Feasibility of Using Biochar as an Eco-Friendly Microfiller in Polymer Concretes

Abstract

1. Introduction

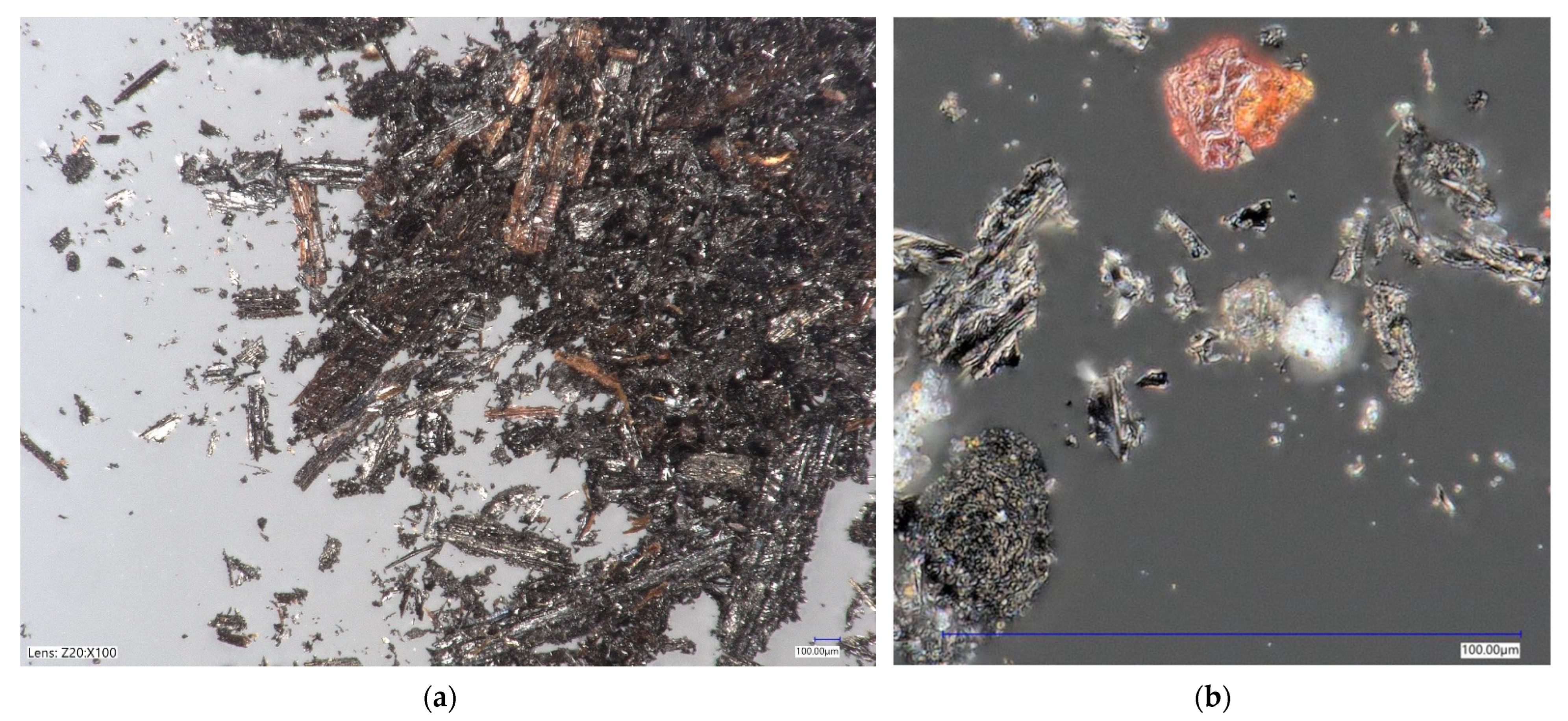

2. Materials and Methods

3. Results

3.1. The Course of Binding

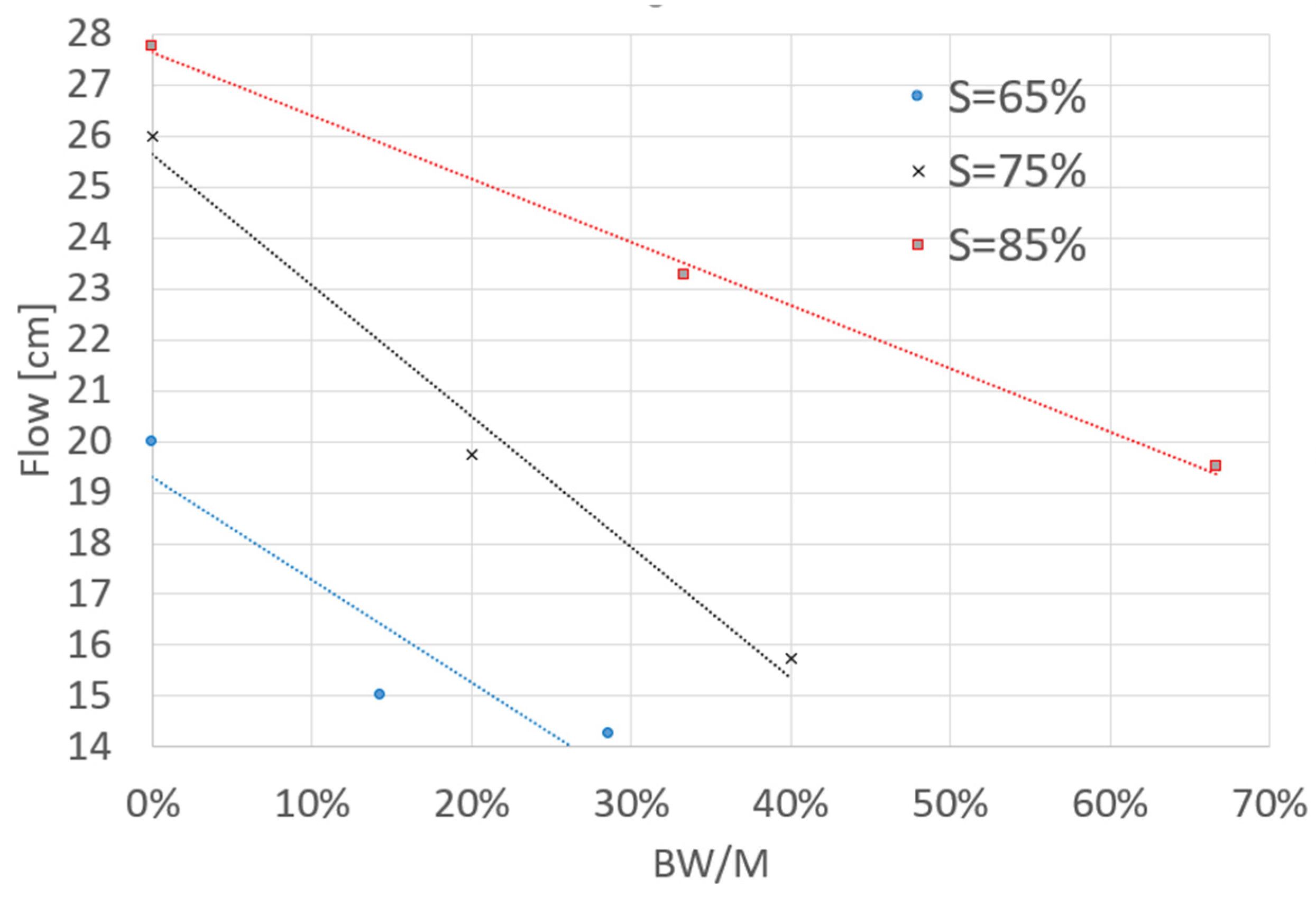

3.2. Consistency

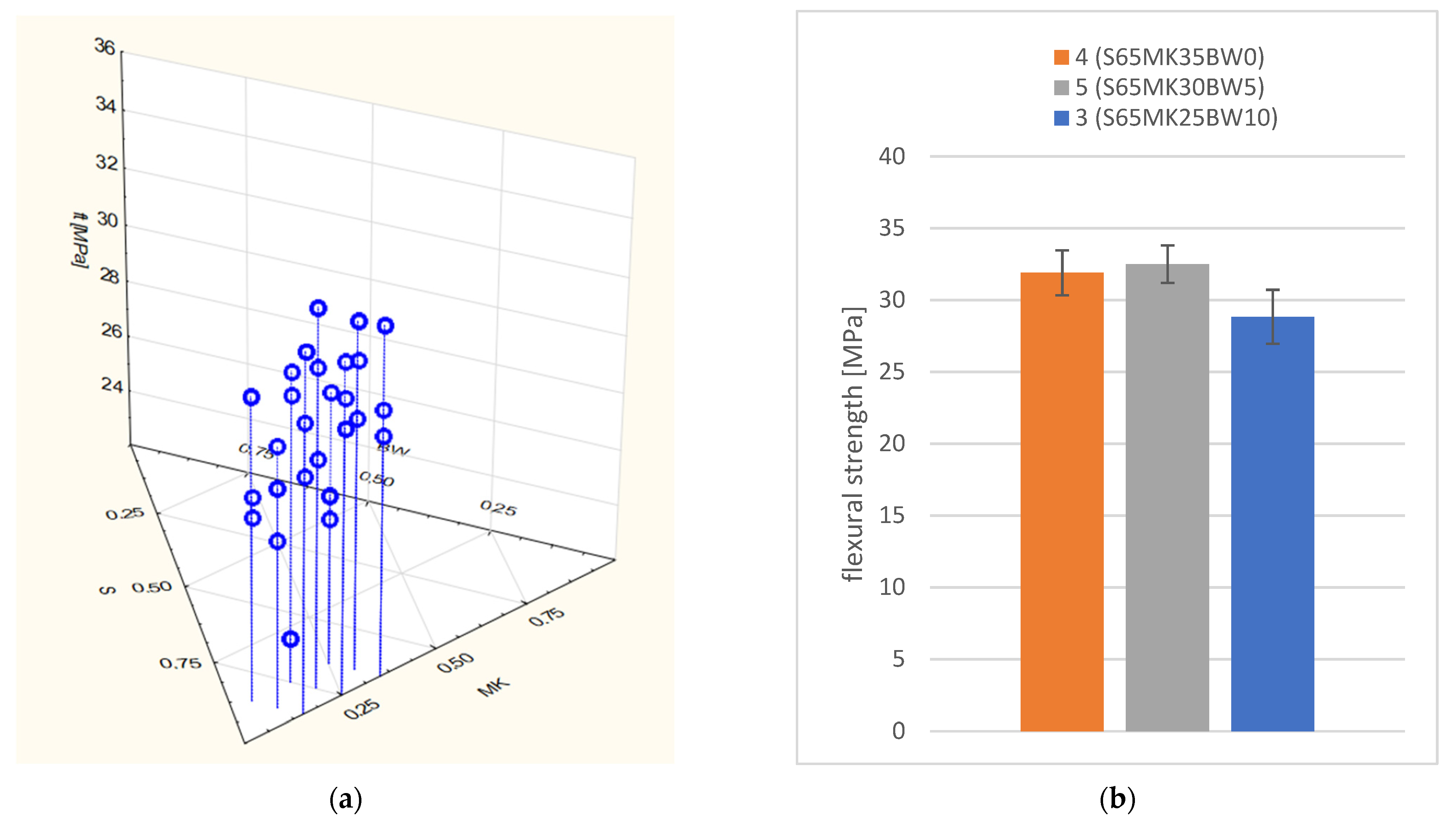

3.3. Flexural Strength

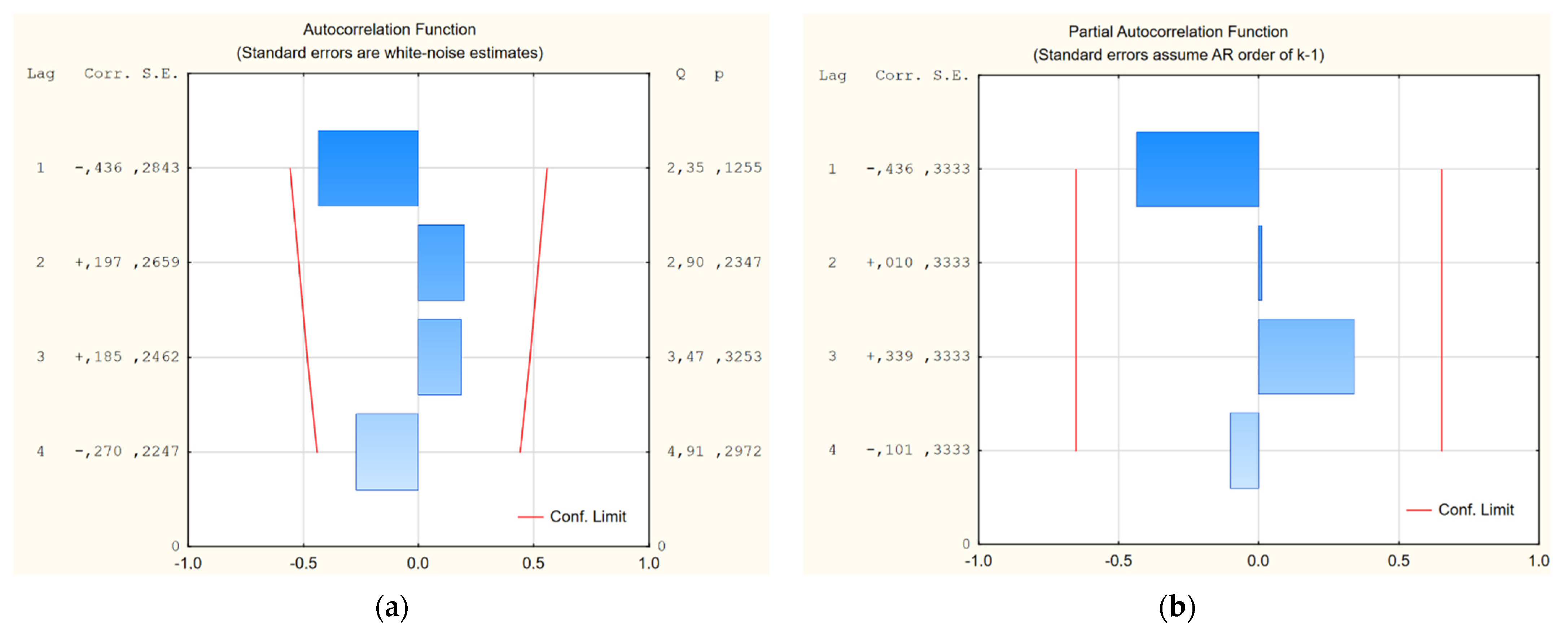

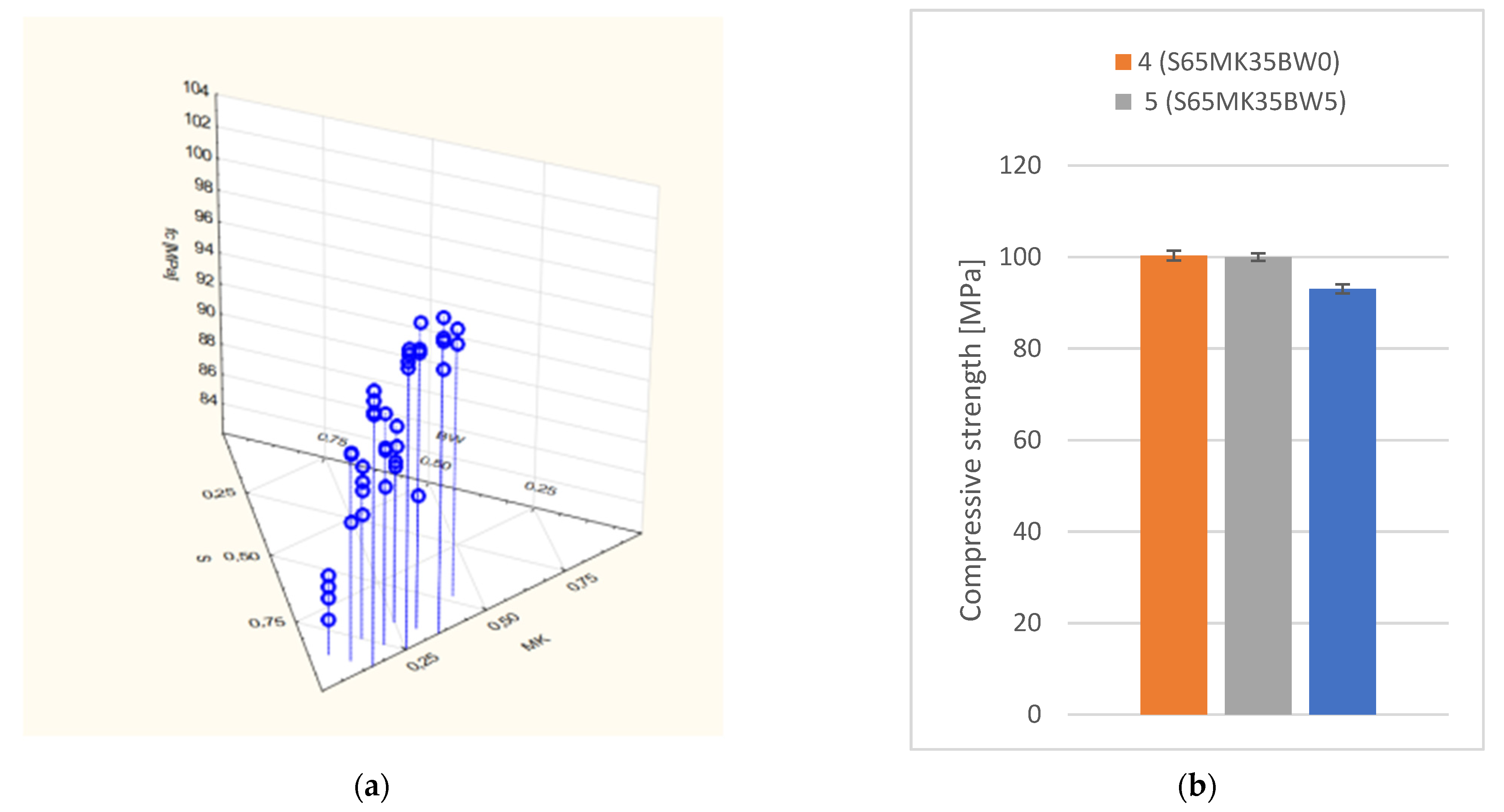

3.4. Compressive Strength

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Anwar, M.; Shah, S.; Alhazmi, H. Recycling and Utilization of Polymers for Road Construction Projects: An Application of the Circular Economy Concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of concrete with recycled aggregates: A circular economy mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Alhazmi, H.; Shah, S.A.R.; Anwar, M.K.; Raza, A.; Ullah, M.K.; Iqbal, F. Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review for Assessment of Recycling and Waste Utilization. Polymers 2021, 13, 2135. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Garbacz, A.; Sokołowska, J.J. Concrete-like polymer composites with fly ashes—Comparative study. Constr. Build. Mater. 2013, 38, 689–699. [Google Scholar] [CrossRef]

- Barbuta, M.; Bucur, R.D.; Cimpeanu, S.M.; Paraschiv, G.; Bucur-Agroecology, D. Wastes in Building Materials Industry; INTECH: Rijeka, Croatia, 2015; Chapter 3; pp. 81–99. ISBN 978-953-51-2130-5. [Google Scholar] [CrossRef]

- Agavriloaia, L.; Oprea, S.; Barbuta, M.; Luca, C. Characterization of polymer concrete with epoxy polyurethane acryl matrix. Constr. Build. Mater. 2012, 12, 190–196. [Google Scholar] [CrossRef]

- Kaya, A.; Kar, F. Properties of concrete containing waste expanded polystyrene and natural resin. Constr. Build. Mater. 2016, 102, 572–578. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Tavares, C.M.L.; Ferreira, A.J.M. Chemical resistance of epoxy and polyester polymer concrete to acids and salts. J. Polym. Eng. 2002, 22, 27–43. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Aliha, M.R.M.; Shokrieh, M.M.; Ayatollahi, M.R. Mechanical durability of an optimized polymer concrete under various thermal cyclic loadings—An experimental study. Constr. Build. Mater. 2014, 64, 308–315. [Google Scholar] [CrossRef]

- Seco, A.; Echeverría, A.M.; Marcelino, S.; García, B.; Espuelas, S. Durability of polyester polymer concretes based on metallurgical wastes for the manufacture of construction and building products. Constr. Build. Mater. 2020, 240, 117907. [Google Scholar] [CrossRef]

- Barbuta, M.; Rujanu, M.; Nicuta, A. Characterization of polymer concrete with different wastes additions. Procedia Technol. 2016, 22, 407–412. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A.; Mahmood, A.H.; Han, T. Carbon sequestration in cementitious composites using biochar and fly ash—Effect on mechanical and durability properties. Constr. Build. Mater. 2021, 291, 123363. [Google Scholar] [CrossRef]

- Saribiyik, M.; Piskin, A.; Saribiyik, A. The effects of waste glass powder usage on polymer concrete properties. Constr. Build. Mater. 2013, 47, 840–844. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Meira-Castro, A.C.; Silva, F.G.; Santos, J.; Meixedo, J.P.; Fiúza, A.; Dinis, M.L.; Alvim, M.R. Re-use assessment of thermoset composite wastes as aggregate and filler replacement for concrete-polymer composite materials: A case study regarding GFRP pultrusion wastes. Resour. Conserv. Recycl. 2015, 104, 417–426. [Google Scholar] [CrossRef]

- Hong, S.; Kim, H.; Park, S.K. Optimal mix and freeze-thaw durability of polysulfide polymer concrete. Constr. Build. Mater. 2016, 127, 539–545. [Google Scholar] [CrossRef]

- Khalid, N.H.A.; Hussin, M.W.; Mirza, J.; Ariffin, N.F.; Ismail, M.A.; Lee, H.S.; Mohamed, A.; Jaya, R.P. Palm oil fuel ash as potential green micro-filler in polymer concrete. Constr. Build. Mater. 2016, 102, 950–960. [Google Scholar] [CrossRef]

- Bulut, H.A.; Sahin, R. A study on mechanical properties of polymer concrete containing electronic plastic waste. Compos. Struct. 2017, 178, 50–62. [Google Scholar] [CrossRef]

- Lokuge, W.P.; Aravinthan, T. Mechanical properties of polymer concrete with different types of resin. In Proceedings of the 22nd Australasian Conference on the Mechanics of Structures and Materials (ACMSM 22): From Materials to Structures: Advancement through Innovation, Sydney, Australia, 11–14 December 2012; CRC Press: Boca Raton, FL, USA, 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Guo, S.; Si, R. Mechanical and durability performance evaluation of crumb rubber-modified epoxy polymer concrete overlays. Constr. Build. Mater. 2019, 203, 469–480. [Google Scholar] [CrossRef]

- Sosoi, G.; Barbuta, M.; Serbanoiu, A.A.; Babor, D.; Burlacu, A. Wastes as aggregate substitution in polymer concrete. Procedia Manuf. 2018, 22, 347–351. [Google Scholar] [CrossRef]

- Kępniak, M.; Woyciechowski, P.; Franus, W. Chemical and physical properties of limestone powder as a potential microfiller of polymer composites. Arch. Civ. Eng. 2017, 63, 67–78. [Google Scholar] [CrossRef]

- Łukowski, P.; Sokołowska, J.J.; Kępniak, M. Wstępna ocena możliwości zastosowania odpadowego pyłu perlitowego w budowlanych kompozytach polimerowych. Bud. Archit. 2014, 13, 119–126. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Malcevschi, A.; Belletti, B.; Milanese, D. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- European Biochar Certificate (EBC). Guidelines for a Sustainable Production of Biochar. Eur. Biochar Found. 2012, 1–22. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A. Promising low cost carbon-based materials to improve strength and toughness in cement composites. Constr. Build. Mater. 2016, 126, 1034–1043. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A.; Restuccia, L.; Ferro, G.A.; Suarez-Riera, D. Biochar-based cement pastes and mortars with enhanced mechanical properties. Frat. Integrita Strutt. 2020, 54, 294–313. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmad, S.; Savi, P.; Tulliani, J.M.; Giorcelli, M.; Ferro, G.A. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar] [CrossRef]

- Gupta, S.; Muthukrishnan, S.; Kua, H.W. Comparing influence of inert biochar and silica rich biochar on cement mortar—Hydration kinetics and durability under chloride and sulfate environment. Constr. Build. Mater. 2021, 268, 121142. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A.; Dalcanale, E.; Domenichelli, I.; Fornoni, P.; Moretti, E. Mechanical characterization of cement-based materials containing biochar from gasification. Constr. Build. Mater. 2020, 246, 118490. [Google Scholar] [CrossRef]

- Ahmad, S.; Khushnood, R.A.; Jagdale, P.; Tulliani, J.M.; Ferro, G.A. High performance self-consolidating cementitious composites by using micro carbonized bamboo particles. Mater. Des. 2015, 76, 223–229. [Google Scholar] [CrossRef]

- Choudhury, I.; Hashmi, M.S.J. (Eds.) Singaravelu Vivekanandhan, Biochar as Sustainable Reinforcement for Polymer Composites. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 10–22. ISBN 9780128131961. [Google Scholar] [CrossRef]

- Poulose, A.M.; Elnour, A.Y.; Anis, A.; Shaikh, H.; Al-Zahrani, S.M.; George, J.; Al-Wabel, M.I.; Usman, A.R.; Ok, Y.S.; Tsang, D.C.; et al. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total Environ. 2018, 619–620, 311–318. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K. The love–hate relationship of pyrolysis biochar and water: A perspective. Sci. Total Environ. 2015, 512–513, 682–685. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.; Margem, F.M. Thermogravimetric Stability of Polymer Composites Reinforced with Less Common Lignocellulosic Fibers—An Overview. J. Mater. Res. Technol. 2012, 1, 117–126. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Structure–mechanics property relationship of waste derived biochars. Sci. Total Environ. 2015, 538, 611–620. [Google Scholar] [CrossRef]

- Alig, I.; Pötschke, P.; Lellinger, D.; Skipa, T.; Pegel, S.; Kasaliwal, G.R.; Villmow, T. Establishment, morphology and properties of carbon nanotube networks in polymer melts. Polymer 2012, 53, 4–28. [Google Scholar] [CrossRef]

- Mohammed, Z.; Jeelani, S.; Rangari, V. Effective reinforcement of engineered sustainable biochar carbon for 3D printed polypropylene biocomposites. Compos. Part C Open Access 2022, 7, 100221. [Google Scholar] [CrossRef]

- Alhelal, A.; Mohammed, Z.; Jeelani, S.; Rangari, V.K. 3D printing of spent coffee ground derived biochar reinforced epoxy composites. J. Compos. Mater. 2021, 55, 3651–3660. [Google Scholar] [CrossRef]

- Reda Taha, M.M. International Congress on Polymers in Concrete (ICPIC 2018): Polymers for Resilient and Sustainable Concrete Infrastructure; Springer: Cham, Switzerland, 2018; pp. 491–500. ISBN 978-3-319-78174-7. [Google Scholar] [CrossRef]

- Czarnecki, L.; Garbacz, A.; Lukowski, P.; Clifton, J. Optimization of Polymer Concrete Composites: Final Report, NIST Interagency/Internal Report (NISTIR); National Institute of Standards and Technology: Gaithersburg, MD, USA, 1999.

| Microfiller | Specific Surface Area, cm2/cm3 | Average Diameter, µm | Mode Diameter, µm | Mean Diameter, µm | Grains under 120 µm, % |

|---|---|---|---|---|---|

| Quartz powder | 7847 | 10.19 | 10.83 | 10.19 | 100 |

| Perlite powder | 4392 | 18.83 | 18.49 | 18.83 | 100 |

| Water sediments | 6046 | 46.25 | 10.81 | 43.25 | 86 |

| Fly ash | 9718 | 35.16 | 41.92 | 35.16 | 98 |

| Biochar | 1921 | 71.93 | 72.29 | 67.22 | 85 |

| Composition Symbol | Volume Proportions, % | Mass Proportion, kg/m3 | |||||

|---|---|---|---|---|---|---|---|

| Resin (S) | Quartz Powder (MK) | Biochar (BW) | Resin | Quartz Powder | Biochar | Sand | |

| 1 (S85MK5BW10) | 85 | 5 | 10 | 451 | 60 | 79 | 1458 |

| 2 (S85MK15BW0) | 85 | 15 | 0 | 451 | 180 | 0 | 1458 |

| 3 (S65MK25BW10) | 65 | 25 | 10 | 345 | 299 | 79 | 1458 |

| 4 (S65MK35BW0) | 65 | 35 | 0 | 345 | 419 | 0 | 1458 |

| 5 (S65MK30BW5) | 65 | 30 | 5 | 345 | 359 | 39 | 1458 |

| 6 (S75MK20BW5) | 75 | 20 | 5 | 398 | 239 | 39 | 1458 |

| 7 (S75MK15BW10) | 75 | 15 | 10 | 398 | 180 | 79 | 1458 |

| 8 (S75MK25BW0) | 75 | 25 | 0 | 398 | 299 | 0 | 1458 |

| 9 (S75MK10BW5) | 75 | 10 | 5 | 451 | 120 | 39 | 1458 |

| Hardening Process | Resin | Composition 8 (S = 75%; BW/M = 0%) | Composition 6 (S = 75%; BW/M = 20%) | Composition 7 (S = 75%; BW/M = 40%) |

|---|---|---|---|---|

| Workability time, min | 70 | 120 | 210 | 210 |

| Gelation time, min | 95 | 160 | 260 | 250 |

| Hardening time, min | 120 | 195 | 310 | 290 |

| Curing time, min | 240 | 330 | 400 | 400 |

| Maximum temperature, °C | 72.3 | 73.7 | 72.5 | 75.5 |

| Composition Number | Volume Proportions, % | Test Results | ||||

|---|---|---|---|---|---|---|

| Resin (S) | Quartz Powder (MK) | Biochar (BW) | Flow, cm | Flexural Strength, MPa | Compressive Strength, MPa | |

| 1 (S85MK5BW10) | 85 | 5 | 10 | 19.5 | 30.0 ± 1.8 | 85.9 ± 0.3 |

| 2 (S85MK15BW0) | 85 | 15 | 0 | 27.8 | 32.2 ± 1.7 | 98.4 ± 1.0 |

| 3 (S65MK25BW10) | 65 | 25 | 10 | 14.3 | 28.8 ± 1.9 | 93.0 ± 1.0 |

| 4 (S65MK35BW0) | 65 | 35 | 0 | 20.0 | 31.9 ± 1.6 | 100.3 ± 1.1 |

| 5 (S65MK30BW5) | 65 | 30 | 5 | 15.0 | 32.5 ± 1.3 | 100.0 ± 0.9 |

| 6 (S75MK20BW5) | 75 | 20 | 5 | 19.7 | 32.7 ± 2.1 | 94.4 ± 1.6 |

| 7 (S75MK15BW10) | 75 | 15 | 10 | 15.7 | 32.3 ± 0.4 | 91.7 ± 1.1 |

| 8 (S75MK25BW0) | 75 | 25 | 0 | 26.0 | 32.3 ± 1.0 | 100.2 ± 0.5 |

| 9 (S75MK10BW5) | 75 | 10 | 5 | 23.5 | 29.5 ± 1.3 | 94.0 ± 1.8 |

| Composition Number | Volume Proportions, % | Statistical Verification | ||||

|---|---|---|---|---|---|---|

| Resin (S) | Quartz Powder (MK) | Biochar (BW) | Mean Compressive Strength, MPa | Predicted Compressive Strength, MPa | Prediction Error, % | |

| 1 (S85MK5BW10) | 85 | 5 | 10 | 85.9 | 88.2 | 2.7 |

| 2 (S85MK15BW0) | 85 | 15 | 0 | 98.4 | 97.7 | −0.7 |

| 3 (S65MK25BW10) | 65 | 25 | 10 | 93.0 | 92.4 | −0.6 |

| 4 (S65MK35BW0) | 65 | 35 | 0 | 100.3 | 101.9 | 1.6 |

| 5 (S65MK30BW5) | 65 | 30 | 5 | 100.0 | 97.2 | −2.8 |

| 6 (S65MK20BW15) | 75 | 20 | 5 | 94.4 | 85.6 | −9.3 |

| 7 (S75MK15BW10) | 75 | 15 | 10 | 91.7 | 90.3 | −1.5 |

| 8 (S75MK25BW0) | 75 | 25 | 0 | 100.2 | 99.8 | −0.4 |

| 9 (S75MK10BW5) | 75 | 10 | 5 | 94.0 | 83.5 | −11.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kępniak, M.; Załęgowski, K.; Woyciechowski, P.; Pawłowski, J.; Nurczyński, J. Feasibility of Using Biochar as an Eco-Friendly Microfiller in Polymer Concretes. Polymers 2022, 14, 4701. https://doi.org/10.3390/polym14214701

Kępniak M, Załęgowski K, Woyciechowski P, Pawłowski J, Nurczyński J. Feasibility of Using Biochar as an Eco-Friendly Microfiller in Polymer Concretes. Polymers. 2022; 14(21):4701. https://doi.org/10.3390/polym14214701

Chicago/Turabian StyleKępniak, Maja, Kamil Załęgowski, Piotr Woyciechowski, Jędrzej Pawłowski, and Jakub Nurczyński. 2022. "Feasibility of Using Biochar as an Eco-Friendly Microfiller in Polymer Concretes" Polymers 14, no. 21: 4701. https://doi.org/10.3390/polym14214701

APA StyleKępniak, M., Załęgowski, K., Woyciechowski, P., Pawłowski, J., & Nurczyński, J. (2022). Feasibility of Using Biochar as an Eco-Friendly Microfiller in Polymer Concretes. Polymers, 14(21), 4701. https://doi.org/10.3390/polym14214701