Glass Powder Additive on Recycled Polypropylene Filaments: A Sustainable Material in 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

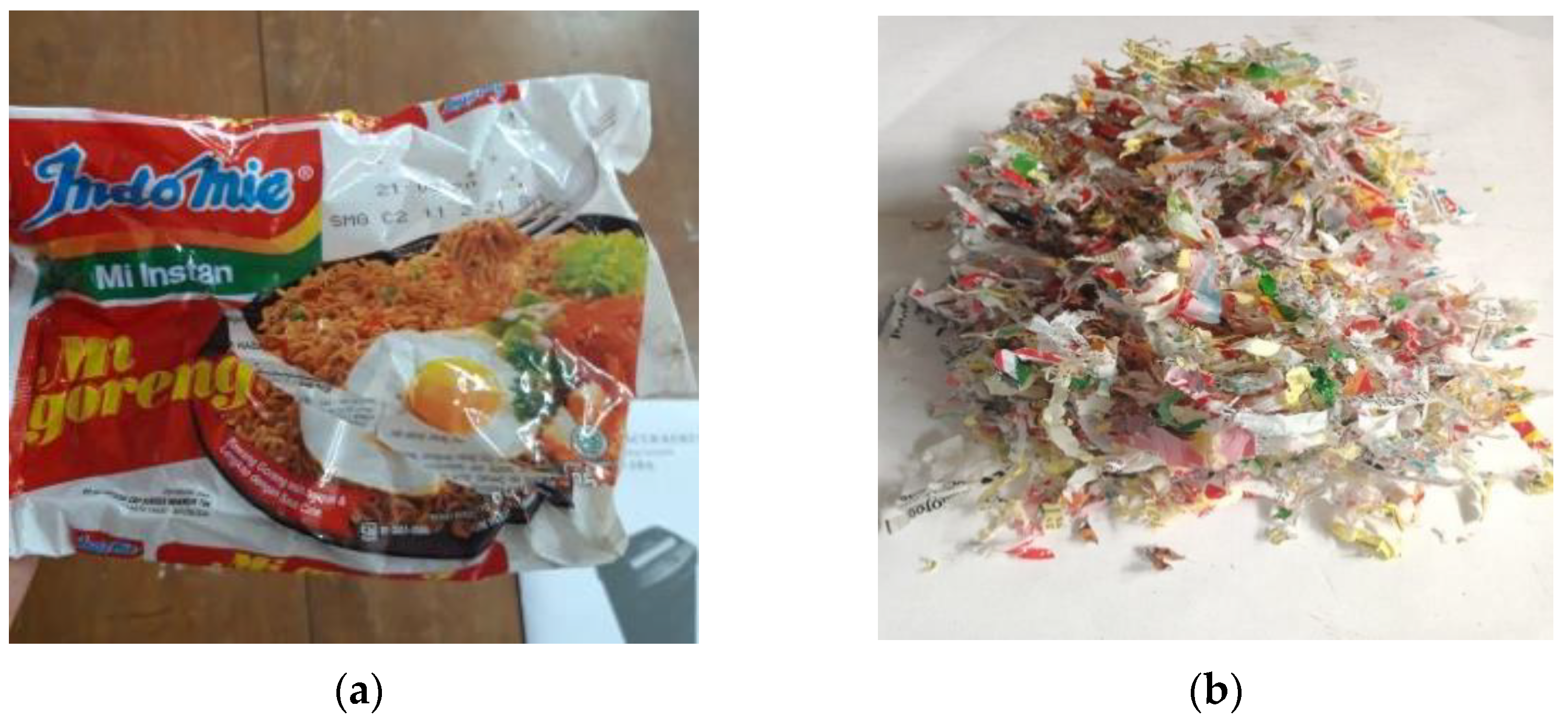

2.1.1. Post-Consumer Recycled Polypropylene Food Packaging

2.1.2. Polypropylene Filament

2.1.3. Glass Powder

2.2. Methodology

2.2.1. Recycled Polypropylene Filament Fabrication

2.2.2. 3D Printing

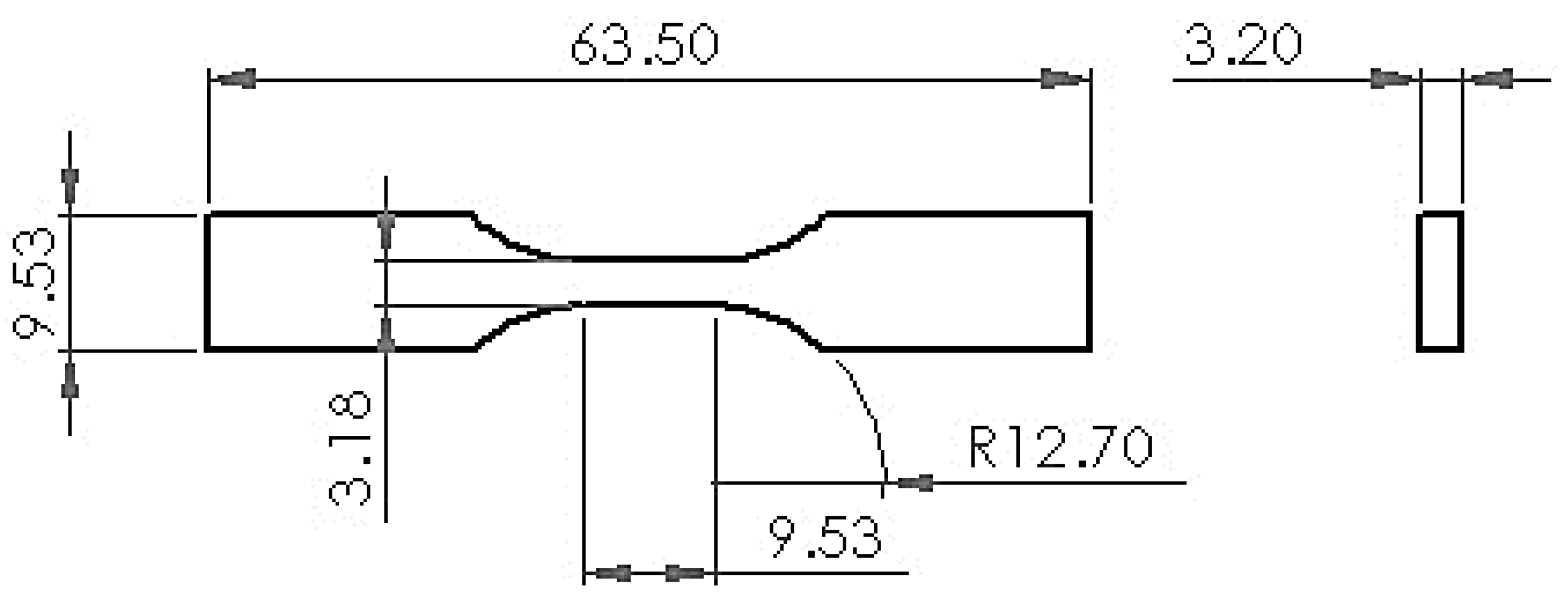

2.2.3. Tensile Testing of 3D Printed Filament

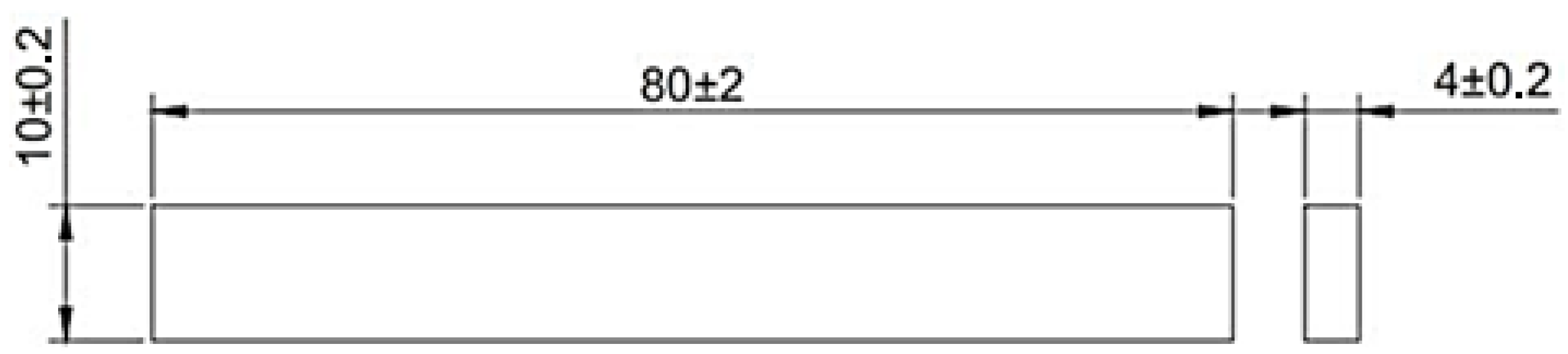

2.2.4. Impact Testing of 3D Printed Filament

2.2.5. Fourier-Transform Infrared Spectroscopy (FTIR)

2.2.6. Thermal Characterization

3. Results

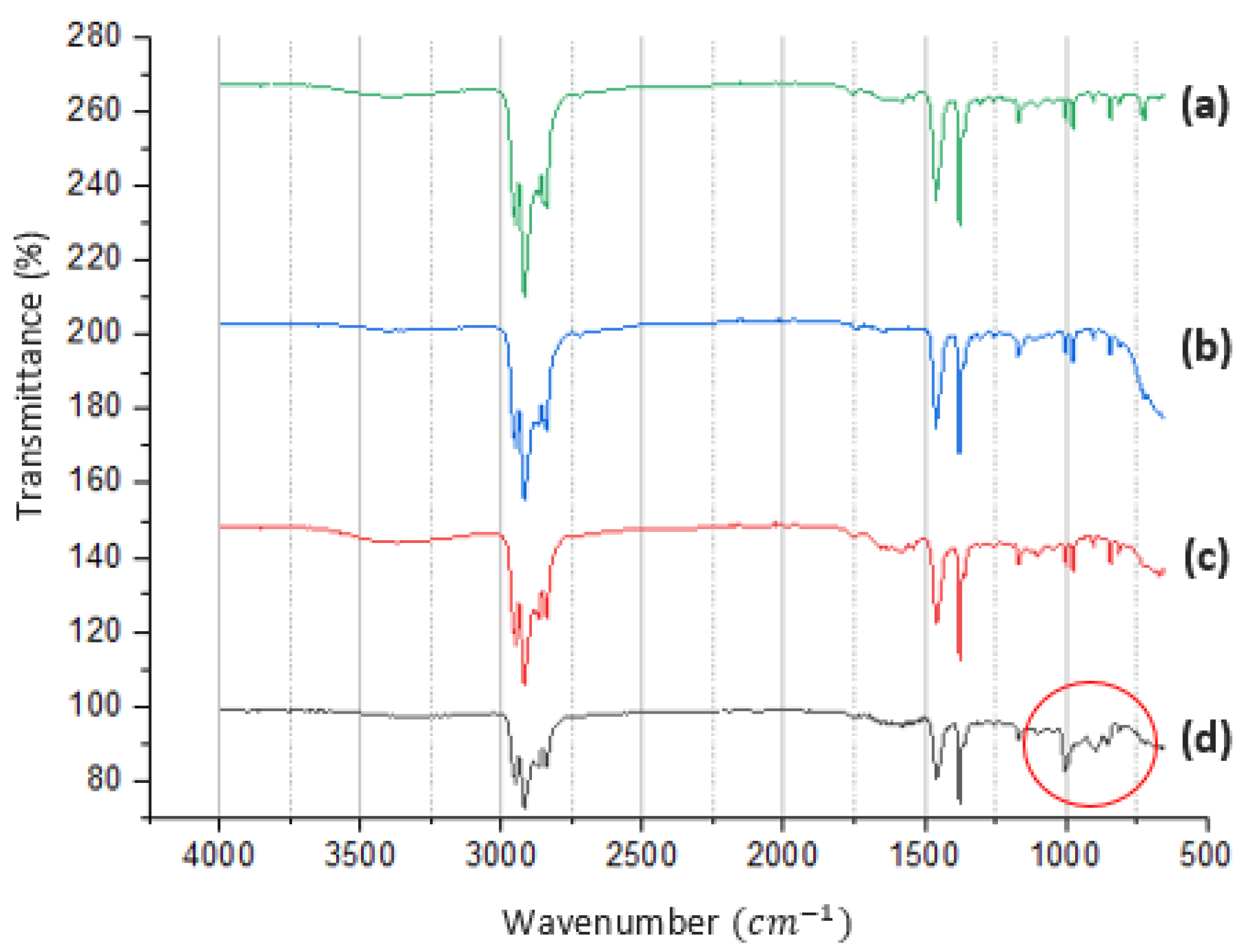

3.1. FTIR

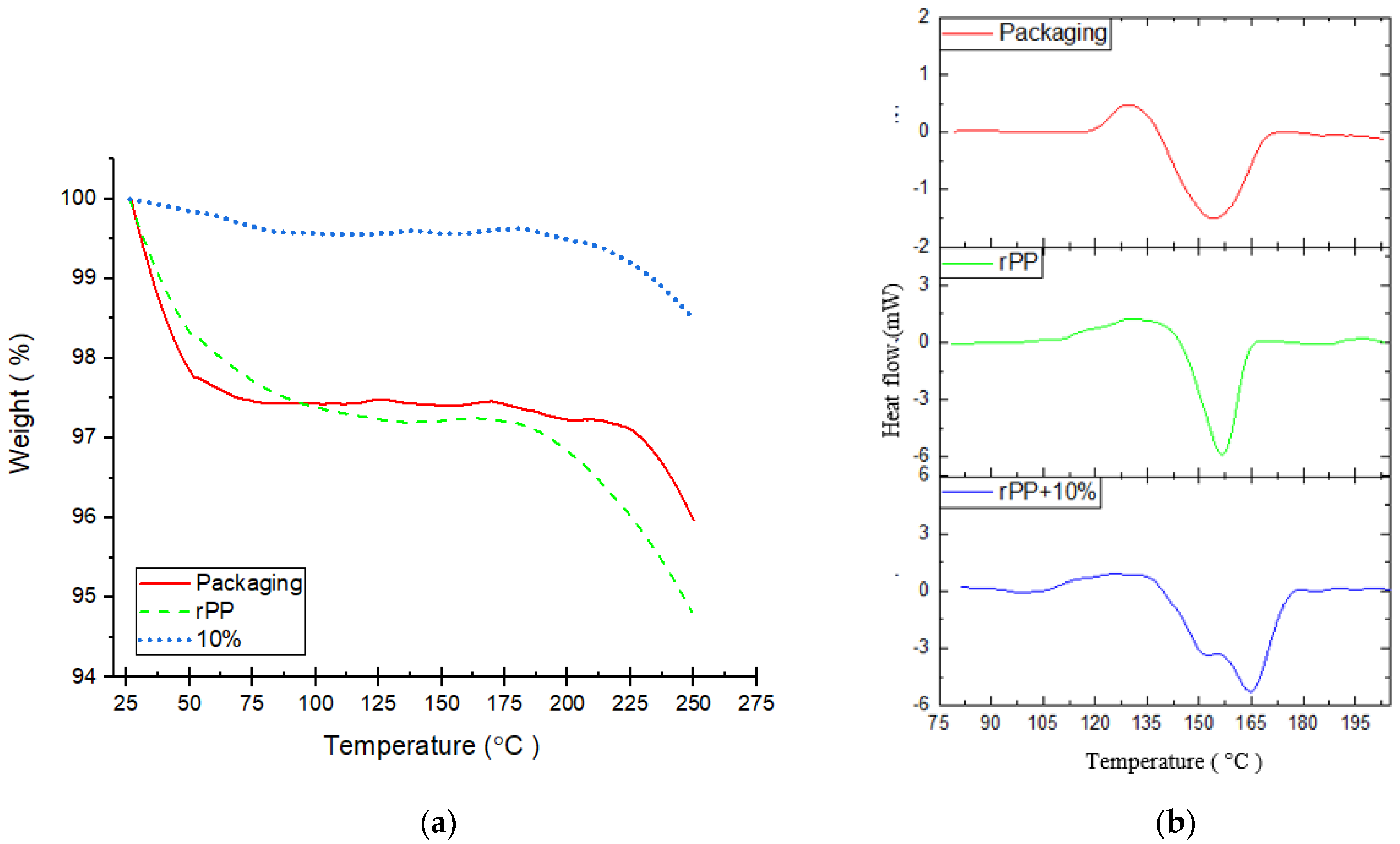

3.2. TGA and DSC

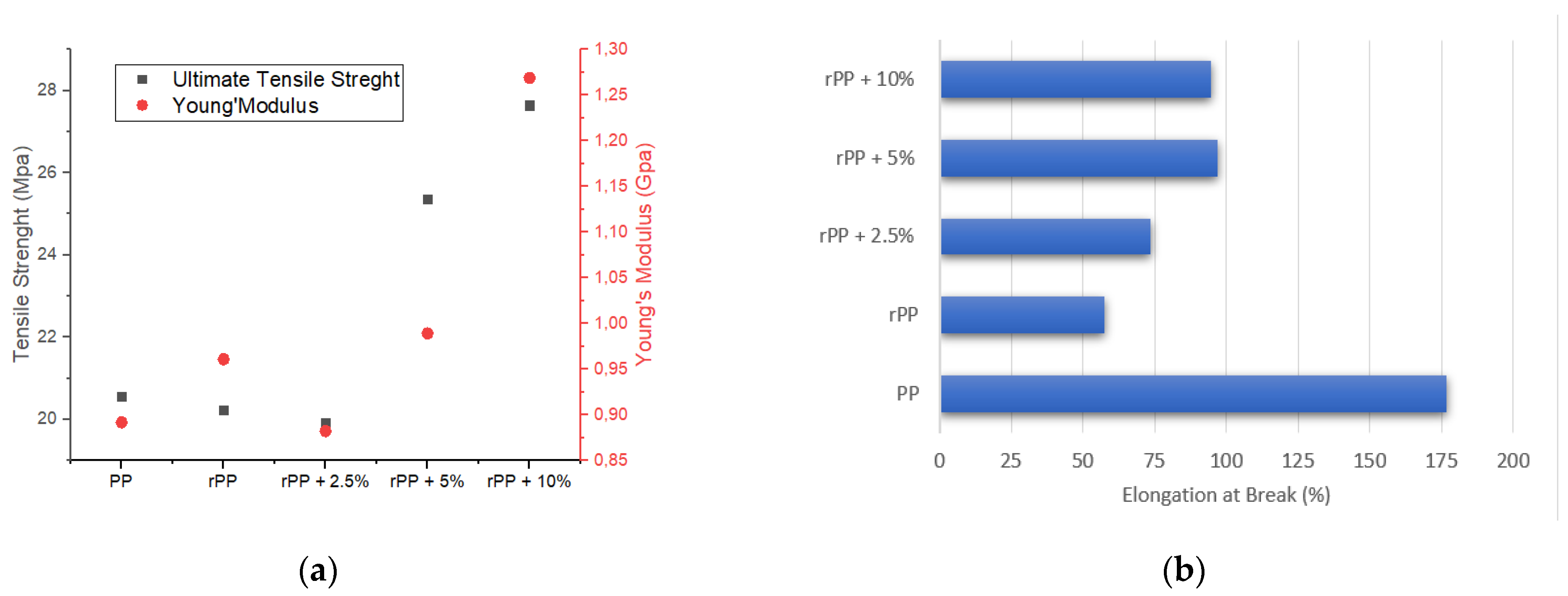

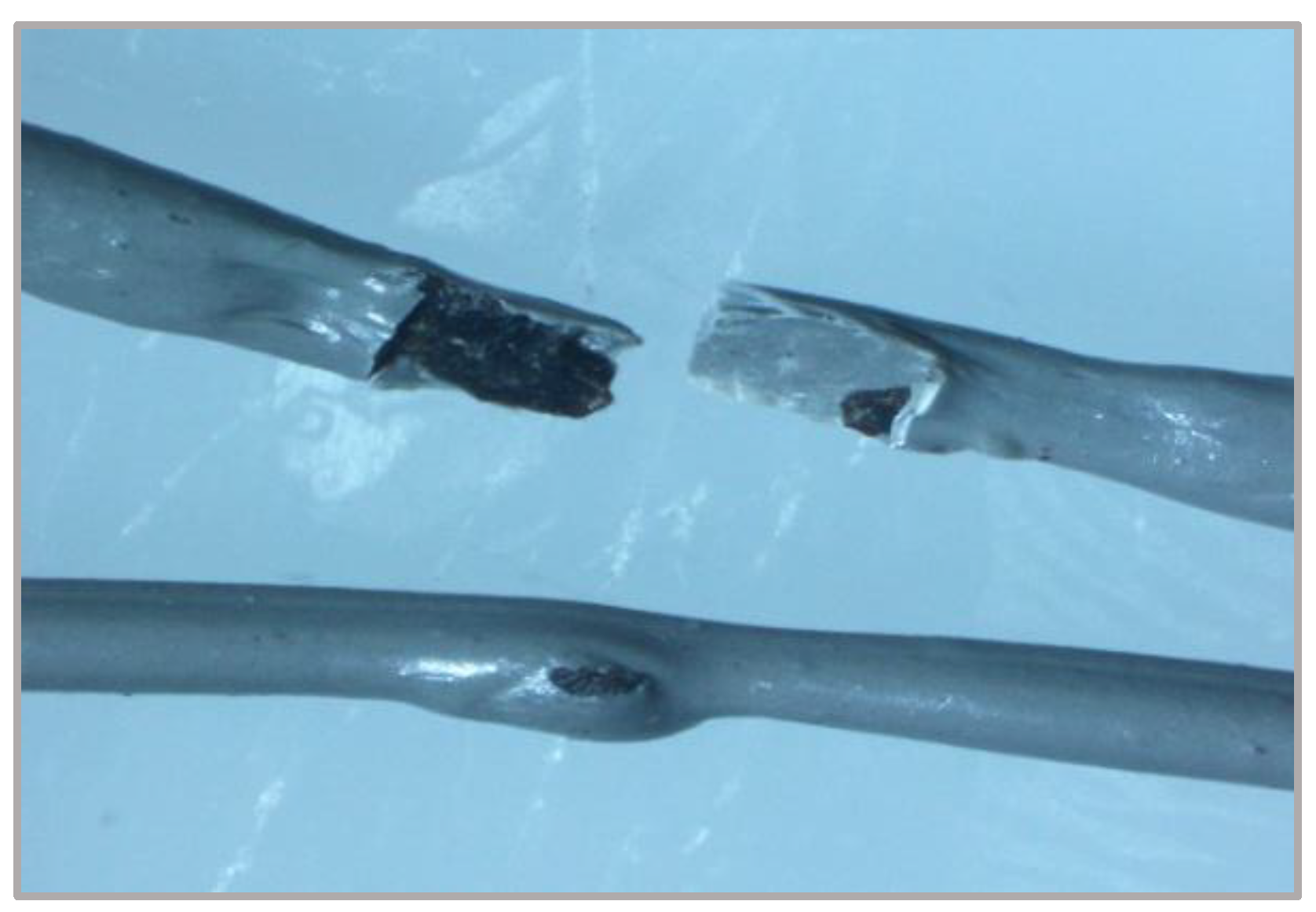

3.3. Tensile Test

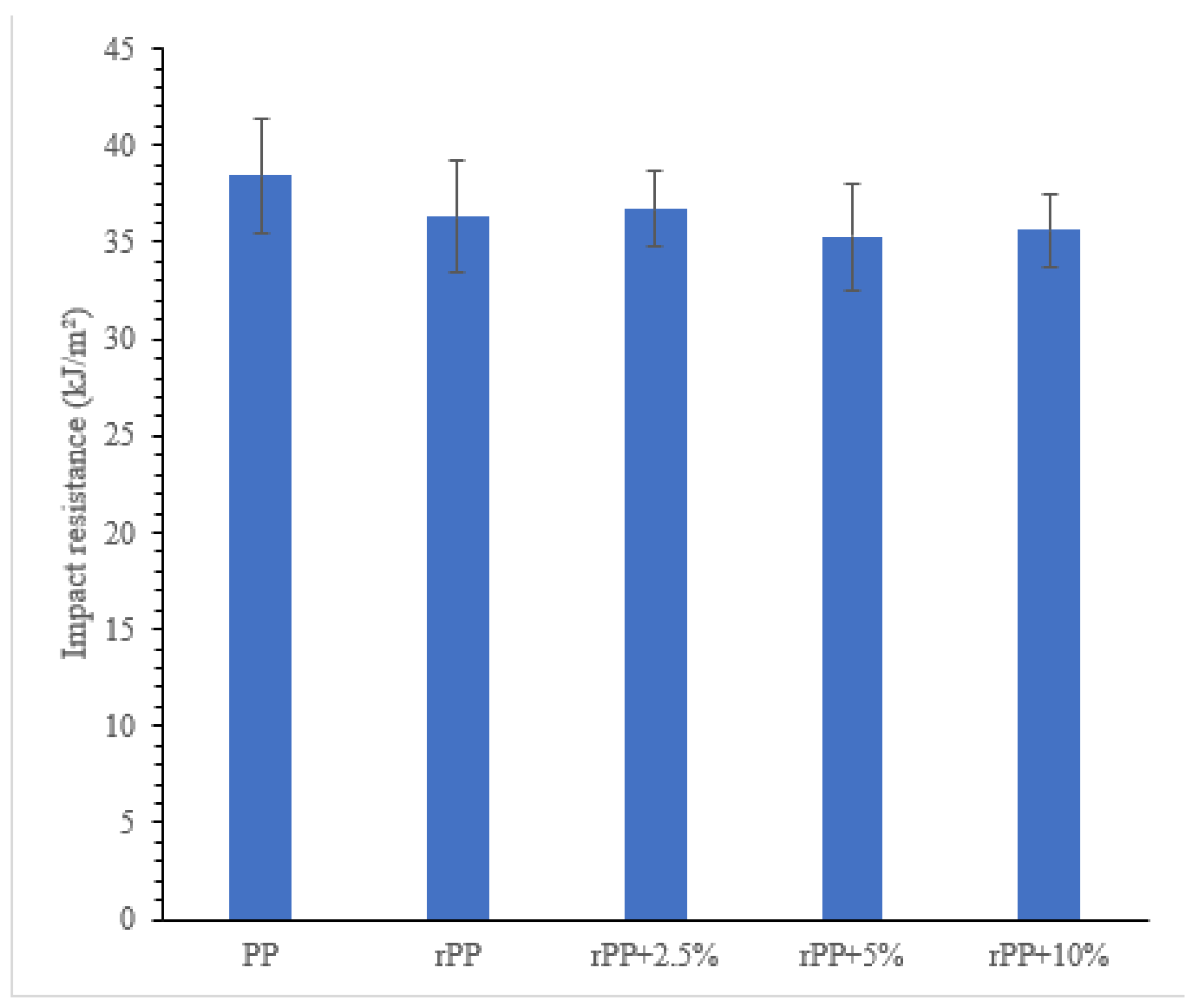

3.4. Impact Test

4. Discussion

4.1. Filament Fabrication Analysis

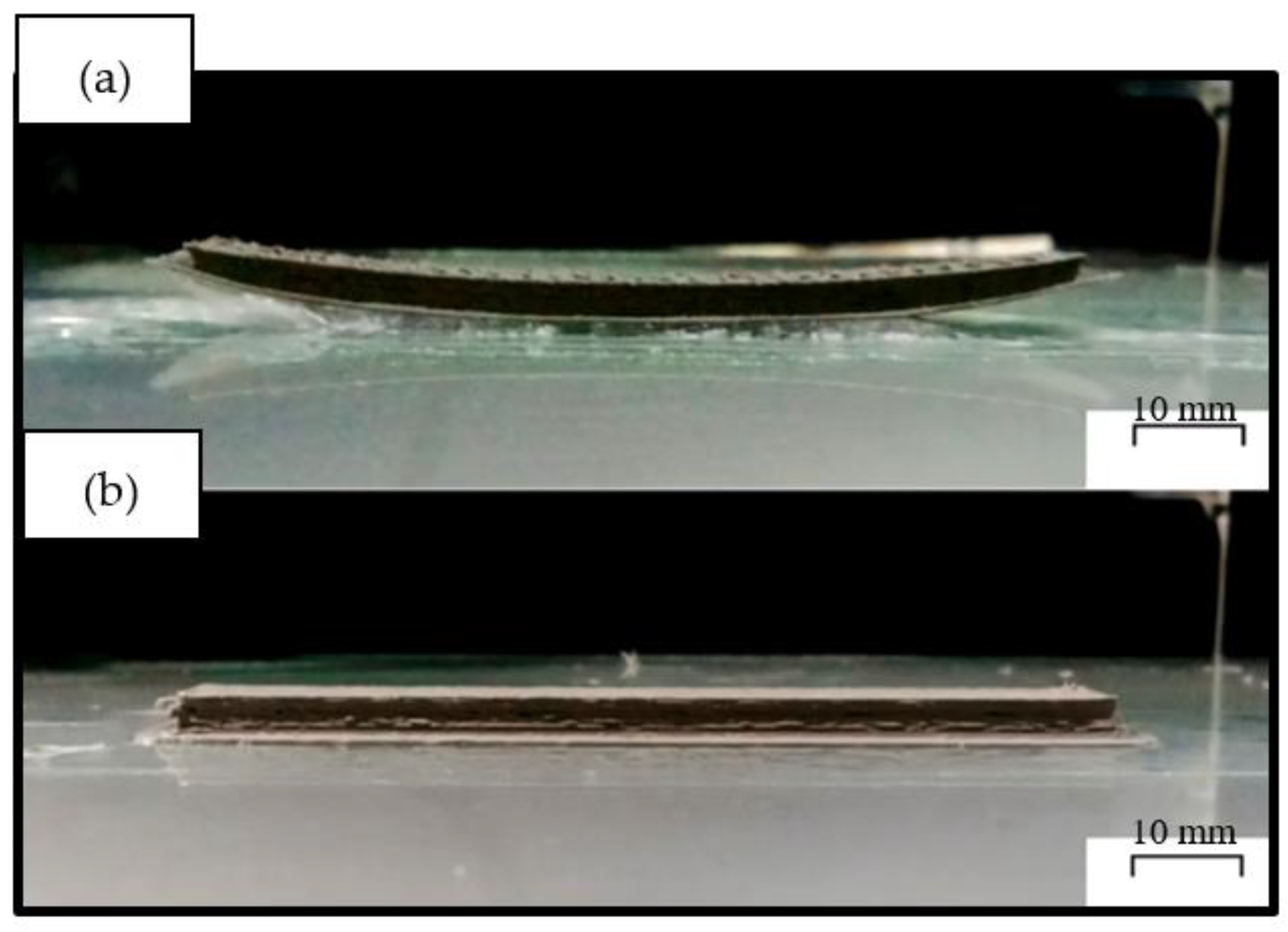

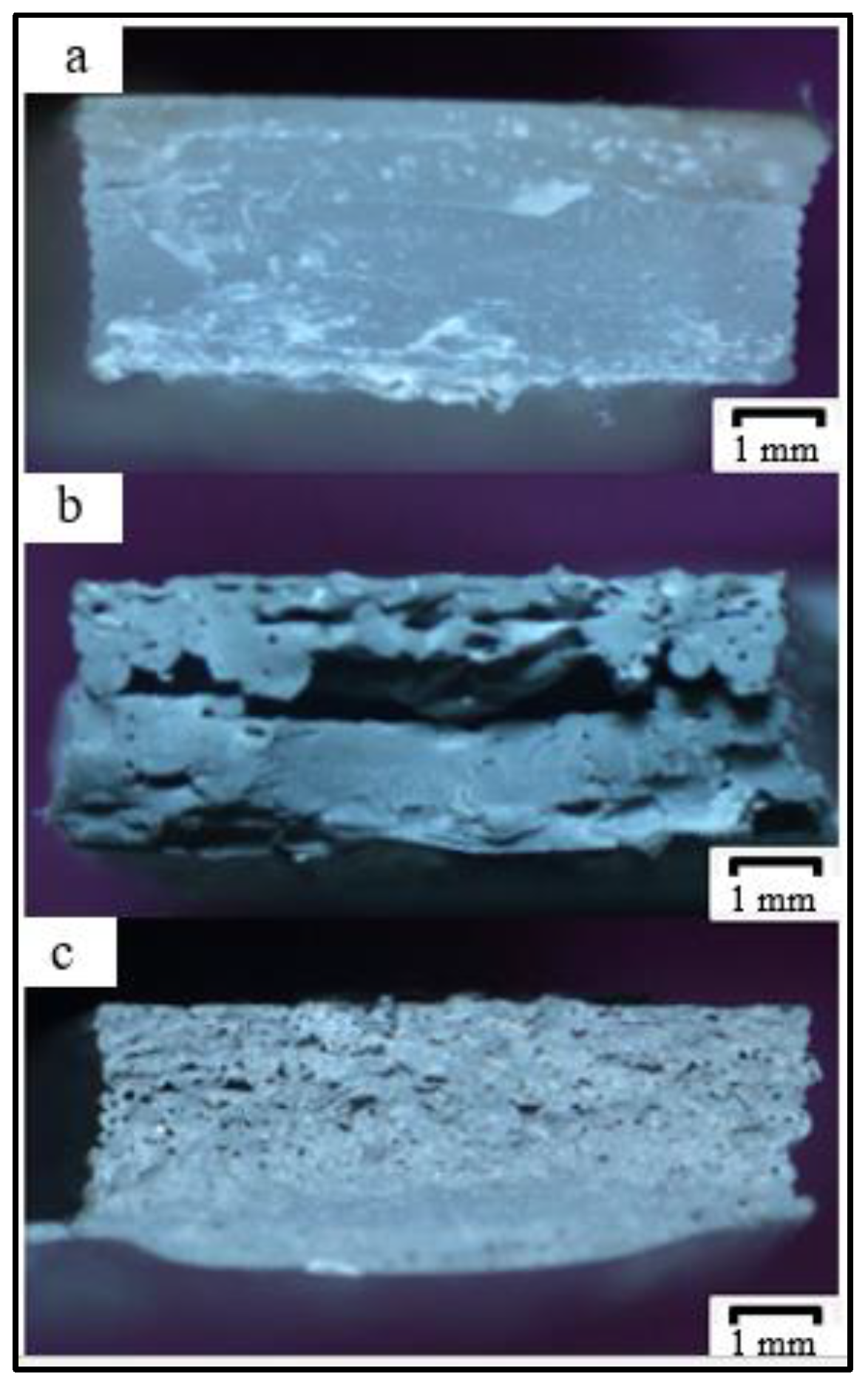

4.2. Printing Filament Analysis

4.3. Material Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elias, H.G.; Ogawa, T.; Kim, Y.H. Syndiotactic Polypropylene. J. Polym. Sci. Polym. Symp. 1985, 72, 79. [Google Scholar] [CrossRef]

- Furukawa, Y. Polymer Chemistry. Sci. Twent. Century 2013, 547–563. [Google Scholar] [CrossRef]

- Vogl, O. Polypropylene: An Introduction. J. Macromol. Sci.-Pure Appl. Chem. 1999, 36A, 1547–1559. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of Fused Deposition Modeling Process Parameters on the Mechanical Properties of a Filled Polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214. [Google Scholar] [CrossRef]

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the Mechanical Properties of Fused Deposition Modelling Natural Fiber Recycled Polypropylene Composites. J. Compos. Sci. 2017, 1, 7. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable Composite Fused Deposition Modelling Filament Using Recycled Pre-Consumer Polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.H.; Rolfe, B.; Gibson, I. Additive Manufacturing a Powerful Tool for the Aerospace Industry. Rapid Prototyp. J. 2021. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 1–30. [Google Scholar] [CrossRef]

- ISO/ASTM International. ISO/ASTM 52900: Additive Manufacturing-General Principles and Terminology. Int. Stand. 2015, 5, 1–26. [Google Scholar]

- Gonzalez Alvarez, A.; Evans, P.L.; Dovgalski, L.; Goldsmith, I. Design, Additive Manufacture and Clinical Application of a Patient-Specific Titanium Implant to Anatomically Reconstruct a Large Chest Wall Defect. Rapid Prototyp. J. 2021, 27, 304–310. [Google Scholar] [CrossRef]

- Kumar Mishra, P.; Ponnusamy, S.; Reddy Nallamilli, M.S. The Influence of Process Parameters on the Impact Resistance of 3D Printed PLA Specimens under Water-Absorption and Heat-Treated Conditions. Rapid Prototyp. J. 2021, 27, 1108–1123. [Google Scholar] [CrossRef]

- Afonso, J.A.; Alves, J.L.; Caldas, G.; Gouveia, B.P.; Santana, L.; Belinha, J. Influence of 3D Printing Process Parameters on the Mechanical Properties and Mass of PLA Parts and Predictive Models. Rapid Prototyp. J. 2021, 27, 487–495. [Google Scholar] [CrossRef]

- Rodrıguez, J.F.; Thomas, J.P.; Renaud, J.E. Design of Fused-Deposition ABS Components for Stiffness and Strength. J. Mech. Des. 2003, 125, 545–551. [Google Scholar] [CrossRef]

- Liao, J.; Brosse, N.; Pizzi, A.; Hoppe, S.; Zhou, X.; Du, G. Characterization and 3D Printability of Poly (Lactic Acid)/Acetylated Tannin Composites. Ind. Crops Prod. 2020, 149, 112320. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Peterson, A.M. Review of Acrylonitrile Butadiene Styrene in Fused Filament Fabrication: A Plastics Engineering-Focused Perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Haigh, J.N.; Dargaville, T.R.; Dalton, P.D. Additive manufacturing with polypropylene microfibers. Mater. Sci. Eng. C 2017, 77, 883–887. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused Deposition Modeling with Polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material Extrusion-Based Additive Manufacturing of Polypropylene: A Review on How to Improve Dimensional Inaccuracy and Warpage. J. Appl. Polym. Sci. 2020, 1–16. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Arifin, Z. A Review on the Fused Deposition Modeling (FDM) 3D Printing: Filament Processing, Materials, and Printing Parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Chong, S.; Yang, T.C.-K.; Lee, K.-C.; Chen, Y.-F.; Juan, J.C.; Tiong, T.J.; Huang, C.-M.; Pan, G.-T. Evaluation of the Physico-Mechanical Properties of Activated-Carbon Enhanced Recycled Polyethylene/Polypropylene 3D Printing Filament. Sādhanā 2020, 45, 57. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Weingrill, G.; Fischinger, T.; Traxler, G.; Schuschnigg, S.; Cardon, L.; Holzer, C. Polypropylene Filled With Glass Spheres in Extrusion-Based Additive Manufacturing: Effect of Filler Size and Printing Chamber Temperature. Macromol. Mater. Eng. 2018, 303. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Mohan Pandey, P. Experimental Investigations on Suitability of Polypropylene (PP) and Ethylene Vinyl Acetate (EVA) in Additive Manufacturing. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2018; Volume 5, pp. 4118–4127. [Google Scholar] [CrossRef]

- Wu, F.; Li, Y.; Lan, X.; Huang, P.; Chong, Y.; Luo, H.; Shen, B.; Zheng, W. Large-Scale Fabrication of Lightweight, Tough Polypropylene/Carbon Black Composite Foams as Broadband Microwave Absorbers. Compos. Commun. 2020, 20, 100358. [Google Scholar] [CrossRef]

- Jin, M.; Neuber, C.; Schmidt, H.W. Tailoring Polypropylene for Extrusion-Based Additive Manufacturing. Addit. Manuf. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F.; Sapkota, J.; Holzer, C. Optimization of Mechanical Properties of Glass-spheres-filled Polypropylene Composites for Extrusion-based Additive Manufacturing. Polym. Compos. 2019, 40, 638–651. [Google Scholar] [CrossRef]

- Pickering, K.; Stoof, D. Sustainable Composite Fused Deposition Modelling Filament Using Post-Consumer Recycled Polypropylene. J. Compos. Sci. 2017, 1, 17. [Google Scholar] [CrossRef]

- Antoniac, I.; Popescu, D.; Zapciu, A.; Antoniac, A.; Miculescu, F.; Moldovan, H. Magnesium Filled Polylactic Acid (PLA) Material for Filament Based 3D Printing. Materials 2019, 12, 719. [Google Scholar] [CrossRef]

- Spoerk, M.; Sapkota, J.; Weingrill, G.; Fischinger, T.; Arbeiter, F.; Holzer, C. Shrinkage and Warpage Optimization of Expanded-Perlite-Filled Polypropylene Composites in Extrusion-Based Additive Manufacturing. Macromol. Mater. Eng. 2017, 302, 1700143. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of Polypropylene/Short Glass Fiber Composite as Fused Deposition Modeling (FDM) Filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A Review of the Fatigue Behavior of 3D Printed Polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Saravanakumar, K.; Arumugam, V.; Souhith, R.; Santulli, C. Influence of Milled Glass Fiber Fillers on Mode I & Mode II Interlaminar Fracture Toughness of Epoxy Resin for Fabrication of Glass/Epoxy Composites. Fibers 2020, 8, 36. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical Characterization of 3D-Printed Polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of Fused Deposition Modeling Process Parameters: A Review of Current Research and Future Prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Bogoeva-Gaceva, G.; Raka, L.; Sorrentino, A. The Effect of Matrix Morphology on Dynamic-Mechanical Properties of Polypropylene/Layered Silicate Nanocomposites. Maced. J. Chem. Chem. Eng. 2017, 36, 251. [Google Scholar] [CrossRef][Green Version]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of Material Properties on Warpage in Fused Deposition Modeling Parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Petersen, H.; Kusano, Y.; Brøndsted, P.; Almdal, K. Preliminary Characterization of Glass Fiber Sizing. In Proceedings of the 34th Risø International Symposium on Materials Science; DTU: Roskilde, Denmark, 2013; Volume 34, pp. 333–340. [Google Scholar]

- Li, Z.; Zhou, W.; Yang, L.; Chen, P.; Yan, C.; Cai, C.; Li, H.; Li, L.; Shi, Y. Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering. Polymers 2019, 11, 135. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Chen, S.; Zhuang, L.; Zheng, C.; Wu, Y. Establishment of a Novel Surface-Imprinting System for Melamine Recognition and Mechanism of Template-Matrix Interactions. J. Mater. Sci. 2014, 49, 2853–2863. [Google Scholar] [CrossRef]

- Linares, A.B.; Jiménez, J.C.; López, P.; de Gáscue, B.R. Biodegradability Study by FTIR and DSC of Polymers Films Based on Polypropylene and Cassava Starch. Orbital 2019, 11, 71–82. [Google Scholar] [CrossRef]

- Krylova, V.; Dukštiene, N. Synthesis and Characterization of Ag Layers Formed on Polypropylene. J. Chem. 2013. [Google Scholar] [CrossRef]

- Bonon, A.J.; Weck, M.; Bonfante, E.A.; Coelho, P.G. Physicochemical Characterization of Three Fiber-Reinforced Epoxide-Based Composites for Dental Applications. Mater. Sci. Eng. C 2016, 69, 905–913. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Palomo, J.G.; Puertas, F. Sodium Silicate Solutions from Dissolution of Glasswastes. Statistical Analysis. Mater. Constr. 2014, 64. [Google Scholar] [CrossRef]

- Sherif, G.; Chukov, D.I.; Tcherdyntsev, V.V.; Torokhov, V.G.; Zherebtsov, D.D. Effect of Glass Fibers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites. Polymers 2020, 12, 902. [Google Scholar] [CrossRef]

- Charles, J.; Ramkumaar, G.R.; Azhagiri, S.; Gunasekaran, S. FTIR and Thermal Studies on Nylon-66 and 30% Glass Fibre Reinforced Nylon-66. E-J. Chem. 2009, 6, 23–33. [Google Scholar] [CrossRef]

- Gautam, C.; Yadav, A.K.; Singh, A.K. A Review on Infrared Spectroscopy of Borate Glasses with Effects of Different Additives. ISRN Ceram. 2012, 2012, 1–17. [Google Scholar] [CrossRef]

- Aumnate, C.; Pongwisuthiruchte, A.; Pattananuwat, P.; Potiyaraj, P. Fabrication of ABS/Graphene Oxide Composite Filament for Fused Filament Fabrication (FFF) 3D Printing. Adv. Mater. Sci. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Hsiao, T.J.; Lee, J.Y.; Mao, Y.C.; Chen, Y.C.; Tsai, J.C.; Lin, S.C.; Ho, R.M. Stereoregular Diblock Copolymers of Syndiotactic Polystyrene Derivatives and Polylactide: Syntheses and Self-Assembled Nanostructures. Macromolecules 2011, 44, 286–298. [Google Scholar] [CrossRef]

- Rudnik, E. Thermal and Thermooxidative Degradation. Compost. Polym. Mater. 2019, 99–126. [Google Scholar] [CrossRef]

- Stoian, S.A.; Gabor, A.R.; Albu, A.M.; Nicolae, C.A.; Raditoiu, V.; Panaitescu, D.M. Recycled Polypropylene with Improved Thermal Stability and Melt Processability. J. Therm. Anal. Calorim. 2019, 138, 2469–2480. [Google Scholar] [CrossRef]

- Yang, J.; Lin, Y.; Wang, J.; Lai, M.; Li, J.; Liu, J.; Tong, X.; Cheng, H. Morphology, Thermal Stability, and Dynamic Mechanical Properties of Atactic Polypropylene/Carbon Nanotube Composites. J. Appl. Polym. Sci. 2005, 98, 1087–1091. [Google Scholar] [CrossRef]

- Salmah, H.; Amri, F.; Kamarudin, H. Properties of Chitosan-Filled Polypropylene (PP) Composites: The Effect of Acetic Acid. Polym.-Plast. Technol. Eng. 2012, 51, 86–91. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Ray, S.; Archer, R.; Arif, K.M. Acrylonitrile Butadiene Styrene and Polypropylene Blend with Enhanced Thermal and Mechanical Properties for Fused Filament Fabrication. Materials 2019, 12, 4167. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar] [CrossRef]

- Montalvo Navarrete, J.I.; Hidalgo-Salazar, M.A.; Escobar Nunez, E.; Rojas Arciniegas, A.J. Thermal and Mechanical Behavior of Biocomposites Using Additive Manufacturing. Int. J. Interact. Des. Manuf. 2018, 12, 449–458. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of Plastic Solid Waste: A State of Art Review and Future Applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Yang, B.X.; Shi, J.H.; Pramoda, K.P.; Goh, S.H. Enhancement of the Mechanical Properties of Polypropylene Using Polypropylene-Grafted Multiwalled Carbon Nanotubes. Compos. Sci. Technol. 2008, 68, 2490–2497. [Google Scholar] [CrossRef]

- Etcheverry, M.; Barbosa, S.E. Glass Fiber Reinforced Polypropylene Mechanical Properties Enhancement by Adhesion Improvement. Materials 2012, 5, 1084–1113. [Google Scholar] [CrossRef] [PubMed]

- Hertle, S.; Drexler, M.; Drummer, D. Additive Manufacturing of Poly(Propylene) by Means of Melt Extrusion. Macromol. Mater. Eng. 2016, 301, 1482–1493. [Google Scholar] [CrossRef]

- Abu Bakar, M.B.; Mohd Ishak, Z.A.; Mat Taib, R.; Rozman, H.D.; Mohamad Jan, S. Flammability and Mechanical Properties of Wood Flour-Filled Polypropylene Composites. J. Appl. Polym. Sci. 2010, 116, 2714–2722. [Google Scholar] [CrossRef]

- Mubarak, Y.A. Tensile and Impact Properties of Microcrystalline Cellulose Nanoclay Polypropylene Composites. Int. J. Polym. Sci. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J. Effect of Fused Layer Modeling (FLM) Processing Parameters on Impact Strength of Cellular Polypropylene. Polymer 2017, 113, 74–80. [Google Scholar] [CrossRef]

| Physical Properties | |

|---|---|

| Density | 0.90 g/cm3 |

| Melting Point | 136 °C/276.8 °F |

| Color | Natural |

| Diameter | 1.75 ± 0.05 mm |

| Net Weight/roll | 800 gr |

| Sample Designation | Composition |

|---|---|

| PP | Pure Polypropylene |

| rPP | Recycle plastic packaging |

| rPP + 2.5% | rPP + 2.5% Glass Powder |

| rPP + 5% | rPP + 5% Glass Powder |

| rPP + 10% | rPP + 10% Glass Powder |

| Parameters | Values |

|---|---|

| Nozzle diameter | 1.0 mm |

| Layer thickness | 0.32 mm |

| Infill degree | 100% |

| Printing speed | 20 mm/s |

| Bed temperature | 80 °C with an insulating layer (rPP and PP) |

| Nozzle temperature | 210 °C (rPP) 220 °C (rPP + Glass Powder) 210 °C (PP) |

| PP | Packaging | rPP | rPP + 10% | Vibrational Mode | ||||

|---|---|---|---|---|---|---|---|---|

| WN | Intensity | WN | Intensity | WN | Intensity | WN | Intensity | |

| 2868.2 | 69.2 | 2870.0 | 70.9 | 2868.2 | 73.8 | 2868.2 | 83.2 | –C-H (CH2) stretching |

| 1459.2 | 68.2 | 1459.3 | 70,6 | 1459.2 | 72,5 | 1459.3 | 80.1 | C-O-H |

| 1578.5 | 94.7 | 1638.2 | 96.4 | 1654.9 | 92.8 | 1656.8 | 95.1 | C=C |

| 1304.6 | 94.2 | 1304.6 | 94.4 | 1304.6 | 93.1 | 1304.6 | 94.5 | C-H (-CH3) |

| 900.2 | 94.9 | 900.2 | 94.5 | 900.2 | 93.6 | 900.2 | 93.3 | C-C bond |

| 840.5 | 89.6 | 842.4 | 90.2 | 840.5 | 88.4 | 840.5 | 90.0 | CH2 |

| 890.83 | 87.34 | Si-H | ||||||

| 849.8 | 89.32 | O-Si-O | ||||||

| 1000.8 | 82.4 | Si-O-Na stretching vibration | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kristiawan, R.B.; Rusdyanto, B.; Imaduddin, F.; Ariawan, D. Glass Powder Additive on Recycled Polypropylene Filaments: A Sustainable Material in 3D Printing. Polymers 2022, 14, 5. https://doi.org/10.3390/polym14010005

Kristiawan RB, Rusdyanto B, Imaduddin F, Ariawan D. Glass Powder Additive on Recycled Polypropylene Filaments: A Sustainable Material in 3D Printing. Polymers. 2022; 14(1):5. https://doi.org/10.3390/polym14010005

Chicago/Turabian StyleKristiawan, Ruben Bayu, Boby Rusdyanto, Fitrian Imaduddin, and Dody Ariawan. 2022. "Glass Powder Additive on Recycled Polypropylene Filaments: A Sustainable Material in 3D Printing" Polymers 14, no. 1: 5. https://doi.org/10.3390/polym14010005

APA StyleKristiawan, R. B., Rusdyanto, B., Imaduddin, F., & Ariawan, D. (2022). Glass Powder Additive on Recycled Polypropylene Filaments: A Sustainable Material in 3D Printing. Polymers, 14(1), 5. https://doi.org/10.3390/polym14010005