Characterization of a Translucent Material Produced from Paulownia tomentosa Using Peracetic Acid Delignification and Resin Infiltration

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Peracetic Acid Delignification

2.2.1. Peracetic Acid Preparation

2.2.2. Delignification

2.3. Transparent Polymer Impregnation

2.4. ATR FT-IR Spectroscopy Analysis

2.5. Lignin and Sugar Content

2.6. Observation of Cell Wall Structure

2.7. Transmittance Measurement

2.8. Bending Strength Measurement

3. Results

3.1. Visual Inspection of Wood Specimens

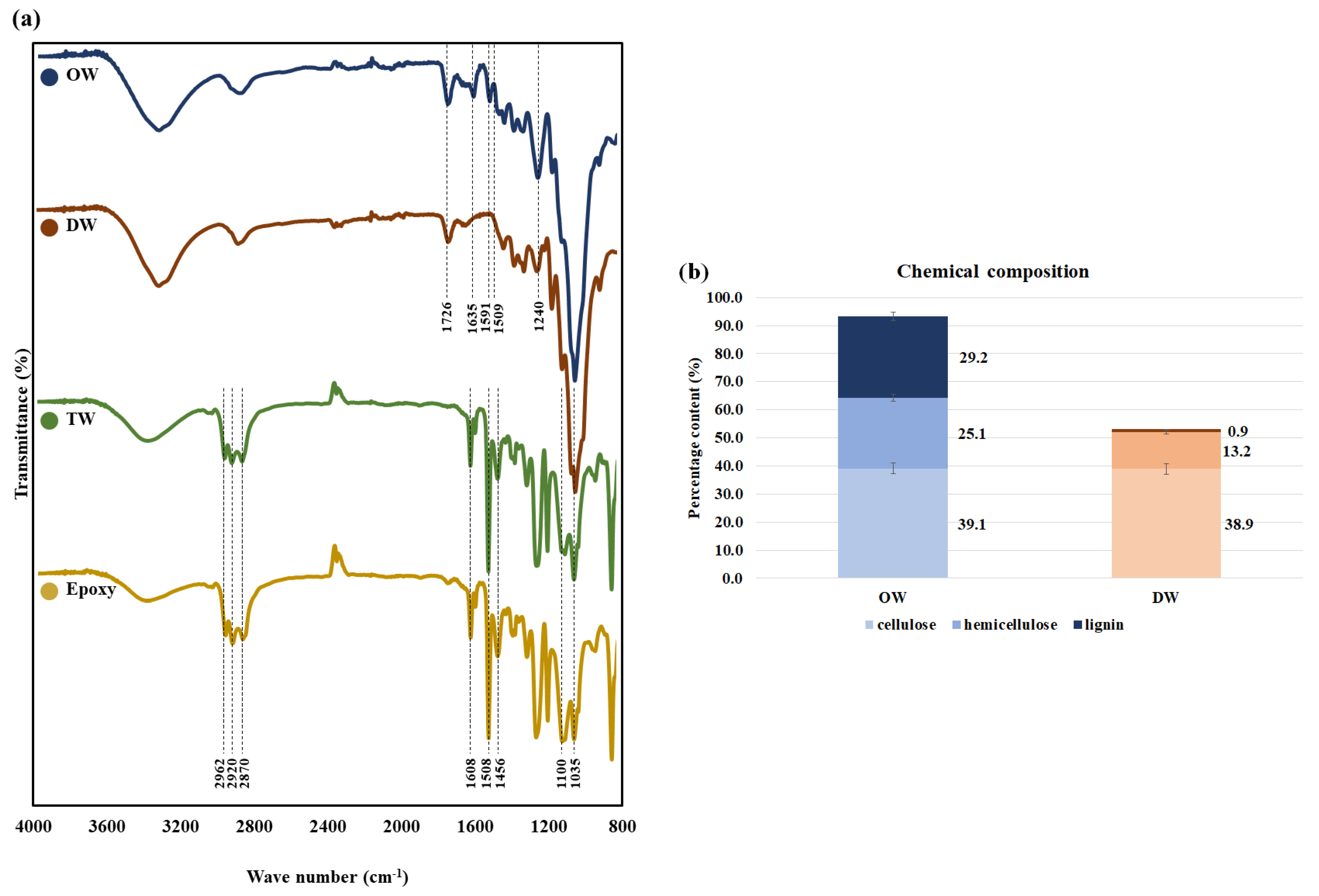

3.2. Functional Group Analysis

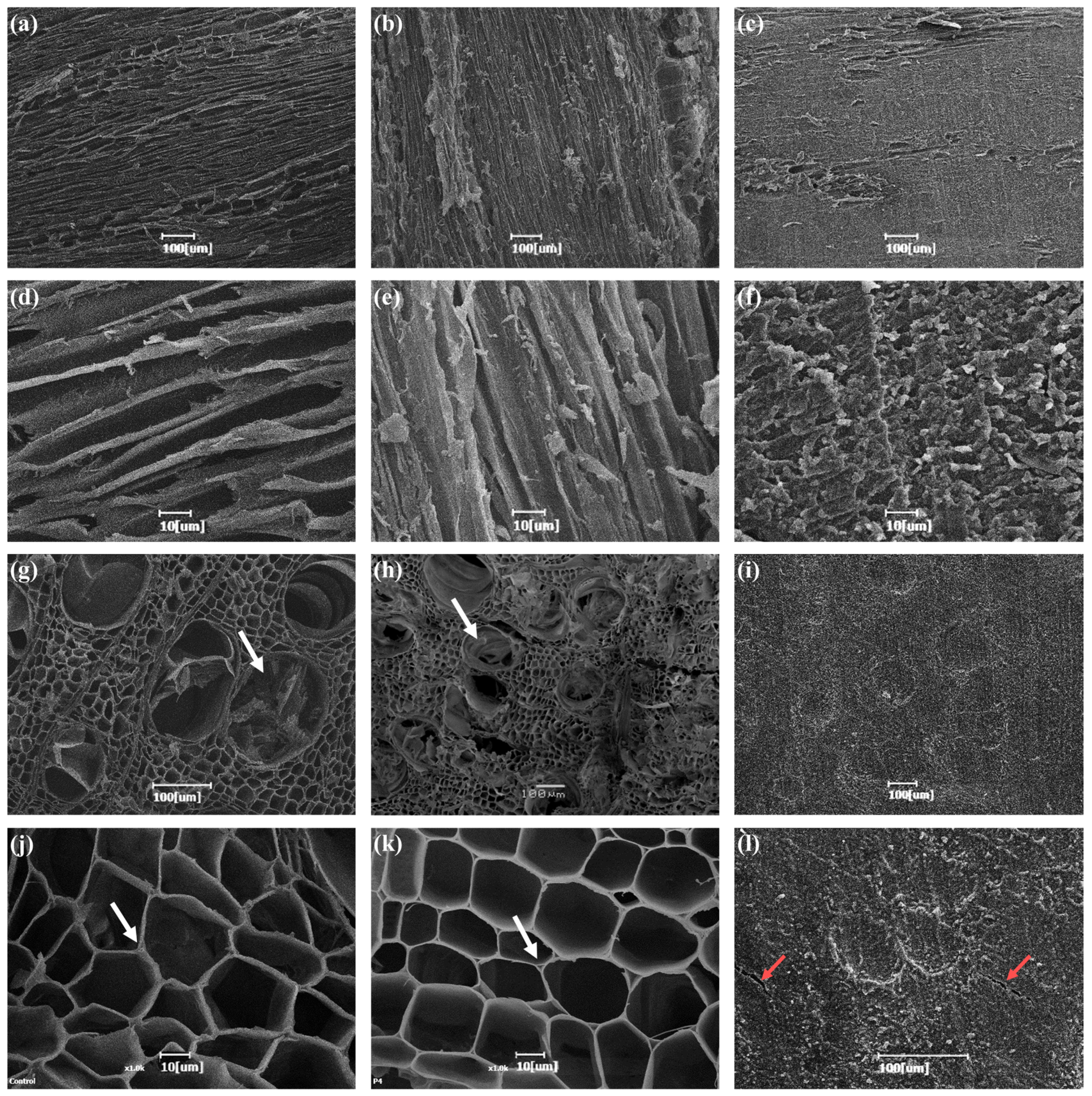

3.3. Changes in Cell Wall Structures

3.4. Transmittance by Section

3.5. Bending Strength by Section

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Keckes, J.; Burgert, I.; Frühmann, K.; Müller, M.; Kölln, K.; Hamilton, M.; Fratzl, P. Cell-wall recovery after irreversible deformation of wood. Nat. Mater. 2003, 2, 810–813. [Google Scholar] [CrossRef] [PubMed]

- Fratzl, P.; Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef]

- Payen, A. Mémoire sur la composition du tissu propre des plantes et du ligneux. Comptes Rendus 1838, 7, 1052–1056. [Google Scholar]

- Jungstedt, E.; Montanari, C.; Östlund, S.; Berglund, L. Mechanical properties of transparent high strength biocomposites from delignified wood veneer. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105853. [Google Scholar] [CrossRef]

- Xu, X. Wood modification with resin impregnation technology for value-added services. SVOA Mater. Sci. Technol. 2020, 2, 9–21. [Google Scholar]

- Fink, S. Transparent wood–a new approach in the functional study of wood structure. Holzforschung 1992, 46, 403–408. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yu, S.; Veinot, J.G.; Linnros, J.; Berglund, L.; Sychugov, I. Luminescent transparent wood. Adv. Opt. Mater. 2017, 5, 1600834. [Google Scholar] [CrossRef]

- Mi, R.; Chen, C.; Keplinger, T.; Pei, Y.; He, S.; Liu, D.; Hu, L. Scalable aesthetic transparent wood for energy efficient buildings. Nat. Commun. 2020, 11, 3836. [Google Scholar] [CrossRef]

- Li, T.; Song, J.; Zhao, X.; Yang, Z.; Pastel, G.; Xu, S.; Hu, L. Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose. Sci. Adv. 2018, 4, eaar3724. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Xu, S.; Kuang, Y.; Gan, W.; Song, J.; Chen, G.; Hu, L. Nature-inspired tri-pathway design enabling high-performance flexible Li–O2 batteries. Adv. Energy Mater. 2019, 9, 1802964. [Google Scholar] [CrossRef]

- Gibbs, H.K.; Ruesch, A. No. Cdiac: New IPCC Tier-1 Global Biomass Carbon Map for the Year 2000; Environmental System Science Data Infrastructure for a Virtual Ecosystem (ESS-DIVE); Carbon Dioxide Information Analysis Center: Oak Ridge, TN, USA, 2008.

- Li, Y.; Yang, X.; Fu, Q.; Rojas, R.; Yan, M.; Berglund, L. Towards centimeter thick transparent wood through interface manipulation. J. Mater. Chem. A 2018, 6, 1094–1101. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, J.H.; Kim, J.H.; Cho, S.M.; Yeon, S.H.; Jeong, H.S.; Lee, S.M.; Choi, I.G. Peracetic acid-induced kraft lignin solubilization and its characterization for selective production of macromolecular biopolymers. Int. J. Biol. Macromol. 2020, 161, 1240–1246. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.; Wang, Z.; Xie, D.; Zhao, P.; Sun, J.; Qin, D.; Cheng, F. Flexible transparent wood enabled by epoxy resin and ethylene glycol diglycidyl ether. J. For. Res. 2021, 32, 1779–1787. [Google Scholar] [CrossRef]

- Wachter, I.; Štefko, T.; Rantuch, P.; Martinka, J.; Pastierová, A. Effect of UV radiation on optical properties and hardness of transparent wood. Polymers 2021, 13, 2067. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Dong, Y.; Ling, Z.; Liu, X.; Shi, S.Q.; Li, J. Transparent wood developed by introducing epoxy vitrimers into a delignified wood template. Compos. Sci. Technol. 2021, 207, 108690. [Google Scholar] [CrossRef]

- Ma, R. Dicarboxylic Acids Platform Chemicals for Valorization of Biorefinery Lignin; Washington State University: Washington, DC, USA, 2016. [Google Scholar]

- Park, S.Y.; Cho, S.M.; Kim, J.C.; Hong, C.; Kim, S.H.; Ryu, G.H.; Choi, I.G. Effects of peracetic acid and hydrogen peroxide concentration on kraft lignin degradation at room temperature. BioResources 2019, 14, 4413–4429. [Google Scholar]

- Kundu, C.; Samudrala, S.P.; Kibria, M.A.; Bhattacharya, S. One-step peracetic acid pretreatment of hardwood and softwood biomass for platform chemicals production. Sci. Rep. 2021, 11, 11183. [Google Scholar] [CrossRef] [PubMed]

- Montanari, C.; Olsén, P.; Berglund, L.A. Interface tailoring by a versatile functionalization platform for nanostructured wood biocomposites. Green Chem. 2020, 22, 8012–8023. [Google Scholar] [CrossRef]

- Bisht, P.; Pandey, K.K.; Barshilia, H.C. Photostable transparent wood composite functionalized with an UV-absorber. Polym. Degrad. Stab. 2021, 189, 109600. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Y.; Yang, F.; Tang, C.; Huang, Q.; Zhang, J. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Hu, L. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Bilotti, E.; Bastiaansen, C.W.; Peijs, T. Transparent semi-crystalline polymeric materials and their nanocomposites: A review. Polym. Eng. Sci. 2020, 60, 2351–2376. [Google Scholar] [CrossRef]

- Qin, J.; Li, X.; Shao, Y.; Shi, K.; Zhao, X.; Feng, T.; Hu, Y. Optimization of delignification process for efficient preparation of transparent wood with high strength and high transmittance. Vacuum 2018, 158, 158–165. [Google Scholar] [CrossRef]

- Lang, A.W.; Li, Y.; De Keersmaecker, M.; Shen, D.E.; Österholm, A.M.; Berglund, L.; Reynolds, J.R. Transparent Wood Smart Windows: Polymer Electrochromic Devices Based on Poly (3, 4-Ethylenedioxythiophene): Poly (Styrene Sulfonate) Electrodes. ChemSusChem 2018, 11, 854–863. [Google Scholar] [CrossRef]

- Jia, C.; Chen, C.; Mi, R.; Li, T.; Dai, J.; Yang, Z.; Hu, L. Clear wood toward high-performance building materials. ACS Nano 2019, 13, 9993–10001. [Google Scholar] [CrossRef]

- Wang, X.; Zhan, T.; Liu, Y.; Shi, J.; Pan, B.; Zhang, Y.; Shi, S.Q. Large-size transparent wood for energy-saving building applications. ChemSusChem 2018, 11, 4086–4093. [Google Scholar] [CrossRef]

| Total Transmittance (%) | Parallel Transmittance (%) | Diffuse Transmittance (%) | Haze (%) | |

|---|---|---|---|---|

| Epoxy | 91.46 (±0.23) | 87.11 (±0.38) | 4.35 (±0.24) | 4.76 (±0.26) |

| TWc | 91.25 (±0.81) | 3.46 (±0.19) | 87.80 (±0.74) | 96.21 (±0.19) |

| TWt | 87.98 (±1.60) | 19.06 (±11.29) | 68.92 (±9.69) | 78.48 (±12.32) |

| OWc | TWc | OWt | TWt | |

|---|---|---|---|---|

| MOE (MPa) | 856.80 (±277.58) | 1406.45 (±284.54) | 4613.47 (±1636.48) | 6089.88 (±1207.09) |

| MOR (MPa) | 8.70 (±0.77) | 41.22 (±3.79) | 56.90 (±16.45) | 96.99 (±14.22) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.-C.; Kim, B.; Park, H.; Kim, Y.; Park, S.-Y. Characterization of a Translucent Material Produced from Paulownia tomentosa Using Peracetic Acid Delignification and Resin Infiltration. Polymers 2022, 14, 4380. https://doi.org/10.3390/polym14204380

Park K-C, Kim B, Park H, Kim Y, Park S-Y. Characterization of a Translucent Material Produced from Paulownia tomentosa Using Peracetic Acid Delignification and Resin Infiltration. Polymers. 2022; 14(20):4380. https://doi.org/10.3390/polym14204380

Chicago/Turabian StylePark, Kyoung-Chan, Byeongho Kim, Hanna Park, Yesun Kim, and Se-Yeong Park. 2022. "Characterization of a Translucent Material Produced from Paulownia tomentosa Using Peracetic Acid Delignification and Resin Infiltration" Polymers 14, no. 20: 4380. https://doi.org/10.3390/polym14204380

APA StylePark, K.-C., Kim, B., Park, H., Kim, Y., & Park, S.-Y. (2022). Characterization of a Translucent Material Produced from Paulownia tomentosa Using Peracetic Acid Delignification and Resin Infiltration. Polymers, 14(20), 4380. https://doi.org/10.3390/polym14204380