Study on Boundary Layer and Surface Hardness of Carbon Black in Natural Rubber Using Atomic Force Microscopy

Abstract

1. Introduction

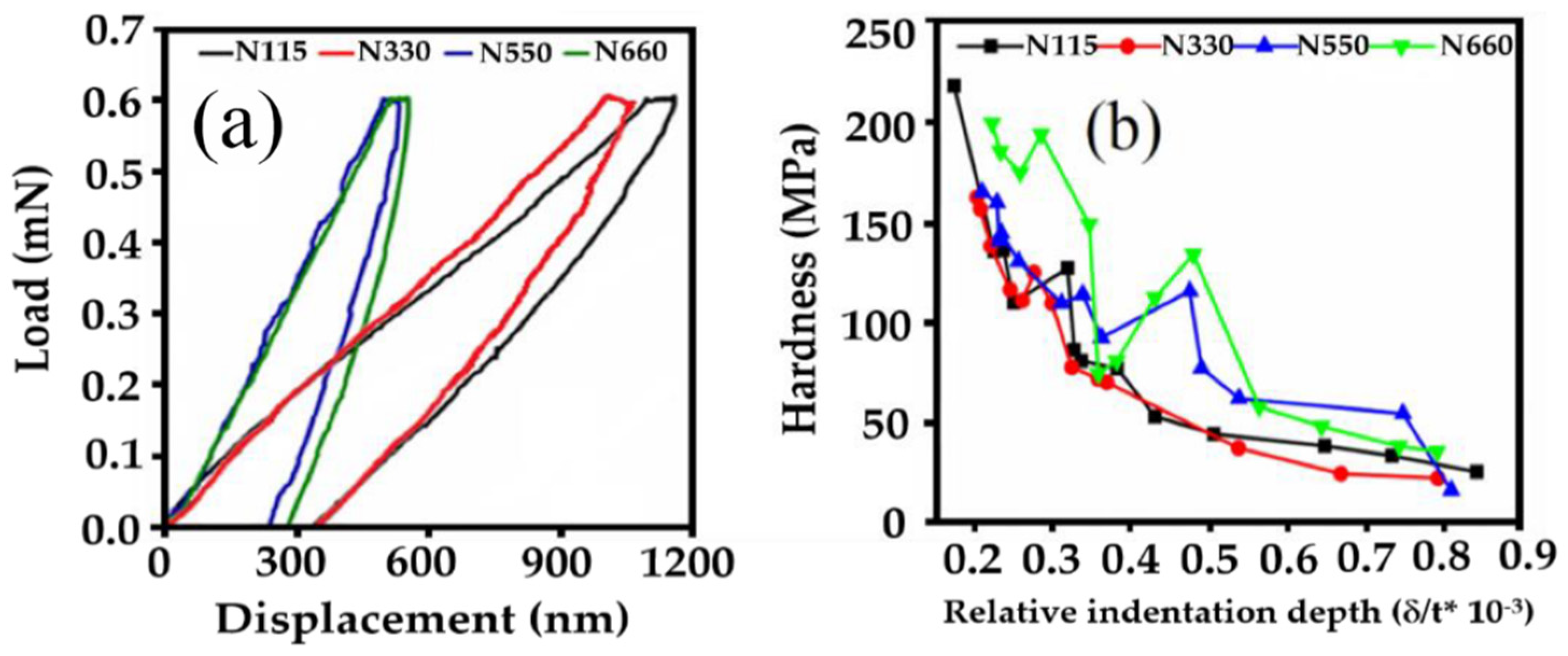

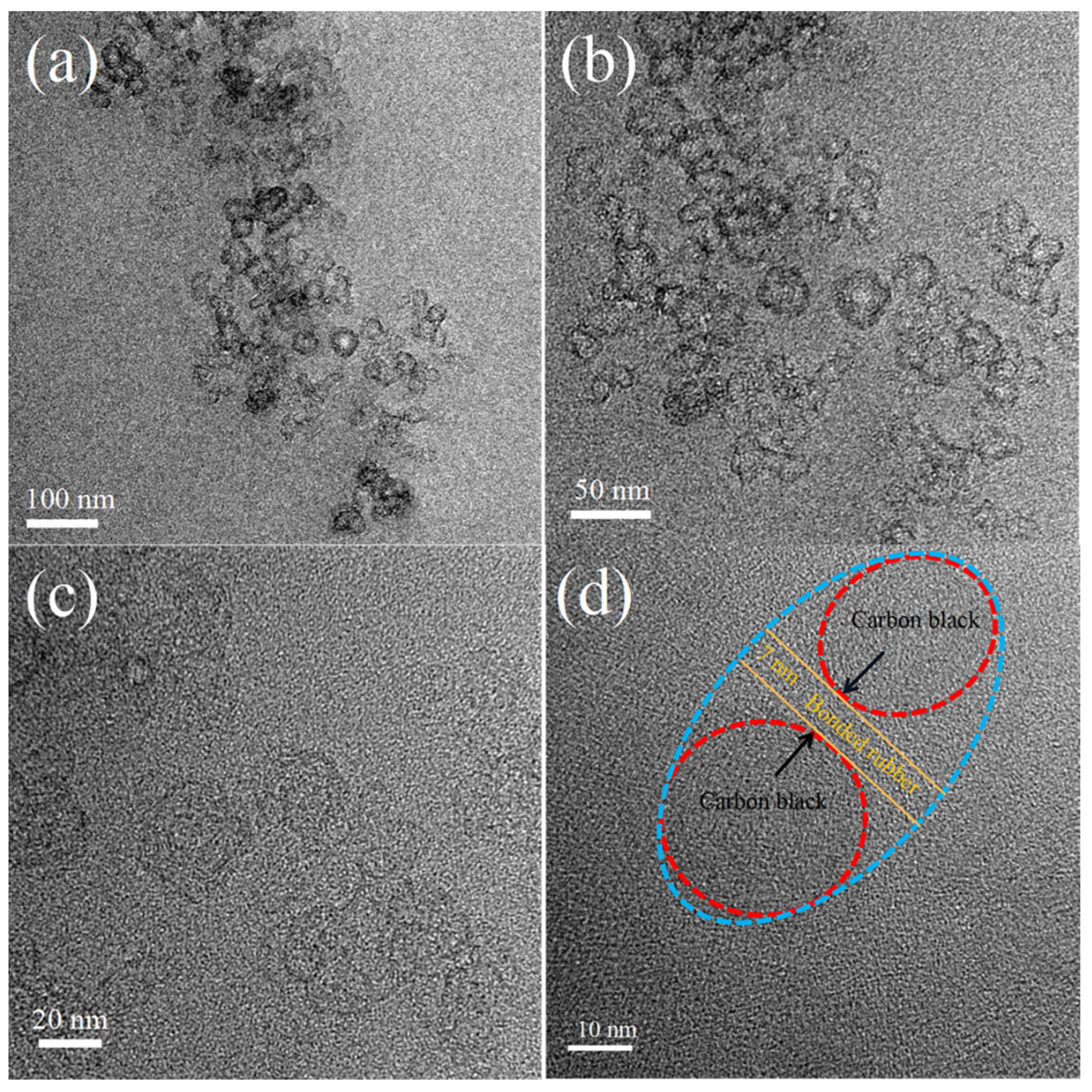

2. Experimental

2.1. Materials

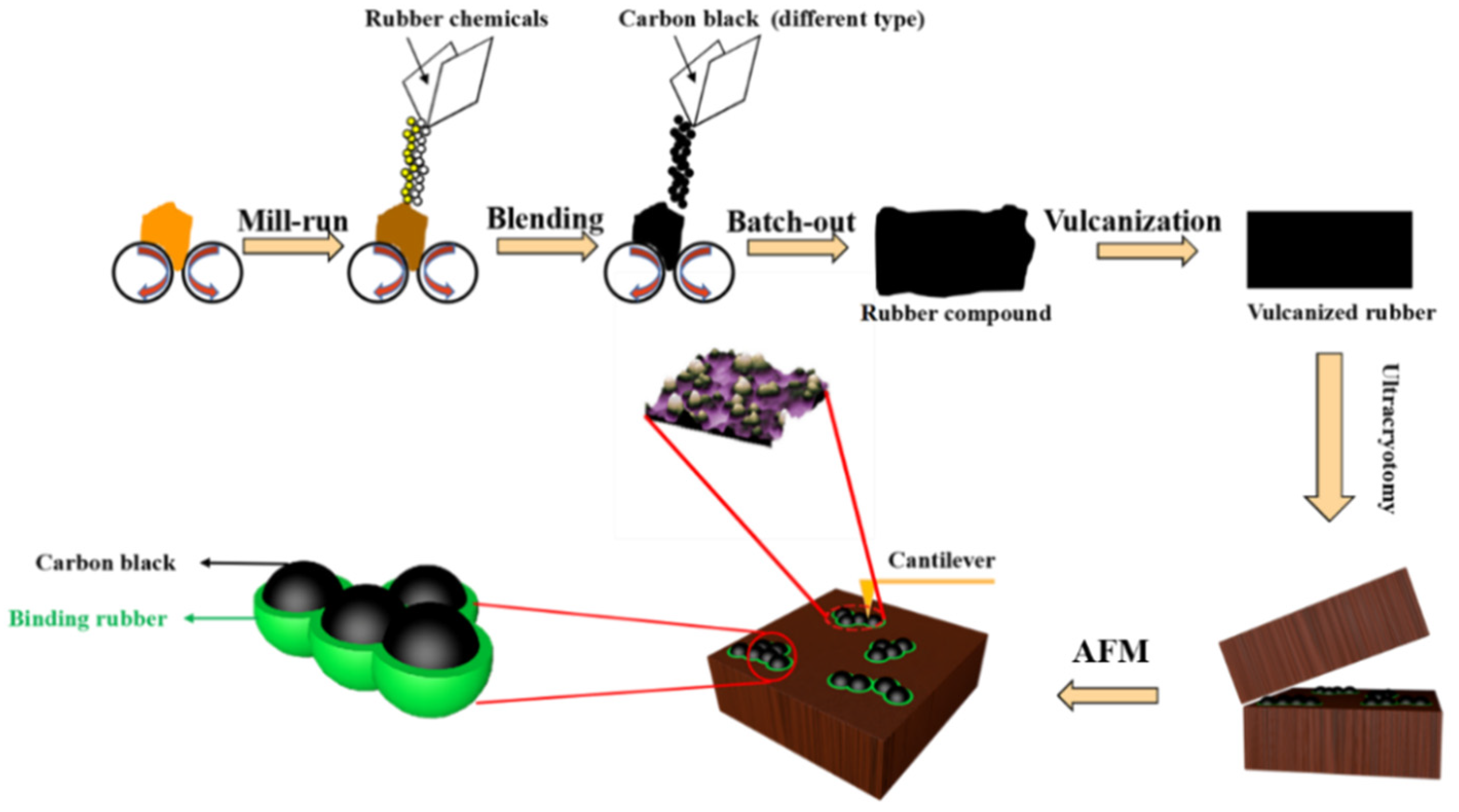

2.2. Preparation of the CB/NR Composites

2.3. Sampling and TEM/AFM Characterization

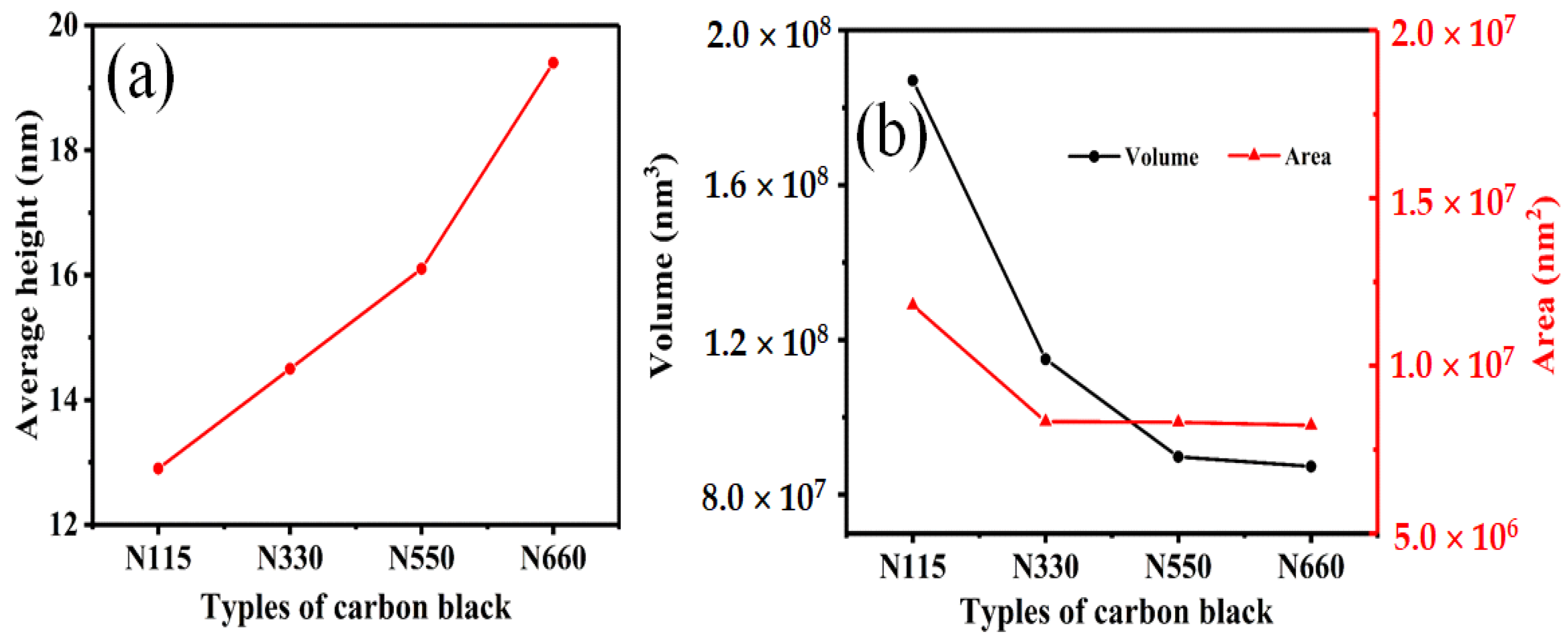

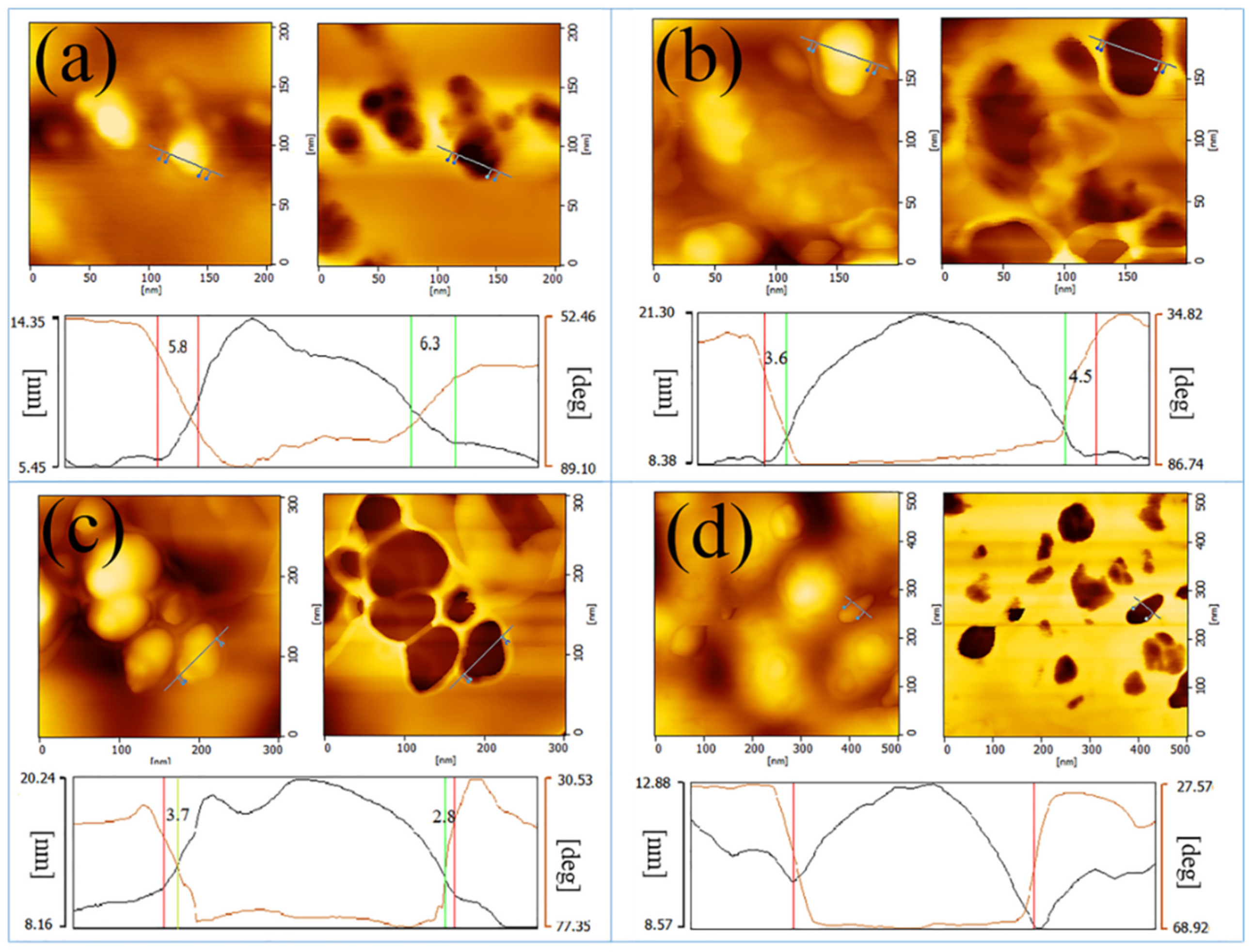

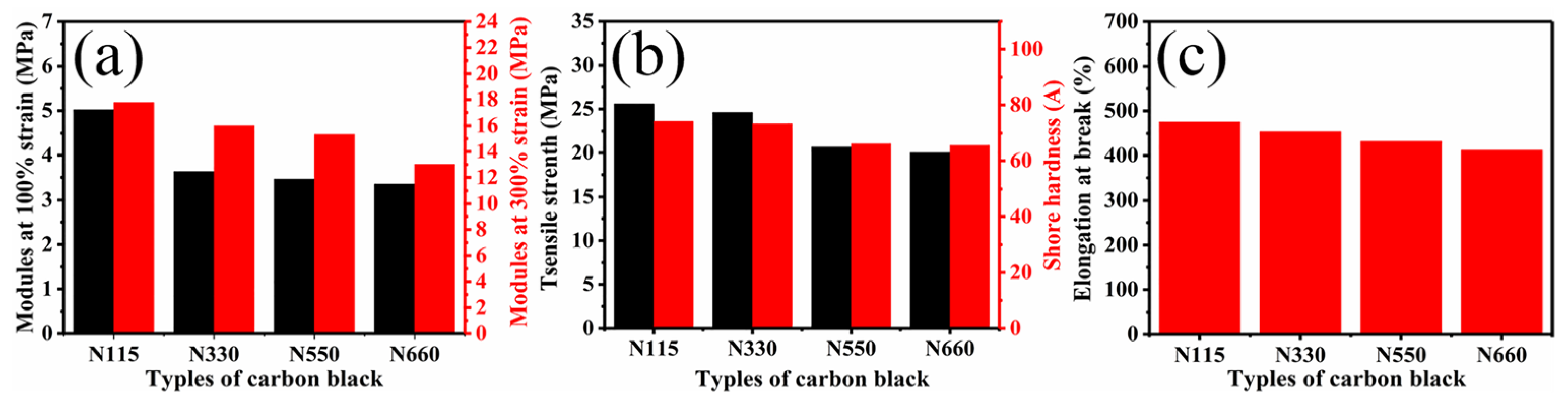

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crosby, F.A.J.; Lee, J.Y. Polymer nanocomposites: The “nano” effect on mechanical properties. Polym. Rev. 2007, 47, 217–229. [Google Scholar] [CrossRef]

- Yoon, B.Y.; Kim, J.Y.; Hong, U.; Oh, M.K.; Kim, M.; Han, S.B.; Nam, J.D.; Suhr, J. Dynamic viscoelasticity of silica-filled styrene-butadiene rubber/polybutadiene rubber (SBR/BR) elastomer composites. Compos. Part B 2020, 187, 107865. [Google Scholar] [CrossRef]

- Cheng, S.S.; Duan, X.Y.; Zhang, Z.Y.; Dong, A.; Zhao, G.Z.; Liu, Y.Q. Preparation of a natural rubber with high thermal conductivity, low heat generation and strong interfacial interaction by using NS-modified graphene oxide. J. Mater. Sci. 2021, 56, 4034–4050. [Google Scholar] [CrossRef]

- Yu, W.W.; Xu, W.Z.; Xia, J.H.; Wei, Y.C.; Luo, M.C. Toughening natural rubber by the innate sacrificial network. Polymer 2020, 194, 122419. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, L.; Lin, Y.; Mi, X. Carbon black filled powdered natural rubber: Preparation, particle size distribution, mechanical properties, and structures. J. Appl. Polym. Sci. 2006, 101, 1763–1774. [Google Scholar] [CrossRef]

- Bokobza, L.; Rahmani, M.; Belin, C.; Bruneel, J.L.; El Bounia, N.E. Blends of carbon blacks and multiwall carbon nanotubes as reinforcing fillers for hydrocarbon rubbers. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 1939–1951. [Google Scholar] [CrossRef]

- Stickney, P.B.; Falb, R.D. Carbon black-rubber interactions and bound rubber. Rubber Chem. Technol. 1964, 37, 1299–1340. [Google Scholar] [CrossRef]

- Donnet, J.B.; Voet, A. Carbon Black Physics, Chemistry and Elastomer Reinforcement; Marcel Dekker: New York, NY, USA, 1976. [Google Scholar]

- Asai, K. Carbon Black Development Situation. Nippon Gomu Kyokaishi 2005, 78, 200–204. [Google Scholar] [CrossRef]

- Jin, Y.Z.; Chen, J.; Fu, Q.S.; Cui, W.J.; Zhang, H.Z. Study on Surface Activity of High-Structure DZ (13) Nano-Carbon Black. Nanosci. Nanotechnol. Lett. 2014, 6, 124–127. [Google Scholar] [CrossRef]

- Saowapark, T.; Chaichana, E.; Jaturapiree, A. Study on Mechanical Properties of Natural Rubber Filled with Molasses Black/Carbon Black Hybrid Filler System. Key Eng. Mater. 2016, 718, 30–35. [Google Scholar]

- Huber, G.; Vilgis, T.A.; Heinrich, G. Universal properties in the dynamical deformation of filled rubbers. J. Phys. Condensed Matter. 1996, 8, L409–L412. [Google Scholar] [CrossRef]

- Liang, X.; Ito, M.; Nakajima, K. Reinforcement Mechanism of Carbon Black-Filled Rubber Nanocomposite as Revealed by Atomic Force Microscopy Nanomechanics. Polymers 2021, 13, 3922. [Google Scholar] [CrossRef]

- Robertson, C.G.; Hardmen, N.J. Nature of Carbon Black Reinforcement of Rubber: Perspective on the Original Polymer Nanocomposite. Polymers 2021, 13, 538. [Google Scholar] [CrossRef]

- Kohjiya, S.; Katoh, A.; Suda, T.; Shimanuki, J.; Ikeda, Y. Visualisation of carbon black networks in rubbery matrix by skeletonization of 3D-TEM image. Polymer 2006, 47, 3298–3301. [Google Scholar] [CrossRef]

- Wang, D.; Liang, X.; Russell, T.P.; Nakajima, K. Visualization and quantification of the chemical and physical properties at a diffusion-induced interface using AFM nanomechanical mapping. Macromolecules 2014, 47, 3761–3765. [Google Scholar] [CrossRef]

- Dokukin, M.E.; Sokolov, I. Quantitative mapping of the elastic modulus of soft materials with Harmoni X and Peak Force QNM AFM modes. Langmuir 2012, 28, 16060–16071. [Google Scholar] [CrossRef]

- Adamcik, J.; Lara, C.; Usov, I.; Jeong, J.S.; Ruggeri, F.S.; Dietler, G.; Lashuel, H.A.; Hamley, I.W.; Mezzenga, R. Measurement of intrinsic properties of amyloid fibrils by the peak force QNM method. Nanoscale 2012, 4, 4426–4429. [Google Scholar] [CrossRef]

- Nakajima, K.; Ito, M.; Nguyen, H.; Liang, X. Nanomechanics of the rubber-filler interface. Rubber Chem. Technol. 2017, 90, 272–284. [Google Scholar] [CrossRef]

- Le Diagon, Y.; Mallarino, S.; Fretigny, C. Particle structuring under the effect of an uniaxial deformation in soft/hard nanocomposites. Eur. Phys. J. E 2007, 22, 77–83. [Google Scholar] [CrossRef]

- Wang, D.; Fujinami, S.; Nakajima, K.; Niihara, K.I.; Inukai, S.; Ueki, H.; Magario, A.; Noguchi, T.; Endo, M.; Nishi, T. Production of a cellular structure in carbon nanotube/natural rubber composites revealed by nanomechanical mapping. Carbon 2010, 48, 3708–3714. [Google Scholar] [CrossRef]

- Vera-Agullo, J.; Gloria-Pereira, A.; Varela-Rizo, H.; Gonzalez, J.L.; Martin-Gullon, I. Comparative study of the dispersion and functional properties of multiwall carbon nanotubes and helical-ribbon carbon nanofibers in polyester nanocomposites. Compos. Sci. Technol. 2009, 69, 1521–1532. [Google Scholar] [CrossRef]

- Xu, W.; Zerda, T.W.; Raab, H.; Goritz, D. 3-D morphological characterization of carbon black aggregates using atomic force microscopy. Carbon 1997, 35, 471–474. [Google Scholar] [CrossRef]

- Johnson, L.L. Atomic force microscopy (AFM) for rubber. Rubber Chem. Technol. 2008, 81, 359. [Google Scholar] [CrossRef]

- Yoshimura, K.; Nakano, K.; Miyake, T.; Hishikawa, Y.; Motojima, S. Effectiveness of carbon microcoils as a reinforcing material for a polymer matrix. Carbon 2006, 44, 2833–2838. [Google Scholar] [CrossRef]

- Omnès, B.; Thuillier, S.; Pilvin, P.; Grohens, Y.; Gillet, S. Effective properties of carbon black filled natural rubber: Experiments and modeling. Compos. Part A-Appl. Sci. Manuf. 2008, 39, 1141–1149. [Google Scholar] [CrossRef]

- Ürk, D.; Demir, E.; Bulut, O.; Çakıroğlu, D.; Cebeci, F.; Lütfi, Ö.M.; Hülya, C. Understanding the polymer type and CNT orientation effect on the dynamic mechanical properties of high volume fraction CNT polymer nanocomposites. Compos. Struct. 2016, 155, 255–262. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Hwang, G.L.; Shieh, Y.T.; Hwang, K.C. Efficient load transfer to polymer-grafted multiwalled carbon nanotubes in polymer composites. Adv. Funct. Mater. 2004, 14, 487–491. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. S. 2011, 42, 2126–2142. [Google Scholar] [CrossRef]

- Xu, W.; Wu, Y.; Gou, X. Effective elastic moduli of nonspherical particle-reinforced composites with inhomogeneous interphase considering graded evolutions of elastic modulus and porosity. Comput. Methods Appl. Mech. Engrg. 2019, 350, 535–553. [Google Scholar] [CrossRef]

- Hilal, R.; Anthony, C.; Alireza, F.B.; Nikos, S.; Vangelis, H. Mechanical properties of glassy polymer nanocomposites via atomistic and continuum models: The role of interphases. Comput. Methods Appl. Mech. Engrg. 2022, 395, 114905. [Google Scholar]

| Component | Composition (phr) |

|---|---|

| NR | 100 |

| Sulfur | 2.5 |

| Steric acid | 3 |

| c-ZnO | 5 |

| CB (N115, N330, N550, N660) | 50 |

| MBTS | 0.6 |

| Item | Particle Size (nm) | NSA (m2 g−1) | STSA (m2 g−1) | Oil Adsorption Number (OAN) (mg g−1) | Ash (%) | |

|---|---|---|---|---|---|---|

| CB | ||||||

| N115 | 16 ± 2 | 140 | 124 | 115 | 0.3 | |

| N330 | 32 ± 4 | 78 | 75 | 100 | 0.4 | |

| N550 | 47 ± 8 | 40 | 36 | 121 | 0.6 | |

| N660 | 63 ± 6 | 34 | 29 | 90 | 0.6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Hu, M.-Y.; Qing, L.; Liu, P.; Li, L.; Li, R.; Yue, C.-X.; Lin, J.-H. Study on Boundary Layer and Surface Hardness of Carbon Black in Natural Rubber Using Atomic Force Microscopy. Polymers 2022, 14, 4642. https://doi.org/10.3390/polym14214642

Chen J, Hu M-Y, Qing L, Liu P, Li L, Li R, Yue C-X, Lin J-H. Study on Boundary Layer and Surface Hardness of Carbon Black in Natural Rubber Using Atomic Force Microscopy. Polymers. 2022; 14(21):4642. https://doi.org/10.3390/polym14214642

Chicago/Turabian StyleChen, Jian, Mao-Yuan Hu, Long Qing, Ping Liu, Lin Li, Rui Li, Cheng-Xi Yue, and Jarrn-Horng Lin. 2022. "Study on Boundary Layer and Surface Hardness of Carbon Black in Natural Rubber Using Atomic Force Microscopy" Polymers 14, no. 21: 4642. https://doi.org/10.3390/polym14214642

APA StyleChen, J., Hu, M.-Y., Qing, L., Liu, P., Li, L., Li, R., Yue, C.-X., & Lin, J.-H. (2022). Study on Boundary Layer and Surface Hardness of Carbon Black in Natural Rubber Using Atomic Force Microscopy. Polymers, 14(21), 4642. https://doi.org/10.3390/polym14214642