Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete

Abstract

1. Introduction

2. Experimental Procedure

2.1. Raw Materials

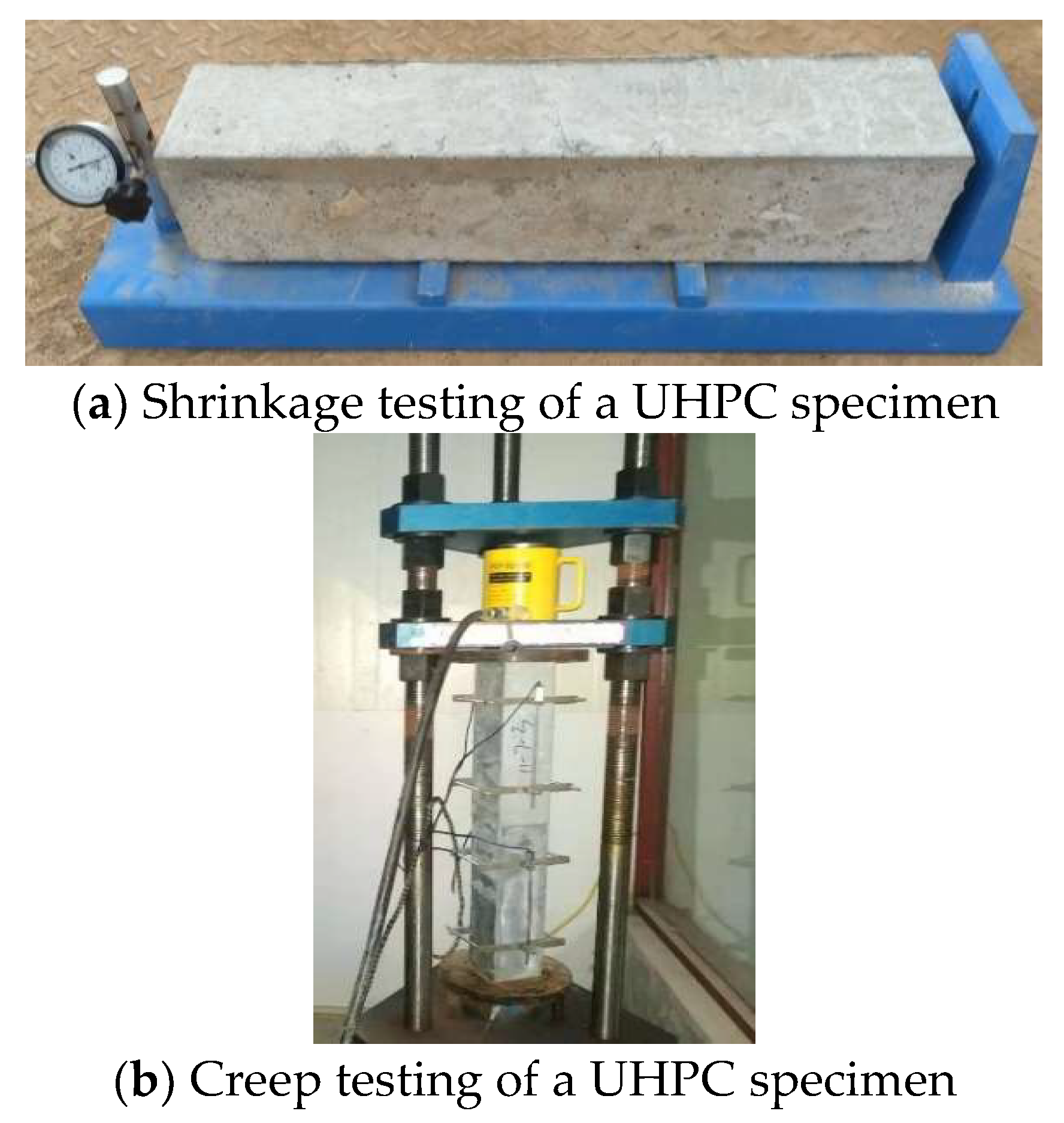

2.2. Experimental Process and Testing Method

3. Results and Discussions

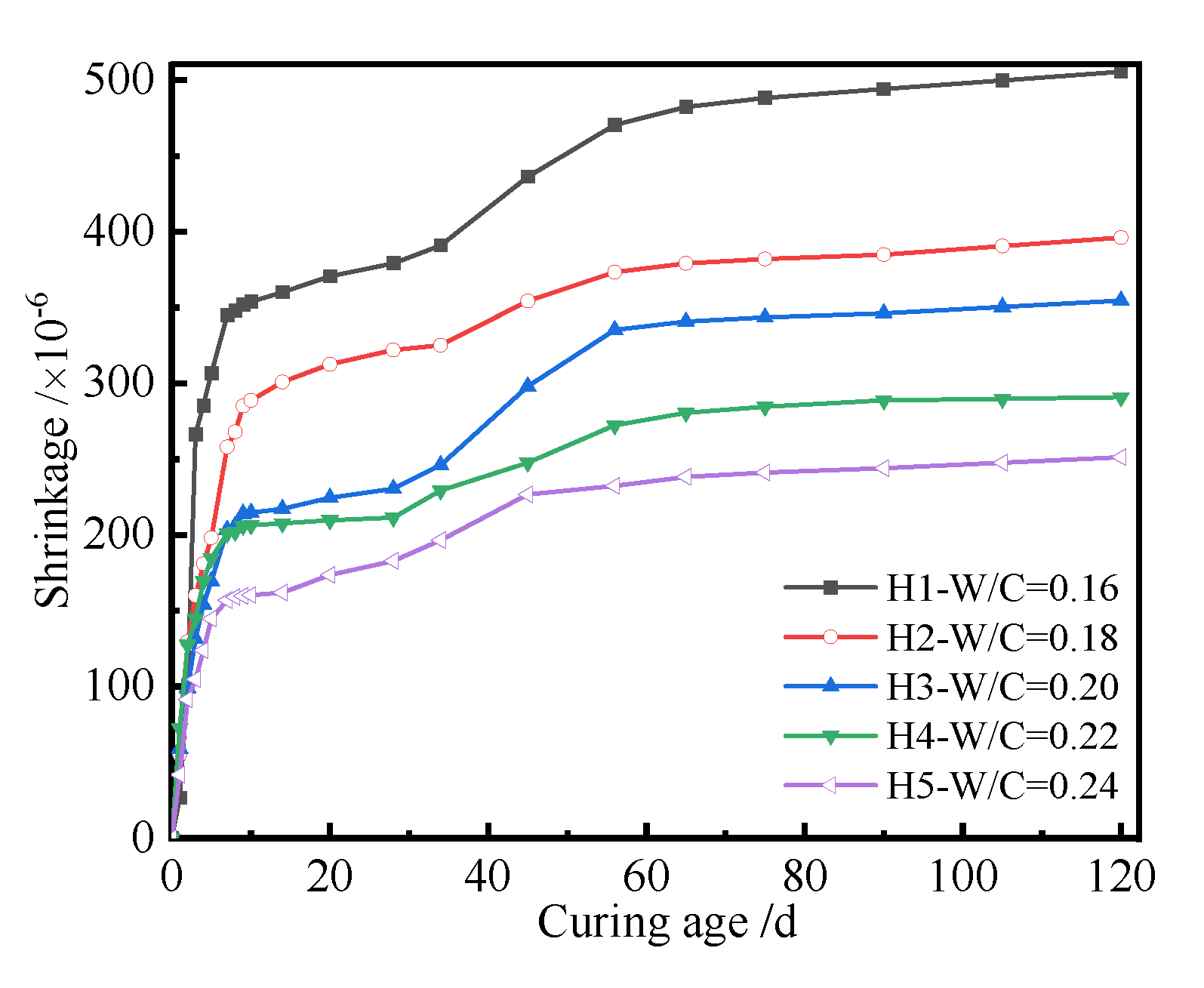

3.1. Effects of W/C on the Shrinkage and Creep of the UHPC

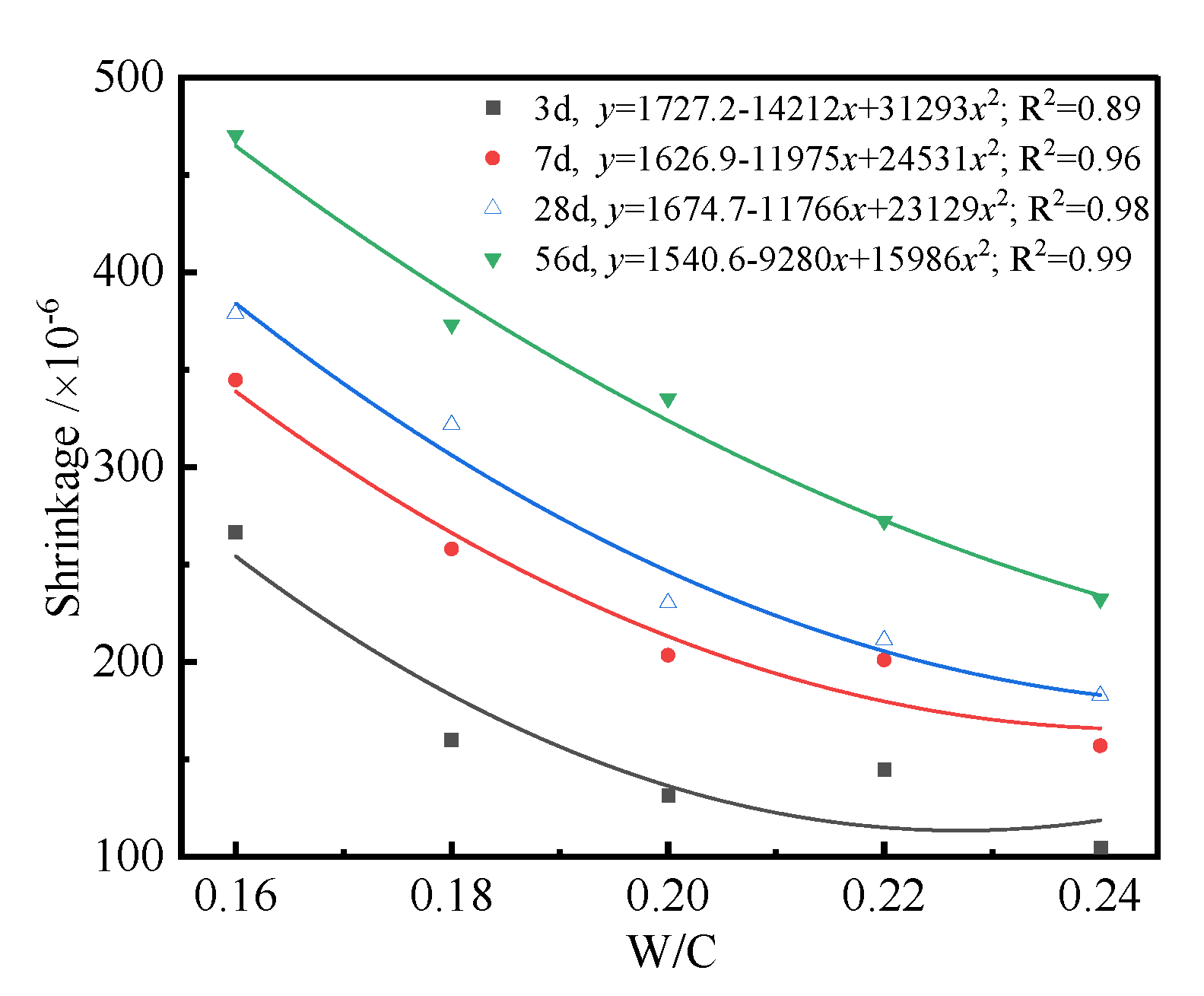

3.1.1. Effect of W/C on Shrinkage of the UHPC

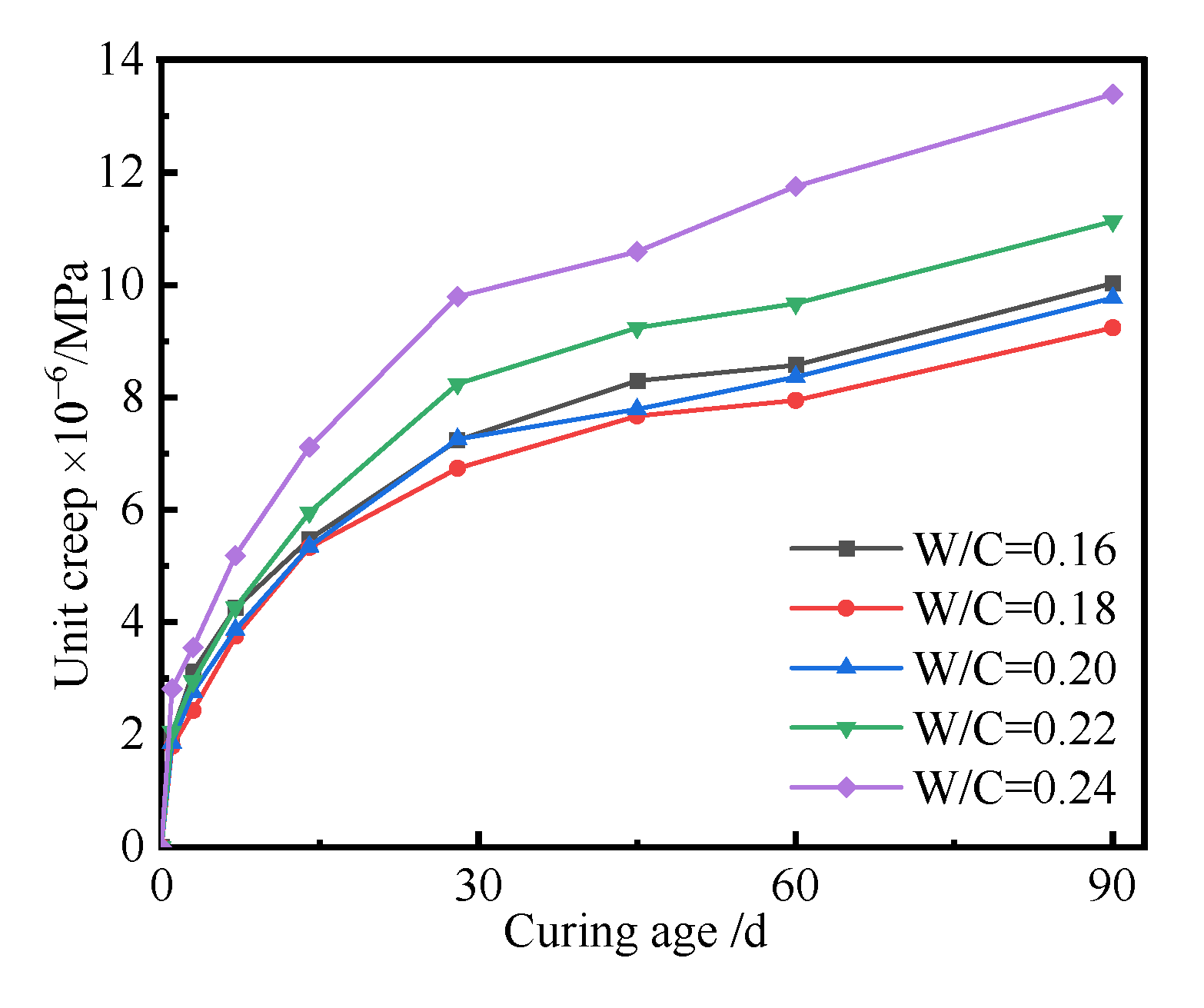

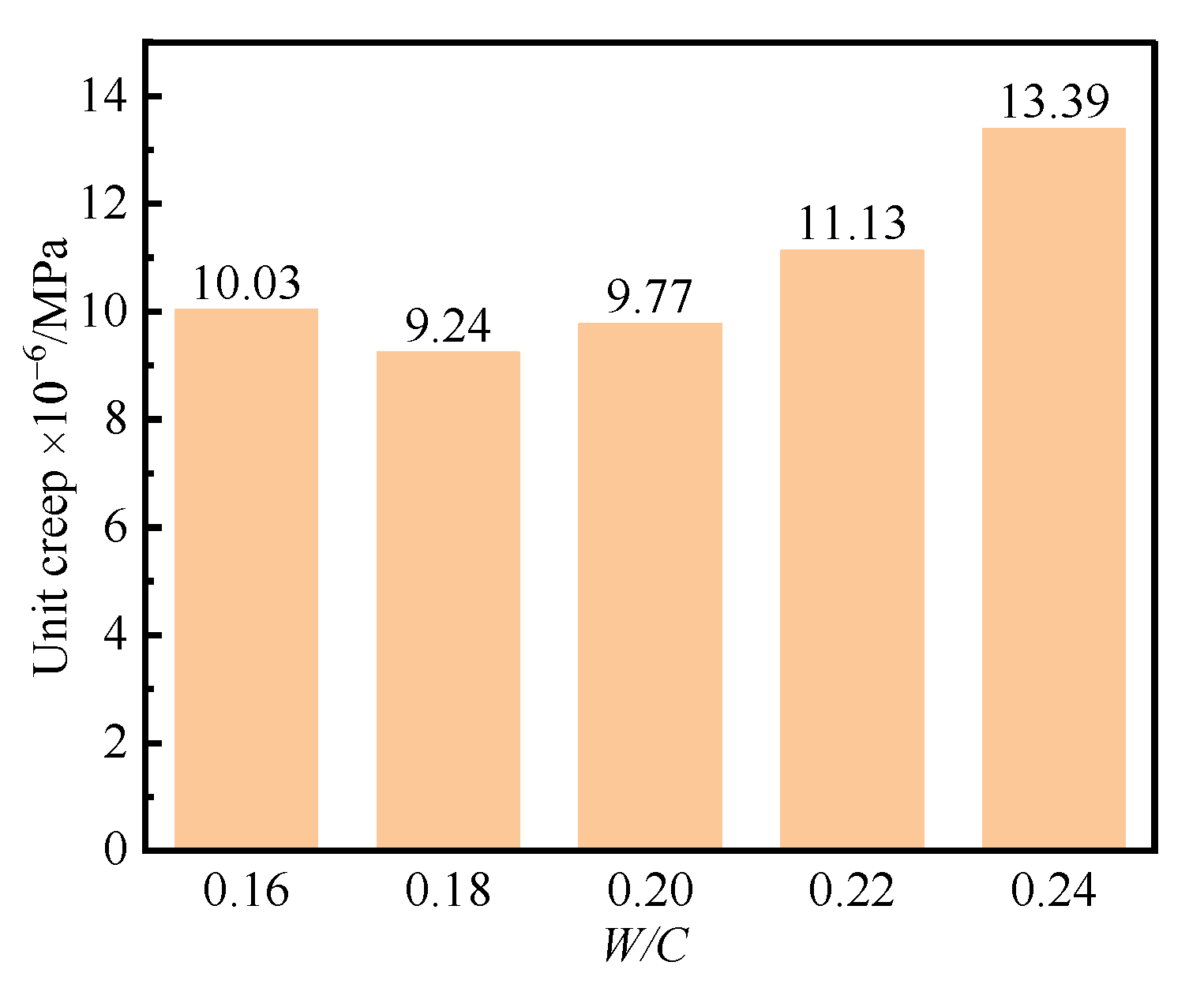

3.1.2. Effect of W/C on the Creep of the UHPC

3.2. Effects of Content of Cementitious Materials on the Shrinkage and Creep of the UHPC

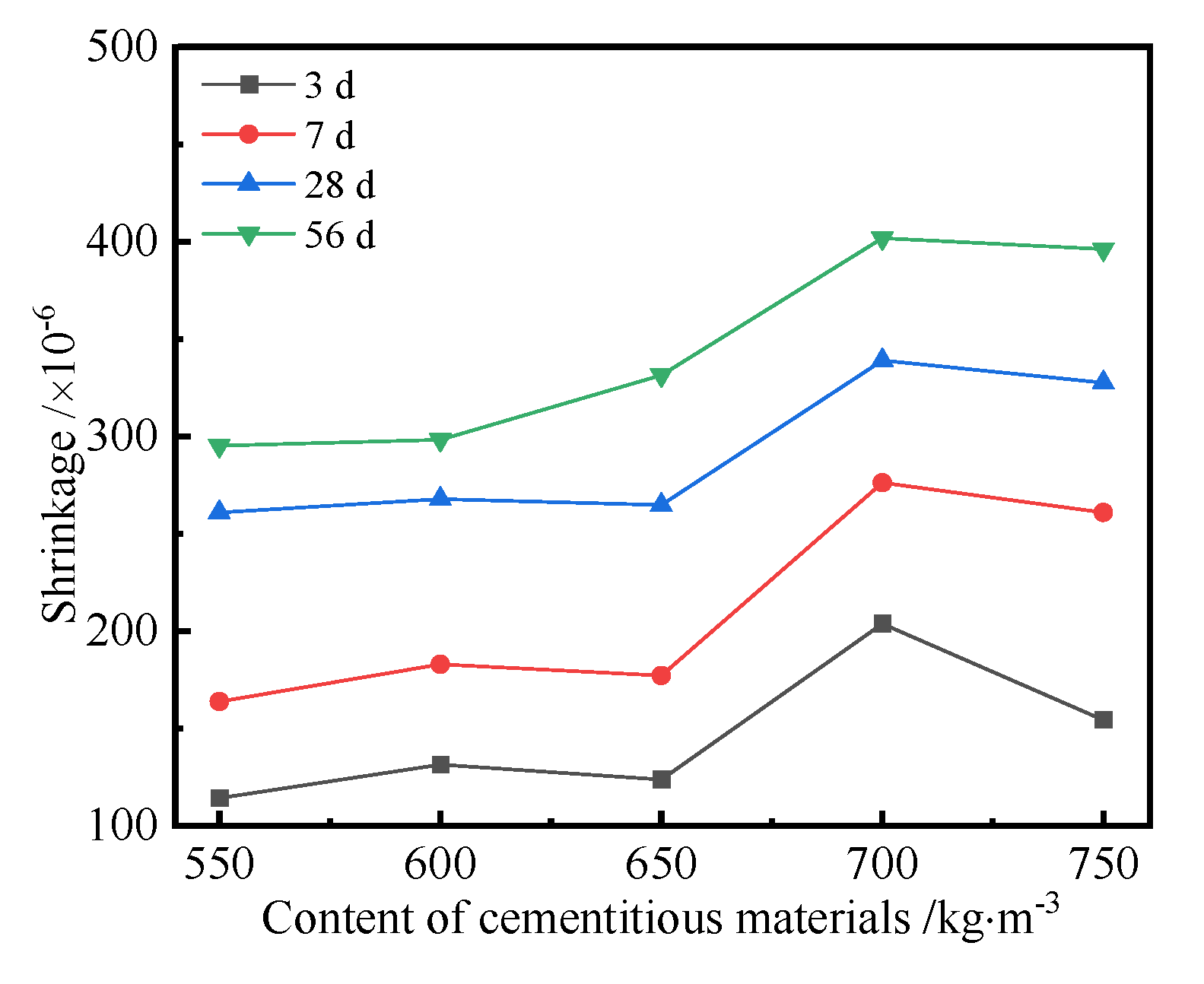

3.2.1. Effect of Cementitious Materials on the Shrinkage of the UHPC

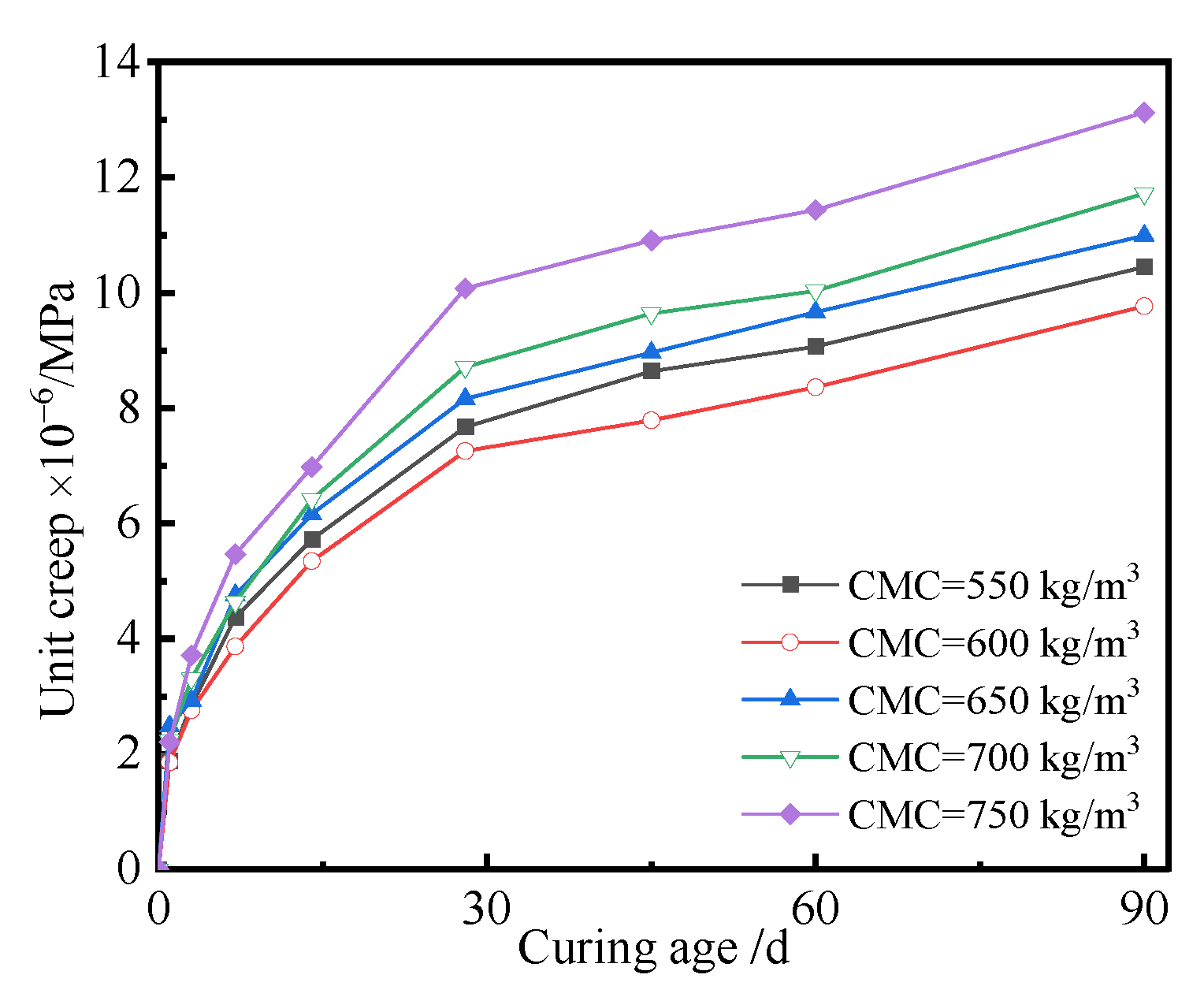

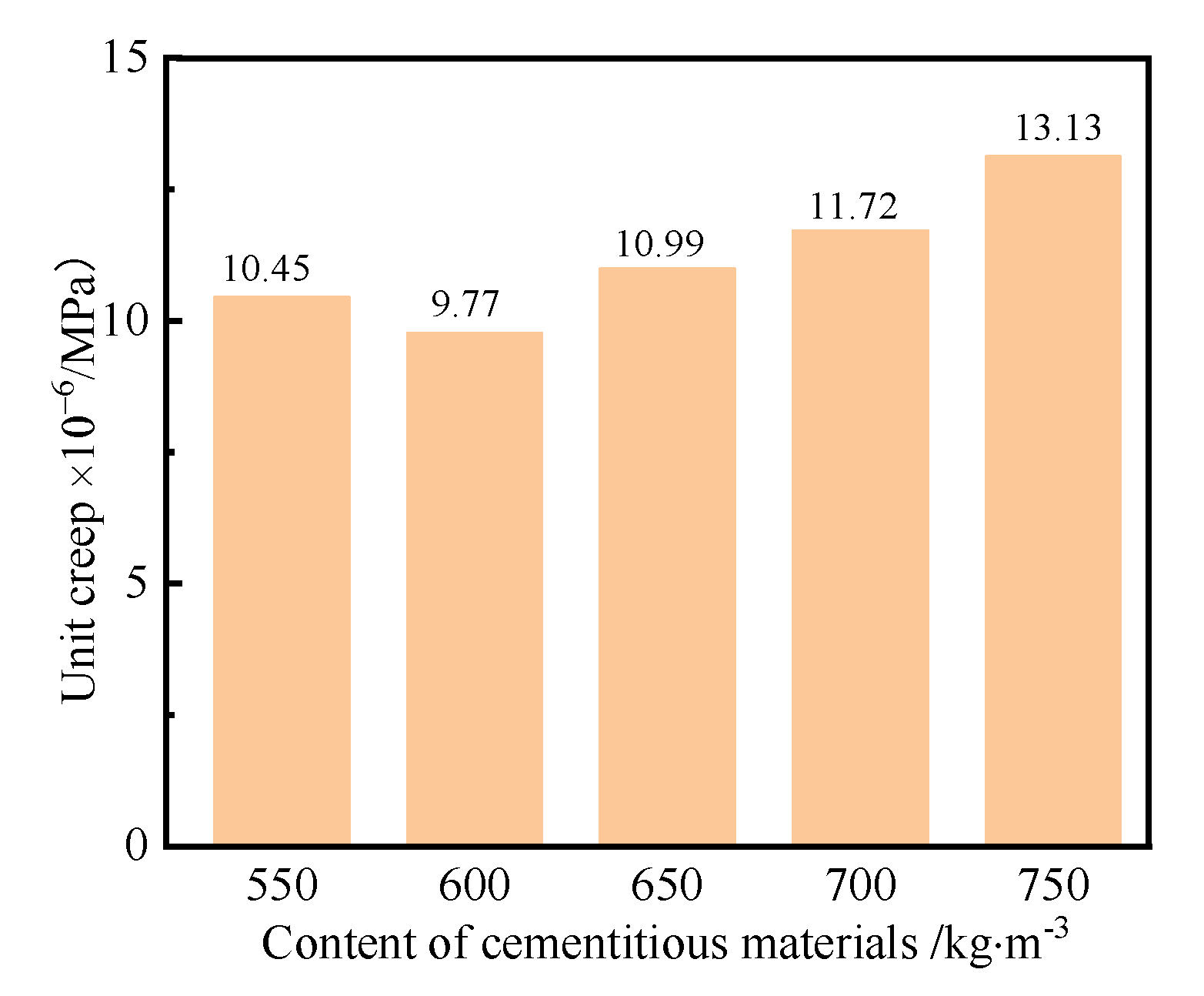

3.2.2. Effect of Cementitious Materials on the Creep of the UHPC

3.3. Type and Content of Fibers on the Shrinkage and Creep of the UHPC

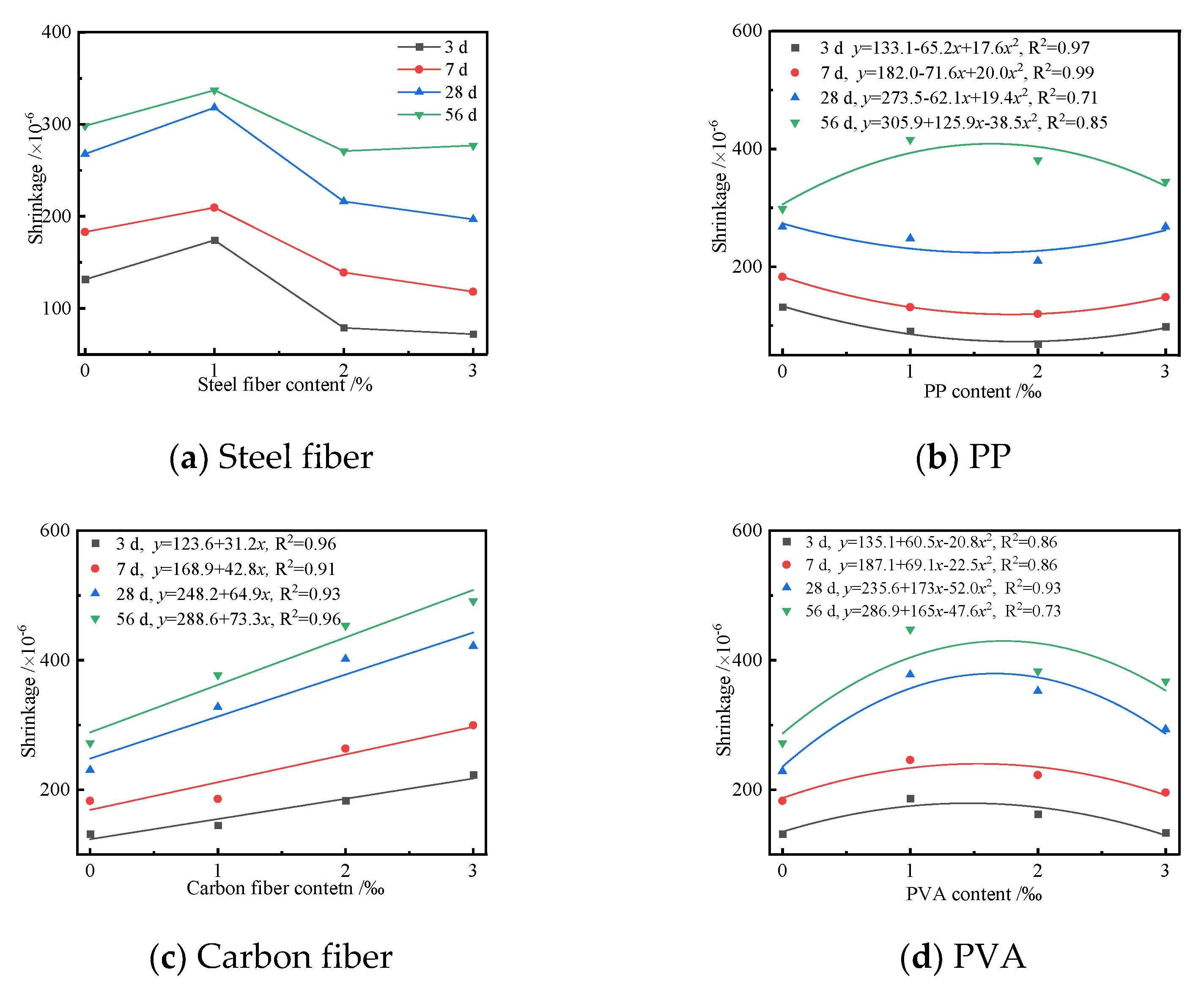

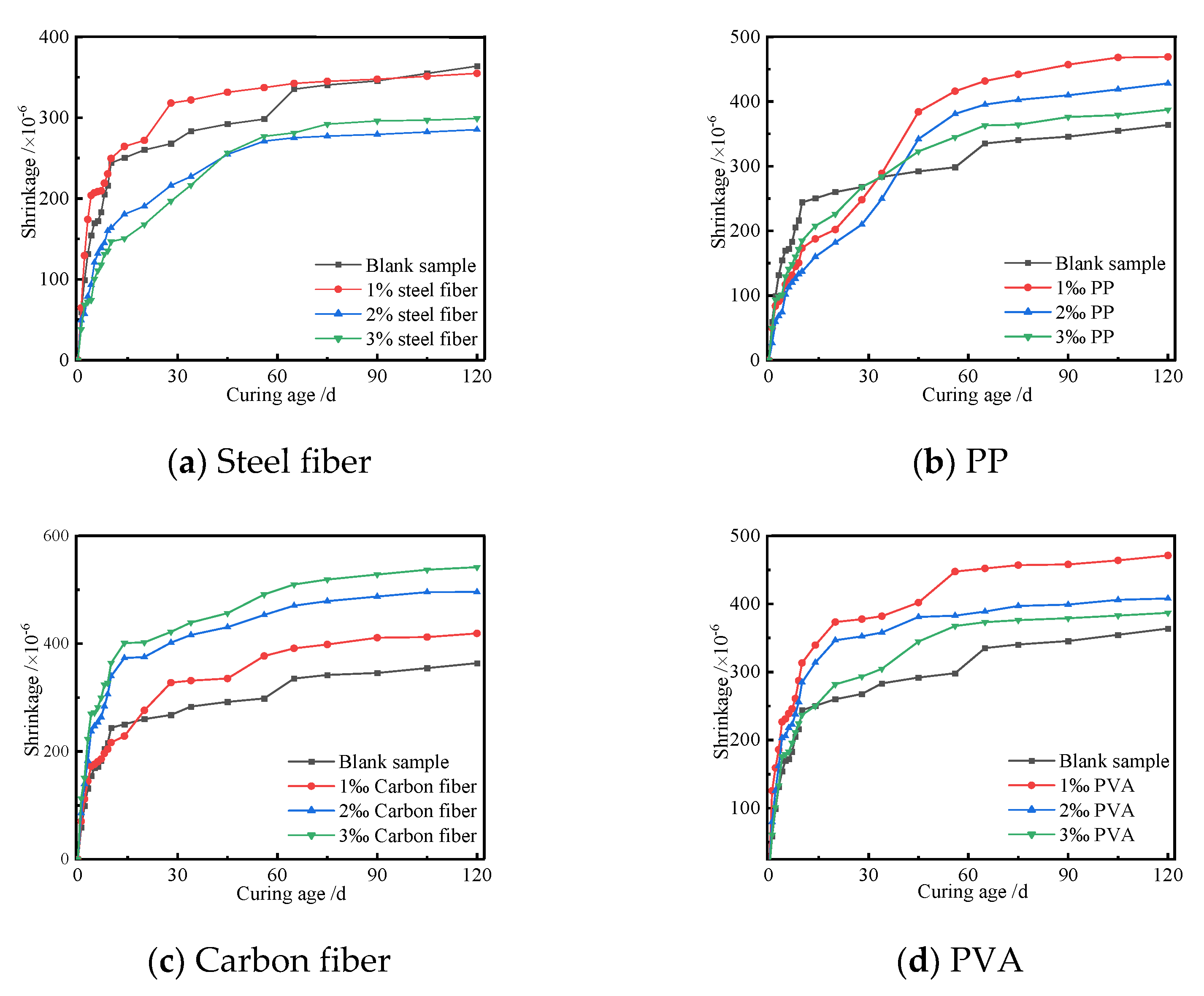

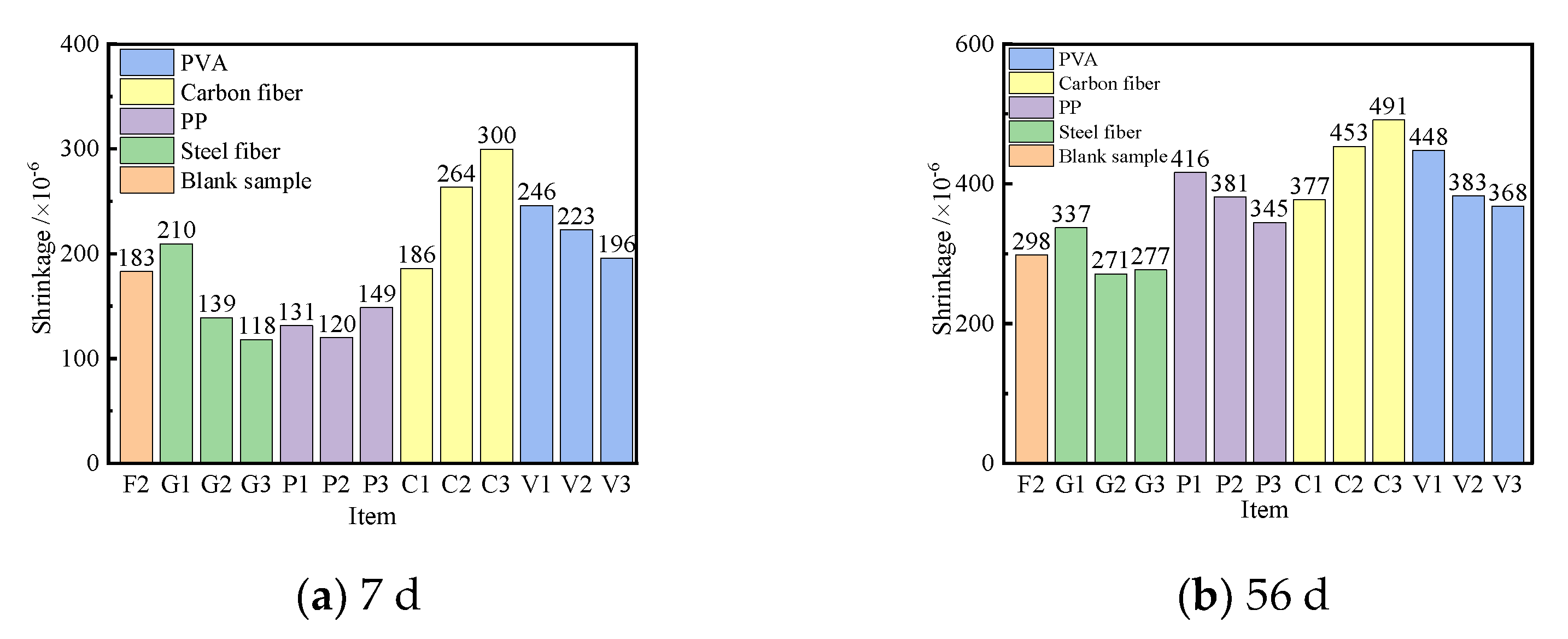

3.3.1. Effect of Fibers on the Shrinkage of the UHPC

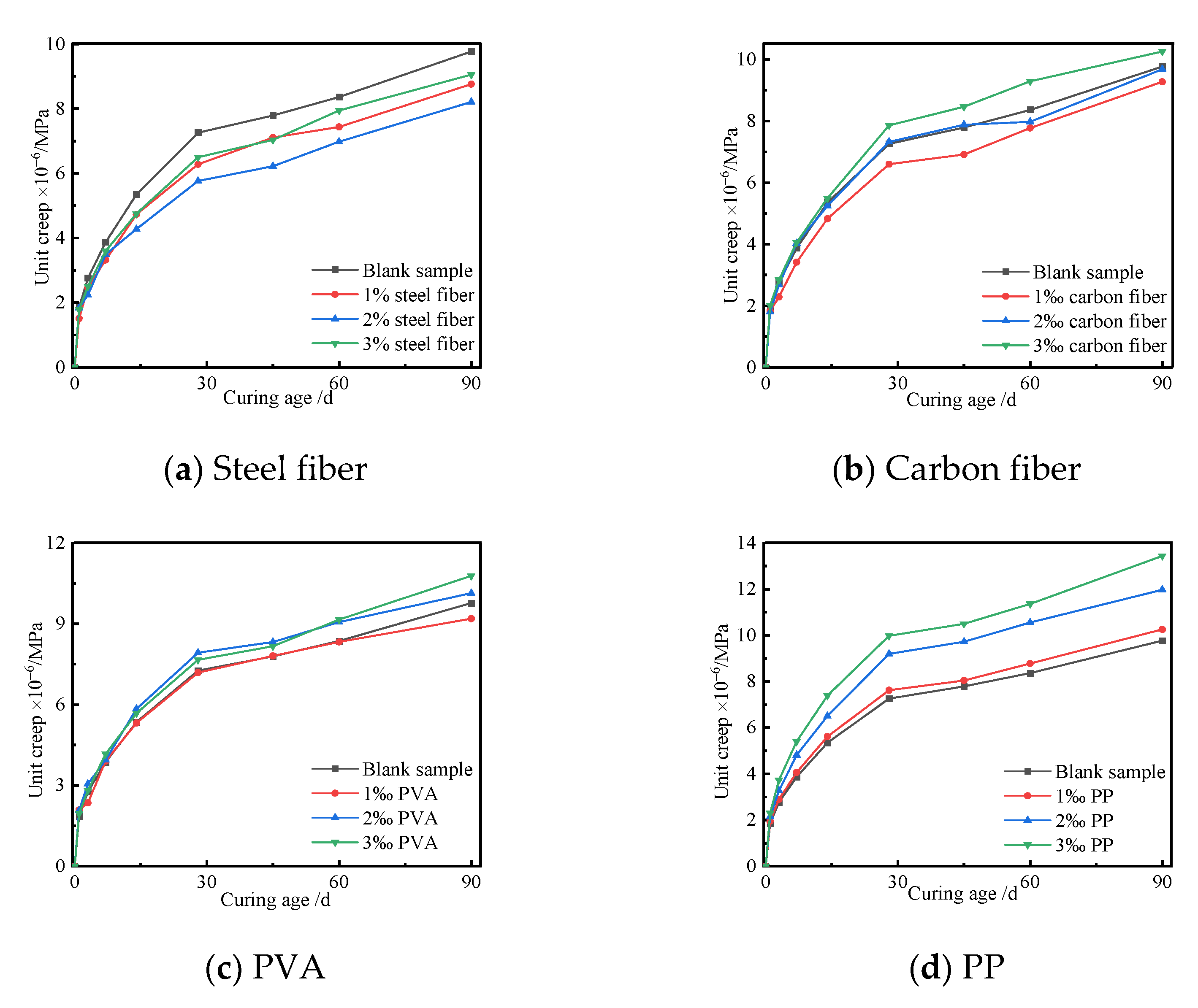

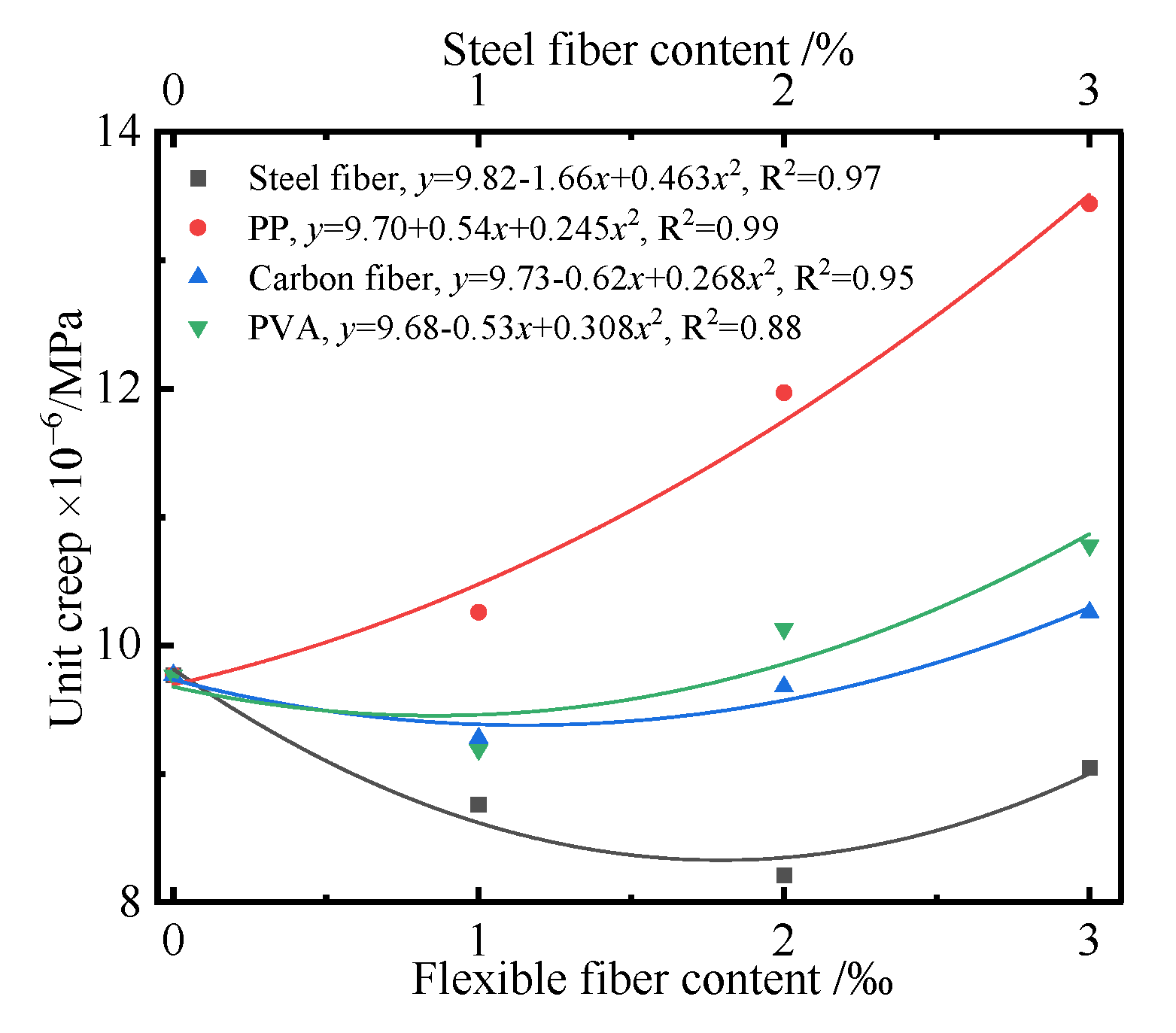

3.3.2. Effect of Fibers on the Creep of the UHPC

4. Conclusions

- The W/C had a significant effect on the shrinkage and unit creep of the UHPC prepared using limestone gravel and river sand with a conventional preparation process. The shrinkage of the UHPC decreased with the increase in W/C, but the unit creep of the UHPC increased. There existed a quadratic function relating the shrinkage and W/C, as well as the unit creep and W/C. The change rate of shrinkage and unit creep of the UHPC at the initial curing age was significant, and it tended to be a constant with the increase in curing age. The smaller the W/C of the UHPC cured for the same age, the more significant the shrinkage and change rate of the UHPC. The shrinkage of the UHPC was caused by the chemical autogenous and drying shrinkages of hardened paste, and the creep of the UHPC was due to the slippage of hydration products and the deformation of the microstructure under the external load.

- The shrinkage and unit creep of the UHPC increased with the increase in the content of the cementitious materials. The content of cementitious materials had a significant effect on the shrinkage of the UHPC when the content of cementitious materials was more than 650 kg/m3. Plenty of hydration products are generated during the hydrating process, resulting in a larger chemical autogenous shrinkage when the content of cementitious materials is high. Moreover, the shrinkage of the UHPC increased with the increase in evaporated free water. The minimum unit creep of the UHPC cured for 90 d was found when the content of cementitious materials is less than 650 kg/m3.

- The types and contents of fibers had different effects on the shrinkage and unit creep of the UHPC. The shrinkage of the UHPC first increased and then decreased with the increase in the content of steel fiber, and there existed a quadratic function that described the relationship between them. The shrinkage of the UHPC was more than that of the blank sample when the content of steel fiber was 1%. There existed a linear functional relationship between the shrinkage of the UHPC and the content of carbon fibers. However, the shrinkage of the UHCP first increased and then decreased with the increase in the content of PVA. Moreover, the shrinkage of UHPC increased with the increase of curing age and then tended to be a constant. The steel fiber had a significant inhibiting effect on the unit creep of the UHPC. Adding PP into the UHPC increased the unit creep. The carbon fiber and PVA had positive and negative effects on the unit creep of the UHPC. The effects of the type and content of fibers on the shrinkage and unit creep of the UHPC were caused by the slenderness ratio, shape, surface roughness, and elasticity modulus of the fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ASTM C1856/C1856M-2017; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM Committee Press: Philadelphia, PA, USA, 2017.

- GB/T 31387-2015; Reactive Powder Concrete. China Building Industry Press: Beijing, China, 2015.

- Mounanga, P.; Cherkaoui, K.; Khelidj, A.; Courtial, M.; de Noirfontaine, M.N.; Dunstetter, F. Extrudable reactive powder concretes hydration, shrinkage and transfer properties. Eur. J. Environ. Civ. Eng. 2012, 16, 99–114. [Google Scholar] [CrossRef][Green Version]

- Roy, D.M.; Gouda, G.R.; Brobowsky, A. Very high strength cement pastes prepared by hot-pressing and other high pressure techniques. Cem. Concr. Res. 1972, 2, 349–366. [Google Scholar] [CrossRef]

- Lankard, D.R. Slurry infiltrated fiber concrete (sifcon): Properties and applications. Concr. Int. 1984, 42, 17–29. [Google Scholar] [CrossRef]

- Roux, N.; Andrade, C.; Sanjuan, M. Experimental study of durability of reactive powder concretes. J. Mater. Civ. Eng. 1996, 8, 1–6. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, K.M. Autogenous shrinkage characteristics of ultra-high performance concrete. J. Korea Concr. Inst. 2011, 23, 295–301. [Google Scholar] [CrossRef][Green Version]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of ultra-high performance fiber reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Siwinski, J.; Szczesniak, A.; Stolarski, A. Modified formula for designing ultra-high-performance concrete with experimental verification. Materials 2020, 13, 4518. [Google Scholar] [CrossRef]

- Carey, A.S.; Howard, I.L.; Scott, D.A.; Moser, R.D.; Shannon, J.; Knizley, A. Impact of materials, proportioning, and curing on ultra-high-performance concrete properties. ACI Mater. J. 2020, 117, 213–222. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Liu, Z.C.; Wang, F.Z. Autogenous shrinkage behavior of ultra-high performance concrete. Constr. Build. Mater. 2019, 226, 459–468. [Google Scholar] [CrossRef]

- Lepage, S.; Baalbaki, M.; Dallaire, E.; Aitcin, P.C. Early shrinkage development in a high performance concrete. Cem. Concr. Aggreg. 1999, 21, 31–35. [Google Scholar]

- Brooks, J.J. 30-year creep and shrinkage of concrete. Mag. Concr. Res. 2005, 57, 545–556. [Google Scholar] [CrossRef]

- Liu, G.J. Research on mechanism of concrete creep. Appl. Mech. Mater. 2014, 670, 441–444. [Google Scholar] [CrossRef]

- Au, F.T.K.; Si, X.T. Accurate time-dependent analysis of concrete bridges considering concrete creep, concrete shrinkage and cable relaxation. Eng. Struct. 2011, 33, 118–126. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Baweja, S. Short form of creep and shrinkage prediction model B3 for structures of medium sensitivity. Mater. Struct. 1996, 29, 587–593. [Google Scholar] [CrossRef]

- Wang, Y.C.; Zhang, B.J.; Hao, S.W. Time-dependent brittle creep-relaxation failure in concrete. Mag. Concr. Res. 2016, 68, 692–700. [Google Scholar] [CrossRef]

- Wu, L.M.; Farzadnia, N.; Shi, C.J.; Zhang, Z.H.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Koh, K.; Ryu, G.; Kang, S.; Park, J.; Kim, S. Shrinkage properties of ultra-high performance concrete (UHPC). Adv. Sci. Lett. 2011, 4, 948–952. [Google Scholar] [CrossRef]

- Aly, T.; Sanjayan, J.G. Mechanism of early age shrinkage of concretes. Mater. Struct. 2009, 42, 461–468. [Google Scholar] [CrossRef]

- Barr, B.; Hoseinian, S.B.; Beygi, M.A. Shrinkage of concrete stored in natural environments. Cem. Concr. Compos. 2003, 25, 19–29. [Google Scholar] [CrossRef]

- Lee, H.K.; Lee, K.M.; Kim, B.G. Autogenous shrinkage of high-performance concrete containing fly ash. Mag. Concr. Res. 2003, 55, 507–515. [Google Scholar] [CrossRef]

- Persson, B. Eight-year exploration of shrinkage in high-performance concrete. Cem. Concr. Res. 2002, 32, 1229–1237. [Google Scholar] [CrossRef]

- Saje, D.; Bandelj, B.; Sustersic, J.; Lopatic, J.; Saje, F. Shrinkage of polypropylene fiber-reinforced high-performance concrete. J. Mater. Civ. Eng. 2011, 23, 941–952. [Google Scholar] [CrossRef]

- Mangat, P.S.; Azari, M.M. A theory for the creep of steel fibre reinforced cement matrices under compression. J. Mater. Sci. 1985, 20, 1119–1133. [Google Scholar] [CrossRef]

- Fujiwara, T. Effect of aggregate on drying shrinkage of concrete. J. Adv. Concr. Technol. 2008, 6, 31–44. [Google Scholar] [CrossRef]

- Aly, T.; Sanjayan, J.G. Effect of pore-size distribution on shrinkage of concretes. J. Mater. Civ. Eng. 2010, 22, 525–532. [Google Scholar] [CrossRef]

- Song, Y.; Wu, Q.E.; Agostini, F.; Skocztlas, F.; Bourbon, X. Concrete shrinkage and creep under drying/wetting cycles. Cem. Concr. Res. 2021, 140, 106308. [Google Scholar] [CrossRef]

- Torrenti, J.M.; Granger, L.; Diruy, M.; Genin, P. Modeling concrete shrinkage under variable ambient conditions. ACI Mater. J. 1999, 96, 35–39. [Google Scholar]

- Sahinagic-Isovic, M.; Markovski, G.; Cecez, M. Shrinkage strain of concrete-causes and types. Gradevinar 2012, 64, 727–734. [Google Scholar]

- Lam, N.N.; Van Hung, L. Mechanical and shrinkage behavior of basalt fiber reinforced ultra-high-performance concrete. Int. J. GEOMATE 2021, 20, 28–35. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kahn, L.F.; Kurtis, K.E. Short-term tensile creep and shrinkage of ultra-high performance concrete. Cem. Concr. Compos. 2009, 31, 147–152. [Google Scholar] [CrossRef]

- Garas, V.Y.; Jayapalan, A.R.; Kahn, L.F.; Kurtis, K.E. Micro- and nanoscale characterization of effect of interfacial transition zone on tensile creep of ultra-high-performance concrete. Transp. Res. Rec. 2010, 2141, 82–88. [Google Scholar] [CrossRef]

- Muller, H.S.; Urrea, F.A.; Kvitsel, V. Creep and shrinkage prediction models for concrete. Beton- Und Stahlbetonbau 2021, 116, 2–18. [Google Scholar]

- Dias-da-Costa, D.; Julio, E.N.B.S. Modelling creep of high strength concrete. Comput. Concr. 2010, 7, 533–547. [Google Scholar] [CrossRef]

- Kim, H.S.; Cho, S.H. Shrinkage stress analysis of concrete slabs with shrinkage strips in a multistory building. Comput. Struct. 2004, 82, 1143–1152. [Google Scholar] [CrossRef]

- ACI Committee 209-1992; Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures. American Concrete Institute: Detroit, MI, USA, 1992.

- CEB-FIP-1990; CEB-FIP Model Code for Concrete Structures. Thomas Tclford Services Ltd.: Lausanne, Switzerland, 1990.

- Forth, J.P. Predicting the tensile creep of concrete. Cem. Concr. Compos. 2015, 55, 70–80. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, J.J.; Li, X.; Zhao, G.Y.; Huo, X.J. Experimental and numerical study on creep and shrinkage effects of ultra high performance concrete beam. Compos. Part B Eng. 2020, 184, 107713. [Google Scholar] [CrossRef]

- Bonneau, O.; Lachemi, M.; Dallaire, E.; Atcin, P.C.; Dugat, J. Mechanical properties and durability of two industrial reactive powder concretes. ACI Mater. J. 1997, 94, 286–289. [Google Scholar]

- Chen, Y.; Liu, P.; Sha, F.; Yin, J.; He, S.S.; Li, Q.H.; Yu, Z.W.; Chen, H.L. Study on the mechanical and rheological properties of ultra-high performance concrete. J. Mater. Res. Technol. 2022, 17, 111–124. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Building Industry Press: Beijing, China, 2016.

- GB/T 50081-2016; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Building Industry Press: Beijing, China, 2016.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Building Industry Press: Beijing, China, 2009.

- Chen, Y.; Liu, P.; Sha, F.; He, S.S.; Lu, G.F.; Yu, Z.W.; Chen, H.L. Preparation and performance of the ultra-high performance mortar based on simplex-centroid design method. J. Mater. Res. Technol. 2021, 15, 3060–3077. [Google Scholar] [CrossRef]

- Cui, C.S. Influence of Cuing Regime on Shrinkage, Creep and Basic Mechanical Properties of Ultra-High Performance Concrete; Beijing Jiaotong University: Beijing, China, 2018. [Google Scholar]

- Yu, J.C. Effect of Fiber on Creep Behavior of Concrete; Yansan University: Qinghuangdao, China, 2013. [Google Scholar]

| Items | Average Length/mm | Average Diameter of Monofilament/μm | Apparent Density/g·cm−3 | Tensile Strength/MPa | Elasticity Modulus/GPa |

|---|---|---|---|---|---|

| Carbon fiber | 6 | 6~14 | 0.4 | 4900 | 240 |

| PVA | 12 | 20~21 | 6~8 | 1400~1600 | 35~39 |

| PP | 12 | 18~48 | >15 | >358 | >3.5 |

| Steel fiber | 32 | 2000 | 7.65 | >1100 | 200~210 |

| Items | W/C | Total Cementitious Materials Weight /kg·m−3 | Cement/kg·m−3 | Fly Ash/kg·m−3 | Silica/kg·m−3 | I Type of Coarse Aggregate/kg·m−3 | Ⅱ Type of Coarse Aggregate/kg·m−3 | Sand/kg·m−3 | Sand Ratio/% | Defoamer Dosage/% | Fiber Type | Fiber Content/% | Water Reducer/% | Compressive Strength at 28 d/MPa |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.2 | 600 | 420 | 108 | 72 | 258.9 | 866.7 | 554.4 | 33 | 3.40 | 86.9 | |||

| S2 | 0.2 | 600 | 420 | 108 | 72 | 243.4 | 815.0 | 621.6 | 37 | 2.80 | 89.8 | |||

| S3/F2/H3 | 0.2 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 2.60 | 100.4 | |||

| S4 | 0.2 | 600 | 420 | 108 | 72 | 212.5 | 711.5 | 756.0 | 45 | 3.40 | 85.4 | |||

| F1 | 0.2 | 550 | 385 | 99 | 66 | 236.1 | 790.5 | 713.4 | 41 | 3.00 | 106 | |||

| F3 | 0.2 | 650 | 455 | 117 | 78 | 219.8 | 736.0 | 664.2 | 41 | 2.20 | 104.5 | |||

| F4 | 0.2 | 700 | 490 | 126 | 84 | 211.7 | 708.7 | 639.6 | 41 | 1.50 | 107.3 | |||

| F5 | 0.2 | 750 | 525 | 135 | 90 | 203.6 | 681.5 | 615.0 | 41 | 0.90 | 110.5 | |||

| H1 | 0.16 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 6.40 | 92.1 | |||

| H2 | 0.18 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 5.30 | 91.2 | |||

| H4 | 0.22 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 2.50 | 95.5 | |||

| H5 | 0.24 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 1.50 | 96.1 | |||

| X1 | 0.2 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 0.5 | — | 101.9 | ||

| X2 | 0.2 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 1 | — | 105.8 | ||

| X3 | 0.2 | 600 | 420 | 108 | 72 | 228.0 | 763.2 | 688.8 | 41 | 1.5 | — | 114 | ||

| C1 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | Carbon fiber | 0.1 | 3.90 | 108.2 | ||

| C2 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 0.2 | 5.30 | 108.8 | |||

| C3 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 41 | 1.5 | 0.3 | 5.80 | 105.5 | |

| P1 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | PP | 0.1 | 5.70 | 89.4 | ||

| P2 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 0.2 | 7.10 | 91.3 | |||

| P3 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 0.3 | 7.90 | 83.4 | |||

| V1 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | PVA | 0.1 | 4.20 | 96.5 | ||

| V2 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 0.2 | 4.10 | 99.5 | |||

| V3 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 0.3 | 3.90 | 102.4 | |||

| G1 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | Steel fiber | 1 | 2.70 | 109 | ||

| G2 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 2 | 3.80 | 122.3 | |||

| G3 | 0.2 | 600 | 420 | 108 | 72 | 228 | 763.2 | 688.8 | 3 | 4.20 | 120.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Liu, P.; Sha, F.; Yu, Z.; He, S.; Xu, W.; Lv, M. Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete. Polymers 2022, 14, 1956. https://doi.org/10.3390/polym14101956

Chen Y, Liu P, Sha F, Yu Z, He S, Xu W, Lv M. Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete. Polymers. 2022; 14(10):1956. https://doi.org/10.3390/polym14101956

Chicago/Turabian StyleChen, Ying, Peng Liu, Fei Sha, Zhiwu Yu, Sasa He, Wen Xu, and Maofeng Lv. 2022. "Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete" Polymers 14, no. 10: 1956. https://doi.org/10.3390/polym14101956

APA StyleChen, Y., Liu, P., Sha, F., Yu, Z., He, S., Xu, W., & Lv, M. (2022). Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete. Polymers, 14(10), 1956. https://doi.org/10.3390/polym14101956