The Investigation of Novel Dynamic Packing Technology for Injection Molded Part Quality Control and Its Production Stability by Using Real-Time PVT Control Method

Abstract

:1. Introduction

2. Materials and Methods

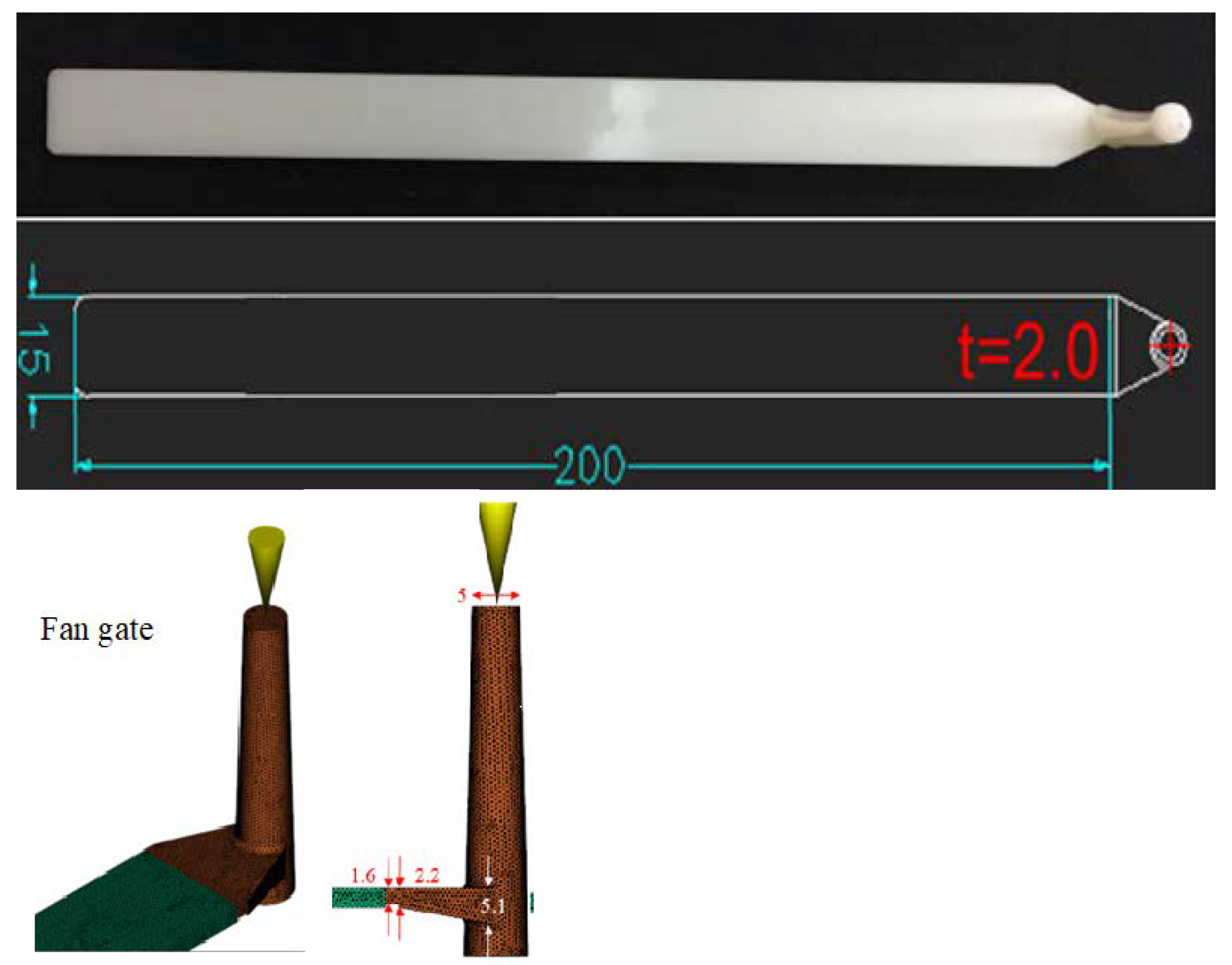

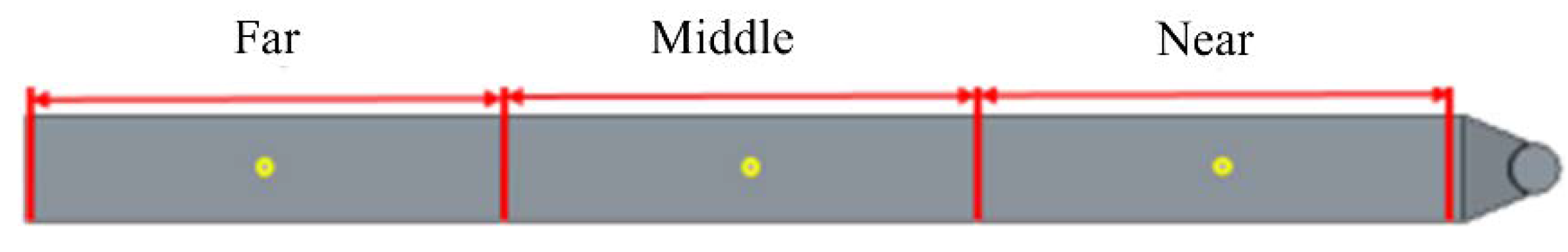

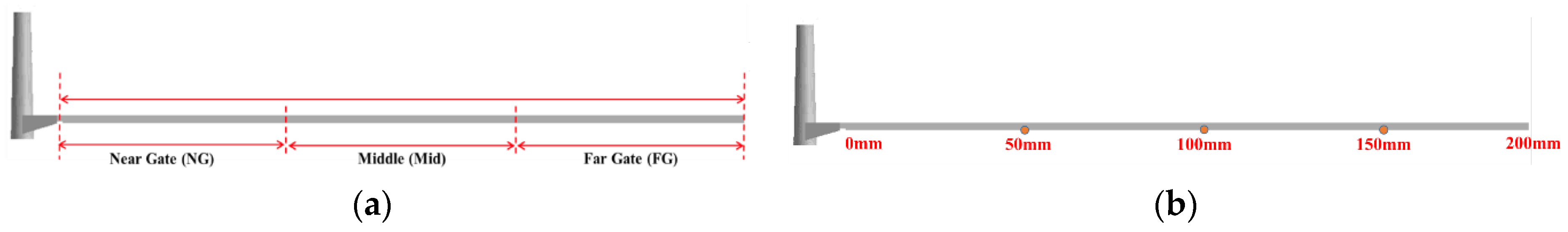

2.1. Sensor Position and Sample Preparation

2.2. Material and Machine

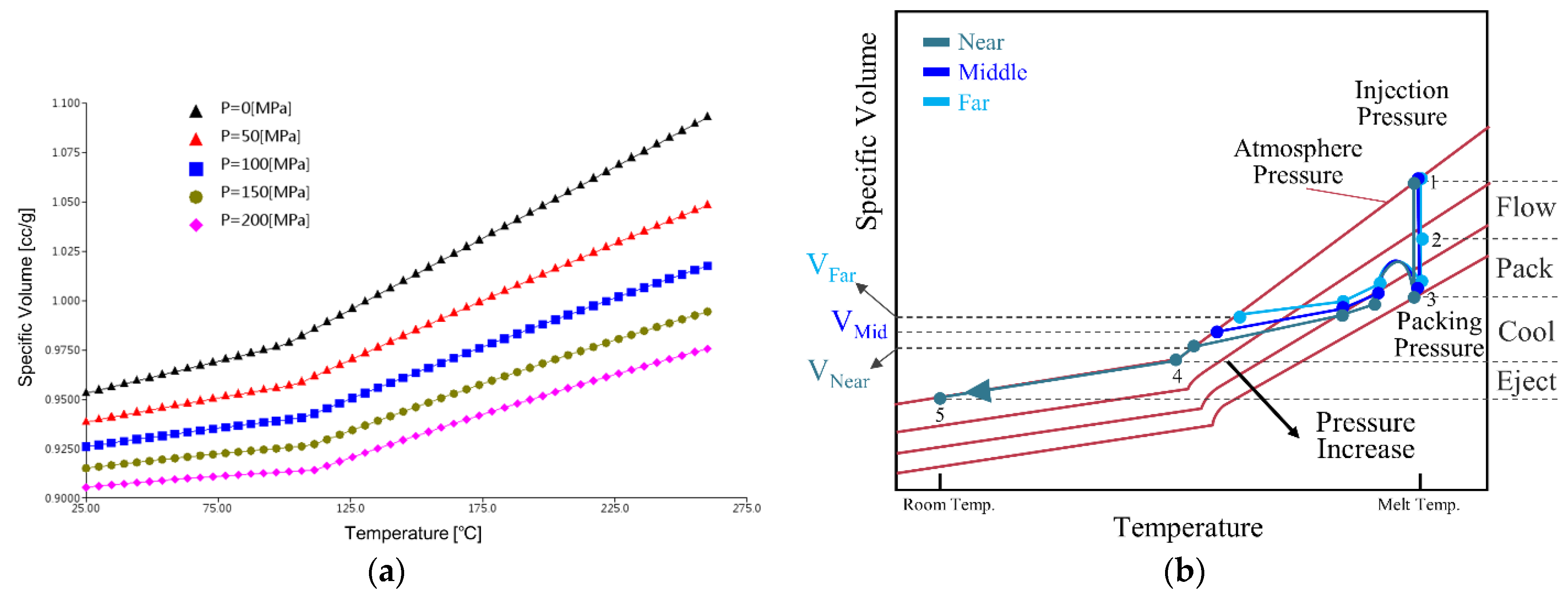

2.3. Data Collection and PVT Theory

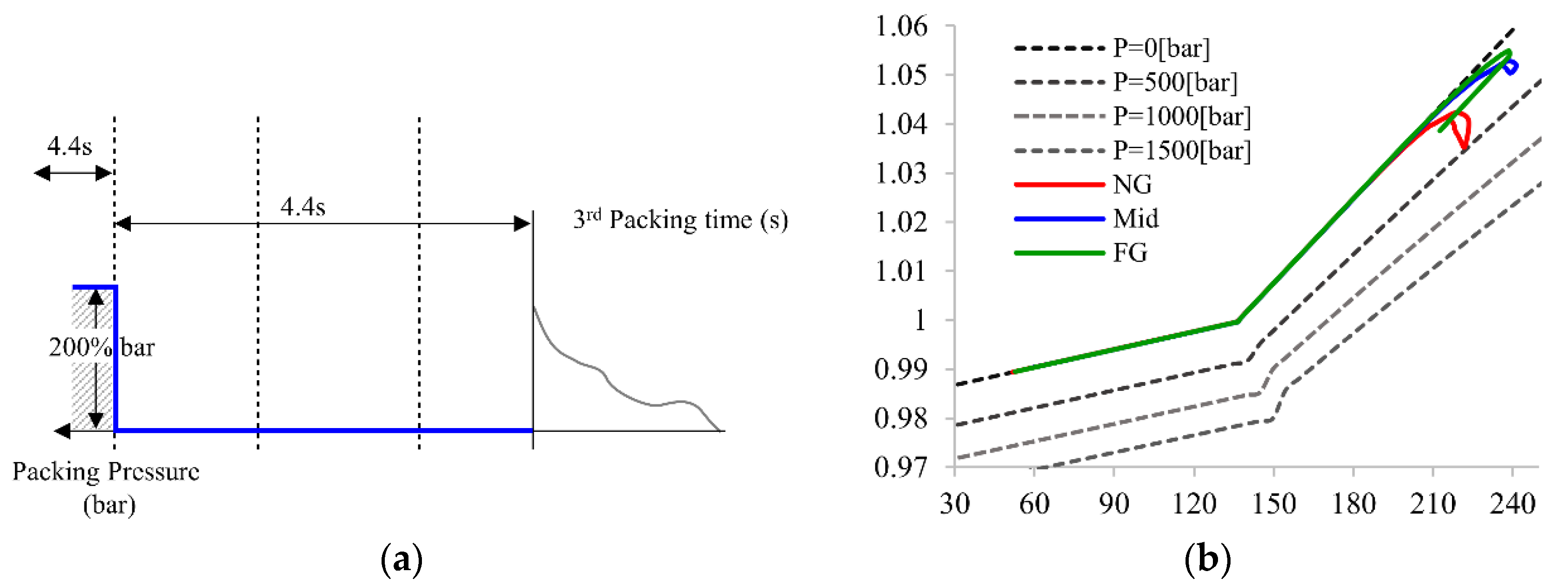

2.4. Design of Experiment

2.5. Quality Measurement

3. Results and Discussion

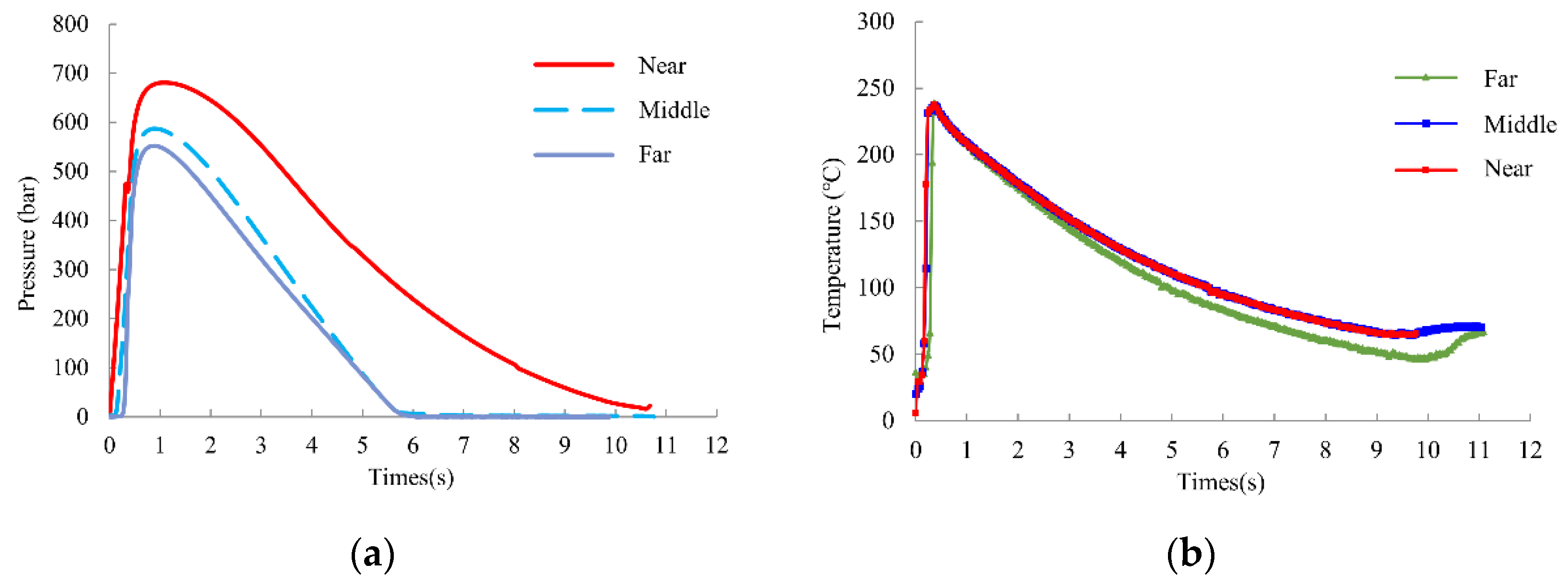

3.1. Establishment of Practical PVT Monitoring

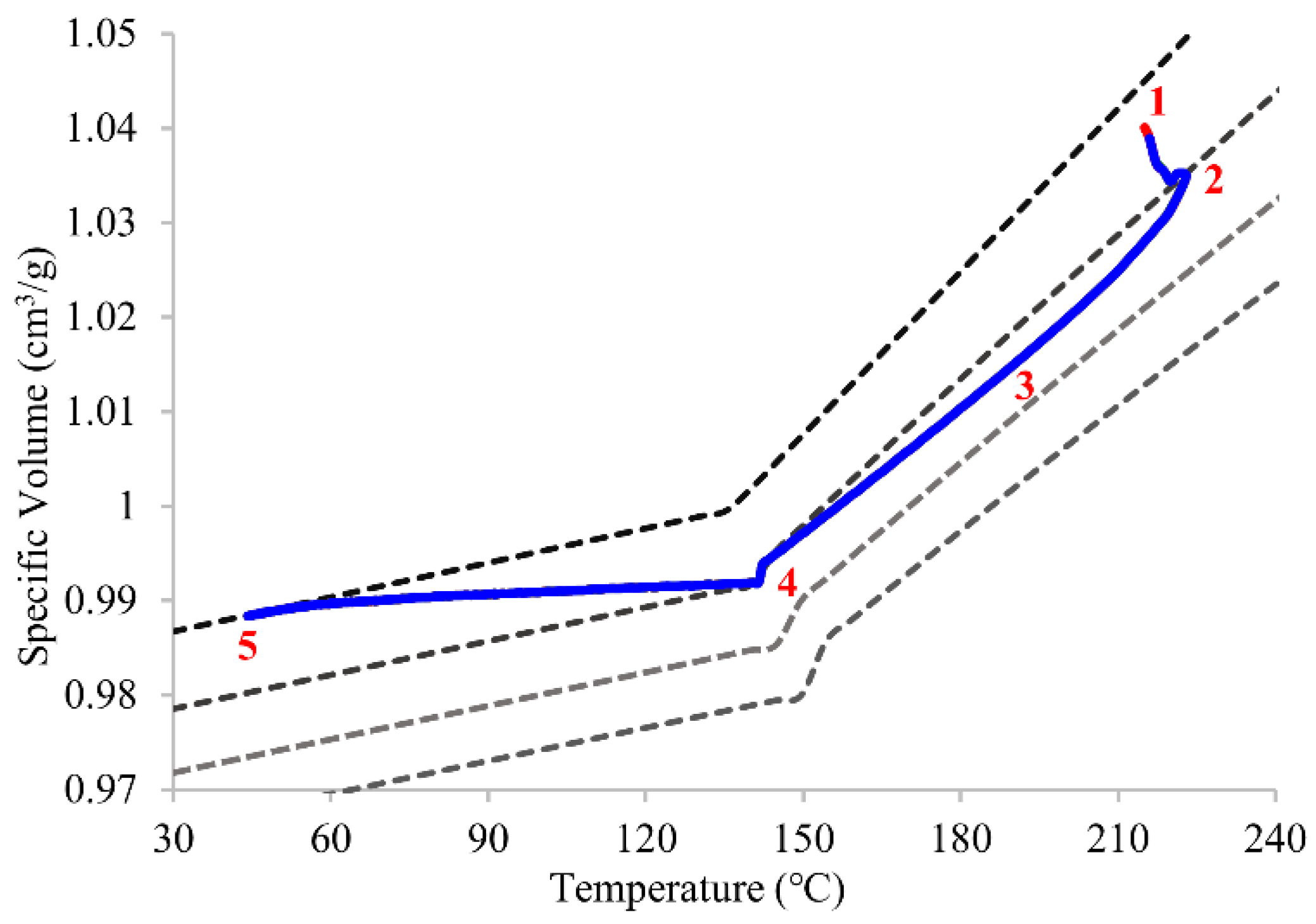

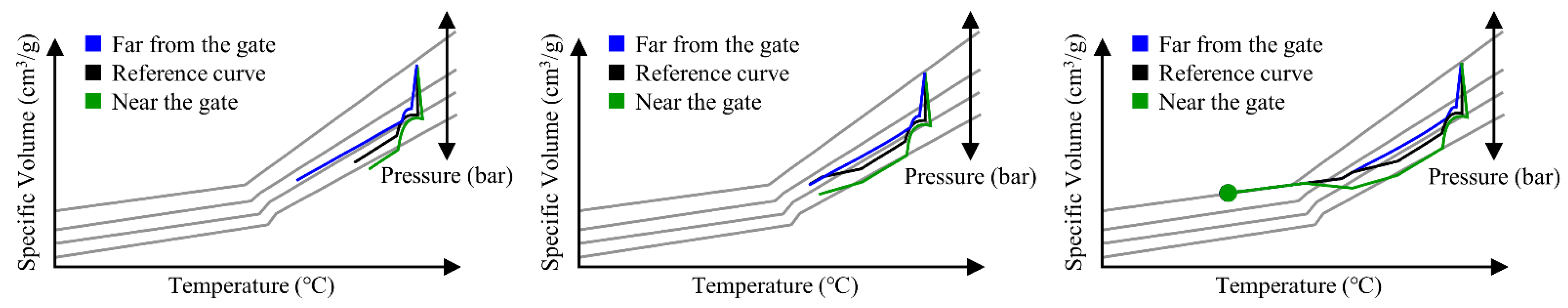

3.1.1. Practical PVT Control Method Establishment

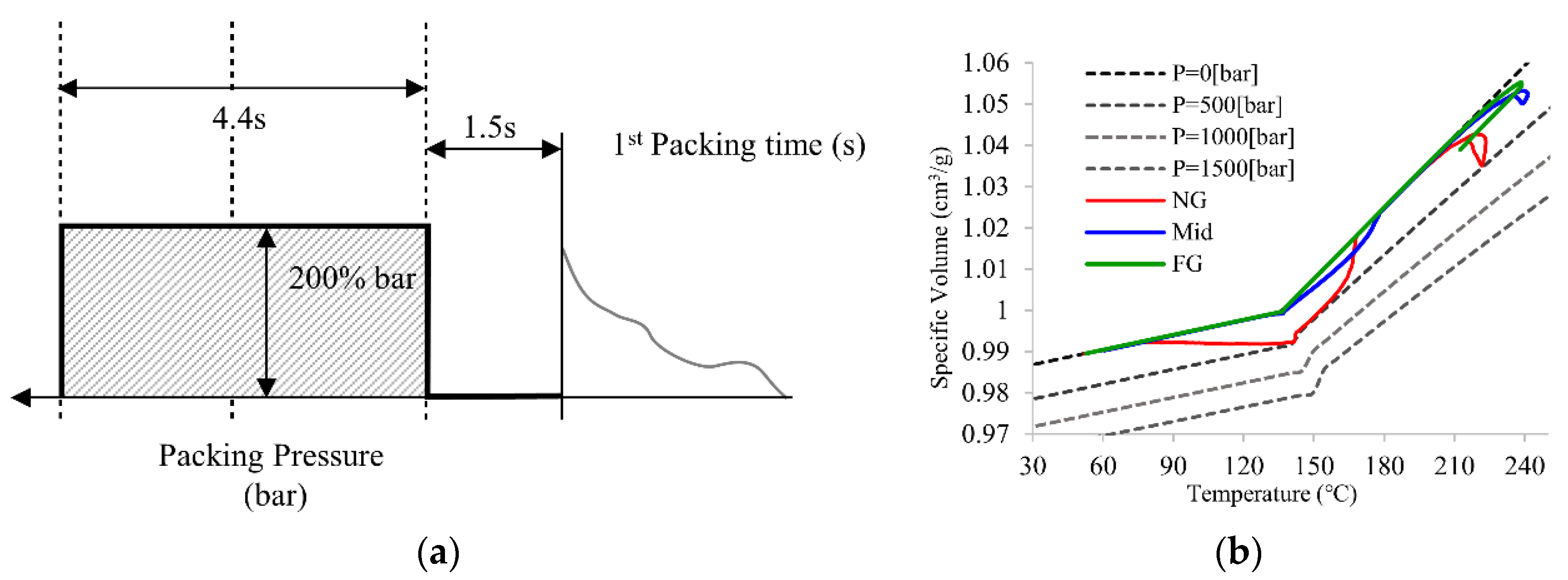

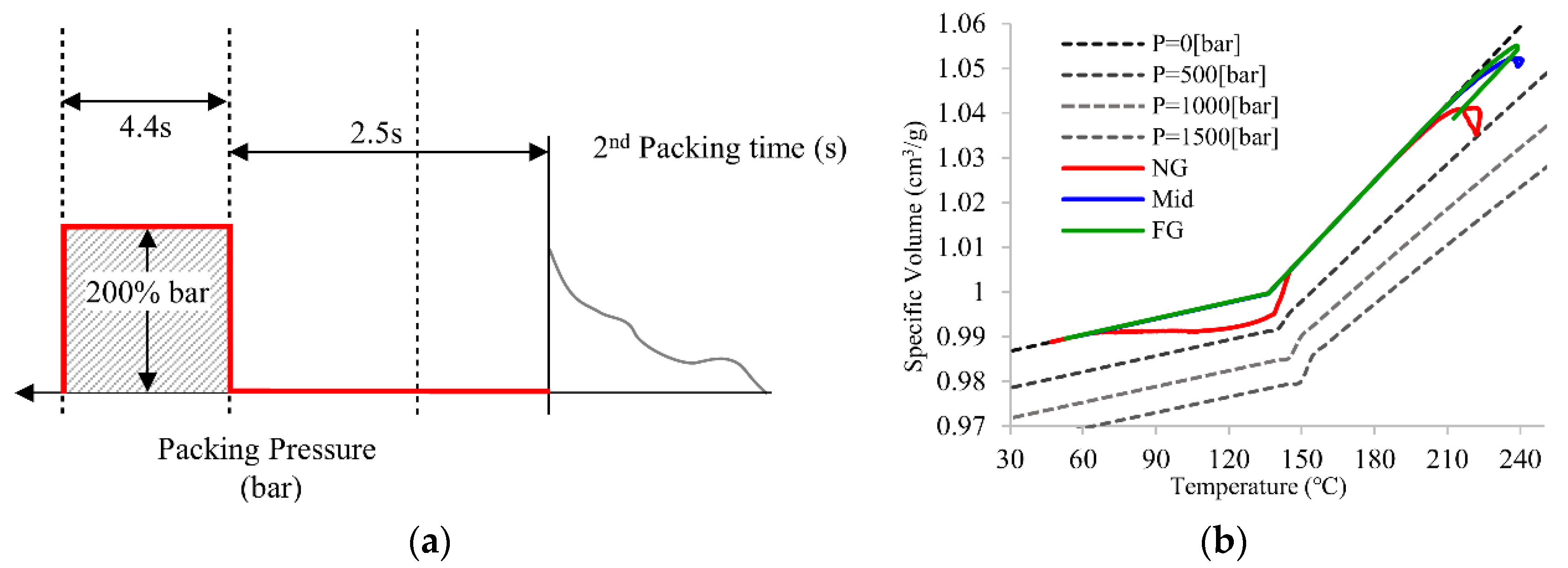

3.1.2. Packing Time Determination by PVT Processing Path

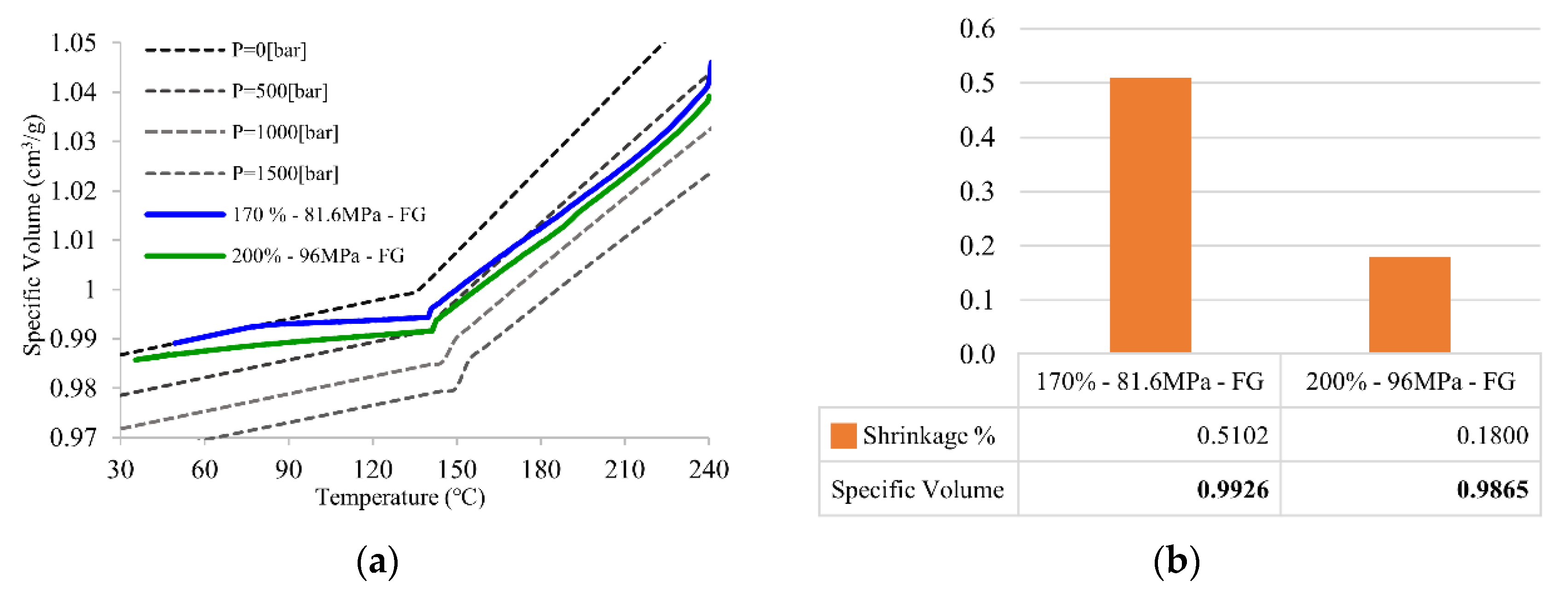

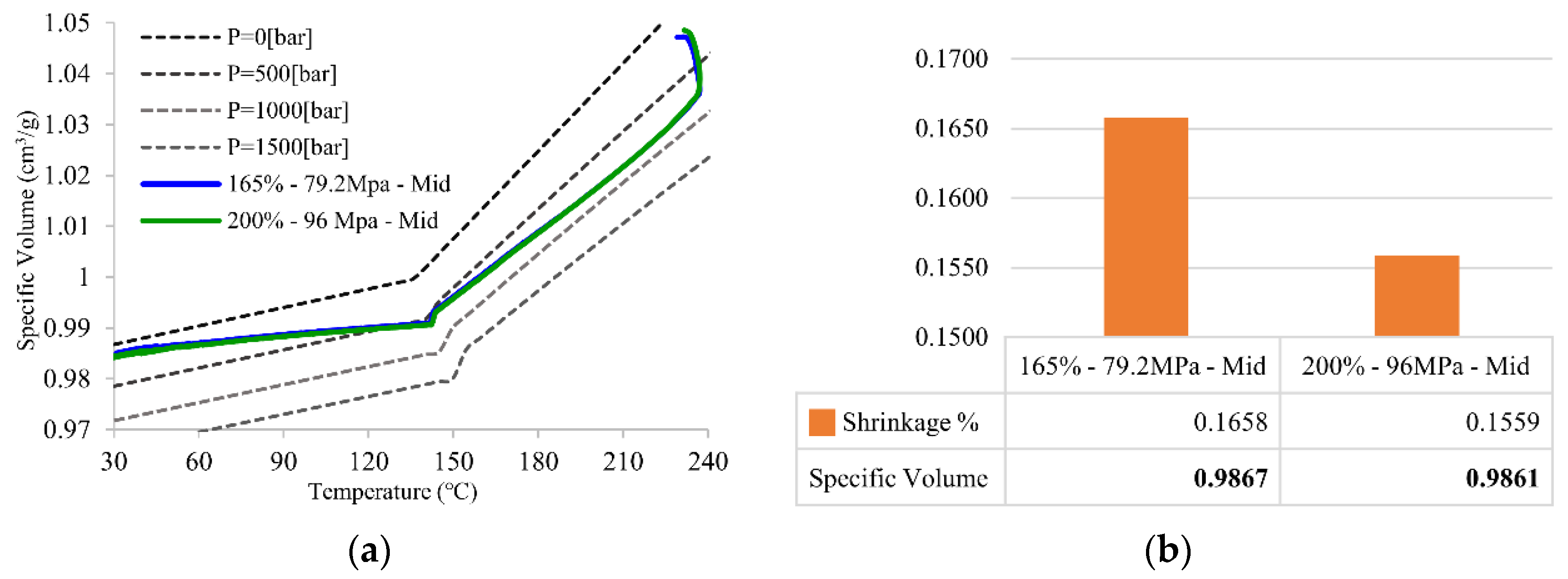

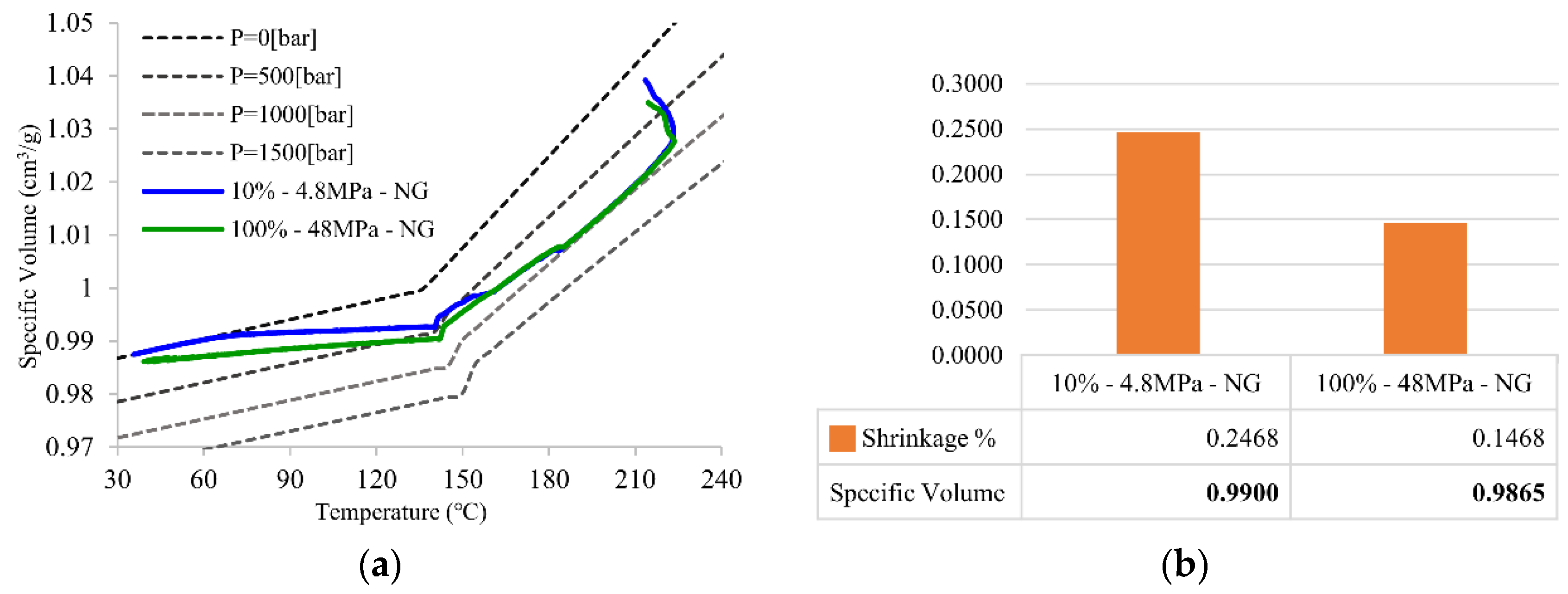

3.1.3. Packing Pressure Determination by PVT Processing Path to the Product Qualities

3.2. Dynamic Packing Technology Establishment

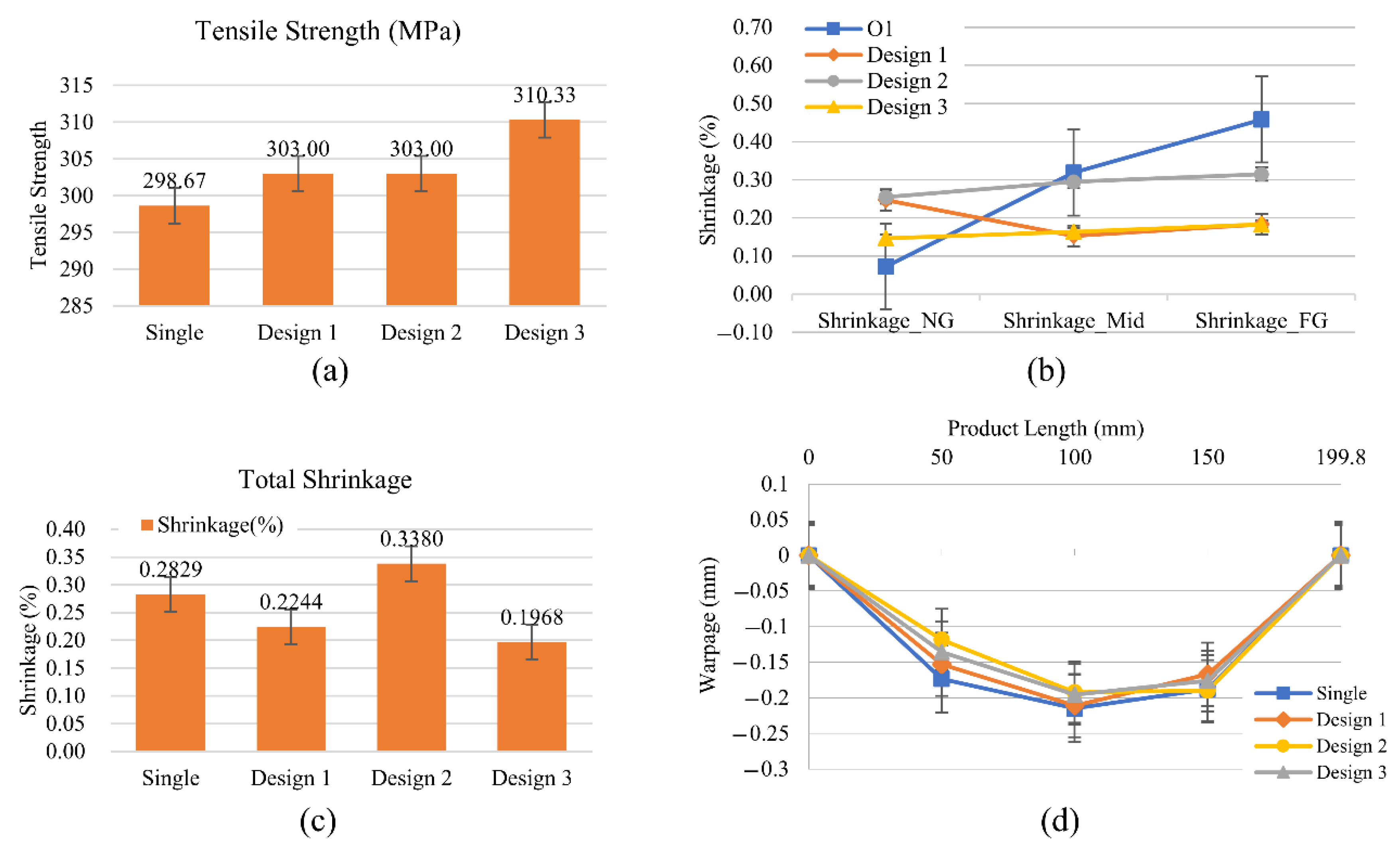

3.2.1. Optimization of Packing Pressure and Packing Time for Dynamic Packing Technology

3.2.2. Investigation of Dynamic Packing Technology for Product Qualities

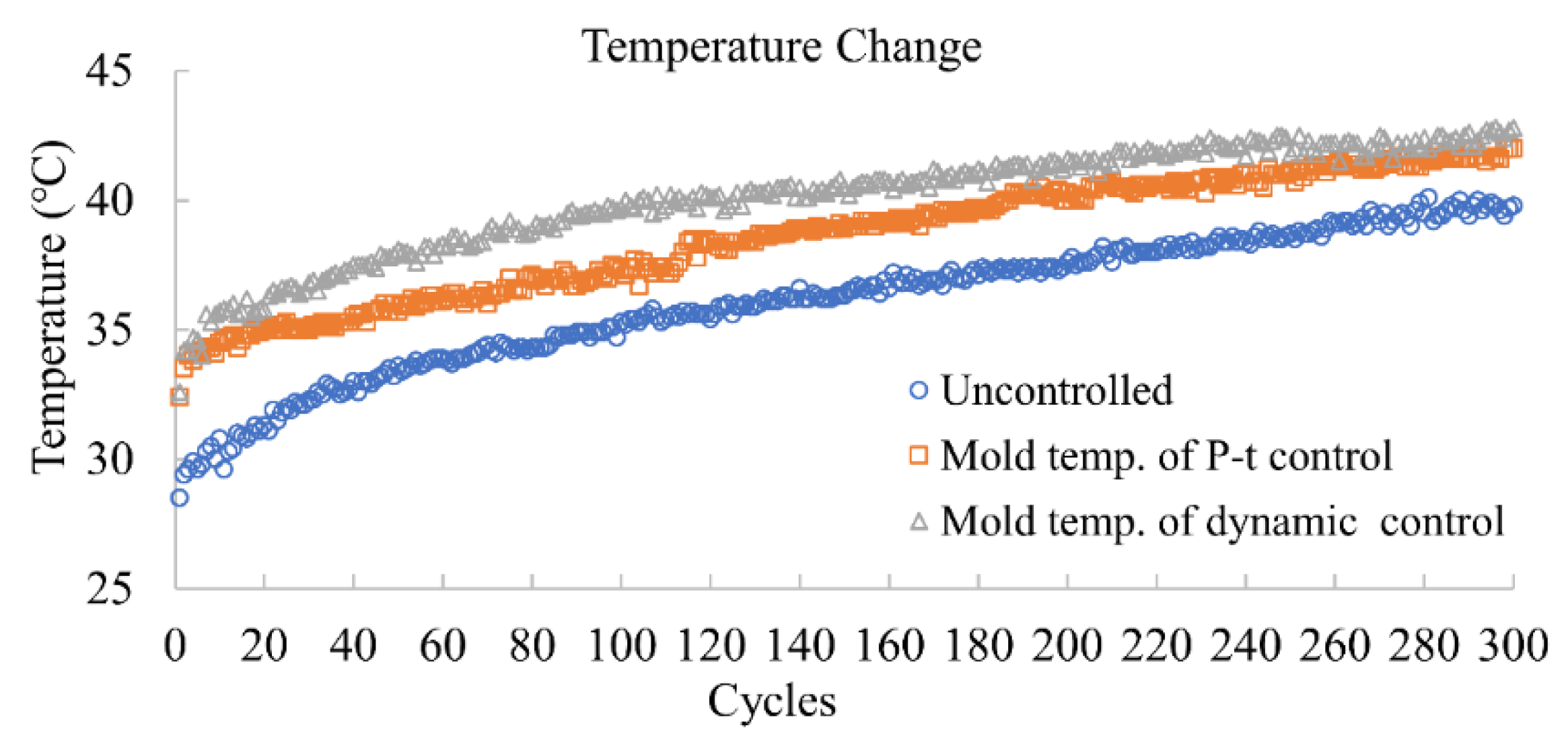

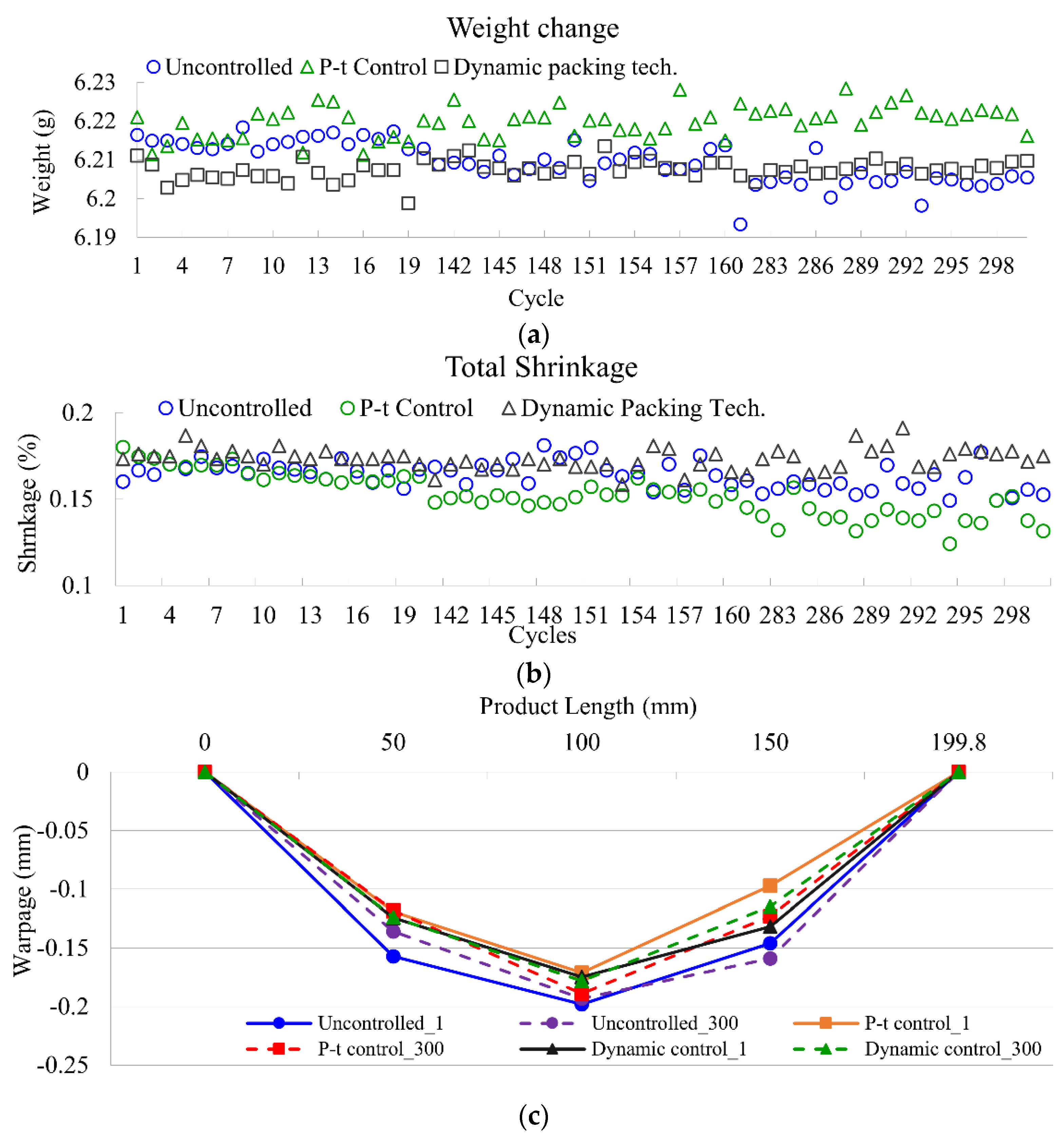

3.3. Quality Repeatibilty on Consecutive Molding Process by Dynamic Packing Technology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Turng, L.S. A Review of Current Developments in Process and Quality Control for Injection Molding. Adv. Polym. Technol. 2005, 24, 165–182. [Google Scholar] [CrossRef]

- Zoller, P.; Walsh, D.J. Standard Pressure-Volume-Temperature Data for Polymers. J. Polym. Sci. A Polym. Chem. 1995, 34, 1365. [Google Scholar]

- Berry, J.M.; Brostow, W.; Hess, M.; Jacobs, E.G. P-V-T Relations in A Series of Longitudinal Polymer Liquid Crystals with Varying Mesogen Concentration. Polymer 1998, 39, 4081–4088. [Google Scholar] [CrossRef]

- Wang, J.; Xie, P.; Ding, Y.; Yang, W. On-Line Testing Equipment of P–V–T Properties of Polymers Based on An Injection Molding Machine. Polym. Test 2009, 28, 228–234. [Google Scholar] [CrossRef]

- Wang, J.; Xie, P.; Yang, W.; Ding, Y. Online Pressure–Volume–Temperature Measurements of Polypropylene Using A Testing Mold to Simulate The Injection- Molding Process. J. Appl. Polym. Sci. 2010, 118, 200–208. [Google Scholar] [CrossRef]

- Wang, J.; Hopmann, C.; Schmitz, M.; Hohlweck, T. Process Dependence of Pressure-Specific Volume-Temperature Measurement for Amorphous Polymer: Acrylonitrile-butadiene-styrene. Polym. Test 2020, 81, 106232. [Google Scholar] [CrossRef]

- Hopmann, C.; Xiao, C.; Kahve, C.E.; Fellerhoff, J. Prediction and Validation of The Specific Volume for Inline Warpage Control in Injection Molding. Polym. Test 2021, 104, 107393. [Google Scholar] [CrossRef]

- Sanchez, R.; Aisa, J.; Martinez, A.; Mercado, D. On The Relationship Between Cooling Setup and Warpage in Injection Molding. Measurement 2012, 45, 1051–1056. [Google Scholar] [CrossRef]

- Chang, Y.H.; Wei, T.H.; Chen, S.C.; Lou, Y.F. The Investigation on PVT Control Method Establishment for Scientific Injection Molding Parameter Setting and Its Quality Control. Polym. Eng. Sci. 2020, 60, 2895–2907. [Google Scholar] [CrossRef]

- Bushko, W.C.; Stokes, V.K. Estimates for Material Shrinkage in Molded Parts Caused by Time-Varying Cavity Pressures. Polym. Eng. Sci. 2019, 59, 1648–1656. [Google Scholar] [CrossRef]

- You, T.Y. Development and Application of Molding-Guide Based Intelligent Reasonable Module for Injection Machine. Master’s Thesis, Chung Yuan Christian University, Taoyuan City, Taiwan, 2011. [Google Scholar]

- Manero, F. Cavity Temperature Measurement and Control in Thermoplastics Injection Moulding. Master’s Thesis, McGill University, Montreal, QC, Canada, 1996. [Google Scholar]

- Huang, M.S. Cavity Pressure Based Grey Prediction of The Filling-to-Packing Switchover Point for Injection Molding. J. Mater. Process. Technol. 2007, 183, 419–424. [Google Scholar] [CrossRef]

- Chang, T.C. Robust process control in injection molding—Process capability comparison for five switchover modes. J. Inj. Molding Technol. 2002, 6, 239–246. [Google Scholar]

- Edwards, R.; Diao, L.; Thomas, C.L. A Comparison of Position, Cavity Pressure, and Ultrasonic Sensors for Switch/Over Control in Injection Molding. SPE ANTEC Technical. Pap. 2003, 1, 586–590. [Google Scholar]

- Kazmer, D.O.; Velusamy, S.; Westerdale, S.; Johnston, S.; Gao, R.X. A Comparison of Seven Filling to Packing Switchover Methods for Injection Molding. Polym. Eng. Sci. 2010, 50, 2031–2043. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Y.; Mao, T.; Zhou, H. Monitoring and Dynamic Control of Quality Stability for Injection Molding Process. J. Mater. Process. Technol. 2017, 249, 358–366. [Google Scholar] [CrossRef]

- Gao, F.; Patterson, W.I.; Kamal, M.R. Cavity Pressure Dynamics and Self-Tuning Control for Filling and Packing Phases of Thermoplastics Injection-Molding. Polym. Eng. Sci. 1996, 36, 1272–1285. [Google Scholar] [CrossRef]

- Lee, M.R. A Cavity Pressure Based Quality Control Method for Injection Molding. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung City, Taiwan, 2003. [Google Scholar]

- Tsai, K.M.; Lan, J.K. Correlation between Runner Pressure and Cavity Pressure within Injection Mold. Int J Adv Manuf Technol 2015, 79, 273–284. [Google Scholar] [CrossRef]

- Wang, J.; Peng, J.; Yang, W. Filling-to-Packing Switchover Mode Based on Cavity Temperature for Injection Molding. Polym.-Plast. Technol. Eng. 2011, 50, 1273. [Google Scholar] [CrossRef]

- Wang, J.; Xie, P.; Ding, Y.; Yang, W. On-Line PVT Properties of Amorphous Polymers. Advanced Material Research 2010, 87–88, 216–222. [Google Scholar] [CrossRef]

- Sheth, H.R.; Nunn, R.E. An Adaptive Control Methodology for The Injection Molding Process. Part 1: Material Data Generation. J. Inj. Molding Technol. 1998, 2, 86–94. [Google Scholar]

- Sheth, H.R.; Nunn, R.E. An Adaptive Control Methodology for The Injection Molding Process. Part 2: Experimental Application. J. Inj. Molding Technol. 2001, 5, 141–151. [Google Scholar]

- Fischer, J.M. Handbook of Molded Part Shrinkage and Warpage; William Andrew: Middlesex, Norwich, NY, USA, 2013. [Google Scholar]

- Menges, G.; Michaeli, W.; Mohren, P. How to Make Injection Molds. Hanser: Cincinnati, OH, USA, 2001. [Google Scholar]

- Chang, Y.H. Investigation on the Establishment of PVT Control Method and Its Application to Injection Molded Part Quality. Ph.D. Thesis, Chung Yuan Christian University, Taoyuan City, Taiwan, 2017. [Google Scholar]

| Single Packing | Design 1 | Design 2 | Design 3 | |

|---|---|---|---|---|

| Melted temp. (°C) | 220 | |||

| Mold temp. (°C) | 30 | |||

| Filling time (s) | 0.7 | |||

| Cooling time (s) | 5.4 | |||

| 1st Packing pressure | 170% | 200% | 1% | 200% |

| 1st Packing time | 4.4 | 1.5 | 0.5 | 1.5 |

| 2nd Packing pressure | null | 130% | 220% | Dynamic |

| 2nd Packing time | 1 | 1 | 1 | |

| 3rd Packing pressure | 90% | Dynamic | Dynamic | |

| 3rd Packing time | 1.9 | 1 | 1.9 | |

| 4th Packing pressure | null | Dynamic | null | |

| 4th Packing time | 1.9 | |||

| Mold Temperature | 30 °C | |||||

| Filling time | 0.7 s | |||||

| Cooling time | 5.4 s | |||||

| Group | A1 | A2 | B1 | B2 | C1 | C2 |

| 1st Packing pressure | 170% | 200% | 200% | |||

| 1st Packing time | 1.5s | |||||

| 2nd Packing pressure | null | 165% | 200% | 165% | ||

| 2nd Packing time | 1s | |||||

| 3rd Packing pressure | null | 10% | 100% | |||

| 3rd Packing time | 1.9s | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.-H.; Chen, S.-C.; Ting, Y.-H.; Feng, C.-T.; Hsu, C.-C. The Investigation of Novel Dynamic Packing Technology for Injection Molded Part Quality Control and Its Production Stability by Using Real-Time PVT Control Method. Polymers 2022, 14, 2720. https://doi.org/10.3390/polym14132720

Chang Y-H, Chen S-C, Ting Y-H, Feng C-T, Hsu C-C. The Investigation of Novel Dynamic Packing Technology for Injection Molded Part Quality Control and Its Production Stability by Using Real-Time PVT Control Method. Polymers. 2022; 14(13):2720. https://doi.org/10.3390/polym14132720

Chicago/Turabian StyleChang, Yung-Hsiang, Shia-Chung Chen, Yu-Hung Ting, Ching-Te Feng, and Chi-Chuan Hsu. 2022. "The Investigation of Novel Dynamic Packing Technology for Injection Molded Part Quality Control and Its Production Stability by Using Real-Time PVT Control Method" Polymers 14, no. 13: 2720. https://doi.org/10.3390/polym14132720

APA StyleChang, Y.-H., Chen, S.-C., Ting, Y.-H., Feng, C.-T., & Hsu, C.-C. (2022). The Investigation of Novel Dynamic Packing Technology for Injection Molded Part Quality Control and Its Production Stability by Using Real-Time PVT Control Method. Polymers, 14(13), 2720. https://doi.org/10.3390/polym14132720