Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

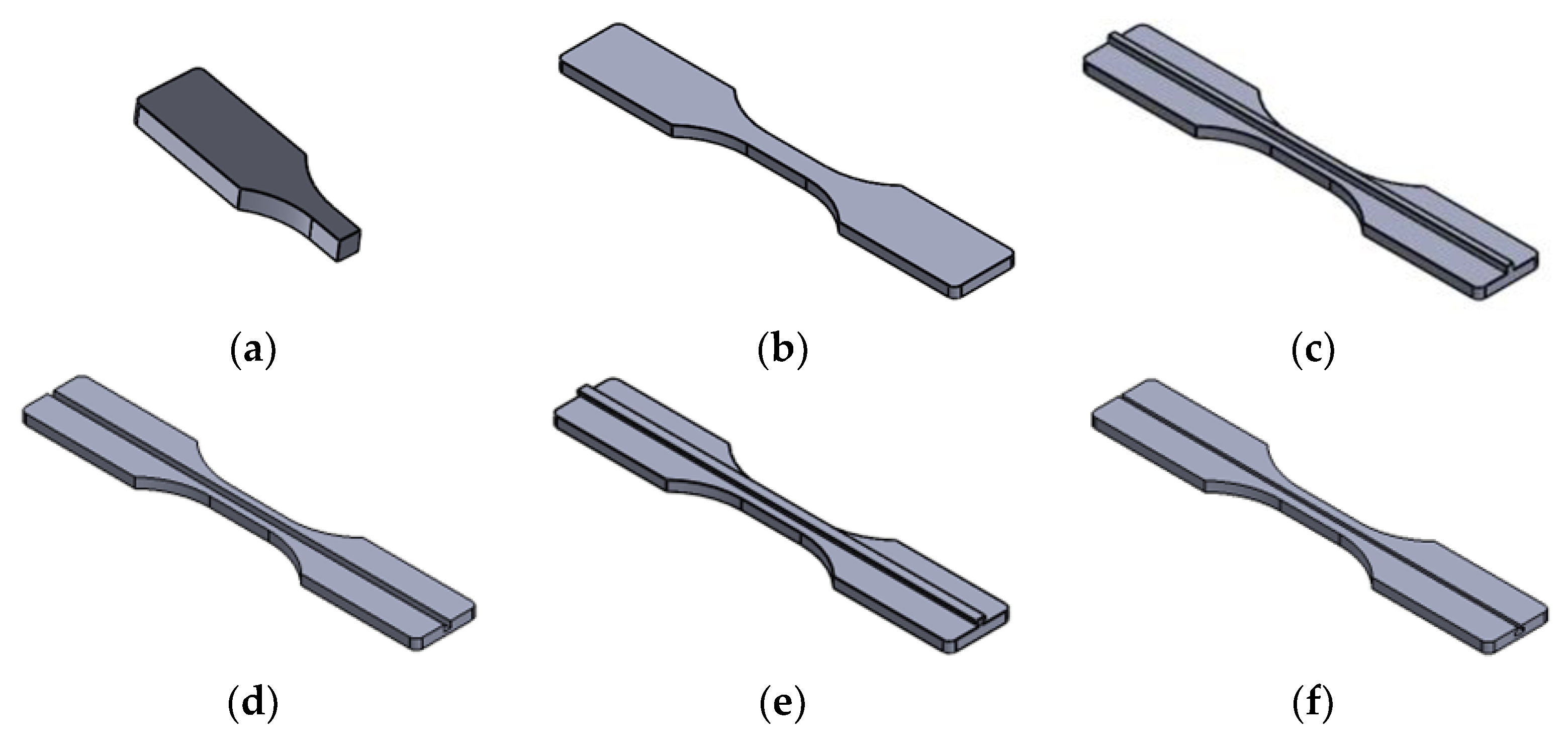

2.2. Preparation of Samples

2.2.1. Details of Fabricated Samples

2.2.2. Fused Deposition Modelling

2.2.3. Injection Molding

2.3. Tensile Test

2.4. Macrostructure Observation

2.5. Statistical Analysis

2.6. Scanning Electron Microscopy

3. Results and Discussion

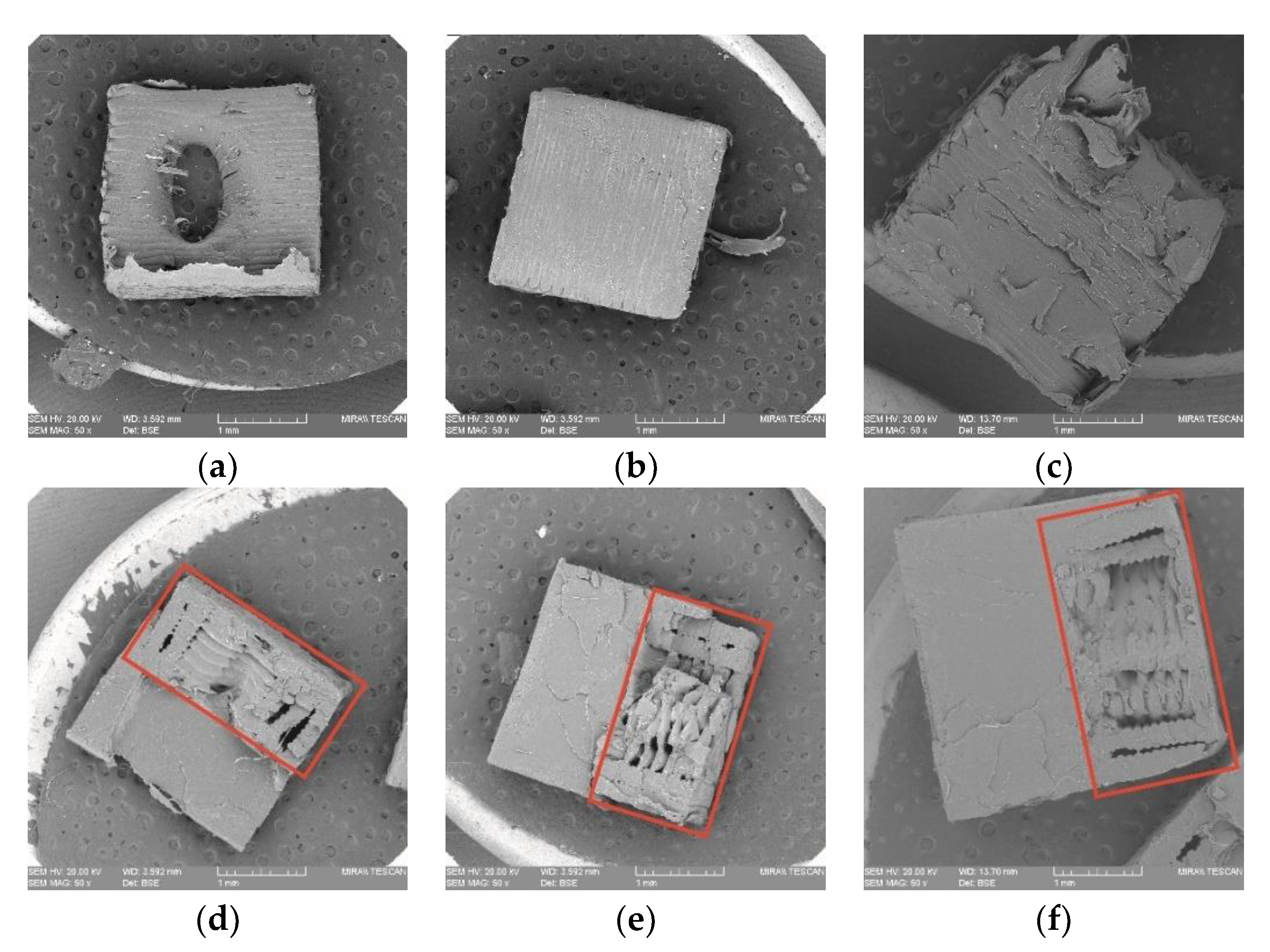

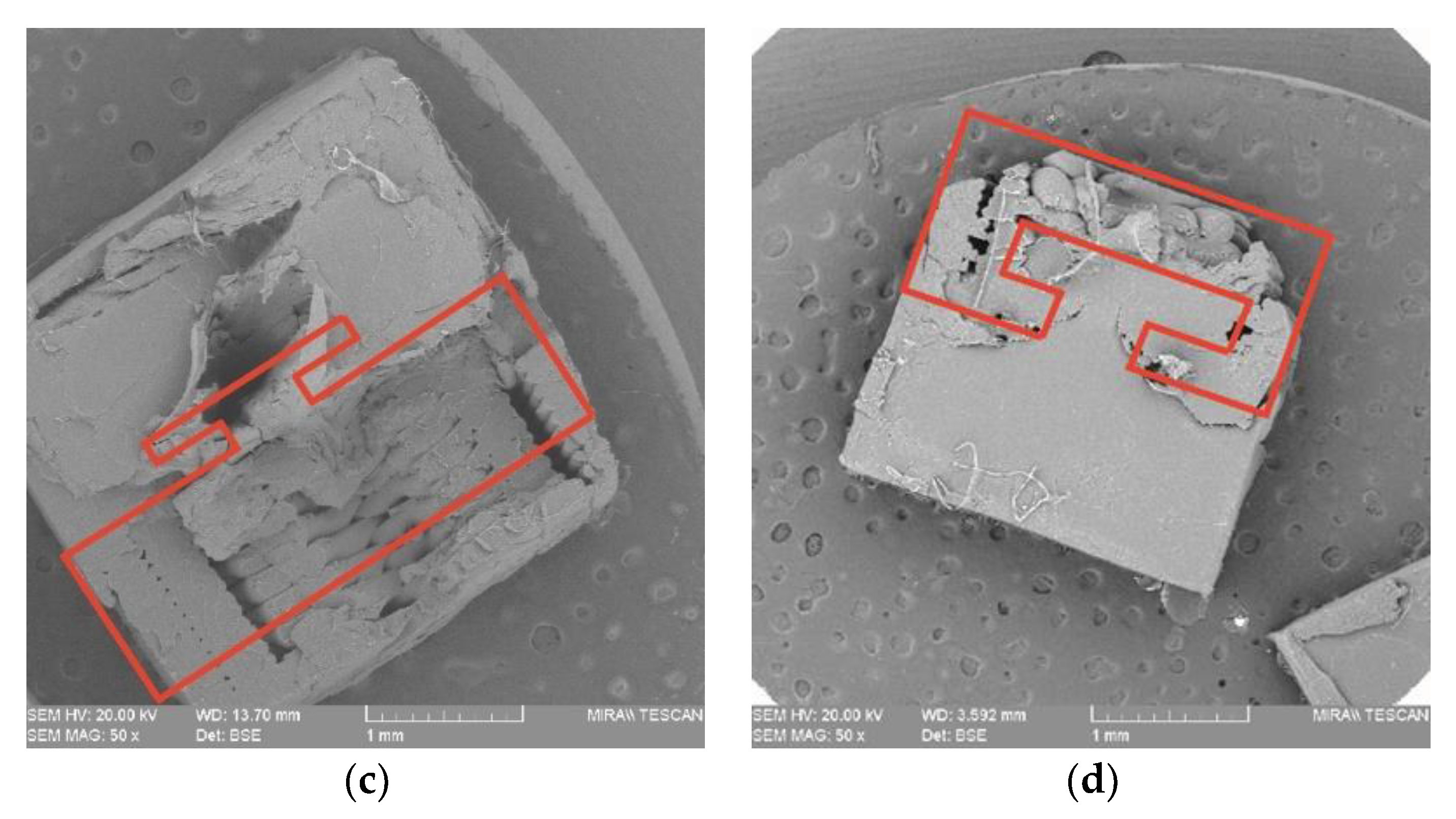

3.1. Macrostructure Observation for All Fabricated Samples

3.2. Tensile Performances for All Fabricated Samples

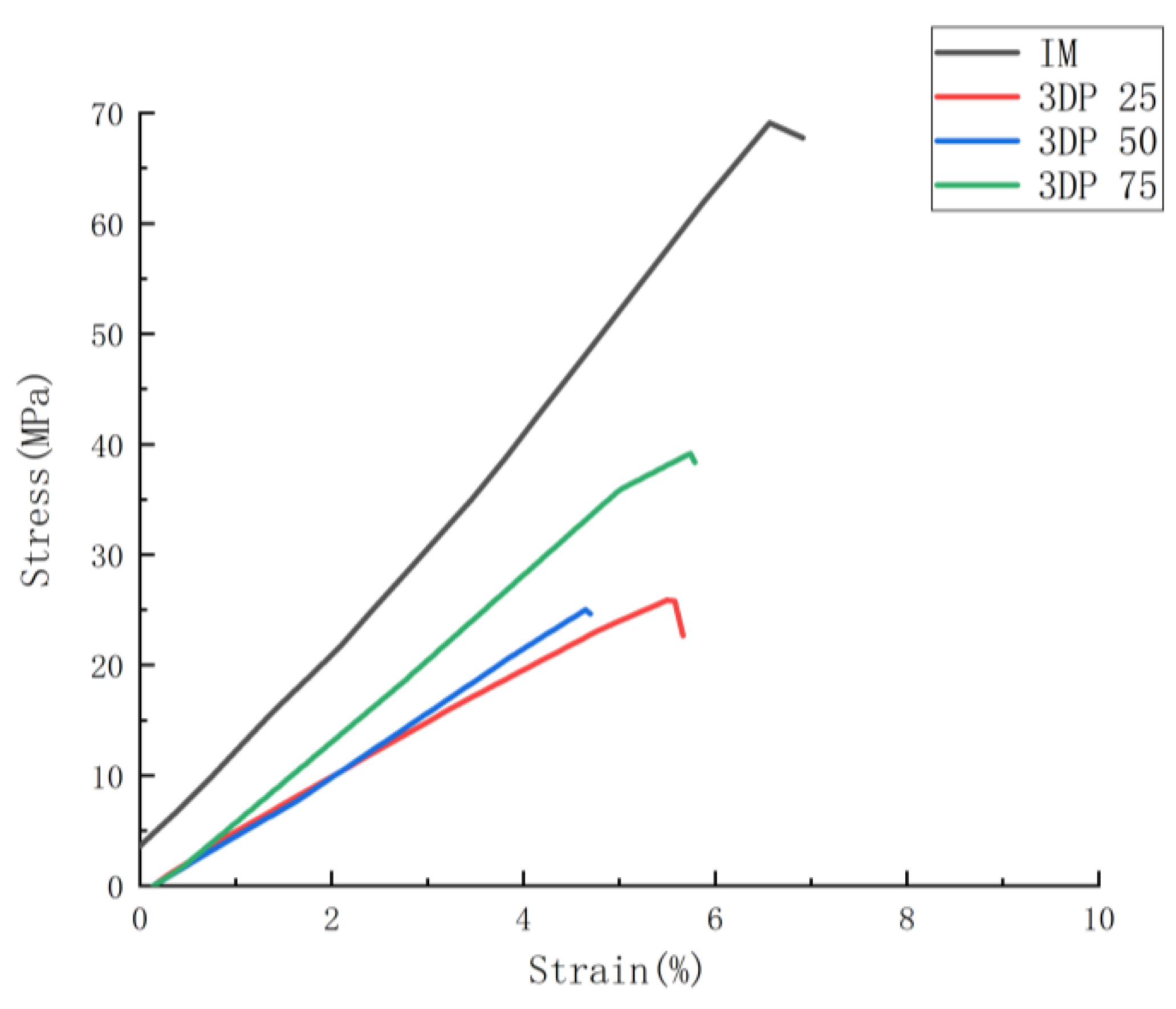

3.2.1. Effects of Manufacturing Technique on the Mechanical Performance

3.2.2. Effects of Infill Density on the Mechanical Performance

3.2.3. Effects of Interface Direction on the Mechanical Performance

3.2.4. Effects of Joint Configuration on the Mechanical Performance

3.3. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Raut, S.; Jatti, V.S.; Khedkar, N.K.; Singh, T.P. Investigation of the Effect of Built Orientation on Mechanical Properties and Total Cost of FDM Parts. Procedia Mater. Sci. 2014, 6, 1625–1630. [Google Scholar] [CrossRef]

- Briatico-Vangosa, F.; Melocchi, A.; Uboldi, M.; Gazzaniga, A.; Zema, L.; Maroni, A. Effect of Polyethylene Glycol Content and Molar Mass on Injection Molding of Hydroxypropyl Methylcellulose Acetate Succinate-Based Gastroresistant Capsular Devices for Oral Drug Delivery. Polymers 2019, 11, 517. [Google Scholar] [CrossRef] [PubMed]

- Qiao, G.; Lu, R.F.; McLean, C. Flexible manufacturing systems for mass customisation manufacturing. Int. J. Mass Cust. 2015, 1, 374. [Google Scholar] [CrossRef]

- Wheelwright, S.C.; Clark, K.B. Revolutionizing Product Development: Quantum Leaps in Speed, Efficiency, and Quality; The Free Press: New York, NY, USA, 1992. [Google Scholar]

- Rosato, D.V.; Rosato, D.V.; Rosato, M.G. (Eds.) The Complete Injection Molding Process. In Injection Molding Handbook, 3rd ed.; Springer: New York, NY, USA, 2000; pp. 1–27. [Google Scholar] [CrossRef]

- Campo, E.A. The Complete Part Design Handbook: For Injection Molding of Thermoplastics; Hanser Publishers: Munich, Germany, 2006. [Google Scholar]

- Mistretta, M.C.; Botta, L.; Morreale, M.; Rifici, S.; Ceraulo, M.; La Mantia, F.P. Injection molding and mechanical properties of bio-based polymer nanocomposites. Materials 2018, 11, 613. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.P.; Chuang, M.T.; Hsiao, Y.H.; Yang, Y.K.; Tsai, C.H. Simulation and experimental study in determining injection molding process parameters for thin-shell plastic parts via design of experiments analysis. Expert Syst. Appl. 2009, 36, 10752–10759. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS With Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Kotlinski, J. Mechanical properties of commercial rapid prototyping materials. Rapid Prototyp. J. 2014, 20, 499–510. [Google Scholar] [CrossRef]

- Lubombo, C.; Huneault, M.A. Effect of infill patterns on the mechanical performance of lightweight 3D-printed cellular PLA parts. Mater. Today Commun. 2018, 17, 214–228. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P. Optimization of fused deposition modeling process using teaching-learning-based optimization algorithm. Eng. Sci. Technol. Int. J. 2016, 19, 587–603. [Google Scholar] [CrossRef]

- Srinivasan, R.; Giannikas, V.; McFarlane, D.; Thorne, A. Customising with 3D printing: The role of intelligent control. Comput. Ind. 2018, 103, 38–46. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Aquino, R.P.; Barile, S.; Grasso, A.; Saviano, M. Envisioning smart and sustainable healthcare: 3D Printing technologies for personalized medication. Futures 2018, 103, 35–50. [Google Scholar] [CrossRef]

- Araújo, M.R.P.; Sa-Barreto, L.L.; Gratieri, T.; Gelfuso, G.M.; Cunha-Filho, M. The Digital Pharmacies Era: How 3D Printing Technology Using Fused Deposition Modeling Can Become a Reality. Pharmaceutics 2019, 11, 128. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Domingos, M.A.N.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive manufacturing of tissues and organs. Prog. Polym. Sci. 2012, 37, 1079–1104. [Google Scholar] [CrossRef]

- Park, S.-I.; Rosen, D.W.; Choi, S.-K.; Duty, C.E. Effective mechanical properties of lattice material fabricated by material extrusion additive manufacturing. Addit. Manuf. 2014, 1, 12–23. [Google Scholar] [CrossRef]

- Rigotti, D.; Dorigato, A.; Pegoretti, A. 3D printable thermoplastic polyurethane blends with thermal energy storage/release capabilities. Mater. Today Commun. 2018, 15, 228–235. [Google Scholar] [CrossRef]

- Roberson, D.A.; Perez, A.R.T.; Shemelya, C.M.; Rivera, A.; MacDonald, E.; Wicker, R.B. Comparison of stress concentrator fabrication for 3D printed polymeric izod impact test specimens. Addit. Manuf. 2015, 7, 1–11. [Google Scholar] [CrossRef]

- Sadia, M.; Arafat, B.; Ahmed, W.; Forbes, R.T.; Alhnan, M.A. Channelled tablets: An innovative approach to accelerating drug release from 3D printed tablets. J. Control. Release 2018, 269, 355–363. [Google Scholar] [CrossRef] [PubMed]

- Shahrubudin, N.; Lee, T.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R. Finite element analysis of thermoplastic polymer extrusion 3D printed material for mechanical property prediction. Addit. Manuf. 2018, 22, 187–196. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Fuenmayor, E.; O'Donnell, C.; Gately, N.; Doran, P.; Devine, D.; Lyons, J.G.; McConville, C.; Major, I. Mass-customization of oral tablets via the combination of 3D printing and injection molding. Int. J. Pharm. 2019, 569, 118611. [Google Scholar] [CrossRef]

- Goyanes, A.; Robles Martinez, P.; Buanz, A.; Basit, A.W.; Gaisford, S. Effect of geometry on drug release from 3D printed tablets. Int. J. Pharm. 2015, 494, 657–663. [Google Scholar] [CrossRef]

- Lim, S.H.; Chia, S.M.Y.; Kang, L.; Yap, K.Y.-L. Three-Dimensional Printing of Carbamazepine Sustained-Release Scaffold. J. Pharm. Sci. 2016, 105, 2155–2163. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Saeed, A.; Lan, W.; Qin, W. Properties of 3D printed dough and optimization of printing parameters. Innov. Food Sci. Emerg. Technol. 2019, 54, 9–18. [Google Scholar] [CrossRef]

- Martinez, P.R.; Goyanes, A.; Basit, A.W.; Gaisford, S. Influence of Geometry on the Drug Release Profiles of Stereolithographic (SLA) 3D-Printed Tablets. AAPS PharmSciTech 2018, 19, 3355–3361. [Google Scholar] [CrossRef]

- Gong, K.; Liu, H.; Huang, C.; Cao, Z.; Fuenmayor, E.; Major, I. Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding. Polymers 2022, 14, 5093. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettere, C. Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 2016, 90, 453–458. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Granada, A.A.G.; Llumà, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Farzadi, A.; Solati-Hashjin, M.; Asadi-Eydivand, M.; Abu Osman, N.A. Effect of Layer Thickness and Printing Orientation on Mechanical Properties and Dimensional Accuracy of 3D Printed Porous Samples for Bone Tissue Engineering. PLoS ONE 2014, 9, e108252. [Google Scholar] [CrossRef]

- Fuenmayor, E.; Forde, M.; Healy, A.V.; Devine, D.M.; Lyons, J.G.; McConville, C.; Major, I. Material Considerations for Fused-Filament Fabrication of Solid Dosage Forms. Pharmaceutics 2018, 10, 44. [Google Scholar] [CrossRef]

- Kishore, V.; Ajinjeru, C.; Nycz, A.; Post, B.; Lindahl, J.; Kunc, V.; Duty, C. Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components. Addit. Manuf. 2017, 14, 7–12. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2016, 51, 451–462. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.; Mahapatra, S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Ulu, E.; Korkmaz, E.; Yay, K.; Ozdoganlar, B.; Kara, L.B. Enhancing the Structural Performance of Additively Manufactured Objects Through Build Orientation Optimization. J. Mech. Des. 2015, 137, 111410. [Google Scholar] [CrossRef]

- Vaezi, M.; Chua, C.K. Effects of layer thickness and binder saturation level parameters on 3D printing process. Int. J. Adv. Manuf. Technol. 2010, 53, 275–284. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Development of Pure Poly Vinyl Chloride (PVC) with Excellent 3D Printability and Macro- and Micro-Structural Properties. Macromol. Mater. Eng. 2022, 2200568. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D printing of PLA-TPU with different component ratios: Fracture toughness, mechanical properties, and morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing-Encapsulated Polycaprolactone–Thermoplastic Polyurethane with High Shape Memory Performances. Adv. Eng. Mater. 2022, 2201309. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. Physical and mechanical properties of PLA composites reinforced by TiO 2 grafted flax fibers. Mater. Des. 2016, 106, 295–304. [Google Scholar] [CrossRef]

- Kim, E.; Shin, Y.-J.; Ahn, S.-H. The effects of moisture and temperature on the mechanical properties of additive manufacturing components: Fused deposition modeling. Rapid Prototyp. J. 2016, 22, 887–894. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Hossain, M.S.; Espalin, D.; Ramos, J.; Perez, M.; Wicker, R. Improved Mechanical Properties of Fused Deposition Modeling-Manufactured Parts Through Build Parameter Modifications. J. Manuf. Sci. Eng. 2014, 136, 061002. [Google Scholar] [CrossRef]

- Kozior, T.; Kundera, C. Evaluation of the Influence of Parameters of FDM Technology on the Selected Mechanical Properties of Models. Procedia Eng. 2017, 192, 463–468. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Jia, Z.; Wang, F.; Zhang, M. Additive Manufacturing of CFRP Composites Using Fused Deposition Modeling: Effects of Process Parameters. In Proceedings of the International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016; Volume 1989, pp. 1–7. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; Mclouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Fuenmayor, E.; Forde, M.; Healy, A.V.; Devine, D.M.; Lyons, J.G.; McConville, C.; Major, I. Comparison of fused-filament fabrication to direct compression and injection molding in the manufacture of oral tablets. Int. J. Pharm. 2019, 558, 328–340. [Google Scholar] [CrossRef]

- Alford, D.; Sackett, P.; Nelder, G. Mass customisation—An automotive perspective. Int. J. Prod. Econ. 2000, 65, 99–110. [Google Scholar] [CrossRef]

- Deradjat, D.; Minshall, T. Implementation of rapid manufacturing for mass customisation. J. Manuf. Technol. Manag. 2017, 28, 95–121. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. Part B Eng. 2019, 176, 107341. [Google Scholar] [CrossRef]

- Boros, R.; Rajamani, P.K.; Kovacs, J.G. Combination of 3D printing and injection molding: Overmolding and overprinting. Express Polym. Lett. 2019, 13, 889–897. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Design of fused-deposition ABS components for stiffness and strength. J. Mech. Des. Trans. ASME 2003, 125, 545–551. [Google Scholar] [CrossRef]

- Tanveer, Q.; Mishra, G.; Mishra, S.; Sharma, R. Effect of infill pattern and infill density on mechanical behaviour of FDM 3D printed Parts—A current review. Mater. Today Proc. 2022, 62, 100–108. [Google Scholar] [CrossRef]

- Baich, L.; Manogharan, G.; Marie, H. Study of infill print design on production cost-time of 3D printed ABS parts. Int. J. Rapid Manuf. 2015, 5, 308. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, P.; Ng, F.L.; Zhou, W.; Nai, S.M.L.; Wei, J. Hybrid manufacturing of γ-TiAl and Ti–6Al–4V bimetal component with enhanced strength using electron beam melting. Compos. Part B Eng. 2020, 207, 108587. [Google Scholar] [CrossRef]

| Batch Name | Type of Samples/Inserts | Infill Density |

|---|---|---|

| FDM 25 | FDM Sample | 25% |

| FDM 50 | FDM Sample | 50% |

| FDM 75 | FDM Sample | 75% |

| IM | IM Sample | —— |

| HL-NJ 25 | Half of Length (No Joint Configuration) | 25% |

| HL-NJ 50 | Half of Length (No Joint Configuration) | 50% |

| HL-NJ 75 | Half of Length (No Joint Configuration) | 75% |

| HT-NJ 25 | Half of Thickness (No Joint Configuration) | 25% |

| HT-NJ 50 | Half of Thickness (No Joint Configuration) | 50% |

| HT-NJ 75 | Half of Thickness (No Joint Configuration) | 75% |

| MC 75 | Half of Thickness Male Cube | 75% |

| FC 75 | Half of Thickness Female Cube | 75% |

| MT 75 | Half of Thickness Male T | 75% |

| FT 75 | Half of Thickness Female T | 75% |

| Parameter | IM Specimens | FDM Specimens | HYM Specimens |

|---|---|---|---|

| Fillet Radius R(mm) | 12.7 | 12.7 | 12.7 |

| Thickness (mm) | 3.2 ± 0.1 | 3.2 ± 0.2 | 3.2 ± 0.1 |

| Total length (mm) | 64 ± 0.1 | 64 ± 0.3 | 64 ± 0.2 |

| Width of joint for injection and FDM (mm) | —— | —— | 3.3 ± 0.2 |

| Width at two ends (mm) | 10 ± 0.2 | 10 ± 0.2 | 10 ± 0.2 |

| Batch Reference | Tensile Stress, σ (MPa) | Young’s Modulus, E (MPa) |

|---|---|---|

| IM | 68.95 ± 1.75 | 1130.07 ± 18.93 |

| FDM 25 | 26.21 ± 1.03 | 612.32 ± 31.80 |

| FDM 50 | 25.43 ± 2.15 | 639.33 ± 30.58 |

| FDM 75 | 38.75 ± 1.92 | 814.30 ± 39.52 |

| Batch Reference | Tensile Stress, σ (MPa) | Young’s Modulus, E (MPa) |

|---|---|---|

| HL-NJ 25 | 12.99 ± 5.78 | 640.88 ± 50.43 |

| HL-NJ 50 | 18.41 ± 2.96 | 720.85 ± 54.68 |

| HL-NJ 75 | 19.09 ± 7.14 | 761.48 ± 71.45 |

| HT-NJ 25 | 53.83 ± 2.96 | 1025.69 ± 45.29 |

| HT-NJ 50 | 55.26 ± 2.98 | 984.15 ± 31.96 |

| HT-NJ 75 | 59.92 ± 1.51 | 1020.13 ± 33.88 |

| MC 75 | 64.74 ± 3.57 | 1057.92 ± 57.45 |

| FC 75 | 68.38 ± 1.03 | 1103.13 ± 33.28 |

| MT 75 | 59.51 ± 3.07 | 1031.50 ± 86.71 |

| FT 75 | 64.16 ± 1.53 | 1100.29 ± 45.77 |

| Source | DF | Ultimate Tensile Stress | |||

|---|---|---|---|---|---|

| SS | MS | F | P | ||

| Model | 4 | 544 | 135.998 | 21.98 | 0 |

| Residual | 45 | 278.5 | 6.189 | ||

| Total | 49 | 822.5 | |||

| Tukey’s Multiple Comparisons Test | Mean Diff. | 95.00% CI of Diff. | Summary | Adjusted p Value |

|---|---|---|---|---|

| NJ75 vs. MC75 | −4.82 | −7.981–−1.659 | *** | 0.0007 |

| NJ75 vs. FC75 | −8.46 | −11.62–−5.299 | **** | <0.0001 |

| NJ75 vs. MT75 | 0.41 | −2.751–3.571 | ns | 0.9959 |

| NJ75 vs. FT75 | −4.24 | −7.401–−1.079 | ** | 0.0036 |

| MC75 vs. FC75 | −3.64 | −6.801–−0.4788 | * | 0.0167 |

| MC75 vs. MT75 | 5.23 | 2.069–8.391 | *** | 0.0002 |

| MC75 vs. FT75 | 0.58 | −2.581–3.741 | ns | 0.9847 |

| FC75 vs. MT75 | 8.87 | 5.709–12.03 | **** | <0.0001 |

| FC75 vs. FT75 | 4.22 | 1.059–7.381 | ** | 0.0038 |

| MT75 vs. FT75 | −4.65 | −7.811–−1.489 | ** | 0.0012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, K.; Liu, H.; Huang, C.; Jiang, Q.; Xu, H.; Cao, Z.; Fuenmayor, E.; Major, I. Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process. Polymers 2022, 14, 5413. https://doi.org/10.3390/polym14245413

Gong K, Liu H, Huang C, Jiang Q, Xu H, Cao Z, Fuenmayor E, Major I. Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process. Polymers. 2022; 14(24):5413. https://doi.org/10.3390/polym14245413

Chicago/Turabian StyleGong, Ke, Handai Liu, Cheng Huang, Qinyu Jiang, Han Xu, Zhi Cao, Evert Fuenmayor, and Ian Major. 2022. "Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process" Polymers 14, no. 24: 5413. https://doi.org/10.3390/polym14245413

APA StyleGong, K., Liu, H., Huang, C., Jiang, Q., Xu, H., Cao, Z., Fuenmayor, E., & Major, I. (2022). Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process. Polymers, 14(24), 5413. https://doi.org/10.3390/polym14245413