Performance-Based Evaluation of Healing Efficiency on Mechanical Properties of Self-Healing Cementitious Materials Incorporated with PMMA/Epoxy Microcapsule

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Characterisation of the Microcapsule

2.3. Preparation of Self-Healing Cementitious Materials

2.4. Characterisation and Evaluation of Self-Healing Performance

2.5. Experimental Design

3. Results and Discussion

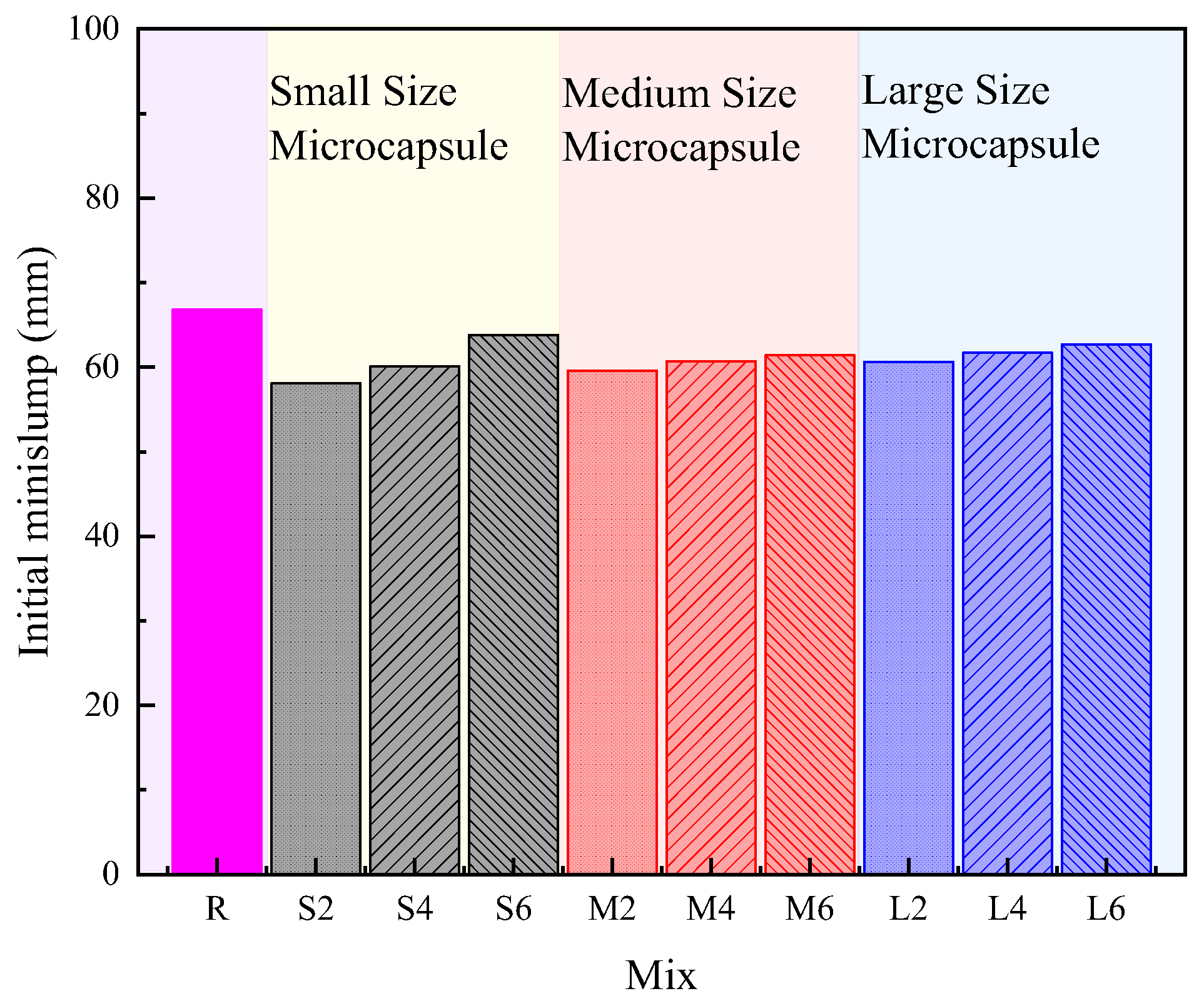

3.1. Effect on Workability

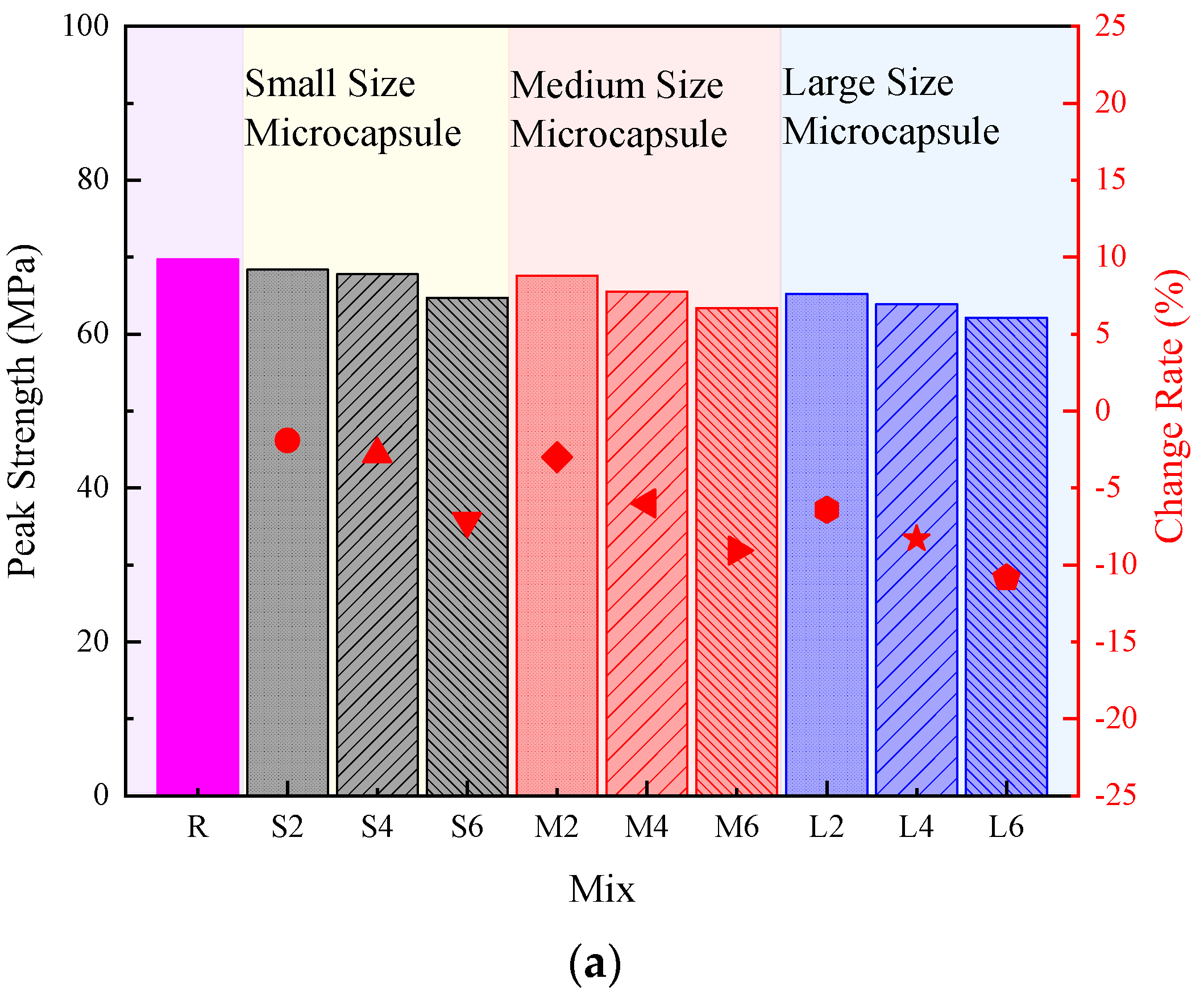

3.2. Effect on Mechanical Property

3.3. Evaluation of Healing Effect by Experimental Design

3.3.1. Model Adequacy Analysis

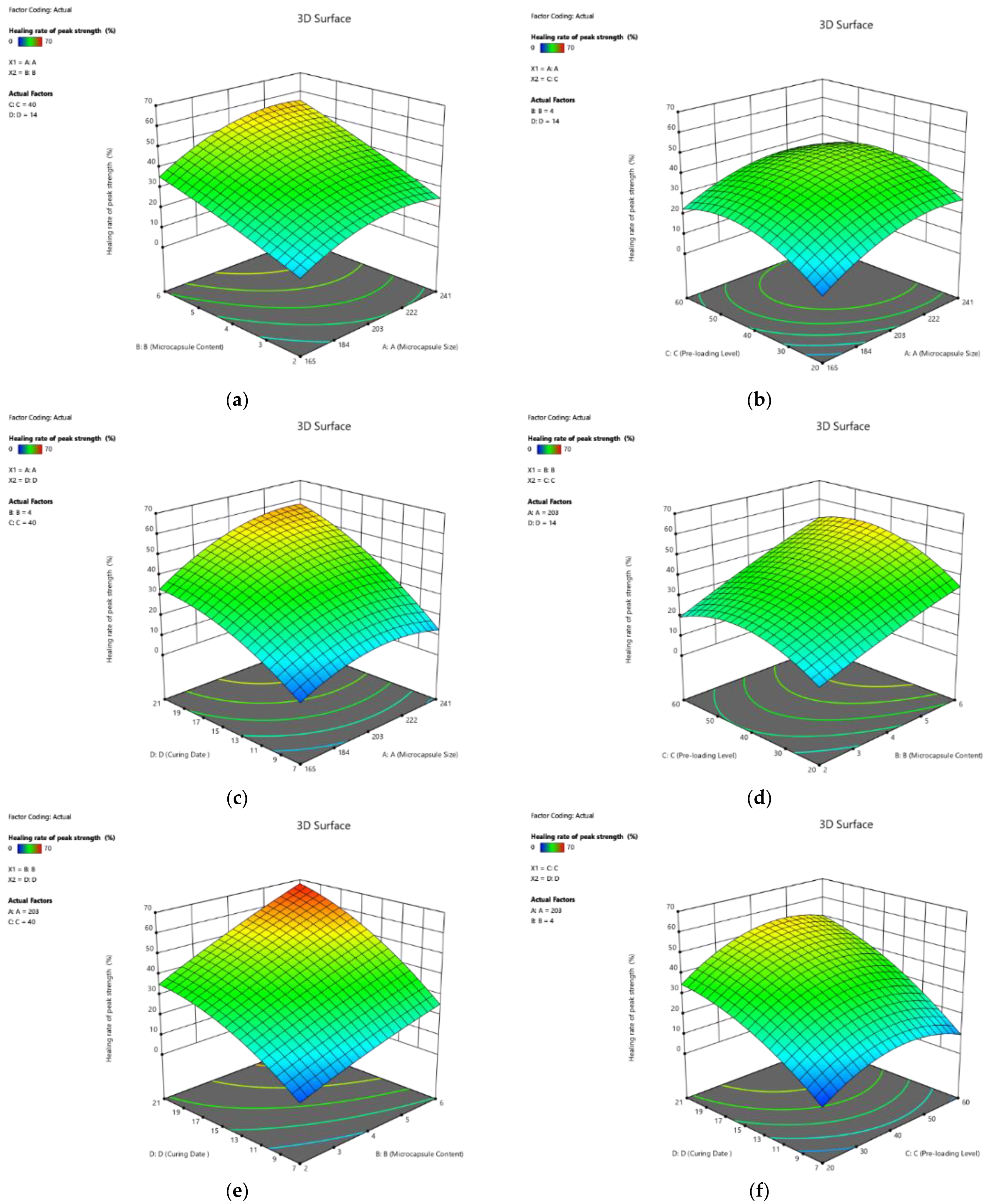

3.3.2. Effect of Variables on the Response of the Model

Effect on Healing Rate of Peak Strength

Effect on Recovery Rate of Peak Strength

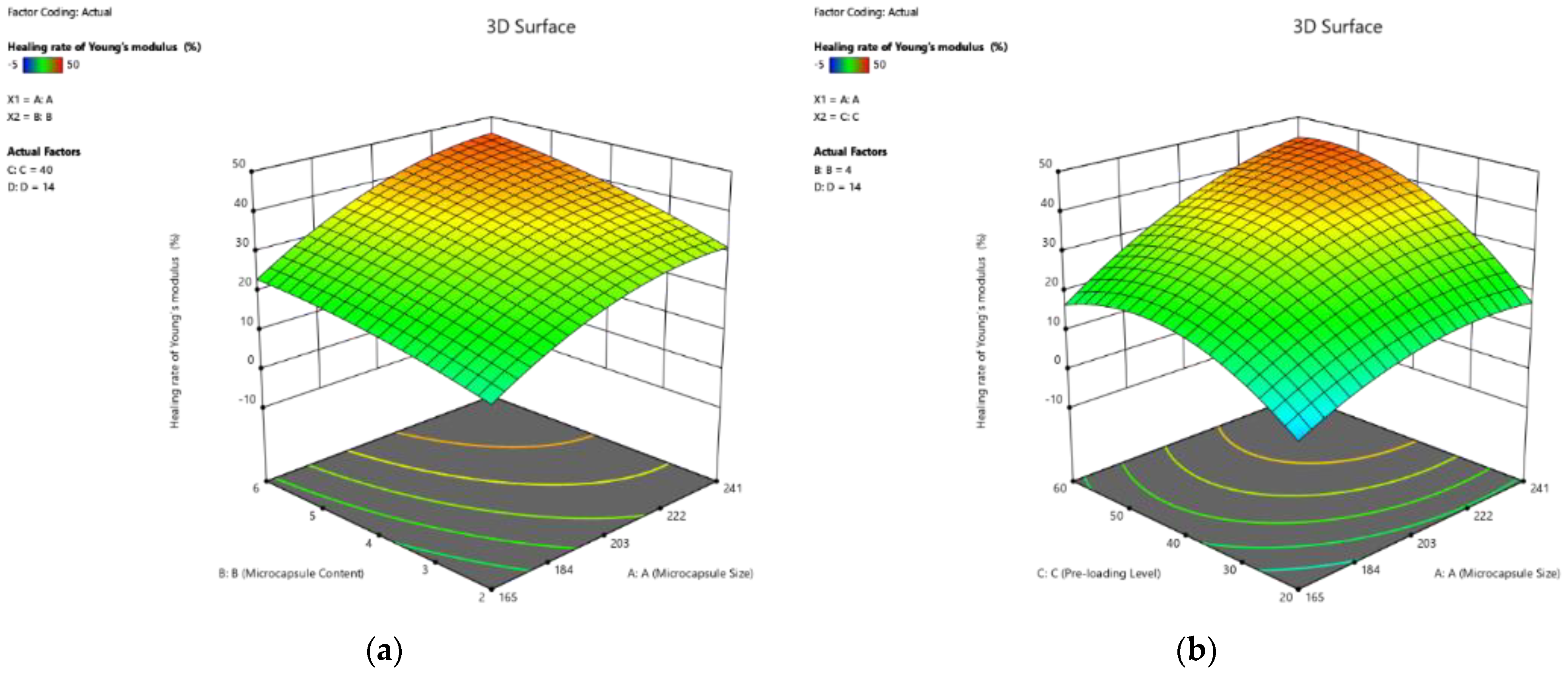

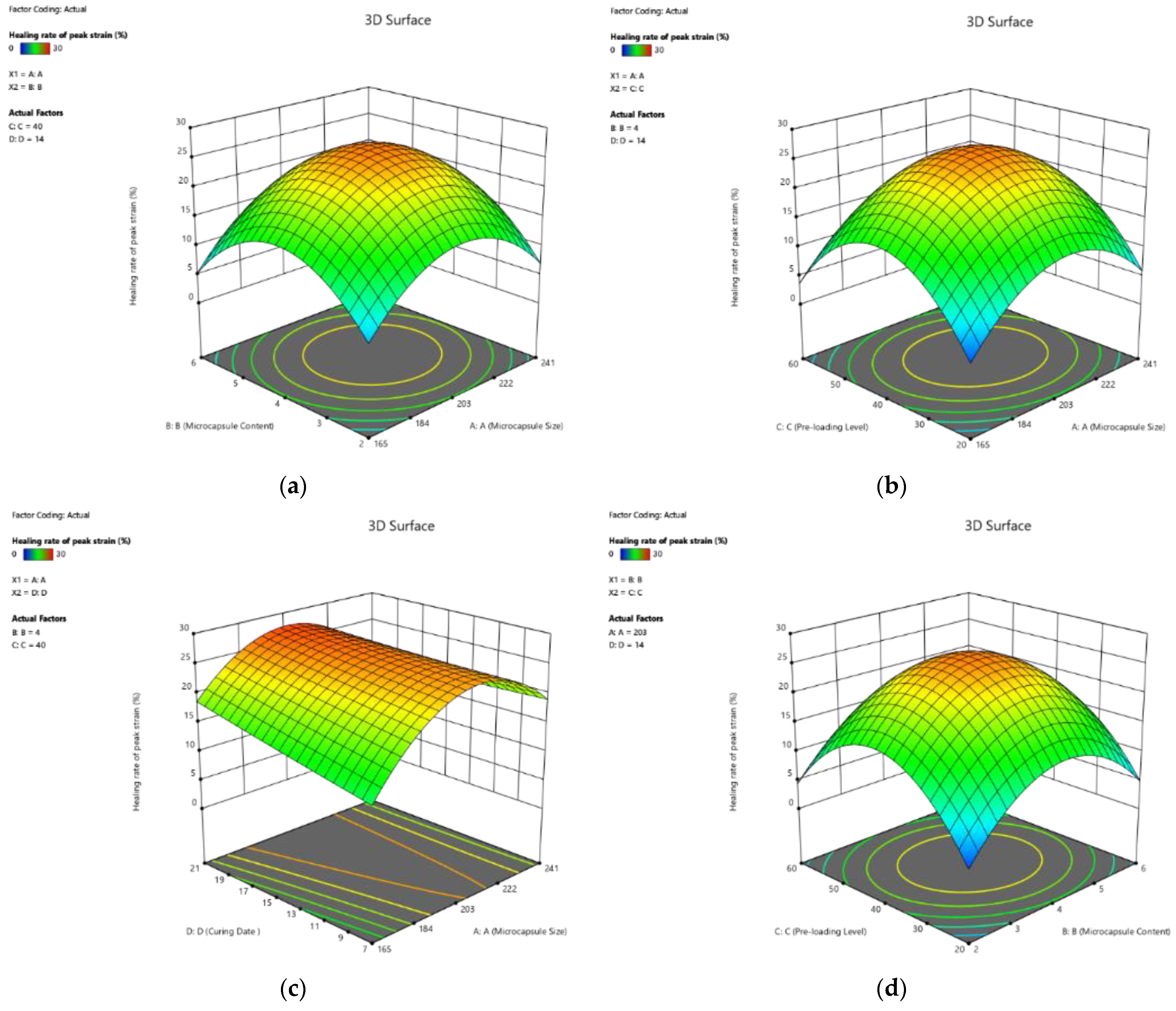

Effect on Healing Rate of Young’s Modulus

Effect on Recovery Rate of Young’s Modulus

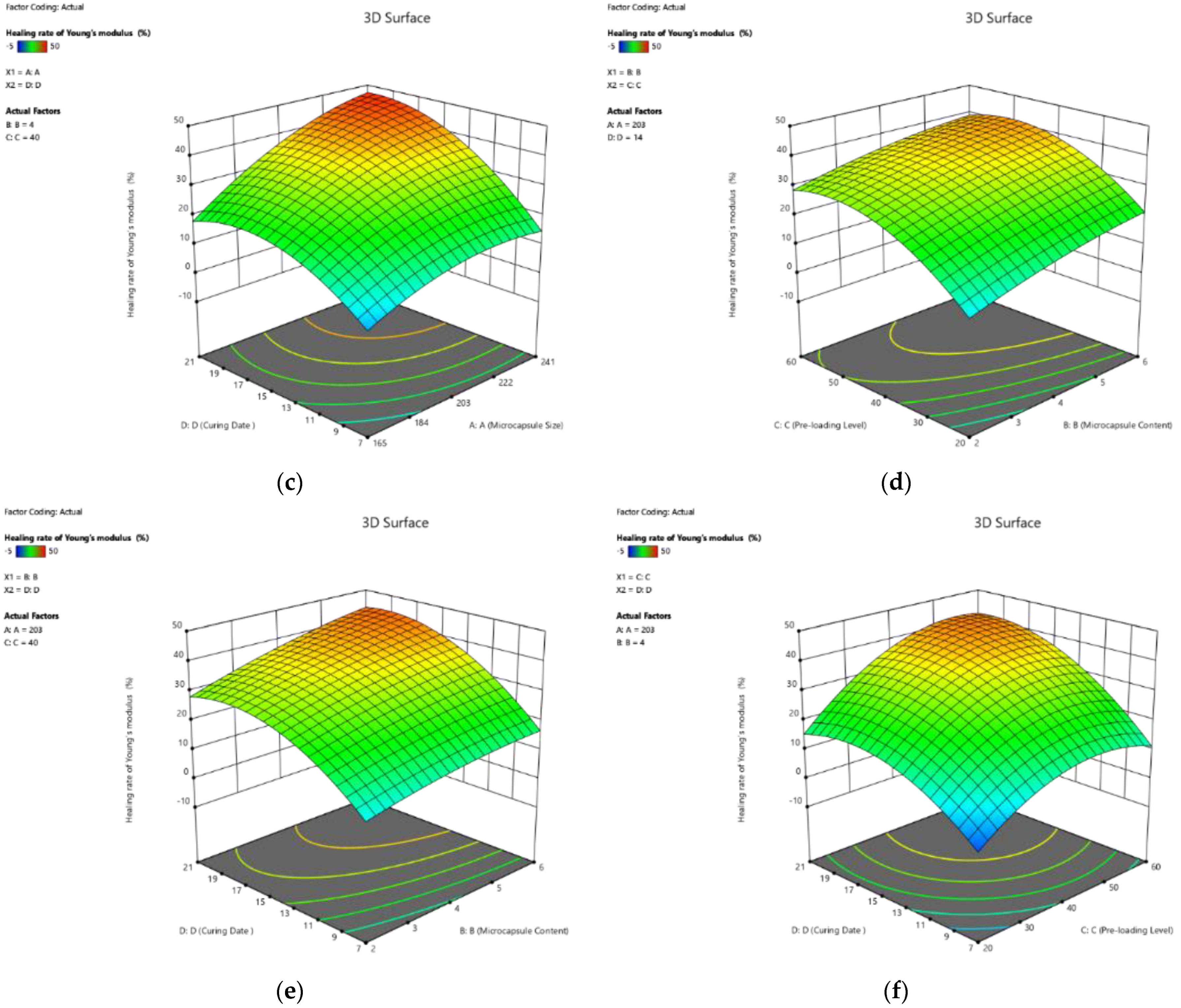

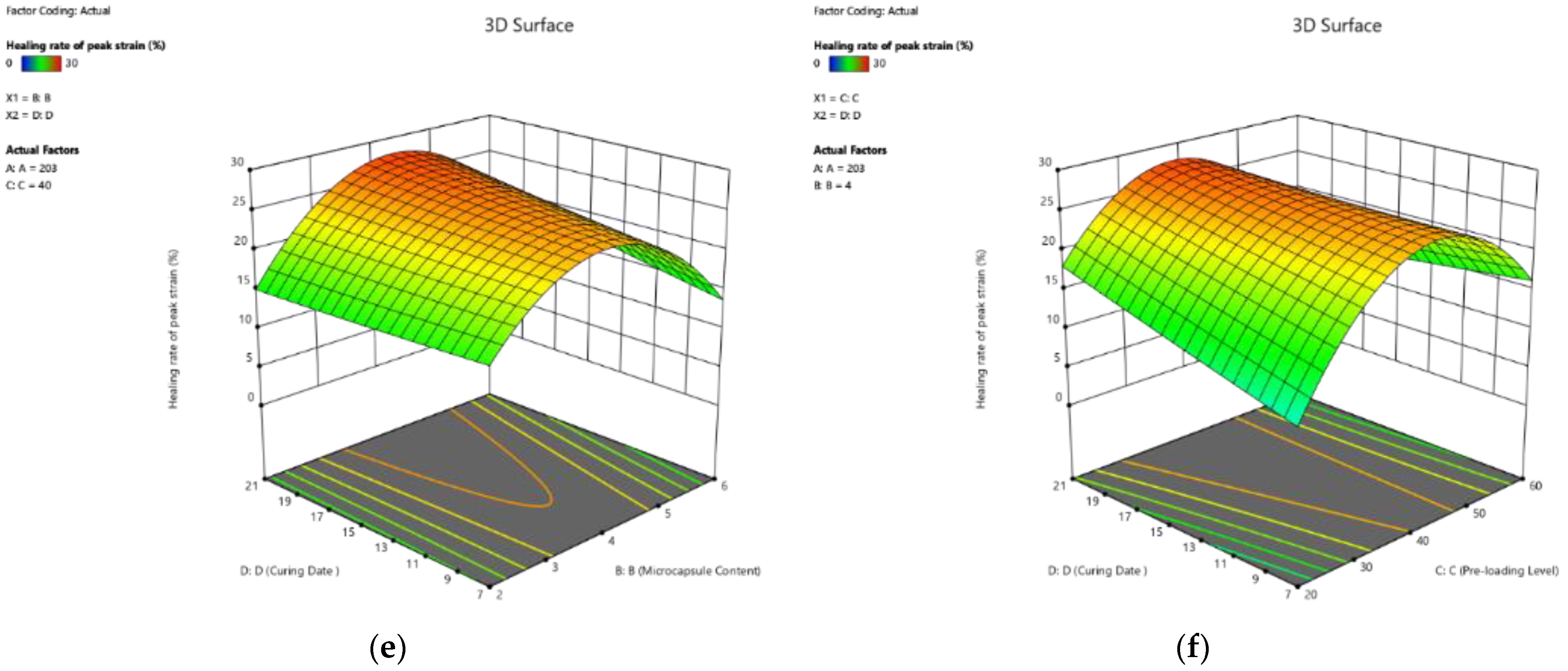

Effect on Healing Rate of Peak Strain

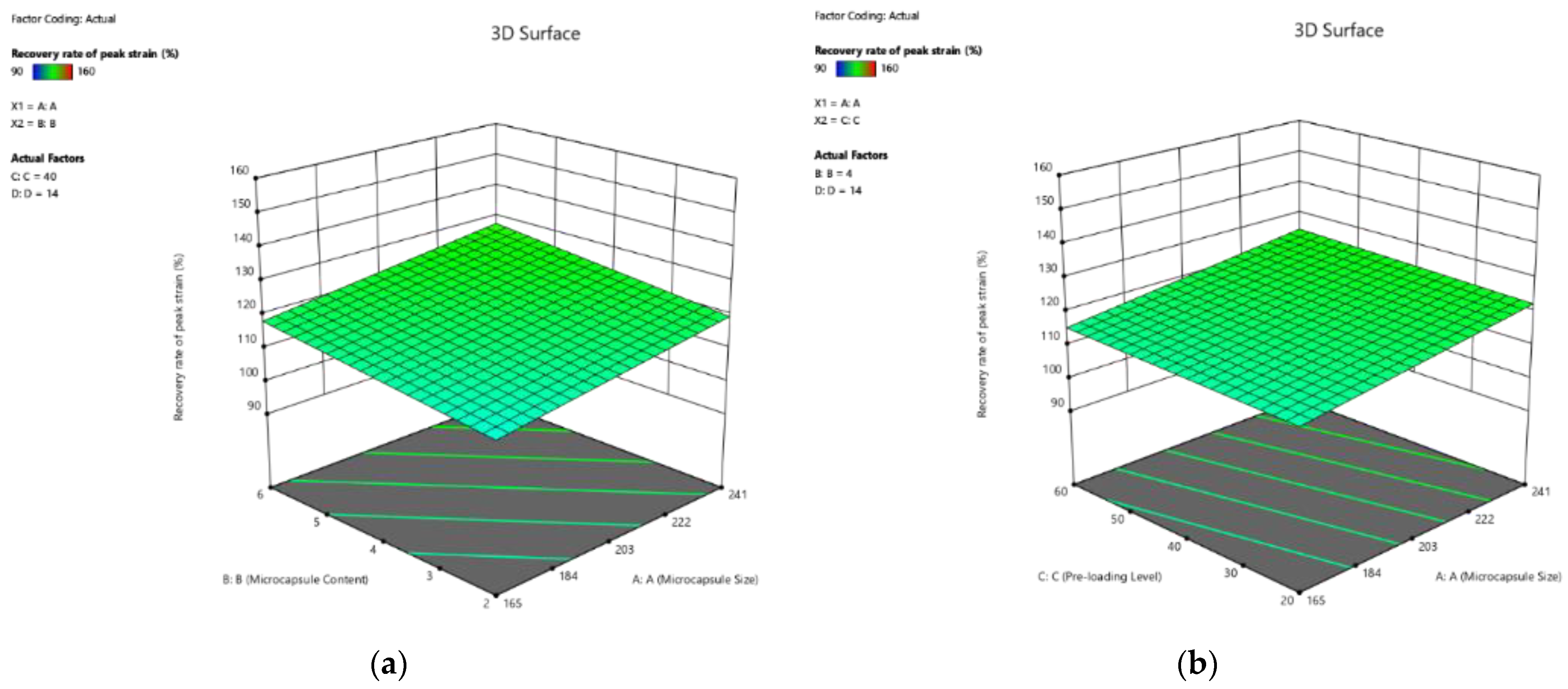

Effect on Recovery Rate of Peak Strain

3.3.3. Discussion

3.4. Desirability Functions for Numerical Optimisation

3.5. Verification

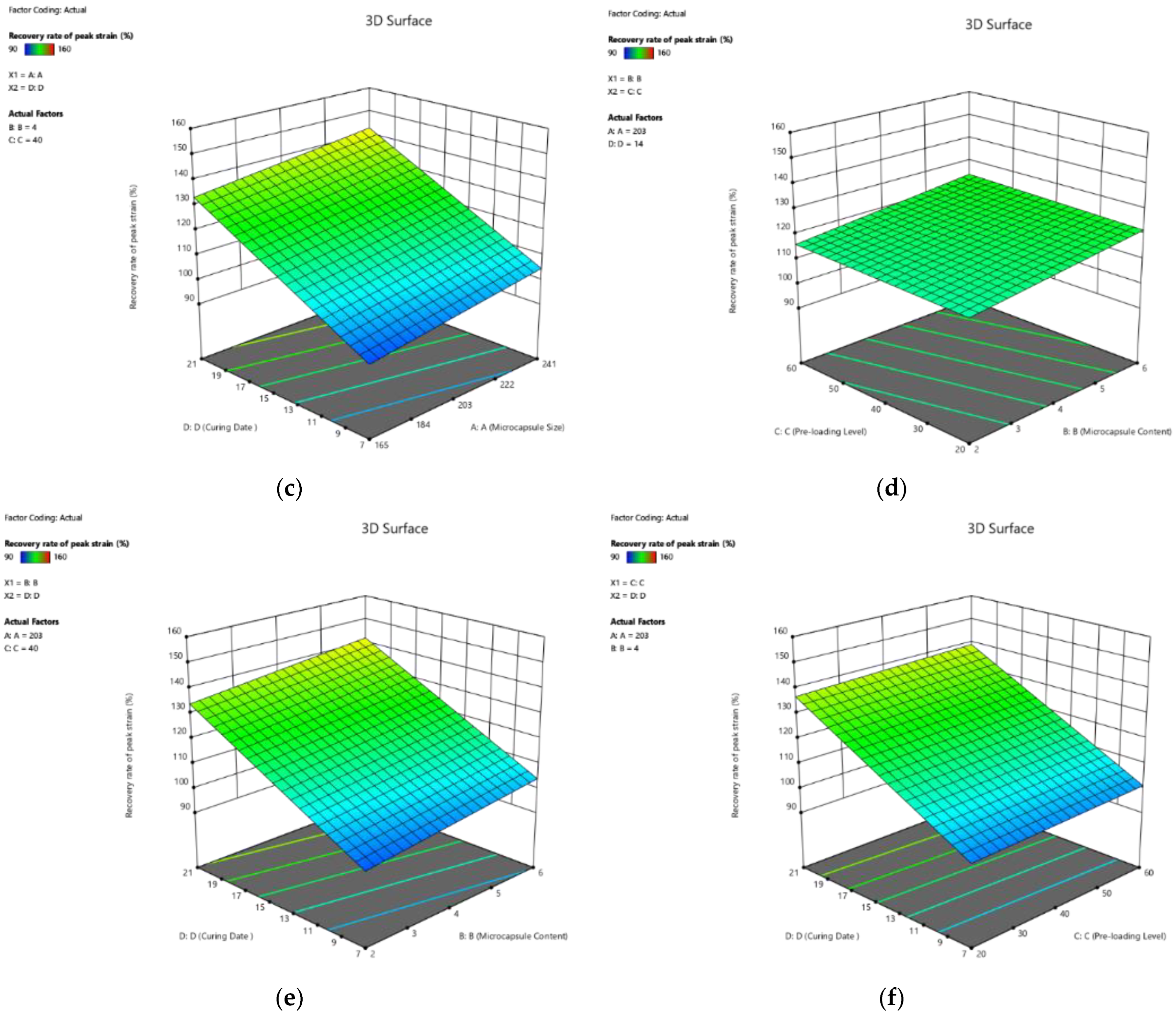

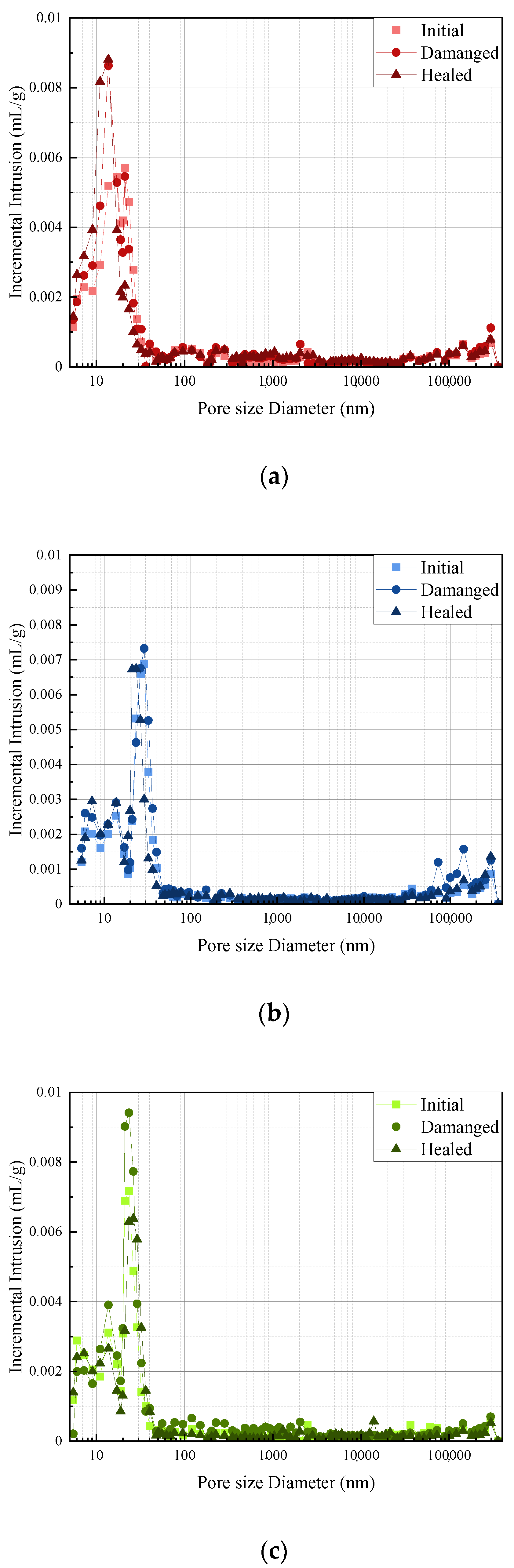

3.6. Pore Structure

4. Conclusions

- Microcapsule size was identified as the significant factor affecting the healing and recovery rate of peak strength, Young’s modulus, and the peak strain of PMMA/epoxy microcapsule-based self-healing cementitious materials. The microcapsule with large size led to a decrease in the mechanical properties of cementitious material, whereas it increased the healing performance of cement pastes.

- The six parameters were influenced by microcapsule content. The increase in microcapsule content was shown to increase the healing and recovery rates of cementitious materials, but it decreased the initial peak strength, Young’s modulus, and the peak strain of hardened cement.

- Pre-loading level obviously affected the healing performance of microcapsules. With the increase in pre-loading, the healing efficiency decreased.

- The curing age has been identified as the most significant factor affecting the healing performance of PMMA/epoxy microcapsule. The extension of curing age is beneficial for cementitious materials to achieve self-healing performance.

- The numerical optimisation showed that the best healing performance for the six responses was 66.62% for the healing rate of peak strength, 152.20% for the recovery rate of peak strength, 44.71% for the healing rate of Young’s modulus, 131.16% for the recovery rate of Young’s modulus, 22.56% for the healing rate of peak strain, and 141.50% for the recovery rate of peak strain with the desirability of 0.9050. The verification process further confirmed the validation of the predicted value generated from the six response models.

- MIP results further confirmed the healing performance of three selected specimens under initial, damaged, and healed states.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Tan, H.; Bao, M.; Liu, X.; Luo, Z.; Wang, P. Low carbon cementitious materials: Sodium sulfate activated ultra-fine slag/fly ash blends at ambient temperature. J. Clean. Prod. 2021, 280, 124363. [Google Scholar] [CrossRef]

- Wang, J.; Ma, B.; Tan, H.; Du, C.; Chu, Z.; Luo, Z.; Wang, P. Hydration and mechanical properties of cement-marble powder system incorporating triisopropanolamine. Constr. Build. Mater. 2021, 266, 121068. [Google Scholar] [CrossRef]

- Ma, Q.; Nanukuttan, S.V.; Basheer, P.A.M.; Bai, Y.; Yang, C. Chloride transport and the resulting corrosion of steel bars in alkali activated slag concretes. Mater. Struct. 2016, 499, 3663–3677. [Google Scholar] [CrossRef] [Green Version]

- Ma, Q.; Du, H.; Zhou, X.; He, K.; Lin, Z.; Yan, F.; Huang, L.; Guo, R. Performance of copper slag contained mortars after exposure to elevated temperatures. Constr. Build. Mater. 2018, 172, 378–386. [Google Scholar] [CrossRef]

- Luo, S.; Zhao, M.; Jiang, Z.; Liu, S.; Yang, L.; Mao, Y.; Pan, C. Microwave preparation and carbonation properties of low-carbon cement. Constr. Build. Mater. 2022, 172, 126239. [Google Scholar] [CrossRef]

- van de Zwaag, S. Self Healing Materials—An Alternative Approach to 20 Centuries of Materials Science; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- Litina, C.; Bumanis, G.; Anglani, G.; Dudek, M.; Maddalena, R.; Amenta, M.; Papaioannou, S.; Pérez, G.; Calvo, J.L.G.; Asensio, E.; et al. Evaluation of Methodologies for Assessing Self-Healing Performance of Concrete with Mineral Expansive Agents: An Interlaboratory Study. Materials 2021, 148, 2024. [Google Scholar] [CrossRef]

- Wang, X.; Chen, S.; Yang, Z.; Ren, J.; Zhang, X.; Xing, F. Self-healing concrete incorporating mineral additives and encapsulated lightweight aggregates: Preparation and application. Constr. Build. Mater. 2021, 301, 124119. [Google Scholar] [CrossRef]

- Wu, X.; Huang, H.; Liu, H.; Hu, J.; Wu, K.; Wei, J.; Yu, Q. A new self-healing agent for accelerating the healing kinetics while simultaneously binding seawater ions in cracked cement paste. Mater. Lett. 2021, 283, 128884. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Moretti, F. Autogenous healing on the recovery of mechanical performance of High Performance Fibre Reinforced Cementitious Composites HPFRCCs: Part 2—Correlation between healing of mechanical performance and crack sealing. Cem. Concr. Compos. 2016, 73, 299–315. [Google Scholar] [CrossRef]

- Li, V.C.; Lim, Y.M.; Chan, Y.-W. Feasibility study of a passive smart self-healing cementitious composite. Compos. Part B Eng. 1998, 296, 819–827. [Google Scholar] [CrossRef]

- Liu, H.; Huang, H.; Wu, X.; Peng, H.; Li, Z.; Hu, J.; Yu, Q. Effects of external multi-ions and wet-dry cycles in a marine environment on autogenous self-healing of cracks in cement paste. Cem. Concr. Res. 2019, 120, 198–206. [Google Scholar] [CrossRef]

- Ding, F.; Wu, X.; Xiang, P.; Yu, Z. New Damage Ratio Strength Criterion for Concrete and Lightweight Aggregate Concrete. ACI Struct. J. 2021, 1186, 165–178. [Google Scholar]

- Zhang, W.; Lin, H.; Xue, M.; Wang, S.; Ran, J.; Su, F.; Zhu, J. Influence of shrinkage reducing admixtures on the performance of cementitious composites: A review. Constr. Build. Mater. 2022, 325, 126579. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T. A review of self-healing concrete for damage management of structures. Adv. Mater. Interfaces 2018, 517, 1800074. [Google Scholar] [CrossRef]

- Xue, C.; Li, W.; Li, J.; Tam, V.W.Y.; Ye, G. A review study on encapsulation-based self-healing for cementitious materials. Struct. Concr. 2019, 201, 198–212. [Google Scholar] [CrossRef] [Green Version]

- Papaioannou, S.; Amenta, M.; Kilikoglou, V.; Gournis, D.; Karatasios, I. Critical Aspects in the Development and Integration of Encapsulated Healing Agents in Cement and Concrete. J. Adv. Concr. Technol. 2021, 194, 301–320. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Wang, X.; Chen, Z.; Xu, W.; Wang, X. Fluorescence labelling and self-healing microcapsules for detection and repair of surface microcracks in cement matrix. Compos. Part B Eng. 2020, 184, 107744. [Google Scholar] [CrossRef]

- Lv, L.; Guo, P.; Xing, F.; Han, N. Trigger efficiency enhancement of polymeric microcapsules for self-healing cementitious materials. Constr. Build. Mater. 2020, 235, 117443. [Google Scholar] [CrossRef]

- Mao, W.; Litina, C.; Al-Tabbaa, A. Development and Application of Novel Sodium Silicate Microcapsule-Based Self-Healing Oil Well Cement. Materials 2020, 132, 456. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Sun, P.; Han, N.; Xing, F. Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite. Materials 2017, 10, 20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ren, J.; Zhang, J.; Wang, X.; Li, D.; Han, N.; Xing, F. Electrochemical Impedance Spectroscopy: A potential approach for detecting the breakage rate of microcapsules for self-healing cementitious materials. Cem. Concr. Compos. 2020, 114, 103776. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; Gu, S.; Wang, R.; Li, J.; Han, X.; Liu, Q. Effect of temperatures on self-healing capabilities of concrete with different shell composition microcapsules containing toluene-di-isocyanate. Constr. Build. Mater. 2020, 247, 118575. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Palmer, D.; Kerr, A.; Al-Tabbaa, A. Polymeric microcapsules with switchable mechanical properties for self-healing concrete: Synthesis, characterisation and proof of concept. Smart Mater. Struct. 2017, 264, 045025. [Google Scholar] [CrossRef]

- Ren, J.; Wang, X.; Li, D.; Han, N.; Dong, B.; Xing, F. Temperature adaptive microcapsules for self-healing cementitious materials. Compos. Part B Eng. 2021, 223, 109138. [Google Scholar] [CrossRef]

- Ren, J.; Wang, X.; Li, D.; Xu, S.; Dong, B.; Xing, F. Performance of temperature adaptive microcapsules in self-healing cementitious materials under different mixing temperatures. Constr. Build. Mater. 2021, 299, 124254. [Google Scholar] [CrossRef]

- Rodriguez, R.; Bekas, D.G.; Flórez, S.; Kosarli, M.; Paipetis, A.S. Development of self-contained microcapsules for optimised catalyst position in self-healing materials. Polymer 2020, 187, 122084. [Google Scholar] [CrossRef]

- Xing, F.; Ni, Z.; Huang, Z. Mechanical properties of microcapsule-basalt fiber/cement composites. Acta Mater. Compos. Sin. 2014, 31, 133. [Google Scholar]

- Wang, X.; Li, Y.; Zhang, C.; Zhang, X. Visualization and quantification of self-healing behaviors of microcracks in cement-based materials incorporating fluorescence-labeled self-healing microcapsules. Constr. Build. Mater. 2022, 315, 125668. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R.; Yu, J. Influence of external environment on self-repairing ability of the cement-based materials containing paraffin/toluene-di-isocyanate microcapsules. Constr. Build. Mater. 2021, 281, 122584. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Wang, Y.; Liu, Y.; Hong, S.; Zhang, J.; Lin, S.; Xing, F. Performance recovery concerning the permeability of concrete by means of a microcapsule based self-healing system. Cem. Concr. Compos. 2017, 78, 84–96. [Google Scholar] [CrossRef]

- Han, T.; Wang, X.; Li, D.; Li, D.; Xing, F.; Ren, J.; Han, N. Stress-strain behaviour and pore structure of microcapsule-based self-healing cementitious composite under triaxial tests. Constr. Build. Mater. 2020, 241, 118009. [Google Scholar] [CrossRef]

- Han, T.; Wang, X.; Li, D.; Li, D.; Xing, F.; Han, N. Influence of strain rate on mechanical characteristic and pore structure of self-healing cementitious composites with epoxy/urea-formaldehyde microcapsules. Constr. Build. Mater. 2021, 268, 121138. [Google Scholar] [CrossRef]

- Ren, J.; Fang, Y.; Ma, Q.; Tan, H.; Luo, S.; Liu, M.; Wang, X. Effect of storage condition on basic performance of polycarboxylate superplasticiser system incorporated sodium gluconate. Constr. Build. Mater. 2019, 223, 852–862. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. Statistical mixture design approach for eco-efficient UHPC. Cem. Concr. Compos. 2015, 55, 17–25. [Google Scholar] [CrossRef]

- Sonebi, M.; Abdalqader, A.; Fayyad, T.; Perrot, A.; Bai, Y. Optimisation of rheological parameters, induced bleeding, permeability and mechanical properties of supersulfated cement grouts. Constr. Build. Mater. 2020, 262, 120078. [Google Scholar] [CrossRef]

- Hou, D.; Chen, D.; Wang, X.; Wu, D.; Ma, H.; Hu, X.; Zhang, Y.; Wang, P.; Yu, R. RSM-based modelling and optimization of magnesium phosphate cement-based rapid-repair materials. Constr. Build. Mater. 2020, 263, 120190. [Google Scholar] [CrossRef]

- Huang, J.; Koroteev, D.D.; Zhang, M. Smartphone-based study of cement-activated charcoal coatings for removal of organic pollutants from water. Constr. Build. Mater. 2021, 300, 124034. [Google Scholar] [CrossRef]

- Wang, X.; Xing, F.; Zhang, M.; Han, N.; Qian, Z. Experimental study on cementitious composites embedded with organic microcapsules. Materials 2013, 69, 4064–4081. [Google Scholar] [CrossRef]

- Navarchian, A.H.; Najafipoor, N.; Ahangaran, F. Surface-modified polymethyl methacrylate microcapsules containing linseed oil for application in self-healing epoxy-based coatings. Prog. Org. Coat. 2019, 132, 288–297. [Google Scholar] [CrossRef]

- Ahangaran, F.; Hayaty, M.; Navarchian, A.H.; Picchioni, F. Micromechanical assessment of PMMA microcapsules containing epoxy and mercaptan as self-healing agents. Polym. Test. 2017, 64, 330–336. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Ding, W.; Liu, Y.; Zhang, J.; Han, N.; Xing, F. Self-healing features in cementitious material with urea–formaldehyde/epoxy microcapsules. Constr. Build. Mater. 2016, 106, 608–617. [Google Scholar] [CrossRef]

- Li, Y.; Bao, J.L.; Guo, Y.L. The relationship between autogenous shrinkage and pore structure of cement paste with mineral admixtures. Construct. Build. Mater 2010, 2410, 1855–1860. [Google Scholar] [CrossRef]

- Ren, J.; Wang, X.; Xu, S.; Luo, Q.; Fang, Y.; Zhu, J.; Xing, F. Effects of polycarboxylate superplasticiser on hydration characteristics and hardened properties of cement blended with seawater. Constr. Build. Mater. 2021, 304, 124660. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Xu, C.; Guan, X.; Zou, D.; Jing, G. Synergy effect of synthetic ettringite modified by citric acid on the properties of ultrafine sulfoaluminat cement-based materials. Cem. Concr. Compos. 2022, 125, 104312. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology RSM as a tool for optimization in analytical chemistry. Talanta 2008, 765, 965–977. [Google Scholar] [CrossRef]

- Litina, C.; Al-Tabbaa, A. First generation microcapsule-based self-healing cementitious construction repair materials. Constr. Build. Mater. 2020, 255, 119389. [Google Scholar] [CrossRef]

- SFaroughi, A.; Huber, C. Crowding-based rheological model for suspensions of rigid bimodal-sized particles with interfering size ratios. Phys. Rev. E 2014, 905, 052303. [Google Scholar] [CrossRef]

- Wang, X.F.; Han, R.; Tao, J.; Han, T.L.; Zhu, G.M.; Tang, J.N.; Han, N.X.; Xing, F. Identification of mechanical parameters of urea-formaldehyde microcapsules using finite-element method. Compos. Part B Eng. 2019, 158, 249–258. [Google Scholar] [CrossRef]

- Wang, X.; Xie, W.; Li, T.; Ren, J.; Zhu, J.; Han, N.; Xing, F. Molecular Dynamics Study on Mechanical Properties of Interface between Urea-Formaldehyde Resin and Calcium-Silicate-Hydrates. Materials 2020, 1318, 4054. [Google Scholar] [CrossRef]

- Han, T.; Wang, X.; Li, D.; Han, N.; Li, D.; Xing, F. Stress and strain behavior of cementitious composites with epoxy/urea-formaldehyde microcapsules under uniaxial tests. J. Ceram. Process. Res. 2019, 20, 46–55. [Google Scholar]

- Al-Tabbaa, A.; Litina, C.; Giannaros, P.; Kanellopoulos, A.; Souza, L. First UK field application and performance of microcapsule-based self-healing concrete. Constr. Build. Mater. 2019, 208, 669–685. [Google Scholar] [CrossRef]

- Wang, X.F.; Han, R.; Han, T.L.; Han, N.X.; Xing, F. Determination of elastic properties of urea-formaldehyde microcapsules through nanoindentation based on the contact model and the shell deformation theory. Mater. Chem. Phys. 2018, 215, 346–354. [Google Scholar] [CrossRef]

- Li, H.X.; Gu, L.N.; Dong, B.Q.; Chen, Q.; Xu, C.; Yang, X.J.; Wang, W.S. Improvements in setting behavior and strengths of cement paste/mortar with EVA redispersible powder using C-S-Hs-PCE. Constr. Build. Mater. 2020, 262, 120097. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | CaO | Fe2O3 | MgO | R2O | f-CaO | SO3 | Loss | Cl− | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20.53 | 4.45 | 62.05 | 3.17 | 2.81 | 0.55 | 0.80 | 2.10 | 1.74 | 0.032 | ||

| C3S | C2S | C3A | C4AF | ||||||||

| 57.58 | 18.55 | 7.14 | 11.37 | ||||||||

| Fineness% | Specific Surface Area m2/kg | Density g/cm3 | Standard Consistency/% | ||||||||

| 0.6 | 359 | 3.12 | 25.80 | ||||||||

| Code | Rotation Speeds/rpm | Particle Size (D50)/µm | Specific Surface Area/m2/kg | Roundness |

|---|---|---|---|---|

| Small | 600 | 164.98 | 39.97 | 0.842 |

| Medium | 400 | 202.38 | 32.91 | 0.844 |

| Large | 200 | 241.16 | 27.91 | 0.834 |

| Code | Cement/g | Water/g | Microcapsule/g | Curing Agent/g | Pre-Loading/% | Curing Age/Days | ||

|---|---|---|---|---|---|---|---|---|

| Small | Medium | Large | ||||||

| R | 600 | 174 | 20%, 40%, 60% | 7, 14, 21 | ||||

| S2 | 12 | 4.8 | ||||||

| S4 | 24 | 9.6 | ||||||

| S6 | 36 | 14.4 | ||||||

| M2 | 12 | 4.8 | ||||||

| M4 | 24 | 9.6 | ||||||

| M6 | 36 | 14.4 | ||||||

| L2 | 12 | 4.8 | ||||||

| L4 | 24 | 9.6 | ||||||

| L6 | 36 | 14.4 | ||||||

| Independent Variables | Symbols | Unit | Actual Values for the Coded Values | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| Microcapsule Size | X1 | µm | 165 | 203 | 241 |

| Microcapsule Content | X2 | wt% | 2 | 4 | 6 |

| Pre-Loading | X3 | % | 20 | 40 | 60 |

| Curing age | X4 | Days | 7 | 14 | 21 |

| Runs | Microcapsule Size (X1) | Microcapsule Content (X2) | Pre-Loading (X3) | Curing Age (X4) |

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 |

| 2 | 0 | −1 | 1 | 0 |

| 3 | 1 | 0 | 0 | 1 |

| 4 | 0 | 0 | −1 | 1 |

| 5 | 1 | 0 | −1 | 0 |

| 6 | 1 | 0 | 1 | 0 |

| 7 | 1 | 0 | 0 | −1 |

| 8 | −1 | 0 | −1 | 0 |

| 9 | 0 | 0 | 1 | −1 |

| 10 | −1 | 0 | 0 | −1 |

| 11 | 0 | 0 | 1 | 1 |

| 12 | 0 | 0 | −1 | −1 |

| 13 | 0 | 0 | 0 | 0 |

| 14 | −1 | 1 | 0 | 0 |

| 15 | 1 | 1 | 0 | 0 |

| 16 | 1 | −1 | 0 | 0 |

| 17 | 0 | 1 | −1 | 0 |

| 18 | 0 | 0 | 0 | 0 |

| 19 | 0 | 1 | 1 | 0 |

| 20 | 0 | −1 | 0 | −1 |

| 21 | 0 | −1 | −1 | 0 |

| 22 | 0 | 1 | 0 | 1 |

| 23 | 0 | 0 | 0 | 0 |

| 24 | 0 | 0 | 0 | 0 |

| 25 | −1 | 0 | 0 | 1 |

| 26 | 0 | −1 | 0 | 1 |

| 27 | −1 | 0 | 1 | 0 |

| 28 | 0 | 1 | 0 | −1 |

| 29 | −1 | −1 | 0 | 0 |

| Run | Factors | Responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Microcapsule Size | Microcapsule Content | Pre-Loading Level | Curing Age | Healing Rate of Peak Strength | Recovery Rate of Peak Strength | Healing Rate of Young’s Modulus | Recovery Rate of Young’s Modulus | Healing Rate of Peak Strain | Recovery Rate of Peak Strain | |

| 1 | 0 | 0 | 0 | 0 | 41.64 | 125.78 | 35.21 | 120.07 | 25.72 | 121.06 |

| 2 | 0 | −1 | 1 | 0 | 19.94 | 108.07 | 29.96 | 109.46 | 3.61 | 112.72 |

| 3 | 1 | 0 | 0 | 1 | 54.83 | 143.71 | 48.22 | 129.99 | 22.55 | 153.28 |

| 4 | 0 | 0 | −1 | 1 | 36.06 | 128.98 | 12.75 | 110.70 | 18.39 | 134.77 |

| 5 | 1 | 0 | −1 | 0 | 29.78 | 122.68 | 16.57 | 111.34 | 2.45 | 116.91 |

| 6 | 1 | 0 | 1 | 0 | 37.04 | 125.17 | 43.84 | 120.60 | 3.37 | 118.72 |

| 7 | 1 | 0 | 0 | −1 | 12.13 | 104.07 | 16.70 | 102.34 | 22.72 | 96.73 |

| 8 | −1 | 0 | −1 | 0 | 6.60 | 98.92 | 8.02 | 103.40 | 3.35 | 110.95 |

| 9 | 0 | 0 | 1 | −1 | 10.20 | 99.29 | 9.80 | 97.64 | 18.84 | 99.66 |

| 10 | −1 | 0 | 0 | −1 | 6.34 | 96.78 | 5.72 | 97.37 | 6.99 | 100.84 |

| 11 | 0 | 0 | 1 | 1 | 50.93 | 135.99 | 39.04 | 123.65 | 14.93 | 139.22 |

| 12 | 0 | 0 | −1 | −1 | 4.08 | 98.67 | −2.42 | 95.81 | 10.16 | 99.84 |

| 13 | 0 | 0 | 0 | 0 | 38.26 | 129.24 | 37.72 | 124.33 | 23.33 | 126.31 |

| 14 | −1 | 1 | 0 | 0 | 41.56 | 131.36 | 19.65 | 111.72 | 7.76 | 121.54 |

| 15 | 1 | 1 | 0 | 0 | 58.77 | 147.94 | 44.57 | 128.45 | 8.06 | 128.38 |

| 16 | 1 | −1 | 0 | 0 | 20.55 | 112.49 | 30.79 | 118.52 | 7.42 | 127.43 |

| 17 | 0 | 1 | −1 | 0 | 32.26 | 123.49 | 22.39 | 115.86 | 4.98 | 117.38 |

| 18 | 0 | 0 | 0 | 0 | 43.40 | 130.10 | 33.28 | 126.45 | 27.49 | 115.33 |

| 19 | 0 | 1 | 1 | 0 | 48.85 | 132.23 | 39.83 | 120.75 | 2.73 | 123.18 |

| 20 | 0 | −1 | 0 | −1 | 7.33 | 99.60 | 8.30 | 97.39 | 13.51 | 100.45 |

| 21 | 0 | −1 | −1 | 0 | 12.45 | 106.60 | 9.71 | 103.04 | 3.26 | 107.33 |

| 22 | 0 | 1 | 0 | 1 | 66.52 | 152.20 | 46.08 | 132.82 | 20.86 | 148.29 |

| 23 | 0 | 0 | 0 | 0 | 42.08 | 123.42 | 31.25 | 118.38 | 26.46 | 117.24 |

| 24 | 0 | 0 | 0 | 0 | 39.16 | 124.31 | 38.02 | 124.36 | 28.22 | 127.31 |

| 25 | −1 | 0 | 0 | 1 | 31.83 | 119.97 | 18.44 | 109.09 | 14.28 | 125.86 |

| 26 | 0 | −1 | 0 | 1 | 39.64 | 129.59 | 29.66 | 116.60 | 12.23 | 129.92 |

| 27 | −1 | 0 | 1 | 0 | 20.78 | 105.96 | 19.22 | 105.01 | 4.86 | 107.80 |

| 28 | 0 | 1 | 0 | −1 | 21.83 | 108.19 | 17.02 | 103.91 | 14.40 | 105.06 |

| 29 | −1 | −1 | 0 | 0 | 11.48 | 100.93 | 10.97 | 101.28 | 10.18 | 117.28 |

| Healing Rate of Peak Strength (Y1) | Recovery Rate of Peak Strength (Y2) | Healing Rate of Young’s Modulus (Y3) | Recovery Rate of Young’s Modulus (Y4) | Healing Rate of Peak Strain (Y5) | Recovery Rate of Peak Strain (Y6) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | |

| Intercept | 40.91 | 126.57 | 35.10 | 122.72 | 26.24 | 118.99 | ||||||

| X1 | 7.88 | <0.0001 | 8.51 | <0.0001 | 9.89 | <0.0001 | 6.95 | <0.0001 | 1.60 | 0.1492 | 4.76 | 0.0093 |

| X2 | 13.20 | <0.0001 | 11.51 | <0.0001 | 5.85 | <0.0001 | 5.60 | <0.0001 | 0.72 | 0.5051 | 4.06 | 0.0240 |

| X3 | 5.54 | <0.0001 | 2.28 | 0.0937 | 9.56 | <0.0001 | 3.08 | 0.0004 | 0.48 | 0.6543 | 1.18 | 0.4916 |

| X4 | 18.16 | <0.0001 | 16.99 | <0.0001 | 11.59 | <0.0001 | 10.70 | <0.0001 | 1.38 | 0.2070 | 19.06 | <0.0001 |

| X1×2 | 2.04 | 0.2555 | 1.25 | 0.5778 | 1.27 | 0.3772 | −0.13 | 0.9137 | 0.77 | 0.6789 | ||

| X1×3 | −1.73 | 0.3312 | −1.14 | 0.6128 | 4.02 | 0.0123 | 1.91 | 0.1231 | −0.15 | 0.9363 | ||

| X1×4 | 4.31 | 0.0253 | 4.11 | 0.0824 | 4.70 | 0.0047 | 3.98 | 0.0042 | −1.86 | 0.3208 | ||

| X2×3 | 2.27 | 0.2071 | 1.82 | 0.4214 | −0.70 | 0.6229 | −0.38 | 0.7485 | −0.65 | 0.7249 | ||

| X2×4 | 3.09 | 0.0935 | 3.51 | 0.1329 | 1.93 | 0.1898 | 2.42 | 0.0562 | 1.94 | 0.3034 | ||

| X3×4 | 2.19 | 0.2236 | 1.60 | 0.4793 | 3.52 | 0.0246 | 2.78 | 0.0317 | −3.04 | 0.1160 | ||

| X12 | −7.40 | <0.0001 | −5.08 | 0.0107 | −4.91 | 0.0005 | −5.08 | <0.0001 | −9.37 | <0.0001 | ||

| X22 | −1.22 | 0.3832 | 0.26 | 0.8813 | −1.63 | 0.1589 | −2.50 | 0.0162 | −9.99 | <0.0001 | ||

| X32 | −10.24 | <0.0001 | −8.07 | 0.0004 | −9.16 | <0.0001 | −7.82 | <0.0001 | −12.25 | <0.0001 | ||

| X42 | −6.15 | 0.0005 | −4.19 | 0.0291 | −9.09 | <0.0001 | −7.81 | <0.0001 | 0.12 | 0.9365 | ||

| Parameters | Importance | Weight | Goal | Predict Value |

|---|---|---|---|---|

| Microcapsule size (X1)/nm | 3 | 1 | Equal to | 203 |

| Microcapsule content (X2)/% | 3 | 1 | In range | 5.59 |

| Pre-loading level (X3)/% | 3 | 1 | In range | 43.56 |

| Curing age (X4)/Day | 3 | 1 | In range | 21 |

| Healing rate of peak strength/% | 5 | 1 | Maximise | 66.52 |

| Recovery rate of peak strength/% | 5 | 1 | Maximise | 152.20 |

| Healing rate of Young’s Modulus/% | 5 | 1 | Maximise | 44.71 |

| Recovery rate of Young’s Modulus/% | 5 | 1 | Maximise | 131.16 |

| Healing rate of peak strain/% | 5 | 1 | Maximise | 22.56 |

| Recovery rate of peak strain/% | 5 | 1 | Maximise | 141.50 |

| Desirability | 0.9050 | |||

| Parameters | Predict Value | Verification | Relative Error | |||

|---|---|---|---|---|---|---|

| Run 1 | Run 2 | Run 3 | Average | |||

| Healing rate of peak strength/% | 66.52 | 67.53 | 64.83 | 58.64 | 63.67 | 95.71 |

| Recovery rate of peak strength/% | 152.20 | 147.67 | 147.95 | 140.05 | 145.22 | 95.42 |

| Healing rate of Young’s Modulus/% | 44.71 | 45.39 | 39.47 | 36.14 | 40.34 | 90.22 |

| Recovery rate of Young’s Modulus/% | 131.16 | 138.64 | 131.72 | 126.32 | 132.22 | 100.81 |

| Healing rate of peak strain/% | 22.56 | 29.71 | 23.16 | 30.13 | 27.66 | 122.62 |

| Recovery rate of peak strain/% | 141.50 | 137.76 | 127.32 | 136.44 | 133.84 | 94.59 |

| Type | State | Porosity (%) | Average Pore Diameter (nm) | Pore Volume (mL/g) | Pore Size Distribution (%) | ||

|---|---|---|---|---|---|---|---|

| <10 nm | 10~100 nm | >100 nm | |||||

| Run 1 | Initial | 12.01 | 18.23 | 0.0619 | 8.88 | 78.12 | 13.00 |

| Damaged | 12.48 | 20.13 | 0.0660 | 8.83 | 74.94 | 16.23 | |

| Healed | 11.95 | 20.47 | 0.0608 | 11.71 | 72.21 | 16.08 | |

| Run 15 | Initial | 11.68 | 21.44 | 0.5082 | 10.49 | 78.01 | 11.50 |

| Damaged | 13.26 | 23.81 | 0.0673 | 9.94 | 74.89 | 15.17 | |

| Healed | 11.38 | 23.13 | 0.0563 | 9.45 | 78.44 | 12.11 | |

| Veri-Run 1 | Initial | 11.52 | 20.41 | 0.0580 | 11.28 | 80.73 | 7.99 |

| Damaged | 13.86 | 24.72 | 0.0732 | 5.79 | 76.70 | 17.51 | |

| Healed | 10.87 | 20.83 | 0.0552 | 11.44 | 81.79 | 6.77 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, J.; Liu, B.; Li, H.; Zhang, J.; Zhu, H.; Xiao, M.; Liu, G.; Luo, S. Performance-Based Evaluation of Healing Efficiency on Mechanical Properties of Self-Healing Cementitious Materials Incorporated with PMMA/Epoxy Microcapsule. Polymers 2022, 14, 2497. https://doi.org/10.3390/polym14122497

Ren J, Liu B, Li H, Zhang J, Zhu H, Xiao M, Liu G, Luo S. Performance-Based Evaluation of Healing Efficiency on Mechanical Properties of Self-Healing Cementitious Materials Incorporated with PMMA/Epoxy Microcapsule. Polymers. 2022; 14(12):2497. https://doi.org/10.3390/polym14122497

Chicago/Turabian StyleRen, Jun, Birunxuan Liu, Hao Li, Ji Zhang, Haiyan Zhu, Meilin Xiao, Guojian Liu, and Shuqiong Luo. 2022. "Performance-Based Evaluation of Healing Efficiency on Mechanical Properties of Self-Healing Cementitious Materials Incorporated with PMMA/Epoxy Microcapsule" Polymers 14, no. 12: 2497. https://doi.org/10.3390/polym14122497

APA StyleRen, J., Liu, B., Li, H., Zhang, J., Zhu, H., Xiao, M., Liu, G., & Luo, S. (2022). Performance-Based Evaluation of Healing Efficiency on Mechanical Properties of Self-Healing Cementitious Materials Incorporated with PMMA/Epoxy Microcapsule. Polymers, 14(12), 2497. https://doi.org/10.3390/polym14122497