Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

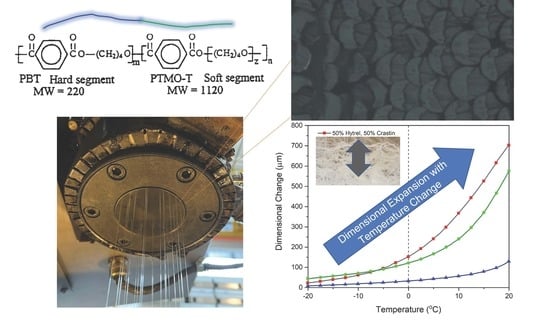

2.2. Bicomponent Co-Extrusion/Spinning

2.3. Rheological Characterization

2.4. Microscopic Analysis

2.5. Thermal Analysis

2.6. Tensile Testing

2.7. Curvature Change Analysis

2.8. Batting Expansion Test

3. Results

3.1. Rheological Behavior

3.2. Fiber Processing and Morphology Optimization

3.3. Thermal Analysis

3.4. Tensile Properties

3.5. Thermo-Mechanical Properties

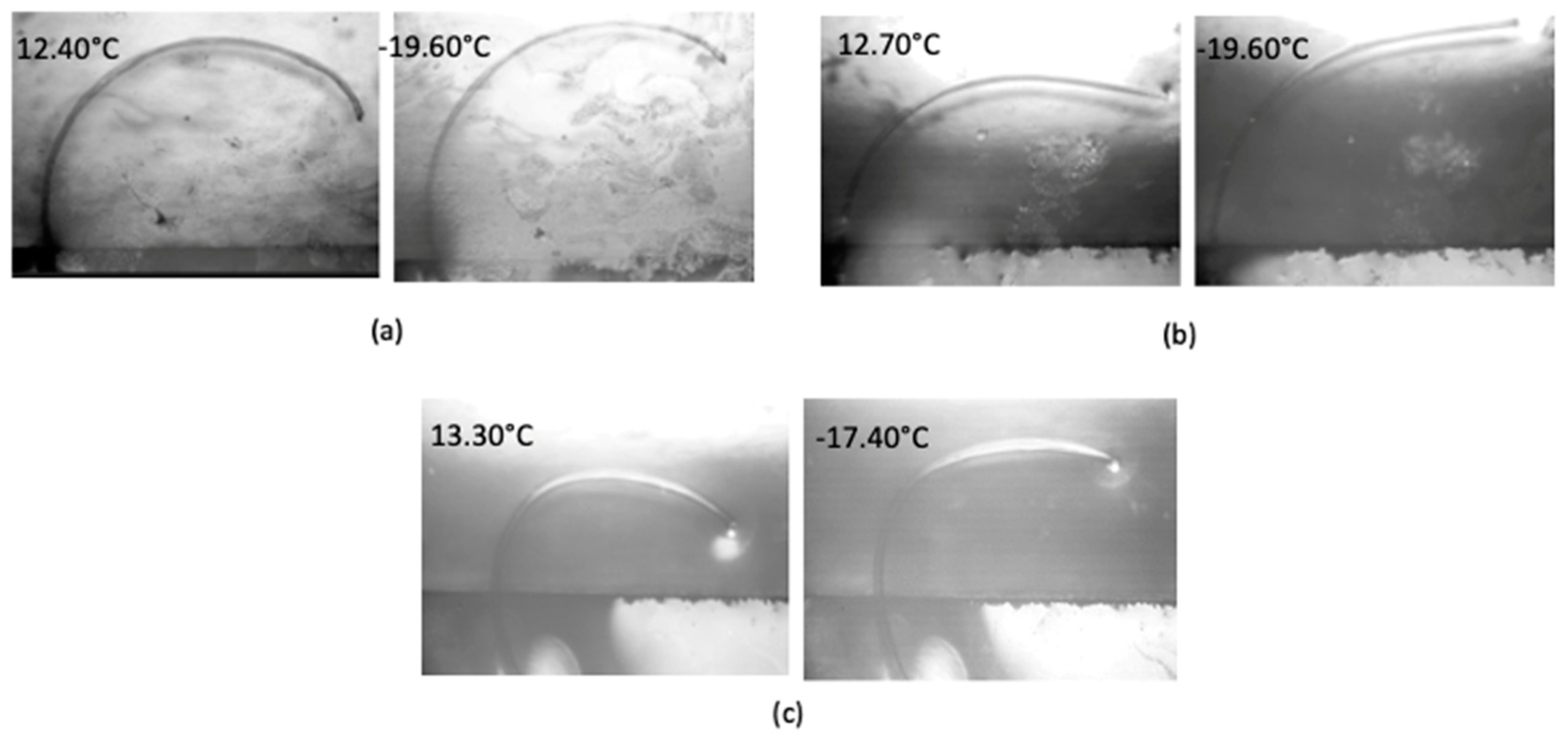

3.6. Fiber Curvature Analysis

3.7. Batting Expansion Testing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chisholm, B.J.; Zimmer, J.G. Isothermal Crystallization Kinetics of Commercially Important Polyalkylene Terephthalates. J. Appl. Polym. Sci. 1999, 76, 1296–1307. [Google Scholar] [CrossRef]

- How Team USA’s Self-Heating Olympic Jackets Work, and a List of the Design Firms That Helped to Create Them–Core77. Available online: https://www.core77.com/posts/73270/How-Team-USAs-Self-Heating-Olympic-Jackets-Work-and-a-List-of-the-Design-Firms-That-Helped-to-Create-Them# (accessed on 25 April 2022).

- Yi, L.; Wang, Y.; Fang, Y.; Zhang, M.; Yao, J.; Wang, L.; Marek, J. Development of core–sheath structured smart nanofibers by coaxial electrospinning for thermo-regulated textiles. RSC Adv. 2019, 9, 21844–21851. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, Y.; Xiao, X.; Fu, J.; Huan, C.; Qi, S.; Zhan, Y.; Zhu, Y.; Xu, G. Novel smart textile with phase change materials encapsulated core-sheath structure fabricated by coaxial electrospinning. Chem. Eng. J. 2019, 355, 532–539. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, J.; Shen, L.; Hu, Y.; Han, J. A smart hollow filament with thermal sensitive internal diameter. J. Appl. Polym. Sci. 2009, 113, 2440–2449. [Google Scholar] [CrossRef]

- Crespy, D.; Rossi, R.M. Temperature-responsive polymers with LCST in the physiological range and their applications in textiles. Polym. Int. 2007, 56, 1461–1468. [Google Scholar] [CrossRef]

- Joci, D. Polymer-Based Smart Coatings for Comfort in Clothing 2 Thermal Comfort Ability of Clothing. Tekstilec 2016, 59, 107–114. [Google Scholar] [CrossRef]

- Plowman, J.E.; Deb-Choudhury, S.; Bryson, W.G.; Clerens, S.; Dyer, J.M. Protein Expression in Orthocortical and Paracortical Cells of Merino Wool Fibers. J. Agric. Food Chem. 2009, 57, 2174–2180. [Google Scholar] [CrossRef]

- Gernhardt, M.; Peng, L.; Burgard, M.; Jiang, S.; Förster, B.; Schmalz, H.; Agarwal, S.; Gernhardt, M.; Peng, L.; Burgard, M.; et al. Tailoring the Morphology of Responsive Bioinspired Bicomponent Fibers. Macromol. Mater. Eng. 2018, 303, 1700248. [Google Scholar] [CrossRef]

- US4159297A–Continuous Process for Production of Latent Crimp Filaments–Google Patents. Available online: https://patents.google.com/patent/US4159297A/en (accessed on 25 April 2022).

- Herbert, K.M.; Schretti, S.; Rowan, S.J.; Weder, C. 50th Anniversary Perspective: Solid-State Multistimuli, Multiresponsive Polymeric Materials. Macromolecules 2017, 50, 8845–8870. [Google Scholar] [CrossRef]

- Ruckdashel, R.; Venkataraman, D.; Park, J.H. Smart textiles: A toolkit to fashion the future. J. Appl. Phys. 2021, 129, 130903. [Google Scholar] [CrossRef]

- Zhang, X.A.; Yu, S.; Xu, B.; Li, M.; Peng, Z.; Wang, Y.; Deng, S.; Wu, X.; Wu, Z.; Ouyang, M.; et al. Dynamic gating of infrared radiation in a textile. Science 2019, 363, 619–623. [Google Scholar] [CrossRef] [PubMed]

- Timoshenko, S. Analysis of Bi-Metal Thermostats. JOSA 1925, 11, 233–255. [Google Scholar] [CrossRef]

- DeCristofano, B.S.; Fossey, S.A.; Welsh, E.A.; Perry, J.; Archambault, D. Temperature-adaptive insulation based on multicomponent fibers of various cross-sections. Mater. Res. Soc. Symp. Proc. 2011, 1312, 137–142. [Google Scholar] [CrossRef]

- Ripa, C.; Latulippe, A.; Sun, H.; Fossey, S.; Drew, C. Curvature Change Analysis of SMART Fibers Used for Temperature Adaptive Insulation. In Proceedings of the Volume 8: Heat Transfer and Thermal Engineering, Salt Lake City, UT, USA, 11–14 November 2019; pp. 1–6. [Google Scholar]

- US8192824B2–Temperature Responsive Smart Textile–Google Patents. Available online: https://patents.google.com/patent/US8192824B2/en (accessed on 27 April 2022).

- Rwei, S.P.; Lin, Y.T.; Su, Y.Y. Study of self-crimp polyester fibers. Polym. Eng. Sci. 2005, 45, 838–845. [Google Scholar] [CrossRef]

- Mukhopadhyay, S. Bi-Component and Bi-Constituent Spinning of Synthetic Polymer Fibres; Woodhead Publishing Limited: Cambridge, UK, 2014; ISBN 9780857094995. [Google Scholar]

- Denton, M.J. The Crimp Curvature Of Bicomponent Fibres. J. Text. Inst. 1982, 73, 253–263. [Google Scholar] [CrossRef]

- White, J.L.; Cakmak, M. Orientation development and crystallization in melt spinning of fibers. Adv. Polym. Technol. 1986, 6, 295–337. [Google Scholar] [CrossRef]

- Rwei, S.; Jue, Z.; Chen, F.L. PBT/PET conjugated fibers: Melt spinning, fiber properties, and thermal bonding. Polym. Eng. Sci. 2004, 44, 331–344. [Google Scholar] [CrossRef]

- Lu, F.-M.; Spruiell, J.E. Influence of processing conditions on structure development and mechanical properties of poly(butylene terephthalate) filament. J. Appl. Polym. Sci. 1986, 31, 1595–1607. [Google Scholar] [CrossRef]

| Take-Off (m/min) | Godet Roll 1 (m/min) | Godet Roll 2 (m/min) | Godet Roll 3 (m/min) | Winder (m/min) | Draw Ratio |

|---|---|---|---|---|---|

| 300 | 325 | 350 | 400 | 500 | 1.67 |

| 300 | 400 | 450 | 500 | 600 | 2.00 |

| 300 | 500 | 550 | 600 | 700 | 2.33 |

| 300 | 500 | 600 | 700 | 800 | 2.67 |

| 300 | 600 | 700 | 800 | 900 | 3.00 |

| 300 | 600 | 750 | 900 | 1000 | 3.33 |

| 300 | 700 | 850 | 1000 | 1100 | 3.67 |

| Draw Ratio | Hytrel Enthalpy (J/g) | Crastin Enthalpy (J/g) | Crastin Crystallinity (%) |

|---|---|---|---|

| 1.67 | 4.592 | 19.625 | 13.488 |

| 2.00 | 5.976 | 20.475 | 14.072 |

| 2.33 | 7.114 | 21.042 | 14.462 |

| 2.67 | 5.996 | 21.124 | 14.518 |

| 3.00 | 7.814 | 23.587 | 16.211 |

| 3.33 | 7.959 | 22.278 | 15.311 |

| 3.67 | 9.682 | 25.759 | 17.704 |

| Draw Ratio | Young’s Modulus (GPa) |

|---|---|

| 1.67 | 1.168 ± 0.012 |

| 2.00 | 1.472 ± 0.125 |

| 2.33 | 1.754 ± 0.130 |

| 2.67 | 1.798 ± 0.065 |

| 3.00 | 1.906 ± 0.120 |

| 3.33 | 2.001 ± 0.145 |

| 3.67 | 2.165 ± 0.187 |

| Temperature Difference (°C) | Diameter (μm) | ||

| 40 | 30 | 20 | |

| Curvature (mm−1) | |||

| 40 | 0.032 | 0.043 | 0.065 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khadse, N.; Ruckdashel, R.; Macajoux, S.; Sun, H.; Park, J.H. Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation. Polymers 2022, 14, 2757. https://doi.org/10.3390/polym14142757

Khadse N, Ruckdashel R, Macajoux S, Sun H, Park JH. Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation. Polymers. 2022; 14(14):2757. https://doi.org/10.3390/polym14142757

Chicago/Turabian StyleKhadse, Ninad, Rebecca Ruckdashel, Shnaidie Macajoux, Hongwei Sun, and Jay Hoon Park. 2022. "Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation" Polymers 14, no. 14: 2757. https://doi.org/10.3390/polym14142757

APA StyleKhadse, N., Ruckdashel, R., Macajoux, S., Sun, H., & Park, J. H. (2022). Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation. Polymers, 14(14), 2757. https://doi.org/10.3390/polym14142757