Polyimide Nanodielectrics Doped with Ultralow Content of MgO Nanoparticles for High-Temperature Energy Storage

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Nanocomposite Films

2.3. Characterization

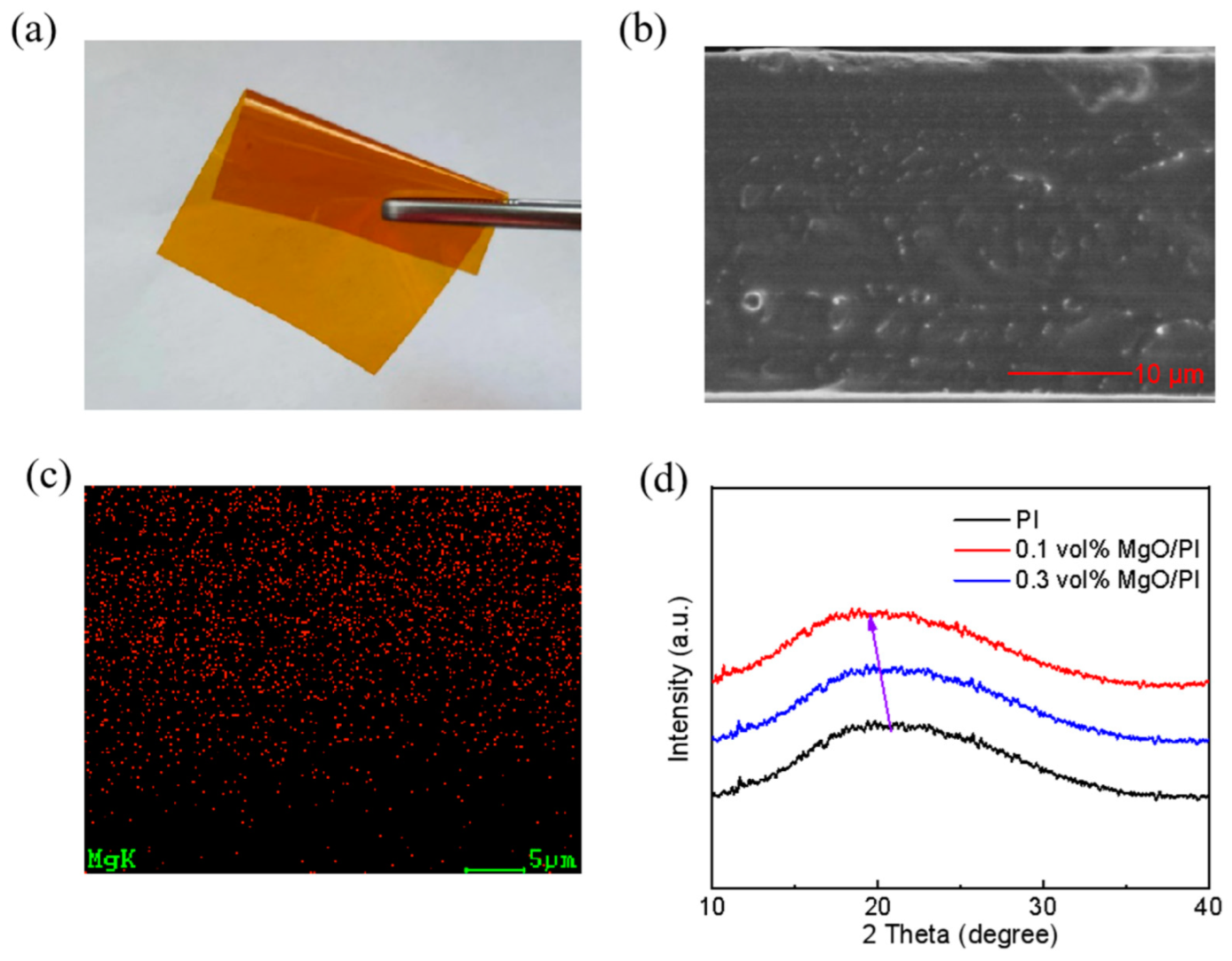

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chu, B.J.; Zhou, X.; Ren, K.L.; Neese, B.; Lin, M.R.; Wang, Q.; Bauer, F.; Zhang, Q.M. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef] [PubMed]

- Mannodi-Kanakkithodi, A.; Trench, G.M.; Huan, T.D.; Ma, R.; Tefferi, M.; Cao, Y.; Sotzing, G.A.; Ramprasad, R. Rational Co-Design of polymer dielectrics for energy storage. Adv. Mater. 2016, 28, 6277–6291. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Li, F.; Liu, Y.; Zhang, Q.H.; Wang, M.; Lan, S.; Zheng, Y.P.; Ma, J.; Gu, L.; Shen, Y.; et al. Ultrahigh-energy density lead-free dielectric films via polymorphic nanodomain design. Science 2019, 365, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.; Zhang, L.L.; Chen, Q.; Irwin, P. High-Temperature capacitor polymer films. J. Electron. Mater. 2014, 43, 4569–4575. [Google Scholar] [CrossRef]

- Zhang, S.H.; Zou, C.; Kushner, D.I.; Zhou, X.; Orchard, R.J.; Zhang, N.Y.; Zhang, Q.M. Semicrystalline polymers with high dielectric constant, melting temperature, and charge-discharge efficiency. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1158–1166. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Y.; Liu, Y.; Li, L.; Liu, Y.; Wang, Q. Dielectric polymers for high-temperature capacitive energy storage. Chem. Soc. Rev. 2021, 50, 6369–6400. [Google Scholar] [CrossRef]

- Fan, B.Y.; Liu, F.H.; Yang, G.; Li, H.; Zhang, G.Z.; Jiang, S.L.; Wang, Q. Dielectric materials for high-temperature capacitors. IET Nanodielectr. 2018, 1, 32–40. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.H.; Zhang, G.Z.; Li, H.U.; Iagodkine, E.; Haque, A.; Chen, L.Q.; Jackson, T.N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef]

- Li, Q.; Yao, F.Z.; Liu, Y.; Zhang, G.Z.; Wang, H.; Wang, Q. High-Temperature Dielectric Materials for Electrical Energy Storage. Annu. Rev. Mater. Res. 2018, 48, 219–243. [Google Scholar] [CrossRef]

- Caliari, L.; Bettacchi, P.; Boni, E.; Montanari, D.; Gamberini, A.; Barbieri, L.; Bergamaschi, F. KEMET film capacitors for high temperature, high voltage and high current. In Proceedings of the CARTS International 2013: The 33rd Symposium for Passive Electronic Components, Houston, TX, USA, 25–28 March 2013; Available online: https://www.researchgate.net/publication/283402491 (accessed on 9 October 2017).

- Zhou, Y.; Li, Q.; Dang, B.; Yang, Y.; Shao, T.; Li, H.; Hu, J.; Zeng, R.; He, J.L.; Wang, Q. A Scalable, High-Throughput, and Environmentally Benign Approach to Polymer Dielectrics Exhibiting Significantly Improved Capacitive Performance at High Temperatures. Adv. Mater. 2018, 30, 1805672. [Google Scholar] [CrossRef]

- Li, H.; Ai, D.; Ren, L.L.; Yao, B.; Han, Z.B.; Shen, Z.H.; Wang, J.J.; Chen, L.Q.; Wang, Q. Scalable Polymer Nanocomposites with Record High-Temperature Capacitive Performance Enabled by Rationally Designed Nanostructured Inorganic Fillers. Adv. Mater. 2019, 31, 1900875. [Google Scholar] [CrossRef] [PubMed]

- Ai, D.; Li, H.; Zhou, Y.; Ren, L.L.; Han, Z.B.; Yao, B.; Zhou, W.; Zhao, L.; Xu, J.M.; Wang, Q. Tuning Nanofillers in In Situ Prepared Polyimide Nanocomposites for High-Temperature Capacitive Energy Storage. Adv. Energy Mater. 2010, 10, 1903881. [Google Scholar] [CrossRef]

- Li, H.; Gadinski, M.R.; Huang, Y.Q.; Ren, L.L.; Zhou, Y.; Ai, D.; Han, Z.B.; Yao, B.; Wang, Q. Crosslinked fluoropolymers exhibiting superior high-temperature energy density and charge–discharge efficiency. Energy Environ. Sci. 2020, 13, 1279–1286. [Google Scholar] [CrossRef] [Green Version]

- Dai, Z.Z.; Bao, Z.W.; Ding, S.; Liu, C.C.; Sun, H.Y.; Wang, H.; Zhou, X.; Wang, Y.C.; Yin, Y.W.; Li, X.G. Scalable Polyimide-poly(Amic Acid) Copolymer Based Nanocomposites for High-Temperature Capacitive Energy Storage. Adv. Mater. 2021, 34, e2101976. [Google Scholar] [CrossRef]

- Tsebriienko, T.; Popov, A.I. Effect of Poly(Titanium Oxide) on the Viscoelastic and Thermophysical Properties of Interpenetrating Polymer Networks. Crystals 2021, 11, 794. [Google Scholar] [CrossRef]

- Aksimentyeva, O.I.; Savchyn, V.P.; Dyakonov, V.P.; Piechota, S.; Horbenko, Y.Y.; Opainych, I.Y.; Demchenko, P.Y.; Popov, A.; Szymczak, H. Modification of polymer-magnetic nanoparticles by luminescent and conducting substances. Mol. Cryst. Liq. Cryst. 2014, 590, 35–42. [Google Scholar] [CrossRef]

- Zhang, K.Y.; Ma, Z.Y.; Deng, H.; Fu, Q. Improving high-temperature energy storage performance of PI dielectric capacitor films through boron nitride interlayer. Adv. Compos. Hybrid Mater. 2021, 5, 238–249. [Google Scholar] [CrossRef]

- Liu, J.; Shen, Z.H.; Xu, W.H.; Zhang, Y.; Qian, X.S.; Jiang, Z.H.; Zhang, Y.H. Interface-Strengthened Polymer Nanocomposites with Reduced Dielectric Relaxation Exhibit High Energy Density at Elevated Temperatures Utilizing a Facile Dual Crosslinked Network. Small 2020, 16, 2000714. [Google Scholar] [CrossRef]

- Tang, Y.D.; Xu, W.H.; Niu, S.; Zhang, Z.C.; Zhang, Y.H.; Jiang, Z.H. Crosslinked dielectric materials for high-temperature capacitive energy storage. J. Mater. Chem. A 2021, 9, 10000. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, X.F.; Ellingford, C.; Zhang, Y.; Chen, S.; Zhou, K.C.; Zhang, D.; Bowen, C.R.; Wan, C.Y. Interface design for high energy density polymer nanocomposites. Chem. Soc. Rev. 2019, 48, 4424–4465. [Google Scholar] [CrossRef] [Green Version]

- Hassan, Y.A.; Hu, H.L. Current status of polymer nanocomposite dielectrics for high-temperature applications. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106064. [Google Scholar] [CrossRef]

- Li, H.; Ren, L.L.; Zhou, Y.; Yao, B.; Wang, Q. Recent progress in polymer dielectrics containing boron nitride nanosheets for high energy density capacitors. High Volt. 2020, 5, 365–376. [Google Scholar] [CrossRef]

- Chen, H.X.; Pan, Z.B.; Wang, W.L.; Chen, Y.Y.; Xing, S.; Cheng, Y.; Ding, X.P.; Liu, J.J.; Zhai, J.W.; Yu, J.H. Ultrahigh discharge efficiency and improved energy density in polymer-based nanocomposite for high-temperature capacitors application. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106266. [Google Scholar] [CrossRef]

- Ren, L.L.; Yang, L.J.; Zhang, S.Y.; Li, H.; Zhou, Y.; Ai, D.; Xie, Z.L.; Zhao, X.T.; Peng, Z.R.; Liao, R.J.; et al. Largely enhanced dielectric properties of polymer composites with HfO2 nanoparticles for high-temperature film capacitors. Compos. Sci. Technol. 2021, 201, 108528. [Google Scholar] [CrossRef]

- Li, L.T.; Dong, J.F.; Hu, R.C.; Chen, X.Q.; Niu, Y.J.; Wang, H. Wide-bandgap fluorides/polyimide composites with enhanced energy storage properties at high temperatures. Chem. Eng. J. 2022, 435, 135059. [Google Scholar] [CrossRef]

- Li, Y.S.; Cheng, S.; Li, Q.; He, J.L. The effect of co-doped with nano-MgO and nano-TiO2 on breakdown strength and aging life of polyimide nanocomposites. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 18–30 October 2020; Volume 10. [Google Scholar]

- Popov, A.I.; Shirmane, L.; Pankratov, V.; Lushchik, A.; Kotlov, A.; Serga, V.E.; Kulikova, L.D.; Chikvaidze, G.; Zimmermann, J. Comparative study of the luminescence properties of macro-and nanocrystalline MgO using synchrotron radiation. Nucl. Instrum. Methods Phys. Res. Sect. B 2013, 310, 23–26. [Google Scholar] [CrossRef]

- Ge, G.H.; Tang, Y.Z.; Li, Y.X.; Huang, L.S. Effect of Environmental Temperature on the Insulating Performance of Epoxy/MgO Nanocomposites. Appl. Sci. 2020, 10, 7018. [Google Scholar] [CrossRef]

- Leonés, A.; Peponi, L.; Fiori, S.; Lieblich, M. Effect of the Addition of MgO Nanoparticles on the Thermally-Activated Shape Memory Behavior of Plasticized PLA Electrospun Fibers. Polymers 2022, 14, 2657. [Google Scholar] [CrossRef]

- Bertasius, P.; Meisak, D.; Macutkevic, J.; Kuzhir, P.; Selskis, A.; Volnyanko, E.; Banys, J. Fine Tuning of Electrical Transport and Dielectric Properties of Epoxy/Carbon Nanotubes Composites via Magnesium Oxide Additives. Polymers 2019, 11, 2044. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.W.; Wang, W.; Zhang, A.Q.; Tan, F.T.; Qiao, X.L. In situ sol–gel preparation of high transparent fluorinated polyimide/nano-MgO hybrid films. J. Sol-Gel Sci. Technol. 2012, 63, 495–500. [Google Scholar] [CrossRef]

- Halasa, A.F.; Wathen, G.D.; Hsu, W.L.; Matrana, B.A.; Massie, J.M. Relationship between interchain spacing of amorphous polymers and blend miscibility as determined by wide-angle X-ray scattering. J. Appl. Polym. Sci. 1991, 43, 183–190. [Google Scholar] [CrossRef]

- Thakur, Y.; Zhang, B.; Dong, R.; Lu, W.C.; Iacob, C.; Runt, J.; Bernholc, J.; Zhang, Q.M. Generating high dielectric constant blends from lower dielectric constant dipolar polymers using nanostructure engineering. Nano Energy 2017, 32, 73–79. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.H.; Yang, W.Y. Fundamentals of Polymer Dielectric for Energy Storage; Science Press: Beijing, China, 2016; pp. 43–68. [Google Scholar]

- Shi, L.; Zhang, C.G.; Du, Y.H.; Zhu, H.; Zhang, Q.; Zhu, S.P. Improving Dielectric Constant of Polymers through Liquid Electrolyte Inclusion. Adv. Funct. Mater. 2020, 31, 2007863. [Google Scholar] [CrossRef]

- Zheng, L.L.; Qi, S.C.; Wang, C.M.; Shi, L. Piezoelectric, dielectric, and ferroelectric properties of high Curie temperature bismuth layer-structured bismuth titanate-tantalate (Bi3TiTaO9). Acta Phys. Sin. 2019, 68, 147701. [Google Scholar] [CrossRef]

- Zhou, W.Y.; Zhang, Y.; Wang, J.J.; Li, H.; Xu, W.H.; Li, B.; Chen, L.Q.; Wang, Q. Lightweight Porous Polystyrene with High Thermal Conductivity by Constructing 3D Interconnected Network of Boron Nitride Nanosheets. ACS Appl. Mater. Interfaces 2020, 12, 46767–46778. [Google Scholar] [CrossRef]

- Li, S.; Nie, H.C.; Wang, G.S.; Liu, N.T.; Zhou, M.X.; Cao, F.; Dong, X.L. Novel AgNbO3-based lead-free ceramics featuring excellent pyroelectric properties for infrared detecting and energy harvesting applications via antiferroelectric/ferroelectric phase boundary design. J. Mater. Chem. C 2019, 7, 4403–4414. [Google Scholar] [CrossRef]

- Guo, S.B.; Yan, S.G.; Cao, F.; Yao, C.H.; Wang, G.S.; Dong, X.L. Research progress of pyroelectric characteristics of lead-free ferroelectric ceramics for infrared detection. Acta Phys. Sin. 2020, 69, 127708. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, Y.H.; Zhang, T.D.; Zhang, C.H.; Zhang, Y.Q.; Zhang, Y.; Chen, Q.G.; Chi, Q.G. Ultrahigh discharge efficiency and excellent energy density in oriented core-shell nanofiber-polyetherimide composites. Energy Storage Mater. 2020, 25, 180–192. [Google Scholar] [CrossRef]

- Thakur, Y.; Zhang, T.; Iacob, C.; Yang, T.N.; Bernholc, J.; Chen, L.Q.; Runt, J.; Zhang, Q.M. Enhancement of the dielectric response in polymer nanocomposites with low dielectric constant fillers. Nanoscale 2017, 9, 10992–10997. [Google Scholar] [CrossRef]

- Zhou, Y.; Yuan, C.; Wang, S.J.; Zhu, Y.J.; Cheng, S.; Yang, X.; Yang, Y.; Hu, J.; He, J.L.; Li, Q. Interface modulated nanocomposites based on polypropylene for high-temperature energy storage. Energy Storage Mater. 2020, 28, 255–263. [Google Scholar] [CrossRef]

| Sample | ∆εr/εr, 25 °C |

|---|---|

| PI | 8.91% |

| 0.05 vol% MgO/PI | 6.25% |

| 0.1 vol% MgO/PI | 5.71% |

| 0.2 vol% MgO/PI | 5.83% |

| 0.3 vol% MgO/PI | 6.14% |

| 40 vol% liquid electrolyte | 6.0% [36] |

| Bi3TiTaO9 ceramics | ≈10% [37] |

| 20 wt% BNNS/c-PS | 13.3% [38] |

| (1 − x)AgNbO3-xLiTaO3 ceramics | ≈66.70% [39] |

| Sr/Ba-SBN ferroelectric ceramics | >150% [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Qin, H.; Song, J.; Liu, M.; Zhang, X.; Wang, S.; Xiong, C. Polyimide Nanodielectrics Doped with Ultralow Content of MgO Nanoparticles for High-Temperature Energy Storage. Polymers 2022, 14, 2918. https://doi.org/10.3390/polym14142918

Li Z, Qin H, Song J, Liu M, Zhang X, Wang S, Xiong C. Polyimide Nanodielectrics Doped with Ultralow Content of MgO Nanoparticles for High-Temperature Energy Storage. Polymers. 2022; 14(14):2918. https://doi.org/10.3390/polym14142918

Chicago/Turabian StyleLi, Ziwei, Hongmei Qin, Jinhui Song, Man Liu, Xiaolin Zhang, Shan Wang, and Chuanxi Xiong. 2022. "Polyimide Nanodielectrics Doped with Ultralow Content of MgO Nanoparticles for High-Temperature Energy Storage" Polymers 14, no. 14: 2918. https://doi.org/10.3390/polym14142918

APA StyleLi, Z., Qin, H., Song, J., Liu, M., Zhang, X., Wang, S., & Xiong, C. (2022). Polyimide Nanodielectrics Doped with Ultralow Content of MgO Nanoparticles for High-Temperature Energy Storage. Polymers, 14(14), 2918. https://doi.org/10.3390/polym14142918