Morphology and Properties of Polyolefin Elastomer/Polyamide 6/Poly(lactic Acid) In Situ Special-Shaped Microfibrillar Composites: Influence of Viscosity Ratio

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Specimen Preparation

2.3. Characterization

3. Results and Discussion

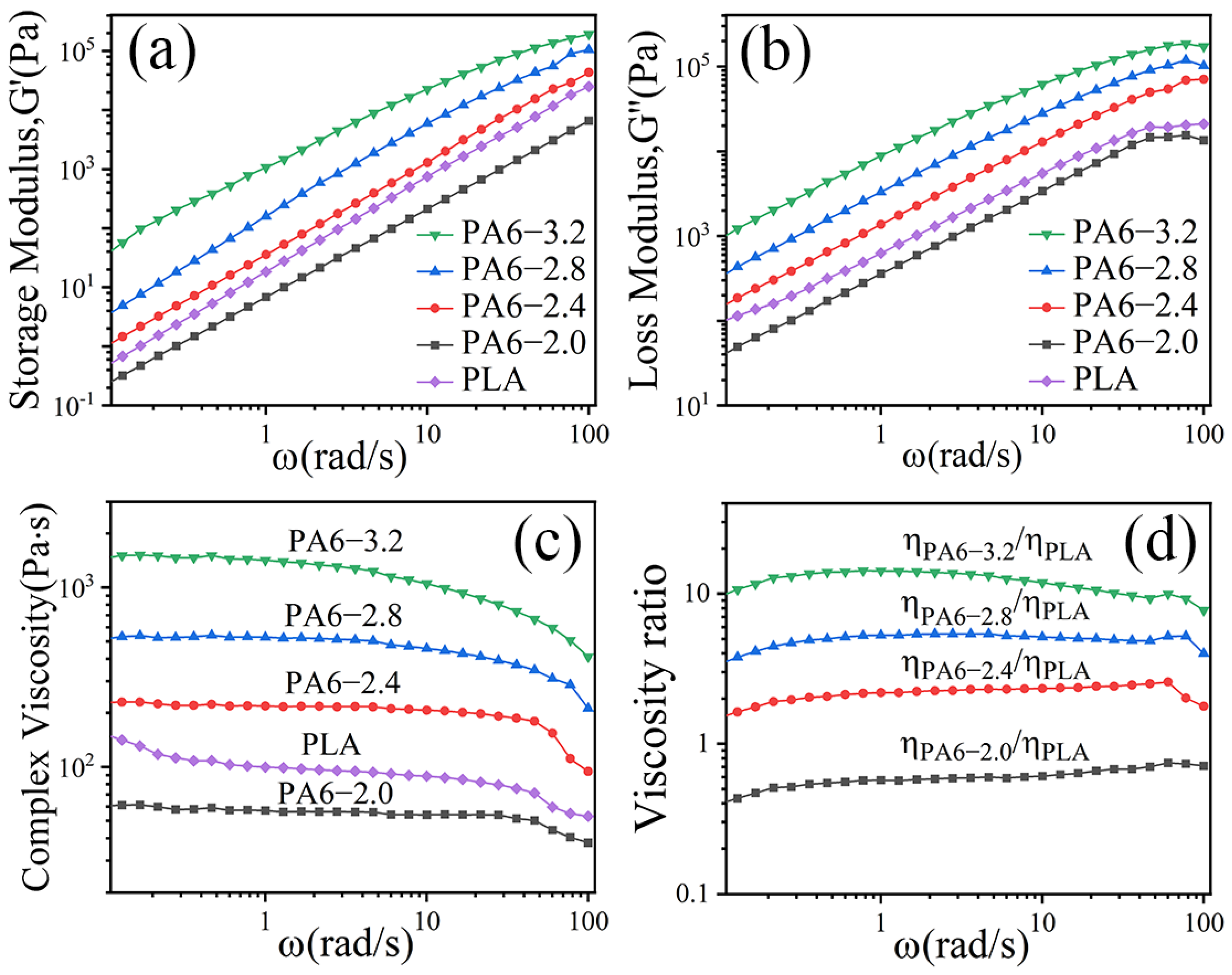

3.1. Viscoelastic Behavior of PA6 and PLA

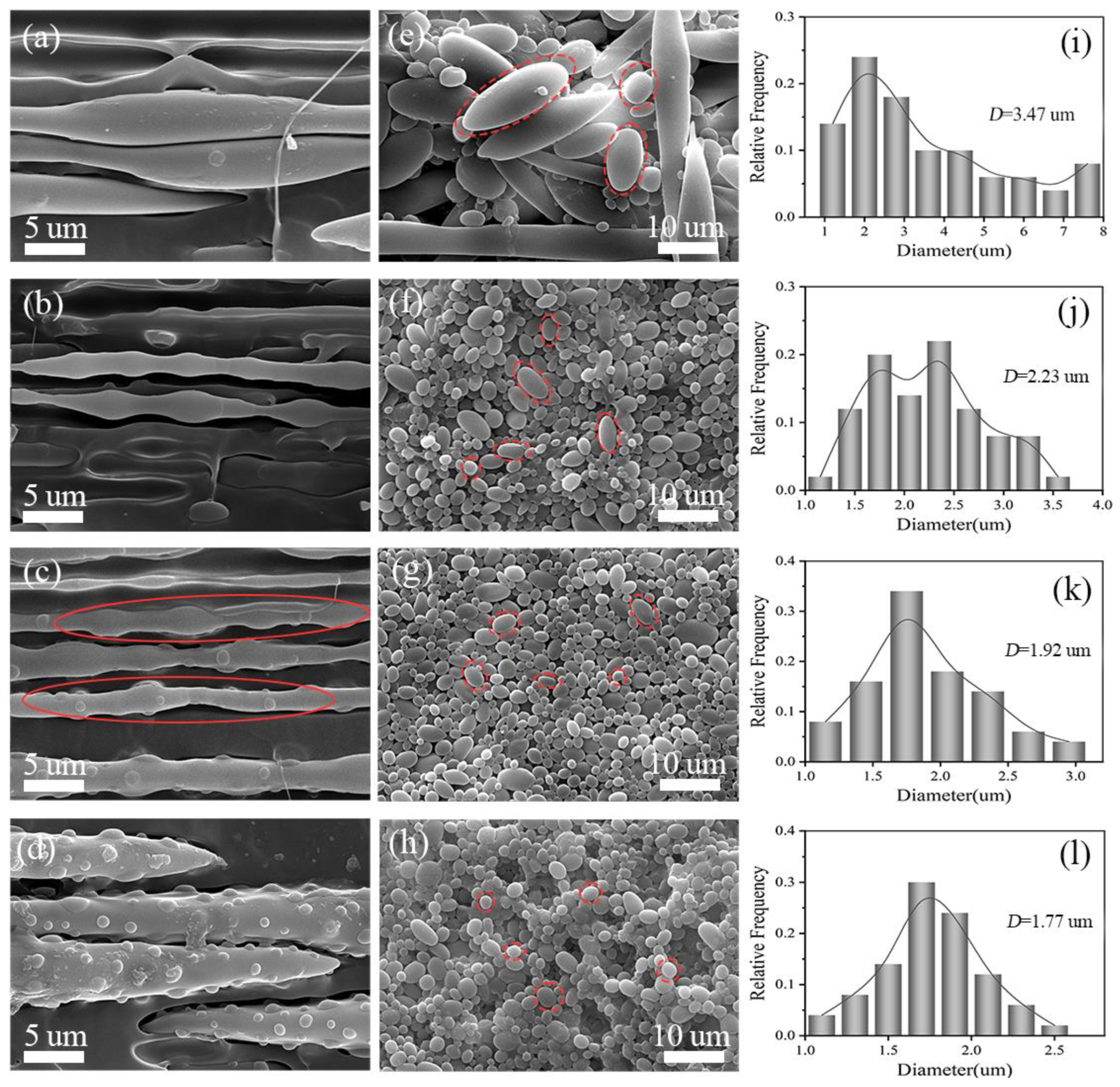

3.2. Morphology and Microstructure of MFCs

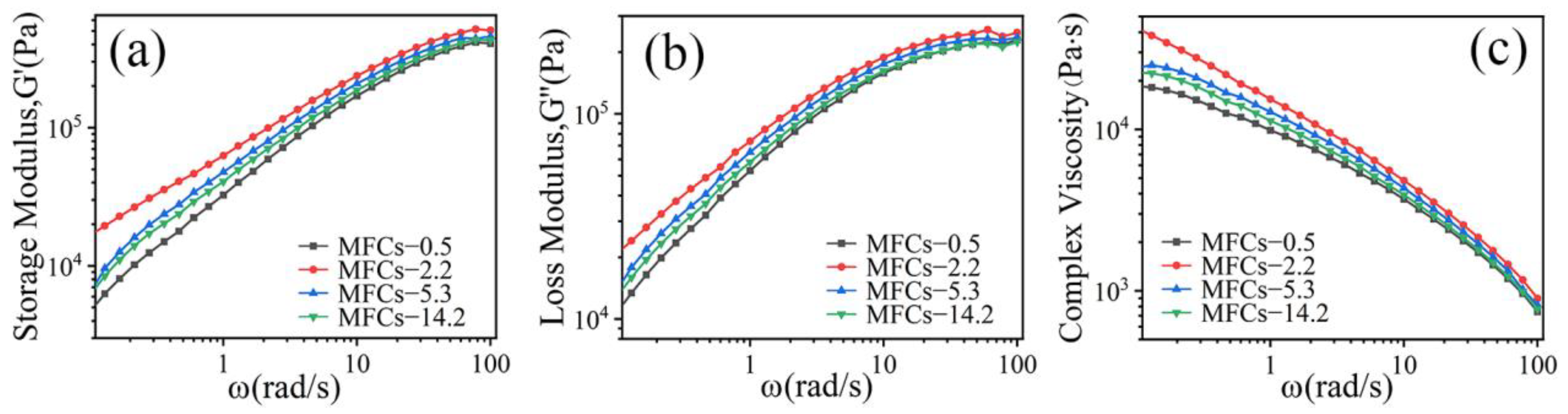

3.3. Rheological Characterization

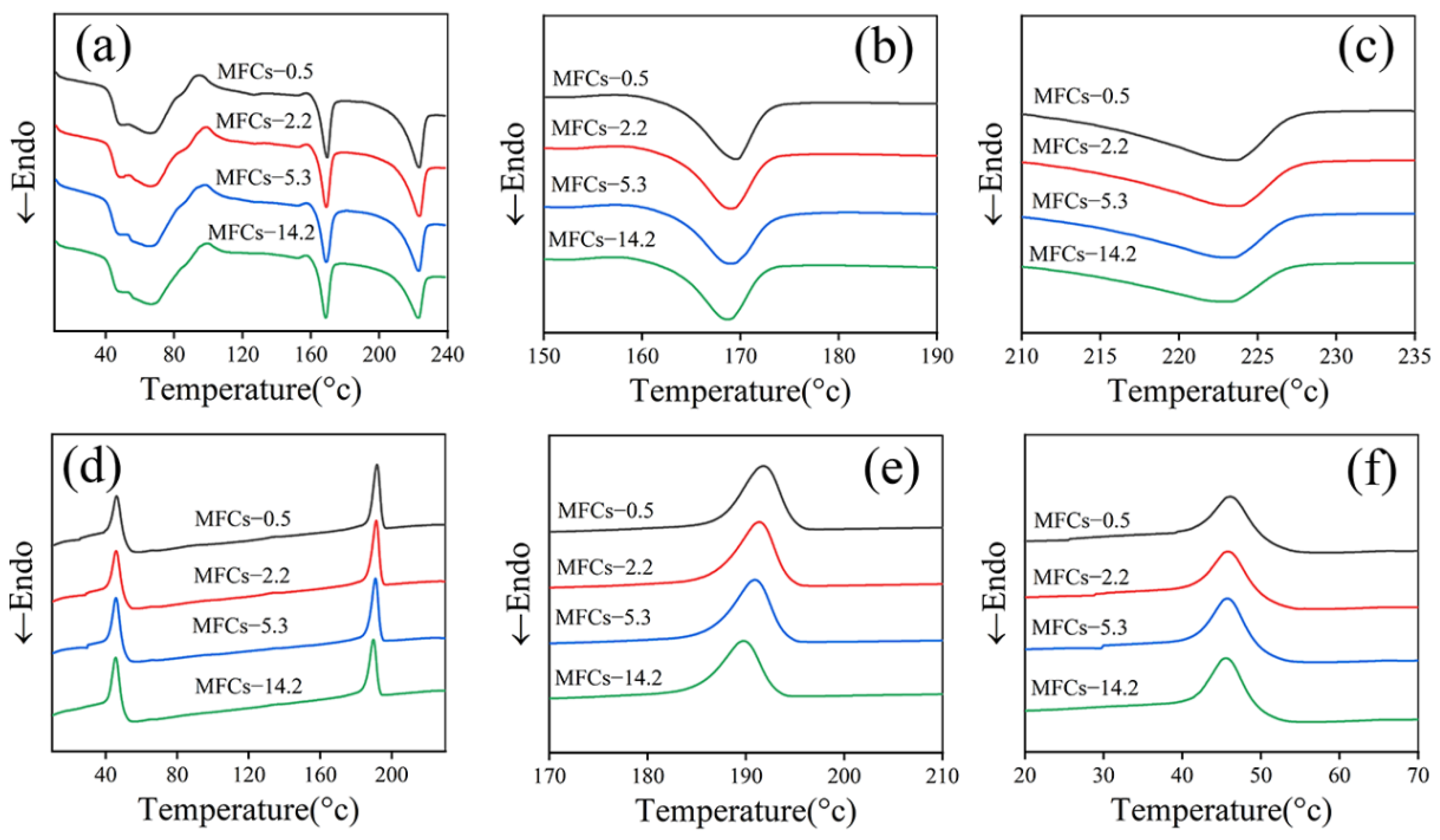

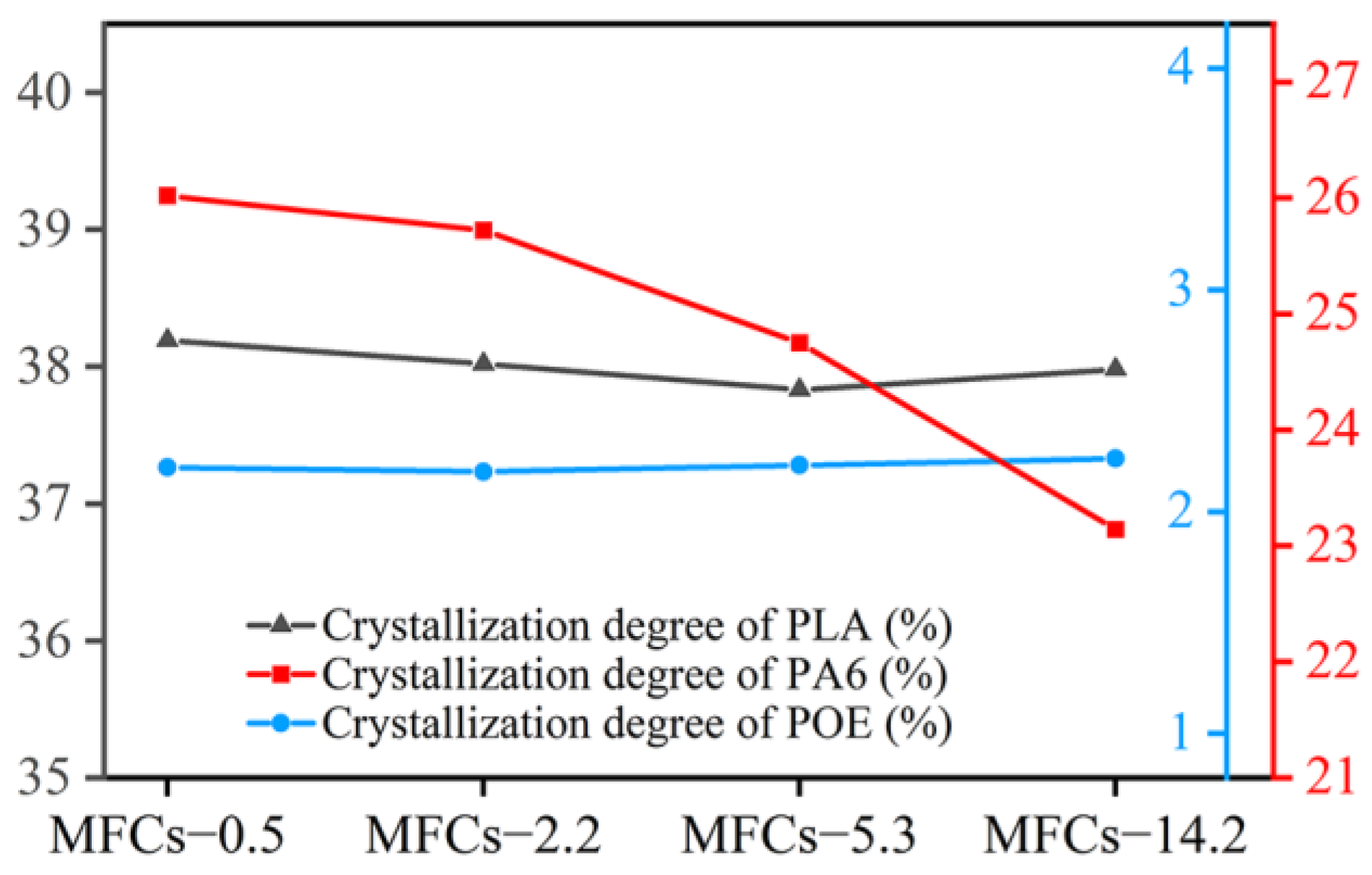

3.4. Thermal Characterization

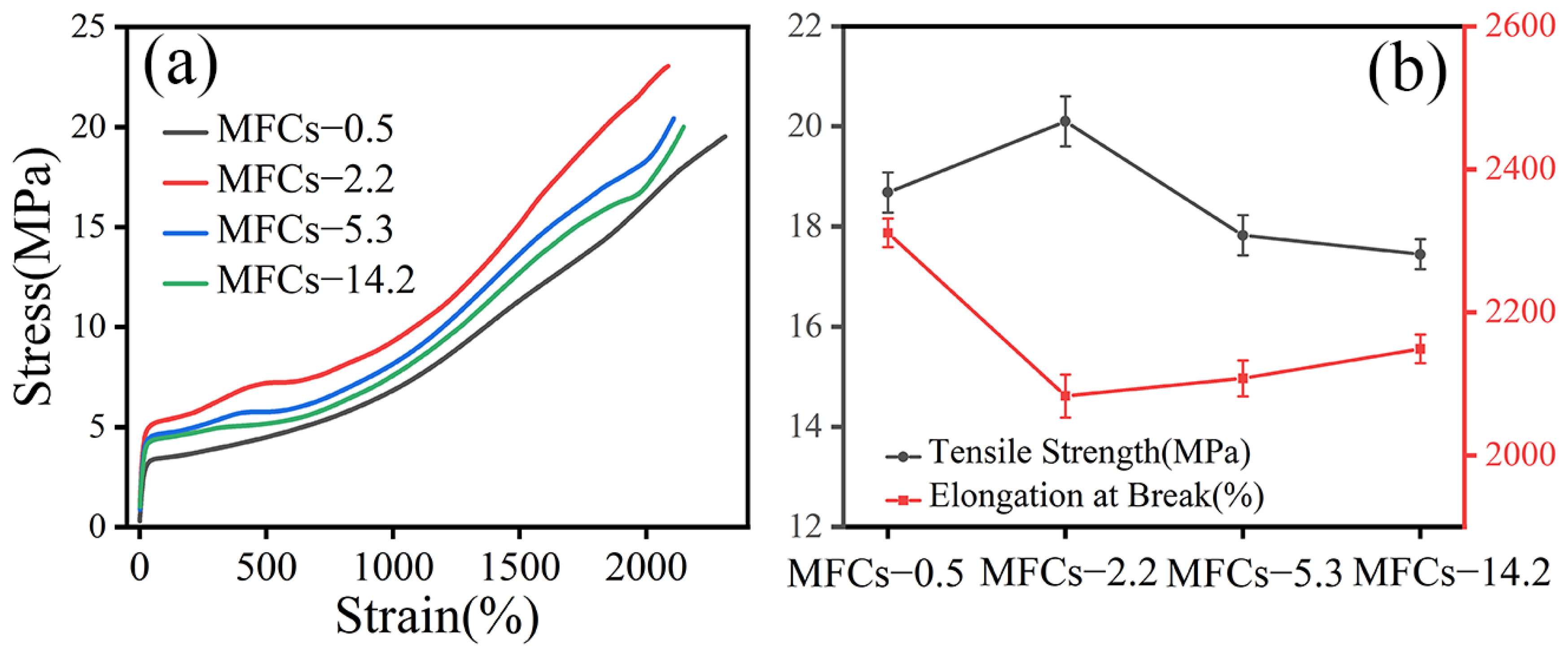

3.5. Mechanical Property

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2018, 53, 709–718. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.M. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 134, 46770. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of flame retardant magnesium hydroxide on the mechanical properties of high density polyethylene composites. J. Reinf. Plast. Compos. 2017, 36, 1802–1816. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.M.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials-An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Sun, X.J.; Yu, Q.; Shen, J.B.; Gao, S.L.; Li, J.; Guo, S.Y. In Situ microfibrillar morphology and properties of polypropyl-ene/polyamide/carbon black composites prepared through multistage stretching extrusion. J. Mater. Sci. 2013, 48, 1214–1224. [Google Scholar] [CrossRef]

- Li, Z.; Shi, Y.J.; Sun, C.X.; Zhang, Q.; Fu, Q. In Situ micro and nano fibrillar reinforced elastomer composites based on polypro-pylene(PP)/ olefinic block copolymer (OBC). Compos. Sci. Technol. 2015, 115, 34–42. [Google Scholar] [CrossRef]

- Maja, K.; Laurens, D.; Ludwig, C.; Kim, R. Relationship between the processing, structure, and Properties of Microfibrillar Composites. Adv. Mater. 2020, 32, 2003938. [Google Scholar]

- Mi, D.; Wang, Y.X.; Kuzmanovic, M.; Laurens, D.; Jiang, Y.X.; Cardon, L.; Zhang, J.; Ragaert, K. Effect of phase Morphology on Mechanical Prop-erties: Oriented/Unoriented PP Crystal Combination with Spherical/Microfibrillar PET Phase. Polymers 2019, 11, 248. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; Thomas, S.; Joseph, K. Morphology, static and dynamic mechanical properties of in situ microfibrillar composites based on polypropylene/poly (ethylene terephthalate) blends. Compos. Part A Appl. Sci. Manuf. 2008, 39, 164–175. [Google Scholar] [CrossRef]

- Rizvi, A.; Park, C.B.P.; Favis, B.D. Tuning viscoelastic and crystallization properties of polypropylene containing in-situ gen-erated high aspect ratio polyethylene terephthalate fibrils. Polymer 2015, 68, 83–91. [Google Scholar] [CrossRef]

- Wang, J.F.; Zhang, X.L.; Zhao, T.; Shen, L.Y.; Wu, H.; Guo, S.Y. Morphologies and properties of polycarbonate/polyethylene in situ microfibrillar composites prepared through multistage stretching extrusion. J. Appl. Polym. Sci. 2014, 131, 40108–40115. [Google Scholar]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.M.; Hsiao, B.S.; Zhong, G.-J. Unprecedented Access to Strong and Ductile Poly(lactic acid) by Introducing In Situ Nanofifibrillar Poly(butylene succinate) for Green Packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Ding, W.D.; Ameli, A.; Park, C. Poly(lactic acid)-Based in situ microfibrillar composites with en-hanced crystallization kinetics, mechanical properties, rheological behavior, and foaming ability. Biomacromolecules 2015, 16, 3925–3935. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Dong, J.; Qi, Y.; Sun, J.; Qin, S. In Situ polyolefin elastomer/poly(trimethylene terephthalate) microfibrillar composites fabricated via multistage stretching extrusion. Fibers Polym. 2016, 17, 1916–1924. [Google Scholar] [CrossRef]

- Dong, J.H.; Qi, Y.H.; Sun, J.; Wei, L.Q.; Qin, S.H. In Situ fibrillation of poly(trimethylene terephthalate) in polyolefin elastomer through multistage stretching extrusion. J. Appl. Polym. Sci. 2016, 133, 43797. [Google Scholar] [CrossRef]

- Li, Z.-M.; Li, L.-B.; Shen, K.-Z.; Yang, M.-B.; Huang, R. In-Situ microfibrillar PET/iPP blend via slit die extrusion, hot stretching, and quenching: Influence of hot stretch ratio on morphology, crystallization, and crystal structure of iPP at a fixed PET concentration. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 4095–4106. [Google Scholar] [CrossRef]

- Sun, J.; Luo, S.S.; Huang, A.R.; Shi, M.; Luo, H.; Wei, L.Q. Double yielding behavior of in situ microfibrillar polyolefin elasto-mer/poly(lactic acid) composites: Effect of microfibrillar morphology. Polym. Eng. Sci. 2020, 60, 1676–1685. [Google Scholar] [CrossRef]

- Shen, J.B.; Wang, M.; Li, J.; Guo, S.Y. In Situ fibrillation of polyamide 6 in isotactic polypropylene occurring in the laminat-ing-multiplying die. Polym. Adv. Technol. 2011, 22, 237–245. [Google Scholar] [CrossRef]

- Lin, B.; Sundararaj, U.; Mighri, F.; Huneault, M.A. Erosion and breakup of polymer drops under simple shear in high viscosity ratio systems. Polym. Eng. Sci. 2003, 43, 891–904. [Google Scholar] [CrossRef]

- Lin, B.; Mighri, F.; Huneault, A.M.A.; Sundararaj, U. Effect of Premade Compatibilizer and Reactive Polymers on Polystyrene Drop Deformation and Breakup in Simple Shear. Macromolecules 2005, 38, 5609–5616. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, R.; Shen, J.; Guo, S. Tunable Shape Memory Performances via Multilayer Assembly of Thermoplastic Polyurethane and Polycaprolactone. ACS Appl. Mater. Interfaces 2016, 8, 1371–1380. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xin, C.; Huang, Y.; Kang, K.; He, Y. Effect of dispersed phase on the morphology of in situ microfibrils and the viscoelastic properties of its composite via direct extrusion. J. Appl. Polym. Sci. 2018, 135, 46286. [Google Scholar] [CrossRef]

- Crevecoeur, G.; Groeninckx, G. Fibril formation in in situ composites of a thermotropic liquid crystalline polymer in a thermoplastic matrix. J. Appl. Polym. Sci. 1993, 49, 839–849. [Google Scholar] [CrossRef]

- Yang, L.; Su, J.; Yang, Q.; Zhang, T.Y.; Zhao, Z.G.; Huang, Y.J.; Liao, X. Effective in situ polyamide 6 microfibrils in isotactic poly-propylene under microinjection molding: Significant improvement of mechanical performance. J. Mater. Sci. 2016, 51, 10386–10399. [Google Scholar] [CrossRef]

- Zhang, Y.; Park, S.-J. In Situ shear-induced mercapto group-activated graphite nanoplatelets for fabricating mechanically strong and thermally conductive elastomer composites for thermal management applications. Compos. Part A Appl. Sci. Manuf. 2018, 112, 40–48. [Google Scholar] [CrossRef]

- Migler, K.B. String Formation in Sheared Polymer Blends: Coalescence, Breakup, and Finite Size Effects. Phys. Rev. Lett. 2001, 86, 1023–1026. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Lin, R.J.T.; Fuchs, C.; Friedrich, K. Contribution of Coalescence to Microfibril Formation in Polymer Blends during Cold Drawing. J. Macromol. Sci. Part B 2007, 46, 183–194. [Google Scholar] [CrossRef]

- Li, C.H.; Jing, T.; Wang, J.F.; Wu, H.; Guo, S.Y.; Zhang, X.; Li, J.; Shen, J.; Chen, R.; Xiong, Y. In Situ Formation of Microfibrillar Crystalline Superstructure: Achieving High-performance Polylactide. ACS Appl. Mater. Interfaces 2017, 9, 25818–25829. [Google Scholar] [CrossRef]

- Huang, Y.; He, Y.; Ding, W.; Yang, K.; Yu, D.; Xin, C. Improved viscoelastic, thermal, and mechanical properties of in situ microfibrillar polypropylene/polyamide 6,6 composites via direct extrusion using a triple-screw extruder. RSC Adv. 2017, 7, 5030–5038. [Google Scholar] [CrossRef]

- Cheng, L.H.; Wang, W.J.; Wang, J.W.; Cao, Y.X.; Li, G.X.; Shen, Y.L. Morphological structure and mechanical properties of in situ microfibrillar composites of modified PA66 with PP. J. Appl. Polym. Sci. 2013, 127, 4044–4051. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Fukuda, K.; Yokohara, T.; Ali, M.A.B.M.; Nobukawa, S. Modification of rheological properties under elonga-tional flow by addition of polymeric fine fibers. Macromol. Mater. Eng. 2012, 297, 654–658. [Google Scholar] [CrossRef]

- Wu, D.F.; Zhang, Y.S.; Zhang, M.; Zhou, W.D. Phase behavior and its viscoelastic response of polylactide/poly(e-caprolactone) blend. Eur. Polym. J. 2008, 44, 2171–2183. [Google Scholar] [CrossRef]

- Lin, X.D.; Chen, W.L. Study of Poly(ethylene terephthalate)/Polypropylene Microfifibrillar Composites. I. Morphological Development in Melt Extrusion. Appl. Polym. Sci. 2003, 89, 1743. [Google Scholar] [CrossRef]

- Li, M.F.; Xiao, R.; Sun, G. Morphology development and size control of poly (trimethylene terephthalate) nanofibers prepared from poly(trimethylene terephthalate)/cellulose acetate butyrate in situ fibrillar composites. J. Mater. Sci. 2011, 46, 4524–4531. [Google Scholar] [CrossRef] [PubMed]

- Favis, B.; Chalifoux, J. Influence of composition on the morphology of polypropylene/polycarbonate blends. Polymer 1988, 29, 1761–1767. [Google Scholar] [CrossRef]

- Huang, W.-Y.; Shen, J.-W.; Chen, X.-M. Effect of composition on phase morphology and mechanical properties of PP/PA66 in situ composites via extrusion-drawing-injection method. J. Mater. Sci. 2003, 38, 541–547. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; Jose, T.; Thomas, S.; Joseph, K. Effect of draw ratio on the microstructure, thermal, tensile and dynamic rheological properties of in situ microfibrillar composites. Eur. Polym. J. 2009, 45, 1738–1747. [Google Scholar] [CrossRef]

- Dong, J.; Huang, A.; Sun, J.; Wei, L.; Luo, S.; Qin, S. Effect of draw ratio on the morphologies and properties of in situ microfibrillar POE/PTT composites. Polym. Compos. 2018, 40, E629–E637. [Google Scholar] [CrossRef]

- Sun, J.; Huang, A.; Luo, S.; Shi, M.; Luo, H.; Sui, Y. Effect of stretching speed on morphologies and properties of in situ microfibrillar POE/PLA composites. J. Thermoplast. Compos. Mater. 2020, 35. [Google Scholar] [CrossRef]

- Xu, L.; Zhong, G.-J.; Ji, X.; Li, Z.-M. Crystallization behavior and morphology of one-step reaction compatibilized microfibrillar reinforced isotactic polypropylene/poly(ethylene terephthalate) (iPP/PET) blends. Chin. J. Polym. Sci. 2011, 29, 540–551. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Mi, D.; Martins, C.I.; Cardon, L.; Ragaert, K. Development of Crystalline Morphology and its rela-tionship with mechanical properties of PP/PET microfibrillar composites containing POE and POE-g-MA. Polymers 2018, 10, 291. [Google Scholar] [CrossRef] [PubMed]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Ishii, M.; Harrass, M. Microfibrillar reinforced composites from PET/PP blends: Processing, morphology and mechanical properties. Compos. Sci. Technol. 2004, 65, 107–116. [Google Scholar] [CrossRef]

- Vahid, H.; Ali, M.Z.; Basil, D.F. Morphology development in poly (lactic acid)/polyamide11 biobased blends: Chain mobility and interfacial interactions. Polymer 2017, 120, 197–208. [Google Scholar]

- Li, W.J.; Schlarb, A.K.; Evstatiev, M. Effect of Viscosity Ratio on the Morphology of PET Microfifibrils in Uncompatibilized and Compatibilized Drawn PET/PP/TiO2 Blends. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 555–562. [Google Scholar] [CrossRef]

- Favis, B.D. The effect of processing parameters on the morphology of an immiscible binary blend. J. Appl. Polym. Sci. 1990, 39, 285–300. [Google Scholar] [CrossRef]

- Utrack, L.A.; Shi, Z.H. Development of polymer blend morphology during compounding in a twin-screw extruder. Part I: Droplet dispersion and coalescence. Polym. Eng. Sci. 1992, 32, 1824–1833. [Google Scholar] [CrossRef]

- Yi, X.; Xu, L.; Wang, Y.; Zhong, G.J.; Ji, X.; Li, Z.M. Morphology and properties of isotactic polypropylene/poly(ethylene tereph-thalate) in situ microfifibrillar reinforced blends: Inflfluence of viscosity ratio. Eur. Polym. J. 2010, 46, 719. [Google Scholar] [CrossRef]

- Zhao, C.X.; Lun, H.M.; Alshrah, M.; Soltani, I.; Lee, P.C.; Park, C.B. Challenge in manufacturing nanofibril composites with low matrix viscosity: Effects of matrix viscosity and fibril content. Eur. Polym. J. 2019, 121, 109310. [Google Scholar] [CrossRef]

- Min, K.; White, J.L.; Fellers, J.F. Development of phase morphology in incompatible polymer blends during mixing and its variation in extrusion. Polym. Eng. Sci. 1984, 24, 1327–1336. [Google Scholar] [CrossRef]

- Zhu, X.L.; Wu, D.; Liu, C.L. Non-isothermal crystallization Kinetics of PA6/PPO blends. China Plast. 2012, 26, 29–34. [Google Scholar]

- Bai, H.; Huang, C.; Xiu, H.; Zhang, Q.; Fu, Q. Enhancing mechanical performance of polylactide by tailoring crystal morphology and lamellae orientation with the aid of nucleating agent. Polymer 2014, 55, 6924–6934. [Google Scholar] [CrossRef]

- Samir, M.A.S.A.; Alloin, F.; Sanchez, J.-Y.; Dufresne, A. Cellulose nanocrystals reinforced poly(oxyethylene). Polymer 2004, 45, 4149–4157. [Google Scholar] [CrossRef]

- Drieskens, M.; Peeters, R.; Mullens, J.; Franco, D.; Lemstra, P.J.; Hristova-Bogaerds, D.G. Structure versus properties relationship pf poly(lactic acid). I. Effect of crystallinity on barrier properties. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 2247–2258. [Google Scholar] [CrossRef]

| Sample | Density (g/cm3) | Melting Index (g/10 min) | Tensile Strength at Break (MPa) | Tensile Elongation at Break (%) |

|---|---|---|---|---|

| POE 8200 | 0.87 | 5.0 (190 °C) | 9.3 | >1000 |

| PLA 4032D | 1.24 | 7.0 (210 °C) | 53 | 6 |

| Sample | PA6-2.0 | PA6-2.4 | PA6-2.8 | PA6-3.2 |

|---|---|---|---|---|

| Material | M2000 | M2400 | M2800 | M3400 |

| Relative Viscosity | 2.07 | 2.46 | 2.81 | 3.28 |

| Density (g/cm3) | 1.14 | 1.14 | 1.14 | 1.14 |

| Melting Index (g/10 min) | 137 | 34.6 | 15.2 | 6.5 |

| Tensile Strength at Break (MPa) | 66 | 61 | 65 | 64 |

| Tensile Elongation at Break (%) | 26 | 39 | 36 | 58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Wang, L.; Sun, J.; Yang, W.; Zhang, H. Morphology and Properties of Polyolefin Elastomer/Polyamide 6/Poly(lactic Acid) In Situ Special-Shaped Microfibrillar Composites: Influence of Viscosity Ratio. Polymers 2022, 14, 4556. https://doi.org/10.3390/polym14214556

Shi M, Wang L, Sun J, Yang W, Zhang H. Morphology and Properties of Polyolefin Elastomer/Polyamide 6/Poly(lactic Acid) In Situ Special-Shaped Microfibrillar Composites: Influence of Viscosity Ratio. Polymers. 2022; 14(21):4556. https://doi.org/10.3390/polym14214556

Chicago/Turabian StyleShi, Min, Lijun Wang, Jing Sun, Wensheng Yang, and Hui Zhang. 2022. "Morphology and Properties of Polyolefin Elastomer/Polyamide 6/Poly(lactic Acid) In Situ Special-Shaped Microfibrillar Composites: Influence of Viscosity Ratio" Polymers 14, no. 21: 4556. https://doi.org/10.3390/polym14214556

APA StyleShi, M., Wang, L., Sun, J., Yang, W., & Zhang, H. (2022). Morphology and Properties of Polyolefin Elastomer/Polyamide 6/Poly(lactic Acid) In Situ Special-Shaped Microfibrillar Composites: Influence of Viscosity Ratio. Polymers, 14(21), 4556. https://doi.org/10.3390/polym14214556