Tensile Behavior of Joints of Strip Ends Made of Polymeric Materials

Abstract

1. Introduction

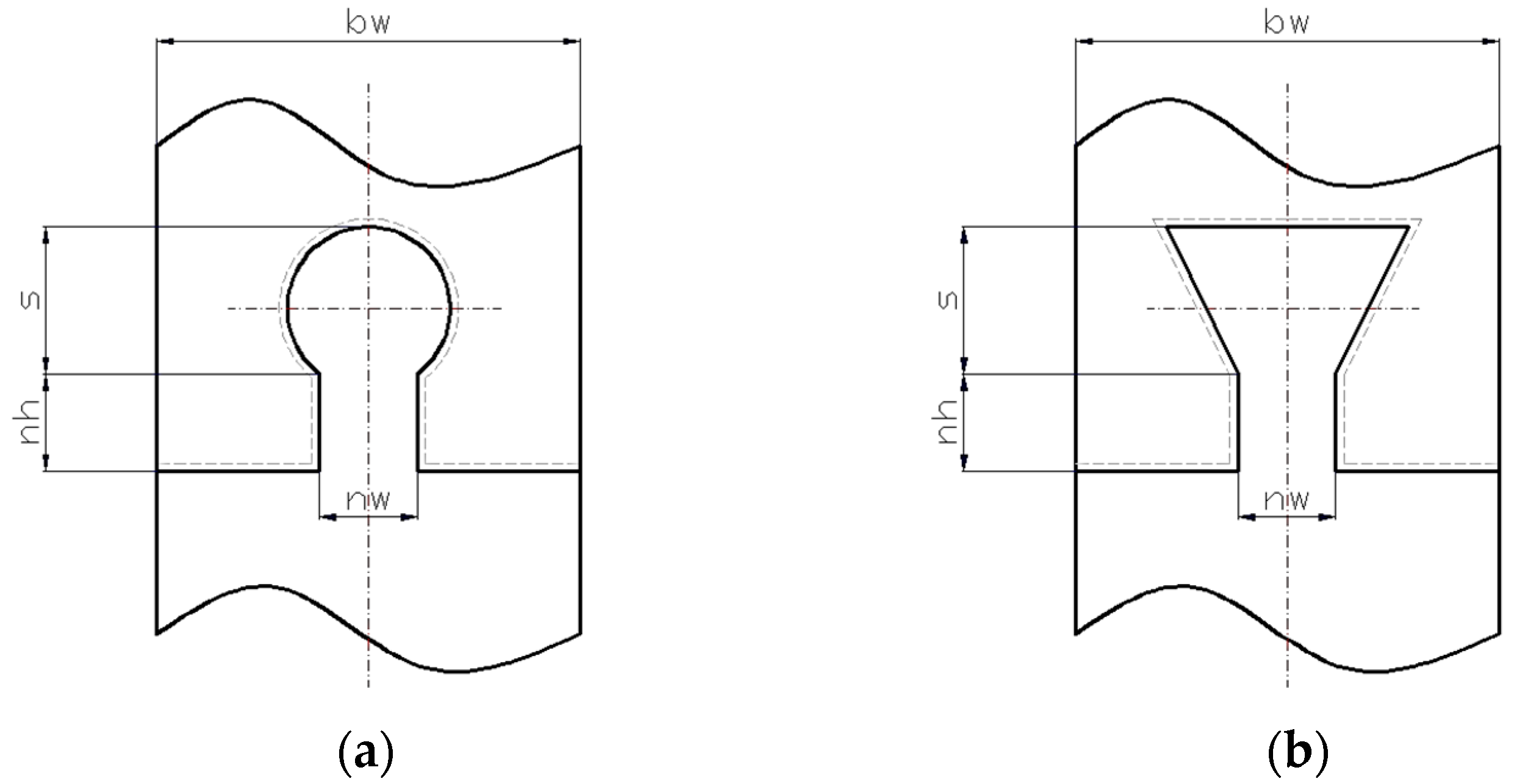

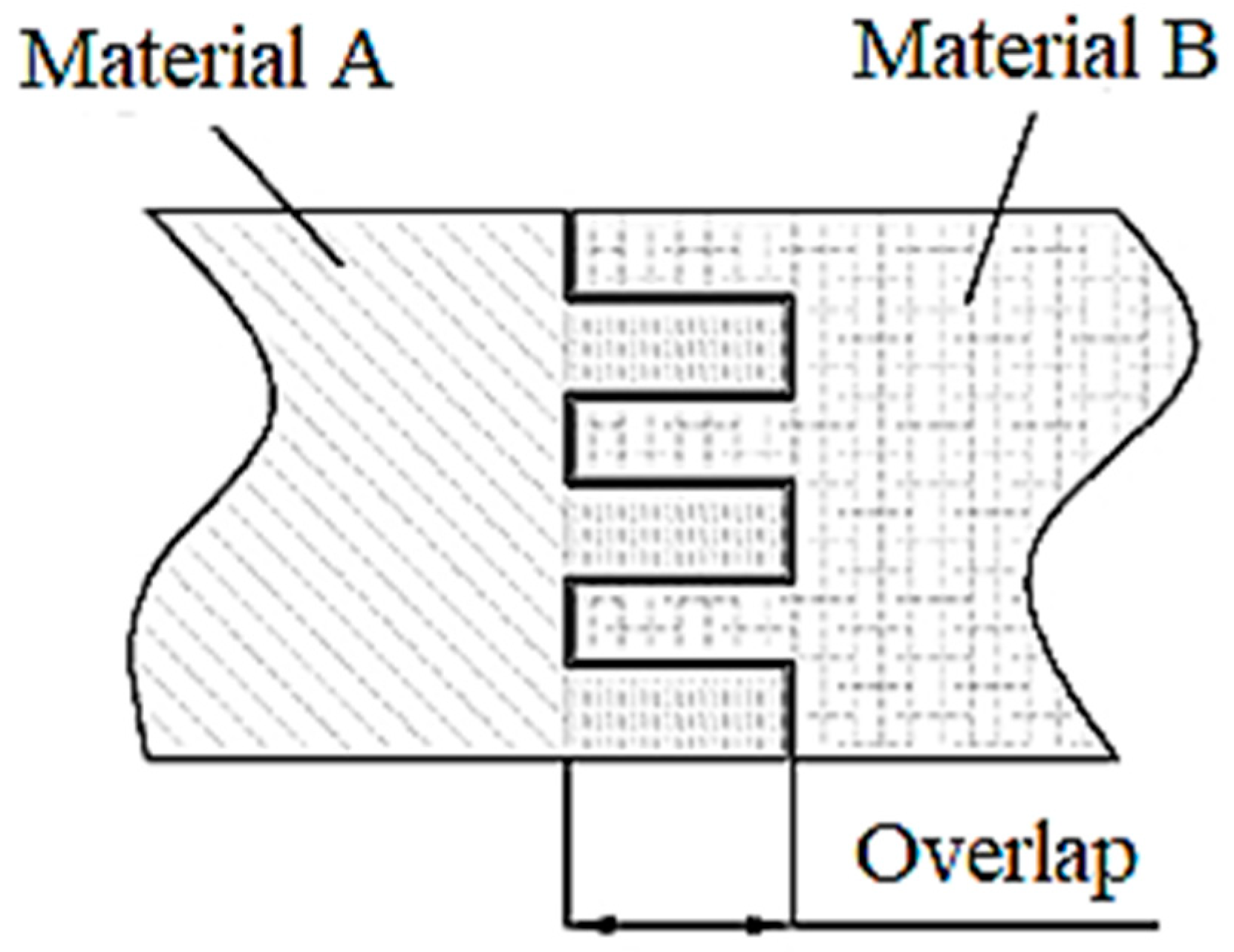

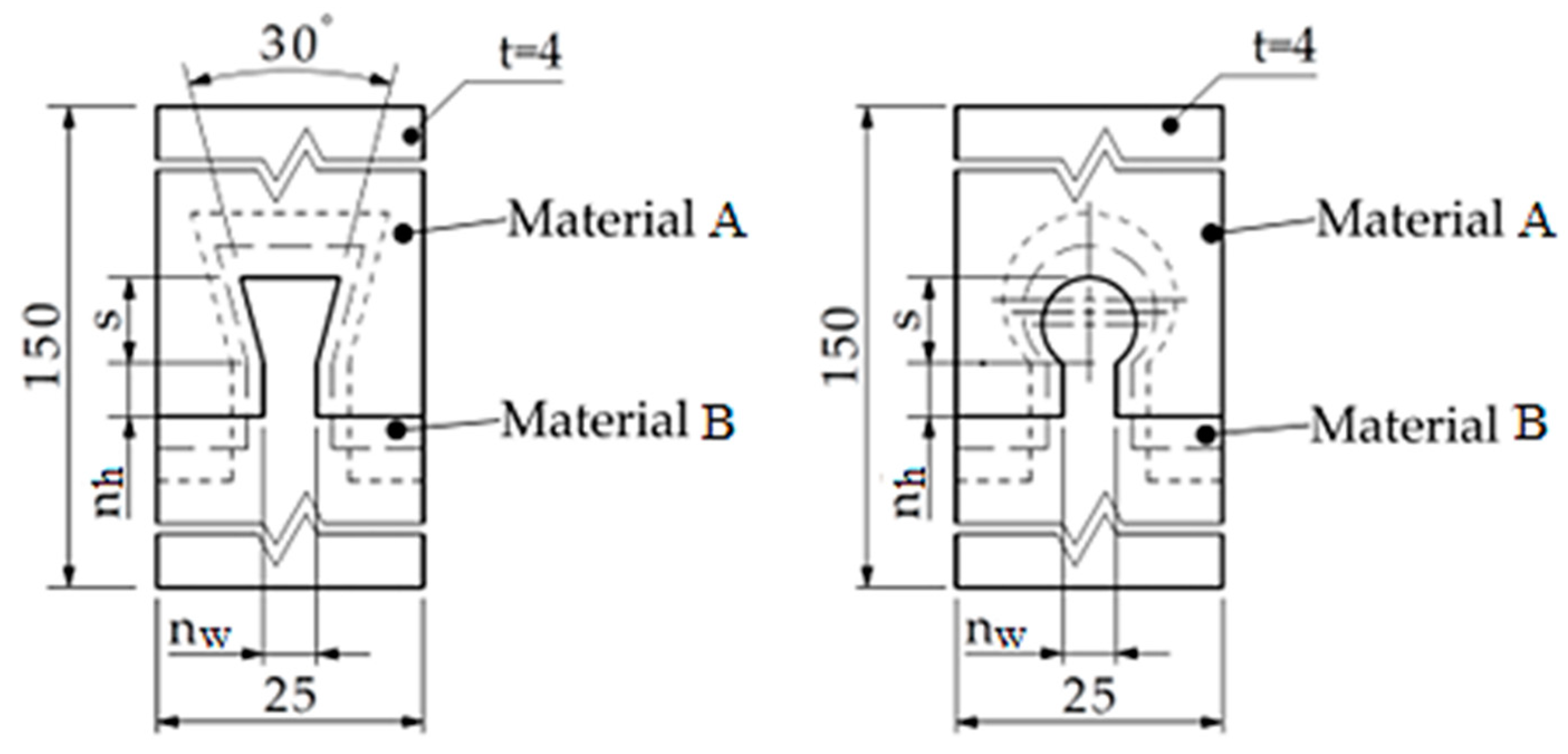

2. Materials and Methods

2.1. Initial Considerations

2.2. Materials

2.3. Experimental Conditions

2.4. The Use of the Finite Element Method to Model Some Aspects of the Tensile Behavior of a Joint

2.5. Using the ANOVA Method to Identify Significant Input Factors

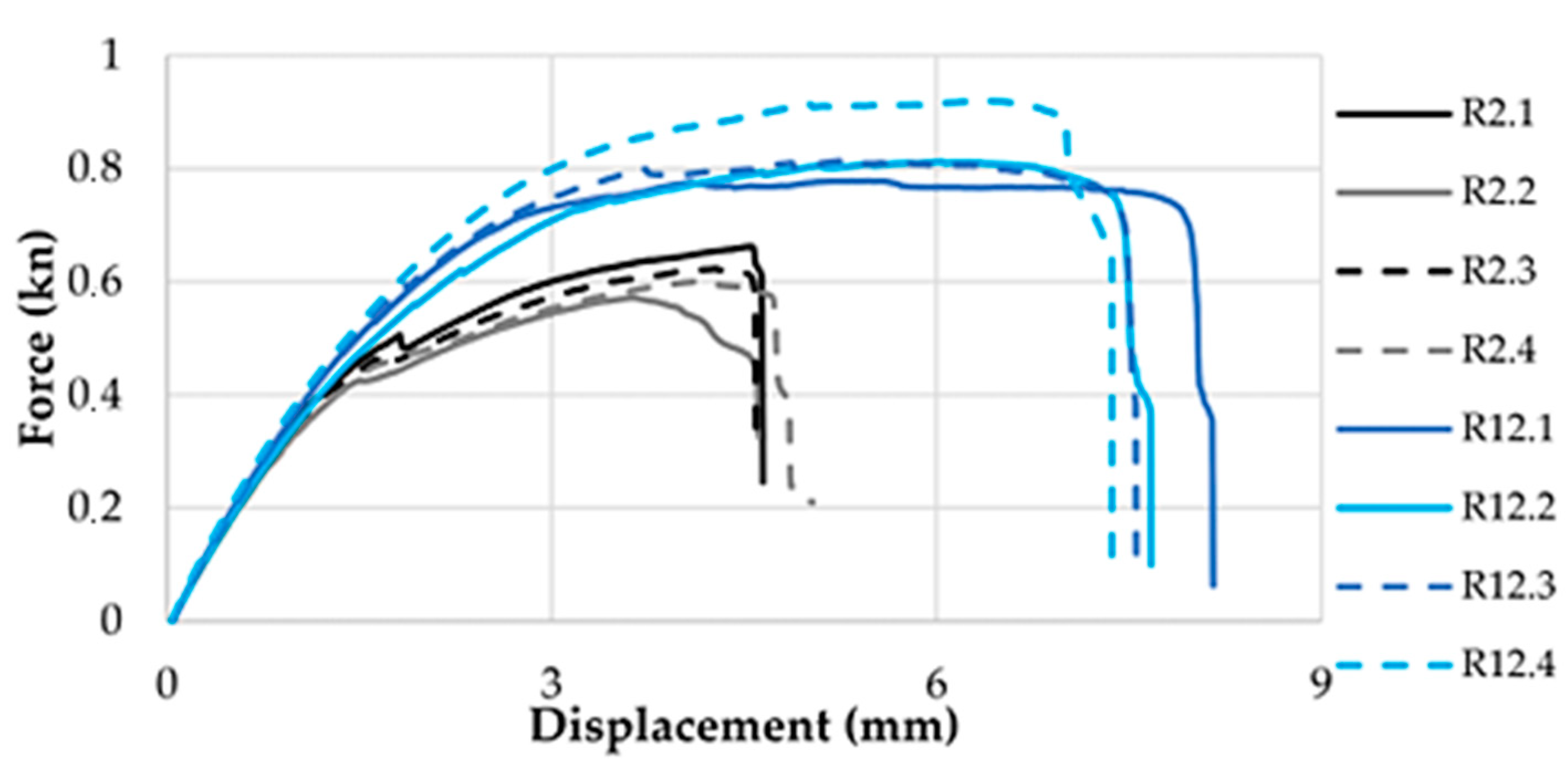

3. Results

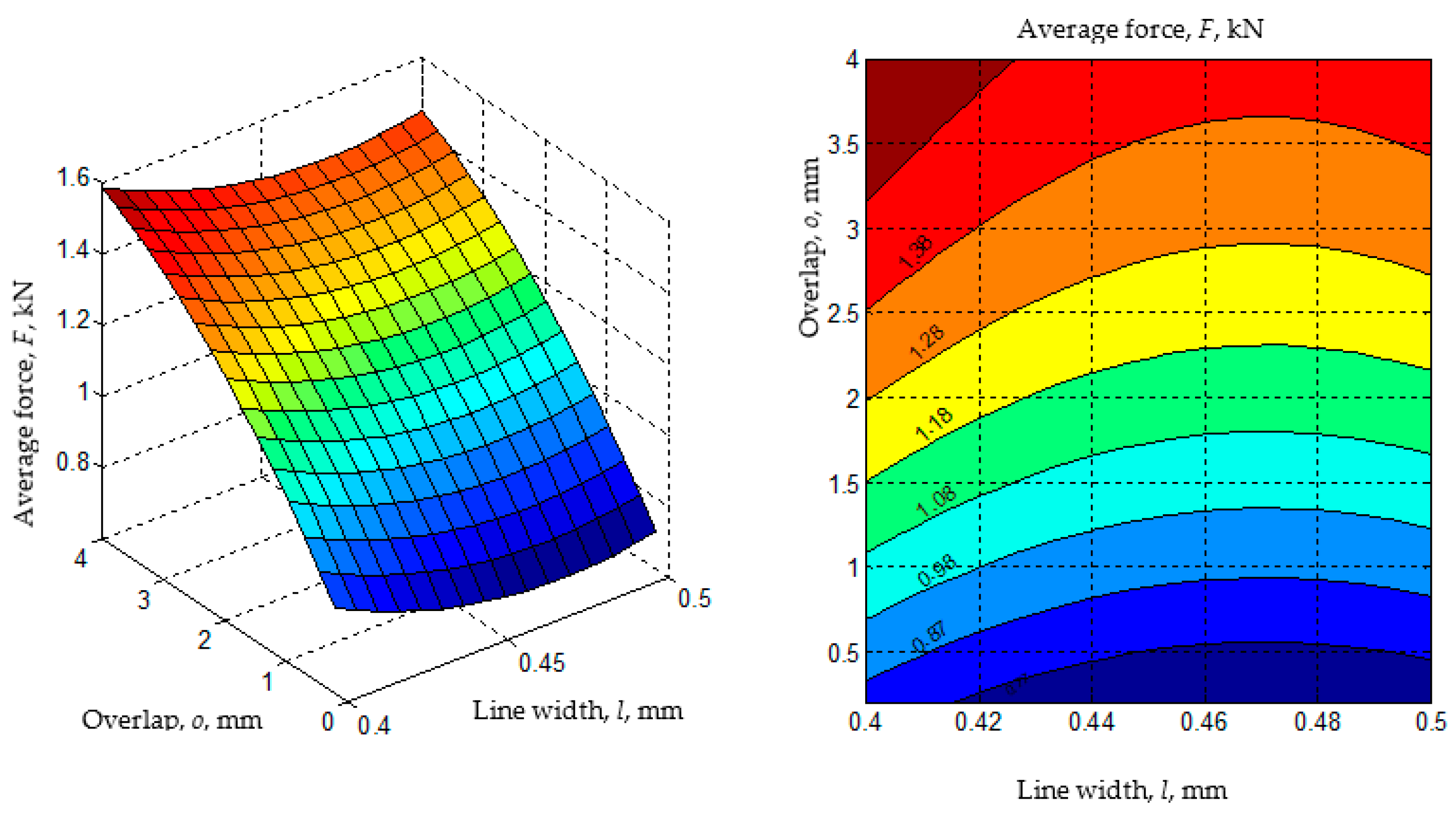

+ 0.0171nh2 + 0.00602s − 0.00121s2 + 1.996now − 0.265now2 − 31.306l + 33.259l2 + 0.306o − 0.0261o2,

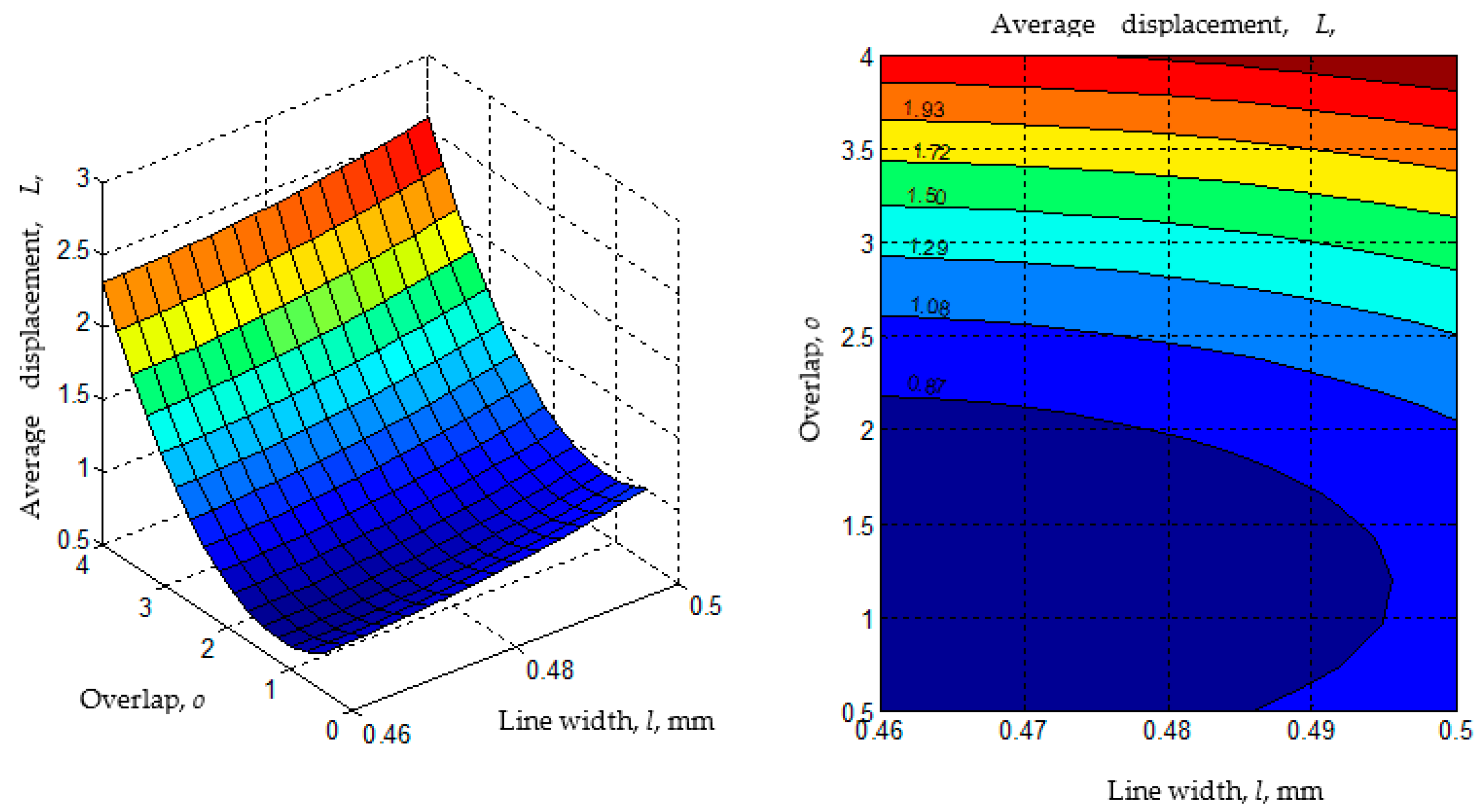

+ 0.0272nh2 + 0.416s − 0.0132s2 + 1.794now − 0.303now2 − 126.527l + 138.649l2 − 0.482o + 0.206o2,

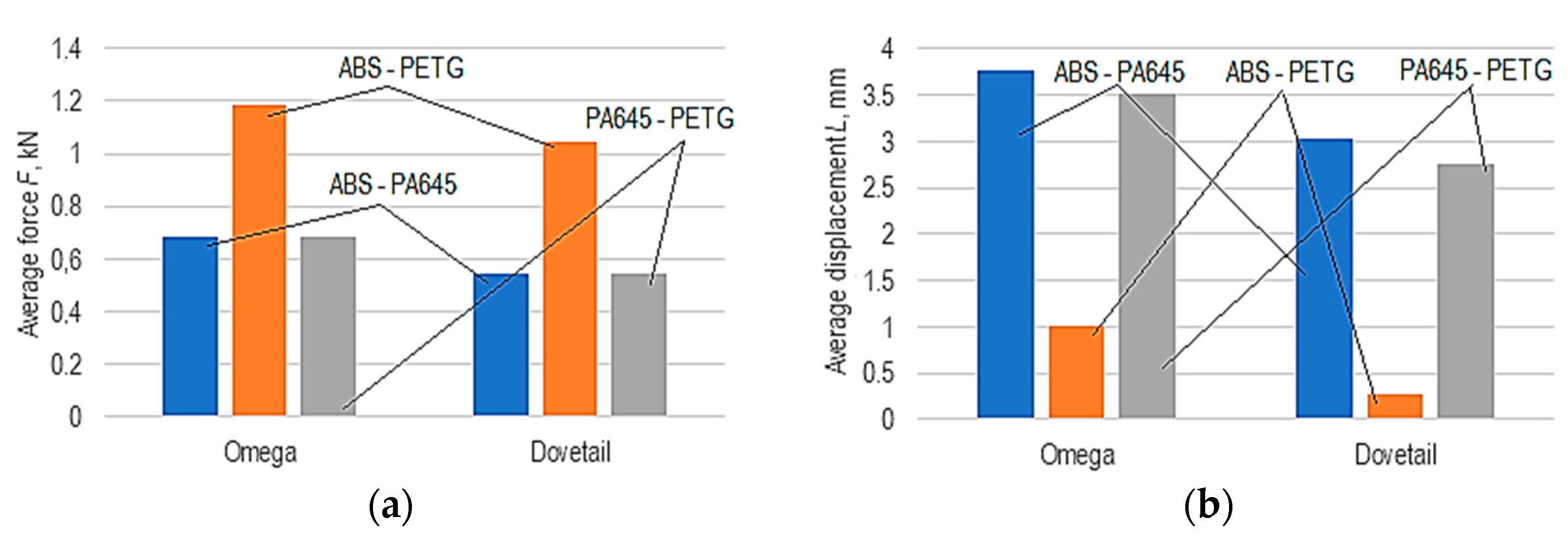

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tiwary, V.K.; Ravi, N.; Arunkumar, P.; Shivakumar, S.; Deshpande, A.S.; Malik, V.R. Investigations on friction stir joining of 3D printed parts to overcome bed size limitation and enhance joint quality for unmanned aircraft systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 4857–4871. [Google Scholar] [CrossRef]

- Lopes, L.R.; Silva, A.F.; Carneiro, O.S. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. J. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, J. Compatibilization of acrylonitrile-butadiene-styrene terpolymer/poly(ethylene glycol-co-1,4-cyclohexanedimethanol terephthalate) blend: Effect on morphology, interface, mechanical properties and hydrophilicity. Appl. Surf. Sci. 2018, 437, 62–69. [Google Scholar] [CrossRef]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The influence of slicing parameters on the multi-material adhesion mechanisms of FDM printed parts: An exploratory study. Virtual. Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Ribeiro, M.; Sousa Carneiro, O. Interface geometries in 3D multi-material prints by fused filament fabrication. Rapid Prototyp. J. 2019, 25, 38–46. [Google Scholar] [CrossRef]

- Andó, M.; Birosz, M.; Jeganmohan, S. Surface bonding of additive manufactured parts from multi-colored PLA materials. Measurement 2021, 169, 108583. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Kravcov, A.; Grzelak, K.; Svoboda, P.; Szachogłuchowicz, I.; Franek, O.; Morozov, N.; Torzewski, J.; Kubeček, P. The examination of restrained joints created in the process of multi-material FFF additive manufacturing technology. Materials 2020, 13, 903. [Google Scholar] [CrossRef] [PubMed]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on additive manufacturing of multi-material parts: Progress and challenges. J. Manuf. Mater. Process. 2022, 6, 4. [Google Scholar] [CrossRef]

- Kuipers, T.; Su, R.; Wu, J.; Wang, C.C.L. Interlaced Topologically Interlocking Lattice for continuous dual-material extrusion. Addit. Manuf. 2022, 50, 102495. [Google Scholar] [CrossRef]

- Acherjee, B. Laser transmission welding of polymers—A review on process fundamentals, material attributes, weldability, and welding techniques. J. Manuf. Process. 2020, 60, 227–246. [Google Scholar] [CrossRef]

- Focke, W.W.; Joseph, S.; Grimbeek, J.; Summers, G.J.; Kretzschmar, B. Mechanical Properties of Ternary Blends of ABS + HIPS + PETG. Polym. Plast. Technol. Eng. 2009, 48, 814–820. [Google Scholar] [CrossRef]

- Fisher, R.A. The Design of Experiments; Oliver and Boyd: Edinburgh/London, UK, 1935; Available online: http://tankona.free.fr/fisher1935.pdf (accessed on 23 July 2022).

- Yates, F. Sir Ronald Fisher and the design of experiments. Biometrix 1964, 20, 307–321. [Google Scholar] [CrossRef]

- Yuangyai, C.; Nembhard, H.B. Design of experiments. In Emerging Nanotechnologies for Manufacturing; Ahmed, V., Jakson, M.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2010; pp. 207–234. Available online: https://www.sciencedirect.com/book/9780815515838/emerging-nanotechnologies-for-manufacturing (accessed on 16 August 2022).

- Pillet, M. Introduction aux Plans d’expériences par la Méthode Taguchi, 2nd ed.; Les Éditions d’Organisation: Paris, France, 1992. [Google Scholar]

- Ross, P.J. Taguchi Techniques for Quality Engineering; McGraw-Hill Companies, Inc.: New York, NY, USA, 1988. [Google Scholar] [CrossRef]

- Roy, R.K. Design of Experiments Using the Taguchi Approach: 16 Steps to Product and Process Improvement; John Willey & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Fraley, S.; Zalewski, J.; Oom, M.; Terrien, B. Design of experiments via Taguchi methods—orthogonal arrays. In Chemical Process Dynamics and Control; Woolf, P., Ed.; Libretext: Ann Arbor, MI, USA, 2022; Available online: https://eng.libretexts.org/Bookshelves/Industrial_and_Systems_Engineering/Book%3A_Chemical_Process_Dynamics_and_Controls_ (accessed on 29 September 2022).

- Kuramochi, N.; Oomuro, Y. Robust design with direct product of the L18 orthogonal arrays. In Proceedings of the 2008 International Symposium on Semiconductor Manufacturing (ISSM), Tokyo, Japan, 27–29 October 2008; pp. 191–194. [Google Scholar]

- Kacker, R.N.; Lagergren, E.S.; Filliben, J.J. Taguchi’s orthogonal arrays are classical designs of experiments. J. Res. Natl. Inst. Stand. Technol. 1991, 96, 577–591. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wang, W.; Shen, W.; Cui, X.; Shao, J. A new hybrid phase-field model for modeling mixed-mode cracking process in anisotropic plastic rock-like materials. Int. J. Plast. 2022, 157, 103395. [Google Scholar] [CrossRef]

- Ermolai, V.; Irimia, A. Influence of nozzle parameters in 3D printing under the manufacturing time. Bull. of the Polytech. Inst. of Iași. Mach. Constr. Sect. 2021, 67, 63–72. [Google Scholar] [CrossRef]

- Stavarache, R.C.; Ermolai, V.; Rîpanu, M.A.; Andrușcă, L.; Mareș, M.; Dodun, O. Infill pattern optimization of fused filament fabrication samples for enhanced mechanical properties. Sci. Bull. Ser. C Fascicle Mech. Tribol. Mach. Manuf. Technol. 2021, 35, 80–85. [Google Scholar]

- Ferretti, P.; Leon-Cardenas, C.; Santi, G.M.; Sali, M.; Ciotti, E.; Frizziero, L.; Donnici, G.; Liverani, A. Relationship between FDM 3D Printing Parameters Study: Parameter Optimization for Lower Defects. Polymers 2021, 13, 2190. [Google Scholar] [CrossRef] [PubMed]

- Sangid, M.D. The physics of fatigue crack initiation. Int. J. Fatigue 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Making Sense of Data: A Practical Guide to Exploratory Data Analysis and Data Mining. A.4 F-DISTRIBUTION. 2022. Available online: https://www.oreilly.com/library/view/making-sense-of/9780470074718/appa-sec004.html (accessed on 28 August 2022).

- Crețu, G. Fundamentals of Experimental Research. In Laboratory Handbook; Asachi, G., Ed.; Technical University of Iași: Iași, Romania, 1992. (In Romanian) [Google Scholar]

| Exp. Run | Input Factors | Output Factors | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Joint Shape, j | Material Pairs, m | Neck Width, nw, mm | Neck Height, nh, mm | Socket Height, s, (mm) | No. of Walls, now | Line Width, l, (mm) | Overlap, o, mm | Avg. Force at Peak, F, kN | Avg. Displacement at Peak, L, mm | |

| R1 | Omega | ABS-PA645 | 5 | 5 | 8 | 3 | 0.4 | 0 | 0.288 | 4.330 |

| R2 | Omega | ABS-PA645 | 8 | 8 | 11 | 4 | 0.45 | 2 | 0.613 | 4.128 |

| R3 | Omega | ABS-PA645 | 11 | 11 | 14 | 5 | 0.5 | 4 | 0.638 | 6.363 |

| R4 | Omega | ABS-PETG | 5 | 5 | 11 | 4 | 0.5 | 4 | 1.628 | 2.253 |

| R5 | Omega | ABS-PETG | 8 | 8 | 14 | 5 | 0.4 | 0 | 0.373 | 0.573 |

| R6 | Omega | ABS-PETG | 11 | 11 | 8 | 3 | 0.45 | 2 | 1.278 | 1.640 |

| R7 | Omega | PA645-PETG | 5 | 8 | 8 | 5 | 0.45 | 4 | 0.555 | 3.095 |

| R8 | Omega | PA645-PETG | 8 | 11 | 11 | 3 | 0.5 | 0 | 0.148 | 4.448 |

| R9 | Omega | PA645-PETG | 11 | 5 | 14 | 4 | 0.4 | 2 | 0.820 | 5.200 |

| R10 | Dovetail | ABS-PA645 | 5 | 11 | 14 | 4 | 0.45 | 0 | 0.100 | 2.860 |

| R11 | Dovetail | ABS-PA645 | 8 | 5 | 8 | 5 | 0.5 | 2 | 0.328 | 1.660 |

| R12 | Dovetail | ABS-PA645 | 11 | 8 | 11 | 3 | 0.4 | 4 | 0.830 | 5.758 |

| R13 | Dovetail | ABS-PETG | 5 | 8 | 14 | 3 | 0.5 | 2 | 0.728 | 0.975 |

| R14 | Dovetail | ABS-PETG | 8 | 11 | 8 | 4 | 0.4 | 4 | 1.613 | 2.273 |

| R15 | Dovetail | ABS-PETG | 11 | 5 | 11 | 5 | 0.45 | 0 | 0.175 | 0.810 |

| R16 | Dovetail | PA645-PETG | 5 | 11 | 11 | 5 | 0.4 | 2 | 0.443 | 2.123 |

| R17 | Dovetail | PA645-PETG | 8 | 5 | 14 | 3 | 0.45 | 4 | 0.738 | 5.070 |

| R18 | Dovetail | PA645-PETG | 11 | 8 | 8 | 4 | 0.5 | 0 | 0.078 | 3.530 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| (1) Layer thickness (mm) | 0.2 | (11) Initial layer speed (mm/s) | 15 |

| (2) No. of top/bottom layers | 5 | (12) Z Hop height (mm) | 1.6 |

| (3) Left extruder seam alignment | Back left | (13) Retraction distance (mm) | 7 |

| (4) Right extruder seam alignment | Back right | (14) Retraction speed (mm/s) | 35 |

| (5) Infill pattern | Gyroid | (15)1 Fan speed (%) | 10|15|30 |

| (6) Infill density (%) | 40 | (16) Brim | Yes |

| (7) Printing temperature (°C) | 245 | (16) Brim width (mm) | 3 |

| (8) Bed temperature (°C) | 65 | (17) Closed environment | Yes |

| (9) Print speed (mm/s) | 30 | (18) Alternate mesh removal | Yes |

| Source | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Joint shape, j | 1 | 58.07 | 58.068 | 58.68 | 84.65 | 0.012 |

| Materials pairs, m | 2 | 152.32 | 153.318 | 76.659 | 111.76 | 0.009 |

| Neck width, nw | 2 | 2.19 | 2.190 | 1.095 | 1.60 | 0.385 |

| Neck height, nh | 2 | 6.52 | 6.524 | 3.262 | 4.76 | 0.174 |

| Socket height, s | 2 | 0.32 | 0.319 | 0.160 | 0.23 | 0.811 |

| Number of walls, now | 2 | 24.70 | 24.701 | 12.351 | 18.01 | 0.053 |

| Line width, l | 2 | 58.32 | 56.324 | 29.162 | 42.51 | 0.023 |

| Overlap, o | 2 | 725.99 | 725.986 | 362.993 | 529.18 | 0.002 |

| Residual error | 2 | 1.37 | 1.372 | 0.686 | ||

| Total | 17 | 1030.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mihalache, A.-M.; Ermolai, V.; Sover, A.; Nagîț, G.; Boca, M.-A.; Slătineanu, L.; Hrițuc, A.; Dodun, O.; Rîpanu, M.-I. Tensile Behavior of Joints of Strip Ends Made of Polymeric Materials. Polymers 2022, 14, 4990. https://doi.org/10.3390/polym14224990

Mihalache A-M, Ermolai V, Sover A, Nagîț G, Boca M-A, Slătineanu L, Hrițuc A, Dodun O, Rîpanu M-I. Tensile Behavior of Joints of Strip Ends Made of Polymeric Materials. Polymers. 2022; 14(22):4990. https://doi.org/10.3390/polym14224990

Chicago/Turabian StyleMihalache, Andrei-Marius, Vasile Ermolai, Alexandru Sover, Gheorghe Nagîț, Marius-Andrei Boca, Laurențiu Slătineanu, Adelina Hrițuc, Oana Dodun, and Marius-Ionuț Rîpanu. 2022. "Tensile Behavior of Joints of Strip Ends Made of Polymeric Materials" Polymers 14, no. 22: 4990. https://doi.org/10.3390/polym14224990

APA StyleMihalache, A.-M., Ermolai, V., Sover, A., Nagîț, G., Boca, M.-A., Slătineanu, L., Hrițuc, A., Dodun, O., & Rîpanu, M.-I. (2022). Tensile Behavior of Joints of Strip Ends Made of Polymeric Materials. Polymers, 14(22), 4990. https://doi.org/10.3390/polym14224990