Recent Developments in Shape Memory Elastomers for Biotechnology Applications

Abstract

1. Introduction

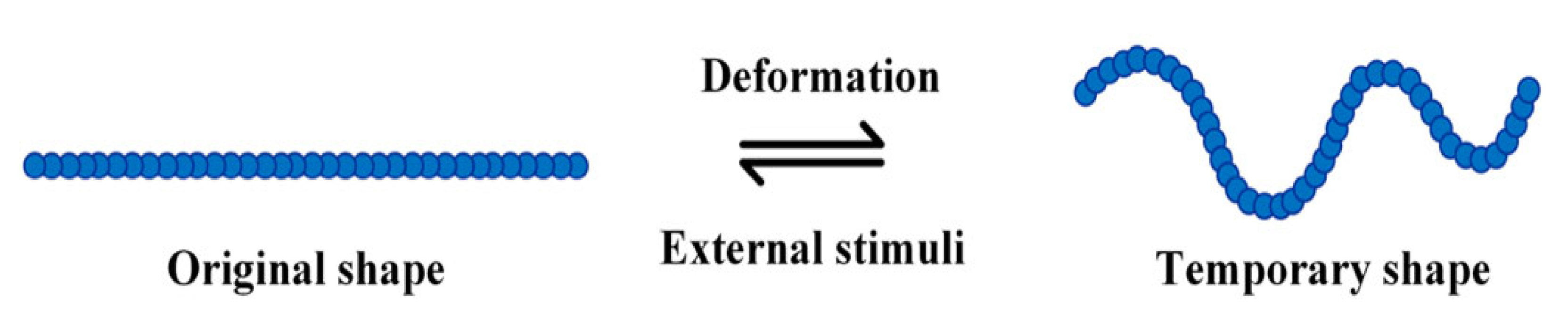

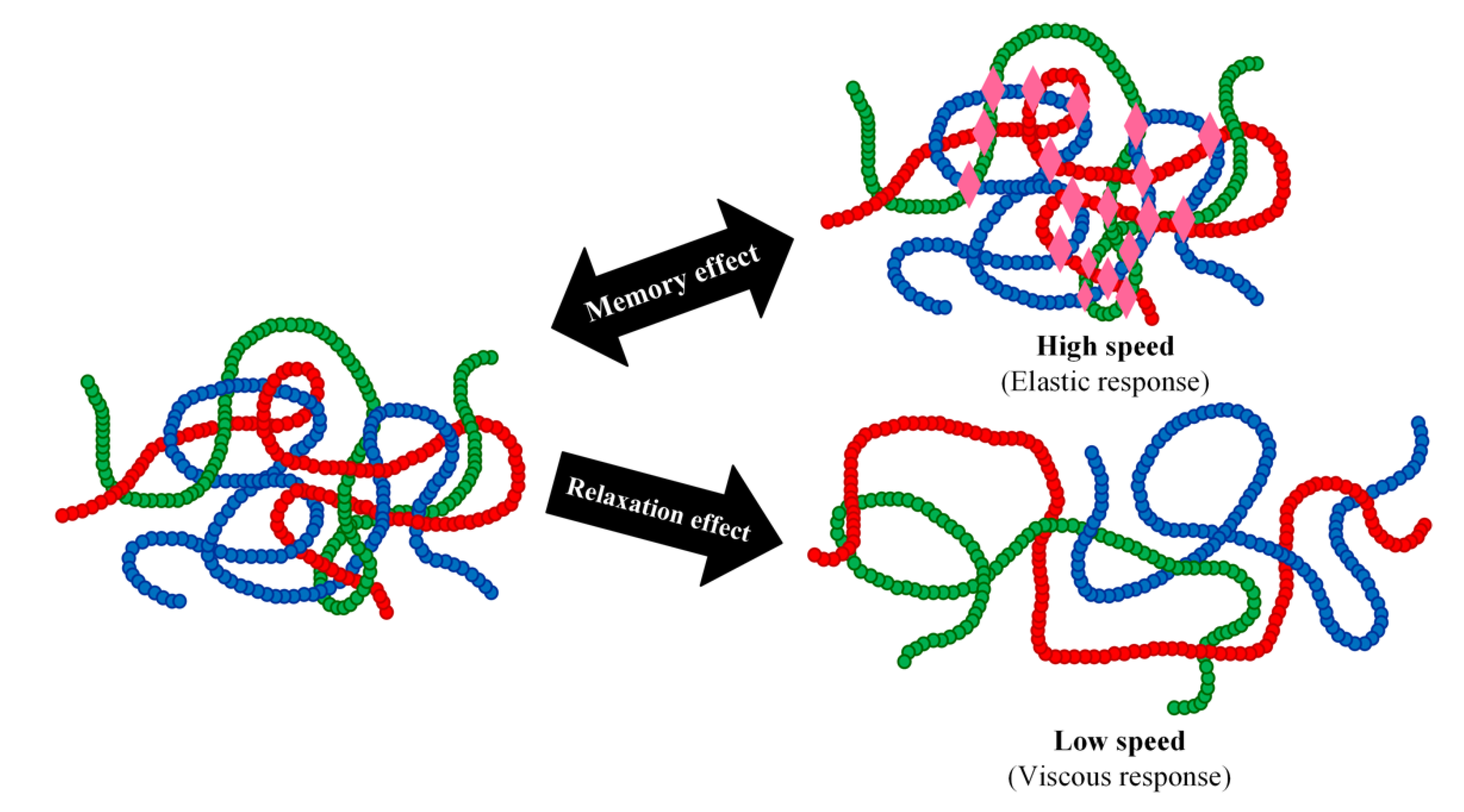

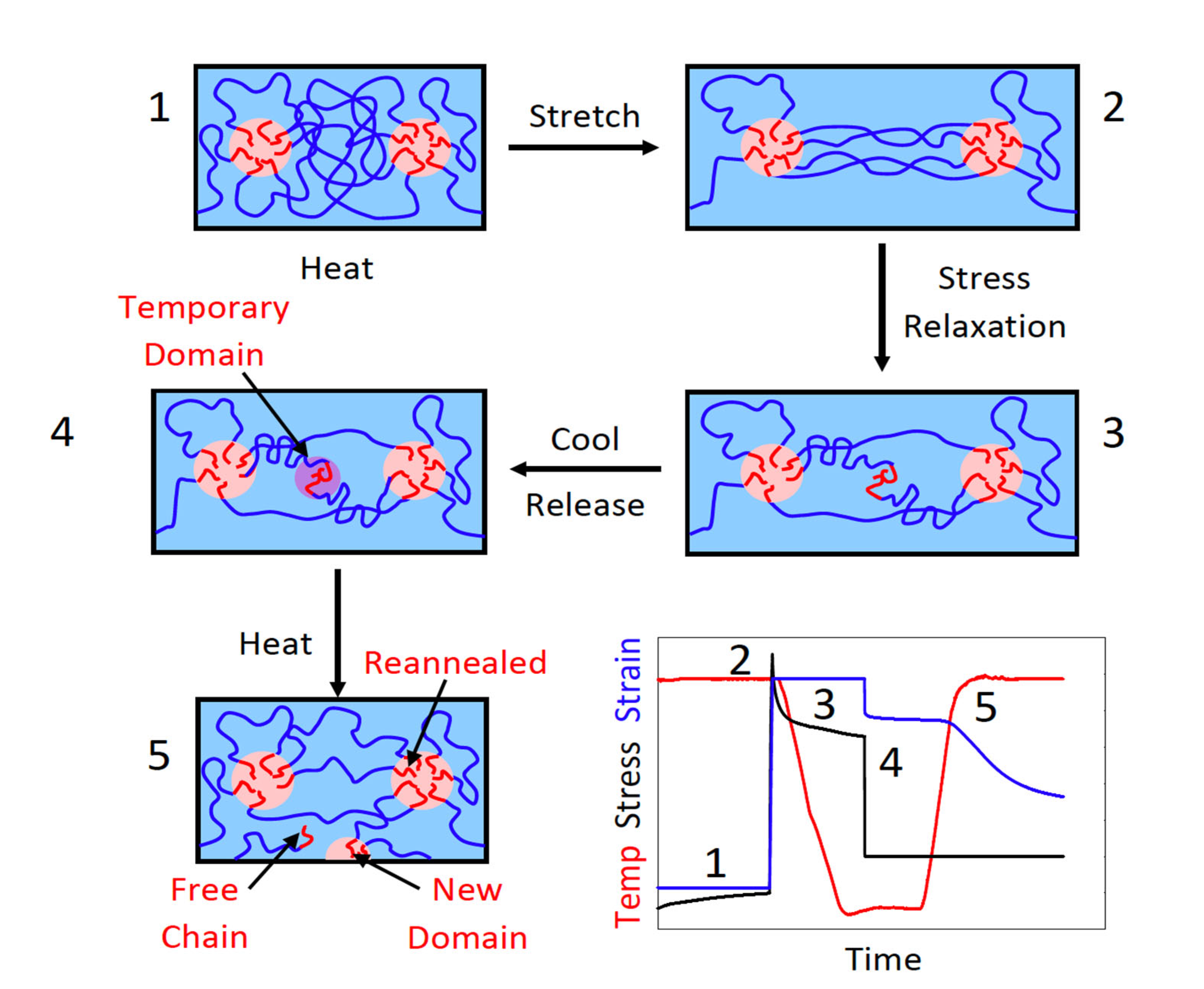

2. Thermodynamic Aspects Governing SMEs

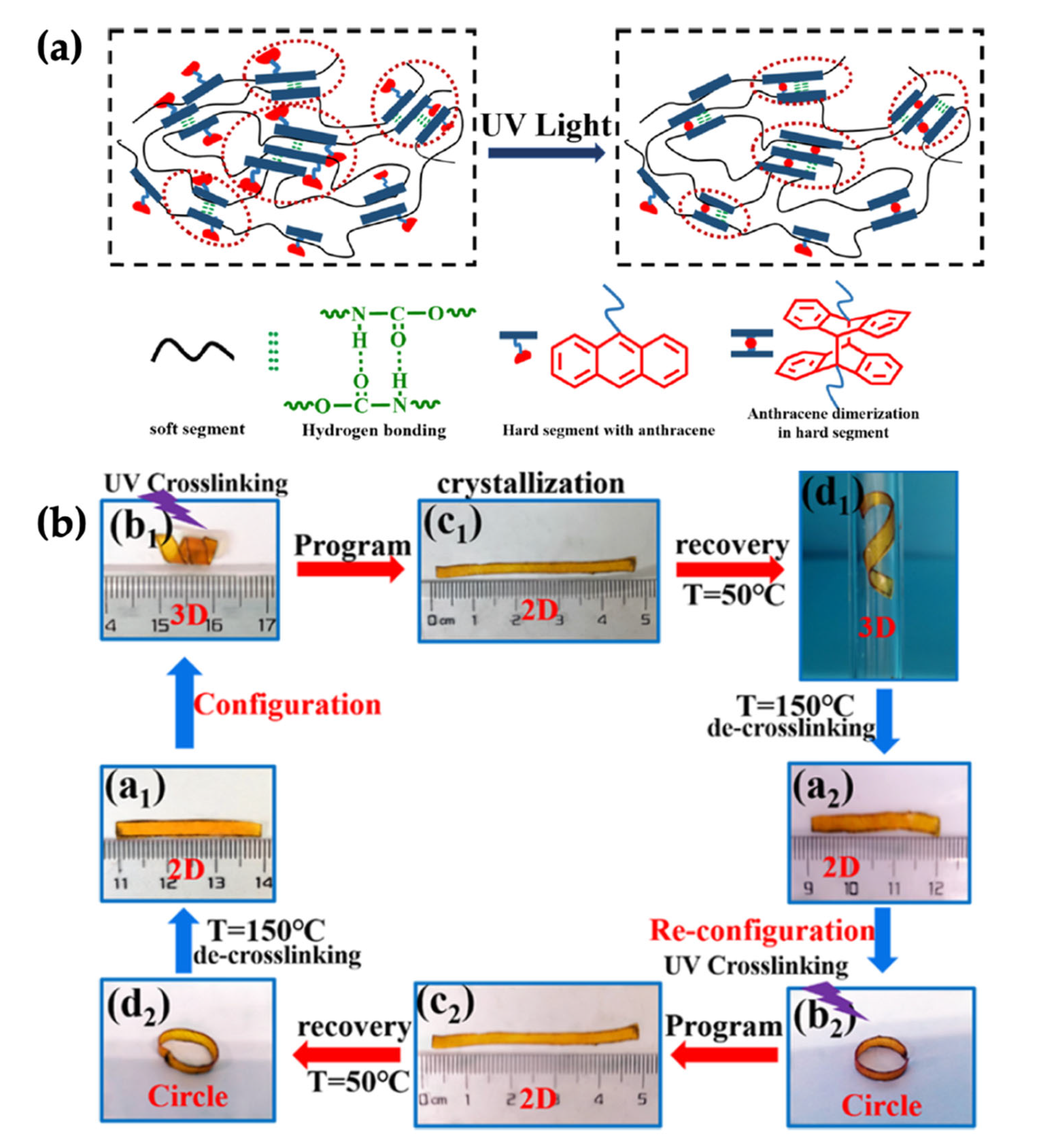

3. Stimuli-Responsive Shape Memory Elastomers

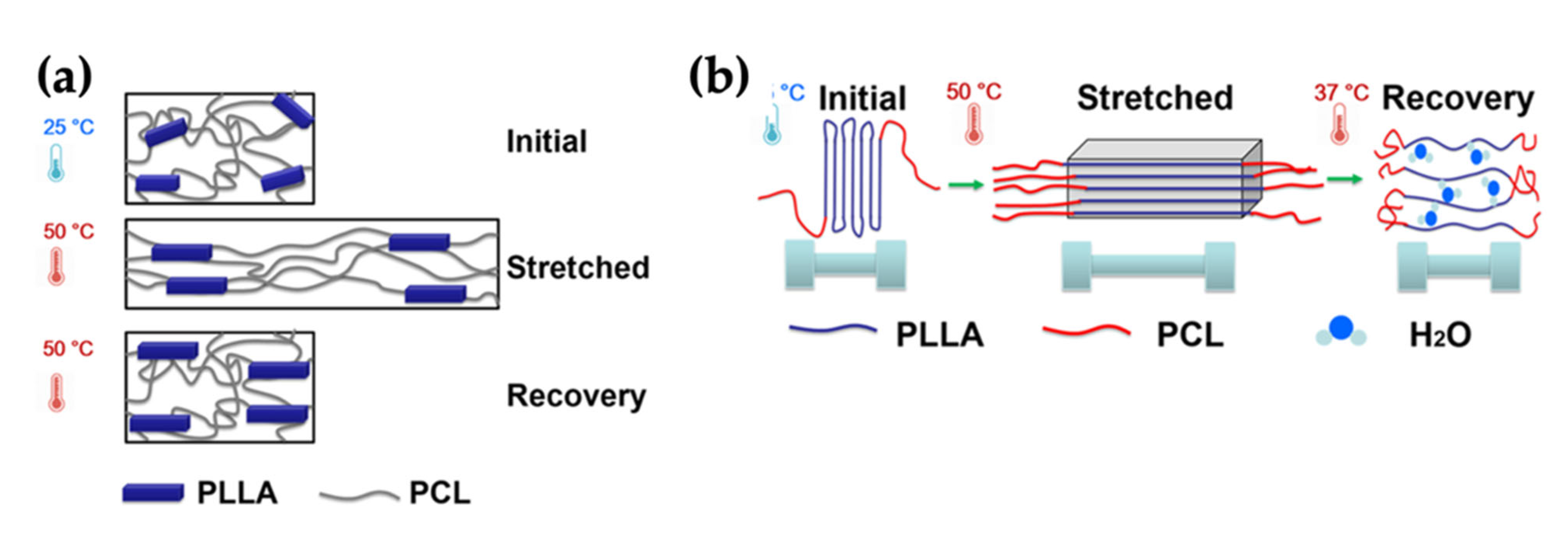

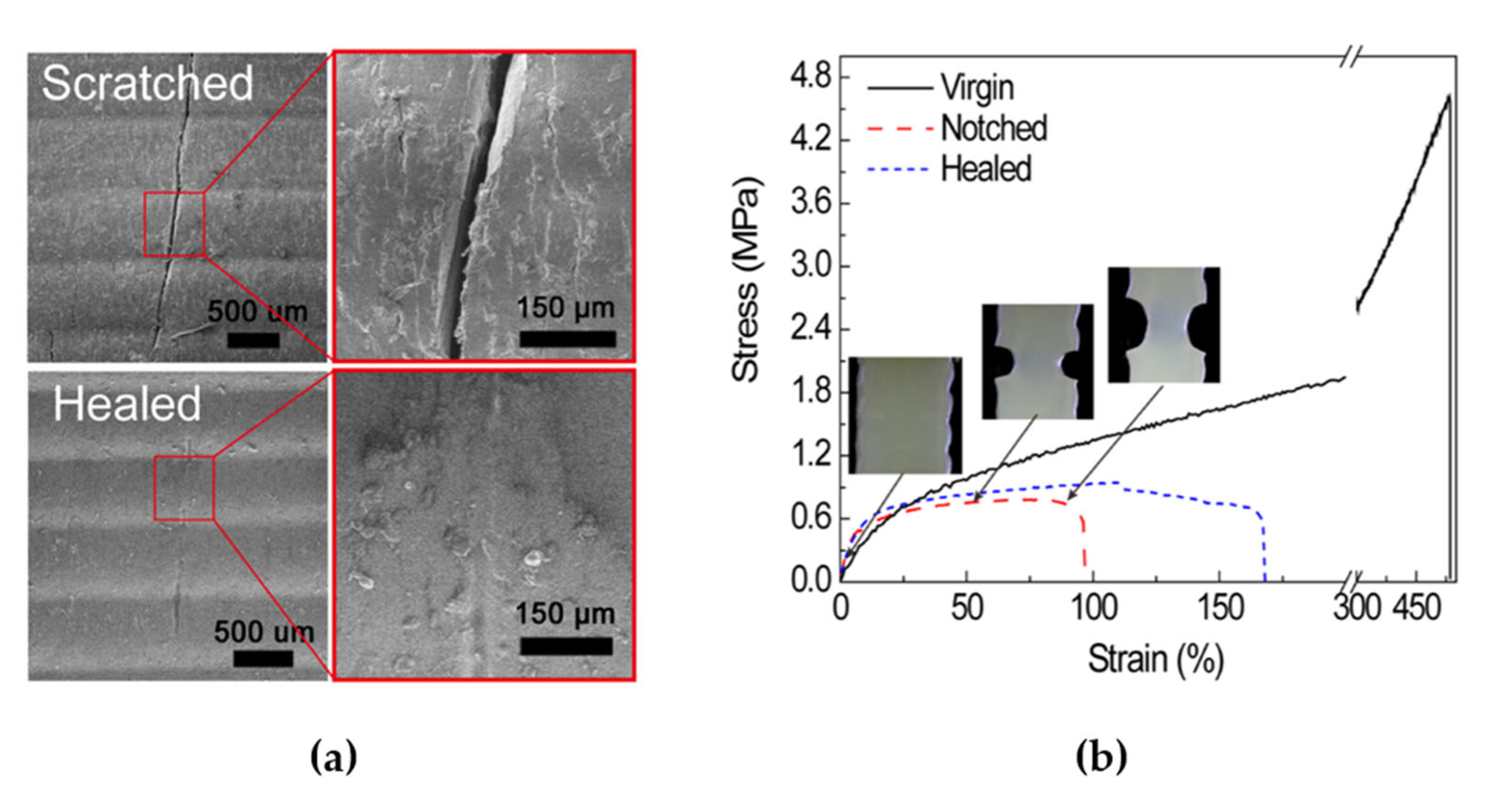

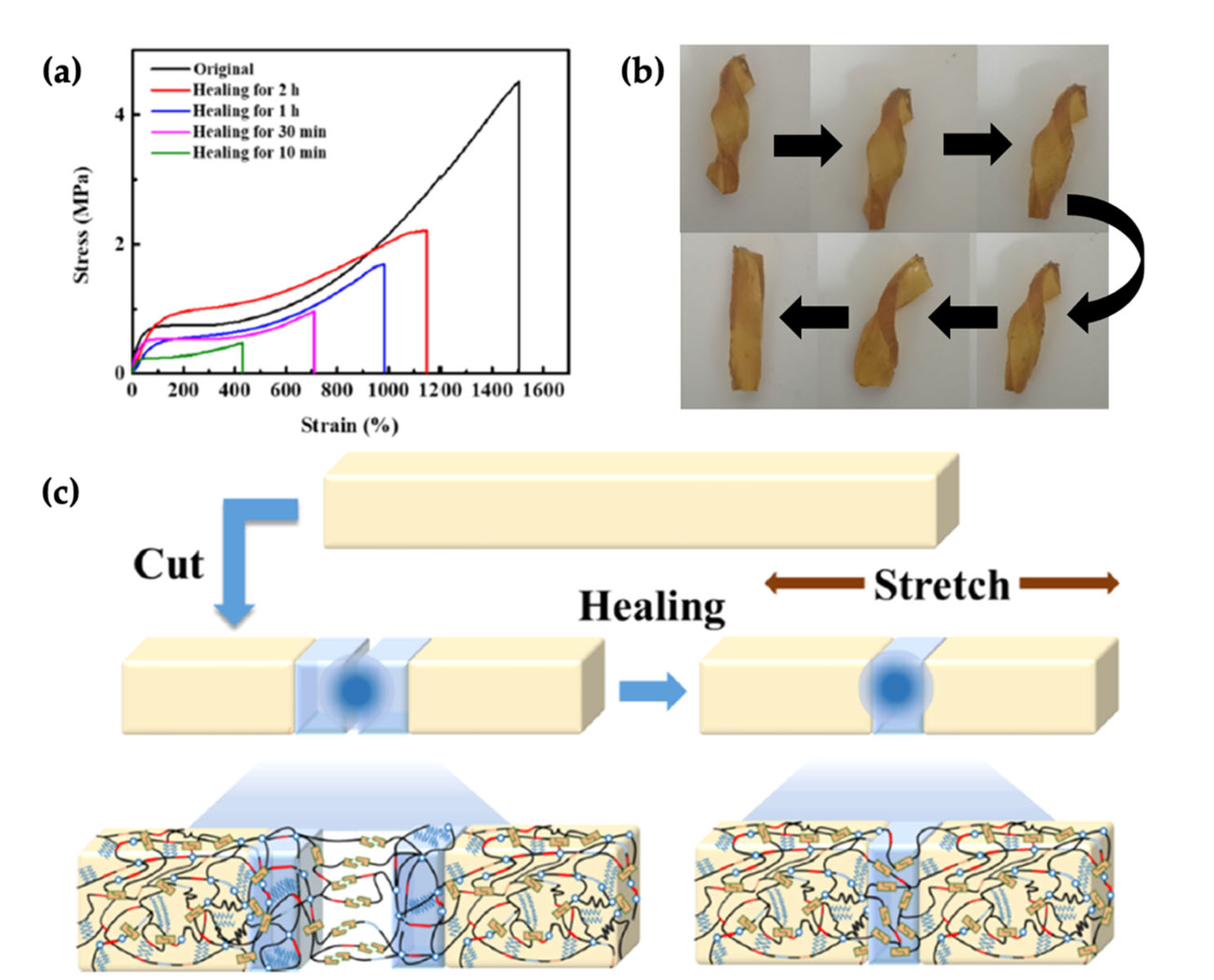

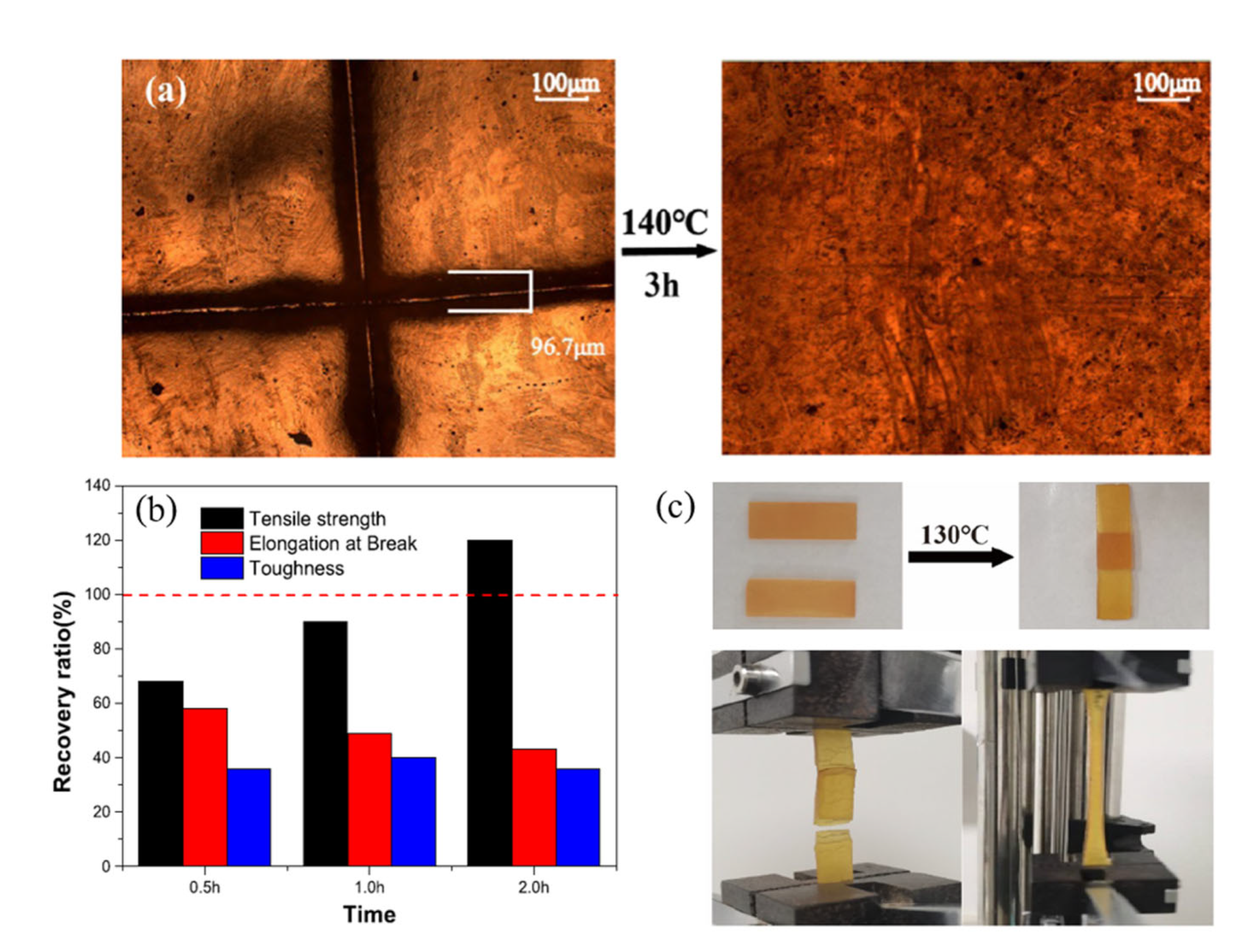

4. Self-Healing Shape Memory Elastomers

5. Thermoplastic Shape Memory Elastomers

6. Antibacterial and Antifouling Shape Memory Elastomers

7. Environmental Applications of Shape Memory Elastomers

8. Conclusions and Future Research Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamila, S. Introduction, Classification and applications of smart materials: An overview. Am. J. Appl. Sci. 2013, 10, 876–880. [Google Scholar] [CrossRef]

- Khoo, Z.; Teoh, J.; Liu, Y.; Chua, C.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Kim, H.C.; Mun, S.; Ko, H.U.; Zhai, L.; Kafy, A.; Kim, J. Renewable smart materials. Smart Mater. Struct. 2016, 25, 073001. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. Multi–stable mechanical metamaterials by elastic buckling instability. J. Mater. Sci. 2019, 54, 3509–3526. [Google Scholar] [CrossRef]

- Brighenti, R.; Li, Y.; Vernerey, F.J. Smart polymers for advanced applications: A mechanical perspective review. Front. Mater. 2020, 7, 196. [Google Scholar] [CrossRef]

- Sobczyk, M.; Wiesenhütter, S.; Noennig, J.R.; Wallmersperger, T. Smart materials in architecture for actuator and sensor applications: A review. J. Intell. Mater. Syst. Struct. 2021, 33, 379–399. [Google Scholar] [CrossRef]

- Panwar, S.; Panjagari, N.R.; Singh, A.K.; Deshwal, G.K.; Badola, R.; Minz, P.S.; Goksen, G.; Rusu, A.; Trif, M. Electrospun smart oxygen indicating tag for modified atmosphere packaging applications: Fabrication, characterization and storage stability. Polymers 2022, 14, 2108. [Google Scholar] [CrossRef]

- Reneker, D.H.; Mattice, W.L.; Quirk, R.P.; Kim, S.J. Macromolecular smart materials and structures. Smart Mater. Struct. 1992, 1, 84–90. [Google Scholar] [CrossRef]

- Cavicchi, K.A. Shape memory polymers from blends of elastomers and small molecule additives. Macromol. Symp. 2015, 358, 194–201. [Google Scholar] [CrossRef]

- Drossel, W.G.; Kunze, H.; Bucht, A.; Weisheit, L.; Pagel, K. Smart3—Smart materials for smart applications. Procedia CIRP 2015, 36, 211–216. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Z.; Li, G.; Wang, Y.; Fu, X.; Zhong, W.H.; Yang, X. A UV–curable epoxy with “soft” segments for 3D–printable shape–memory materials. J. Mater. Sci. 2018, 53, 12650–12661. [Google Scholar] [CrossRef]

- Meurer, J.; Bätz, T.; Hniopek, J.; Jäger, M.; Zechel, S.; Schmitt, M.; Popp, J.; Hager, M.D.; Schubert, U.S. Synthesis and characterization of metallopolymer networks featuring triple shape–memory ability based on different reversible metal complexes. Polymers 2022, 14, 1833. [Google Scholar] [CrossRef] [PubMed]

- Khadem, E.; Kharaziha, M.; Bakhsheshi-Rad, H.R.; Das, O.; Berto, F. Cutting–edge progress in stimuli–responsive bioadhesives: From synthesis to clinical applications. Polymers 2022, 14, 1709. [Google Scholar] [CrossRef] [PubMed]

- González-Jiménez, A.; Bernal-Ortega, P.; Salamanca, F.M.; Valentin, J.L. Shape–memory composites based on ionic elastomers. Polymers 2022, 14, 1230. [Google Scholar] [CrossRef] [PubMed]

- Gunes, I.; Cao, F.; Jana, S. Evaluation of nanoparticulate fillers for shape memory polyurethane nanocomposites. Polymer 2008, 49, 2223–2234. [Google Scholar] [CrossRef]

- Huang, W.M.; Ding, Z.; Wang, C.C.; Wei, J.; Zhao, Y.; Purnawali, H. Shape memory materials. Mater. Today 2010, 13, 54–61. [Google Scholar] [CrossRef]

- Kuriyagawa, M.; Kawamura, T.; Hayashi, S.; Nitta, K.-h. Effects of addition of hindered phenol compounds to a segmented polyurethane with shape memory on mechanical yielding. J. Mater. Sci. 2011, 46, 1264–1271. [Google Scholar] [CrossRef][Green Version]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape–memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, Y.; Huang, H.; Lu, J. Recent advances in shape–memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015, 49–50, 3–33. [Google Scholar] [CrossRef]

- Lin, T.; Li, S.; Ke, J.; Zheng, Y.; Yu, Y. Unique shape memory elastomer associated with reversible sacrificial hydrogen bonds: Tough and flexible when below its Tg. Adv. Eng. Mater. 2018, 20, 1800051. [Google Scholar] [CrossRef]

- Chen, H.-M.; Wang, L.; Zhou, S.-B. Recent progress in shape memory polymers for biomedical applications. Chin. J. Polym. Sci. 2018, 36, 905–917. [Google Scholar] [CrossRef]

- Hasan, S.M.; Touchet, T.; Jayadeep, A.; Maitland, D.J. Controlling morphology and physio–chemical properties of stimulus–responsive polyurethane foams by altering chemical blowing agent content. Polymers 2022, 14, 2288. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.; Chen, G.; Liao, Y.; Lu, X.; Hu, S.; Gan, T.; Handschuh-Wang, S.; Zhang, X. Self–healable and recyclable dual-shape memory liquid metal—Elastomer composites. Polymers 2022, 14, 2259. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Chen, D. Heterogeneous solid-state plasticity of a multi-functional metallo-supramolecular shape-memory polymer towards arbitrary shape programming. Polymers 2022, 14, 1598. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Mather, Review of progress in shape–memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Rousseau, I.A. Challenges of shape memory polymers: A review of the progress toward overcoming SMP’s limitations. Polym. Eng. Sci. 2008, 48, 2075–2089. [Google Scholar] [CrossRef]

- Oliver, K.; Seddon, A.; Trask, R.S. Morphing in nature and beyond: A review of natural and synthetic shape-changing materials and mechanisms. J. Mater. Sci. 2016, 51, 10663–10689. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kéki, S. Review of progress in shape memory epoxies and their composites. Polymers 2018, 10, 34. [Google Scholar] [CrossRef]

- Wang, L.; Luo, B.; Wu, D.; Liu, Y.; Li, L.; Liu, H. Fabrication and characterization of thermal-responsive biomimetic small-scale shape memory wood composites with high tensile strength, high anisotropy. Polymers 2019, 11, 1892. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Mather, P.T. Preparation and characterization of shape memory elastomeric composites. Macromolecules 2009, 42, 7251–7253. [Google Scholar] [CrossRef]

- Li, J.; Rodgers, W.R.; Xie, T. Semi–crystalline two–way shape memory elastomer. Polymer 2011, 52, 5320–5325. [Google Scholar] [CrossRef]

- Belmonte, A.; Guzmán, D.; Fernández-Francos, X.; de la Flor, S. Effect of the network structure and programming temperature on the shape–memory response of thiol-epoxy “click” systems. Polymers 2015, 7, 2146–2164. [Google Scholar] [CrossRef]

- Song, X.; Chi, H.; Li, Z.; Li, T.; Wang, F. Star–shaped crosslinker for multifunctional shape memory polyurethane. Polymers 2020, 12, 740. [Google Scholar] [CrossRef] [PubMed]

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference, 2nd ed.; Springer: London, UK, 2008; p. 1339. [Google Scholar]

- McKeen, L.W. The Effect of Sterilization on Plastics and Elastomers, 3rd ed.; PDL Handbook Series; William Andrew: Norwich, NY, USA, 2012. [Google Scholar]

- Suethao, S.; Shah, D.U.; Smitthipong, W. Recent progress in processing functionally graded polymer foams. Materials 2020, 13, 4060. [Google Scholar] [CrossRef] [PubMed]

- Suethao, S.; Ponloa, W.; Phongphanphanee, S.; Wong-Ekkabut, J.; Smitthipong, W. Current challenges in thermodynamic aspects of rubber foam. Sci. Rep. 2021, 11, 6097. [Google Scholar] [CrossRef]

- Suethao, S.; Phongphanphanee, S.; Wong-ekkabut, J.; Smitthipong, W. The relationship between the morphology and elasticity of natural rubber foam based on the concentration of the chemical blowing agent. Polymers 2021, 13, 1091. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Wang, T.X.; Chen, H.M.; Renata, C.; He, L.W.; Lv, P.; Wang, C.C. An overview of elastic polymeric shape memory materials for comfort fitting. Mater. Des. 2017, 136, 238–248. [Google Scholar] [CrossRef]

- Wee, J.S.-H.; Chai, A.B.; Ho, J.-H. Fabrication of shape memory natural rubber using palmitic acid. J. King Saud Univ. Sci. 2017, 29, 494–501. [Google Scholar] [CrossRef]

- Lovšin, M.; Brandl, D.; Glavan, G.; Belyaeva, I.A.; Cmok, L.; Čoga, L.; Kalin, M.; Shamonin, M.; Drevenšek-Olenik, I. Reconfigurable surface micropatterns based on the magnetic field–induced shape memory effect in magnetoactive elastomers. Polymers 2021, 13, 4422. [Google Scholar] [CrossRef]

- Rim, M.; Kang, D.-G.; Ko, H.; Wi, Y.; Kim, W.; Kim, S.; Hyeong, J.; Kim, N.; Jeong, K.-U. Shape–morphing thermoactuators: Tetrathiafulvalene–based polymer networks with an effective phonon conduction pathway. Chem. Mater. 2022, 34, 718–727. [Google Scholar] [CrossRef]

- Chen, H.; Li, Y.; Liu, Y.; Gong, T.; Wang, L.; Zhou, S. Highly pH–sensitive polyurethane exhibiting shape memory and drug release. Polym. Chem. 2014, 5, 5168–5174. [Google Scholar] [CrossRef]

- Thakur, S.; Hu, J. Polyurethane: A shape memory polymer (SMP). In Aspects of Polyurethanes; Yılmaz, F., Ed.; InTech: Rijeka, Croatia, 2017; pp. 53–71. [Google Scholar]

- Gupta, A.; Maharjan, A.; Kim, B.S. Shape memory polyurethane and its composites for various applications. Appl. Sci. 2019, 9, 4694. [Google Scholar] [CrossRef]

- Hu, J.; Feng, Z.; Xu, X.; Gao, W.; Ning, N.; Yu, B.; Zhang, L.; Tian, M. UV reconfigurable shape memory polyurethane with a high recovery ratio under large deformation. Ind. Eng. Chem. Res. 2021, 60, 2144–2153. [Google Scholar] [CrossRef]

- Wu, W.; Zhou, Y.; Li, J.; Wan, C. Shape memory and self–healing behavior of styrene–butadiene–styrene/ethylene–methacrylic acid copolymer (SBS/EMAA) elastomers containing ionic interactions. J. Appl. Polym. Sci. 2020, 137, 48666. [Google Scholar] [CrossRef]

- Pantoja, M.; Jian, P.-Z.; Cakmak, M.; Cavicchi, K.A. Shape memory properties of polystyrene–block–poly(ethylene–co–butylene)–block–polystyrene (SEBS) ABA triblock copolymer thermoplastic elastomers. ACS Appl. Polym. Mater. 2019, 1, 414–424. [Google Scholar] [CrossRef]

- Gu, X.; Mather, P.T. Water–triggered shape memory of multiblock thermoplastic polyurethanes (TPUs). RSC Adv. 2013, 3, 15783–15791. [Google Scholar] [CrossRef]

- Niu, G. Water triggered shape memory materials. Sci. Insights 2013, 3, 49–50. [Google Scholar] [CrossRef]

- Invernizzi, M.; Turri, S.; Levi, M.; Suriano, R. 4D printed thermally activated self–healing and shape memory polycaprolactone–based polymers. Eur. Polym. J. 2018, 101, 169–176. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, S.; Chong, K.C.; Wang, S.; Liu, B. Near–infrared light–induced shape memory, self–healable and anti–bacterial elastomers prepared by incorporation of a diketopyrrolopyrrole–based conjugated polymer. Mater. Chem. Front. 2019, 3, 836–841. [Google Scholar] [CrossRef]

- Shibasaki, Y.; Mori, T.; Fujimori, A.; Jikei, M.; Sawada, H.; Oishi, Y. Poly(amide–ether) thermoplastic elastomers based on monodisperse aromatic amide hard segments as shape–memory and moisture–responsive materials. Macromolecules 2018, 51, 9430–9441. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Yao, C. Biomass shape memory elastomers with rapid self–healing properties and high recyclability. Biomacromolecules 2021, 22, 2768–2776. [Google Scholar] [CrossRef]

- Prasopdee, T.; Smitthipong, W. Effect of fillers on the recovery of rubber foam: From theory to applications. Polymers 2020, 12, 2745. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-Y.; Lin, M.-C.; Shiu, B.-C.; Lou, C.-W.; Lin, J.-H.; Chen, Y.-S. Novel composite planks made of shape memory polyurethane foaming material with two–step foaming process. Polymers 2022, 14, 275. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.X.; Renata, C.; Chen, H.M.; Huang, W.M. Elastic shape memory hybrids programmable at around body–temperature for comfort fitting. Polymers 2017, 9, 674. [Google Scholar] [CrossRef] [PubMed]

- Rupérez, M.J.; Monserrat, C.; Alemany, S.; Juan, M.C.; Alcañíz, M. Contact model, fit process and, foot animation for the virtual simulator of the footwear comfort. Comput. Aided Des. 2010, 42, 425–431. [Google Scholar] [CrossRef]

- International Trade Centre. List of Exporters for the Selected Product in 2021. Product: 640319 Sports Footwear, with Outer Soles of Rubber, Plastics, Leather or Composition Leather and Uppers of Leather (Excluding Ski–Boots, Cross–Country Ski Footwear, Snowboard Boots and Skating Boots with Ice or Roller Skates Attached). 2021. Available online: https://www.trademap.org/Country_SelPro-uct.aspx?nvpm=1%7c%7c%7c%7c%7c640319%7c%7c%7c6%7c1%7c1%7c2%7c1%7c1%7c2%7c1%7c1%7c1 (accessed on 25 June 2022).

- International Trade Centre. List of Exporters for the Selected Product in 2021. Product: 940490 “Articles of Bedding and Similar Furnishing, Fitted with Springs or Stuffed or Internally Filled with Any Material or of Cellular Rubber or Plastics (Excl. Mattress Supports, Mattresses, Sleeping Bags, Pneumatic or Water Mattresses, Blankets, Covers, Quilts, Bedspreads, Eiderdowns and Duvets “Comforters”). 2021. Available online: https://www.trademap.org/Country_SelProduct.aspx?nvpm=1%7c%7c%7c%7c%7c940490%7c%7c%7c6%7c1%7c1%7c1%7c1%7c1%7c2%7c1%7c1%7c1 (accessed on 25 June 2022).

- MarketsandMarkets Research Private Ltd. Arkema S.A (France) and BASF SE (Germany) Are Leading Players in the Construction Elastomers Market 2021. Available online: https://www.marketsandmarkets.com/ResearchInsight/construction–elastomers–market.asp (accessed on 25 June 2022).

- Behl, M.; Lendlein, A. Shape–memory polymers. Mater. Today 2007, 10, 20–28. [Google Scholar] [CrossRef]

- Dolynchuk, O.; Kolesov, I.; Radusch, H.-J. Thermodynamic description and modeling of two–way shape–memory effect in crosslinked semicrystalline polymers. Polym. Adv. Technol. 2014, 25, 1307–1314. [Google Scholar] [CrossRef]

- Oikonomou, P.; Sanopoulou, M.; Papadokostaki, K.G. Blends of poly(vinyl alcohol) and poly(vinyl pyrrolidone): Interrelation between the degree of hydration and thermal and mechanical properties. Ind. Eng. Chem. Res. 2021, 60, 14203–14212. [Google Scholar] [CrossRef]

- Pilate, F.; Toncheva, A.; Dubois, P.; Raquez, J.-M. Shape–memory polymers for multiple applications in the materials world. Eur. Polym. J. 2016, 80, 268–294. [Google Scholar] [CrossRef]

- Pakornpadungsit, P.; Smitthipong, W.; Chworos, A. Self–assembly nucleic acid–based biopolymers: Learn from the nature. J. Polym. Res. 2018, 25, 45. [Google Scholar] [CrossRef]

- Lendlein, A.; Behl, M.; Hiebl, B.; Wischke, C. Shape–memory polymers as a technology platform for biomedical applications. Expert Rev. Med. Devices 2010, 7, 357–379. [Google Scholar] [CrossRef] [PubMed]

- Zheng, F.; Bai, Y.; Wang, Q.; Wang, T. Switchable friction properties induced by shape memory effect. J. Mater. Sci. 2014, 49, 8394–8401. [Google Scholar] [CrossRef]

- Wang, K.; Strandman, S.; Zhu, X.X. A mini review: Shape memory polymers for biomedical applications. Front. Chem. Sci. Eng. 2017, 11, 143–153. [Google Scholar] [CrossRef]

- Wu, F.; Chen, L.; Li, Y.; Lee, K.I.; Fei, B. Super–tough hydrogels from shape–memory polyurethane with wide–adjustable mechanical properties. J. Mater. Sci. 2017, 52, 4421–4434. [Google Scholar] [CrossRef]

- Ge, Q.; Luo, X.; Rodriguez, E.D.; Zhang, X.; Mather, P.T.; Dunn, M.L.; Qi, H.J. Thermomechanical behavior of shape memory elastomeric composites. J. Mech. Phys. Solids 2012, 60, 67–83. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, R.; Li, X.; Cheng, B.; Zhang, Y.; Yang, X.; Zhao, X.; Zhao, Y.; Huang, W. 4D printing of shape memory polyurethane via stereolithography. Eur. Polym. J. 2018, 101, 120–126. [Google Scholar] [CrossRef]

- Li, J.; Duan, Q.; Zhang, E.; Wang, J. Applications of shape memory polymers in kinetic buildings. Adv. Mater. Sci. Eng. 2018, 2018, 7453698. [Google Scholar] [CrossRef]

- Ping, P.; Wang, W.; Chen, X.; Jing, X. Poly(ε–caprolactone) polyurethane and its shape–memory property. Biomacromolecules 2005, 6, 587–592. [Google Scholar] [CrossRef]

- Bianchi, M.; Scarpa, F.; Smith, C.W.; Whittell, G.R. Physical and thermal effects on the shape memory behaviour of auxetic open cell foams. J. Mater. Sci. 2010, 45, 341–347. [Google Scholar] [CrossRef]

- Messori, M.; Esposti, M.D.; Paderni, K.; Pandini, S.; Passera, S.; Riccò, T.; Toselli, M. Chemical and thermomechanical tailoring of the shape memory effect in poly(ε–caprolactone)–based systems. J. Mater. Sci. 2013, 48, 424–440. [Google Scholar] [CrossRef]

- Chien, Y.-C.; Chuang, W.-T.; Jeng, U.S.; Hsu, S.-H. Preparation, characterization, and mechanism for biodegradable and biocompatible polyurethane shape memory elastomers. ACS Appl. Mater. Interfaces 2017, 9, 5419–5429. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Zhang, Z.; Liu, D.; Ren, T.; Wan, D.; Pu, H. Triple–stimuli responsive shape memory effect of novel polyolefin elastomer/lauric acid/carbon black nanocomposites. Compos. Sci. Technol. 2019, 169, 45–51. [Google Scholar] [CrossRef]

- Song, Q.; Chen, H.; Zhou, S.; Zhao, K.; Wang, B. Hu, Thermo– and pH–sensitive shape memory polyurethane containing carboxyl groups. Polym. Chem. 2016, 7, 1739–1746. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, J.; Tian, W. Shape memory polymer composites of poly(styrene–b–butadiene–b–styrene) copolymer/liner low density polyethylene/Fe3O4 nanoparticles for remote activation. Appl. Sci. 2016, 6, 333. [Google Scholar] [CrossRef]

- Kuang, X.; Chen, K.; Dunn, C.K.; Wu, J.; Li, V.C.F.; Qi, H.J. 3D printing of highly stretchable, shape–memory, and self–healing elastomer toward novel 4D printing. ACS Appl. Mater. Interfaces 2018, 10, 7381–7388. [Google Scholar] [CrossRef]

- Zhuo, S.; Liu, Y.; Zhou, L.; Feng, X. Enhanced dual–responsive shape memory nanocomposites with rapid and efficient self–healing capability. J. Mater. Sci. 2018, 53, 13936–13948. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, D.; Yan, X.; Chen, J.; Dong, S.; Zheng, B.; Huang, F. Self–healing supramolecular gels formed by crown ether based host–guest interactions. Angew. Chem. Int. Ed. 2012, 51, 7011–7015. [Google Scholar] [CrossRef]

- Li, L.; Smitthipong, W.; Zeng, H. Mussel–inspired hydrogels for biomedical and environmental applications. Polym. Chem. 2015, 6, 353–358. [Google Scholar] [CrossRef]

- Li, J.; Ning, Z.; Yang, W.; Yang, B.; Zeng, Y. Hydroxyl–terminated polybutadiene–based polyurethane with self–healing and reprocessing capabilities. ACS Omega 2022, 7, 10156–10166. [Google Scholar] [CrossRef]

- Buaksuntear, K.; Limarun, P.; Suehao, S.; Smitthipong, W. Non-covalent interaction on the self-healing of mechanical properties in supramolecular polymers. Int. J. Mol. Sci. 2022, 23, 6902. [Google Scholar] [CrossRef] [PubMed]

- Cui, R.; Ding, J.; Chen, Y. Magnesium acrylate induced interfacial compatibilization of EPDM/PP thermoplastic vulcanizate and shape memory behavior. Compos. Part A Appl. Sci. Manuf. 2019, 122, 27–35. [Google Scholar] [CrossRef]

- Ratna, D.; Karger-Kocsis, J. Recent advances in shape memory polymers and composites: A review. J. Mater. Sci. 2008, 43, 254–269. [Google Scholar] [CrossRef]

- Thakur, S.; Barua, S.; Karak, N. Self–healable castor oil based tough smart hyperbranched polyurethane nanocomposite with antimicrobial attributes. RSC Adv. 2015, 5, 2167–2176. [Google Scholar] [CrossRef]

- Simões, D.N.; Pittol, M.; Tomacheski, D.; Ribeiro, V.F.; Santana, R.M.C. Thermoplastic elastomers containing zinc oxide as antimicrobial additive under thermal accelerated ageing. Mater. Res. 2017, 20, 325–330. [Google Scholar] [CrossRef][Green Version]

- Yao, L.; Gao, H.; Lin, Z.; Dai, Q.; Zhu, S.; Li, S.; Liu, C.; Feng, Q.; Li, Q.; Wang, G.; et al. A shape memory and antibacterial cryogel with rapid hemostasis for noncompressible hemorrhage and wound healing. Chem. Eng. J. 2022, 428, 131005. [Google Scholar] [CrossRef]

- Inoue, K.; Yamashiro, M.; Iji, M. Recyclable shape–memory polymer: Poly(lactic acid) crosslinked by a thermoreversible Diels–Alder reaction. J. Appl. Polym. Sci. 2009, 112, 876–885. [Google Scholar] [CrossRef]

- Hu, J.L.; Lu, J. Shape memory polymers in textiles. Adv. Sci. Technol. 2012, 80, 30–38. [Google Scholar]

- Hu, J. Shape Memory Polymers: Fundamentals, Advances and Applications; Smithers Rapra Technology Ltd.: Shawbury, UK, 2014; pp. 1–48. [Google Scholar]

| Polymer | Elastomer |

|---|---|

| Range from highly crosslinked to no crosslinks | Slightly crosslinked |

| Range from being flexible to rigid | Flexible and elastic |

| Wide range of glass transition temperatures | Typically low (sub-zero) glass transition temperature |

| Elastomer | Trigger | Potential Applications | References |

|---|---|---|---|

| Tetrathiafulvalene polymer networks | Thermal, Light | Thermoactuating smart sunshade and sensors | [43] |

| Polyurethane | Thermal, pH, UV irradiation | Pressure bandages, Bone tissue engineering, Smart textiles, Self-healing materials, Shielding, Heat-shrinkable films, Stent materials, etc. | [44,45,46,47] |

| Polybutadiene | Thermal | Self-healing materials, Automobiles, Electronics, Medical equipment, Sports materials, and Shoes. | [48] |

| Polystyrene | Thermal | Sealants, Coatings, Adhesives, and Automotive parts. | [49] |

| Poly(ε–caprolactone) | Thermal, Water, Light | Water-responsive sensors, Actuators, Medical devices, Self-tightening sutures, Smart stents, and Artificial scaffolds. | [50,51,52,53] |

| Poly(ether–b–amide) | Moisture | Biomedical and industrial applications | [54] |

| Polyamide elastomers | Thermal | Self-healing materials, Intelligent electronic devices, Bionic materials | [55] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suethao, S.; Prasopdee, T.; Buaksuntear, K.; Shah, D.U.; Smitthipong, W. Recent Developments in Shape Memory Elastomers for Biotechnology Applications. Polymers 2022, 14, 3276. https://doi.org/10.3390/polym14163276

Suethao S, Prasopdee T, Buaksuntear K, Shah DU, Smitthipong W. Recent Developments in Shape Memory Elastomers for Biotechnology Applications. Polymers. 2022; 14(16):3276. https://doi.org/10.3390/polym14163276

Chicago/Turabian StyleSuethao, Supitta, Thridsawan Prasopdee, Kwanchai Buaksuntear, Darshil U. Shah, and Wirasak Smitthipong. 2022. "Recent Developments in Shape Memory Elastomers for Biotechnology Applications" Polymers 14, no. 16: 3276. https://doi.org/10.3390/polym14163276

APA StyleSuethao, S., Prasopdee, T., Buaksuntear, K., Shah, D. U., & Smitthipong, W. (2022). Recent Developments in Shape Memory Elastomers for Biotechnology Applications. Polymers, 14(16), 3276. https://doi.org/10.3390/polym14163276