Nanoparticles for Biomedical Application and Their Synthesis

Abstract

1. Introduction

2. Polymeric Nanoparticles in Biomedical Application

2.1. Polymeric Nanoparticles in the Treatment of Inflammation

2.2. Polymeric Nanoparticles in the Treatment of Cancer

2.3. Polymeric Nanoparticles in the Treatment of Infectious Diseases

2.4. Polymeric Nanoparticles in Implants and Prosthetic Devices

2.5. Polymeric Nano-Particles as Theranostic Devices

2.6. Other Applications

3. Synthesis of Nanoparticles for Biomedical Application

4. Characterization of Biomedical Active Nano-Particles

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khursheed, R.; Dua, K.; Vishwas, S.; Gulati, M.; Jha, N.K.; Aldhafeeri, G.M.; Alanazi, F.G.; Goh, B.H.; Gupta, G.; Paudel, K.R.; et al. Biomedical applications of metallic nanoparticles in cancer: Current status and future perspectives. Biomed. Pharmacother. 2022, 150, 112951. [Google Scholar] [CrossRef]

- Rezić, I. Determination of engineered nanoparticles on textiles and in textile wastewaters. TrAC Trends Anal. Chem. 2011, 30, 1159–1167. [Google Scholar] [CrossRef]

- Rezić, I. Engineered Nanoparticles in Textiles Textile Wastewaters. In Analysis Risk of Nanomaterials in Environmental Food Samples; Farre, M., Barcelo, D., Eds.; Elsevier: Chennai, India, 2012; Volume 59, pp. 235–264. [Google Scholar]

- Anfray, C.; Mainini, F.; Andón, F.T. Nanoparticles for immunotherapy. Front. Nanosci. 2020, 16, 265–306. [Google Scholar]

- Jesus, M.D.L.F.; Grazu, V. Nanobiotechnology: Inorganic Nanoparticles vs Organic Nanoparticles, Frontiers of Nanoscience; Palmer, R.E., Ed.; Elsevier: Oxford, UK, 2012; Volume 4. [Google Scholar]

- Lopez-Sanchez, J.A.; Dimitratos, N.; Hammond, C.; Brett, G.L.; Kesavan, L.; White, S.; Miedziak, P.; Tiruvalam, R.; Jenkins, R.L.; Carley, A.F.; et al. Facile removal of stabilizer-ligands from supported gold nanoparticles. Nat. Chem. 2011, 3, 551–556. [Google Scholar] [CrossRef] [PubMed]

- Genet, C.; Ebbesen, T.W. Light in tiny holes. Nature 2007, 445, 39–46. [Google Scholar] [CrossRef] [PubMed]

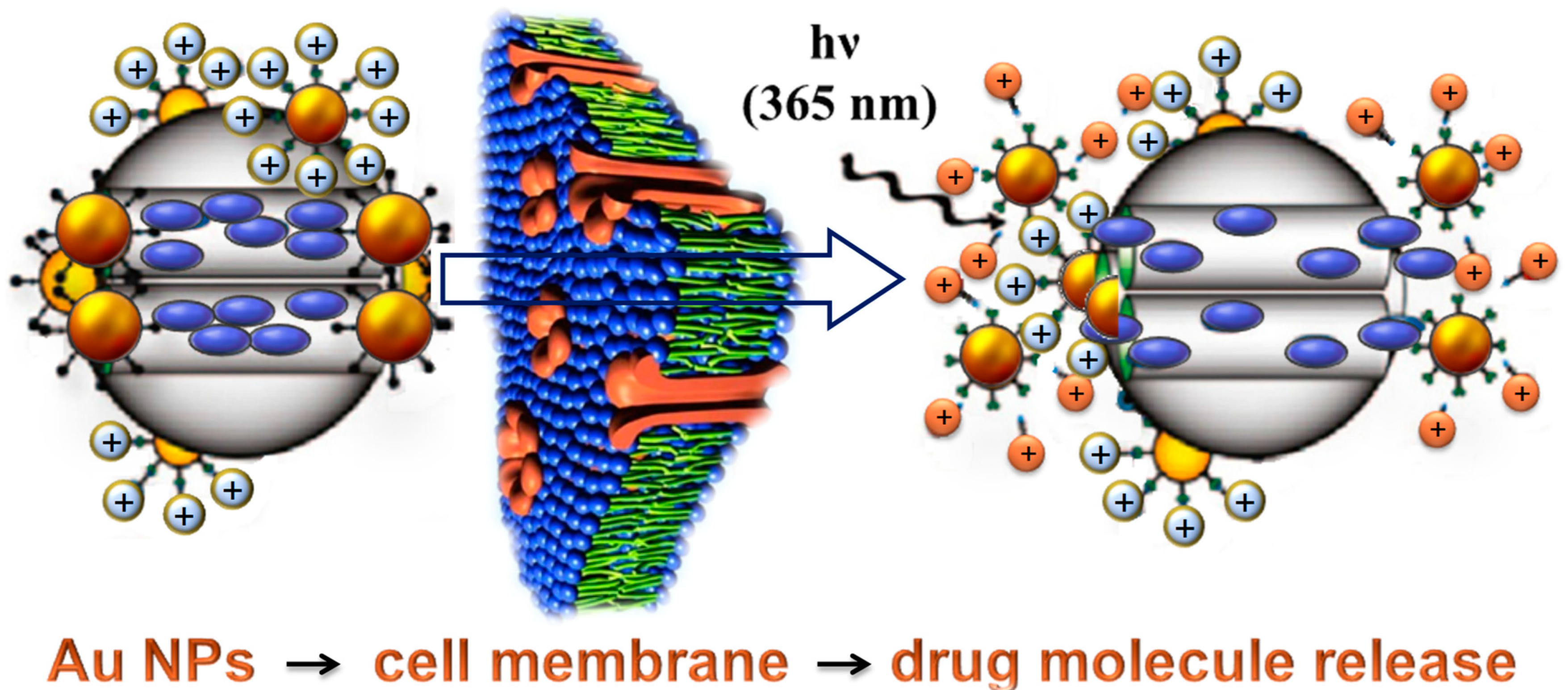

- Ding, Y.; Jiang, Z.; Saha, K.; Kim, C.S.; Kim, S.T.; Landis, R.F.; Rotello, V.M. Gold Nanoparticles for Nucleic Acid Delivery. Mol. Ther. 2014, 22, 1075–1083. [Google Scholar] [CrossRef] [PubMed]

- Rezić, I.; Zeiner, M.; Steffan, I. Determination of 28 selected elements in textiles by axially viewed inductively coupled plasma optical emission spectrometry. Talanta 2011, 83, 865–871. [Google Scholar] [CrossRef] [PubMed]

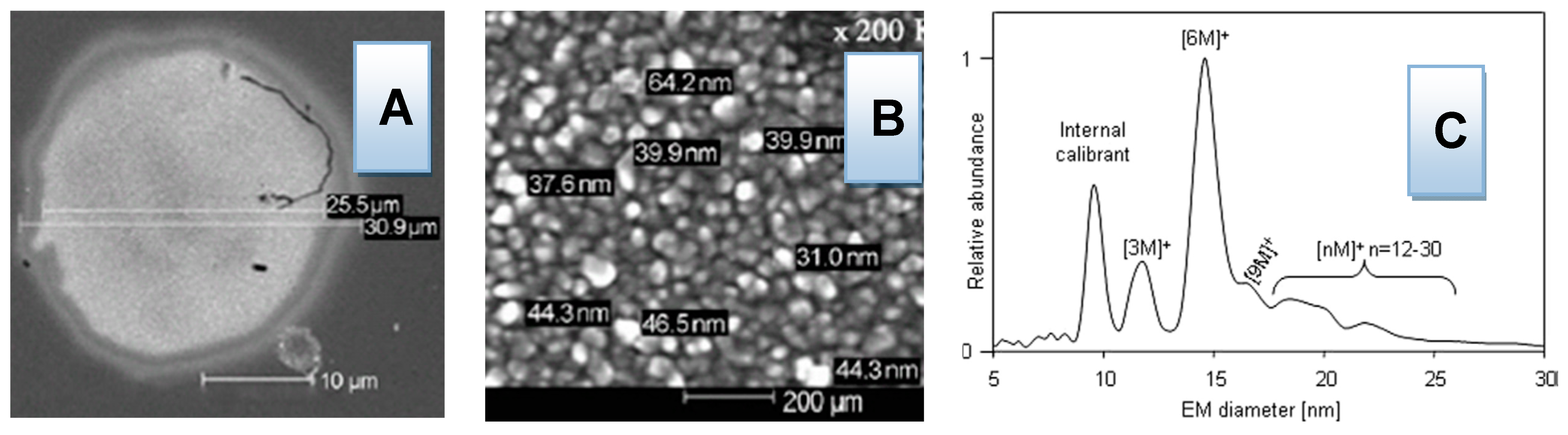

- Hinterwirth, H.; Wiedmer, S.K.; Moilanen, M.; Lehner, A.; Allmaier, G.; Waitz, T.; Lindner, W.; Lämmerhofer, M. Comparative method evaluation for size and size-distribution analysis of gold nanoparticles. J. Sep. Sci. 2013, 36, 2952–2961. [Google Scholar] [CrossRef]

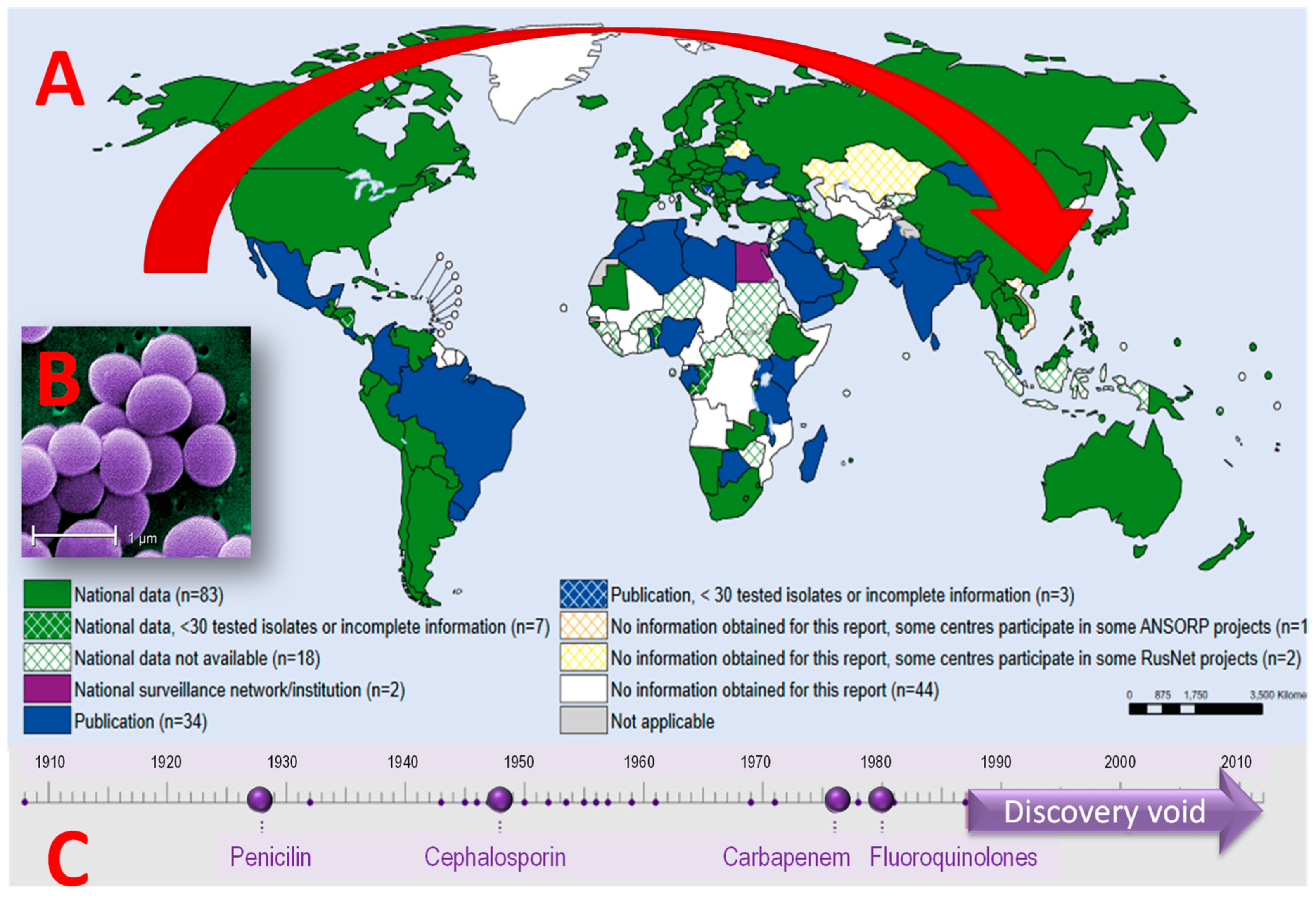

- World Health Organization. Antimicrobial Resistance Global Report on Surveillance. Available online: https://www.who.int/drugresistance/documents/surveillancereport/en/ (accessed on 2 October 2022).

- Van Hal, S.J.; Jensen, S.O.; Vaska, V.L.; Espedido, B.A.; Paterson, D.L.; Gosbell, I.B. Predictors of mortality in Staphylococcus aureus bacteremia. Clin. Microbiol. Rev. 2012, 25, 362–386. [Google Scholar] [CrossRef]

- Arduino, J.M. DRPH Photo Credit: Janice Haney Carr Center for Disease Control Prevention’s Public Health Image Library PHIL, ID #11157. Available online: https://phil.cdc.gov/Details.aspx?pid=11156 (accessed on 2 October 2022).

- Hanberger, H.; Walther, S.; Leone, M.; Barie, P.S.; Rello, J.; Lipman, J.; Marshall, J.C.; Anzueto, A.; Sakr, Y.; Pickkers, P.; et al. Increased mortality associated with meticillin-resistant Staphylococcus aureus (MRSA) infection in the Intensive Care Unit: Results from the EPIC II study. Int. J. Antimicrob. Agents 2011, 38, 331–335. [Google Scholar] [CrossRef]

- Hiramatsu, K.; Aritaka, N.; Hanaki, H.; Kawasaki, S.; Hosoda, Y.; Hori, S.; Fukuchi, Y.; Kobayashi, I. Dissemination in Japanese hospitals of strains of Staphylococcus aureus heterogeneously resistant to vancomycin. Lancet 1997, 350, 1670–1673. [Google Scholar] [CrossRef]

- McCaig, L.F.; McDonald, L.C.; Mandal, S.; Jernigan, D.B. Staphylococcus aureus–associated skin and soft tissue infections in ambulatory care. Emerg. Infect. Dis. 2006, 12, 1715. [Google Scholar] [CrossRef] [PubMed]

- Wieneke, A.A.; Roberts, D.; Gilbert, R.J. Staphylococcal food poisoning in the United Kingdom, 1969–90. Epidemiol. Infect. 1993, 110, 519–531. [Google Scholar] [CrossRef]

- Sheehy, S.; Atkins, B.; Bejon, P.; Byren, I.; Wyllie, D.; Athanasou, N.; Berendt, A.; McNally, M. The microbiology of chronic osteomyelitis: Prevalence of resistance to common empirical anti-microbial regimens. J. Infect. 2010, 60, 338–343. [Google Scholar] [CrossRef] [PubMed]

- Khatib, R.; Johnson, L.B.; Sharma, M.; Fakih, M.G.; Ganga, R.; Riederer, K. Persistent Staphylococcus aureus bacteremia: Incidence and outcome trends over time. Scand. J. Infect. Dis. 2009, 41, 4–9. [Google Scholar] [CrossRef] [PubMed]

- Fowler, V.G.; Miro, J.M.; Hoen, B.; Cabell, C.H.; Abrutyn, E.; Rubinstein, E.; Corey, G.R.; Spelman, D.; Bradley, S.F.; Barsic, B.; et al. Staphylococcus aureus endocarditis: A consequence of medical progress. JAMA 2005, 293, 3012–3021. [Google Scholar] [CrossRef]

- Tong, S.Y.C.; Davis, J.S.; Eichenberger, E.; Holland, T.L.; Fowler, V.G., Jr. Staphylococcus aureus Infections: Epidemiology, Pathophysiology, Clinical Manifestations, and Management. Clin. Microbiol. Rev. 2015, 28, 603–661. [Google Scholar] [CrossRef]

- Ammerlaan, H.; Seifert, H.; Harbarth, S.; Brun-Buisson, C.; Torres, A.; Antonelli, M.; Kluytmans, J.; Bonten, M. Study on European Practices of Infections with Staphylococcus aureus (SEPIA) Study Group Adequacy of Antimicrobial Treatment and Outcome of Staphylococcus aureus Bacteremia in 9 Western European Countries. Clin. Infect. Dis. 2009, 49, 997–1005. [Google Scholar] [CrossRef]

- Gotland, N.; Uhre, M.L.; Mejer, N.; Skov, R.; Petersen, A.; Larsen, A.R.; Benfield, T.; Danish Staphylococcal Bacteremia Study Group. Long-term mortality and causes of death associated with Staphylococcus aureus bacteremia. A matched cohort study. J. Infect. 2016, 73, 346–357. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. Antibacterial Activity of Nanomaterials. Nanomaterials 2018, 8, 359. [Google Scholar] [CrossRef]

- Al-Dhabi, N.A.; Mohammed Ghilan, A.K.; Arasu, M.V. Characterization of silver nanomaterials derived from marine Streptomyces sp. al-dhabi-87 and its in vitro application against multidrug resistant and extended-spectrum beta-lactamase clinical pathogens. Nanomaterials 2018, 8, 279. [Google Scholar] [CrossRef] [PubMed]

- Wijnhoven, S.W.; Peijnenburg, W.J.; Herberts, C.A.; Hagens, W.I.; Oomen, A.G.; Heugens, E.H.; Roszek, B.; Bisschops, J.; Gosens, I.; Van De Meent, D.; et al. Nano-silver—A review of available data and knowledge gaps in human and environmental risk assessment. Nanotoxicology 2009, 3, 109–138. [Google Scholar] [CrossRef]

- Blecher, K.; Nasir, A.; Friedman, A. The growing role of nanotechnology in combating infectious disease. Virulence 2011, 2, 395–401. [Google Scholar] [CrossRef] [PubMed]

- Huh, A.J.; Kwon, Y.J. “Nanoantibiotics”: A new paradigm for treating infectious diseases using nanomaterials in the antibiotics resistant era. J. Control. Release 2011, 156, 128–145. [Google Scholar] [CrossRef]

- Shah, M.A.; Ahmad, T. Principles of Nanoscience and Nanotechnology; Alpha Science International: London, UK; Oxford, UK, 2010; pp. 10–20. [Google Scholar]

- Pelgrift, R.Y.; Friedman, A.J. Nanotechnology as a therapeutic tool to combat microbial resistance. Adv. Drug Deliv. Rev. 2013, 65, 1803–1815. [Google Scholar] [CrossRef]

- Abramovitz, I.; Wisblech, D.; Zaltsman, N.; Weiss, E.I.; Beyth, N. Intratubular Antibacterial Effect of Polyethyleneimine Nanoparticles: An Ex Vivo Study in Human Teeth. J. Nanomater. 2015, 2015, 1–5. [Google Scholar] [CrossRef]

- Stoimenov, P.K.; Klinger, R.L.; Marchin, G.L.; Klabunde, K.J. Metal Oxide Nanoparticles as Bactericidal Agents. Langmuir 2002, 18, 6679–6686. [Google Scholar] [CrossRef]

- Magiorakos, A.P.; Srinivasan, A.; Carey, R.B.; Carmeli, Y.; Falagas, M.E.; Giske, C.G.; Harbarth, S.; Hindler, J.F.; Kahlmeter, G.; Olsson-Liljequist, B.; et al. Multidrug-resistant, extensively drug-resistant prug-resistant bacteria: An international expert proposal for interim stard definitions for acquired resistance. Clin. Microbiol. Infect. 2012, 183, 268–281. [Google Scholar] [CrossRef]

- Varner, K.E.; El-Badawy, A.; Feldhake, D.; Venkatapathy, R. State-of-the-Science Review: Everything Nanosilver and More; US Environmental Protection Agency: Washington, DC, USA, 2010. [Google Scholar]

- Kesić, A.; Horozić, E. Prednosti i neželjeni efekti primjene metalnih nanočestica i metalnih oksida u farmaceutskim i kozmetičkim preparatima. Šesti Međunarodni Kongr. Biomed. I Geonauke-Utic. Zivotn. Sred. Na Zdr. Ljud. 2016, 1, 218–225. [Google Scholar]

- Sehmi, S.K.; Noimark, S.D.; Pike, S.; Bear, J.C.; Peveler, W.J.; Williams, C.K.; Shaffer, M.; Allan, E.; Parkin, I.P.; MacRobert, A.J. Enhancing the Antibacterial Activity of Light-Activated Surfaces Containing Crystal Violet and ZnO Nanoparticles: Investigation of Nanoparticle Size, Capping Ligand, and Dopants. ACS Omega 2016, 1, 334–343. [Google Scholar] [CrossRef]

- Panáček, A.; Kvítek, L.; Smékalová, M.; Večeřová, R.; Kolář, M.; Röderová, M.; Dyčka, F.; Šebela, M.; Prucek, R.; Tomanec, O.; et al. Bacterial resistance to silver nanoparticles and how to overcome it. Nat. Nanotechnol. 2017, 13, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Grohmann, E. Available online: https://prof.beuth-hochschule.de/grohmann/ (accessed on 30 September 2022).

- Shkodra-Pula, B.; Vollrath, A.; Schubert, U.S.; Schubert, S. Polymer-based nanoparticles for biomedical applications. In Frontiers of Nanoscience; Elsevier: Amsterdam, The Netherlands, 2020; Volume 16, pp. 233–252. ISBN 978-0-08-102828-5. [Google Scholar]

- Franco, D.; Calabrese, G.; Guglielmino, S.P.P.; Conoci, S. Metal-Based Nanoparticles: Antibacterial Mechanisms and Biomedical Application. Microorganisms 2022, 10, 1778. [Google Scholar] [CrossRef] [PubMed]

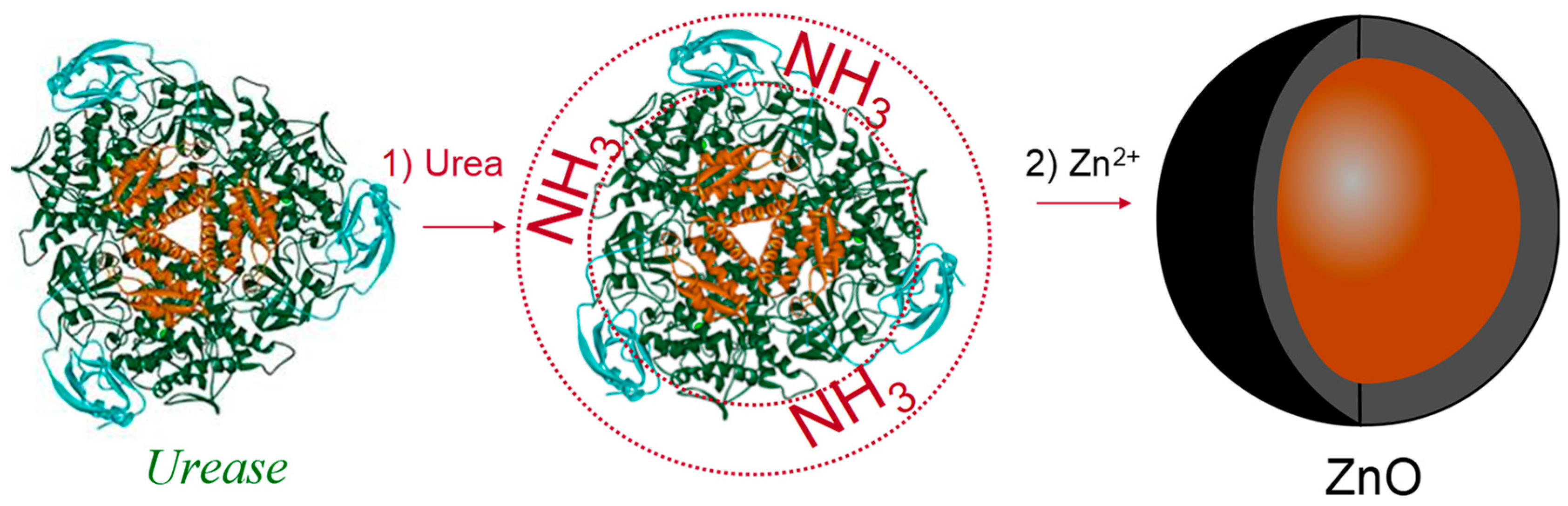

- Unuma, H.; Hirose, Y.; Ito, M.; Watanabe, K. Preparation of the Precursor of Porous Alumina Particles using Immobilized Urease in Alginate Gel Templates. J. Ceram. Soc. Jpn. 2004, 112, 409–411. [Google Scholar] [CrossRef][Green Version]

- Unuma, H.; Matsushima, Y.; Kawai, T. Enzyme-mediated synthesis of ceramic materials. J. Ceram. Soc. Jpn. 2011, 119, 623–630. [Google Scholar] [CrossRef]

- Li, X.; Xu, H.; Chen, Z.-S.; Chen, G. Biosynthesis of Nanoparticles by Microorganisms and Their Applications. J. Nanomater. 2011, 2011, 1–16. [Google Scholar] [CrossRef]

- Mandal, D.; Bolander, M.E.; Mukhopadhyay, D.; Sarkar, G.; Mukherjee, P. The use of microorganisms for the formation of metal nanoparticles and their application. Appl. Microbiol. Biotechnol. 2006, 69, 485–492. [Google Scholar] [CrossRef]

- Stoddart, A. Enzyme catalysis. Nat. Mater. 2012, 11, 910. [Google Scholar] [CrossRef]

- Chen, L.; Shen, Y.; Xie, A.; Huang, B.; Jia, R.; Guo, R.; Tang, W. Bacteria-Mediated Synthesis of Metal Carbonate Minerals with Unusual Morphologies and Structures. Cryst. Growth Des. 2008, 9, 743–754. [Google Scholar] [CrossRef]

- Sondi, I.; Matijević, E. Homogeneous Precipitation of Calcium Carbonates by Enzyme Catalyzed Reaction. J. Colloid Interface Sci. 2001, 238, 208–214. [Google Scholar] [CrossRef]

- Sondi, I.; Matijević, E. Homogeneous Precipitation by Enzyme Catalyzed Reactions. II. Strontium Barium Carbonates. Chem. Mater. 2003, 15, 1322–1326. [Google Scholar] [CrossRef]

- Zhao, J.; Sekikawa, H.; Kawai, T.; Unuma, H. Ferrimagnetic magnetite hollow microspheres prepared via enzymatically precipitated iron hydroxide on a urease-bearing polymer template. J. Ceram. Soc. Jpn. 2009, 117, 344–346. [Google Scholar] [CrossRef][Green Version]

- Kawashita, M.; Takayama, Y.; Kokubo, T.; Takaoka, G.H.; Araki, N.; Hiraoka, M. Enzymatic Preparation of Hollow Yttrium Oxide Microspheres for In Situ Radiotherapy of Deep-Seated Cancer. J. Am. Ceram. Soc. 2006, 89, 1347–1351. [Google Scholar] [CrossRef]

- Hamaya, T.; Takizawa, T.; Hidaka, H.; Horikoshi, K. A new method for the preparation of magnetic alginate beads. J. Chem. Eng. Jpn. 1993, 26, 223–224. [Google Scholar] [CrossRef][Green Version]

- Kato, S.; Makino, T.; Unuma, H.; Takahashi, M. Enzyme Catalyzed Preparation of Hollow Alumina Precursor Using Emulsion Template. J. Ceram. Soc. Jpn. 2001, 109, 369–371. [Google Scholar] [CrossRef][Green Version]

- Kato, S.; Unuma, H.; Ota, T.; Takahashi, M. Homogeneous Precipitation of Hydrous Tin Oxide Powders at Room Temperature Using Enzymatically Induced Gluconic Acid as a Precipitant. J. Am. Ceram. Soc. 2004, 83, 986–988. [Google Scholar] [CrossRef]

- Yeom, B.; Char, K. Nanostructured CaCO3 Thin Films Formed on the Urease Multilayers Prepared by the Layer-by-Layer Deposition. Chem. Mater. 2009, 22, 101–107. [Google Scholar] [CrossRef]

- Kawai, T.; Sekikawa, H.; Unuma, H. Preparation of hollow hydroxyapatite microspheres utilizing poly(divinylbenzene) as a template. J. Ceram. Soc. Jpn. 2009, 117, 340–343. [Google Scholar] [CrossRef]

- Kawashita, M.; Sadaoka, K.; Kokubo, T.; Saito, T.; Takano, M.; Araki, N.; Hiraoka, M. Enzymatic preparation of hollow magnetite microspheres for hyperthermic treatment of cancer. J. Mater. Sci. Mater. Med. 2006, 17, 605–610. [Google Scholar] [CrossRef] [PubMed]

- Malel, E.; Ludwig, R.; Gorton, L.; Madnler, D. Local Deposition of Au Nanpoarticles by Direct Electron Transfer through Cellobiose Dehydrogenase. Chem. A Eur. J. 2010, 16, 11697–11706. [Google Scholar] [CrossRef]

- Rodrigues-Lorenzo, L.; Rica, R.; Alvarez-Puebla, R.A.; Liz-Marzan, L.M. Plasmonic nanosensors with inverse sensitivity by means of enzyme guided crystal growth. Nat. Mater. 2012, 11, 604–607. [Google Scholar]

- Allmaier, G.; Bacher, G.; Kaufman, S.L.; Szymanski, W.W. Molecular mass determination of noncovalent complexes biopolymers—Proteins carbohydrates–by applying a gas-phase electrophoretic mobility mass analyzer. J. Aerosol Sci. 1999, 30, S303–S304. [Google Scholar] [CrossRef]

- Allmaier, G.; Laschober, C.; Reischl, G.P.; Szymanski, W.W. Austrian Patent Surgical Cutting and Fastening Instrument with Closure Trigger Locking Mechanism. Patent 502 207 A1 2007 02, 15 February 2007. [Google Scholar]

- Allmaier, G.; Laschober, C.; Szymanski, W.W. 2008 Nano ES GEMMA nad PDMA, New Tools for the Analysis of Nanobioparticles–Protein Complexes, Lipoparticles, Viruses. J. Am. Soc. Mass Spectrom. 2008, 19, 1062–1068. [Google Scholar] [CrossRef]

- Kallinger, P.; Weiss, V.; Lehner, A.; Allmaier, G.; Szymanski, W. Analysis hling of bio-nanoparticles environmental nanoparticles using electrostatic aerosol mobility. Particuology 2013, 11, 14–19. [Google Scholar] [CrossRef]

- Rezić, I.; Rezić, T.; Bokić, L. Optimization of the TLC separation of seven amino acids. J. Planar Chromatogr. Mod. TLC 2007, 20, 173–177. [Google Scholar] [CrossRef]

- Rezić, I.; Majdak, M.; Kirin, P.; Vinceković, M.; Jurić, S.; Sopko, S.; Vlahoviček Kahlina, K.; Somogyi Škoc, M. Functionalized Microcapsules with Silver for Medical Textiles. In Proceedings of the 14th Scientific-Professional Symposium Textile Science and Economy: Book of Abstracts, Tekstilno-tehnološki fakultet, Zagreb, Croatia, 26 January 2022. [Google Scholar]

- Rezić, I. Prediction of the surface tension of surfactant mixtures for detergent formulation using Design Expert software. Mon. Chem.-Chem. Mon. 2011, 142, 1219–1225. [Google Scholar] [CrossRef]

- Rezić, I.; Somogyi Škoc, M.; Pokrovac, I.; Ljoljić Bilić, V.; Kosalec, I. Characterization of materials with nanoparticles and their biological and environmental impact. In Proceedings of the 141ST Iastem International Conference/International Academy of Science, Technology, Engineering and Management, Vienna, Austria, 25–26 September 2018; pp. 54–57. [Google Scholar]

- Rezić, I.; Ćurković, L.; Ujević, M. Simple methods for characterization of metals in historical textile threads. Talanta 2010, 82, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Rezić, I.; Ćurković, L.; Ujević, M. Study of microstructure and corrosion kinetic of steel guitar strings in artificial sweat solution. Mater. Corros. 2010, 61, 524–529. [Google Scholar] [CrossRef]

- Rezić, I.; Steffan, I. ICP-OES determination of metals present in textile materials. Microchem. J. 2007, 85, 46–51. [Google Scholar] [CrossRef]

- Rezić, I. Optimization of ultrasonic extraction of 23 elements from cotton. Ultrason. Sonochem. 2009, 16, 63–69. [Google Scholar] [CrossRef]

- Rezić, I.; Rolich, T. Artificial neural networks in chromatography spectroscopy. In Artificial Neural Networks; Nova Science Publishers: New York, NY, USA, 2011; pp. 123–138. [Google Scholar]

- Rezić, I. Thin layer chromatographic monitoring of sonolytic degradation of surfactants in wastewaters. J. Planar Chromatogr. Mod. TLC 2019, 26, 96–101. [Google Scholar] [CrossRef]

- Reich, E.S. Ultimate upgrade for US synchrotron. Nature 2013, 501, 148–149. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Schmitt, B.; Brönnimann, C.; Eikenberry, E.F.; Gozzo, F.; Hörmann, C.; Horisberger, R.; Patterson, B. Mythen detector system. Nucl. Instrum. Methods Phys. Res. A 2003, 501, 267–272. [Google Scholar] [CrossRef]

- Brönnimann, C.; Baur, R.; Eikenberry, E.F.; Kohout, S.; Lindner, M.; Schmitt, B.; Horisberger, R. A pixel read-out chip for the PILATUS project. Nucl. Instrum. Methods Phys. Res. A 2001, 465, 235–272. [Google Scholar] [CrossRef]

- Petkov, V.; Peng, Y.; Williams, G.; Huang, B.; Tomalia, D.; Ren, Y. Structure of gold nanoparticles suspended in water studied by x-ray diffraction and computer simulations. Phys. Rev. B 2005, 72, 195402. [Google Scholar] [CrossRef]

- Jacques, S.D.M.; Di Michiel, M.; Kimber, S.A.J.; Yang, X.; Cernik, R.J.; Beale, A.M.; Billinge, S.J.L. Pair distribution function computed tomography. Nat. Commun. 2013, 4, 2536. [Google Scholar] [CrossRef] [PubMed]

- Sherma, B.; Mani, S.; Sarma, T.K. Biogenic Growth of Alloys Core Shell Nanostructures Using Urease as a Nanoreactor at Ambient Conditions. Nat. Sci. Rep. 2013, 3, 1–8. [Google Scholar] [CrossRef]

- De la Rica, R.; Matsui, H. Urease as a Nanoreactor for Growing Crystalline ZnO Nanoshells at Room Temperature. Angewte Chem. Int. Ed. 2008, 47, 5415–5417. [Google Scholar] [CrossRef]

- Granquist, C.G. Transparent conductors as solar energy materials: A panoramic review. Sol. Energy Mater. Sol. Cells 2007, 91, 1529–1598. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Lezec, H.J.; Ghaemi, H.F.; Thio, T.; Wolff, P.A. Extraordinary optical transmission through sub-wavelength hole arrays. Nature 1998, 391, 667–669. [Google Scholar] [CrossRef]

- Martinaga Pintarić, L.; Somogi Škoc, M.; Ljoljić Bilić, V.; Pokrovac, I.; Kosalec, I.; Rezić, I. Synthesis, modification and characterization of antimicrobial textile surface containing ZnO nanoparticles. Polymers 2020, 12, 1210. [Google Scholar] [CrossRef]

- Rezić, I.; Majdak, M.; Bilić, V.L.; Pokrovac, I.; Martinaga, L.; Škoc, M.S.; Kosalec, I. Development of Antibacterial Protective Coatings Active against MSSA and MRSA on Biodegradable Polymers. Polymers 2021, 13, 659. [Google Scholar] [CrossRef] [PubMed]

- Rezić, I.; Somogyi Škoc, M.; Majdak, M.; Jurić, S.; Stracenski, K.S.; Vinceković, M. Functionalization of Polymer Surface with Antimicrobial Microcapsules. Polymers 2022, 14, 1961. [Google Scholar] [CrossRef] [PubMed]

- Rezić, I.; Škoc, M.S.; Majdak, M.; Jurić, S.; Stracenski, K.S.; Vlahoviček-Kahlina, K.; Vinceković, M. ICP-MS Determination of Antimicrobial Metals in Microcapsules. Molecules 2022, 27, 3219. [Google Scholar] [CrossRef] [PubMed]

- Vukoja, D.; Vlainić, J.; Ljolić Bilić, V.; Martinaga, L.; Rezić, I.; Brlek Gorski, D.; Kosalec, I. Innovative Insights into In Vitro Activity of Colloidal Platinum Nanoparticles against ESBL-Producing Strains of Escherichia coli and Klebsiella pneumoniae. Pharmaceutics 2022, 14, 1714. [Google Scholar] [CrossRef]

- Rezić, I.; Kracher, D.; Oros, D.; Mujadžić, S.; Anđelini, M.; Kurtanjek, Ž.; Ludwig, R.; Rezić, T. Application of Causality Modelling for Prediction of Molecular Properties for Textile Dyes Degradation by LPMO. Molecules 2022, 27, 6390. [Google Scholar] [CrossRef]

- Egbuna, C.; Parmar, V.K.; Jeevanandam, J.; Ezzat, S.M.; Patrick-Iwuanyanwu, K.C.; Adetunji, C.O.; Khan, J.; Onyeike, E.N.; Uche, C.Z.; Akram, M.; et al. Toxicity of Nanoparticles in Biomedical Application: Nanotoxicology. J. Toxicol. 2021, 2021, 1–21. [Google Scholar] [CrossRef]

- Blanco-Andujar, C.; Thanh, N.T. Synthesis of nanoparticles for biomedical applications. Annu. Rep. Sect. A Inorg. Chem. 2010, 106, 553–568. [Google Scholar] [CrossRef]

- Uthaman, A.; Lal, H.; Thomas, S. Fundamentals of Silver Nanoparticles and Their Toxicological Aspects. In Polymer Nanocomposites Based on Silver Nanoparticles. Engineering Materials; Lal, H.M., Thomas, S., Li, T., Maria, H.J., Eds.; Springer: Cham, Switzerland, 2021; pp. 1–24. [Google Scholar]

- Dikshit, P.K.; Kumar, J.; Das, A.K.; Sadhu, S.; Sharma, S.; Singh, S.; Gupta, P.K.; Kim, B.S. Green synthesis of metallic nanoparticles: Applications and limitations. Catalysts 2021, 11, 902. [Google Scholar] [CrossRef]

- De Silva, C.; Nawawi, N.M.; Abd Karim, M.M.; Abd Gani, S.; Masarudin, M.J.; Gunasekaran, B.; Ahmad, S.A. The mechanistic action of biosynthesised silver nanoparticles and its application in aquaculture and livestock industries. Animals 2021, 11, 2097. [Google Scholar] [CrossRef]

- Xu, L.; Yi-Yi, W.; Huang, J.; Chun-Yuan, C.; Zhen-Xing, W.; Xie, H. Silver nanoparticles: Synthesis, medical applications and biosafety. Theranostics 2020, 10, 8996–9031. [Google Scholar] [CrossRef]

- Almatroudi, A. Silver nanoparticles: Synthesis, characterisation and biomedical applications. Open Life Sci. 2020, 15, 819–839. [Google Scholar] [CrossRef] [PubMed]

- Barani, H.; Mahltig, B. Microwave-assisted synthesis of silver nanoparticles: Effect of reaction temperature and precursor concentration on fluorescent property. J. Clust. Sci. 2020, 1, 1–11. [Google Scholar] [CrossRef]

- Patil, A.H.; Jadhav, S.A.; More, V.B.; Sonawane, K.D.; Patil, P.S. Novel one step sonosynthesis and deposition technique to prepare silver nanoparticles coated cotton textile with antibacterial properties. Colloid J. 2019, 81, 720–727. [Google Scholar] [CrossRef]

- Kuntyi, O.; Shepida, M.; Sozanskyi, M.; Sukhatskiy, Y.; Mazur, A.; Kytsya, A.; Bazylyak, L. Sonoelectrochemical synthesis of silver nanoparticles in sodium polyacrylate solution. Biointerface Res. Appl. Chem. 2021, 11, 12202–12214. [Google Scholar]

- Seku, K.; Gangapuram, B.R.; Pejjai, B.; Kadimpati, K.K.; Golla, N. Microwave-assisted synthesis of silver nanoparticles and their application in catalytic, antibacterial and antioxidant activities. J. Nanostruct. Chem. 2018, 8, 179–188. [Google Scholar] [CrossRef]

- Tola, O.H.; Oluwole, O.I.; Omotayo, A.B. Synthesis and characterization of silver nanoparticles from ecofriendly materials: A review. Int. J. Eng. Res. Technol. 2020, 9, 782–795. [Google Scholar]

- Naganthran, A.; Verasoundarapandian, G.; Khalid, F.E.; Masarudin, M.J.; Zulkharnain, A.; Nawawi, N.M.; Karim, M.; Abdullah, C.A.C.; Ahmad, S.A. Synthesis, Characterization and Biomedical Application of Silver Nanoparticles. Materials 2022, 15, 427. [Google Scholar] [CrossRef]

| NPs | Diameter | NPs | Diameter | NPs | Diameter |

|---|---|---|---|---|---|

| Ag | 1.5–350 um | Eu2O3 | 30–58 nm | Pr6O11 | 15–30 nm |

| Al | 18 or 80 nm | Fe | 25–250 nm | Si | 30–70 nm |

| Au | 50–150 nm | Gd2O3 | 15–80 nm | SiO2 | 15–80 nm |

| B2O3 | 40–80 nm | In2O3 | 30–50 nm | Sm2O3 | 15–55 nm |

| BaSO4 | 1–5 um | In(OH)3 | 20–70 nm | SnO2 | 45–60 nm |

| C | 3–400 nm | La2O3 | 15–30 nm | SrTiO3 | 100 nm |

| CeO2 | 15–105 nm | Li4Ti5O12 | 20–60 nm | Ti | 30–50 nm |

| Co | 28 nm | MgO | 20–100 nm | W | 50 nm |

| Cr | 50 nm | Mg(OH)2 | 15 nm | Y2O3 | 20–40 nm |

| Cu | 25–500 nm | Mn2O3 | 30–60 nm | YbF3 | 40–80 nm |

| Dy2O3 | 30 or 55 nm | Mo | 70 nm | Zn | 80–130 nm |

| Er2O3 | 20–53 nm | Ni | 20–50 nm | ZrC | 30–60 nm |

| Modality | Nanoparticle/Agent | |

|---|---|---|

| Imaging | Optical scattering | Au nanoshells, nanorodes, nanocages |

| PET, SPECT | Radioisotope 198Au | |

| CT | Au NPs | |

| Therapeutic actuation | Phototermal | Au nanoshells, nanocages |

| Photoacoustic | NIR-absorbing Au NPs | |

| Chemotherapy | Au NPs loaded with anticancer drugs | |

| Gene therapy | Au NPs loaded with RNA, DNA |

| Biological System | Effect | Size, nm | Biological System | Effect | Size, nm |

|---|---|---|---|---|---|

| Acinetobacter baumannii | Antibacterial | 5–30 | Micrococcus luteus | Growth inhibition | ~20–~30 |

| Acinetobacter | Growth inhibition | ~20–100 | multidrug resistant Pseudomonas aeruginosa | Inhibition of biofilm formation | 20–30 |

| Aeromonas | Growth inhibition | ~20–100 | multidrug-resistant Escherichia coli | Antibacterial | ~6 |

| Aspergillus foetidus | Antifungal | 104.9 | multidrug-resistant Klebsiella pneumoniae | Antibacterial | ~6 |

| Aspergillus fumigatus | Antifungal | 5–30 | Staphylococcus aureus | Bactericide | ~10–~100 |

| Aspergillus niger | Antifungal | 4.75–8.31 | Paenibacillus koreensis | Antibacterial | ~10 |

| Aspergillus oryzae | Antifungal | 104.9 | Penicillium | Antifungal | >42 |

| Aspergillus | Antifungal | 7–20 | Peptostreptococcus | Antibacterial | ~100 |

| Aspergillus terreus | Antifungal | Nije specificirano | Pichia pastoris | Antifungal | 9–10 |

| Bacillus cereus | Antibacterial | 120 | Propionibacterium acnes | Antibacterial | 20–70 |

| Bacillus megaterium | Antibacterial | 24 | Proteus mirabilis | Cytotoxic | Not specified |

| Bacillus mycoides | Bactericide | 16 | Proteus vulgaricus | Antibacterial | 50–70 |

| Bacillus pumulis | Bactericide | Not specified | Pseudomonas aeruginosa | Antibacterial | 1–12 |

| Bifidobacterium | Antibacterial | ~100 | Rhizoctonia bataticola | Antifungal | ~2–40 |

| Bordetella pertussis Candida albicans | Growth inhibition | ~20–~30 | Saccharomyces | Antifungal | ~15 |

| Candida albicans ATCC 10239 | Antifungal | ~20–45 | Salmonella paratyphi | Antibacterial | 63–90 |

| Candida glabrata ATCC90030 | Antifungal | Not specified | Scedosporium JAS1 | Antifungal | Not specified |

| Candida tropicalis | Antifungal | Not specified | Serratia marcescens | Antibacterial | Not specified |

| Citrobacter | Growth inhibition | ~20–100 | Shigella flexneri MTCC 1475 | Antibacterial | 17–29 |

| Cryptococcus neoformans | Antifungal | 50–70 | Staphylococcus aureus | Antibacterial | 1–12 |

| Eschericia coli MTCC 443 | Bactericide | 8–12 | Staphylococcus aureus ATCC 25923 | Antibacterial | 5–25 |

| Enterobacter aerogenes | Antibacterial | 8–12 | Staphylococcus aureus ATCC BAA-1721 | Antibacterial | ~89 |

| Enterococcus faecalis | Antibacterial | ~89 | Staphylococcus epidermidis | Antibacterial | 20–70 |

| Fusarium oxysporum | Antifungal | 104.9 | Streptococcus | Antibacterial | 15 |

| Klebsiella pneumoniae | Antibacterial | ~6 | Trichopyton rubrum | Antifungal | ~15 |

| Lactobacillus acidophilus | Bactericide | 16 | Vibrio cholerae | Antibacterial | 5–25 |

| Listeria monocytogenes | Antibacterial | 17–29 | Xanthomonas campestris | Antibacterial | ~54 |

| MRSA | Growth inhibition | 198–595 | Yersinia enterocolitica | Antibacterial | - |

| Area | Application of Silver Nanoparticles |

|---|---|

| Anesteziology | Coating on breathing masks, endotracheal tubes for mechanical ventilation assistance |

| Cardiology | Coating on the tracking catheter |

| Stomatology | Adhesives in dental materials, silver-filled SiO2 nanocomposite resins |

| Diagnostics | Ultra-sensitive and ultra-fast platform for clinical tests for myocardial infarction diagnosis, fluorescence detection of RNA |

| Drug release | Remote laser induced opening microcapsules |

| Eye care | Contrasts on contact lenses |

| Visualisation | Nomenclatures for marking cells |

| Neurosurgery | Coating of the catheter for the drainage of cerebrospinal fluid |

| Orthopedics | Bone cement additives, joint replacement implants, orthopedic socks |

| Drugs | Treatments for dermatitis, ulcerative colitis and acne, HIV-1 inhibition |

| Surgery | Coats in medical textiles—surgical suits and masks |

| Urology | Plastered on surgical nets for pelvic reconstruction |

| Microorganisms | Nanoparticles | Temperature, °C | Size (nm) | Shape |

|---|---|---|---|---|

| Rhodococcus species | Au | 37 | 5–15 | sphere |

| Shewanella oneidensis | Au | 30 | 12 ± 5 | sphere |

| Plectonemaboryanum | Au | 25–100 | <10–25 | cube |

| Plectonema boryanum | Au | 25 | 10–600 | octahedral |

| Escherichia coli | Au | 37 | 20–30 | triangle |

| Yarrowia lipolytica | Au | 30 | 15 | triangle |

| Rhodopseudomonas capsulate | Au | 30 | 10–20 | sphere |

| Brevibacterium casei | Au, Ag | 37 | 10–50 | sphere |

| Trichoderma viride | Ag | 27 | 5–40 | sphere |

| Phaenerochaete chrysosporium | Ag | 37 | 50–200 | pyramidal |

| Bacillus cereus | Ag | 37 | 4–5 | sphere |

| Lactobacillus species | Ba, TiO3 | 25 | 20–80 | tetragonal |

| Fusarium oxysporum | CdSe | 10 | 9–15 | sphere |

| Escherichia coli | Cd, Te | 37 | 2.0–3.2 | sphere |

| Fusariumoxysporum | CdCO3, PbCO3 | 27 | 120–200 | sphere |

| Lactobacillus | CdS | 25–60 | 4.9 ± 0.2 | sphere |

| Pyrobaculum islandicum | Cr, Mn, U, Tc | 100 | different | sphere |

| Shewanella oneidensis | Fe3O4 | 28 | 40–50 | hexagonal |

| Enterobacter species | Hg | 30 | 2–5 | sphere |

| Desulfovibrio desulfuricans | Pd | 25 | 50 | sphere |

| Shewanella algae | Pt | 25 | 5 | - |

| Saccharomyces cerevisiae | Sb2O3 | 25–60 | 2–10 | sphere |

| Shewanella species | Se | 30 | 181 ± 40 | sphere |

| Fusarium oxysporum | SrCO3 | 27 | 10–50 | needle like |

| Fusarium oxysporum | TiO2 | 300 | 6–13 | sphere |

| Fusarium oxysporum | ZrO2 | 25 | 3–11 | sphere |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezić, I. Nanoparticles for Biomedical Application and Their Synthesis. Polymers 2022, 14, 4961. https://doi.org/10.3390/polym14224961

Rezić I. Nanoparticles for Biomedical Application and Their Synthesis. Polymers. 2022; 14(22):4961. https://doi.org/10.3390/polym14224961

Chicago/Turabian StyleRezić, Iva. 2022. "Nanoparticles for Biomedical Application and Their Synthesis" Polymers 14, no. 22: 4961. https://doi.org/10.3390/polym14224961

APA StyleRezić, I. (2022). Nanoparticles for Biomedical Application and Their Synthesis. Polymers, 14(22), 4961. https://doi.org/10.3390/polym14224961