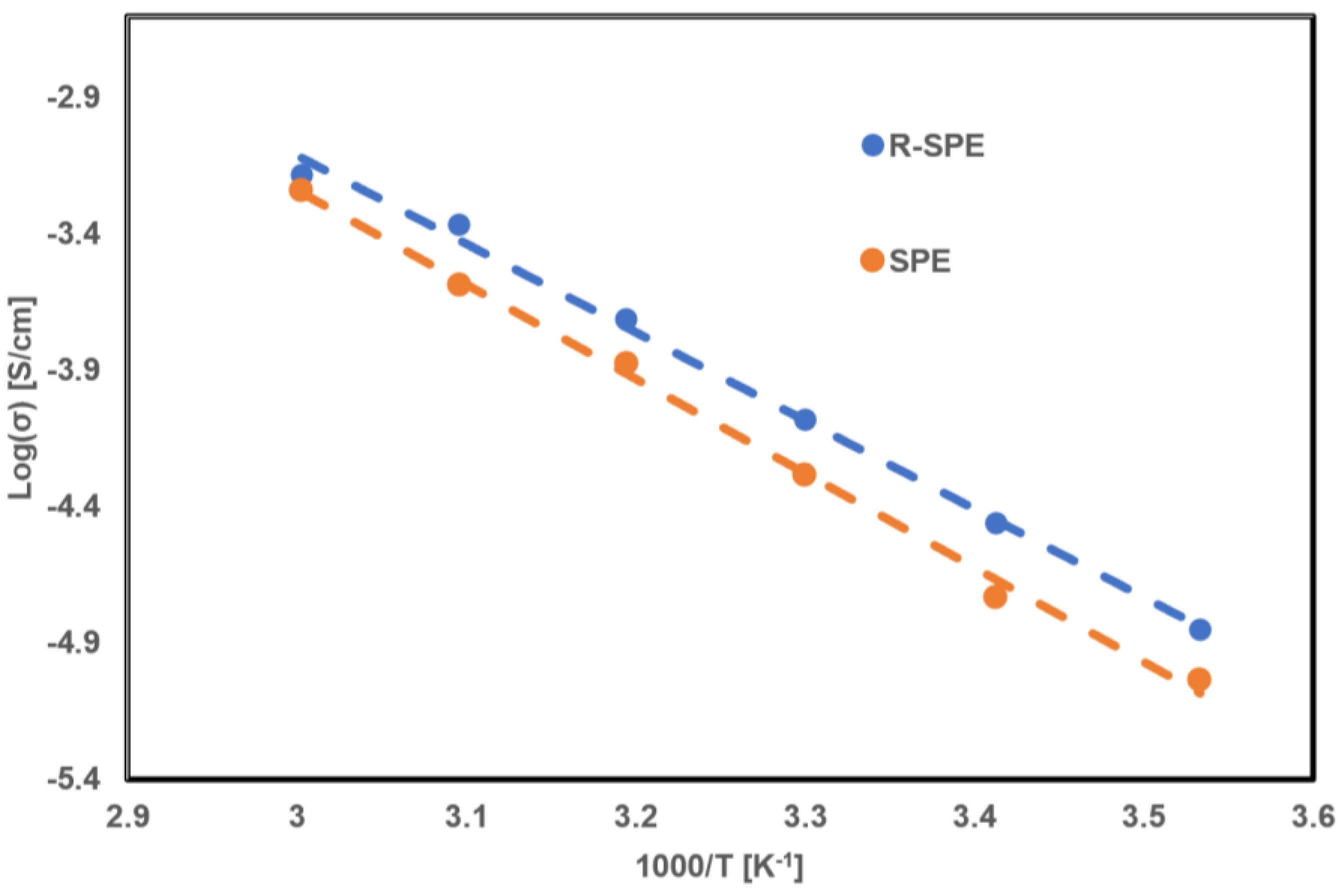

3.1. Ionic Conductivity

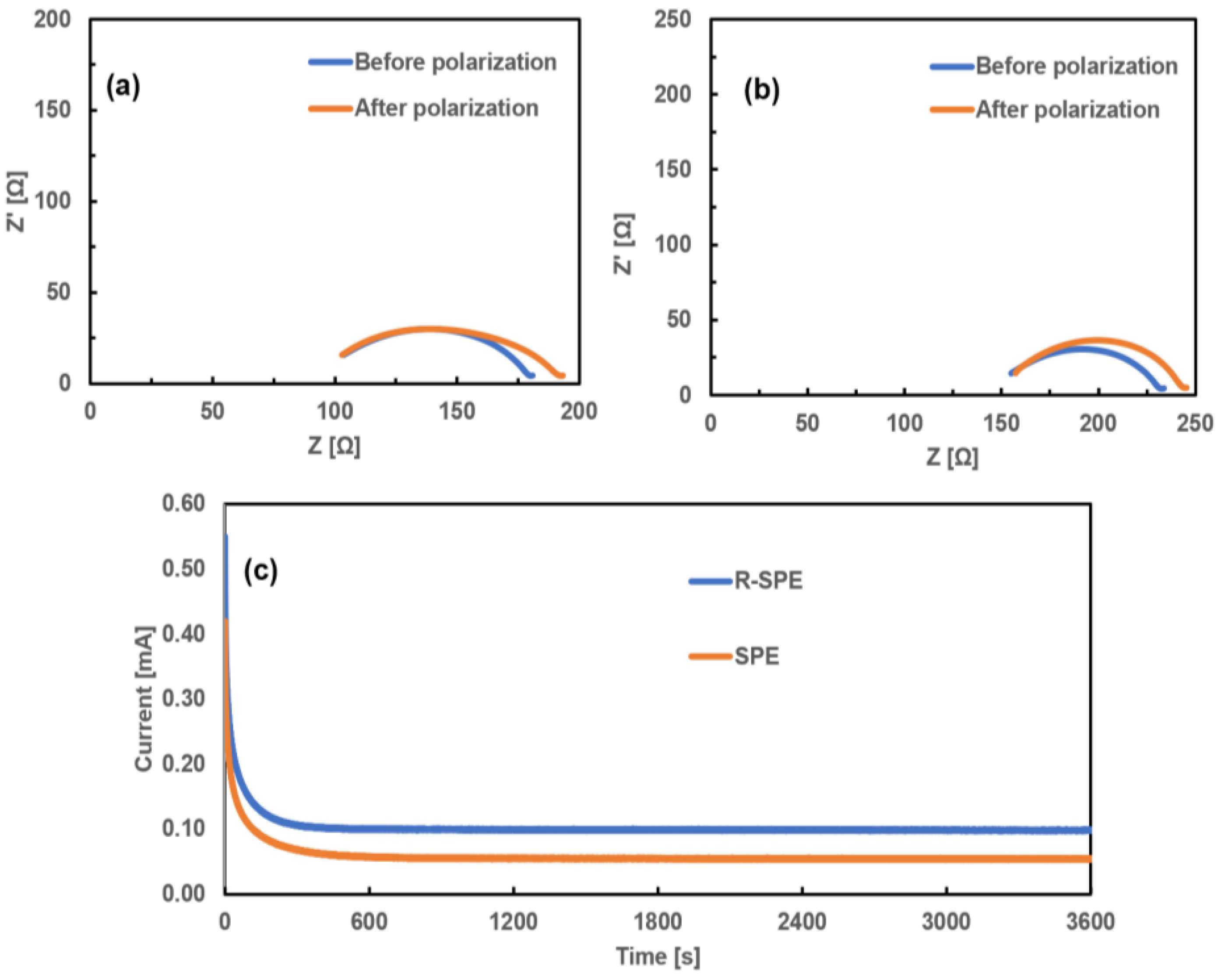

3.2. Direct Current (DC) Polarization and Transference Number

3.3. Linear Sweep Voltammetry (LSV)

3.4. Symmetrical Cell Cycling

3.5. Galvano-Static Charge–Discharge Cycling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hannah Ritchie and Max Roser (2020)—“CO₂ and Greenhouse Gas Emissions”. Available online: https://ourworldindata.org/ (accessed on 25 November 2021).

- Wan, J.; Xie, J.; Mackanic, D.; Burke, W.; Bao, Z.; Cui, Y. Status, promises, and challenges of nanocomposite solid-state electrolytes for safe and high performance lithium batteries. Mater. Today Nano 2018, 4, 1–16. [Google Scholar] [CrossRef]

- Kim, H.; Jeong, G.; Kim, Y.-U.; Kim, J.-H.; Park, C.-M.; Sohn, H.-J. Metallic anodes for next generation secondary batteries. Chem. Soc. Rev. 2013, 42, 9011–9034. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yao, Z.; Zhao, C.; Verhallen, T.; Tabor, D.P.; Liu, M.; Ooms, F.; Kang, F.; Aspuru-Guzik, A.; Hu, Y.-S.; et al. Interface chemistry of an amide electrolyte for highly reversible lithium metal batteries. Nat. Commun. 2020, 11, 4188. [Google Scholar] [CrossRef]

- Albertus, P.; Anandan, V.; Ban, C.; Balsara, N.; Belharouak, I.; Buettner-Garrett, J.; Chen, Z.; Daniel, C.; Doeff, M.; Dudney, N.J.; et al. Challenges for and Pathways toward Li-Metal-Based All-Solid-State Batteries. ACS Energy Lett. 2021, 6, 1399–1404. [Google Scholar] [CrossRef]

- Lv, F.; Wang, Z.; Shi, L.; Zhu, J.; Edström, K.; Mindemark, J.; Yuan, S. Challenges and development of composite solid-state electrolytes for high-performance lithium ion batteries. J. Power Sources 2019, 441, 227175. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Shen, L.; Liu, Q.; Ma, J.; Lv, W.; He, Y.; Yang, Q. Progress and Perspective of Ceramic/Polymer Composite Solid Electrolytes for Lithium Batteries. Adv. Sci. 2020, 7, 1903088. [Google Scholar] [CrossRef] [Green Version]

- Fergus, J.W. Ceramic and polymeric solid electrolytes for lithium-ion batteries. J. Power Sources 2010, 195, 4554–4569. [Google Scholar] [CrossRef]

- Yue, L.; Ma, J.; Zhang, J.; Zhao, J.; Dong, S.; Liu, Z.; Cui, G.; Chen, L. All solid-state polymer electrolytes for high-performance lithium ion batteries. Energy Storage Mater. 2016, 5, 139–164. [Google Scholar] [CrossRef]

- Yu, Q.; Jiang, K.; Yu, C.; Chen, X.; Zhang, C.; Yao, Y.; Jiang, B.; Long, H. Recent progress of composite solid polymer electrolytes for all-solid-state lithium metal batteries. Chin. Chem. Lett. 2021, 32, 2659–2678. [Google Scholar] [CrossRef]

- Jiang, Y.; Yan, X.; Ma, Z.; Mei, P.; Xiao, W.; You, Q.; Zhang, Y. Development of the PEO Based Solid Polymer Electrolytes for All-Solid State Lithium Ion Batteries. Polymers 2018, 10, 1237. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Zhao, X.; Suo, Z.; Zou, C.; Runt, J.; Liu, S. Electrical breakdown and ultrahigh electrical energy density in poly(vinylidene fuoride-hexafuoropropylene) copolymer. Appl. Phys. Lett. 2009, 94, 162901. [Google Scholar] [CrossRef] [Green Version]

- Han, W.; Kim, T.; Yoo, B.; Park, H.-H. Tunable Dielectric Properties of Poly(vinylidenefluoride-co-hexafluoropropylene) Films with Embedded Fluorinated Barium Strontium Titanate Nanoparticles. Sci. Rep. 2018, 8, 4086. [Google Scholar] [CrossRef] [Green Version]

- Mindemark, J.; Lacey, M.J.; Bowden, T.M.; Brandell, D. Beyond PEO—Alternative host materials for Li + -conducting solid polymer electrolytes. Prog. Polym. Sci. 2018, 81, 114–143. [Google Scholar] [CrossRef]

- Fasciani, C.; Panero, S.; Hassoun, J.; Scrosati, B. Novel configuration of poly(vinylidenedifluoride)-based gel polymer electrolyte for application in lithium-ion batteries. J. Power Sources 2015, 294, 180–186. [Google Scholar] [CrossRef]

- Golodnitsky, D.; Strauss, E.; Peled, E.; Greenbaum, S. Review—On Order and Disorder in Polymer Electrolytes. J. Electrochem. Soc. 2015, 162, A2551–A2566. [Google Scholar] [CrossRef]

- Robbins, A.B.; Minnich, A.J. Crystalline polymers with exceptionally low thermal conductivity studied using molecular dynamics. Appl. Phys. Lett. 2015, 107, 201908. [Google Scholar] [CrossRef] [Green Version]

- Mileva, D.; Tranchida, D.; Gahleitner, M. Designing polymer crystallinity: An industrial perspective. Polym. Cryst. 2018, 1, e10009. [Google Scholar] [CrossRef]

- Tashiro, K. Handbook of Polymer Crystallization; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 165–196. [Google Scholar] [CrossRef]

- Chang, C.-W.; Lai, W.-C. A strategy for preparing solid polymer electrolytes via the electrospinning process. J. Taiwan Inst. Chem. Eng. 2020, 116, 279–285. [Google Scholar] [CrossRef]

- St-Onge, V.; Cui, M.; Rochon, S.; Daigle, J.-C.; Claverie, J.P. Reducing crystallinity in solid polymer electrolytes for lithium-metal batteries via statistical copolymerization. Commun. Mater. 2021, 2, 83. [Google Scholar] [CrossRef]

- Tarascon, J.-M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Croce, F.; Sacchetti, S.; Scrosati, B. Advanced, lithium batteries based on high-performance composite polymer electrolytes. J. Power Sources 2006, 162, 685–689. [Google Scholar] [CrossRef]

- Lee, H.S.; Yang, X.Q.; McBreen, J.; Xu, Z.S.; Skotheim, T.A.; Okamoto, Y. Ionic Conductivity of a Polymer Electrolyte with Modified Carbonate as a Plasticizer for poly(ethylene oxide). J. Electrochem. Soc. 1994, 141, 886–889. [Google Scholar] [CrossRef]

- Zhan, H.; Wu, M. Excellent Performances of Composite Polymer Electrolytes with Porous Vinyl-Functionalized SiO2 Nanoparticles for Lithium Metal Batteries. Polymers 2021, 13, 2468. [Google Scholar] [CrossRef]

- Xu, L.; Li, G.; Guan, J.; Wang, L.; Chen, J.; Zheng, J. Garnet-doped composite polymer electrolyte with high ionic conductivity for dendrite-free lithium batteries. J. Energy Storage 2019, 24, 100767. [Google Scholar] [CrossRef]

- Wang, H.; Cui, X.; Zhang, C.; Gao, H.; Du, W.; Chen, Y. Promotion of Ionic Conductivity of PEO-Based Solid Electrolyte Using Ultrasonic Vibration. Polymers 2020, 12, 1889. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Ren, Y.; Wang, M.; He, J.; Huo, W.; Tang, H. Improving the Conductivity of Solid Polymer Electrolyte by Grain Reforming. Nanoscale Res. Lett. 2020, 15, 122. [Google Scholar] [CrossRef] [PubMed]

- Mathies, L.; Diddens, D. Transport mechanism of lithium ions in non-coordinating P(VdF-HFP) copolymer matrix. Solid State Ion. 2020, 357, 115497. [Google Scholar] [CrossRef]

- Wang, F.; Li, L. Influence of additives in PVDF-base solid polymer electrolyte. Sustain. Energy Fuels 2018, 2, 492–498. [Google Scholar] [CrossRef]

- Ataollahi, N.; Ahmad, A.; Hamzah, H.; Rahman, M.; Sabirin, M.N. Ionic Conductivity of PVDF-HFP/MG49 Based Solid Polymer Electrolyte. Adv. Mater. Res. 2012, 501, 29–33. [Google Scholar] [CrossRef]

- Gonçalves, R.; Miranda, D.; Almeida, A.M.L.D.F.; Silva, M.; Meseguer-Dueñas, J.M.; Ribelles, J.G.; Lanceros-Méndez, S.; Costa, C. Solid polymer electrolytes based on lithium bis(trifluoromethanesulfonyl)imide/poly(vinylidene fluoride -co-hexafluoropropylene) for safer rechargeable lithium-ion batteries. Sustain. Mater. Technol. 2019, 21, e00104. [Google Scholar] [CrossRef] [Green Version]

- Leš, K.; Jordan, C.-S. Ionic conductivity enhancement in solid polymer electrolytes by electrochemical in situ formation of an interpenetrating network. RSC Adv. 2020, 10, 41296–41304. [Google Scholar] [CrossRef]

- Colin, J.E.; Vincent, A. Electrochemical measurement of transference numbers in polymer electrolytes. Polymer 1987, 28, 2324–2328. [Google Scholar]

- Eftekhari, A. Lithium-Ion Batteries with High Rate Capabilities. ACS Sustain. Chem. Eng. 2017, 5, 2799–2816. [Google Scholar]

| T (°C) | Impedance (Ω) SPE | Impedance (Ω) R-SPE | Ionic Conductivity (S/cm) SPE | Ionic Conductivity (S/cm) R-SPE |

|---|---|---|---|---|

| 10 | 343 | 223 | 9.17 × 10−6 | 1.40 × 10−5 |

| 20 | 170 | 91 | 1.85 × 10−5 | 3.44 × 10−5 |

| 30 | 60 | 38 | 5.21 × 10−5 | 8.28 × 10−5 |

| 40 | 23 | 16 | 1.33 × 10−4 | 1.93 × 10−4 |

| 50 | 12 | 7 | 2.58 × 10−4 | 4.31 × 10−4 |

| 60 | 5 | 4 | 5.75 × 10−4 | 6.56 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yadav, P.; Beheshti, S.H.; Kathribail, A.R.; Ivanchenko, P.; Mierlo, J.V.; Berecibar, M. Improved Performance of Solid Polymer Electrolyte for Lithium-Metal Batteries via Hot Press Rolling. Polymers 2022, 14, 363. https://doi.org/10.3390/polym14030363

Yadav P, Beheshti SH, Kathribail AR, Ivanchenko P, Mierlo JV, Berecibar M. Improved Performance of Solid Polymer Electrolyte for Lithium-Metal Batteries via Hot Press Rolling. Polymers. 2022; 14(3):363. https://doi.org/10.3390/polym14030363

Chicago/Turabian StyleYadav, Poonam, Seyed Hamidreza Beheshti, Anish Raj Kathribail, Pavlo Ivanchenko, Joeri Van Mierlo, and Maitane Berecibar. 2022. "Improved Performance of Solid Polymer Electrolyte for Lithium-Metal Batteries via Hot Press Rolling" Polymers 14, no. 3: 363. https://doi.org/10.3390/polym14030363

APA StyleYadav, P., Beheshti, S. H., Kathribail, A. R., Ivanchenko, P., Mierlo, J. V., & Berecibar, M. (2022). Improved Performance of Solid Polymer Electrolyte for Lithium-Metal Batteries via Hot Press Rolling. Polymers, 14(3), 363. https://doi.org/10.3390/polym14030363