Clay-Alginate Beads Loaded with Ionic Liquids: Potential Adsorbents for the Efficient Extraction of Oil from Produced Water

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instrumentations

2.2. Methodology

2.2.1. Preparation of the Synthetic Produced Water

2.2.2. Preparation of the Clay-Alginate-IL Beads

2.2.3. Adsorption Study

2.2.4. Process Optimization

2.2.5. Characterization of the Materials Used in the Adsorption Study

2.2.6. Regeneration Study of the Clay-Alginate-IL Beads

3. Results and Discussion

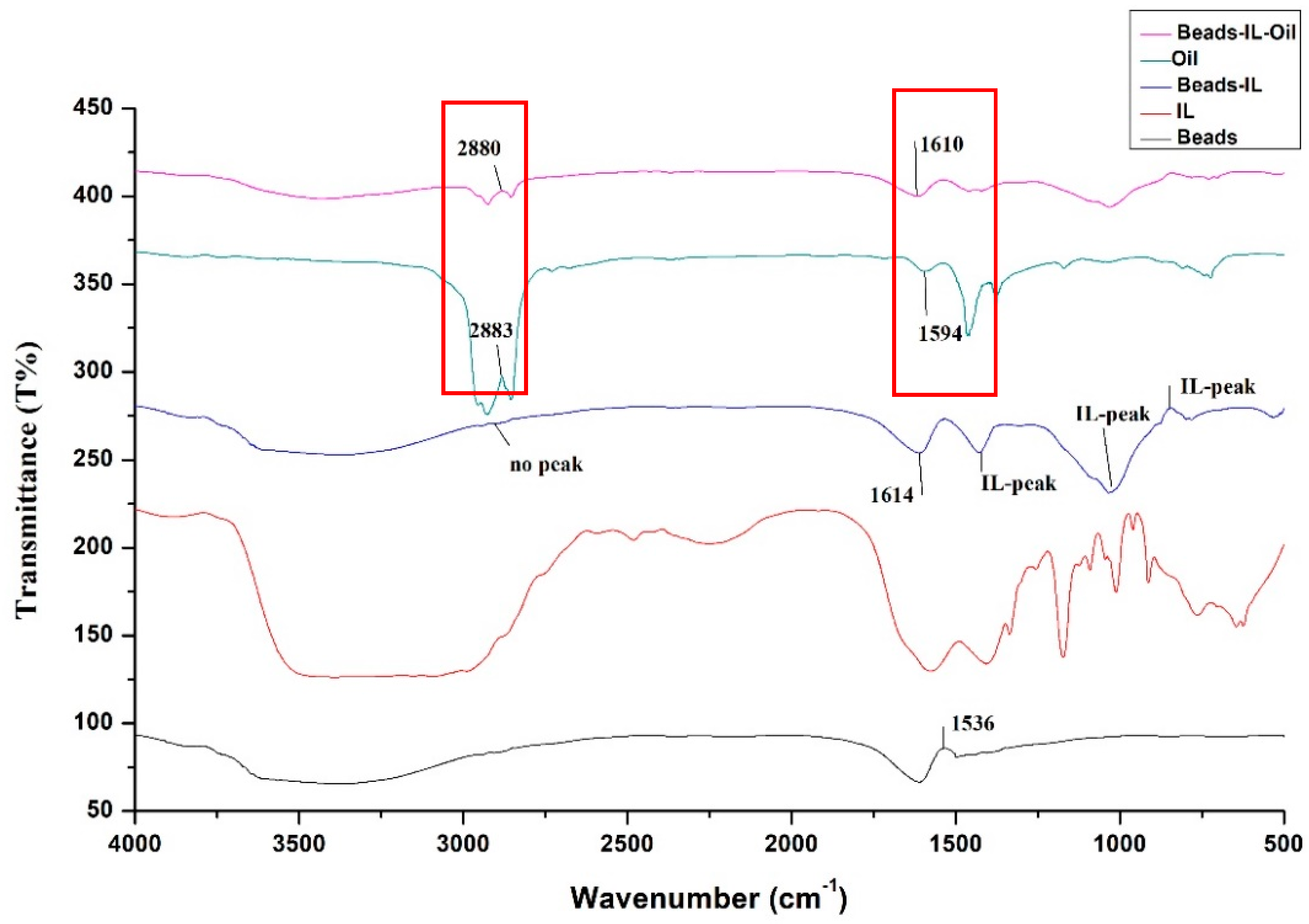

3.1. FTIR Analysis of the Materials Used in the Adsorption Process

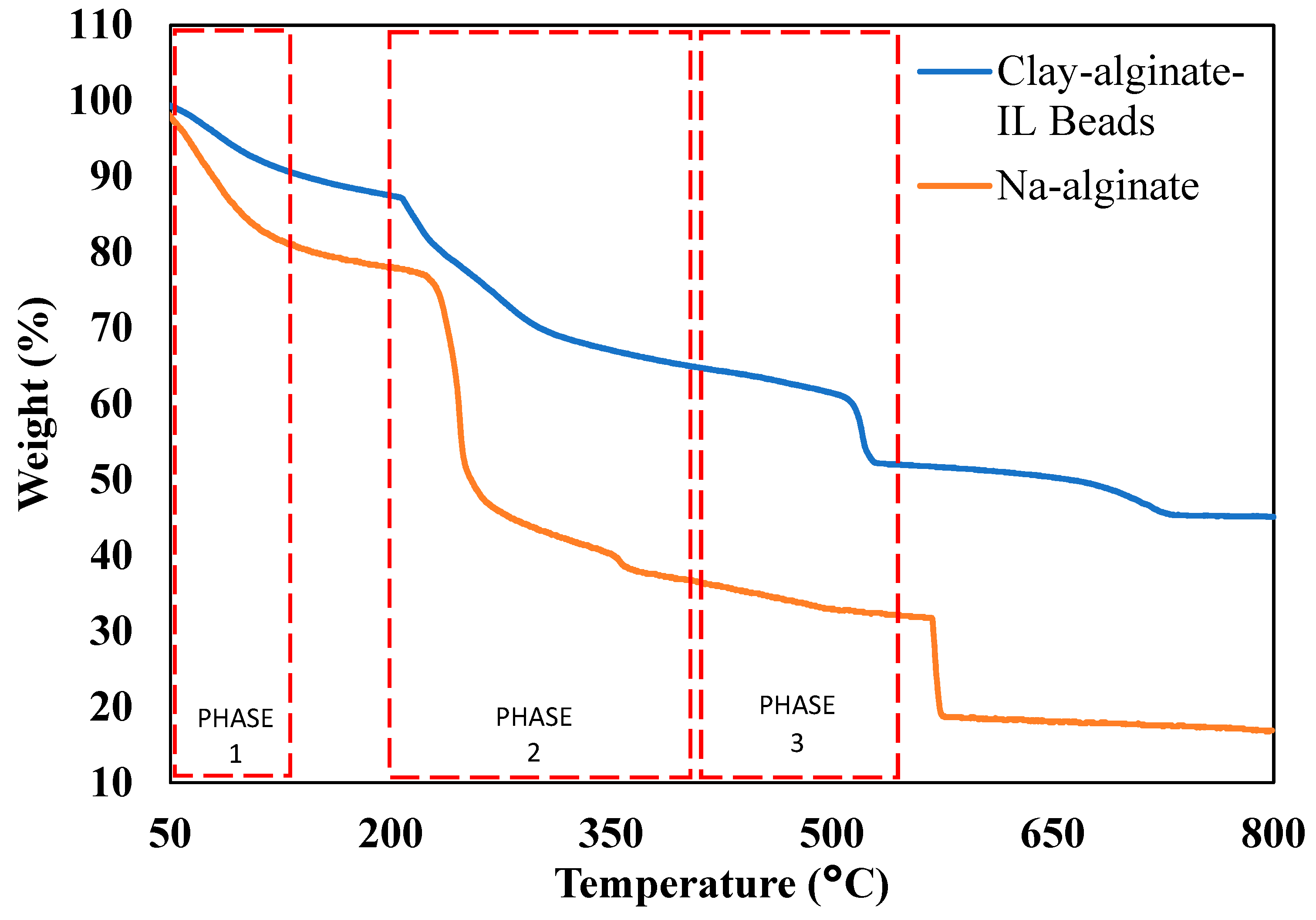

3.2. TGA of the Clay-Alginate-ILs Beads and the Na-Alginate Used in the Adsorption Process

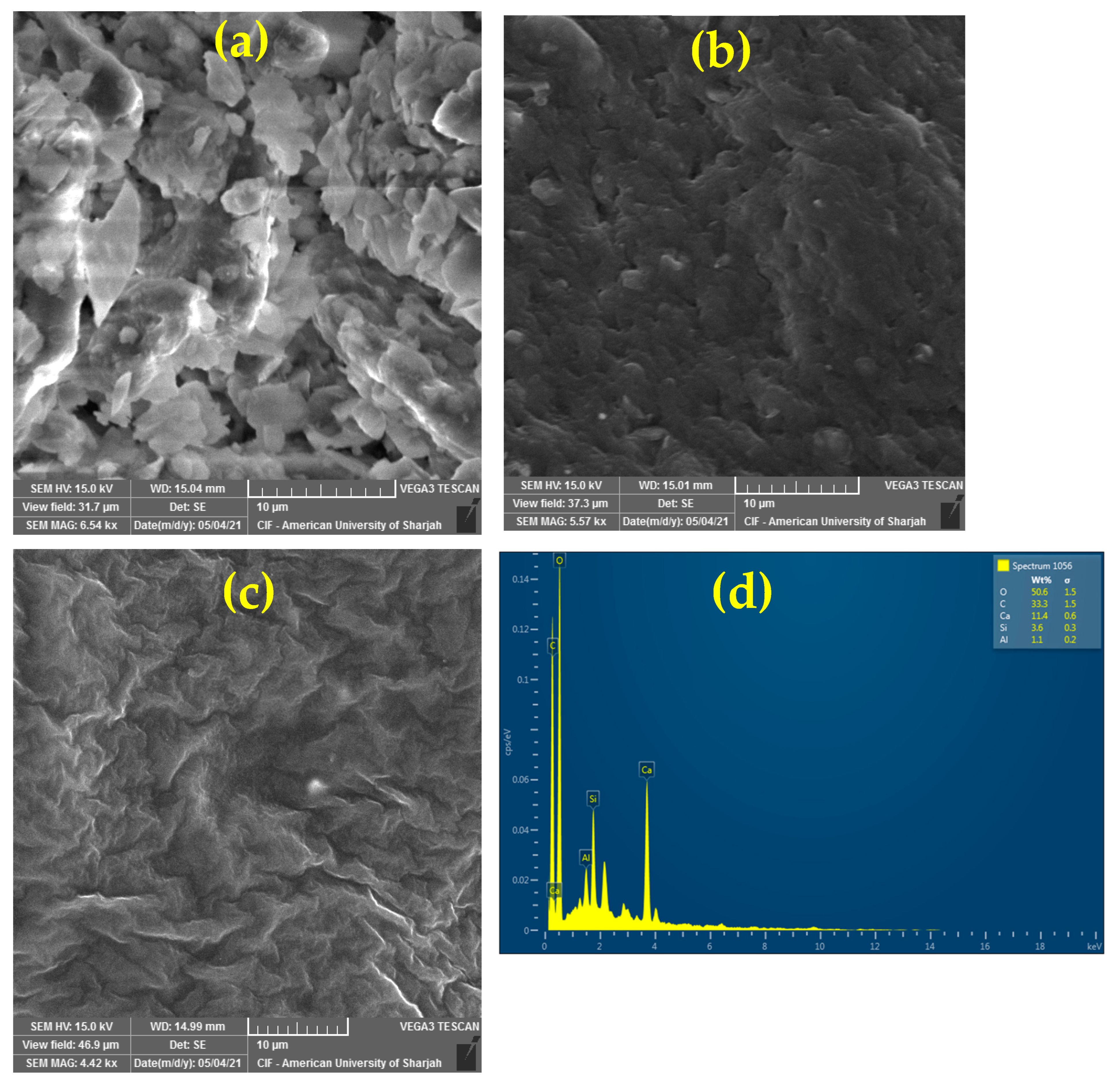

3.3. SEM-EDX Analysis of the Clay-Alginate-ILs Beads

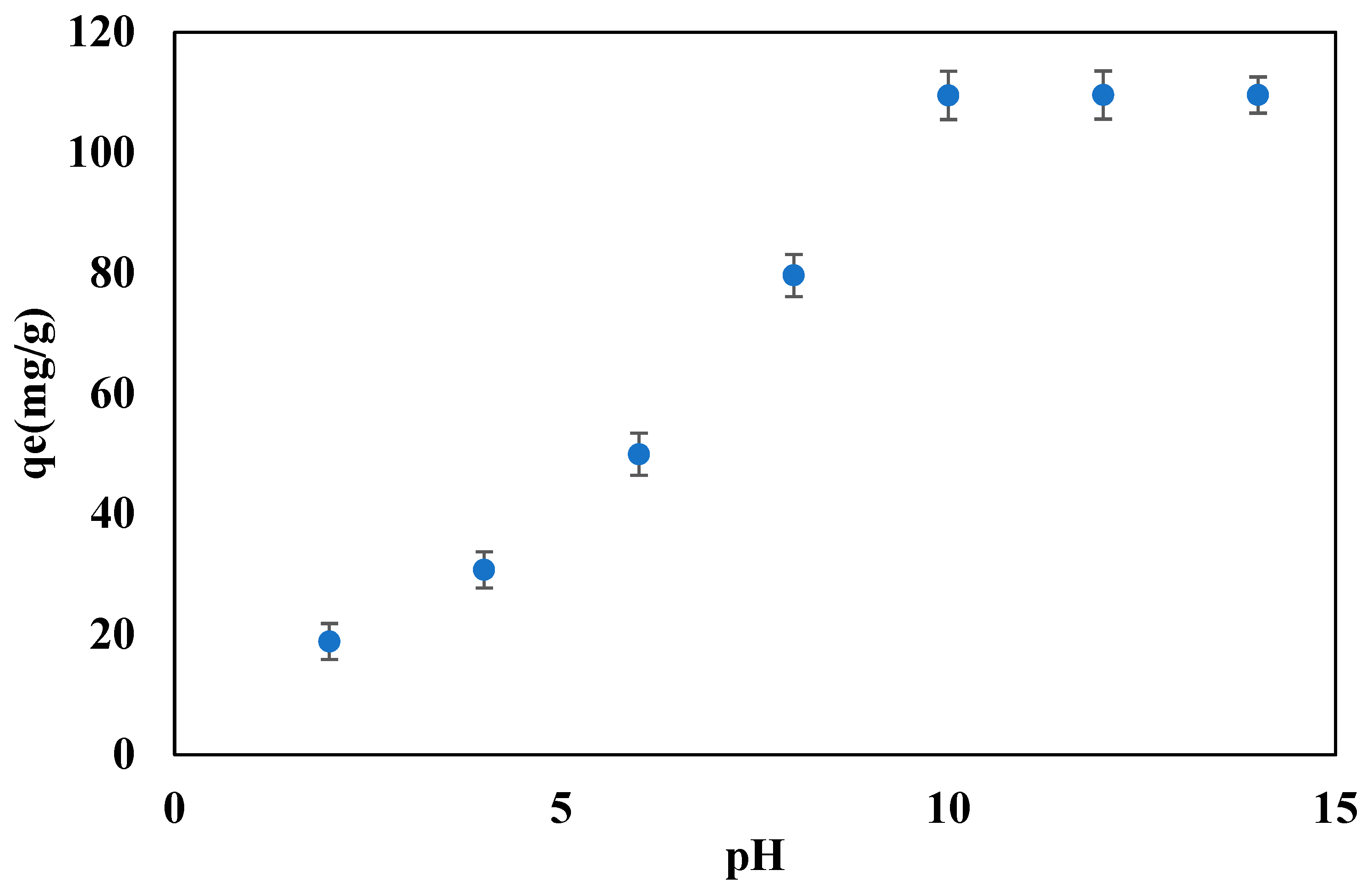

3.4. Effect of the pH of the PW Solution on the Adsorption Capacity of the Beads

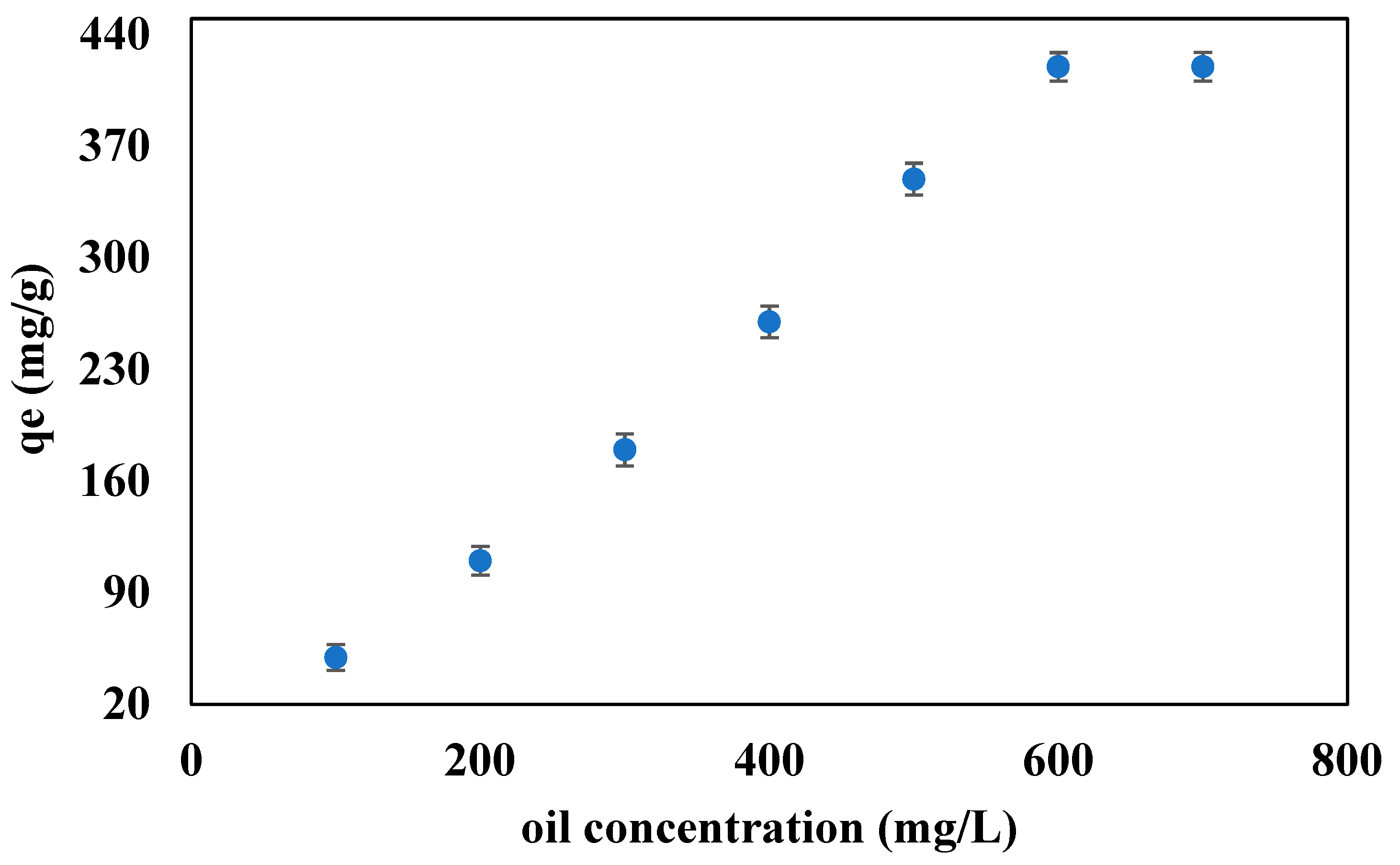

3.5. Effect of the Oil Initial Concentration on the Adsorption Capacity of the Beads

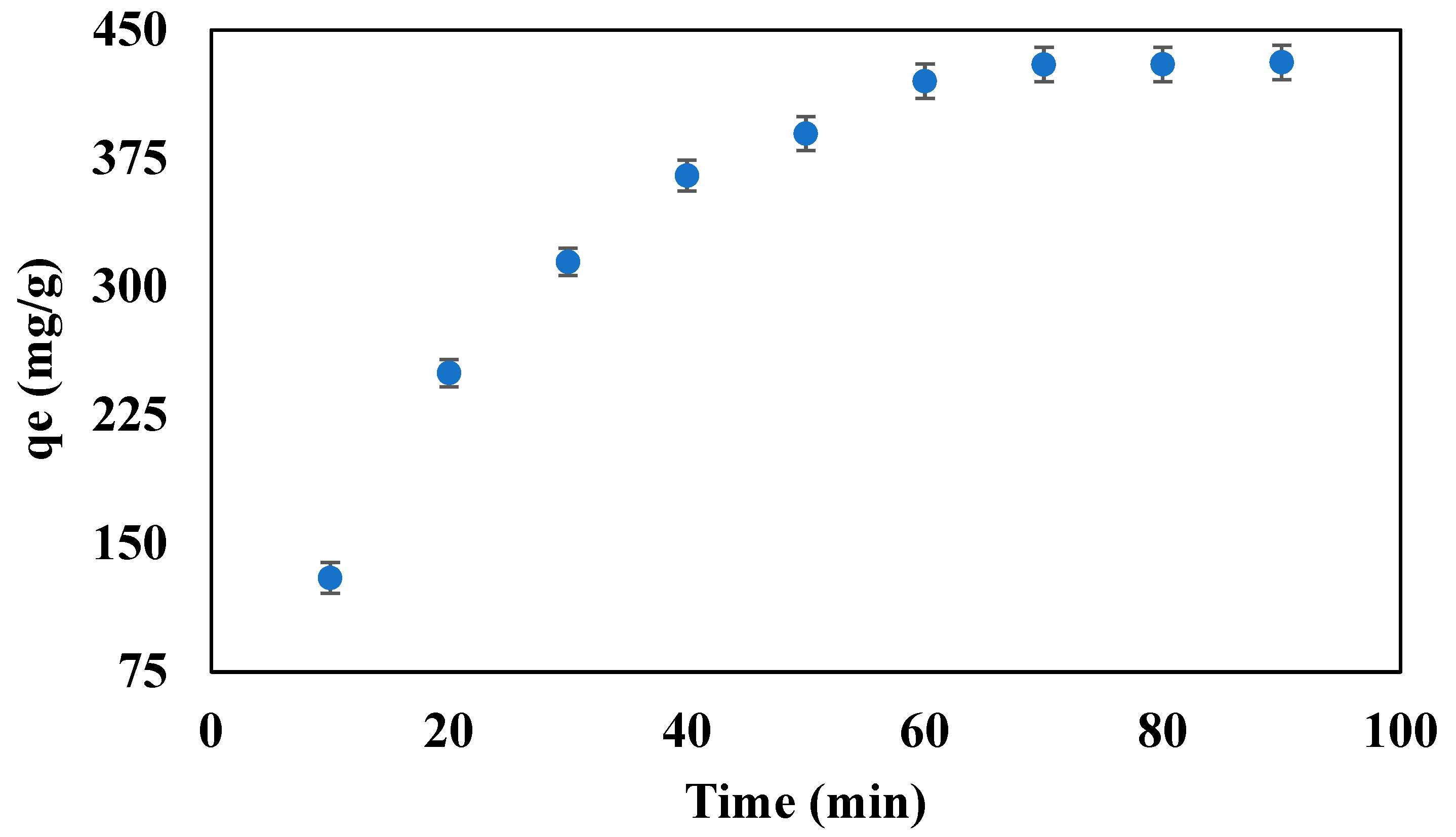

3.6. Effect of the Contact Time on the Adsorption Capacity of the Beads

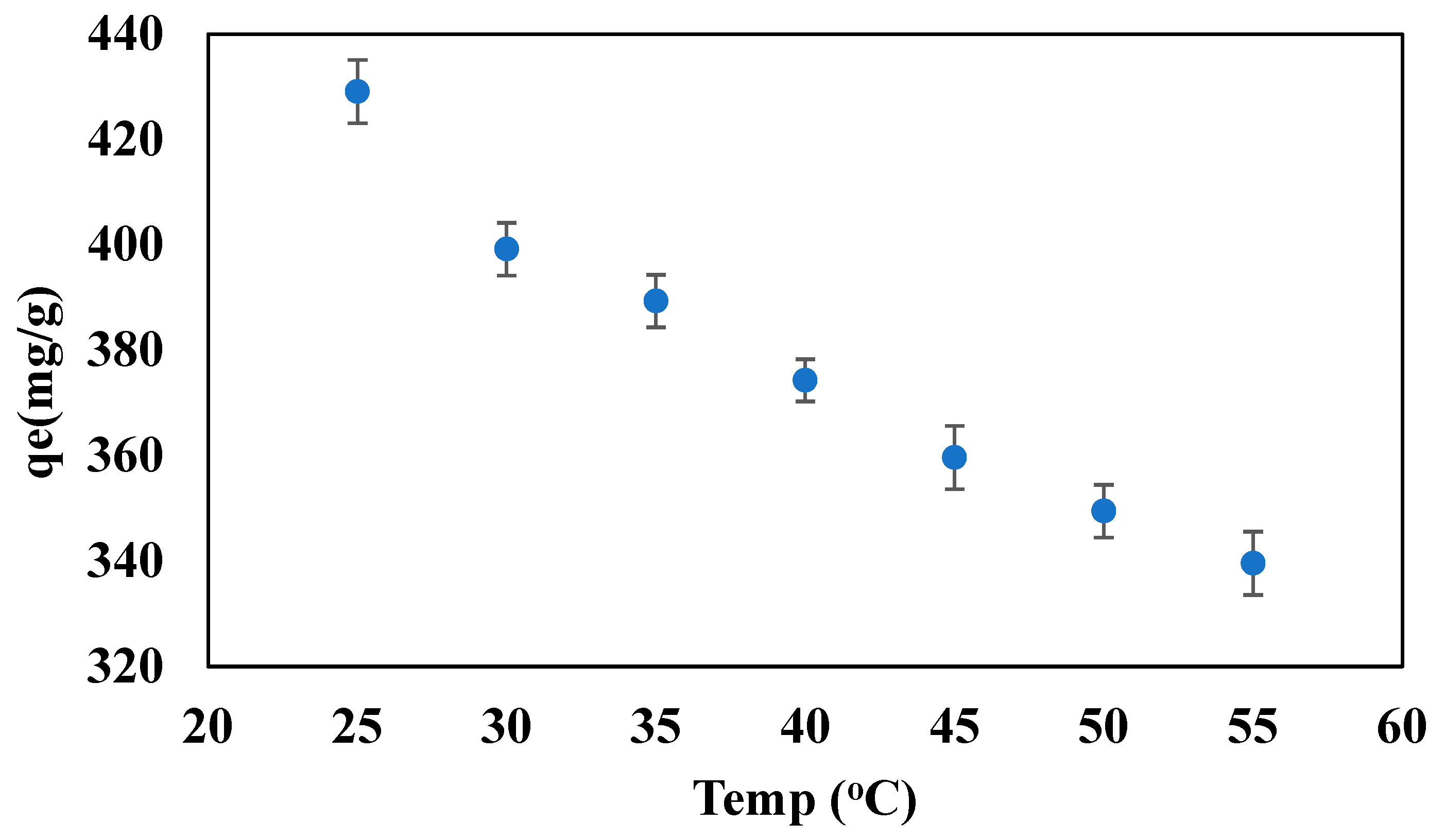

3.7. Effect of the Temperature on the Adsorption Capacity of the Beads

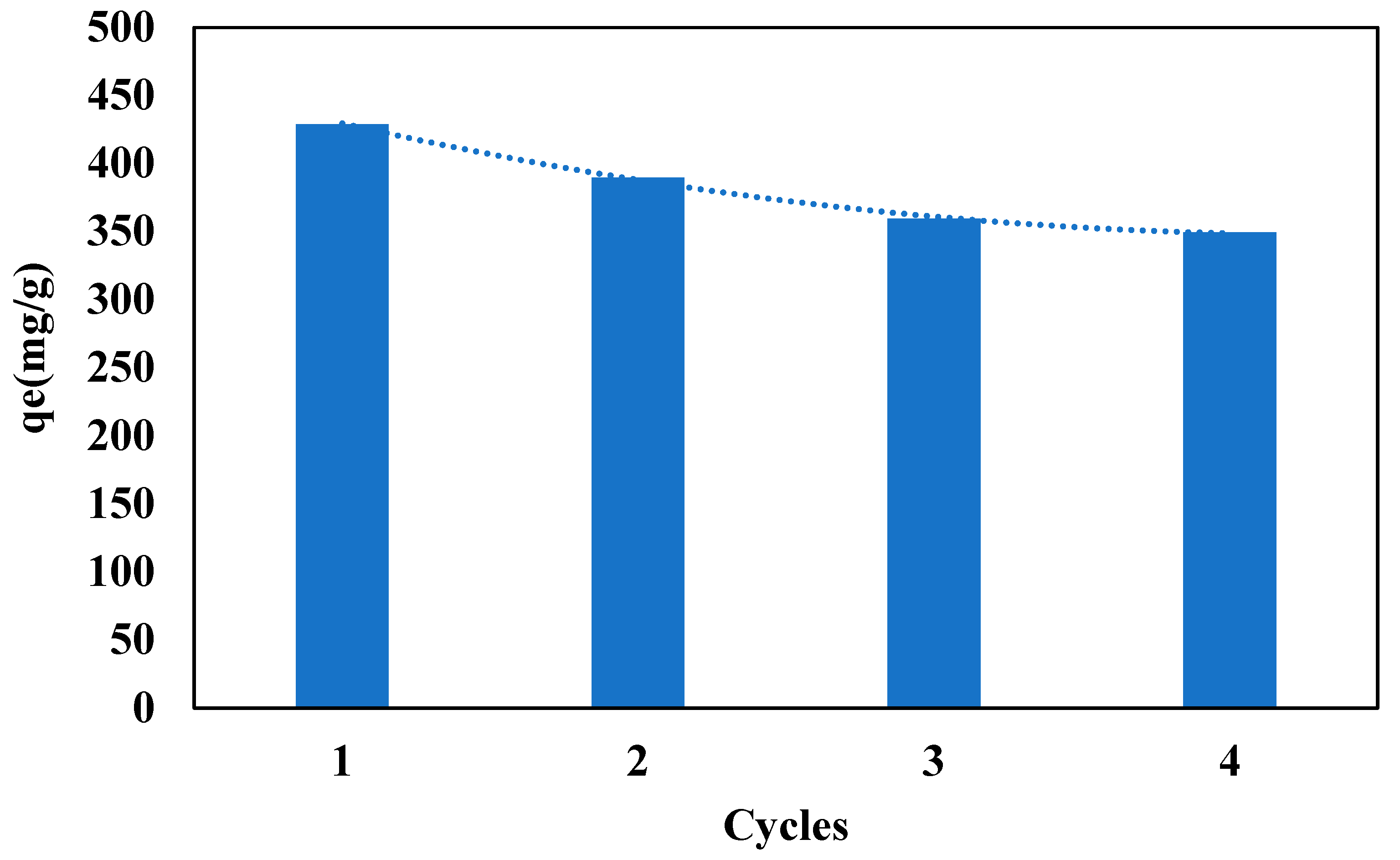

3.8. Regeneration Study of the Beads Used in the Adsorption Process

3.9. Adsorption Kinetics for the Adsorption of Oil onto the Clay-Alginate-ILs Beads’ Surface

3.10. Adsorption in a Pseudo-Second Order Isotherm

3.11. Comparison with the Literature Data

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Ghouti, M.A.; Al-Kaabi, M.A.; Ashfaq, M.Y. Produced water characteristics, treatment and reuse: A review. J. Water Process Eng. 2019, 28, 222–239. [Google Scholar] [CrossRef]

- Igunnu, E.T.; Chen, G.Z. Produced water treatment technologies. Int. J. Low-Carbon Technol. 2014, 9, 157–177. [Google Scholar] [CrossRef]

- Hedar, Y. Budiyono Pollution Impact and Alternative Treatment for Produced Water. In Proceedings of the E3S Web of Conferences 2018, Semarang, Indonesia, 15–16 August 2018; Volume 31, p. 03004. [Google Scholar] [CrossRef]

- Show, P.L.; Thangalazhy-Gopakumar, S.; Foo, D.C.Y. Sustainable technologies for waste reduction and pollutants removals. Clean Technol. Environ. Policy 2021, 23, 1–2. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Pendashteh, A.; Abdullah, L.C.; Biak, D.R.A.; Madaeni, S.S.; Abidin, Z.Z. Review of technologies for oil and gas produced water treatment. J. Hazard. Mater. 2009, 170, 530–551. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.J. Adsorption of non-steroidal anti-inflammatory drugs from aqueous solution using activated carbons: Review. J. Environ. Manag. 2017, 190, 274–282. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, B.K.; Gallagher, E. Emerging Technologies with reference to IUFoST. Innov. Food Sci. Emerg. Technol. 2017, 44, 1. [Google Scholar] [CrossRef]

- Guo, D.; Wang, H.; Fu, P.; Huang, Y.; Liu, Y.; Lv, W.; Wang, F. Diatomite precoat filtration for wastewater treatment: Filtration performance and pollution mechanisms. Chem. Eng. Res. Des. 2018, 137, 403–411. [Google Scholar] [CrossRef]

- Xie, Y.; Ren, L.; Zhu, X.; Gou, X.; Chen, S. Physical and chemical treatments for removal of perchlorate from water–A review. Process Saf. Environ. Prot. 2018, 116, 180–198. [Google Scholar] [CrossRef]

- Trellu, C.; Chaplin, B.P.; Coetsier, C.; Esmilaire, R.; Cerneaux, S.; Causserand, C.; Cretin, M. Electro-oxidation of organic pollutants by reactive electrochemical membranes. Chemosphere 2018, 208, 159–175. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Kumar, A.; Syam Babu, D.; Scaria, J.; Suresh Kumar, M. Treatment of mixed industrial wastewater by electrocoagulation and indirect electrochemical oxidation. Chemosphere 2020, 251, 126437. [Google Scholar] [CrossRef]

- Khader, E.H.; Mohammed, T.; Mirghaffari, N.; Thj, M. Use of natural coagulants for removal of COD, oil and turbidity from produced waters in the petroleum industry. J. Pet. Environ. Biotechnol. 2018, 9, 3. [Google Scholar] [CrossRef]

- Elazzouzi, M.; Haboubi, K.; Elyoubi, M.S. Electrocoagulation flocculation as a low-cost process for pollutants removal from urban wastewater. Chem. Eng. Res. Des. 2017, 117, 614–626. [Google Scholar] [CrossRef]

- Verma, A.K.; Dash, R.R.; Bhunia, P. A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J. Environ. Manag. 2012, 93, 154–168. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.T.; Xu, S.S.; Li, Z.H.; An, X.H.; Zhou, L.; Zhang, Y.L.; Shiang, F.Q. Progress of applied research on TiO2 photocatalysis-membrane separation coupling technology in water and wastewater treatments. Chin. Sci. Bull. 2010, 55, 1345–1353. [Google Scholar] [CrossRef]

- Tanhaei, B.; Pourafshari Chenar, M.; Saghatoleslami, N.; Hesampour, M.; Kallioinen, M.; Sillanpää, M.; Mänttäri, M. Removal of nickel ions from aqueous solution by micellar-enhanced ultrafiltration, using mixed anionic–non-ionic surfactants. Sep. Purif. Technol. 2014, 138, 169–176. [Google Scholar] [CrossRef]

- Tanhaei, B.; Pourafshari Chenar, M.; Saghatoleslami, N.; Hesampour, M.; Laakso, T.; Kallioinen, M.; Sillanpää, M.; Mänttäri, M. Simultaneous removal of aniline and nickel from water by micellar-enhanced ultrafiltration with different molecular weight cut-off membranes. Sep. Purif. Technol. 2014, 124, 26–35. [Google Scholar] [CrossRef]

- Gupta, V.K.; Mittal, A.; Jhare, D.; Mittal, J. Batch and bulk removal of hazardous colouring agent Rose Bengal by adsorption techniques using bottom ash as adsorbent. RSC Adv. 2012, 2, 8381–8389. [Google Scholar] [CrossRef]

- Han, R.; Wang, Y.; Zou, W.; Wang, Y.; Shi, J. Comparison of linear and nonlinear analysis in estimating the Thomas model parameters for methylene blue adsorption onto natural zeolite in fixed-bed column. J. Hazard. Mater. 2007, 145, 331–335. [Google Scholar] [CrossRef]

- Rashed, M.N. Adsorption technique for the removal of organic pollutants from water and wastewater. Org. Pollut. Monit. Risk Treat. 2013, 7, 167–194. [Google Scholar]

- Ayati, A.; Shahrak, M.N.; Tanhaei, B.; Sillanpää, M. Emerging adsorptive removal of azo dye by metal–organic frameworks. Chemosphere 2016, 160, 30–44. [Google Scholar] [CrossRef]

- Ayati, A.; Tanhaei, B.; Sillanpää, M. Lead(II)-ion removal by ethylenediaminetetraacetic acid ligand functionalized magnetic chitosan–aluminum oxide–iron oxide nanoadsorbents and microadsorbents: Equilibrium, kinetics, and thermodynamics. J. Appl. Polym. Sci. 2017, 134, 44360. [Google Scholar] [CrossRef]

- Tanhaei, B.; Ayati, A.; Bamoharram, F.F.; Lahtinen, M.; Sillanpää, M. A novel magnetic Preyssler acid grafted chitosan nano adsorbent: Synthesis, characterization and adsorption activity. J. Chem. Technol. Biotechnol. 2016, 91, 1452–1460. [Google Scholar] [CrossRef]

- Tanhaei, B.; Ayati, A.; Bamoharram, F.F.; Sillanpää, M. Magnetic EDTA Functionalized Preyssler Cross Linked Chitosan Nanocomposite for Adsorptive Removal of Pb(II) Ions. CLEAN Soil Air Water 2017, 45, 1700328. [Google Scholar] [CrossRef]

- Zeraatkar Moghaddam, A.; Ghiamati, E.; Pourashuri, A.; Allahresani, A. Modified nickel ferrite nanocomposite/functionalized chitosan as a novel adsorbent for the removal of acidic dyes. Int. J. Biol. Macromol. 2018, 120, 1714–1725. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Cho, C.W.; Song, M.H.; Bediako, J.K.; Yun, Y.S.; Choi, Y.E. Potentiometric titration data on the enhancement of sorption capacity of surface-modified biosorbents: Functional groups scanning method. Clean Technol. Environ. Policy 2018, 20, 2191–2199. [Google Scholar] [CrossRef]

- Albayati, T.M.; Sabri, A.A.; Abed, D.B. Functionalized SBA-15 by amine group for removal of Ni (II) heavy metal ion in the batch adsorption system. Desalination Water Treat. 2020, 174, 301–310. [Google Scholar] [CrossRef]

- Alardhi, S.M.; Albayati, T.M.; Alrubaye, J.M. Adsorption of the methyl green dye pollutant from aqueous solution using mesoporous materials MCM-41 in a fixed-bed column. Heliyon 2020, 6, e03253. [Google Scholar] [CrossRef]

- Amirfirouzkouhi, H.; Kharat, A.N. Application of ionic liquids as recyclable green catalysts for selective alkylation of phenol. Sep. Purif. Technol. 2018, 196, 132–139. [Google Scholar] [CrossRef]

- Sivapragasam, M.; Moniruzzaman, M.; Goto, M. Recent advances in exploiting ionic liquids for biomolecules: Solubility, stability and applications. Biotechnol. J. 2016, 11, 1000–1013. [Google Scholar] [CrossRef]

- Ishida, T. The Dynamical Properties on Ionic Liquids: Insights from Molecular Dynamics Study. In Ionic Liquids-New Aspects for the Future; IntechOpen: London, UK, 2013. [Google Scholar] [CrossRef]

- Zhu, A.; Jiang, T.; Wang, D.; Han, B.; Liu, L.; Huang, J.; Zhang, J.; Sun, D. Direct aldol reactions catalyzed by 1,1,3,3-tetramethylguanidine lactate without solvent. Green Chem. 2005, 7, 514–517. [Google Scholar] [CrossRef]

- Mital, D.; Liaqat, S.; Nancarrow, P.; Ibrahim, T.; Jabbar, N.A.; Khamis, M. Thermal Conductivities of NTf2-Based Ionic Liquids: Experimental Measurement and Prediction via Group Contribution Methods. J. Chem. Eng. Data 2022, 67. [Google Scholar] [CrossRef]

- Tian, Y.; Feng, X.; Zhang, Y.; Yu, Q.; Wang, X.; Tian, M. Determination of Volatile Water Pollutants Using Cross-Linked Polymeric Ionic Liquid as Solid Phase Micro-Extraction Coatings. Polymers 2020, 12, 292. [Google Scholar] [CrossRef] [PubMed]

- Sas, O.G.; Sánchez, P.B.; González, B.; Domínguez, Á. Removal of phenolic pollutants from wastewater streams using ionic liquids. Sep. Purif. Technol. 2020, 236, 116310. [Google Scholar] [CrossRef]

- Herce-Sesa, B.; Pirkwieser, P.; López-López, J.A.; Jirsa, F.; Moreno, C. Selective liquid phase micro-extraction of metal chloro-complexes from saline waters using ionic liquids. J. Clean. Prod. 2020, 262, 121415. [Google Scholar] [CrossRef]

- Almeida, H.F.D.; Neves, M.C.; Trindade, T.; Marrucho, I.M.; Freire, M.G. Supported ionic liquids as efficient materials to remove non-steroidal anti-inflammatory drugs from aqueous media. Chem. Eng. J. 2020, 381, 122616. [Google Scholar] [CrossRef]

- Priyanka, V.P.; Gardas, R.L. Mono- and di- cationic ionic liquids based aqueous biphasic systems for the extraction of diclofenac sodium. Sep. Purif. Technol. 2020, 234, 116048. [Google Scholar] [CrossRef]

- Esmaeili, N.; Kokabi, N.; Kolvari, E. Speciation of arsenic in wastewater samples based on pyributicarbamate /ionic liquids by dispersive liquid-liquid microextraction. Anal. Methods Environ. Chem. J. 2020, 3, 41–48. [Google Scholar] [CrossRef]

- Chen, P.; Xie, F.; Tang, F.; McNally, T. Ionic Liquid (1-Ethyl-3-methylimidazolium Acetate) Plasticization of Chitosan-Based Bionanocomposites. ACS Omega 2020, 5, 19070–19081. [Google Scholar] [CrossRef]

- Jafer, A.S.; Hassan, A.A. Removal of oil content in oilfield produced water using chemically modified kiwi peels as efficient low-cost adsorbent. J. Phys. Conf. Ser. 2019, 1294, 072013. [Google Scholar] [CrossRef]

- Sabri, M.A.; Ibrahim, T.H.; Khamis, M.I.; Nancarrow, P.; Hassan, M.F. Spent caustic treatment using hydrophobic room temperatures ionic liquids. J. Ind. Eng. Chem. 2018, 65, 325–333. [Google Scholar] [CrossRef]

- Halim, N.S.A.; Wirzal, M.D.H.; Hizam, S.M. Recent Development on Electrospun Nanofiber Membrane for Produced Water Treatment: A review. J. Environ. Chem. Eng. 2021, 9, 104613. [Google Scholar] [CrossRef]

- Yasir, N.; Khan, A.S.; Hassan, M.F.; Ibrahim, T.H.; Khamis, M.I.; Nancarrow, P. Ionic Liquid Agar–Alginate Beads as a Sustainable Phenol Adsorbent. Polymers 2022, 14, 984. [Google Scholar] [CrossRef]

- Pawar, R.R.; Lalhmunsiama; Gupta, P.; Sawant, S.Y.; Shahmoradi, B.; Lee, S.M. Porous synthetic hectorite clay-alginate composite beads for effective adsorption of methylene blue dye from aqueous solution. Int. J. Biol. Macromol. 2018, 114, 1315–1324. [Google Scholar] [CrossRef] [PubMed]

- Marangoni Júnior, L.; da Silva, R.G.; Anjos, C.A.R.; Vieira, R.P.; Alves, R.M.V. Effect of low concentrations of SiO2 nanoparticles on the physical and chemical properties of sodium alginate-based films. Carbohydr. Polym. 2021, 269, 118286. [Google Scholar] [CrossRef] [PubMed]

- Shah, N.S.; Khan, J.A.; Sayed, M.; Iqbal, J. Nano-zerovalent copper as a Fenton-like catalyst for the degradation of ciprofloxacin in aqueous solution. J. Water Process Eng. 2020, 37, 101325. [Google Scholar] [CrossRef]

- Kubra, K.T.; Salman, M.S.; Hasan, M.N.; Islam, A.; Hasan, M.M.; Awual, M.R. Utilizing an alternative composite material for effective copper(II) ion capturing from wastewater. J. Mol. Liq. 2021, 336, 116325. [Google Scholar] [CrossRef]

- Khan, A.S.; Ibrahim, T.H.; Khamis, M.I.; Nancarrow, P.; Iqbal, J.; AlNashef, I. Preparation of sustainable activated carbon-alginate beads impregnated with ionic liquid for phenol decontamination. J. Clean. Prod. 2021, 321, 128899. [Google Scholar] [CrossRef]

- Babaei, A.A.; Alavi, S.N.; Akbarifar, M.; Ahmadi, K.; Ramazanpour Esfahani, A.; Kakavandi, B. Experimental and modeling study on adsorption of cationic methylene blue dye onto mesoporous biochars prepared from agrowaste. Desalin. Water Treat. 2016, 57, 27199–27212. [Google Scholar] [CrossRef]

- Lutfee, T.; Al-Najar, J.A.; Abdulla, F.M. Removal of oil from produced water using biosorbent. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012198. [Google Scholar] [CrossRef]

- Chai, J.B.; Au, P.I.; Mubarak, N.M.; Khalid, M.; Ng, W.P.Q. Adsorption of heavy metal from industrial wastewater onto low-cost Malaysian kaolin clay–based adsorbent. Environ. Sci. Pollut. Res. 2020, 27, 13949–13962. [Google Scholar] [CrossRef]

- Ibrahim, T.H.; Sabri, M.A.; Khamis, M.I.; Amin Elsayed, Y.; Sara, Z.; Hafez, B. Produced water treatment using olive leaves. Desalination Water Treat. 2017, 60, 129–136. [Google Scholar] [CrossRef]

- Ibrahim, T.H.; Gulistan, A.S.; Khamis, M.I.; Ahmed, H.; Aidan, A. Produced water treatment using naturally abundant pomegranate peel. New Pub Balaban 2015, 57, 6693–6701. [Google Scholar] [CrossRef]

- Gulistan, A.S.; Ibrahim, T.H.; Khamis, M.I.; ElSayed, Y. Application of eggplant peels powder for the removal of oil from produced water. New Pub Balaban 2015, 57, 15724–15732. [Google Scholar] [CrossRef]

- Karnib, M.; Kabbani, A.; Holail, H.; Olama, Z. Heavy Metals Removal Using Activated Carbon, Silica and Silica Activated Carbon Composite. Energy Procedia 2014, 50, 113–120. [Google Scholar] [CrossRef]

- Alsulaili, A.D.; Fahim, A.M. Oil removal from produced water by agriculture waste adsorbents. Int. J. Environ. Waste Manag. 2020, 25, 12–31. [Google Scholar] [CrossRef]

- Abou Chacra, L.; Sabri, M.A.; Ibrahim, T.H.; Khamis, M.I.; Hamdan, N.M. Application of graphene nanoplatelets and graphene magnetite for the removal of emulsified oil from produced water. J. Environ. Chem. Eng. 2018, 6, 3018–3033. [Google Scholar] [CrossRef]

- Ibrahim, T.H.; Sabri, M.A.; Khamis, M.I. Application of multiwalled carbon nanotubes and its magnetite derivative for emulsified oil removal from produced water. Environ. Technol. 2018, 40, 3337–3350. [Google Scholar] [CrossRef]

- Ewis, D.; Benamor, A.; Ba-Abbad, M.M.; Nasser, M.; El-Naas, M.; Qiblawey, H. Removal of Oil Content from Oil-Water Emulsions Using Iron Oxide/Bentonite Nano Adsorbents. J. Water Process Eng. 2020, 38, 101583. [Google Scholar] [CrossRef]

| Kinetic Models | Parameters | Values |

|---|---|---|

| Pseudo first order | k1 (min−1) | 0.0922 |

| R2 | 0.9241 | |

| Pseudo second order | k2 (g/mg min−1) | 1.6 × 10−3 |

| R2 | 0.9970 |

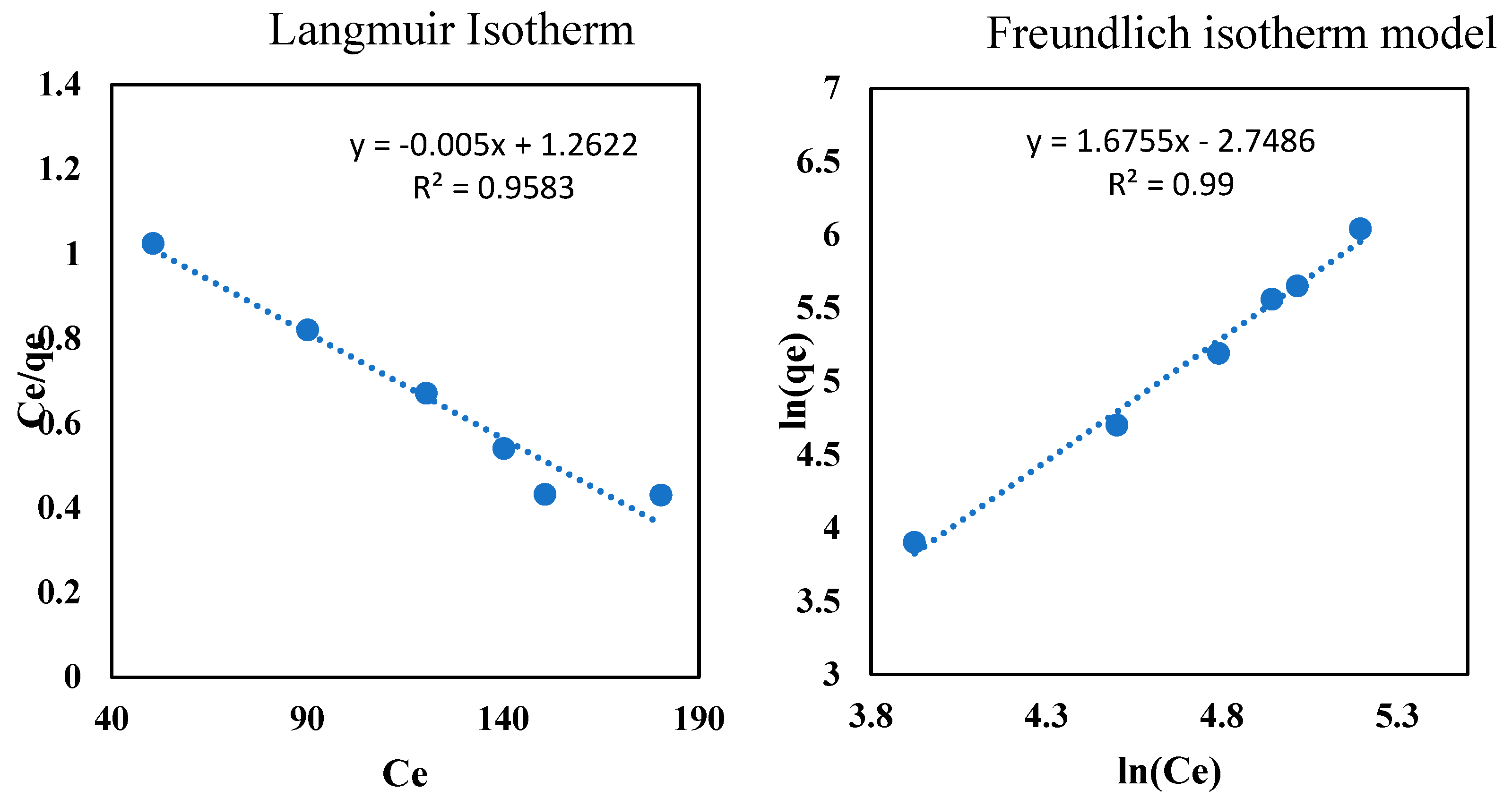

| Isotherm Model | Parameters | Values (25 °C) |

|---|---|---|

| Langmuir model | b (L/mg) | 0.00529 |

| qmax (mg/g) | 243.9 | |

| R2 | 0.998 | |

| Freundlich model | Kf (mg/g) (L/mg)1/n | 0.2239 |

| n | 0.5968 | |

| R2 | 0.99 |

| Adsorbents | Adsorption Capacity (mg/g) | Reference |

|---|---|---|

| Kiwi peels | - | [41] |

| Walnut shell | - | [57] |

| Date pits | - | [57] |

| Graphene | 100 | [58] |

| Graphene magnetite | 80 | [58] |

| Olive leaves | 143 | [53] |

| Pomegranate peels | 555 | [54] |

| Multiwalled carbon nanotubes and their derivates | - | [59] |

| Organo-clay | 67 | [59] |

| Modified bentonite | 49 | [59] |

| Eggplant peels | 834 | [55] |

| Iron oxide nano adsorbents | - | [60] |

| Clay-alginate -IL beads | 244 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liaqat, S.; Ibrahim, T.H.; Khamis, M.I.; Nancarrow, P.; Abouleish, M.Y. Clay-Alginate Beads Loaded with Ionic Liquids: Potential Adsorbents for the Efficient Extraction of Oil from Produced Water. Polymers 2022, 14, 4440. https://doi.org/10.3390/polym14204440

Liaqat S, Ibrahim TH, Khamis MI, Nancarrow P, Abouleish MY. Clay-Alginate Beads Loaded with Ionic Liquids: Potential Adsorbents for the Efficient Extraction of Oil from Produced Water. Polymers. 2022; 14(20):4440. https://doi.org/10.3390/polym14204440

Chicago/Turabian StyleLiaqat, Shehzad, Taleb H. Ibrahim, Mustafa I. Khamis, Paul Nancarrow, and Mohamed Yehia Abouleish. 2022. "Clay-Alginate Beads Loaded with Ionic Liquids: Potential Adsorbents for the Efficient Extraction of Oil from Produced Water" Polymers 14, no. 20: 4440. https://doi.org/10.3390/polym14204440

APA StyleLiaqat, S., Ibrahim, T. H., Khamis, M. I., Nancarrow, P., & Abouleish, M. Y. (2022). Clay-Alginate Beads Loaded with Ionic Liquids: Potential Adsorbents for the Efficient Extraction of Oil from Produced Water. Polymers, 14(20), 4440. https://doi.org/10.3390/polym14204440