Structure and Performance Attributes Optimization and Ranking of Gamma Irradiated Polymer Hybrids for Industrial Application

Abstract

:1. Introduction

- The material selection model based on fuzzy multi-attribute decision-making, proposed originally by Liao [16], is rather complex in nature and requires significantly large computational time.

- The model based on the ‘utility’ functions for multi-objective material optimization proposed by Ashby [17] is simple, but its effectiveness is questionable.

- A material selection model known as ELECTRE, based on multi-attribute decision-making, uses the theme of outranking-relationship among the attributes [18] but can only compute the partial prioritization among small numbers of alternatives.

- Bahraminasab and Jahan [19] recently used the comprehensive VIKOR model for the selection of a femoral-component for TKR. The results are satisfactory to some extent; however, this study is site-specific and needs to be amended for consideration at other replacement sites.

2. Theoretical Considerations on Optimization Model

3. Essential Attributes for Industrial Applications of UHMWPE

3.1. Oxidation Index (OI)

3.2. Cross-Linking Yield

3.3. Percent Crystallinity (Xc) and Crystalline Lamellae Thickness (Lc)

- Tm is equal to the melting temperature of the hybrid;

- T°m = the equilibrium-melting temperature of 100% crystalline PE is equal to 145.7 °C;

- ρc is the crystalline phase density, and its value is equal to 1.005 g/cm−3;

- σ is the surface energy which is equal to 95.7 × 10−7;

- ΔHm is the enthalpy peak area of a 100% crystalline PE and its value is equal to 290 J/g.

3.4. Mechanical Characteristics

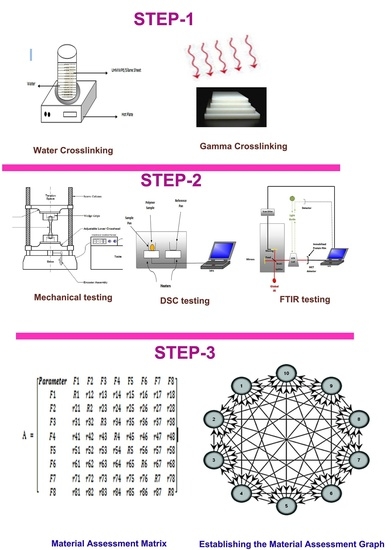

4. Methodology

4.1. Experimental

4.1.1. Materials

4.1.2. Hybrid’s Preparations and Modifications

- For samples labeled as HY-0, 0.4 phr VTES was mixed with acetone then poured into 10 g of UHMWPE powder. The admixture was mixed and dried for further treatment with boiling water for approximately 24 h

- For samples labeled as HY-30, HY-65, and HY-100, 0.4 phr VTES was mixed with acetone then poured into 10 g of UHMWPE powder. The admixture was mixed and dried for further treatment with 30, 65, and 100 kGy of gamma dose, respectively.

4.1.3. Hybrid’s Characterization

5. Attributes Based Ranking

6. Results and Discussion

- Oxidation strength is the first and foremost requirement; therefore, the lowest value of OI and higher value of Eoxidation are required. OI is considered as a LOV factor, while Eoxidation is labeled as an HOV factor.

- Higher cross-linking yield is the major reason for treating/modifying UHMWPE since its introduction. Therefore, GC (which is ASTM standard for measuring the cross-linking yield) is labeled as an HOV factor.

- The major advantage of UHMWPE-based material is that the mechanical energy, which is usually absorbed through the crystalline phase, is dissipated via its long-chain vibrations, and all-trans interphase regions play the role of transferring the absorbed energy from the crystalline phase to an amorphous one. Therefore, higher contents of crystalline centers are beneficial for the efficient dissipation of absorbed mechanical energy into the surroundings. A higher value of (%) Xc is therefore required, thus justifying its labeling as an HOV factor.

- The importance of Tm (°C) and EThermal (KJ/mol) contributions are negligible and cannot be neglected when considering the long-term service characteristics of UHMWPE-based biomaterials. As a result, in this study, these factors are labeled as LOV factors.

- Usually, crystallite centers are the major source for the dissipation of mechanical energy via long-chain vibrations. In this regard, the mobility of crystalline lamellae for the process of energy dissipation should be higher, which points towards the importance of crystalline lamellae of an adequate thickness for the increased efficacy of UHMWPE as energy dissipaters. In this study, Lc (nm) is included in the list of LOV factors.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussain, M.; Naqvi, R.A.; Abbas, N.; Khan, S.M.; Nawaz, S.; Hussain, A.; Zahra, N.; Khalid, M.W. Ultra-High-Molecular-Weight-Polyethylene (UHMWPE) as a Promising Polymer Material for Biomedical Applications: A Concise Review. Polymers 2020, 12, 323. [Google Scholar] [CrossRef] [Green Version]

- Bracco, P.; Oral, E. Vitamin E-stabilized UHMWPE for total joint implants: A review. Clin. Orthop. Relat. Res. 2011, 469, 2286–2293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Costa, L.; Bracco, P. Mechanisms of cross-linking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 467–487. [Google Scholar]

- Kurtz, S.M. The UHMWPE Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Shafiq, M.; Mehmood, M.S.; Yasin, T. On the structural and physicochemical properties of gamma irradiated UHMWPE/silane hybrid. Mat. Chem. Phys. 2013, 143, 425–433. [Google Scholar] [CrossRef]

- Mehmood, M.S.; Sanawar, A.; Siddiqui, N.; Yasin, T. Quantification of silane grafting efficacy, weak IR vibration bands and percentage crystallinity in post e-beam irradiated UHMWPE. Polym. Bull. 2017, 74, 213–227. [Google Scholar] [CrossRef]

- Sharma, V.; Bose, S.; Kundu, B.; Bodhak, S.; Mitun, D.; Balla, V.K.; Basu, B. Probing the Influence of γ-Sterilization on the Oxidation, Crystallization, Sliding Wear Resistance, and Cytocompatibility of Chemically Modified Graphene-Oxide-Reinforced HDPE/UHMWPE Nanocomposites and Wear Debris. ACS Biomat. Sci. Eng. 2020, 6, 1462–1475. [Google Scholar] [CrossRef] [PubMed]

- Kang, K.-T.; Son, J.; Kim, H.-J.; Baek, C.; Kwon, O.-R.; Koh, Y.-G. Wear predictions for UHMWPE material with various surface properties used on the femoral component in total knee arthroplasty: A computational simulation study. J. Mater. Sci. Mater. Med. 2017, 28, 105. [Google Scholar] [CrossRef] [PubMed]

- Jahan, A.; Ismail, M.; Sapuan, S.; Mustapha, F. Material screening and choosing methods–A review. Mater. Des. 2010, 31, 696–705. [Google Scholar] [CrossRef]

- Griza, S.; Reguly, A.; Strohaecker, T. Total hip stem failure due to weld procedure and material selection misuse. Eng. Fail. Anal. 2010, 17, 555–561. [Google Scholar] [CrossRef]

- Chatterjee, P.; Athawale, V.M.; Chakraborty, S. Selection of materials using compromise ranking and outranking methods. Mater. Des. 2009, 30, 4043–4053. [Google Scholar] [CrossRef]

- Majumdar, A. Selection of raw materials in textile spinning industry using fuzzy multi-criteria decision making approach. Fibers Polym. 2010, 11, 121–127. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, L.; Liu, Z.; Sutherland, J.W. Multi-criteria decision making and uncertainty analysis for materials selection in environmentally conscious design. Int. J. Adv. Manuf. Technol. 2011, 52, 21–432. [Google Scholar] [CrossRef]

- Cicek, K.; Celik, M. Multiple attribute decision-making solution to material selection problem based on modified fuzzy axiomatic design-model selection interface algorithm. Mater. Des. 2010, 31, 2129–2133. [Google Scholar] [CrossRef]

- Chatterjee, P.; Athawale, V.M.; Chakraborty, S. Materials selection using complex proportional assessment and evaluation of mixed data methods. Mater. Des. 2011, 32, 851–860. [Google Scholar] [CrossRef]

- Liao, T.W. A fuzzy multicriteria decision-making method for material selection. J. Manuf. Syst. 1996, 15, 1–12. [Google Scholar] [CrossRef]

- Ashby, M. Multi-objective optimization in material design and selection. Acta Mater. 2000, 48, 359–369. [Google Scholar] [CrossRef]

- Shanian, A.A.; Savadogo, O. A material selection model based on the concept of multiple attribute decision making. Mater. Des. 2006, 27, 329–337. [Google Scholar] [CrossRef]

- Bahraminasab, M.; Jahan, A. Material selection for femoral component of total knee replacement using comprehensive VIKOR. Mater. Des. 2011, 32, 4471–4477. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. A comprehensive review on material selection for polymer matrix composites subjected to impact load. Def. Technol. 2021, 17, 257–277. [Google Scholar] [CrossRef]

- Allien, V.; Kumar, H.; Desai, V. Free vibration analysis and selection of composite for high strength and stiffness using multi-attribute decision making. Int. J. Mater. Res. 2021, 112, 189–197. [Google Scholar] [CrossRef]

- Sharba, M.J.; Al-Mostaaf, M.J. Thermoplastic Polymer Selection for Optimal Thermal Efficiency of Composite Syrup Vessel. In Materials Science Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2021; pp. 35–44. [Google Scholar]

- El-Sheikh, H.; MacDonald, B.; Hashmi, M. Material selection in the design of the femoral component of cemented total hip replacement. J. Mater. Process. Technol. 2002, 122, 309–317. [Google Scholar] [CrossRef]

- Quigley, F.; Buggy, M.; Birkinshaw, C. Selection of elastomeric materials for compliant-layered total hip arthroplasty. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2002, 216, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Prendergast, P.; Monaghan, J.; Taylor, D. Materials selection in the artificial hip joint using finite element stress analysis. Clin. Mater. 1989, 4, 361–376. [Google Scholar] [CrossRef]

- Ghorbani, M.; Li, X.; Zangi, S.; Amraei, N. On the eigenvalue and energy of extended adjacency matrix. Appl. Math. Comput. 2021, 397, 125939. [Google Scholar] [CrossRef]

- Vecchio, D.A.; Mahler, S.H.; Hammig, M.D.; Kotov, N.A. Structural Analysis of Nanoscale Network Materials Using Graph Theory. ACS Nano 2021, 15, 12847–12859. [Google Scholar] [CrossRef]

- Bakhsh, A.A. Gamma-Ray Modified Polymer/Clay Composites: Synthesis, Characterization, and Formulation Optimization Using Multivariate Calculus and Graph Theory. Energies 2021, 14, 2724. [Google Scholar] [CrossRef]

- Chen, W.-K. Graph Theory and its Engineering Applications; World Scientific Publishing Company: Singapore, 1997; Volume 5. [Google Scholar]

- Bang-Jensen, J.; Gutin, G.Z. Digraphs: Theory, Algorithms and Applications; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Rao, R.V. A material selection model using graph theory and matrix approach. Mater. Sci. Eng. A 2006, 431, 248–255. [Google Scholar] [CrossRef]

- Implants for Surgery—Ultra-High-Molecular-Weight Polyethylene—Part 4: Oxidation Index Measurement Method; 5834-4:2005; ISO: Genewa, Switzerland, 2005.

- Farag, M.M. Quantitative methods of materials selection. In Handbook of Materials Selection; Wiley: Hoboken, NJ, USA, 2002; pp. 1–24. [Google Scholar]

| Material Attribute/Property | UHMWPE/Silane Hybrids | |||

|---|---|---|---|---|

| HY-0 | HY-30 | HY-65 | HY-100 | |

| OI | 0.17 | 0.42 | 0.24 | 0.54 |

| Gel Contents (%) | 84.7 | 90.1 | 91 | 75 |

| Xc (%) | 50.1 | 54.3 | 52.2 | 53.9 |

| Tm (°C) | 137.1 | 133.3 | 133.7 | 131.8 |

| Lc (nm) | 10.8 | 7.5 | 7.8 | 6.7 |

| Eoxidation (eV) | 122 | 133 | 170 | 190 |

| EThermal (eV) | 446 | 440 | 370 | 361 |

| Eb (%) | 357 | 452 | 360 | 324 |

| YS (MPa) | 21.7 | 22.7 | 25.3 | 30.7 |

| YM (MPa) | 422 | 738 | 817 | 984 |

| Parameters | OI | GC (%) | Xc (%) | Tm (°C) | Lc (nm) | Eoxidation (eV) | EThermal (eV) | Eb (%) | YS (MPa) | YM (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| OI | R1 | 0.5 | 0.745 | 0.955 | 0.955 | 0.665 | 0.955 | 0.745 | 0.665 | 0.745 |

| GC (%) | 0.5 | R2 | 0.745 | 0.955 | 0.955 | 0.745 | 0.955 | 0.745 | 0.665 | 0.745 |

| Xc (%) | 0.255 | 0.255 | R3 | 0.255 | 0.5 | 0.665 | 0.335 | 0.41 | 0.5 | 0.5 |

| Tm (°C) | 0.045 | 0.045 | 0.745 | R4 | 0.5 | 0.59 | 0.5 | 0.59 | 0.665 | 0.665 |

| Lc (nm) | 0.045 | 0.045 | 0.5 | 0.5 | R5 | 0.59 | 0.5 | 0.59 | 0.665 | 0.665 |

| Eoxidation (eV) | 0.335 | 0.255 | 0.335 | 0.41 | 0.41 | R6 | 0.41 | 0.335 | 0.41 | 0.335 |

| EThermal (eV) | 0.045 | 0.045 | 0.665 | 0.5 | 0.5 | 0.59 | R7 | 0.335 | 0.41 | 0.41 |

| Eb (%) | 0.255 | 0.255 | 0.590 | 0.41 | 0.41 | 0.665 | 0.665 | R8 | 0.335 | 0.41 |

| YS (MPa) | 0.335 | 0.335 | 0.5 | 0.335 | 0.335 | 0.59 | 0.59 | 0.665 | R9 | 0.5 |

| YM (MPa) | 0.255 | 0.255 | 0.5 | 0.335 | 0.335 | 0.665 | 0.59 | 0.59 | 0.5 | R10 |

| Material Attribute/Property | UHMWPE/Silane Hybrids | |||

|---|---|---|---|---|

| HY-0 | HY-30 | HY-65 | HY-100 | |

| OI | 1.00 | 0.40 | 0.71 | 0.31 |

| Gel Contents (%) | 0.93 | 0.99 | 1.00 | 0.82 |

| Xc (%) | 0.92 | 1.00 | 0.96 | 0.99 |

| Tm (°C) | 0.96 | 0.99 | 0.99 | 1.00 |

| Lc (nm) | 0.62 | 0.90 | 0.86 | 1.00 |

| Eoxidation (eV) | 0.64 | 0.70 | 0.89 | 1.00 |

| EThermal (eV) | 0.81 | 0.82 | 0.98 | 1.00 |

| Eb (%) | 0.79 | 1.00 | 0.80 | 0.72 |

| YS (MPa) | 0.71 | 0.74 | 0.82 | 1.00 |

| YM (MPa) | 0.43 | 0.75 | 0.83 | 1.00 |

| Sample | Suitability Index Value | Ranking |

|---|---|---|

| HY-0 | 2488.43 | 4th |

| HY-30 | 2637.2 | 3rd |

| HY-65 | 3050.24 | 1st |

| HY-100 | 2890.47 | 2nd |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serbaya, S.H.; Abualsauod, E.H.; Basingab, M.S.; Bukhari, H.; Rizwan, A.; Mehmood, M.S. Structure and Performance Attributes Optimization and Ranking of Gamma Irradiated Polymer Hybrids for Industrial Application. Polymers 2022, 14, 47. https://doi.org/10.3390/polym14010047

Serbaya SH, Abualsauod EH, Basingab MS, Bukhari H, Rizwan A, Mehmood MS. Structure and Performance Attributes Optimization and Ranking of Gamma Irradiated Polymer Hybrids for Industrial Application. Polymers. 2022; 14(1):47. https://doi.org/10.3390/polym14010047

Chicago/Turabian StyleSerbaya, Suhail H., Emad H. Abualsauod, Mohammed Salem Basingab, Hatim Bukhari, Ali Rizwan, and Malik Sajjad Mehmood. 2022. "Structure and Performance Attributes Optimization and Ranking of Gamma Irradiated Polymer Hybrids for Industrial Application" Polymers 14, no. 1: 47. https://doi.org/10.3390/polym14010047

APA StyleSerbaya, S. H., Abualsauod, E. H., Basingab, M. S., Bukhari, H., Rizwan, A., & Mehmood, M. S. (2022). Structure and Performance Attributes Optimization and Ranking of Gamma Irradiated Polymer Hybrids for Industrial Application. Polymers, 14(1), 47. https://doi.org/10.3390/polym14010047