A Multiscale Study of CFRP Based on Asymptotic Homogenization with Application to Mechanical Analysis of Composite Pressure Vessels

Abstract

:1. Introduction

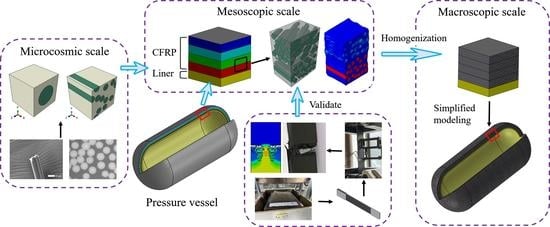

2. Asymptotic Homogenization of CFRP

2.1. Asymptotic Expansion

2.2. Multiscale Analysis

2.2.1. Microscopic Model

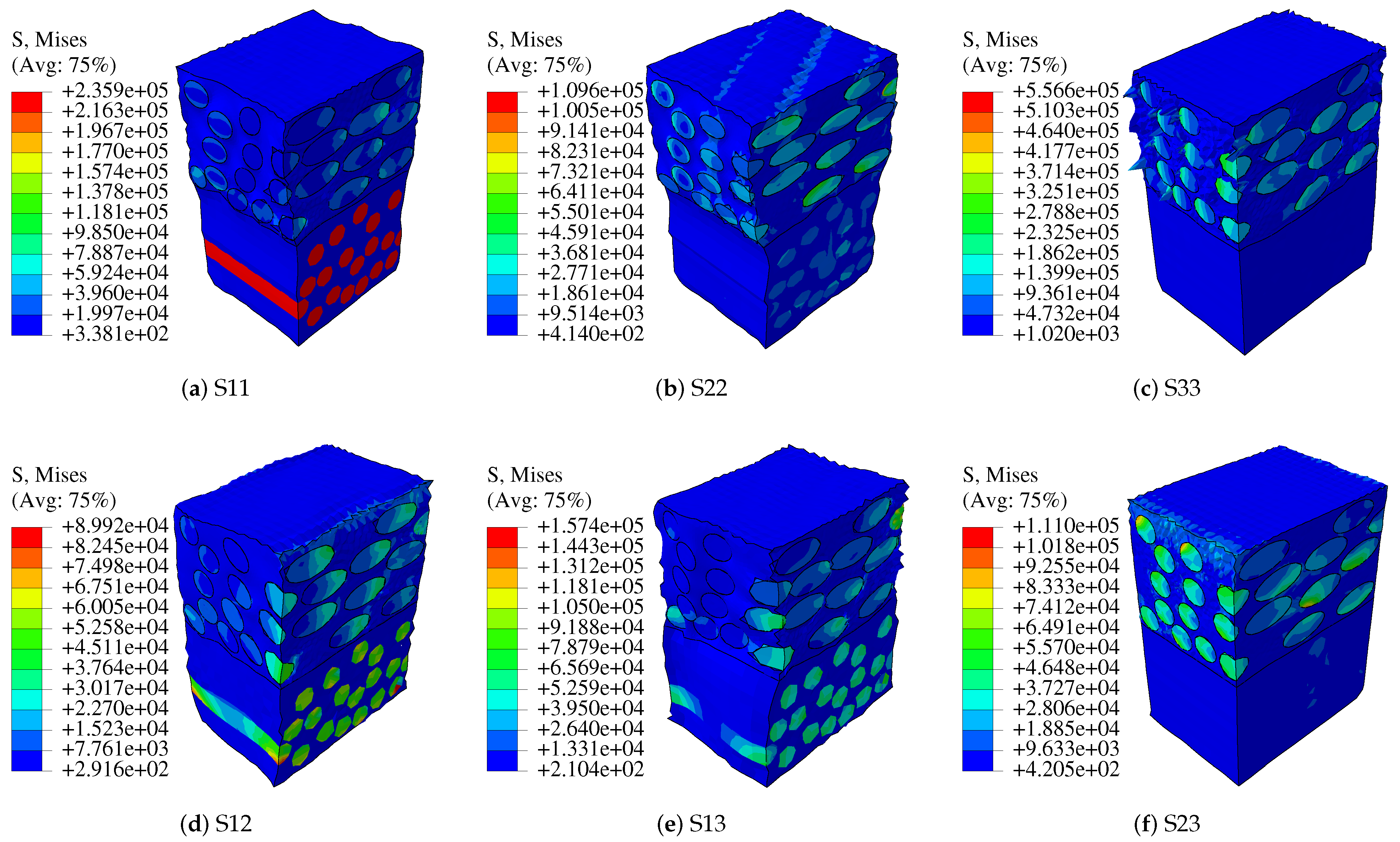

2.2.2. Mesoscopic Model

2.2.3. Validation on the Macroscopic Scale

3. Experimental Program

3.1. Specimen Preparation

3.2. Tensile Experiment

3.3. CFRP Laminate Homogenization Theoretical Study

3.3.1. Rule of Mixtures

Longitudinal Modulus

Transverse Modulus

3.4. Experimental Results

3.4.1. Longitudinal Uniaxial Stretching

3.4.2. Transverse Uniaxial Stretching

3.4.3. Macroscopic Perspective

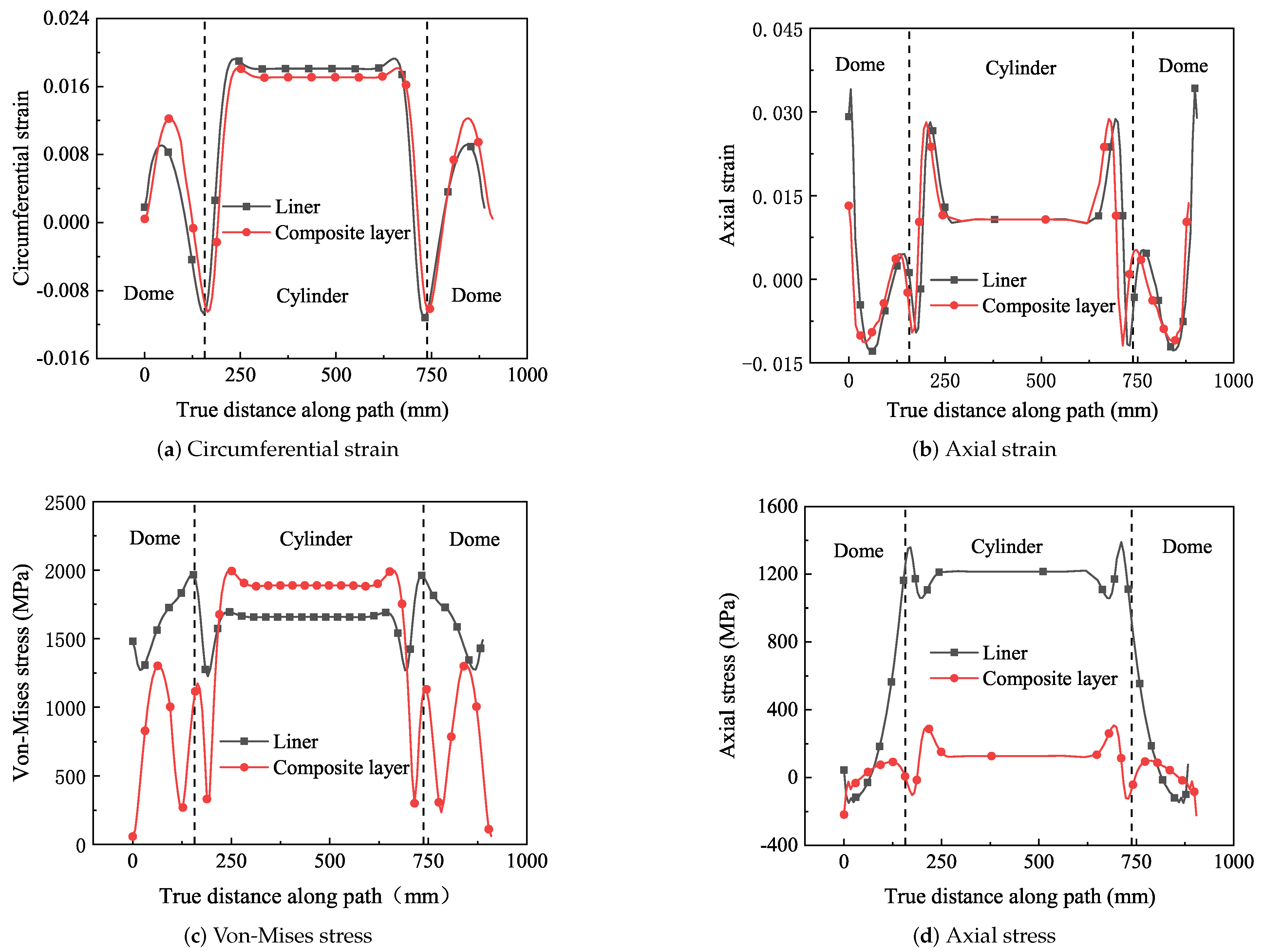

4. Mechanical Analysis of Type Pressure Vessel

5. Conclusions

- (1)

- From a micro perspective, the homogenized elastic moduli of CFRP with the same fiber volume fraction but different fiber numbers have some deviation but are within an acceptable range. The homogenized elastic moduli and homogenized Poisson’s ratio are reasonable. At the mesoscopic level, it is not necessary to establish all the layering models but to establish partial structural models that can reflect the layering laws, so as to predict the overall structural parameters.

- (2)

- The simulation results from a macroscopic perspective are consistent with the uniaxial tensile test results of the specimens, indicating that the ultimate strength and elastic moduli of CFRP structures can be predicted without considering the failure modes inside the structure.

- (3)

- A method to solve the properties of CFRP structures is developed by combining the processive homogenization approach with ABAQUS finite element analysis. Applying this method to type pressure vessels, the complexity of the model can be simplified, and the prediction result of burst pressure is reasonable. The cylinder and the transition region of the pressure vessel will be destroyed first, and the distributions of stress and strain can also be predicted.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Meyer, C.S.; Catugas, I.G.; Gillespie, J.W., Jr.; Haque, B.Z. Investigation of normal, lateral, and oblique impact of microscale projectiles into unidirectional glass/epoxy composites. Def. Technol. 2021; in press. [Google Scholar] [CrossRef]

- Li, D.; Lu, C.; Wang, L.; Du, S.; Yang, Y. A reconsideration of the relationship between structural features and mechanical properties of carbon fibers. Mater. Sci. Eng. 2017, 685, 65–70. [Google Scholar] [CrossRef]

- Liu, Z.; Xia, Y.; Guo, S. Characterization methods of delamination in a plain woven cfrp composite. J. Mater. Sci. 2019, 54, 13157–13174. [Google Scholar] [CrossRef]

- Barthélémy, H.; Weber, M.; Barbier, F. Hydrogen storage: Recent improvements and industrial perspectives. Int. J. Hydrogen Energy 2017, 42, 7254–7262. [Google Scholar] [CrossRef]

- Dönmez, A.; Rasoolinejad, M.; Bažant, Z.P. Size effect on frp external reinforcement and retrofit of concrete structures. J. Compos. Constr. 2020, 24, 04020056. [Google Scholar] [CrossRef]

- Tan, P.; Tong, L.; Steven, G.; Ishikawa, T. Behavior of 3d orthogonal woven cfrp composites. part i. experimental investigation. Compos. Part Appl. Sci. Manuf. 2000, 31, 259–271. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, C.; Liu, Y.; Zhou, P.; Yu, Z.; Yuan, S. Wet spun polyacrylonitrile-based hollow-mesoporous fibers with different draw ratios. Polymer 2019, 179, 121618. [Google Scholar] [CrossRef]

- Sepetcioglu, H.; Tarakcioglu, N. Fatigue behavior of graphene nanoplatelets reinforced and unreinforced basalt/epoxy composite pressure vessels subjected to low-velocity impact under internal pressure. J. Compos. Mater. 2021, 55, 4361–4373. [Google Scholar] [CrossRef]

- Bensoussan, A.; Lions, J.-L.; Papanicolaou, G. Asymptotic Analysis for Periodic Structures; American Mathematical Soc.: Providence, RI, USA, 2011; Volume 374. [Google Scholar]

- Bakhvalov, N.S.; Panasenko, G. Homogenisation: Averaging Processes in Periodic Media: Mathematical Problems in the Mechanics of Composite Materials; Springer: Berlin/Heidelberg, Germany, 2012; Volume 36. [Google Scholar]

- Tang, H.; Huang, H.; Liu, C.; Liu, Z.; Yan, W. Multi-scale modelling of structure-property relationship in additively manufactured metallic materials. Int. J. Mech. Sci. 2021, 194, 106185. [Google Scholar] [CrossRef]

- Xu, K.; Xu, X. Meso-mechanical analysis of 3d braided composites based on a finite element model. J. Eng. Appl. Sci. 2007, 2, 1553–1562. [Google Scholar]

- Zhang, C.; Xu, X. Finite element analysis of 3d braided composites based on three unit-cells models. Compos. Struct. 2013, 98, 130–142. [Google Scholar] [CrossRef]

- Ji, X.; Khatri, A.M.; Chia, E.S.; Cha, R.K.; Yeo, B.T.; Joshi, S.C.; Chen, Z. Multi-scale simulation and finite-element-assisted computation of elastic properties of braided textile reinforced composites. J. Compos. Mater. 2014, 48, 931–949. [Google Scholar] [CrossRef]

- Cai, Y.; Sun, H. Numerical prediction of viscoelastic behaviors of three-dimensionally braided resin matrix composites. J. Mater. Sci. Eng. 2012, 30, 271–275. [Google Scholar]

- Yin, D.-M.; Li, B.-M.; Xiao, H.-C. Prediction of three-dimensional elastic behavior of filament-wound composites based on the bridging model. Def. Technol. 2021, 17, 609–616. [Google Scholar] [CrossRef]

- Chen, L.; Tao, X.; Choy, C. Mechanical analysis of 3-d braided composites by the finite multiphase element method. Compos. Sci. Technol. 1999, 59, 2383–2391. [Google Scholar] [CrossRef]

- Zhai, J.-J.; Cheng, S.; Zeng, T.; Wang, Z.-H.; Fang, D.-N. Extended multiscale fe approach for steady-state heat conduction analysis of 3d braided composites. Compos. Sci. Technol. 2017, 151, 317–324. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, W.; Domaszewski, M. Microstructure modelling and prediction of effective elastic properties of 3d multiphase and multilayer braided composite. Mater. Sci. Technol. 2011, 27, 1213–1221. [Google Scholar] [CrossRef]

- Zhang, C.; Binienda, W.K.; Goldberg, R.K.; Kohlman, L.W. Meso-scale failure modeling of single layer triaxial braided composite using finite element method. Compos. Part Appl. Sci. Manuf. 2014, 58, 36–46. [Google Scholar] [CrossRef]

- May, M.; Nossek, M.; Petrinic, N.; Hiermaier, S.; Thoma, K. Adaptive multi-scale modeling of high velocity impact on composite panels. Compos. Part Appl. Sci. Manuf. 2014, 58, 56–64. [Google Scholar] [CrossRef]

- Zhang, C.; Li, N.; Wang, W.; Binienda, W.K.; Fang, H. Progressive damage simulation of triaxially braided composite using a 3d meso-scale finite element model. Compos. Struct. 2015, 125, 104–116. [Google Scholar] [CrossRef]

- Zhang, C.; Binienda, W.K. Multi-scale finite element simulation of triaxially braided composite. In Proceedings of the 28th Annual Technical Conference of the American Society for Composites 2013 (ASC 2013), State College, PA, USA, 9–11 September 2013; Volume 1, pp. 232–251. [Google Scholar]

- Šmilauer, V.; Hoover, C.G.; Bažant, Z.P.; Caner, F.C.; Waas, A.M.; Shahwan, A.K.W. Multiscale simulation of fracture of braided composites via repetitive unit cells. Eng. Fract. Mech. 2011, 78, 901–918. [Google Scholar] [CrossRef]

- Tang, H.; Zhou, G.; Sun, Q.; Avinesh, O.; Meng, Z.; Engler-Pinto, C.; Su, X. Experimental and computational analysis of bending fatigue failure in chopped carbon fiber chip reinforced composites. Compos. Struct. 2021, 275, 114402. [Google Scholar] [CrossRef] [PubMed]

- Liao, B.; Du, Y.; Zheng, J.; Wang, D.; Lin, Y.; Tao, R.; Zhou, C. Prediction of residual burst strength for composite pressure vessels after low velocity impact. Int. J. Hydrogen Energy 2020, 45, 10962–10976. [Google Scholar] [CrossRef]

- Nguyen, B.N.; Simmons, K.L. A multiscale modeling approach to analyze filament-wound composite pressure vessels. J. Compos. Mater. 2013, 47, 2113–2123. [Google Scholar] [CrossRef]

- Harada, S.; Arai, Y.; Araki, W.; Iijima, T.; Kurosawa, A.; Ohbuchi, T.; Sasaki, N. A simplified method for predicting burst pressure of type iii filament-wound cfrp composite vessels considering the inhomogeneity of fiber packing. Compos. Struct. 2018, 190, 79–90. [Google Scholar] [CrossRef]

- Li, B.; Chen, J.; Lv, Y.; Huang, L.; Zhang, X. Influence of humidity on fatigue performance of cfrp: A molecular simulation. Polymers 2020, 13, 140. [Google Scholar] [CrossRef] [PubMed]

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar fracture toughness of cfrp laminates incorporating multi-walled carbon nanotubes. Polymers 2015, 7, 1020–1045. [Google Scholar]

- Liu, P.; Chu, J.; Hou, S.; Zheng, J. Micromechanical damage modeling and multiscale progressive failure analysis of composite pressure vessel. Comput. Mater. Sci. 2012, 60, 137–148. [Google Scholar] [CrossRef]

- Liu, P.F.; Zheng, J. Progressive failure analysis of carbon fiber/epoxy composite laminates using continuum damage mechanics. Mater. Sci. Eng. 2008, 485, 711–717. [Google Scholar]

- Liu, P.; Zheng, J. Recent developments on damage modeling and finite element analysis for composite laminates: A review. Mater. Des. 2010, 31, 3825–3834. [Google Scholar] [CrossRef]

- Zhai, H.; Bai, T.; Wu, Q.; Yoshikawa, N.; Xiong, K.; Chen, C. Time-domain asymptotic homogenization for linear-viscoelastic composites: Mathematical formulae and finite element implementation. Compos. Part Open Access 2022, 8, 100248. [Google Scholar] [CrossRef]

- Zhai, H.; Wu, Q.; Yoshikawa, N.; Xiong, K.; Chen, C. Space-time asymptotic expansion method for transient thermal conduction in the periodic composite with temperature-dependent thermal properties. Comput. Mater. Sci. 2021, 194, 110470. [Google Scholar] [CrossRef]

- Yuan, Z.; Fish, J. Toward realization of computational homogenization in practice. Int. J. Numer. Methods Eng. 2008, 73, 361–380. [Google Scholar] [CrossRef]

- Babuška, I. Homogenization approach in engineering. In Computing Methods in Applied Sciences and Engineering; Springer: Berlin/Heidelberg, Germany, 1976; pp. 137–153. [Google Scholar]

- ASTM. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials, Astm d3039/d3039m-17; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Kang, H.; He, P.; Zhang, C.; Dai, Y.; Lv, H.; Zhang, M.; Yang, D. Stress—Strain and burst failure analysis of fiber wound composite material high-pressure vessel. Polym. Polym. Compos. 2021, 29, 1291–1303. [Google Scholar] [CrossRef]

- Leh, D.; Saffré, P.; Francescato, P.; Arrieux, R.; Villalonga, S. A progressive failure analysis of a 700-bar type iv hydrogen composite pressure vessel. Int. J. Hydrogen Energy 2015, 40, 13206–13214. [Google Scholar] [CrossRef]

| Density | E | ||

|---|---|---|---|

| T700SC-12K | 1.8 | 230,000 | 0.3 |

| 914 epoxy | 1.69 | 4000 | 0.39 |

| A fiber | 75,757.58 | 9132.42 | 9132.42 | 0.36 | 0.36 | 0.51 |

| Fibers | 80,645.16 | 8410.43 | 8703.22 | 0.37 | 0.37 | 0.54 |

| 48,702.089 | 10,630.608 | 18,525.380 | 0.36 | 0.29 | 0.23 | 3229.035 | 4418.718 | 3624.764 |

| Value | 181 | 10.3 | 0.28 | 0.49 | 5.17 | 2150 | 2150 | 298 | 298 | 778 |

| Aluminum(6061) | ||||

|---|---|---|---|---|

| Value | 70 | 0.3 | 246 | 324 |

| 112,359.551 | 10,288.066 | 8928.571 | 0.17 | 0.18 | 0.46 | 5173.306 | 1484.781 | 5540.166 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Gao, S.; Song, M.; Chen, Y.; Zhao, X.; Liang, J.; Feng, J. A Multiscale Study of CFRP Based on Asymptotic Homogenization with Application to Mechanical Analysis of Composite Pressure Vessels. Polymers 2022, 14, 2817. https://doi.org/10.3390/polym14142817

Zhang N, Gao S, Song M, Chen Y, Zhao X, Liang J, Feng J. A Multiscale Study of CFRP Based on Asymptotic Homogenization with Application to Mechanical Analysis of Composite Pressure Vessels. Polymers. 2022; 14(14):2817. https://doi.org/10.3390/polym14142817

Chicago/Turabian StyleZhang, Nan, Shuai Gao, Meili Song, Yang Chen, Xiaodong Zhao, Jianguo Liang, and Jun Feng. 2022. "A Multiscale Study of CFRP Based on Asymptotic Homogenization with Application to Mechanical Analysis of Composite Pressure Vessels" Polymers 14, no. 14: 2817. https://doi.org/10.3390/polym14142817

APA StyleZhang, N., Gao, S., Song, M., Chen, Y., Zhao, X., Liang, J., & Feng, J. (2022). A Multiscale Study of CFRP Based on Asymptotic Homogenization with Application to Mechanical Analysis of Composite Pressure Vessels. Polymers, 14(14), 2817. https://doi.org/10.3390/polym14142817