Flexural Behavior of a Novel Textile-Reinforced Polymer Concrete

Abstract

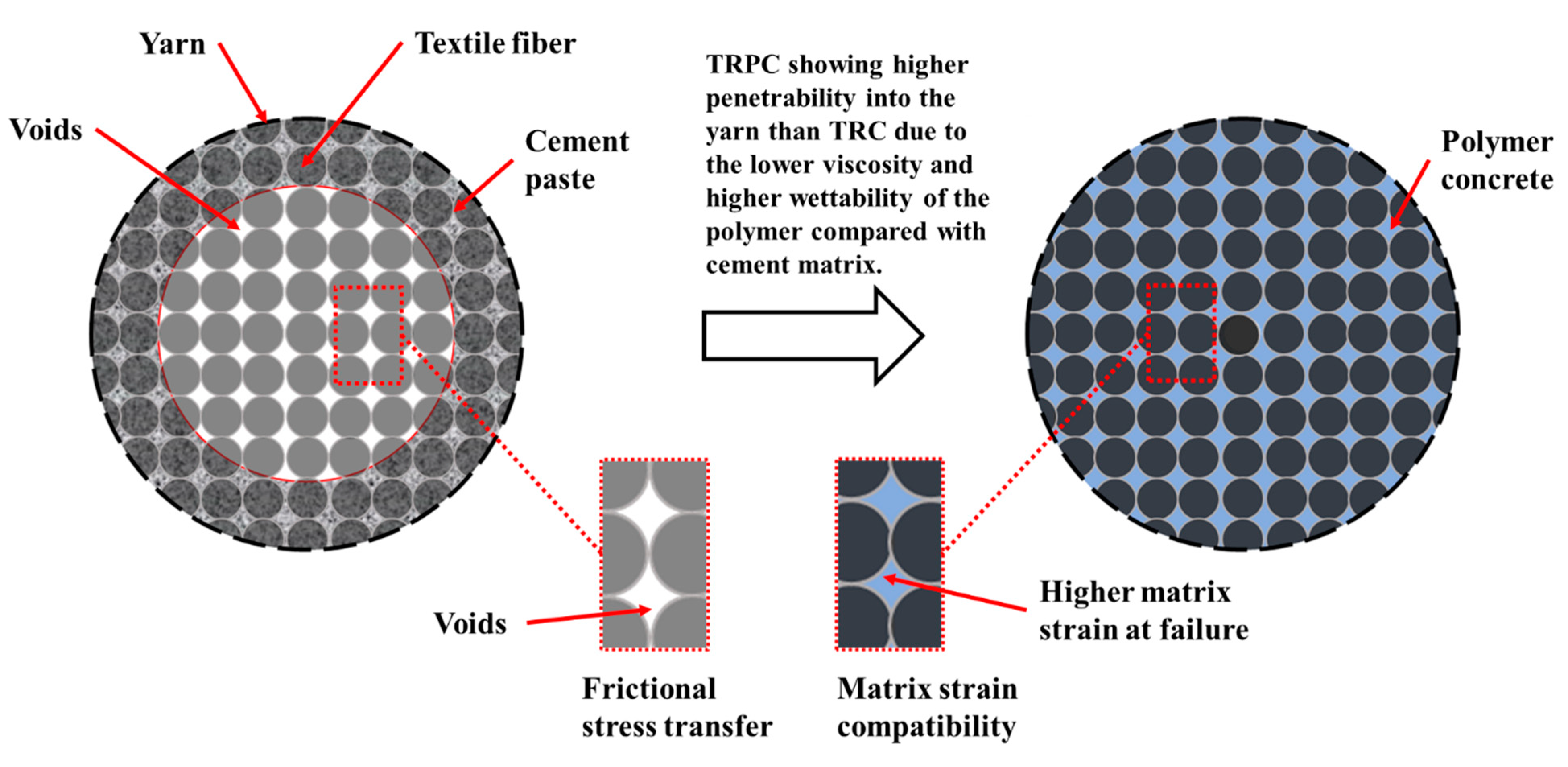

:1. Introduction

2. Materials and Methods

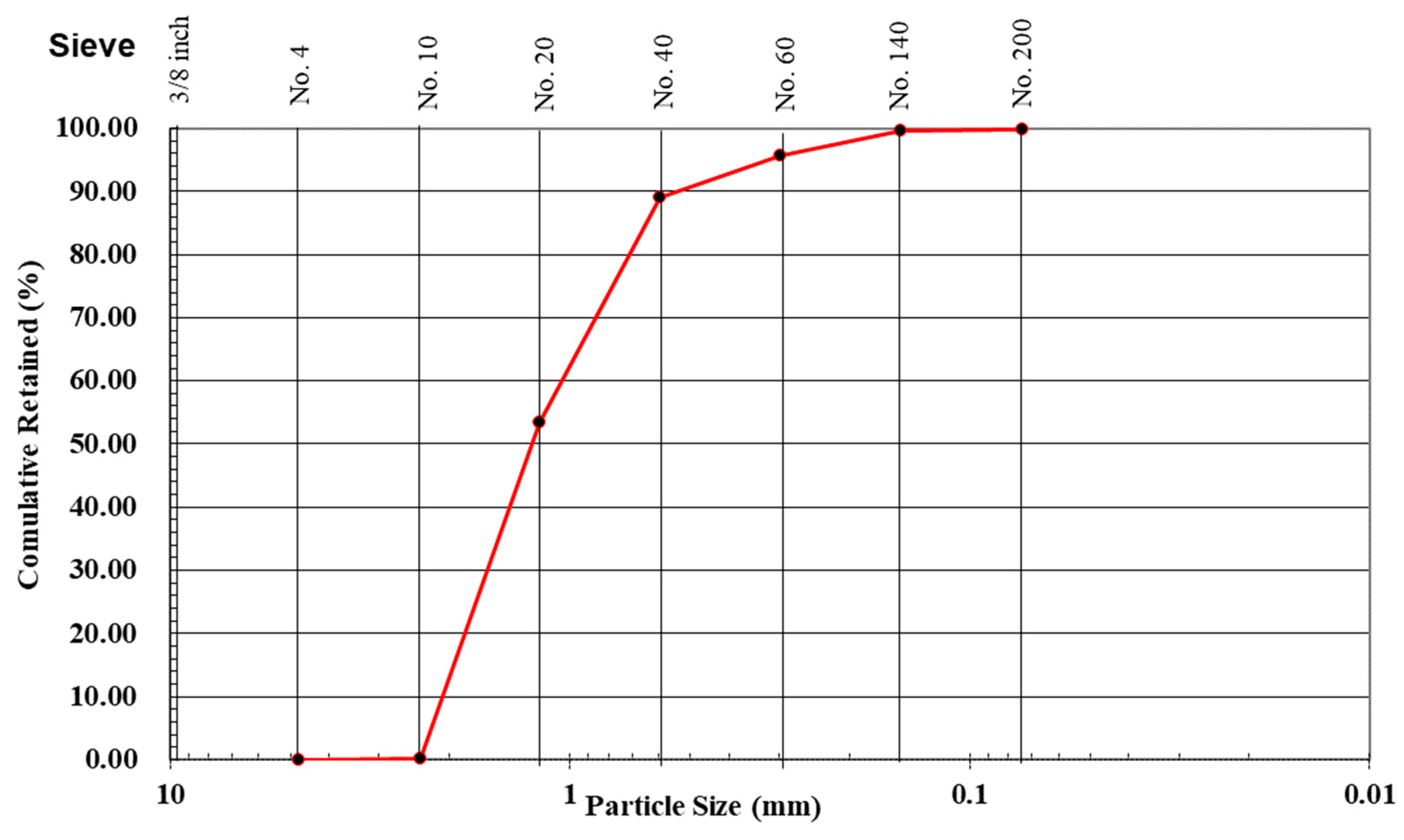

2.1. Materials

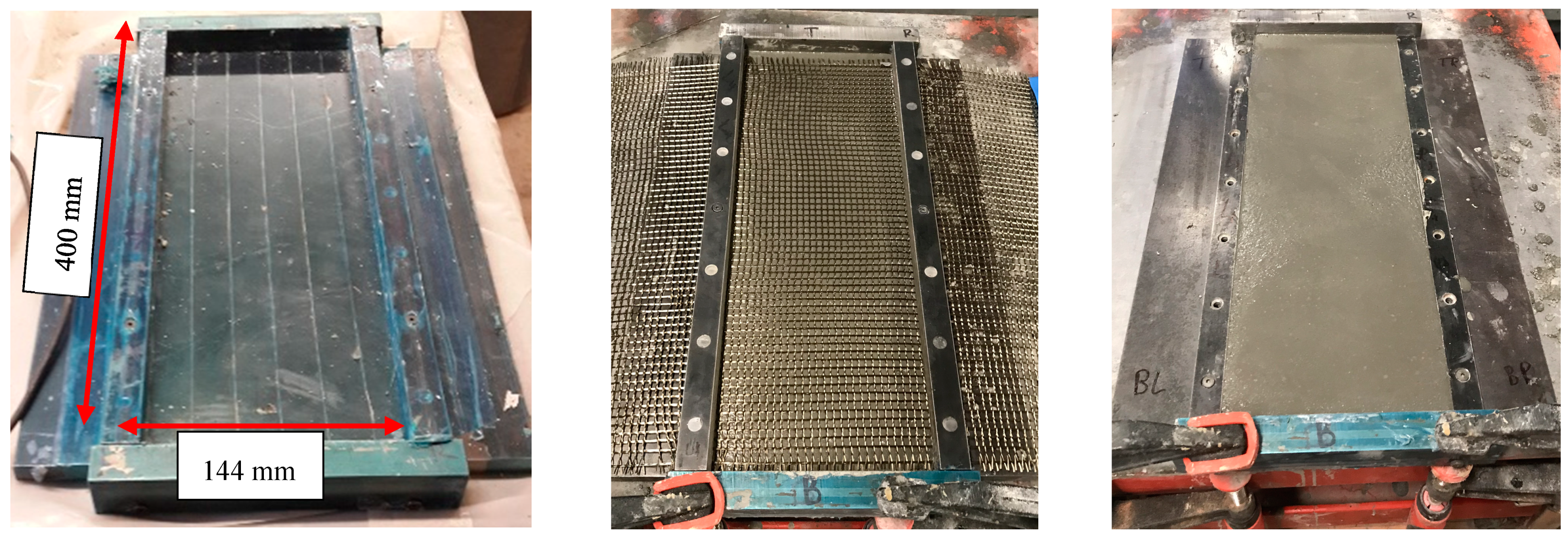

2.2. Mixing and Casting

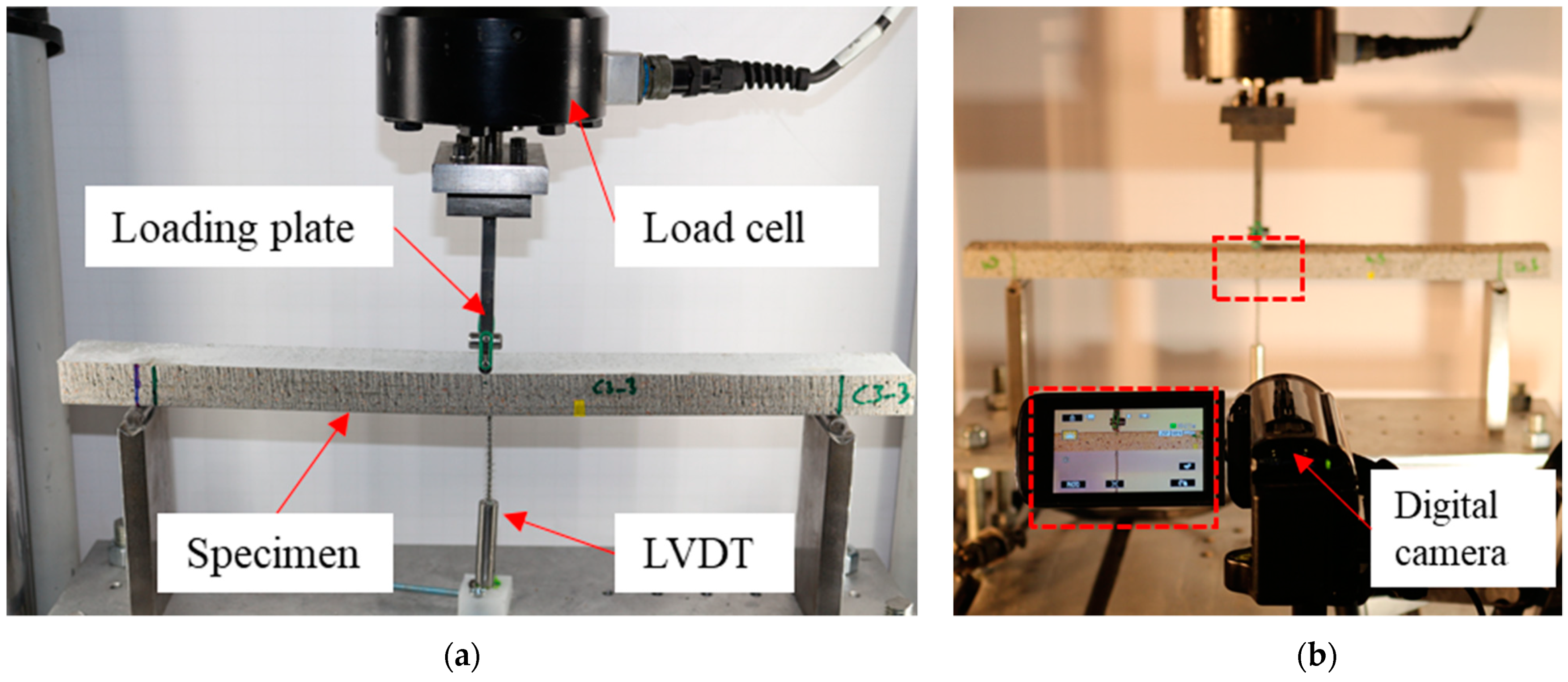

2.3. Flexure Test Setup

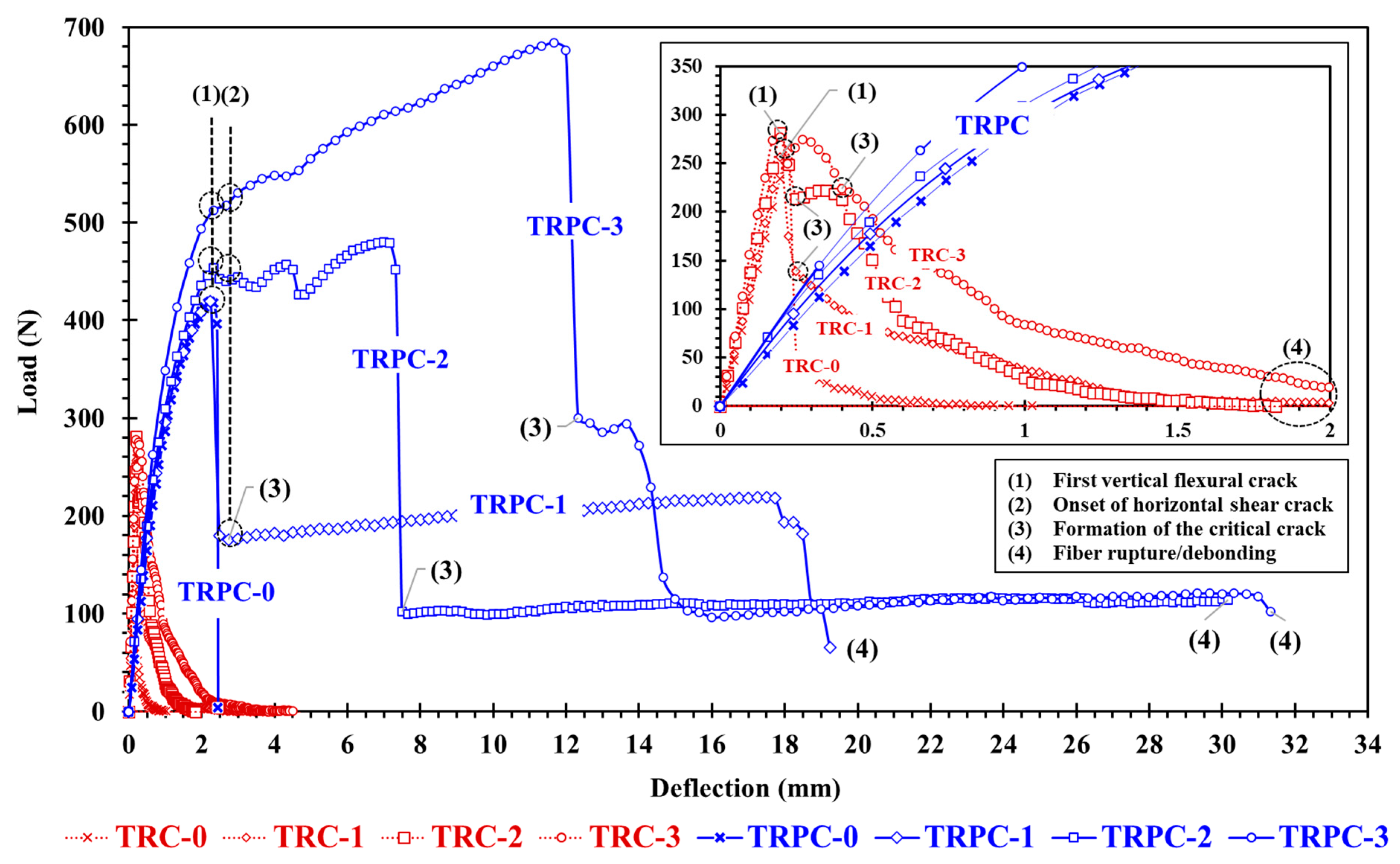

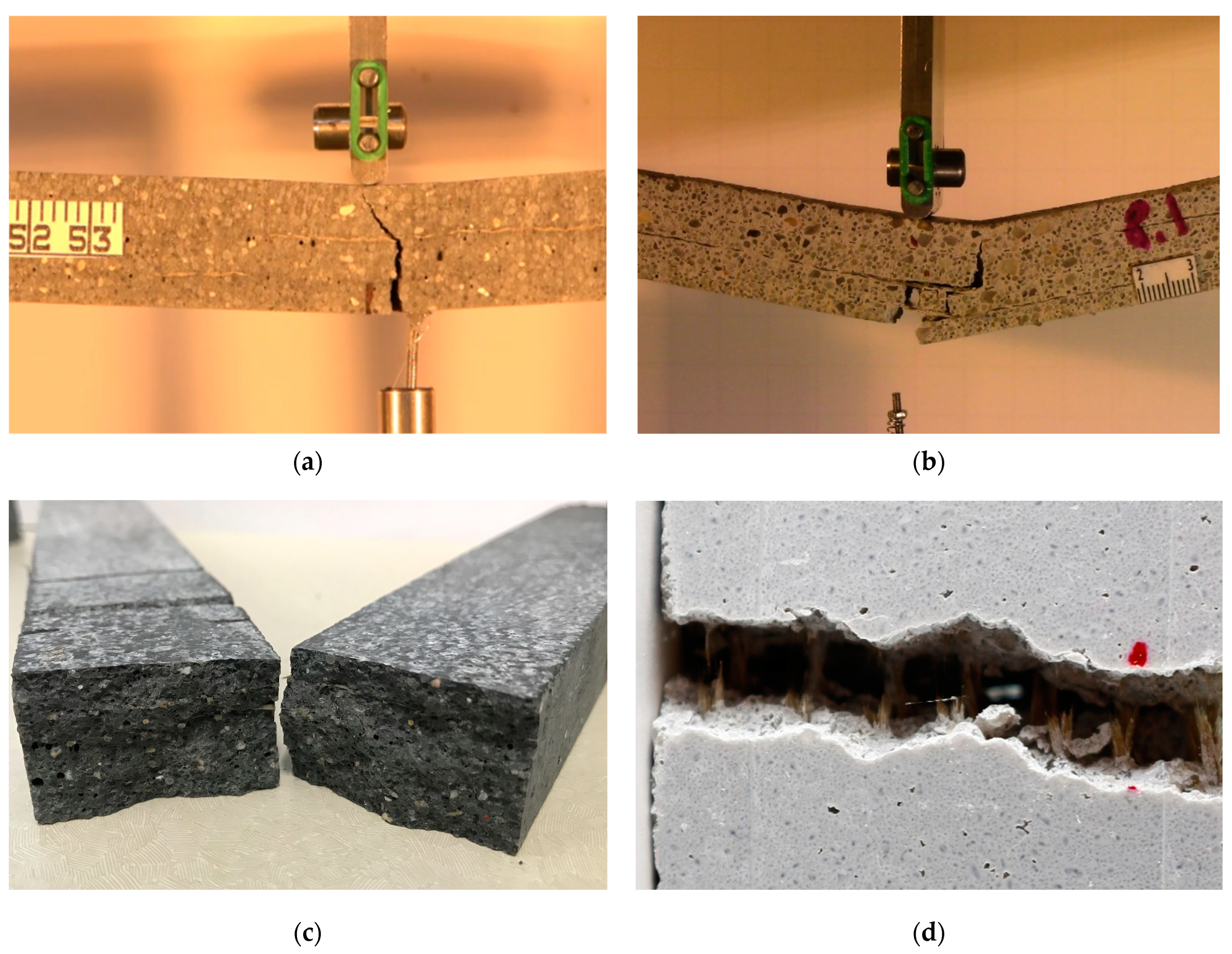

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Kulas, C. Actual Applications and Potential of Textile-Reinforced Concrete. GRC 2015, 2015, 1–11. [Google Scholar]

- Lepenies, I.G.; Richter, M.; Zastrau, B.W. A Multi-Scale Analysis of Textile Reinforced Concrete Structures. PAMM 2008, 8, 10553–10554. [Google Scholar] [CrossRef]

- Volkova, A.; Paykov, A.; Semenov, S.; Stolyarov, O.; Melnikov, B. Flexural Behavior of Textile-Reinforced Concrete. MATEC Web Conf. 2016, 53, 01016. [Google Scholar] [CrossRef] [Green Version]

- Žák, J.; Štemberk, P.; Vodička, J. Production of a Textile Reinforced Concrete Protective Layers with Non-Woven Polypropylene Fabric. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012054. [Google Scholar] [CrossRef]

- Gries, T.; Raina, M.; Quadflieg, T.; Stolyarov, O. Manufacturing of Textiles for Civil Engineering Applications. In Textile Fibre Composites in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 3–24. [Google Scholar]

- Triantafillou, T. Textile Fibre Composites in Civil Engineering; Woodhead Publishing: Waltham, MA, USA, 2016. [Google Scholar]

- Peled, A.; Bentur, A.; Mobasher, B. Textile Reinforced Concrete; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Du, Y.; Zhang, X.; Zhou, F.; Zhu, D.; Zhang, M.; Pan, W. Flexural Behavior of Basalt Textile-Reinforced Concrete. Constr. Build. Mater. 2018, 183, 7–21. [Google Scholar] [CrossRef]

- Sharei, E.; Scholzen, A.; Hegger, J.; Chudoba, R. Structural Behavior of a Lightweight, Textile-Reinforced Concrete Barrel Vault Shell. Compos. Struct. 2017, 171, 505–514. [Google Scholar] [CrossRef]

- Abdel-Emam, M.; Soliman, E.; Nassr, A.; Khair-Eldeen, W.; Abd-Elshafy, A. Dynamic Behavior of Textile Reinforced Polymer Concrete Using Split Hopkinson Pressure Bar. In Proceedings of the International Congress on Polymers in Concrete (ICPIC 2018), Washington, DC, USA, 29 April–1 May 2018; Taha, M.M.R., Ed.; Springer International Publishing: Washington, DC, USA, 2018; pp. 389–395. [Google Scholar]

- Williams Portal, N.; Lundgren, K.; Wallbaum, H.; Malaga, K. Sustainable Potential of Textile-Reinforced Concrete. J. Mater. Civ. Eng. 2015, 27, 04014207. [Google Scholar] [CrossRef]

- Brückner, A.; Ortlepp, R.; Curbach, M. Textile Reinforced Concrete for Strengthening in Bending and Shear. Mater. Struct. 2006, 39, 741–748. [Google Scholar] [CrossRef]

- Schladitz, F.; Frenzel, M.; Ehlig, D.; Curbach, M. Bending Load Capacity of Reinforced Concrete Slabs Strengthened with Textile Reinforced Concrete. Eng. Struct. 2012, 40, 317–326. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Koutas, L.N.; Bournas, D.A. Textile-Reinforced Mortar (TRM) versus Fiber-Reinforced Polymers (FRP) in Shear Strengthening of Concrete Beams. Compos. Part B Eng. 2015, 77, 338–348. [Google Scholar] [CrossRef] [Green Version]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile Reinforced Mortar (TRM) versus FRP as Strengthening Material of URM Walls: Out-of-Plane Cyclic Loading. Mater. Struct. 2008, 41, 143–157. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G. Tensile Behaviour of Mortar-Based Composites for Externally Bonded Reinforcement Systems. Compos. Part B Eng. 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Wang, J.; Wan, C.; Zeng, Q.; Shen, L.; Malik, M.A.; Yan, D. Effect of Eccentricity on Retrofitting Efficiency of Basalt Textile Reinforced Concrete on Partially Damaged Masonry Columns. Compos. Struct. 2020, 232, 111585. [Google Scholar] [CrossRef]

- Truong, B.T.; Bui, T.T.; Limam, A.; Si Larbi, A.; Le Nguyen, K.; Michel, M. Experimental Investigations of Reinforced Concrete Beams Repaired/Reinforced by TRC Composites. Compos. Struct. 2017, 168, 826–839. [Google Scholar] [CrossRef]

- Verbruggen, S.; Aggelis, D.G.; Tysmans, T.; Wastiels, J. Bending of Beams Externally Reinforced with TRC and CFRP Monitored by DIC and AE. Compos. Struct. 2014, 112, 113–121. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural Strengthening of RC Beams Using Textile Reinforced Mortar—Experimental and Numerical Study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Milani, G.; Poggi, C. Mechanical Properties and Numerical Modeling of Fabric Reinforced Cementitious Matrix (FRCM) Systems for Strengthening of Masonry Structures. Compos. Struct. 2014, 107, 711–725. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental Analysis on Bond between PBO-FRCM Strengthening Materials and Concrete. Compos. Part B Eng. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Kong, K.; Mesticou, Z.; Michel, M.; Si Larbi, A.; Junes, A. Comparative Characterization of the Durability Behaviour of Textile-Reinforced Concrete (TRC) under Tension and Bending. Compos. Struct. 2017, 179, 107–123. [Google Scholar] [CrossRef]

- Hegger, J.; Voss, S. Investigations on the Bearing Behaviour and Application Potential of Textile Reinforced Concrete. Eng. Struct. 2008, 30, 2050–2056. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Zhu, D.; Mobasher, B. Impact Behavior of Sisal Fiber Cement Composites under Flexural Load. ACI Mater. J. 2011, 108, 168–177. [Google Scholar]

- Pakravan, H.R.; Jamshidi, M.; Rezaei, H. Effect of Textile Surface Treatment on the Flexural Properties of Textile-Reinforced Cementitious Composites. J. Ind. Text. 2016, 46, 116–129. [Google Scholar] [CrossRef]

- Tsesarsky, M.; Peled, A.; Katz, A.; Anteby, I. Strengthening Concrete Elements by Confinement within Textile Reinforced Concrete (TRC) Shells—Static and Impact Properties. Constr. Build. Mater. 2013, 44, 514–523. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Zhang, G. Durability of Basalt Fibers and Composites in Corrosive Environments. J. Compos. Mater. 2015, 49, 873–887. [Google Scholar] [CrossRef]

- Larrinaga, P.; Chastre, C.; Biscaia, H.C.; San-José, J.T. Experimental and Numerical Modeling of Basalt Textile Reinforced Mortar Behavior under Uniaxial Tensile Stress. Mater. Des. 2014, 55, 66–74. [Google Scholar] [CrossRef]

- Rambo, D.A.S.; de Andrade Silva, F.; Toledo Filho, R.D.; da Fonseca Martins Gomes, O. Effect of Elevated Temperatures on the Mechanical Behavior of Basalt Textile Reinforced Refractory Concrete. Mater. Des. 1980–2015 2015, 65, 24–33. [Google Scholar] [CrossRef]

- Zhu, D.; Gencoglu, M.; Mobasher, B. Low Velocity Flexural Impact Behavior of AR Glass Fabric Reinforced Cement Composites. Cem. Concr. Compos. 2009, 31, 379–387. [Google Scholar] [CrossRef]

- Morelli, F.; Amico, C.; Salvatore, W.; Squeglia, N.; Stacul, S. Influence of Tension Stiffening on the Flexural Stiffness of Reinforced Concrete Circular Sections. Materials 2017, 10, 669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meskenas, A.; Kaklauskas, G.; Daniunas, A.; Bacinskas, D.; Jakubovskis, R.; Gribniak, S.; Gelazius, V. Determination of the Stress–Crack Opening Relationship of SFRC by an Inverse Analysis. Mech. Compos. Mater. 2014, 49, 685–690. [Google Scholar] [CrossRef]

- Gribniak, V.; Ng, P.-L.; Tamulenas, V.; Misiūnaitė, I.; Norkus, A.; Šapalas, A. Strengthening of Fibre Reinforced Concrete Elements: Synergy of the Fibres and External Sheet. Sustainability 2019, 11, 4456. [Google Scholar] [CrossRef] [Green Version]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical Properties of FRCM Using Carbon Fabrics with Different Coating Treatments. Compos. Part B Eng. 2016, 88, 220–228. [Google Scholar] [CrossRef]

- Hartig, J.; Häußler-Combe, U. A model for the uniaxial tensile behaviour of Textile Reinforced Concrete (TRC) covering effects at the micro and meso scales. In Proceedings of the ECF18, Dresden, Germany, 30 August–3 September 2010. [Google Scholar]

- Häußler-Combe, U.; Hartig, J. Bond and Failure Mechanisms of Textile Reinforced Concrete (TRC) under Uniaxial Tensile Loading. Cem. Concr. Compos. 2007, 29, 279–289. [Google Scholar] [CrossRef]

- Häußler-Combe, U.; Jesse, F.; Curbach, M. Textile Reinforced Concrete-Overview, Experimental and Theoretical Investigations. In Fracture Mechanics of Concrete Structures, Proceedings of the Fifth International Conference on Fracture Mechanics of Concrete and Concrete Structures, Ia-FraMCos, Vail, CO, USA, 12–16 April 2004; Volume 204, pp. 12–16.

- Fowler, D.W. Polymers in Concrete: A Vision for the 21st Century. Cem. Concr. Compos. 1999, 21, 449–452. [Google Scholar] [CrossRef]

- ACI Committee 548. Guide for the Use of Polymers in Concrete, ACI 548. IR-09; American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- Chmielewska, B.; Czarnecki, L.; Sustersic, J.; Zajc, A. The Influence of Silane Coupling Agents on the Polymer Mortar. Cem. Concr. Compos. 2006, 28, 803–810. [Google Scholar] [CrossRef]

- Chrissafis, K.; Bikiaris, D. Can Nanoparticles Really Enhance Thermal Stability of Polymers? Part I: An Overview on Thermal Decomposition of Addition Polymers. Thermochim. Acta 2011, 523, 1–24. [Google Scholar] [CrossRef]

- Liang, J.-Z. Reinforcement and Quantitative Description of Inorganic Particulate-Filled Polymer Composites. Compos. Part B Eng. 2013, 51, 224–232. [Google Scholar] [CrossRef]

- Aghazadeh Mohandesi, J.; Refahi, A.; Sadeghi Meresht, E.; Berenji, S. Effect of Temperature and Particle Weight Fraction on Mechanical and Micromechanical Properties of Sand-Polyethylene Terephthalate Composites: A Laboratory and Discrete Element Method Study. Compos. Part B Eng. 2011, 42, 1461–1467. [Google Scholar] [CrossRef]

- Boudenne, A.; Ibos, L.; Fois, M.; Majesté, J.C.; Géhin, E. Electrical and Thermal Behavior of Polypropylene Filled with Copper Particles. Compos. Part Appl. Sci. Manuf. 2005, 36, 1545–1554. [Google Scholar] [CrossRef]

- Takahashi, S.; Imai, Y.; Kan, A.; Hotta, Y.; Ogawa, H. Dielectric and Thermal Properties of Isotactic Polypropylene/Hexagonal Boron Nitride Composites for High-Frequency Applications. J. Alloys Compd. 2014, 615, 141–145. [Google Scholar] [CrossRef]

- Danes, F.; Garnier, B.; Dupuis, T. Predicting, Measuring, and Tailoring the Transverse Thermal Conductivity of Composites from Polymer Matrix and Metal Filler. Int. J. Thermophys. 2003, 24, 771–784. [Google Scholar] [CrossRef]

- Wereszczak, A.A.; Morrissey, T.G.; Volante, C.N.; Farris, P.J.; Groele, R.J.; Wiles, R.H.; Wang, H. Thermally Conductive MgO-Filled Epoxy Molding Compounds. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 1994–2005. [Google Scholar] [CrossRef]

- Olalla, B.; Carrot, C.; Fulchiron, R.; Boudimbou, I.; Peuvrel-disdier, E. Analysis of the Influence of Polymer Viscosity on the Dispersion of Magnesium Hydroxide in a Polyolefin Matrix. Rheol. Acta 2012, 51, 235–247. [Google Scholar] [CrossRef]

- Cavodeau, F.; Otazaghine, B.; Sonnier, R.; Lopez-Cuesta, J.-M.; Delaite, C. Fire Retardancy of Ethylene-Vinyl Acetate Composites—Evaluation of Synergistic Effects between ATH and Diatomite Fillers. Polym. Degrad. Stab. 2016, 129, 246–259. [Google Scholar] [CrossRef]

- Mechanical Properties of Mg(OH)2/Polypropylene Composites Modified by Functionalized Polypropylene-Mai-2003-Journal of Applied Polymer Science-Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/full/10.1002/app.11762 (accessed on 11 March 2020).

- Tanaka, T.; Kozako, M.; Okamoto, K. Toward High Thermal Conductivity Nano Micro Epoxy Composites with Sufficient Endurance Voltage. J. Int. Counc. Electr. Eng. 2012, 2, 90–98. [Google Scholar] [CrossRef] [Green Version]

- Xia, T.; Cao, Y.; Oyler, N.A.; Murowchick, J.; Liu, L.; Chen, X. Strong Microwave Absorption of Hydrogenated Wide Bandgap Semiconductor Nanoparticles. ACS Appl. Mater. Interfaces 2015, 7, 10407–10413. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Ferreira, A.J.M. The Influence of Notch Depth on the Fracture Mechanics Properties of Polymer Concrete. Int. J. Fract. 2003, 124, 33–42. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Ferreira, A.J.M. Assessment of Fracture Properties of Epoxy Polymer Concrete Reinforced with Short Carbon and Glass Fibers. Constr. Build. Mater. 2004, 18, 523–528. [Google Scholar] [CrossRef]

- Yu, P.; Manalo, A.; Ferdous, W.; Abousnina, R.; Salih, C.; Heyer, T.; Schubel, P. Investigation on the Physical, Mechanical and Microstructural Properties of Epoxy Polymer Matrix with Crumb Rubber and Short Fibres for Composite Railway Sleepers. Constr. Build. Mater. 2021, 295, 123700. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Ferdous, W.; Benmokrane, B.; Nguyen, K.T.Q. Synergistic Effects of Hygrothermal Conditions and Solar Ultraviolet Radiation on the Properties of Structural Particulate-Filled Epoxy Polymer Coatings. Constr. Build. Mater. 2021, 277, 122336. [Google Scholar] [CrossRef]

- Murcia, D.H.; Abdellatef, M.; Genedy, M.; Taha, M.M.R. Rheological Characterization of Three-Dimensional-Printed Polymer Concrete. Mater. J. 2021, 118, 189–201. [Google Scholar] [CrossRef]

- ASTM C1437-20, C01 Committee. Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Rebeiz, K.S. Time-Temperature Properties of Polymer Concrete Using Recycled PET. Cem. Concr. Compos. 1995, 17, 119–124. [Google Scholar] [CrossRef]

- Rebeiz, K.S. Precast Use of Polymer Concrete Using Unsaturated Polyester Resin Based on Recycled PET Waste. Constr. Build. Mater. 1996, 10, 215–220. [Google Scholar] [CrossRef]

- Tawfik, M.E.; Eskander, S.B. Polymer Concrete from Marble Wastes and Recycled Poly(Ethylene Terephthalate). J. Elastomers Plast. 2006, 38, 65–79. [Google Scholar] [CrossRef]

- Ohama, Y.; Demura, K. Relation between Curing Conditions and Compressive Strength of Polyester Resin Concrete. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 241–244. [Google Scholar] [CrossRef]

- ASTM C39-17b, C09 Committee. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Du, Y.; Zhang, X.; Liu, L.; Zhou, F.; Zhu, D.; Pan, W. Flexural Behaviour of Carbon Textile-Reinforced Concrete with Prestress and Steel Fibres. Polymers 2018, 10, 98. [Google Scholar] [CrossRef] [Green Version]

- Halvaei, M.; Jamshidi, M.; Latifi, M.; Ejtemaei, M. Experimental Investigation and Modelling of Flexural Properties of Carbon Textile Reinforced Concrete. Constr. Build. Mater. 2020, 262, 120877. [Google Scholar] [CrossRef]

- Williams Portal, N.; Nyholm Thrane, L.; Lundgren, K. Flexural Behaviour of Textile Reinforced Concrete Composites: Experimental and Numerical Evaluation. Mater. Struct. 2016, 50, 4. [Google Scholar] [CrossRef] [Green Version]

- Başyiğit, C.; Çomak, B.; Kılınçarslan, Ş.; Serkan Üncü, İ. Assessment of Concrete Compressive Strength by Image Processing Technique. Constr. Build. Mater. 2012, 37, 526–532. [Google Scholar] [CrossRef]

- Mantawy, I.; Chennareddy, R.; Genedy, M.; Taha, M.R. Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction. Infrastructures 2019, 4, 31. [Google Scholar] [CrossRef] [Green Version]

- Vipulanandan, C.; Dharmarajan, N.; Ching, E. Mechanical Behaviour of Polymer Concrete Systems. Mater. Struct. 1988, 21, 268–277. [Google Scholar] [CrossRef]

- Toufigh, V.; Hosseinali, M.; Shirkhorshidi, S.M. Experimental Study and Constitutive Modeling of Polymer Concrete’s Behavior in Compression. Constr. Build. Mater. 2016, 112, 183–190. [Google Scholar] [CrossRef]

- Teramoto, A.; Watanabe, M.; Murakami, R.; Ohkubo, T. Visualization of Internal Crack Growth Due to Alkali–Silica Reaction Using Digital Image Correlation. Constr. Build. Mater. 2018, 190, 851–860. [Google Scholar] [CrossRef]

- Carloni, C.; Subramaniam, K.V. Investigation of Sub-Critical Fatigue Crack Growth in FRP/Concrete Cohesive Interface Using Digital Image Analysis. Compos. Part B Eng. 2013, 51, 35–43. [Google Scholar] [CrossRef]

- Alam, S.Y.; Loukili, A.; Grondin, F. Monitoring Size Effect on Crack Opening in Concrete by Digital Image Correlation. Eur. J. Environ. Civ. Eng. 2012, 16, 818–836. [Google Scholar] [CrossRef]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G. Analysis of Residual Flexural Stiffness of Steel Fiber-Reinforced Concrete Beams with Steel Reinforcement. Materials 2020, 13, 2698. [Google Scholar] [CrossRef]

- Choi, S.-W.; Choi, J.; Lee, S.-C. Probabilistic Analysis for Strain-Hardening Behavior of High-Performance Fiber-Reinforced Concrete. Materials 2019, 12, 2399. [Google Scholar] [CrossRef] [Green Version]

- Heras Murcia, D.; Minnig, C.; Gisiger, J.; Rösli, U.; Stormont, J.C.; Reda Taha, M. Nano Sealant for CO2 Seal Integrity and Overcoring at Mont Terri. In Proceedings of the 15th International Conference on Greenhouse Gas Control Technologies, GHGT-15, Virtual, 15–18 March 2021. [Google Scholar]

| Reference Conventional Concrete | PC | |

|---|---|---|

| Portland Cement | 689 | - |

| Water | 172 | - |

| Superplasticizer | 21 | - |

| Aggregate | 1378 | 2002 |

| Polymer Resin | - | 251 |

| Mesh Window Size | 5.00 mm | Maximum Load-Weft | 45,000 N/m |

| Total Weight/Area | 220 g/m2 | Elongation at break-Warp | 6.7% |

| Weight Resin Coating | No resin coating | Elongation at break-Weft | 3.5% |

| Thickness | 0.6–0.7 mm | Breaking Elongation-Warp | 13.5 mm |

| Maximum Load-Warp | 48,000 N/m | Breaking Elongation-Weft | 7.1 mm |

| Specimen | Horizontal Crack Length * (mm) | Horizontal Crack Width * (mm) |

|---|---|---|

| TRC-0 | No horizontal crack | |

| TRC-1 | ||

| TRC-2 | ||

| TRC-3 | ||

| TRPC-0 | ||

| TRPC-1 | 34.6 | 0.24 |

| TRPC-2 | 51.3 | 0.45 |

| TRPC-3 | 27.5 | 0.75 |

| Specimen | Vertical Crack Area * (mm2) | Vertical Crack Width * (mm) |

|---|---|---|

| TRC-0 | 4.28 | 0.39 |

| TRC-1 | 9.46 | 0.58 |

| TRC-2 | 13.42 | 0.65 |

| TRC-3 | 17.81 | 0.85 |

| TRPC-0 | 4.8 | 0.29 |

| TRPC-1 | 27.0 | 1.04 |

| TRPC-2 | 42.7 | 1.84 |

| TRPC-3 | 113.8 | 2.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murcia, D.H.; Çomak, B.; Soliman, E.; Reda Taha, M.M. Flexural Behavior of a Novel Textile-Reinforced Polymer Concrete. Polymers 2022, 14, 176. https://doi.org/10.3390/polym14010176

Murcia DH, Çomak B, Soliman E, Reda Taha MM. Flexural Behavior of a Novel Textile-Reinforced Polymer Concrete. Polymers. 2022; 14(1):176. https://doi.org/10.3390/polym14010176

Chicago/Turabian StyleMurcia, Daniel Heras, Bekir Çomak, Eslam Soliman, and Mahmoud M. Reda Taha. 2022. "Flexural Behavior of a Novel Textile-Reinforced Polymer Concrete" Polymers 14, no. 1: 176. https://doi.org/10.3390/polym14010176

APA StyleMurcia, D. H., Çomak, B., Soliman, E., & Reda Taha, M. M. (2022). Flexural Behavior of a Novel Textile-Reinforced Polymer Concrete. Polymers, 14(1), 176. https://doi.org/10.3390/polym14010176