High Efficiency Membranes Based on PTMSP and Hyper-Crosslinked Polystyrene for Toxic Volatile Compounds Removal from Wastewater

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of PTMSP and PTMSP/HCPS Membranes

2.3. Particle Size Distribution

2.4. Membrane Characterization

2.5. Contact Angle Measurement

2.6. Vacuum Pervaporation

3. Results

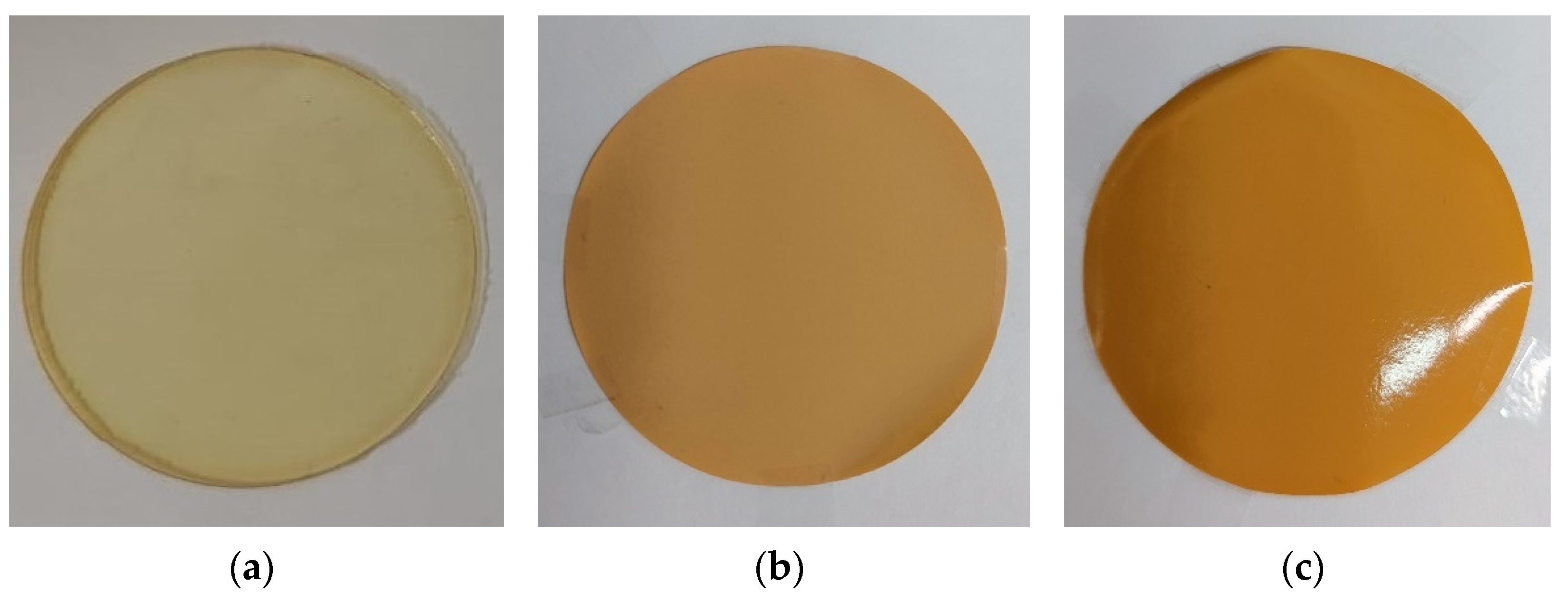

3.1. PTMSP/HCPS Membranes

3.2. Pervaporation Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ge, J.C.; Choi, N.J. Performance of Electrospun Nanofibrous Membranes for Trapping of BTX Aromatic Hydrocarbons and Heavy Metal Ions: Mechanisms, Isotherms and Kinetics. J. Clean. Prod. 2019, 217, 388–397. [Google Scholar] [CrossRef]

- Torkaman, R.; Kazemian, H.; Soltanieh, M. Removal of Btx Compounds from Wastewaters Using Template Free Mfi Zeolitic Membrane. Iran. J. Chem. Chem. Eng. 2010, 29, 91–98. [Google Scholar]

- Lima, L.F.; de Andrade, J.R.; da Silva, M.G.; Vieira, M.G. Fixed Bed Adsorption of Benzene, Toluene, and Xylene (BTX) Contaminants from Monocomponent and Multicomponent Solutions Using a Commercial Organoclay. Ind. Eng. Chem. Res. 2017, 56, 6326–6336. [Google Scholar] [CrossRef]

- Abdullahi, M.E.; Abu Hassan, M.A.; Zainon Noor, Z.; Raja Ibrahim, R.K. Temperature and Air–Water Ratio Influence on the Air Stripping of Benzene, Toluene and Xylene. Desalination Water Treat. 2015, 54, 2832–2839. [Google Scholar] [CrossRef]

- Tijmensen, M.J.; Faaij, A.P.; Hamelinck, C.N.; van Hardeveld, M.R. Exploration of the Possibilities for Production of Fischer Tropsch Liquids and Power via Biomass Gasification. Biomass Bioenergy 2002, 23, 129–152. [Google Scholar] [CrossRef]

- Uragami, T.; Matsuoka, Y.; Miyata, T. Permeation and Separation Characteristics in Removal of Dilute Volatile Organic Compounds from Aqueous Solutions through Copolymer Membranes Consisted of Poly (Styrene) and Poly (Dimethylsiloxane) Containing a Hydrophobic Ionic Liquid by Pervaporation. J. Membr. Sci. 2016, 506, 109–118. [Google Scholar] [CrossRef]

- Koter, S.; Kujawska, A.; Kujawski, W. Modeling of Transport and Separation in a Thermopervaporation Process. J. Membr. Sci. 2015, 480, 129–138. [Google Scholar] [CrossRef]

- Nourani, E.A.; Mortaheb, H.R.; Ehsani, M.R. Pervaporative Performances of Mixed Matrix Membranes Filled with Silica/Silicalite-1 Particles for Purification of Toluene from Dilute Aqueous Solution. J. Environ. Chem. Eng. 2014, 2, 888–898. [Google Scholar] [CrossRef]

- Grushevenko, E.A.; Podtynnikov, I.A.; Golubev, G.S.; Volkov, V.V.; Borisov, I.L. Polyheptylmethylsiloxane—A Novel Material for Removal of Oxygenates from Water by Pervaporation. Pet. Chem. 2018, 58, 941–948. [Google Scholar] [CrossRef]

- Chovau, S.; Dobrak, A.; Figoli, A.; Galiano, F.; Simone, S.; Drioli, E.; Sikdar, S.K.; Van der Bruggen, B. Pervaporation Performance of Unfilled and Filled PDMS Membranes and Novel SBS Membranes for the Removal of Toluene from Diluted Aqueous Solutions. Chem. Eng. J. 2010, 159, 37–46. [Google Scholar] [CrossRef]

- Rozicka, A.; Niemistö, J.; Keiski, R.L.; Kujawski, W. Apparent and Intrinsic Properties of Commercial PDMS Based Membranes in Pervaporative Removal of Acetone, Butanol and Ethanol from Binary Aqueous Mixtures. J. Membr. Sci. 2014, 453, 108–118. [Google Scholar] [CrossRef]

- Rom, A.; Friedl, A. Investigation of Pervaporation Performance of POMS Membrane during Separation of Butanol from Water and the Effect of Added Acetone and Ethanol. Sep. Purif. Technol. 2016, 170, 40–48. [Google Scholar] [CrossRef]

- Golubev, G.S.; Borisov, I.L.; Volkov, V.V. Performance of Commercial and Laboratory Membranes for Recovering Bioethanol from Fermentation Broth by Thermopervaporation. Russ. J. Appl. Chem. 2018, 91, 1375–1381. [Google Scholar] [CrossRef]

- Wu, X.M.; Zhang, Q.G.; Soyekwo, F.; Liu, Q.L.; Zhu, A.M. Pervaporation Removal of Volatile Organic Compounds from Aqueous Solutions Using the Highly Permeable PIM-1 Membrane. AIChE J. 2016, 62, 842–851. [Google Scholar] [CrossRef]

- Satilmis, B.; Uyar, T. Electrospinning of Ultrafine Poly (1-Trimethylsilyl-1-Propyne)[PTMSP] Fibers: Highly Porous Fibrous Membranes for Volatile Organic Compound Removal. ACS Appl. Polym. Mater. 2019, 1, 787–796. [Google Scholar] [CrossRef]

- Golubev, G.S.; Borisov, I.L.; Volkov, V.V. Thermopervaporative Removal of Isopropanol and Butanol from Aqueous Media Using Membranes Based on Hydrophobic Polysiloxanes. Pet. Chem. 2018, 58, 975–982. [Google Scholar] [CrossRef]

- Talluri, V.; Patakova, P.; Moucha, T.; Vopicka, O. Transient and Steady Pervaporation of 1-Butanol–Water Mixtures through a Poly [1-(Trimethylsilyl)-1-Propyne](Ptmsp) Membrane. Polymers 2019, 11, 1943. [Google Scholar] [CrossRef] [Green Version]

- Yampolskii, Y. Polymeric Gas Separation Membranes. Macromolecules 2012, 45, 3298–3311. [Google Scholar] [CrossRef]

- Nagai, K.; Masuda, T.; Nakagawa, T.; Freeman, B.D.; Pinnau, I. Poly [1-(Trimethylsilyl)-1-Propyne] and Related Polymers: Synthesis, Properties and Functions. Prog. Polym. Sci. 2001, 26, 721–798. [Google Scholar] [CrossRef]

- Golubev, G.S.; Volkov, V.V.; Borisov, I.L.; Volkov, A.V. High Free Volume Polymers for Pervaporation. Curr. Opin. Chem. Eng. 2022, 36, 100788. [Google Scholar] [CrossRef]

- Dorkenoo, K.D.; Pfromm, P.H. Accelerated Physical Aging of Thin Poly [1-(Trimethylsilyl)-1-Propyne] Films. Macromolecules 2000, 33, 3747–3751. [Google Scholar] [CrossRef]

- Nagai, K.; Nakagawa, T. Effects of Aging on the Gas Permeability and Solubility in Poly (1-Trimethylsilyl-1-Propyne) Membranes Synthesized with Various Catalysts. J. Membr. Sci. 1995, 105, 261–272. [Google Scholar] [CrossRef]

- Yi, S.; Wan, Y. Volatile Organic Compounds (VOCs) Recovery from Aqueous Solutions via Pervaporation with Vinyltriethoxysilane-Grafted-Silicalite-1/Polydimethylsiloxane Mixed Matrix Membrane. Chem. Eng. J. 2017, 313, 1639–1646. [Google Scholar] [CrossRef]

- Smith, S.J.; Hou, R.; Konstas, K.; Akram, A.; Lau, C.H.; Hill, M.R. Control of Physical Aging in Super-Glassy Polymer Mixed Matrix Membranes. Acc. Chem. Res. 2020, 53, 1381–1388. [Google Scholar] [CrossRef]

- Apel, P.Y.; Bobreshova, O.V.; Volkov, A.V.; Volkov, V.V.; Nikonenko, V.V.; Stenina, I.A.; Filippov, A.N.; Yampolskii, Y.P.; Yaroslavtsev, A.B. Prospects of Membrane Science Development. Membr. Membr. Technol. 2019, 1, 45–63. [Google Scholar] [CrossRef] [Green Version]

- Jeong, D.; Oh, J.; Yum, I.; Lee, Y. Removal of VOCs from Their Aqueous Solution by Pervaporation with PDMS-Zeolite Composite Membrane. Desalination Water Treat. 2010, 17, 242–247. [Google Scholar] [CrossRef]

- Jia, Z.; Wu, G. Metal-Organic Frameworks Based Mixed Matrix Membranes for Pervaporation. Microporous Mesoporous Mater. 2016, 235, 151–159. [Google Scholar] [CrossRef]

- Ong, Y.K.; Shi, G.M.; Le, N.L.; Tang, Y.P.; Zuo, J.; Nunes, S.P.; Chung, T.-S. Recent Membrane Development for Pervaporation Processes. Prog. Polym. Sci. 2016, 57, 1–31. [Google Scholar] [CrossRef] [Green Version]

- Penkova, A.V.; Acquah, S.F.; Sokolova, M.P.; Dmitrenko, M.E.; Toikka, A.M. Polyvinyl Alcohol Membranes Modified by Low-Hydroxylated Fullerenol C60 (OH) 12. J. Membr. Sci. 2015, 491, 22–27. [Google Scholar] [CrossRef]

- Yeh, T.-M.; Wang, Z.; Mahajan, D.; Hsiao, B.S.; Chu, B. High Flux Ethanol Dehydration Using Nanofibrous Membranes Containing Graphene Oxide Barrier Layers. J. Mater. Chem. A 2013, 1, 12998–13003. [Google Scholar] [CrossRef]

- Volkov, A.V.; Bakhtin, D.S.; Kulikov, L.A.; Terenina, M.V.; Golubev, G.S.; Bondarenko, G.N.; Legkov, S.A.; Shandryuk, G.A.; Volkov, V.V.; Khotimskiy, V.S. Stabilization of Gas Transport Properties of PTMSP with Porous Aromatic Framework: Effect of Annealing. J. Membr. Sci. 2016, 517, 80–90. [Google Scholar] [CrossRef]

- Golubev, G.S.; Borisov, I.L.; Litvinova, E.G.; Khotimsky, V.S.; Bakhtin, D.S.; Pastukhov, A.V.; Davankov, V.A.; Volkov, V.V. A Novel Hybrid Material Based on Polytrimethylsilylpropyne and Hypercrosslinked Polystyrene for Membrane Gas Separation and Thermopervaporation. Pet. Chem. 2017, 57, 498–510. [Google Scholar] [CrossRef]

- Ji, W.; Sikdar, S.K. Pervaporation Using Adsorbent-Filled Membranes. Ind. Eng. Chem. Res. 1996, 35, 1124–1132. [Google Scholar] [CrossRef]

- Panek, D.; Konieczny, K. Preparation and Applying the Membranes with Carbon Black to Pervaporation of Toluene from the Diluted Aqueous Solutions. Sep. Purif. Technol. 2007, 57, 507–512. [Google Scholar] [CrossRef]

- Yu, S.; Jiang, Z.; Ding, H.; Pan, F.; Wang, B.; Yang, J.; Cao, X. Elevated Pervaporation Performance of Polysiloxane Membrane Using Channels and Active Sites of Metal Organic Framework CuBTC. J. Membr. Sci. 2015, 481, 73–81. [Google Scholar] [CrossRef]

- Khosravi, M.J.; Hosseini, S.M.; Vatanpour, V. Performance improvement of PES membrane decorated by Mil-125 (Ti)/chitosan nanocomposite for removal of organic pollutants and heavy metal. Chemosphere 2022, 290, 133335. [Google Scholar] [CrossRef]

- Amiri, S.; Asghari, A.; Vatanpour, V.; Rajabi, M. Fabrication and characterization of a novel polyvinyl alcohol-graphene oxide-sodium alginate nanocomposite hydrogel blended PES nanofiltration membrane for improved water purification. Sep. Purif. Technol. 2020, 250, 117216. [Google Scholar] [CrossRef]

- Barzegar, H.; Shahsavarifar, S.; Vatanpour, V.; Masteri-Farahani, M. Peroxopolyoxometalate nanoparticles blended PES membrane with improved hydrophilicity, anti-fouling, permeability, and dye separation properties. J. Appl. Polym. Sci. 2021, 138, 50764. [Google Scholar] [CrossRef]

- Davankov, V.A.; Tsyurupa, M.P. Hypercrosslinked Polymeric Networks and Adsorbing Materials: Synthesis, Properties, Structure, and Applications; Elsevier: Amsterdam, The Netherlands, 2010; ISBN 0-444-53701-5. [Google Scholar]

- Shantarovich, V.P.; Suzuki, T.; He, C.; Davankov, V.A.; Pastukhov, A.V.; Tsyurupa, M.P.; Kondo, K.; Ito, Y. Positron Annihilation Study of Hyper-Cross-Linked Polystyrene Networks. Macromolecules 2002, 35, 9723–9729. [Google Scholar] [CrossRef]

- Tsyurupa, M.P.; Davankov, V.A. Porous Structure of Hypercrosslinked Polystyrene: State-of-the-Art Mini-Review. React. Funct. Polym. 2006, 66, 768–779. [Google Scholar] [CrossRef]

- Hackbarth, F.V.; Vilar, V.J.; De Souza, G.B.; de Souza, S.; De Souza, A.A.U. Benzene, Toluene and o-Xylene (BTX) Removal from Aqueous Solutions through Adsorptive Processes. Adsorption 2014, 20, 577–590. [Google Scholar] [CrossRef]

- Golubev, G.; Bakhtin, D.; Makaev, S.; Borisov, I.; Volkov, A. Hybrid Microporous Polymeric Materials with Outstanding Permeability and Increased Gas Transport Stability: PTMSP Aging Prevention by Sorption of the Polymerization Catalyst on HCPS. Polymers 2021, 13, 1922. [Google Scholar] [CrossRef] [PubMed]

- Volkov, V.; Borisov, I.; Golubev, G.; Vasilevsky, V.; Matveev, D.; Bondarenko, G.; Volkov, A. Sorption-assisted Thermopervaporation Method for Organics Recovery from ABE Fermentation Broth. J. Chem. Technol. Biotechnol. 2020, 95, 40–51. [Google Scholar] [CrossRef]

- Purolite Ion Exchange Resin Manufacturer. Purolite. Available online: http://www.purolite.com/index (accessed on 12 May 2022).

- Bakhtin, D.; Bazhenov, S.; Polevaya, V.; Grushevenko, E.; Makaev, S.; Karpacheva, G.; Volkov, V.; Volkov, A. Aging of Thin-Film Composite Membranes Based on Crosslinked PTMSP/PEI Loaded with Highly Porous Carbon Nanoparticles of Infrared Pyrolyzed Polyacrylonitrile. Membranes 2020, 10, 419. [Google Scholar] [CrossRef] [PubMed]

- Coker, A.K. Ludwig’s Applied Process Design for Chemical and Petrochemical Plants; Elsevier: Oxford, UK, 2007; Volume 1. [Google Scholar]

- GESTIS Substance Database. Available online: https://gestis-database.dguv.de/ (accessed on 12 May 2022).

- Pocket Guide to Chemical Hazards |NIOSH| CDC. Available online: https://www.cdc.gov/niosh/npg/default.html (accessed on 12 May 2022).

- Anjum, H.; Johari, K.; Gnanasundaram, N.; Appusamy, A.; Thanabalan, M. Impact of Surface Modification on Adsorptive Removal of BTX onto Activated Carbon. J. Mol. Liq. 2019, 280, 238–251. [Google Scholar] [CrossRef]

- Panek, D.; Konieczny, K. Applying filled and unfilled polyether-block-amide membranes to separation of toluene from wastewaters by pervaporation. Desalination 2008, 222, 280–285. [Google Scholar] [CrossRef]

- Jian, K.; Pintauro, P.N. Asymmetric PVDF hollow-fiber membranes for organic/water pervaporation separations. J. Membr. Sci. 1997, 135, 41–53. [Google Scholar] [CrossRef]

- Uragami, T.; Yamada, H.; Miyata, T. Removal of dilute volatile organic compounds in water through graft copolymer membranes consisting of poly (alkylmethacrylate) and poly (dimethylsiloxane) by pervaporation and their membrane morphology. J. Membr. Sci. 2001, 187, 255–269. [Google Scholar] [CrossRef]

- Wu, H.; Liu, L.; Pan, F.; Hu, C.; Jiang, Z. Pervaporative removal of benzene from aqueous solution through supramolecule calixarene filled PDMS composite membranes. Sep. Purif. Technol. 2006, 51, 352–358. [Google Scholar] [CrossRef]

- Matavos-Aramyan, S.; Bagheri, G.; Jazebizadeh, M.H. Pervaporation separation of toluene from aqueous solutions using nano-based PEBA/NaX mixed matrix membrane. Silicon 2019, 11, 1725–1730. [Google Scholar] [CrossRef]

| Membranes | Conditions | Organic Component, wt% | Total Flux, kg/m2∙h | Separation Factor | PSI, kg/m2∙h | Ref. |

|---|---|---|---|---|---|---|

| MFI | 30 °C | 0.01 (Benzene) | 0.12 | 64 | 7.6 | [2] |

| 0.01 (Toluene) | 0.25 | 53 | 13 | |||

| 0.01 (o-Xylene) | 0.18 | 35 | 4.3 | |||

| PEBA | 25 °C; 0.001 bar | 0.02 (Toluene) | 0.02 | 2450 | 49 | [34] |

| PEBA with 15% carbon black | 25 °C; 0.001 bar | 0.02 (Toluene) | 0.033 | 1800 | 59.4 | [34] |

| PDMS | 25 °C; 0.001 bar | 0.02 (Toluene) | 0.7 | 80 | 55.3 | [34] |

| PDMS with 15% carbon black | 25 °C; 0.001 bar | 0.02 (Toluene) | 0.3 | 200 | 59.7 | [34] |

| PEBA | 25 °C; 0.001 bar | 0.05 (Toluene) | 0.03 | 1500 | 45 | [51] |

| PEBA with 15% carbon black | 25 °C; 0.001 bar | 0.05 (Toluene) | 0.049 | 920 | 45 | [51] |

| Polyvinylidene fluoride hollow-fiber | 25 °C; 0.025 bar | 0.08 (Benzene) | 0.26 | 250 | 65 | [52] |

| Poly(ethylmethacrylate)-PDMS | 40 °C; 1.3 × 10−5 bar | 0.06 (Benzene) | 0.018 | 2400 | 43.2 | [53] |

| Poly(methylmethacrylate)-PDMS | 40 °C; 1.3 × 10−5 bar | 0.05 (Benzene) | 0.017 | 3700 | 63 | [53] |

| PDMS | 60 °C; 0.01 bar | 0.14 (Benzene) | 0.15 | 3302 | 495.2 | [54] |

| PDMS with 3% tert-butylcalix [4] arene (CA) | 60 °C; 0.01 bar | 0.14 (Benzene) | 0.13 | 5604 | 728.4 | [54] |

| Polyether-block-amide (PEBA) | 0.01 bar | 0.03 (Toluene) | 0.085 | 60 | 5 | [55] |

| PEBA with 2% NaX nanozeolite | 0.01 bar | 0.03 (Toluene) | 0.11 | 60 | 6.5 | [55] |

| PTMSP | 30 °C, 5 × 10−5 bar | 0.15 (Benzene) | 0.17 | 440 | 74.6 | This work |

| 0.05 (Toluene) | 0.09 | 701 | 63 | |||

| 0.016 (o-Xylene) | 0.15 | 588 | 88 | |||

| PTMSP/HCPS 5 wt% | 30 °C, 5 × 10−5 bar | 0.15 (Benzene) | 0.23 | 560 | 128.6 | This work |

| 0.05 (Toluene) | 0.11 | 721 | 79.2 | |||

| 0.016 (o-Xylene) | 0.17 | 650 | 110.3 | |||

| PTMSP/HCPS 10 wt% | 30 °C, 5 × 10−5 bar | 0.15 (Benzene) | 0.45 | 725 | 325.8 | This work |

| 0.05 (Toluene) | 0.21 | 818 | 171.6 | |||

| 0.016 (o-Xylene) | 0.24 | 831 | 199.2 | |||

| PTMSP/HCPS 30 wt% | 30 °C, 5 × 10−5 bar | 0.15 (Benzene) | 0.83 | 1238 | 1027 | This work |

| 0.05 (Toluene) | 0.36 | 1017 | 365.8 | |||

| 0.016 (o-Xylene) | 0.38 | 1046 | 397.1 | |||

| PTMSP/HCPS 50 wt% | 30 °C, 5 × 10−5 bar | 0.15 (Benzene) | 1.15 | 1037 | 1191 | This work |

| 0.05 (Toluene) | 0.52 | 1040 | 540.3 | |||

| 0.016 (o-Xylene) | 0.56 | 1008 | 563.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golubev, G.; Sokolov, S.; Rokhmanka, T.; Makaev, S.; Borisov, I.; Khashirova, S.; Volkov, A. High Efficiency Membranes Based on PTMSP and Hyper-Crosslinked Polystyrene for Toxic Volatile Compounds Removal from Wastewater. Polymers 2022, 14, 2944. https://doi.org/10.3390/polym14142944

Golubev G, Sokolov S, Rokhmanka T, Makaev S, Borisov I, Khashirova S, Volkov A. High Efficiency Membranes Based on PTMSP and Hyper-Crosslinked Polystyrene for Toxic Volatile Compounds Removal from Wastewater. Polymers. 2022; 14(14):2944. https://doi.org/10.3390/polym14142944

Chicago/Turabian StyleGolubev, Georgy, Stepan Sokolov, Tatyana Rokhmanka, Sergey Makaev, Ilya Borisov, Svetlana Khashirova, and Alexey Volkov. 2022. "High Efficiency Membranes Based on PTMSP and Hyper-Crosslinked Polystyrene for Toxic Volatile Compounds Removal from Wastewater" Polymers 14, no. 14: 2944. https://doi.org/10.3390/polym14142944

APA StyleGolubev, G., Sokolov, S., Rokhmanka, T., Makaev, S., Borisov, I., Khashirova, S., & Volkov, A. (2022). High Efficiency Membranes Based on PTMSP and Hyper-Crosslinked Polystyrene for Toxic Volatile Compounds Removal from Wastewater. Polymers, 14(14), 2944. https://doi.org/10.3390/polym14142944