Comparative Study on the Behavior of Reinforced Concrete Beam Retrofitted with CFRP Strengthening Techniques

Abstract

1. Introduction

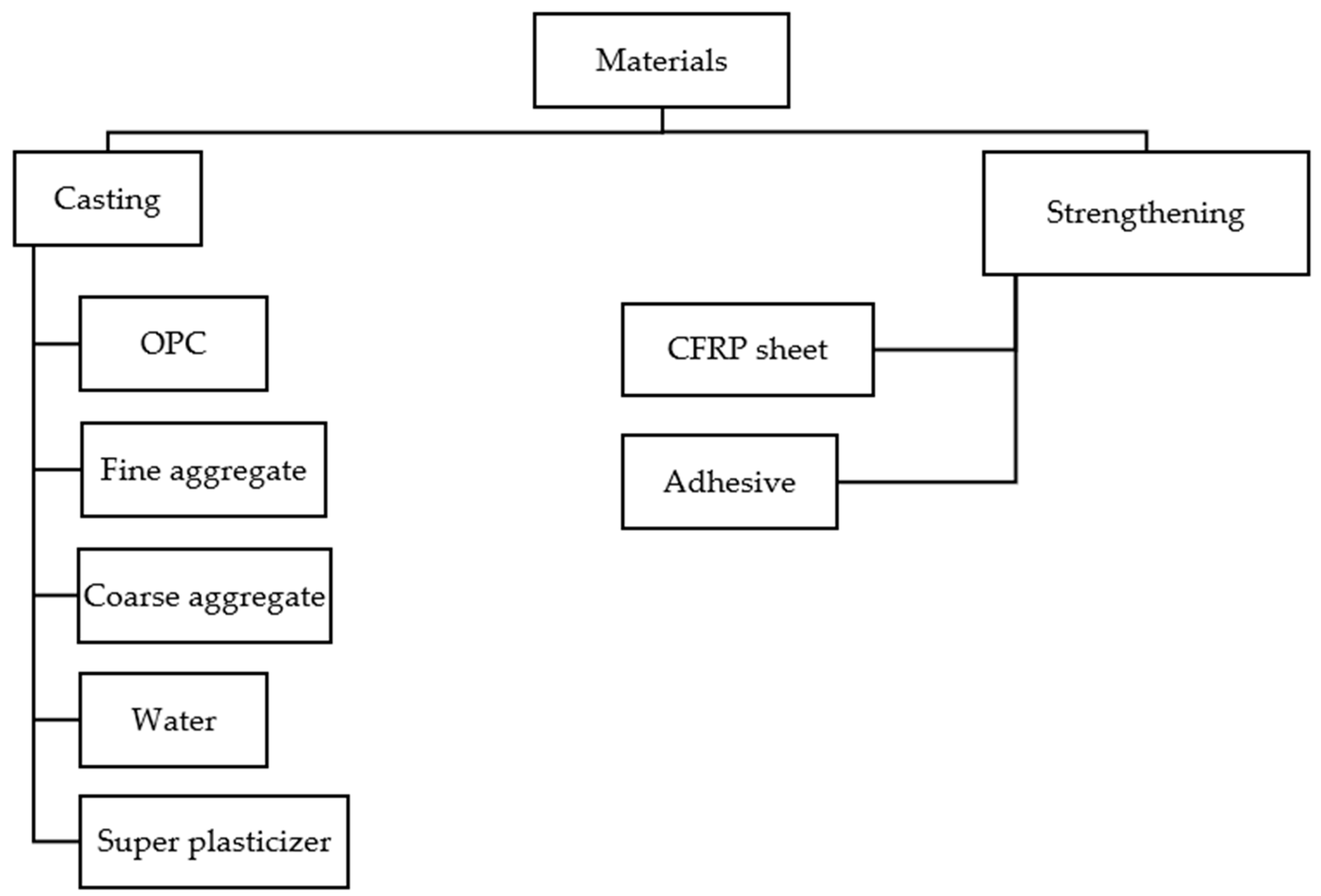

2. Specimen Details and Material Properties

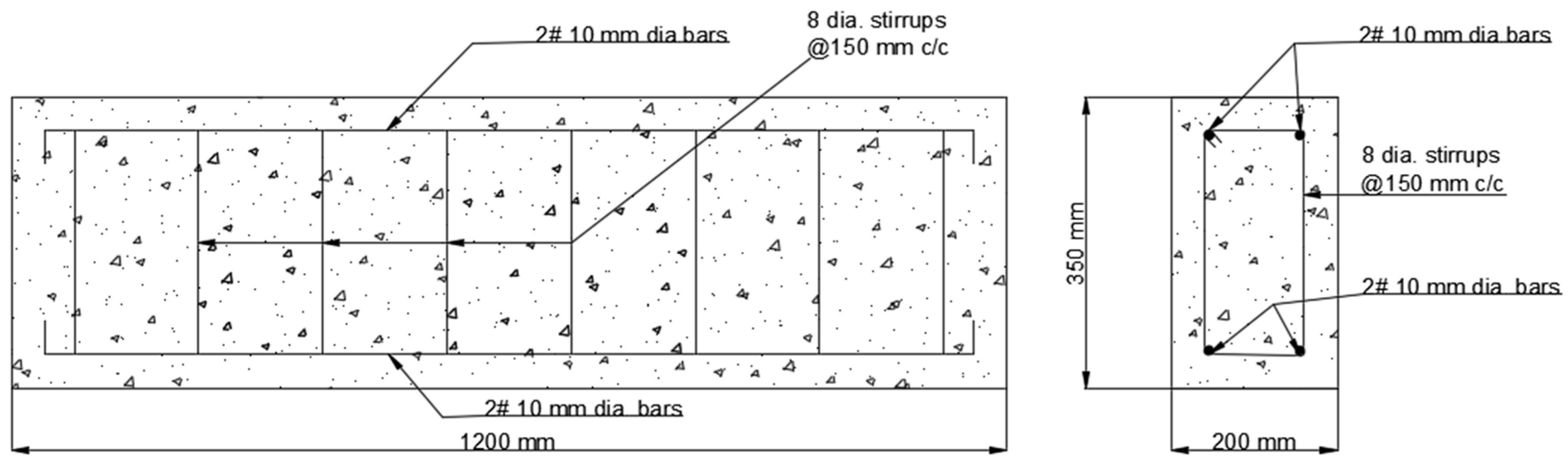

2.1. Specimen Details

2.2. Material Used for Casting of Beam

2.2.1. Ordinary Portland Cement (OPC)

2.2.2. Aggregates

| Property | Value |

|---|---|

| Specific gravity | 2.71 |

| Shape | Angular |

| Fineness Modulus | 2.25 |

| Color | Grey |

| Maximum size | 20 |

| IS Sieve Size (mm) | Weight of Aggregate Retained | % of Total Weight Retained | Cumulative % Retained | % Age Passing | |||

|---|---|---|---|---|---|---|---|

| I | II | III | Avg. | ||||

| 20 | 23 | 35 | 61 | 39.7 | 3.8 | 3.6 | 96.1 |

| 16 | 113 | 63 | 89 | 86.3 | 8.6 | 13.6 | 86.3 |

| 12.5 | 271 | 179 | 280 | 250.8 | 23.9 | 25.9 | 64.4 |

| 10 | 352 | 389 | 329 | 349.6 | 34.7 | 73.3 | 28.1 |

| 4.75 | 239 | 323 | 239 | 269.8 | 27.9 | 100.1 | 0.7 |

| PAN | 9 | 11 | 3 | 7.0 | 0.7 | ||

| Property | Value |

|---|---|

| Specific Gravity | 2.70 |

| Fineness | 2.79 |

| Water Absorption | 0.6% |

| IS Sieve Size (mm) | Weight of Aggregate Retained | % of Total Weight Retained | Cumulative % Retained | % Age Passing | |||

|---|---|---|---|---|---|---|---|

| I | II | III | Avg. | ||||

| 10 mm | - | - | - | - | - | - | - |

| 4.75 mm | 40 | 30 | 38 | 36 | 3.6 | 3.6 | 96.4 |

| 2.36 mm | 31 | 28 | 28 | 29 | 2.9 | 6.5 | 93.5 |

| 1.18 mm | 52 | 40 | 42 | 44.7 | 4.5 | 10.9 | 89.0 |

| 600 μ | 82 | 74 | 72 | 76 | 7.6 | 18.6 | 81.4 |

| 300 μ | 318 | 238 | 290 | 282 | 28.2 | 46.8 | 53.2 |

| 150 μ | 438 | 510 | 464 | 470.7 | 47.1 | 93.8 | 6.2 |

| 75 μ | 36 | 68 | 56 | 53.3 | 5.3 | 99.2 | 0.8 |

| PAN | 3 | 12 | 10 | 8.3 | 0.8 | - | - |

2.2.3. Superplasticizer

2.2.4. CFRP Sheet

2.2.5. Sikadur 330 IN

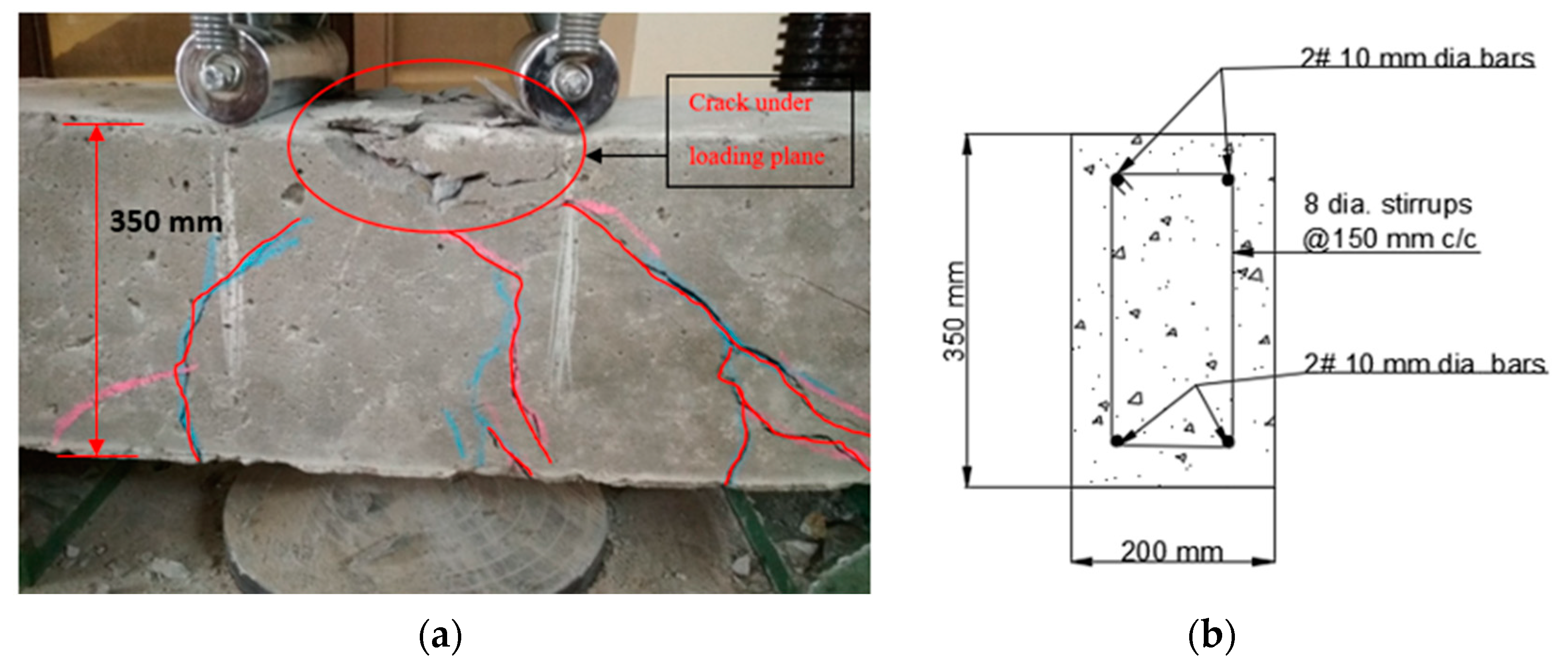

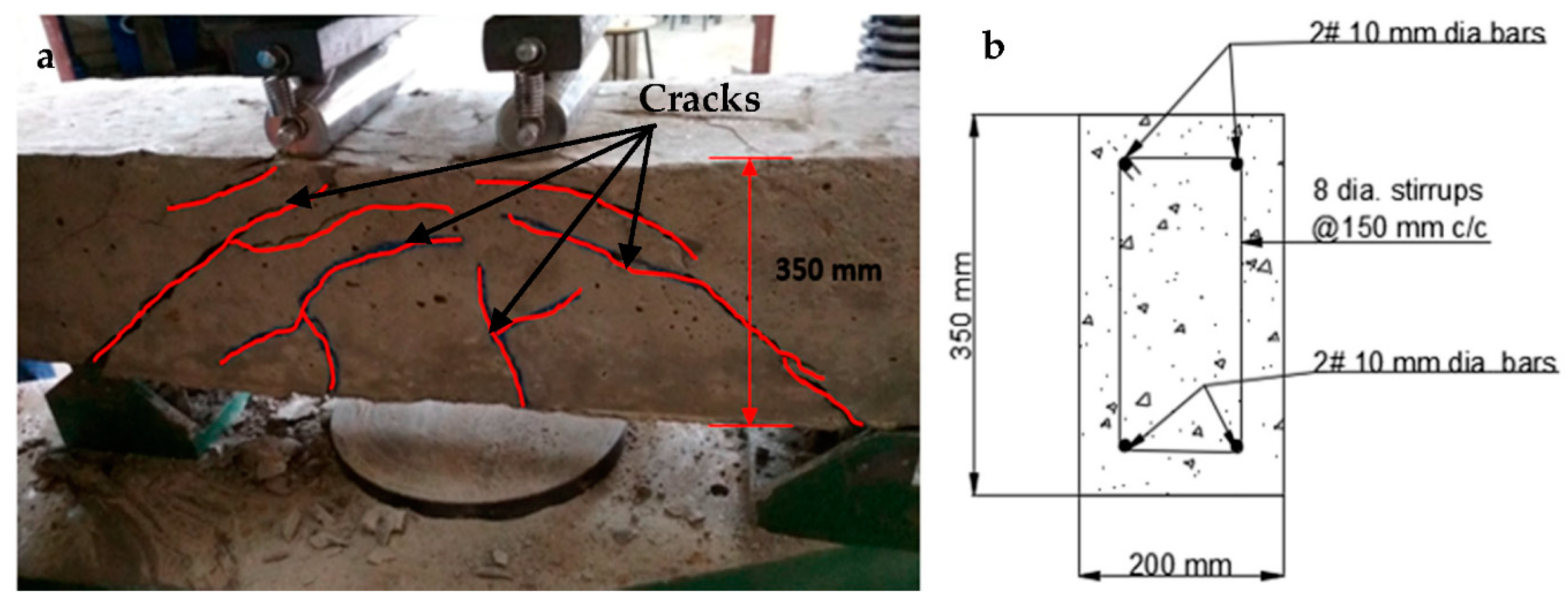

3. Experimental Program

3.1. Loading on Controlled Beam

3.2. Retrofitting of Beams

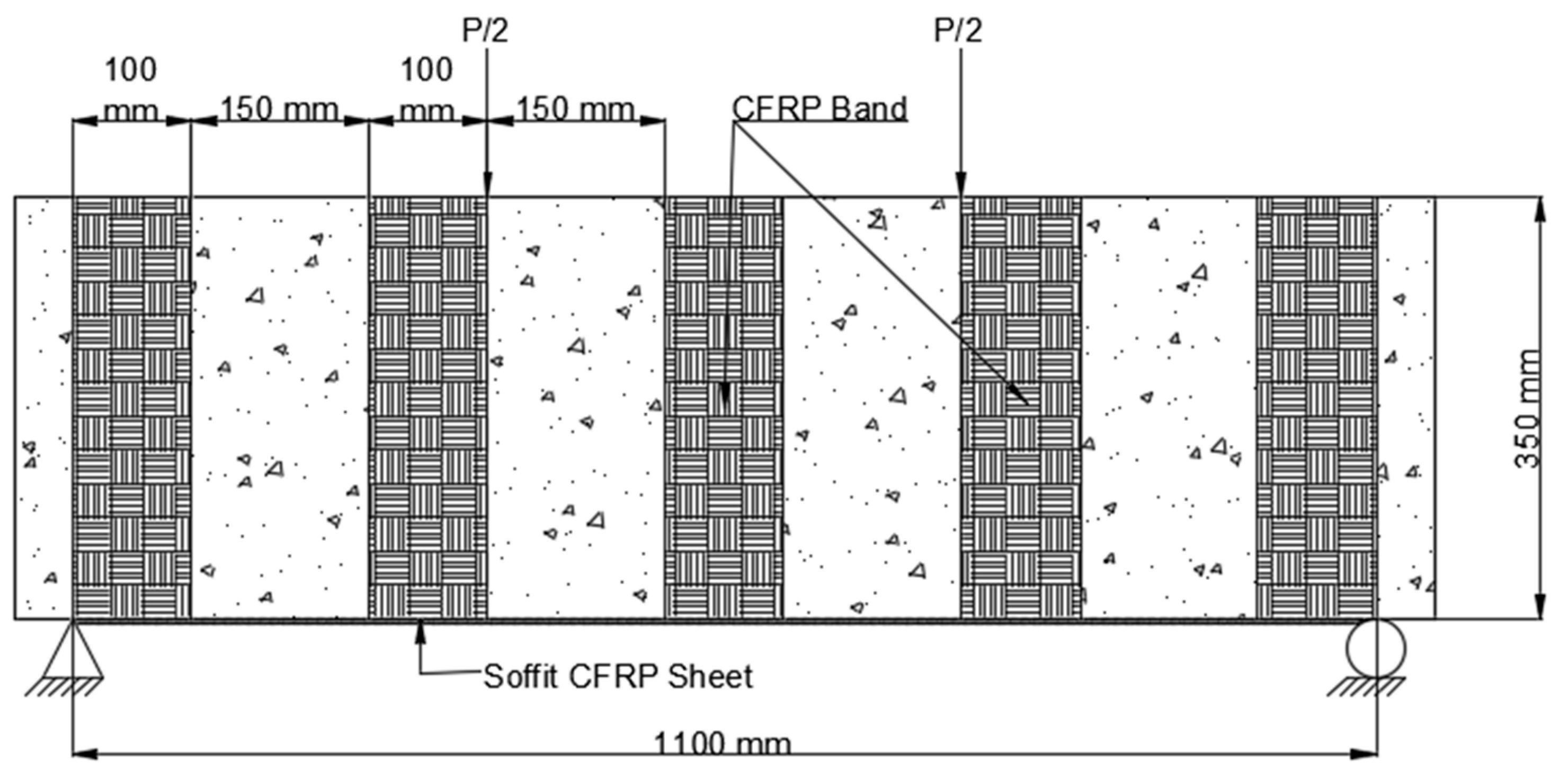

- As depicted in Figure 8, the U-straps were located every 150 mm and wrapped the beam’s bottom surface, as well as both sides and faces, to a height of 350 mm in Scheme 1 (B1). The U-straps were 100 mm in width. The U-shaped CFRP sheets were applied to reinforce the beams in both shear and flexural modes, as well as to demonstrate a flexural failure model.

- 2.

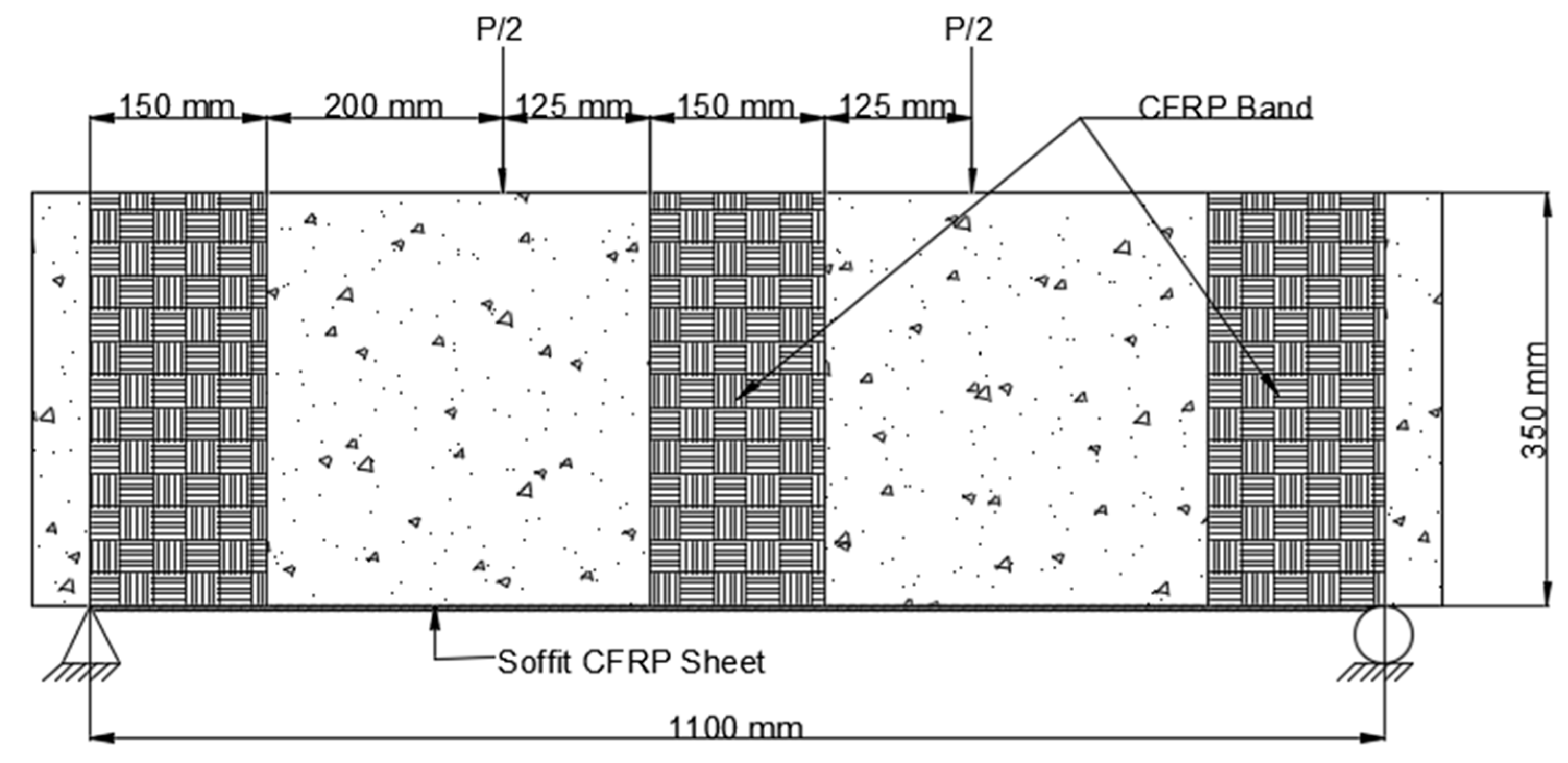

- Two U-straps were mounted at the end of the tension face CFRP sheet and one in the center of the beam in Scheme 2 (B2), which was similar to Scheme 1. They encased the soffit and extended it on both sides of 350 mm in height. The U-straps had a width of 150 mm. Figure 9 shows how U-straps were used to secure the CFRP flexural face sheet and prevent it from debonding.

- 3.

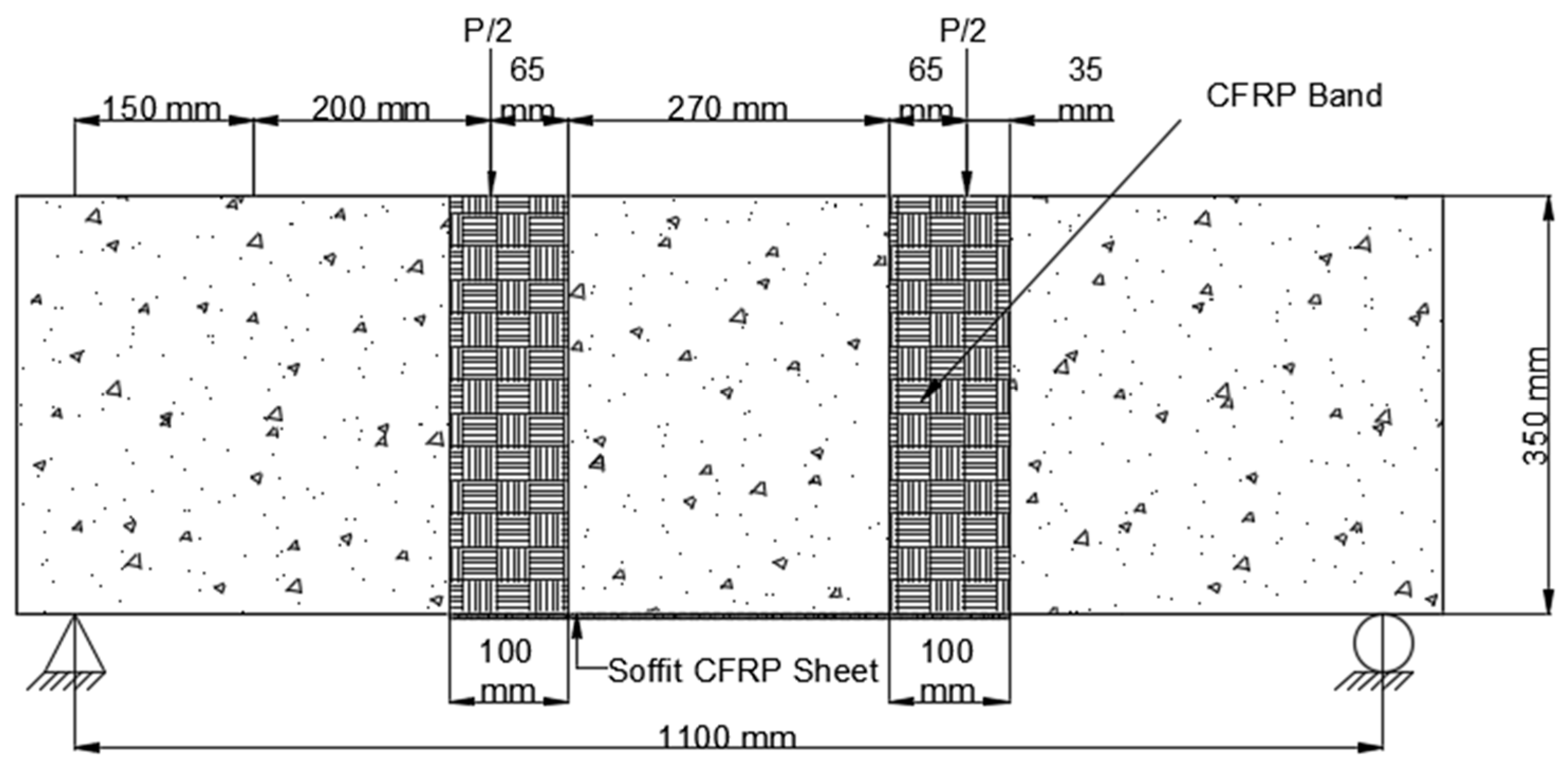

- The CFRP sheet used in Scheme 3 (B3) was 1100 mm long and 200 mm wide, with fibers arranged parallel to the axis of the beam. This CFRP sheet was encased across the side faces of the beam to a height of 65 mm above the tension face, as shown in Figure 10.

- 4.

- Scheme 4 (B4) was similar to Scheme 2, with the exception that the CFRP sheet was enclosed across the side faces of the beam to a height of 150 mm above the tension face, as shown in Figure 11.

- The CFRP sheet was implemented in the constant moment area in Scheme 5 (B5). Two CFRP U-straps with fibers aligned in the direction of the beam’s longitudinal axis, which was bounded by the soffit, were mounted under the load point. The CFRP sheet was 470 mm long and 200 mm broad, and the fibers aligned in a direction corresponding to the longitudinal axis of the beam, which was confined to the beam’s soffit (i.e., oblique direction). Thoroughly wrapped the beam’s bottom surface and covered both sides to a width of 100 mm and a height of 350 mm, as shown in Figure 12.

- 2.

- The constant moment zone, which was 470 mm long and 250 mm wide, was also applied to Scheme 6. (B6). As indicated in Figure 13, the CFRP sheet was wrapped across the beam side to a height of 350 mm above the tension face of the beam.

- 3.

- Scheme 7 (B7) was equivalent to Scheme 3, except the CFRP sheet was 370 mm long and placed at the constant moment zone (see Figure 14).

4. Results and Discussions

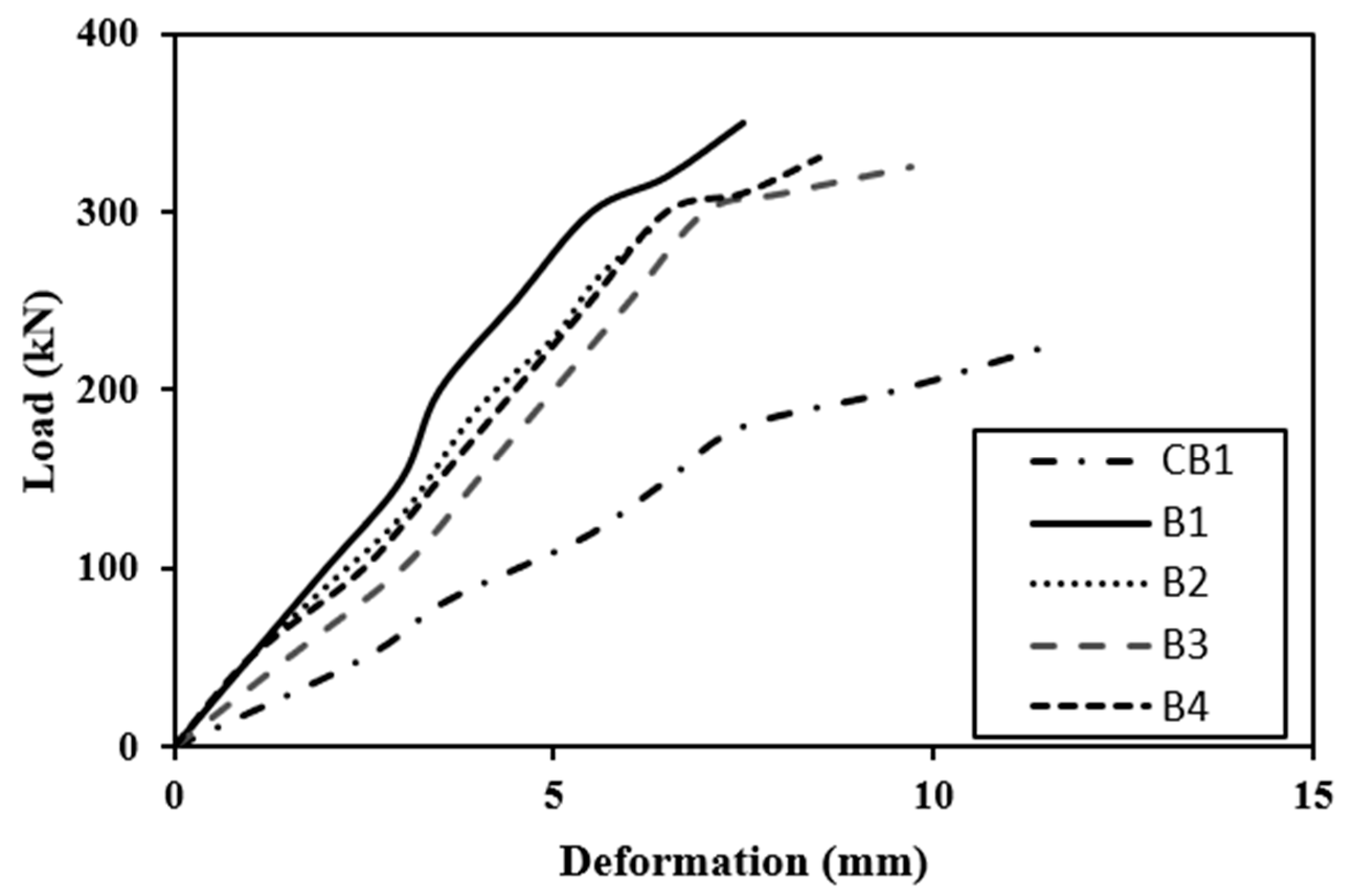

4.1. Load-Deflection Behavior

4.1.1. Controlled Beam (CB1)

4.1.2. Strengthened Beams

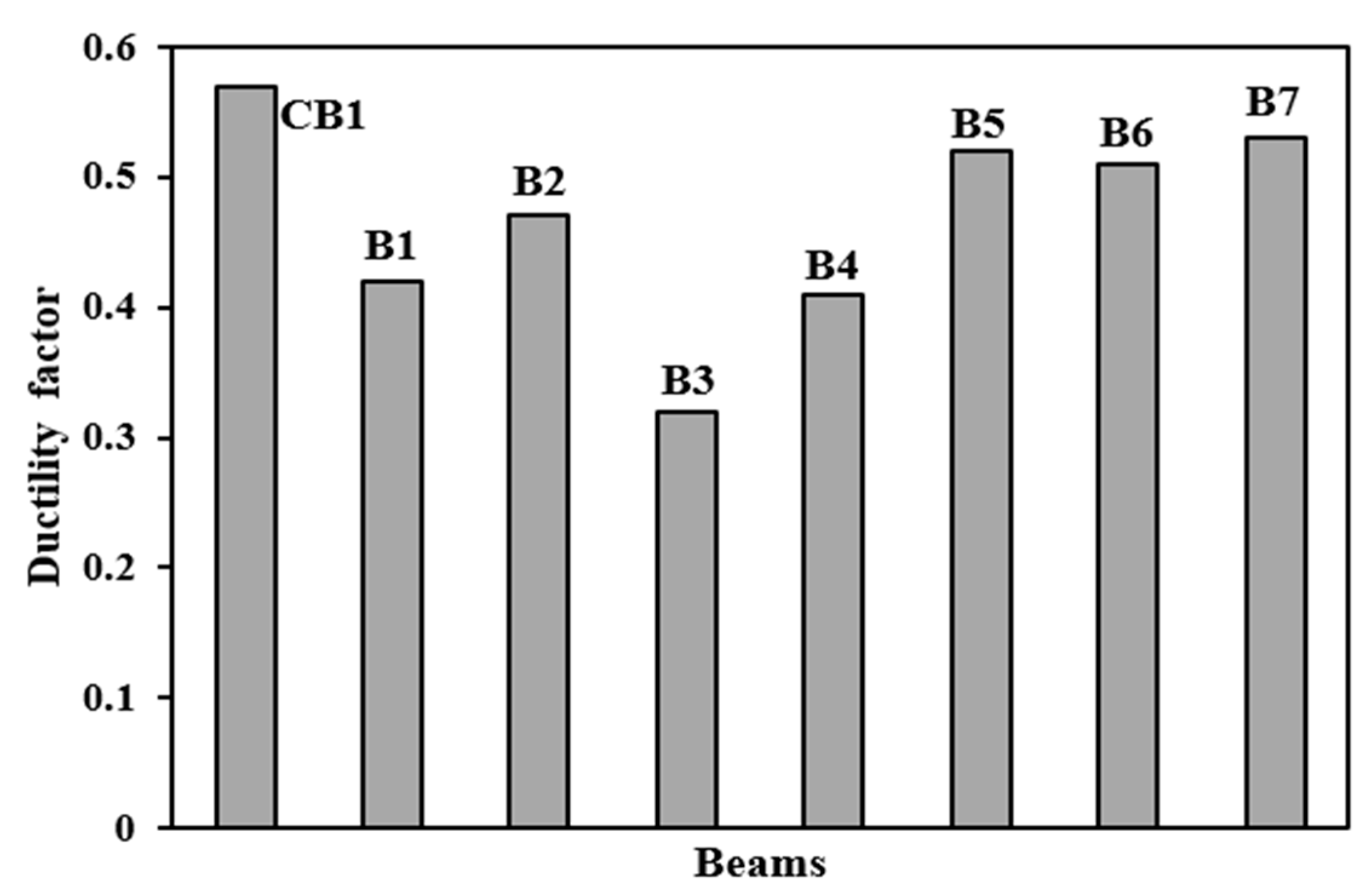

4.2. Ductility Factor

4.3. Stress–Strain Behavior of Beams

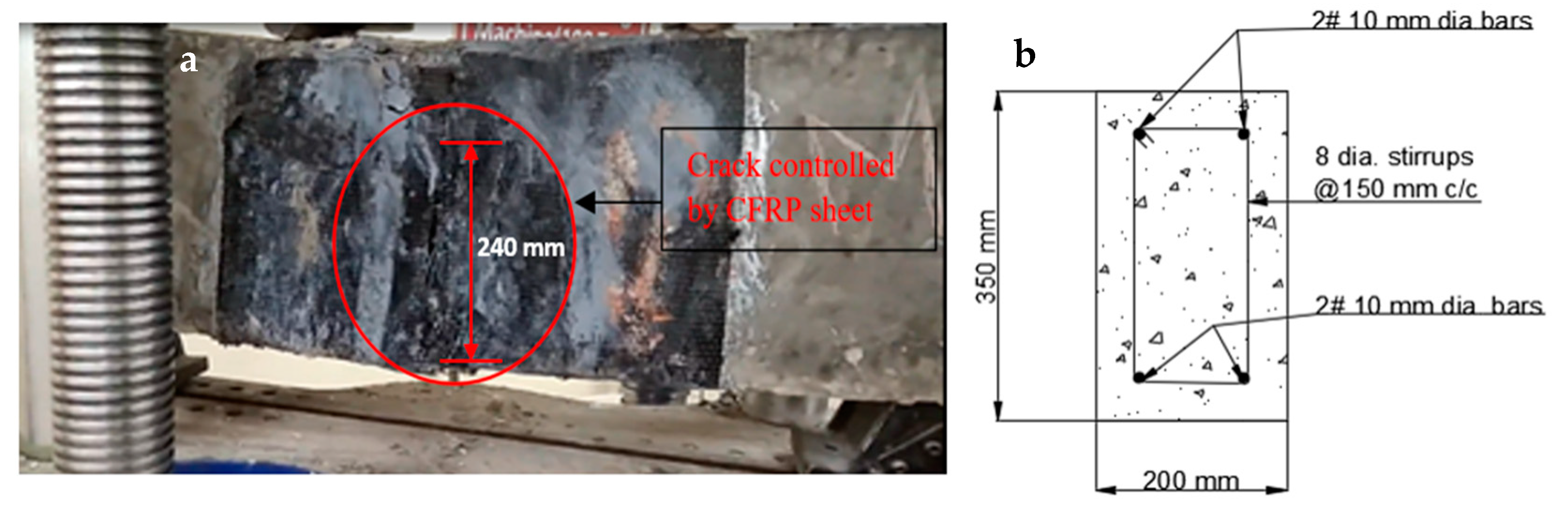

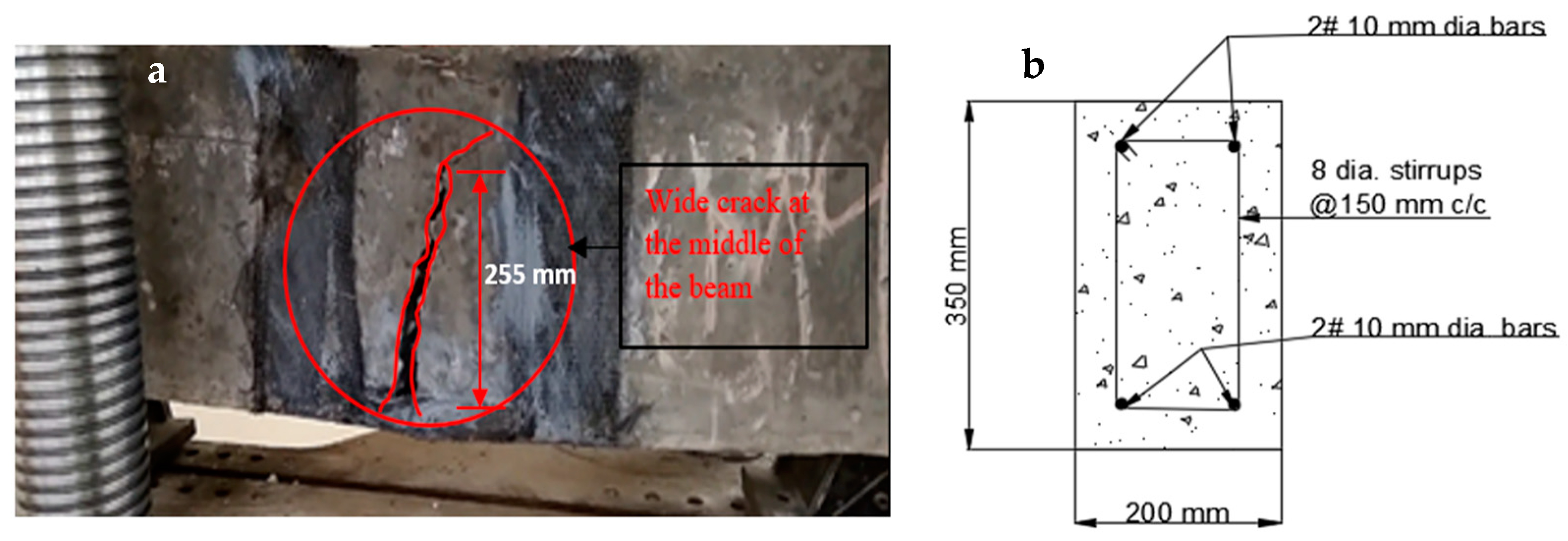

4.4. Modes of Failures and Crack Patterns

4.4.1. Different Types of Failures

4.4.2. Crack Patterns

5. Conclusions

- When CFRP sheets are used to reinforce preloaded damaged RC beams, functional stability is lost while the maximum load of the damaged beams is increased beyond that of the control beam. The CFRP sheet strengthening technique was more significant than the overall number applied to enhance the strengthening of damaged beams, as demonstrated in the Series A and Series B beams.

- Wrapping CFRP sheet across side faces of RC beams with tension face bonding provided adequate stiffness and bearing of the ultimate load to a significant extent, as seen in B3, B4, and B7 beams while wrapping the hogging moment zone of the beams with the approaches discussed effectively restored the beams’ strength.

- The U-shaped CFRP sheet anchors the tension facing CFRP and inhibits it from debonding. In preloaded beams, the use of a U-shaped CFRP sheet is advantageous. In the B1, B2, and B5 beams, the stiffness of retrofitted CFRP sheets was enhanced when contrasted to the stiffness of the control beam.

- At first, the stress distribution in concrete was linear. The distribution of concrete stress becomes nonlinear after a cracking load. The proper anchorage of the CFRP sheet to the supports is responsible for the linear variation in strain. The proper anchorage prevented the CFRP sheet from debonding from the concrete.

- The deformation of the retrofitted beam is reduced to a point below the control beam when the CFRP sheet is utilized for retrofitting. CFRP sheet retrofitting beams have more reduced failure widths than the control beams. The study reveals that flexural failure is the most common failure mode, including concrete crushing and steel rupture, which improve retrofitting effectiveness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Achudhan, D.; Vandhana, S.; Shalini. Strengthening and retrofitting of RC beams using fiber-reinforced polymers. Mater. Today Proc. 2019, 16, 361–366. [Google Scholar] [CrossRef]

- Kim, H.S.; Shin, Y.S. Flexural behavior of reinforced concrete (RC) beams retrofitted with hybrid fiber-reinforced polymers (FRPs) under sustaining loads. Compos. Struct. 2011, 93, 802–811. [Google Scholar] [CrossRef]

- Jawdhari, A.; Harik, I.; Fam, A. Behavior of reinforced concrete beams strengthened with CFRP rod panels CRP 195. Structures 2018, 16, 239–253. [Google Scholar] [CrossRef]

- Baggio, D.; Soudki, K.; Noël, M. Strengthening of shear critical RC beams with various FRP systems. Constr. Build. Mater. 2014, 66, 634–644. [Google Scholar] [CrossRef]

- SAllam, S.M.; Ebeido, T.I. Retrofitting of RC beams pre-damaged in shear using CFRP sheets. Alex. Eng. J. 2003, 42, 87–101. [Google Scholar]

- Bousselham, A.; Chaallal, O. Experimental investigations on the influence of size on the performance of RC T-beams retrofitted in shear with CFRP fabrics. Eng. Struct. 2013, 56, 1070–1079. [Google Scholar] [CrossRef]

- Holschemacher, K.; Iqbal, S.; Ali, A.; Bier, T.A. Strengthening of RC beams using lightweight self-compacting cementitious composite. Procedia Eng. 2017, 172, 369–376. [Google Scholar] [CrossRef]

- Alhadid, M.M.A.; Youssef, M.A. Analysis of reinforced concrete beams strengthened using concrete jackets. Eng. Struct. 2017, 132, 172–187. [Google Scholar] [CrossRef]

- Mansour, W.; Tayeh, B.A. The shear behaviour of RC beams strengthened by various ultra-high-performance fiber-reinforced concrete systems. Adv. Civ. Eng. 2020, 18, 2139054. [Google Scholar] [CrossRef]

- Khalaf, Q.A. Comparative Study for Strengthening Techniques of RC Beams Using Concrete Jackets and Steel Plates. Master’s Thesis, The Islamic University of Gaza, Gaza, Palestine, 2015. [Google Scholar]

- Heiza, K.; Nabil, A.; Meleka, N.; Tayel, M. State-of-the-art review: Strengthening of reinforced concrete structures e different strengthening techniques. In Proceedings of the 6th International Conference on Nanotechnology in Construction, Cairo, Egypt, 1 March 2014; Volume 6. [Google Scholar]

- Abu Hamam, I.M. Rehabilitation Needs for Existing Buildings in the Gaza Strip. Master’s Thesis, The Islamic University of Gaza, Gaza, Palestine, 2008. [Google Scholar]

- Ziara, M.; Touqan, S.; Naser, K. Evaluation of Housing Affordability and Conditions in PALESTINE, Special Presentation. In Proceedings of the International Conference on Affordable Housing in Palestine, Birzeit University, Birzeit, Palestine, 1–3 November 1996. [Google Scholar]

- Attar, H.S.; Esfahani, M.R.; Ramezani, A. Experimental investigation of flexural and shear strengthening of RC beams using fiber-reinforced self-consolidating concrete jackets. Structure 2020, 27, 46–53. [Google Scholar] [CrossRef]

- Hassan, A.; Aldhafairi, F.; Abd-EL-Hafez, L.M.; Abouelezz, A.E.Y. Retrofitting of different types of reinforced concrete beams after exposure to elevated temperature. Eng. Struct. 2019, 194, 420–430. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Papadopoulos, C.P.; Pourzitidis, C.N.; Fotis, D.; Sideris, K.K. Application of a Reinforced Self-Compacting Concrete Jacket in damaged reinforced concrete beams under monotonic and repeated loading. J. Eng. 2013, 2013, 912983. [Google Scholar] [CrossRef]

- Hussein, M.; Kunieda, M.; Nakamura, H. Strength and ductility of RC beams strengthened with steel-reinforced strain-hardening cementitious composites. Cem. Concr. Compos. 2012, 34, 1061–1066. [Google Scholar] [CrossRef]

- Shahidan, S.; Tayeh, B.A.; Jamaludin, A.A.; Bahari, N.A.A.S.; Mohd, S.S.; Ali, N.Z.; Khalid, F.S. Physical and mechanical properties of self-compacting concrete containing superplasticizer and metakaolin. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012004. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Thermou, G.E.; Pantazopoulou, S.J. Behaviour of rehabilitated RC beams with self-compacting concrete jacketing—Analytical model and test results. Constr. Build. Mater. 2014, 55, 257–273. [Google Scholar] [CrossRef]

- Deifalla, A. Refining the torsion design of fibered concrete beams reinforced with FRP using multi-variable non-linear regression analysis for experimental results. Eng. Struct. 2021, 226, 111394. [Google Scholar] [CrossRef]

- Salem, N.M.; Deifalla, A. Evaluation of the Strength of Slab-Column Connections with FRPs Using Machine Learning Algorithms (Open Access). Polymers 2022, 14, 1517. [Google Scholar] [CrossRef]

- Yao, Z.H.; Yao, Q.L.; Huang, S.M.; Song, B. Experimental Study on Flexural Behavior of RC Beams Strengthened with SMPM. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008; pp. 12–17. [Google Scholar]

- Gayathri, S.; Kirthiga, T. Experimental and analytical investigation of RC beam with welded wire mesh as shear reinforcement. Int. Res. J. Eng. Technol. 2018, 5, 2078–2081. [Google Scholar]

- Sayhood, E.K.; Ali, A.A.; Sharhan, Z.S. Strengthening of two-way reinforced concrete slabs using different techniques. Int. J. Curr. Eng. Technol. 2017, 7, 993–1000. [Google Scholar]

- Zhang, W.; Liu, X.; Huang, Y.; Tong, M.N. Reliability-based analysis of the flexural strength of concrete beams reinforced with hybrid BFRP and steel rebars. Archiv. Civ. Mech. Eng. 2022, 22, 171. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Naja, M.; Shihada, S.; Arafa, M. Repairing and strengthening of damaged RC columns using thin concrete jacketing. Adv. Civ. Eng. 2019, 2019, 2987412. [Google Scholar] [CrossRef]

- Hallaq, A.A.; Tayeh, B.A.; Shihada, S. Investigation of the bond strength between existing concrete substrate and UHPC as a repair material. Int. J. Eng. Adv. Technol. 2017, 6, 210–217. [Google Scholar]

- Tayeh, B.A.; Abu Bakar, B.H.; Johari, M.A.M.; Zeyad, A.M. Microstructural analysis of the adhesion mechanism between old concrete substrate and UHPFC. J. Adhes. Sci. Technol. 2014, 28, 1846–1864. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Johari, M.A.; Voo, Y.L. Evaluation of bond strength between normal concrete substrate and ultra-high-performance fiber concrete as a repair material. Procedia Eng. 2013, 54, 554–563. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.A.; Johari, M.M. Mechanical properties of old concrete-UHPFC interface. In Proceedings of the Concrete Repair, Rehabilitation and Retrofitting III: 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR-3, Cape Town, South Africa, 3–5 September 2012; CRC Press: Boca Raton, FL, USA, 2012; p. 373. [Google Scholar]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Ratnam, M.M. Existing concrete textures: Their effect on adhesion with fiber concrete overlay. Proc. Inst. Civ. Eng. Struct. Build. 2014, 167, 355–368. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, W.; Luo, Y.; Wang, L.; Peng, J.; Zhang, J. Interface shear strength between self-compacting concrete and carbonated concrete. J. Mater. Civ. Eng. 2020, 32, 04020113. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Luo, Y.; Wang, L. Effects of interface orientations on bond strength between old conventional concrete and new self-consolidating concrete. ACI Struct. J. 2020, 117, 191–201. [Google Scholar]

- Gonzalez-Taboada, I.; Gonzalez-Fonteboa, B.; Martinez-Abella, F.; Seara-Paz, S. Thixotropy and interlayer bond strength of self-compacting recycled concrete. Constr. Build Mater. 2018, 161, 479–488. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, X.; Zhao, Q. Experimental and numerical investigation of scattering gravels on the surface bond strength of self-compacting concrete. Constr. Build Mater. 2017, 145, 11–19. [Google Scholar] [CrossRef]

- Ziara, M.M. Behavior of beams strengthened with steel fiber RC overlays. J. Adv. Conc. Technol. 2009, 7, 111–121. [Google Scholar] [CrossRef][Green Version]

- Ziara, M.M. Structural upgrading of RC beams using composite overlays. J. Constr. Build Mater. 2000, 14, 397–406. [Google Scholar] [CrossRef]

- Nalanth, N.; Venkatesan, P.V.; Ravikumar, M.S. Evaluation of the fresh and hardened properties of steel fiber reinforced self-compacting concrete using recycled aggregates as a replacement material. Adv. Civ. Eng. 2014, 2014, 671547. [Google Scholar]

- Deifalla, A. A strength and deformation model for prestressed lightweight concrete slabs under two-way shear. Adv. Struct. Eng. 2021, 24, 3144–3155. [Google Scholar] [CrossRef]

- Deifalla, A. A mechanical model for concrete slabs subjected to combined punching shear and in-plane tensile forces. Eng. Struct. 2021, 231, 111787. [Google Scholar] [CrossRef]

- Aslani, F.; Nejadi, S. Mechanical properties of conventional and self-compacting concrete: An analytical study. Constr. Build Mater. 2012, 36, 330–347. [Google Scholar] [CrossRef]

- Juradin, S.; Baloevic, G.; Harapin, A. Experimental testing of the effects of fine particles on the properties of the self-compacting lightweight concrete. Adv. Mater. Sci. Eng. 2012, 2012, 398567. [Google Scholar] [CrossRef]

- Wei, J.; Xie, Z.; Zhang, W.; Luo, X.; Yang, Y.; Chen, B. Experimental study on circular steel tube-confined reinforced UHPC columns under axial loading. Eng. Struct. 2021, 230, 111599. [Google Scholar] [CrossRef]

- Shaaban, I.G.; Shaheen, Y.B.I.; Elsayed, E.L.; Kamal, O.A.; Adesina, P.A. Flexural behaviour and theoretical prediction of lightweight ferrocement composite beams. Constr. Mater. 2018, 9, e00204. [Google Scholar] [CrossRef]

- Tena-Colunga, A.; Hernandez-Marquez, O.; Arachnida-Aranda, H.I. Strengthening of reinforced concrete prismatic and haunched beams using light jacketing. J. Build Eng. 2020, 32, 101757. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, Y.; Wang, L.; Zhang, J.; Wu, W.; Yang, C. Flexural strengthening of damaged RC T-beams using self-compacting concrete jacketing under different sustaining load. Constr. Build Mater. 2018, 172, 185–195. [Google Scholar] [CrossRef]

- Duong, H.M.; Tran, T.Q.; Kopp, R.; Myint, S.M.; Peng, L. Chapter 1—Direct Spinning of Horizontally Aligned Carbon Nanotube Fibers and Films from the Floating Catalyst Method. In Micro and Nano Technologies, Nanotube Superfiber Materials, 2nd ed.; Schulz, M.J., Shanov, V., Yin, Z., Cahay, M., Eds.; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 3–29. [Google Scholar]

- Duong, H.M.; Myint, S.M.; Tran, T.Q.; Le, D.K. Chapter 6—Post-Spinning Treatments to Carbon Nanotube Fibers. In the Textile Institute Book Series, Carbon Nanotube Fibers and Yarns; Miao, M., Ed.; Woodhead Publishing: Norwich, NY, USA, 2020; pp. 103–134. [Google Scholar]

- Wan, B.; Petrou, M.F.; Harries, K.A. The Effect of the Presence of Water on the Durability of Bond between CFRP and Concrete. J. Reinf. Plast. Compos. 2006, 25, 875–890. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.-F. Axial Strength of Eccentrically Loaded FRP-Confined Short Concrete Columns. Polymers 2020, 12, 1261. [Google Scholar] [CrossRef]

- Zhang, D.; Gu, X.-L.; Yu, Q.-Q.; Huang, H.; Wan, B.; Jiang, C. Fully probabilistic analysis of FRP-to-concrete bonded joints considering model uncertainty. Compos. Struct. 2018, 185, 786–806. [Google Scholar] [CrossRef]

- Zhang, C.; Ali, A. The advancement of seismic isolation and energy dissipation mechanisms based on friction. Soil Dyn. Earthq. Eng. 2021, 146, 106746. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Pospisil, S.; Wu, T. Experimental Investigation on Rehabilitation of Corroded RC Columns with BSP and HPFL under Combined Loadings. J. Struct. Eng. 2020, 146, 04020157. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Yang, S. Experimental study of predamaged columns strengthened by HPFL and BSP under combined load cases. Struct. Infrastruct. Eng. 2020, 17, 1210–1227. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Y.; Yang, R.; Liu, P. Experimental Analysis of Bearing Capacity of Basalt Fiber Reinforced Concrete Short Columns under Axial Compression. Coatings 2022, 12, 654. [Google Scholar] [CrossRef]

- Yuan, J.; Lei, D.; Shan, Y.; Tong, H.; Fang, X.; Zhao, J. Direct Shear Creep Characteristics of Sand Treated with Microbial-Induced Calcite Precipitation. Int. J. Civ. Eng. 2022, 20, 763–777. [Google Scholar] [CrossRef]

- Shan, Y.; Zhao, J.; Tong, H.; Yuan, J.; Lei, D.; Li, Y. Effects of activated carbon on liquefaction resistance of calcareous sand treated with microbially induced calcium carbonate precipitation. Soil Dyn. Earthq. Eng. 2022, 161, 107419. [Google Scholar] [CrossRef]

- Hu, Z.; Shi, T.; Cen, M.; Wang, J.; Zhao, X.; Zeng, C.; Zhao, Z. Research progress on lunar and Martian concrete. Constr. Build. Mater. 2022, 343, 128117. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J.; Chen, H.; Shao, L. Shear Strength and Mesoscopic Characteristics of Basalt Fiber–Reinforced Loess after Dry–Wet Cycles. J. Mater. Civ. Eng. 2022, 34, 04022083. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Influence of dry-wet cycles on the strength behavior of basalt-fiber reinforced loess. Eng. Geol. 2022, 302, 106645. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J.; Li, Y.; Wang, S. Disturbed State Concept–Based Model for the Uniaxial Strain-Softening Behavior of Fiber-Reinforced Soil. Int. J. Geomech. 2022, 22, 4022092. [Google Scholar] [CrossRef]

- Sheng, C.; He, G.; Hu, Z.; Chou, C.; Shi, J.; Li, J.; Ning, F. Yarn on yarn abrasion failure mechanism of ultrahigh molecular weight polyethylene fiber. J. Eng. Fibers Fabr. 2021, 16, 1925832385. [Google Scholar] [CrossRef]

- Ning, F.; He, G.; Sheng, C.; He, H.; Wang, J.; Zhou, R.; Ning, X. Yarn on yarn abrasion performance of high modulus polyethylene fiber improved by graphene/polyurethane composites coating. J. Eng. Fibers Fabr. 2021, 16, 1558925020983563. [Google Scholar] [CrossRef]

- Chen, F.; Jin, Z.; Wang, E.; Wang, L.; Jiang, Y.; Guo, P.; He, X.; Gao, X. Relationship model between surface strain of concrete and expansion force of reinforcement rust. Sci. Rep. 2021, 11, 4208. [Google Scholar] [CrossRef]

- Chen, F.X.; Zhong, Y.C.; Gao, X.Y.; Jin, Z.Q.; Wang, E.D.; Zhu, F.P.; Shao, X.X.; He, X.Y. Non-uniform Model of Relationship between Surface Strain and Rust Expansion Force of Reinforced Concrete. Sci. Rep. 2020, 11, 8741. [Google Scholar] [CrossRef]

- Cheng, H.; Sun, L.; Wang, Y.; Chen, X. Effects of actual loading waveforms on the fatigue behaviours of asphalt mixtures. Int. J. Fatigue 2021, 151, 106386. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, L.; Sun, L. Bridging the Gap between Laboratory and Field Moduli of Asphalt Layer for Pavement Infrastructure Design and Assessment: A Comprehensive Loading Frequency-Based Approach. Front. Struct. Civ. Eng. 2022, 16, 267–280. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, Y.; Kong, Z.; He, J.; Wu, H. Development of Similar Materials for Liquid-Solid Coupling and Its Application in Water Outburst and Mud Outburst Model Test of Deep Tunnel. Geofluids 2022, 2022, 8784398. [Google Scholar] [CrossRef]

- Zhu, Z.; Wu, Y.; Liang, Z. Mining-Induced Stress and Ground Pressure Behavior Characteristics in Mining a Thick Coal Seam with Hard Roofs. Front. Earth Sci. 2022, 10, 843191. [Google Scholar] [CrossRef]

- Shi, L.; Xiao, X.; Wang, X.; Liang, H.; Wang, D. Mesostructural characteristics and evaluation of asphalt mixture contact chain complex networks. Constr. Build. Mater. 2022, 340, 127753. [Google Scholar] [CrossRef]

- Xu, H.; Wang, X.; Liu, C.; Chen, J.; Zhang, C. A 3D root system morphological and mechanical model based on L-Systems and its application to estimate the shear strength of root-soil composites. Soil Tillage Res. 2021, 212, 105074. [Google Scholar] [CrossRef]

- Lan, M.Y.; Zheng, M.B.; Shi, T.; Ma, C.; Liu, Y.; Zhao, Z. Crack resistance property of carbon nanotubes-modified concrete. Mag. Concr. Res. 2022. [Google Scholar] [CrossRef]

- Gu, M.; Mo, H.; Qiu, J.; Yuan, J.; Xia, Q. Behavior of Floating Stone Columns Reinforced with Geogrid Encasement in Model Tests. Front. Mater. 2022, 503, 980851. [Google Scholar] [CrossRef]

- Wang, J.; Meng, Q.; Zou, Y.; Qi, Q.; Tan, K.; Santamouris, M.; He, B. Performance synergism of pervious pavement on stormwater management and urban heat island mitigation: A review of its benefits, key parameters, and co-benefits approach. Water Res. 2022, 221, 118755. [Google Scholar] [CrossRef]

| Sr. No. | Property | Experimental Values | Code Provision IS: 8112:2013 |

|---|---|---|---|

| 1 | Blaine’s Fineness (cm2/gm) | - | 2250 |

| 2 | Normal Consistency (% Age of Cement by Weight) | 29 | - |

| 3 | Setting Time (min) | ||

| a. Initial Setting Time (min) | 125 | >30 | |

| b. Final Setting Time (min) | 355 | <600 | |

| 4 | Compressive Strength (MPa) | ||

| a. 3 Days | 26 | 23 | |

| b. 7 Days | 39 | 33 | |

| c. 28 Days | 47 | 43 |

| Properties | Value |

|---|---|

| Tensile Strength (MPa) | 4000 |

| Color | Black |

| Modulus of Elasticity (MPa) | 230 |

| Physical State | Liquid |

| Ph (concentrate) | ≥6 |

| Chemical Base | Modified Polycarboxylate |

| Odour | Slight/faint |

| Water solubility | Soluble |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiwary, A.K.; Singh, S.; Kumar, R.; Sharma, K.; Chohan, J.S.; Sharma, S.; Singh, J.; Kumar, J.; Deifalla, A.F. Comparative Study on the Behavior of Reinforced Concrete Beam Retrofitted with CFRP Strengthening Techniques. Polymers 2022, 14, 4024. https://doi.org/10.3390/polym14194024

Tiwary AK, Singh S, Kumar R, Sharma K, Chohan JS, Sharma S, Singh J, Kumar J, Deifalla AF. Comparative Study on the Behavior of Reinforced Concrete Beam Retrofitted with CFRP Strengthening Techniques. Polymers. 2022; 14(19):4024. https://doi.org/10.3390/polym14194024

Chicago/Turabian StyleTiwary, Aditya Kumar, Sandeep Singh, Raman Kumar, Kamal Sharma, Jasgurpreet Singh Chohan, Shubham Sharma, Jujhar Singh, Jatinder Kumar, and Ahmed Farouk Deifalla. 2022. "Comparative Study on the Behavior of Reinforced Concrete Beam Retrofitted with CFRP Strengthening Techniques" Polymers 14, no. 19: 4024. https://doi.org/10.3390/polym14194024

APA StyleTiwary, A. K., Singh, S., Kumar, R., Sharma, K., Chohan, J. S., Sharma, S., Singh, J., Kumar, J., & Deifalla, A. F. (2022). Comparative Study on the Behavior of Reinforced Concrete Beam Retrofitted with CFRP Strengthening Techniques. Polymers, 14(19), 4024. https://doi.org/10.3390/polym14194024