Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Tensile Tests

2.2. Rotating Fatigue Tests

3. Fatigue Test Results and Discussion

4. Conclusions

- Comparison of different infill densities of FFF (3D printed) specimens and infill patterns and their influence on mechanical and fatigue properties;

- Different cycle rate values;

- Numerical modelling, using finite element method, based on proposed analytical models and findings;

- Fracture surface analysis;

- Surface roughness influence on fatigue fracture and cyclic durability;

- Influence of ultraviolet radiation and temperature on FFF polymer specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM F2792-12a. Standard Terminology for Additive Manufacturing Technologies. Available online: www.astm.org (accessed on 1 March 2021).

- Caulfield, B.; McHugh, P.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Sharma, M.; Ziemian, C. Anisotropic Mechanical Properties of ABS Parts Fabricated by Fused Deposition Modelling. Mech. Eng. 2012. [Google Scholar] [CrossRef]

- Rendeki, S.; Nagy, B.; Bene, M.; Pentek, A.; Toth, L.; Szanto, Z.; Told, R.; Maroti, P. An Overview on Personal Protective Equipment (PPE) Fabricated with Additive Manufacturing Technologies in the Era of COVID-19 Pandemic. Polymers 2020, 12, 2703. [Google Scholar] [CrossRef] [PubMed]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Barkhad, M.S.; Abu-Jdayil, B.; Mourad, A.H.I.; Iqbal, M.Z. Thermal Insulation and Mechanical Properties of Polylactic Acid (PLA) at Different Processing Conditions. Polymers 2020, 12, 2091. [Google Scholar] [CrossRef] [PubMed]

- Gong, B.; Cui, S.; Zhao, Y.; Sun, Y.; Ding, Q. Strain-controlled fatigue behaviors of porous PLA-based scaffolds by 3D-printing technology. J. Biomater. Sci. Polym. Ed. 2017, 28, 2196–2204. [Google Scholar] [CrossRef] [PubMed]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef]

- Senatov, F.; Niaza, K.; Stepashkin, A.; Kaloshkin, S. Low-cycle fatigue behavior of 3d-printed PLA-based porous scaffolds. Compos. Part B Eng. 2016, 97, 193–200. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Johnson, G.A.; French, J.J. Evaluation of Infill Effect on Mechanical Properties of Consumer 3D Printing Materials. Adv. Technol. Innov. 2018, 3, 179–184. [Google Scholar]

- Ma, Y.-Q.; Pang, Y.-Y. Mechanism study on char formation of zinc acetylacetonate on ABS resin. Chin. J. Polym. Sci. 2015, 33, 772–782. [Google Scholar] [CrossRef]

- Datta, P.; Guha, C.; Sarkhel, G. Effect of Na-ionomer on dynamic rheological, dynamic mechanical and creep properties of acrylonitrile styrene acrylate (ASA)/Na+1poly (ethylene-co-methacrylic acid) ionomer blend. Polym. Adv. Technol. 2014, 25, 1454–1463. [Google Scholar] [CrossRef]

- Datta, P.; Guha, C.; Sarkhel, G. Study of Dynamic Rheological, Dynamic Mechanical and Creep Properties of Acrylonitrile Styrene Acrylate (ASA)/Zn+2poly(ethylene-co-methacrylic acid) Ionomer Blend. J. Macromol. Sci. Part A 2014, 51, 820–830. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Van Der Klift, F.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) Tensile Test Specimens. Open J. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef]

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. J. Compos. Sci. 2017, 1, 8. [Google Scholar] [CrossRef]

- Liu, X.; Shapiro, V. Homogenization of material properties in additively manufactured structures. Comput. Des. 2016, 78, 71–82. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Nikzad, M.; Iovenitti, P.G. Effects of Build Orientations on Tensile Properties of PLA Material Processed by FDM. Adv. Mater. Res. 2014, 1044–1045, 31–34. [Google Scholar] [CrossRef]

- Tymrak, B.; Kreiger, M.; Pearce, J. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef] [PubMed]

- Montero, M.; Roundy, S.; Odell, D. Material characterization of fused deposition modeling (FDM) ABS by designed experiments. Proc. Rapid Prototyp. Manuf. Conf. 2001, 1–21. [Google Scholar]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef]

- Ezeh, O.; Susmel, L. On the fatigue strength of 3D-printed polylactide (PLA). Procedia Struct. Integr. 2018, 9, 29–36. [Google Scholar] [CrossRef]

- Ziemian, S.; Okwara, M.; Ziemian, C.W. Tensile and fatigue behavior of layered acrylonitrile butadiene styrene. Rapid Prototyp. J. 2015, 21, 270–278. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Performance of ABS Specimens Obtained by Fused Filament Fabrication. Materials 2018, 11, 2521. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef]

- Raise3D. PLA Filament—Premium Filament. Raise3D. Premium PLA Safety and Technical Data Sheet. 2019. Available online: https://s1.raise3d.com/2020/12/PLA-Data-Sheet.zip (accessed on 1 March 2021).

- Raise3D. ABS Filament—Premium Filament. Raise3D Premium ABS Safety and Technical Data Sheet. 2017. Available online: https://s1.raise3d.com/2020/12/ABS-Data-Sheet.zip (accessed on 1 March 2021).

- Prima Creator. PrimaSelect ASA+ PrimaCreator. PrimaSelect Safety and Technical Data Sheet. 2019. Available online: https://cdn.shopify.com/s/files/1/2424/8853/files/Prima_ASA__webb.pdf?293 (accessed on 1 March 2021).

- Kampker, A.; Triebs, J.B.; Ayvaz, P.; Ilic, D. Investigation of FLM materials for application in high-temperature and high-vibration automotive environments. Procedia CIRP 2019, 81, 358–362. [Google Scholar] [CrossRef]

- Ibrahim, D.; Ding, S.; Sun, S. Roughness Prediction for FDM Produced Surfaces. In Proceedings of the International Conference Recent treads in Engineering & Technology (ICRET’2014), Batam, Indonesia, 13–14 February 2014; pp. 13–17. [Google Scholar]

- Alsoufi, M.S.; Elsayed, A.E. How Surface Roughness Performance of Printed Parts Manufactured by Desktop FDM 3D Printer with PLA+ is Influenced by Measuring Direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar] [CrossRef]

- Burhan, I.; Kim, H.S. S-N Curve Models for Composite Materials Characterisation: An Evaluative Review. J. Compos. Sci. 2018, 2, 38. [Google Scholar] [CrossRef]

- Poberezhnyi, L.; Maruschak, P.; Prentkovskis, O.; Danyliuk, I.; Pyrig, T.; Brezinová, J. Fatigue and failure of steel of offshore gas pipeline after the laying operation. Arch. Civ. Mech. Eng. 2016, 16, 524–536. [Google Scholar] [CrossRef]

| Material/Property | PLA | ABS | ASA+ |

|---|---|---|---|

| Density (g/cm3 at 21.5 °C; ISO 1183) | 1.20 | 1.10–1.15 | 1.10 |

| Melt Flow Rate (g/10 min) | 210 °C/2.16 kg = 7 ÷ 11 | 220 °C/10 kg = 9 ÷ 14 | 260 °C/5 kg = 45 |

| Melting temperature (°C) | 150 | - | 228 |

| Glass transition temperature (°C) | 61 | 98.1 | 98 |

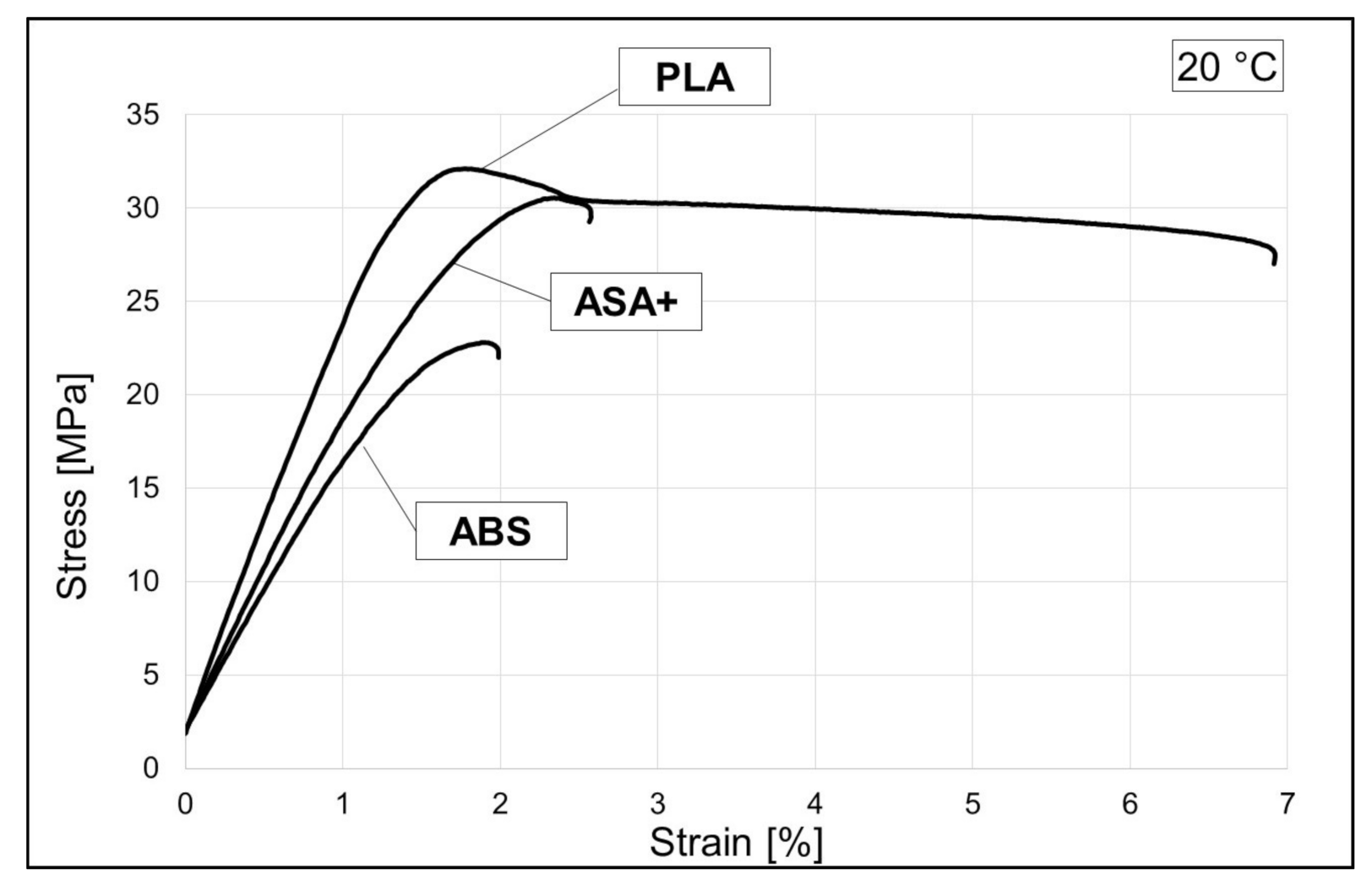

| Property | This paper | Manufacturer [31] | [Reference] |

|---|---|---|---|

| Young’s modulus (MPa) | 2923 | 2623 ± 330 | 3340 [22] |

| Tensile strength (MPa) | 32.1 | 46.6 ± 0.9 | 48.5 [22] |

| Property | This paper | Manufacturer [32] | [Reference] |

|---|---|---|---|

| Young’s modulus (MPa) | 2182 | 2174 ± 285 | 1960 ± 60 [5]; 1538 [21] |

| Tensile strength (MPa) | 22.8 | 33.3 ± 0.8 | 32.8 ± 0.6 [5] 38.65 [21] |

| Property | This paper | Manufacturer [33] | [Reference] |

|---|---|---|---|

| Young’s modulus (MPa) | 1996 | 2020 | 1398.3 [34] |

| Tensile strength (MPa) | 29.9 | 48 | 23 [34] |

| Coefficient/Cycle Rate | 10 Hz | 20 Hz | 30 Hz |

|---|---|---|---|

| α | 1488.2 | 349.6 | 474.5 |

| β | −0.4219 | −0.227 | −0.284 |

| Coefficient/Cycle Rate | 10 Hz | 20 Hz | 30 Hz |

|---|---|---|---|

| α | 70,213.8 | 1133.9 | 236.8 |

| β | −0.926 | −0.487 | −0.250 |

| Coefficient/Cycle Rate | 10 Hz | 20 Hz | 30 Hz |

|---|---|---|---|

| α | 3797.1 | 6574.1 | 753.6 |

| β | −0.561 | −0.671 | −0.361 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brčić, M.; Kršćanski, S.; Brnić, J. Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials. Polymers 2021, 13, 1020. https://doi.org/10.3390/polym13071020

Brčić M, Kršćanski S, Brnić J. Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials. Polymers. 2021; 13(7):1020. https://doi.org/10.3390/polym13071020

Chicago/Turabian StyleBrčić, Marino, Sanjin Kršćanski, and Josip Brnić. 2021. "Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials" Polymers 13, no. 7: 1020. https://doi.org/10.3390/polym13071020

APA StyleBrčić, M., Kršćanski, S., & Brnić, J. (2021). Rotating Bending Fatigue Analysis of Printed Specimens from Assorted Polymer Materials. Polymers, 13(7), 1020. https://doi.org/10.3390/polym13071020

.JPG)