Realization of Circular Economy of 3D Printed Plastics: A Review

Abstract

:1. Introduction

2. Application of 3D Printing

3. Current Status and Problems of 3D Printing

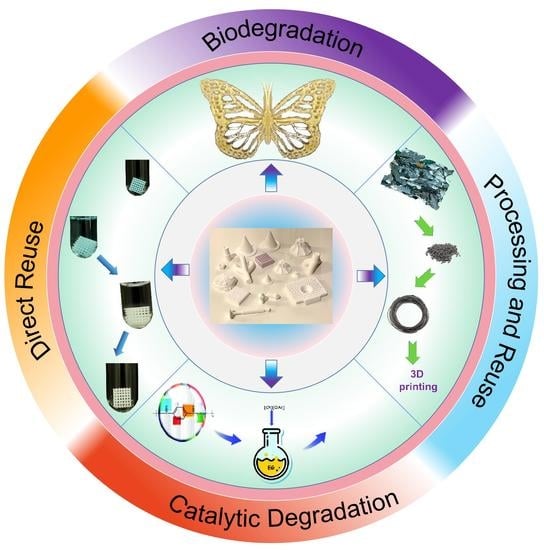

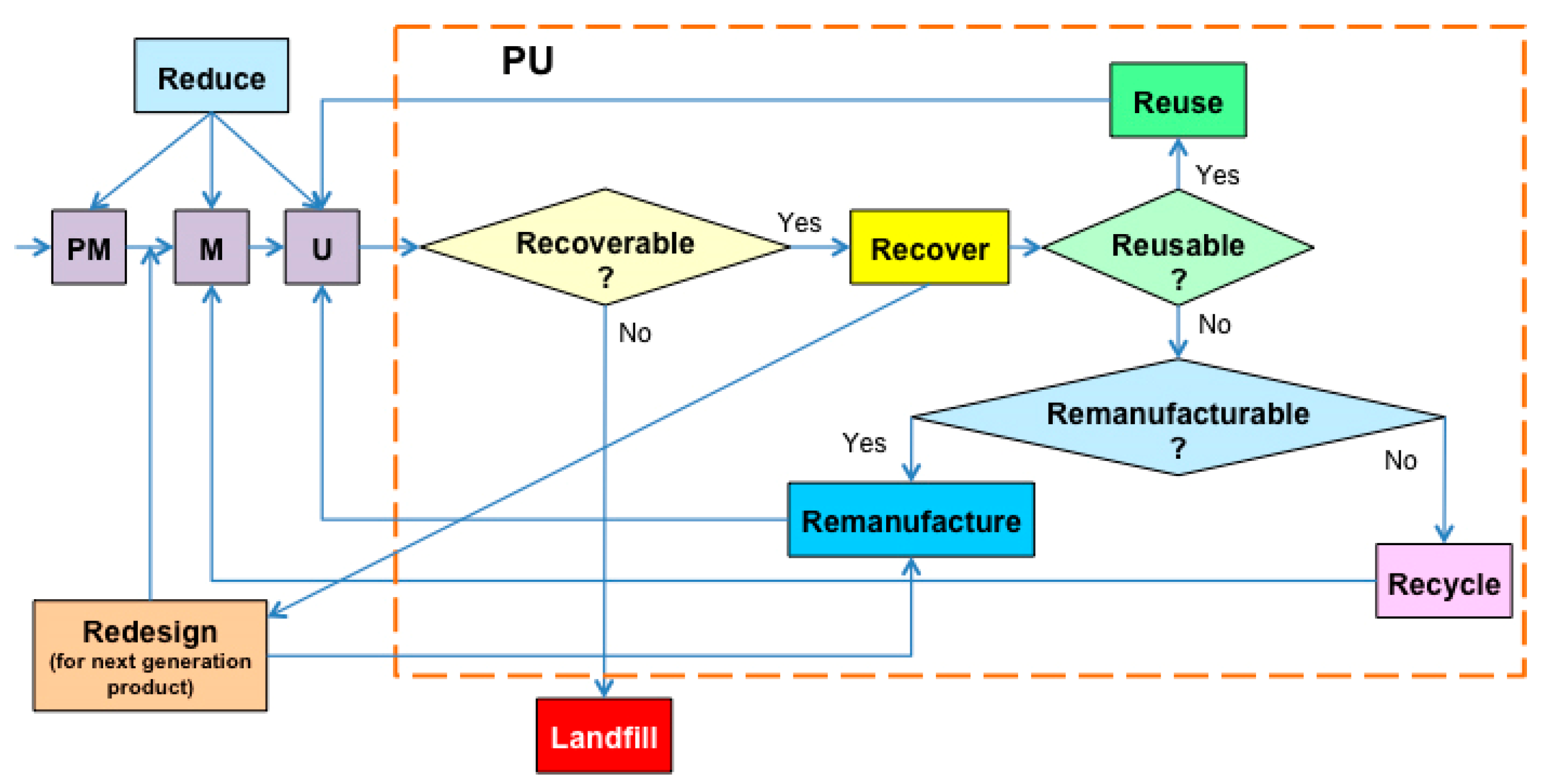

4. Circular Application of 3D Printing Waste

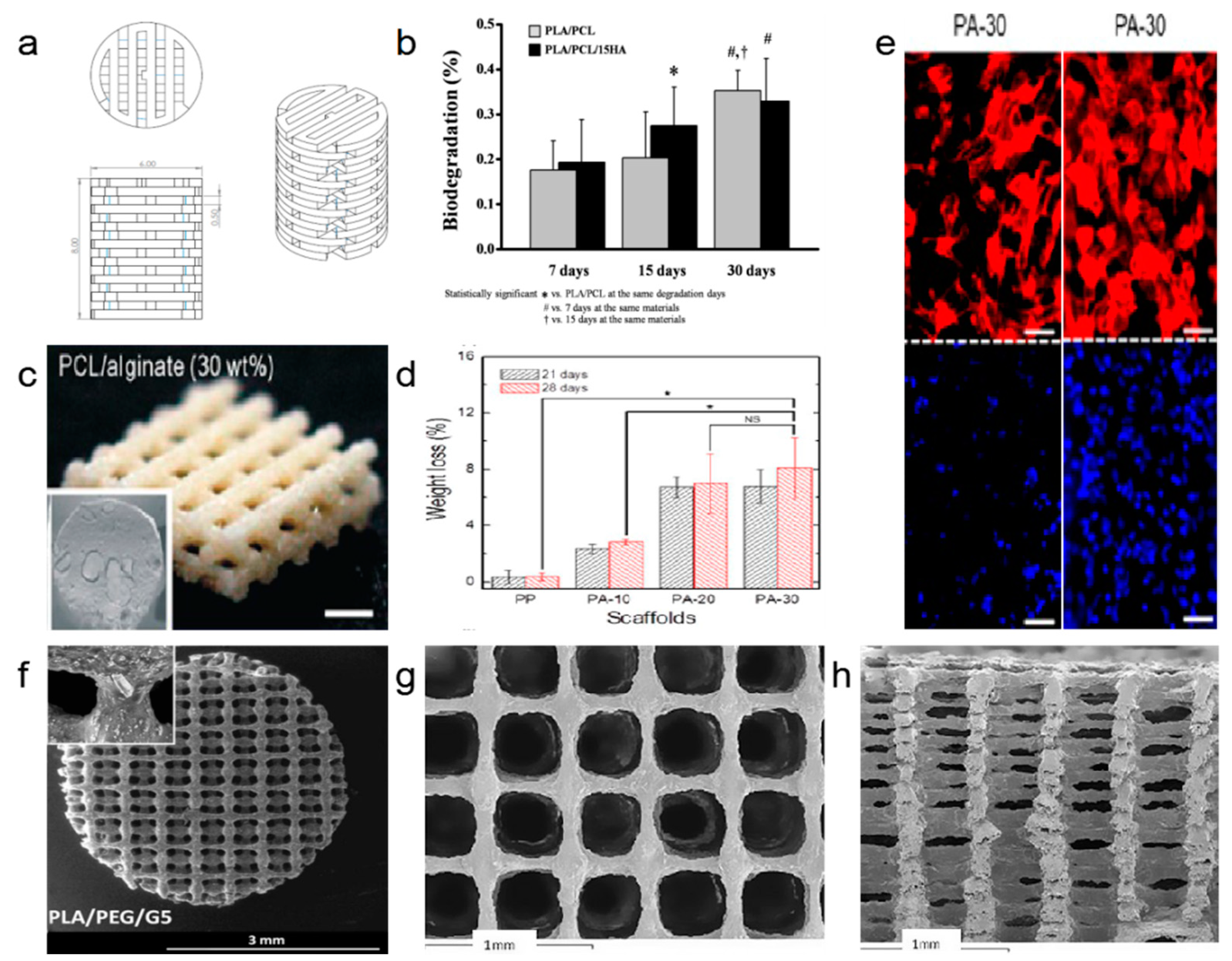

4.1. Biodegradation Makes 3D Printing Materials Harmless

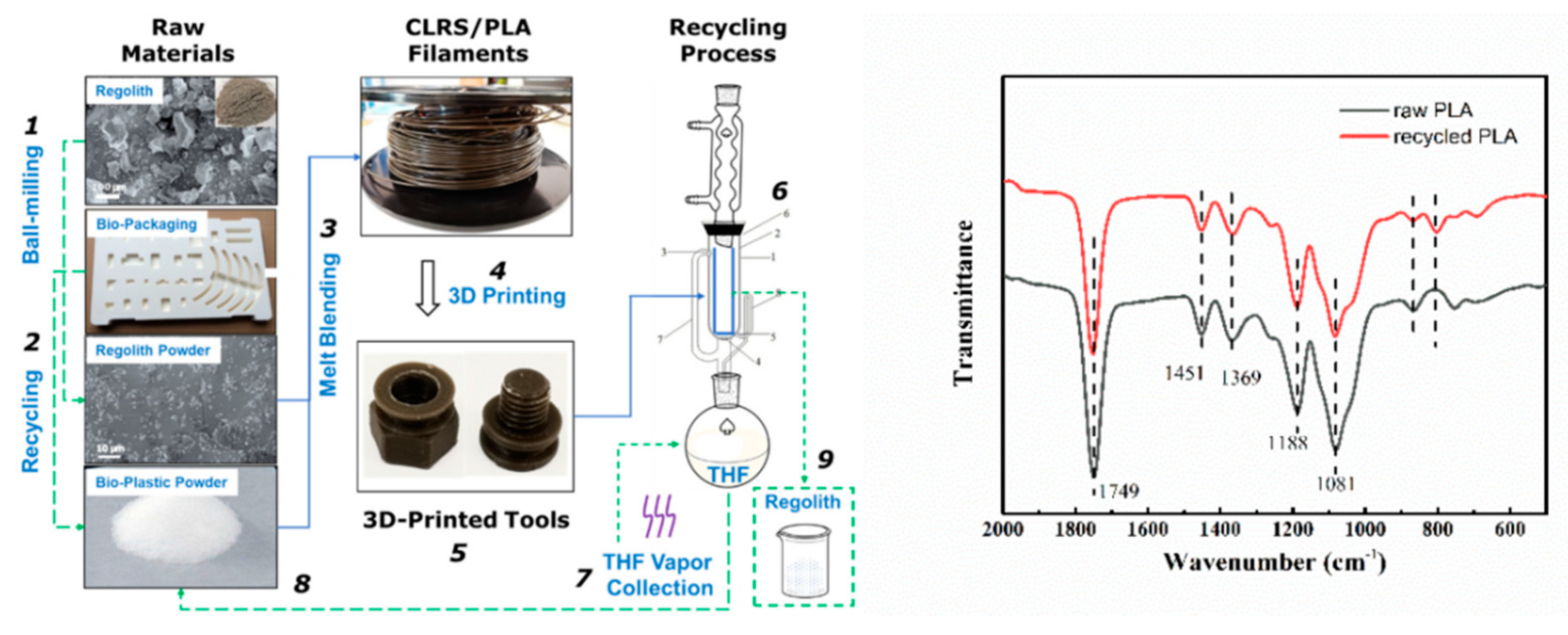

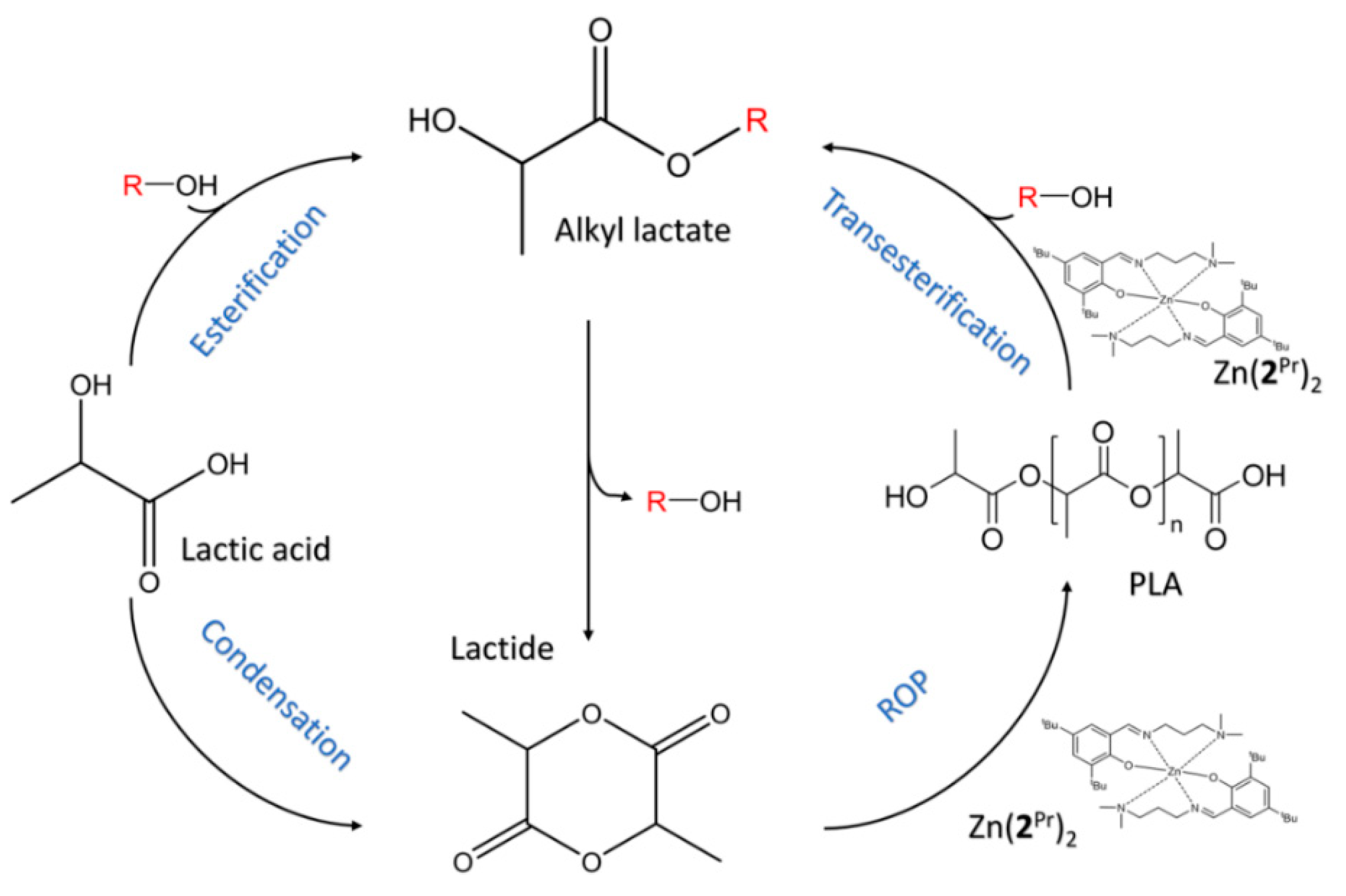

4.2. Degradation by Catalyst/Solvent

4.3. Direct Reuse of 3D Printed Waste Plastics

4.4. 3D printing Waste Plastic Processing and Reuse

5. Recommendation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Samak, N.A.; Jia, Y.; Sharshar, M.M.; Mu, T.; Yang, M.; Peh, S.; Xing, J. Recent advances in biocatalysts engineering for polyethylene terephthalate plastic waste green recycling. Environ. Int. 2020, 145, 106144. [Google Scholar] [CrossRef]

- Sharma, B.; Jain, P. Deciphering the Advances in Bioaugmentation of Plastic Wastes. J. Clean. Prod. 2020, 275, 123241. [Google Scholar] [CrossRef]

- Available online: https://wrap.org.uk/blog/2021/02/shared-vision-more-sustainable-food-system-why-now-more-ever-we-need-courtauld (accessed on 27 February 2021).

- Song, Y. A Study on the Latest EU Plastic Restriction Act in the Perspective of Circular Economy Law. Environ. Prot. Circ. Econ. 2019, 39, 1–4. [Google Scholar]

- Zhu, D. A review of circular economy development in European countries over the last decade and its implicat. China Popul. Resour. Environ. 2017, 27, 9–16. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef] [Green Version]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Han, Q.; Weng, X.; Zou, Y.; Yang, Y.; Zhang, K.; Yang, K.; Xu, X.; Wang, C.; Qin, Y.; et al. The precision and reliability evaluation of 3-dimensional printed damaged bone and prosthesis models by stereo lithography appearance. Medicine 2018, 97, 9797. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.; Sim, J.; Kim, H.; Shin, D.; Hong, D. Application of LOM for Freeform Architecture. J. Korean Soc. Precis. Eng. 2017, 34, 903–909. [Google Scholar] [CrossRef]

- Jing, J.; Chen, Y.; Shi, S.; Yang, L.; Lambin, P. Facile and Scalable Fabrication of Highly Thermal Conductive Polyethylene/Graphene Nanocomposites by Combining Solid-State Shear Milling and FDM 3D-Printing Aligning Methods. Chem. Eng. J. 2020, 402, 126218. [Google Scholar] [CrossRef]

- Acord, K.A.; Dupuy, A.D.; Bertoli, U.S.; Zheng, B.; West, W.C.; Chen, Q.N.; Shapiro, A.A.; Schoenung, J.M. Morphology, Microstructure, and Phase States in Selective Laser Sintered Lithium Ion Battery Cathodes. J. Mater. Process. Technol. 2020, 288, 116827. [Google Scholar] [CrossRef]

- Shin, Y.J.; Shafranek, R.T.; Tsui, J.H.; Walcott, J.; Kim, D.H. 3D bioprinting of mechanically tuned bioinks derived from cardiac decellularized extracellular matrix. Acta Biomater. 2020, 119, 75–88. [Google Scholar] [CrossRef]

- Wang, H.; Xu, H.; Zhang, J.; Yu, S.; Zhang, M. The effect of 3D-printed plastic teeth on scores in a tooth morphology course in a Chinese university. BMC Med. Educ. 2020, 20, 469. [Google Scholar] [CrossRef] [PubMed]

- Costa, P.F.; Vaquette, C.; Zhang, Q.; Reis, R.L.; Ivanovski, S.; Hutmacher, D.W. Advanced tissue engineering scaffold design for regeneration of the complex hierarchical periodontal structure. Clin. Periodontol. 2014, 41, 283–294. [Google Scholar] [CrossRef]

- Vaquette, C.; Wei, F.; Yin, X.; Hamlet, S.; Hutmacher, D.W.; Ivanovski, S. A biphasic scaffold design combined with cell sheet technology for simultaneous regeneration of alveolar bone/periodontal ligament complex. Biomaterials 2012, 33, 5560–5573. [Google Scholar] [CrossRef] [PubMed]

- Tsai, K.; Lin, H.; Chen, Y.; Lin, C.; Hsu, T.; Kao, C.; Chua, C.K. Laser Sintered Magnesium-Calcium Silicate/Poly-ε-Caprolactone Scaffold for Bone Tissue Engineering. Materials 2017, 10, 65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wurm, M.C.; Möst, T.; Bergauer, B.; Rietzel, D.; Neukam, F.W.; Cifuentes, S.C.; Wilmowsky, C.V. In-vitro evaluation of Polylactic acid (PLA) manufactured by fused deposition modeling. J. Biol. Eng. 2017, 11, 29. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Hong, C.; Lin, J.; Jin, X.; Xu, W. Make it swing: Fabricating personalized roly-poly toys. Comput. Aided Geom. Des. 2016, 43, 226–236. [Google Scholar] [CrossRef]

- Song, P.; Wang, X.; Tang, X.; Fu, C.; Xu, H.; Liu, L.; Mitra, N.J. Computational design of wind-up toys. ACM Trans. Graph. 2017, 36, 1–13. [Google Scholar] [CrossRef]

- Spahiu, T.; Canaj, E.; Shehi, E. 3D printing for clothing production. J. Eng. Fibers Fabr. 2020, 15, 1–8. [Google Scholar] [CrossRef]

- Zwicker, A.P.; Bloom, J.; Albertson, R.; Gershman, S. The suitability of 3D printed plastic parts for laboratory use. Am. J. Phys. 2015, 83, 281–285. [Google Scholar] [CrossRef]

- Gao, N.; Hou, H. Sound absorption characteristic of micro-helix metamaterial by 3D printing. Theor. Appl. Mech. Lett. 2018, 8, 63–67. [Google Scholar] [CrossRef]

- Tsung-yen, H.; Raj, D.; Brian, C.; Travis, T.T. 3D Printing: Current use in facial plastic and reconstructive surgery. Curr. Opin. Otolaryngol. Head Neck Surg. 2017, 25, 291–299. [Google Scholar] [CrossRef]

- Chen, S.; Yi, H.; Luo, Z.; Zhuge, X.; Luo, K. The 3DPrinting Polymers and Their Printing Technologies. Mater. Rep. 2016, 30, 54–59. [Google Scholar] [CrossRef]

- Keyin. Available online: http://www.keyin.cn/news/sczc/201504/20-1084132.shtml (accessed on 13 January 2021).

- CCID. Available online: Http://www.mtx.cn/#/report?id=683539 (accessed on 24 December 2020).

- Zhang, L. Application and development of chemical materials in 3D printing. Chem. Ind. 2017, 35, 37–41. [Google Scholar] [CrossRef]

- Thunsiri, K.; Pitjamit, S.; Pothacharoen, P.; Pruksakorn, D.; Nakkiew, W.; Wattanutchariya, W. The 3D-Printed Bilayer’s Bioactive-Biomaterials Scaffold for Full-Thickness Articular Cartilage Defects Treatment. Materials 2020, 13, 3417. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Kim, G. PCL/alginate composite scaffolds for hard tissue engineering: Fabrication, characterization, and cellular activities. ACS Comb. Sci. 2015, 17, 87–99. [Google Scholar] [CrossRef]

- Serra, T.; Ortiz-Hernandez, M.; Engel, E.; Planell, J.; Navarro, M. Relevance of PEG in PLA-based blends for tissue engineering 3D-printed scaffolds. Mater. Sci. Eng. C 2014, 38, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Serra, T.; Planell, J.A.; Navarro, M. High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater. 2013, 9, 5521–5530. [Google Scholar] [CrossRef] [PubMed]

- Maharana, T.; Mohanty, B.; Negi, Y.S. Melt-solid polycondensation of lactic acid and its biodegradability. Prog. Polym. Sci. 2009, 34, 99–124. [Google Scholar] [CrossRef]

- Isun3d Products. Available online: Http://www.isun3d.com/show-5.html/ (accessed on 14 December 2020).

- Li, H.; Zhao, W.; Wu, X.; Li, Q.; Tian, J.; Wang, G. 3D Printing and Solvent Dissolution Recycling of Polylactide-Lunar Regolith Composites by Material Extrusion Approach. Polymers 2020, 12, 1724. [Google Scholar] [CrossRef] [PubMed]

- Román-Ramírez, L.A.; Powders, M.; McKeown, P.; Wood, J. Ethyl Lactate Production from the Catalytic Depolymerisation of Post-consumer Poly(lactic acid). Polym. Environ. 2020, 28, 2956–2964. [Google Scholar] [CrossRef]

- Yang, M.; Hu, J.; Xiong, N.; Xu, B.; Wen, Y.; Liu, Y. Preparation and properties of PLA/PHBV/PBAT blends 3D printing filament. Mater. Res. Express 2019, 6, 065401. [Google Scholar] [CrossRef]

- Fuentes, M.A.V.; Thakur, S.; Wu, F.; Misra, M.; Gregori, S.; Mohanty, A.K. Study on the 3D printability of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/poly(lactic acid) blends with chain extender using fused filament fabrication. Sci. Rep. 2020, 10, 11804. [Google Scholar] [CrossRef]

- Kontarova, S.; Prikryl, R.; Melcova, V.; Mencik, P.; Horalek, M.; Figalla, S.; Plavec, R.; Feranc, J.; Sadilek, J.; Pospisilova, A. Printability, Mechanical and Thermal Properties of Poly(3-Hydroxybutyrate)-Poly(Lactic Acid)-Plasticizer Blends for Three-Dimensional (3D) Printing. Materials 2020, 13, 4736. [Google Scholar] [CrossRef]

- Pereira, T.F.; Oliveira, M.F.; Maia, I.A.; Silva, J.V.L.; Costa, M.F.; Thiré, R.M.S.M. 3D Printing of Poly(3-hydroxybutyrate) Porous Structures Using Selective Laser Sintering. Macromol. Symp. 2012, 319, 64–73. [Google Scholar] [CrossRef]

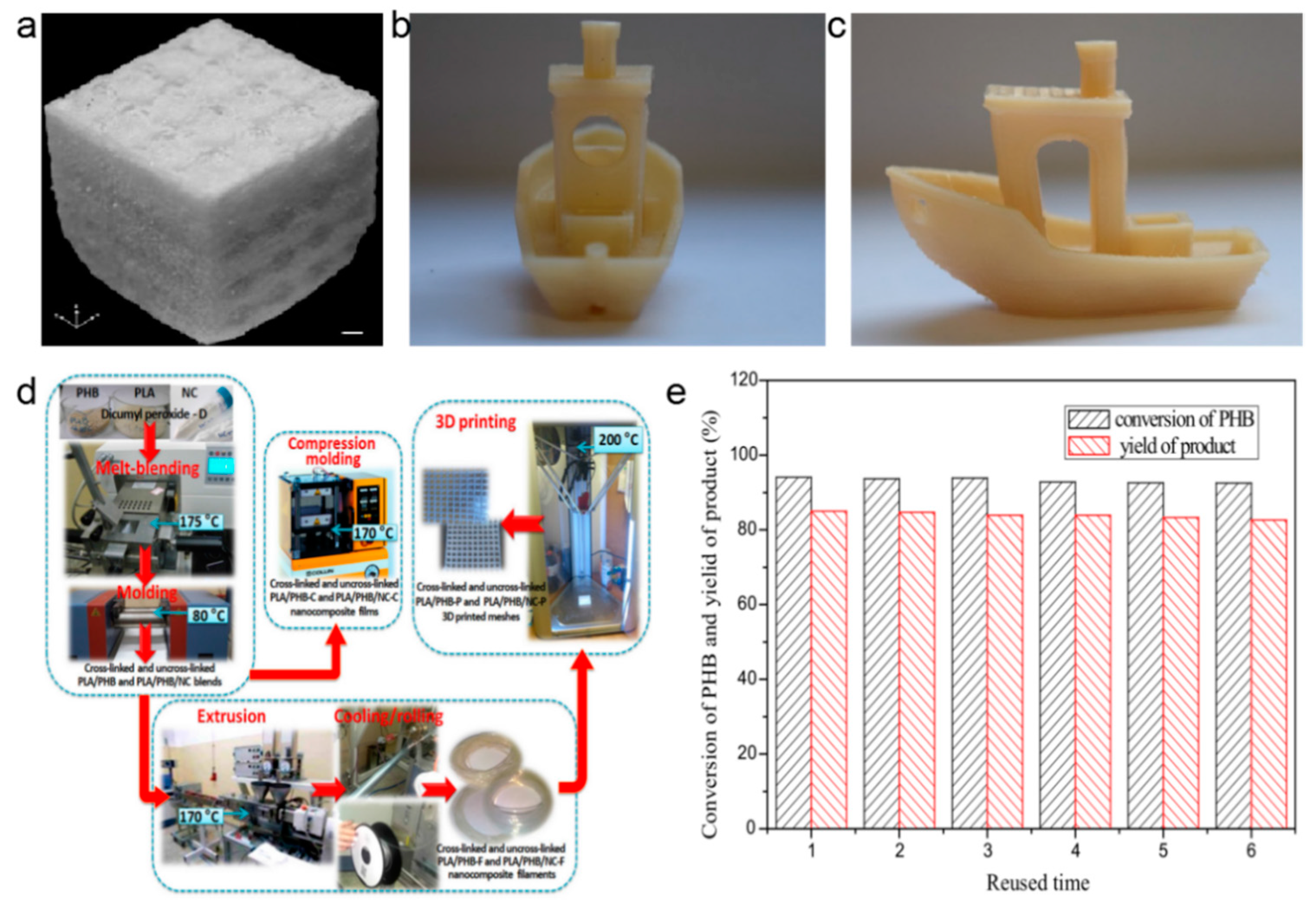

- Frone, A.N.; Batalu, D.; Chiulan, I.; Oprea, M.; Gabor, A.R.; Nicolae, C.A.; Raditoiu, V.; Trusca, R.; Panaitescu, D.M. Morpho-Structural. Thermal and Mechanical Properties of PLA/PHB/Cellulose Biodegradable Nanocomposites Obtained by Compression Molding, Extrusion, and 3D Printing. Nanomaterials 2020, 10, 51. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Liu, F.; Wang, H.; Wang, C.; Yu, S.; Liu, S. Methanolysis of microbial polyester poly(3-hydroxybutyrate) catalyzed by Br0nsted-Lewis acidic ionic liquids as a new method towards sustainable development. Polym. Degrad. Stab. 2018, 147, 215–221. [Google Scholar] [CrossRef]

- Song, X.; Wang, H.; Wang, C.; Liu, F.; Yu, S.; Liu, S.; Song, Z. Chemical Recycling of Bio-based Poly(3-hydroxybutyrate) Wastes Under Methanolysis Condition Catalyzed by Fe-Containing Magnetic Ionic Liquid. J. Polym. Environ. 2019, 27, 862–870. [Google Scholar] [CrossRef]

- Yan, D.; Xin, J.; Zhao, Q.; Gao, K.; Lu, X.; Wang, G.; Zhang, S. Fe-Zr-O catalyzed base-free aerobic oxidation of 5-HMF to 2,5-FDCA as a bio-based polyester monomer. Catal. Sci. Technol. 2018, 8, 164–175. [Google Scholar] [CrossRef]

- Liu, B.; Lu, X.; Ju, Z.; Sun, P.; Xin, J.; Yao, X.; Zhao, Q.; Zhang, S. Ultrafast homogeneous glycolysis of waste polyethylene terephthalate via a dissolution-degradation strategy. Ind. Eng. Chem. Res. 2018, 57, 16239–16245. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, X.; Yao, H.; Zhou, Q.; Xin, J.; Lu, X.; Zhang, S. Degradation of poly(ethylene terephthalate) catalyzed by metal-free choline-based ionic liquids. Green Chem. 2020, 22, 3122–3133. [Google Scholar] [CrossRef]

- Hou, D.; Xin, J.; Lu, X.; Gou, X.; Dong, H.; Ren, B.; Zhang, S. Conversion of bis(2-hydroxyethylene terephthalate) into 1,4-cyclohexanedimethanol by selective hydrogenation using RuPtSn/Al2O3. RSC Adv. 2016, 6, 48737–48744. [Google Scholar] [CrossRef]

- Guo, X.; Xin, J.; Lu, X.; Ren, B.; Zhang, S. Preparation of 1,4-cyclohexanedimethanol by selective hydrogenation of a waste PET monomer bis(2-hydroxyethylene terephthalate). RSC Adv. 2015, 5, 485–492. [Google Scholar] [CrossRef]

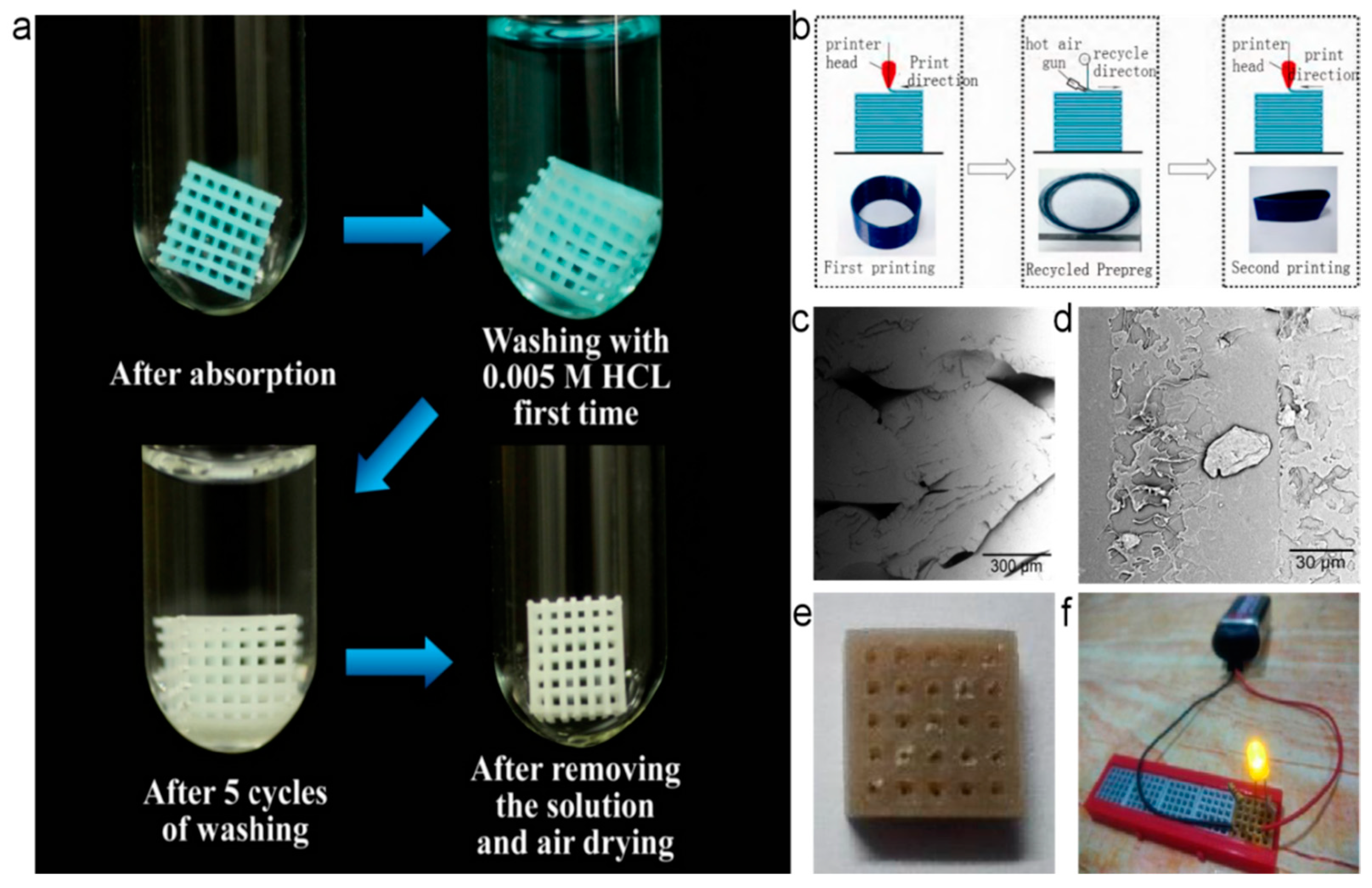

- Wang, Z.; Wang, J.; Li, M.; Sun, K.; Liu, C. Three-dimensional Printed Acrylonitrile Butadiene Styrene Framework Coated with Cu-BTC Metal-organic Frameworks for the Removal of Methylene Blue. Sci. Rep. 2014, 4, 5939. [Google Scholar] [CrossRef]

- Exconde, M.K.J.E.; Co, J.A.A.; Manapat, J.Z.; Magdaluyo, E.R. Materials Selection of 3D Printing Filament and Utilization of Recycled Polyethylene Terephthalate (PET) in a Redesigned Breadboard. Procedia CIRP 2019, 84, 28–32. [Google Scholar] [CrossRef]

- Liu, T.; Tian, X.; Zhu, W.; Li, D. Mechanism and Performance of 3D Printing and Recycling for Continuous Carbon Fiber Reinforced PLA Composites. J. Mech. Eng. 2019, 55, 128–134. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled Poly (Lactic Acid)-based 3D Printed Sustainable Biocomposites: A Comparative Study with Injection Molding. Mater. Today Sustain. 2019, 7–8, 100027. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [Green Version]

- Isabelle, A. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

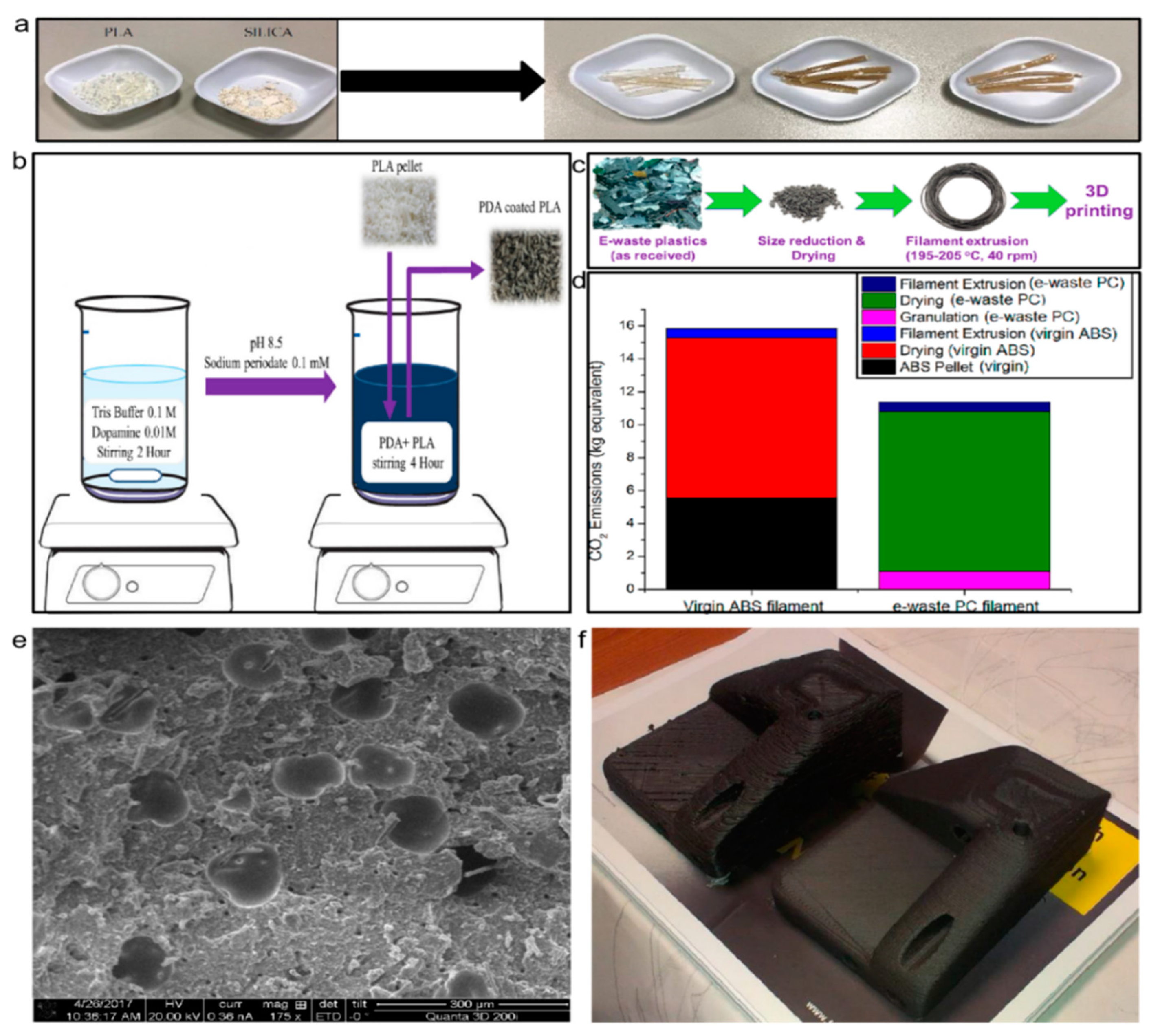

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Zhao, X.; Hwang, K.; Lee, D.; Kim, T.; Kim, N. Enhanced mechanical properties of self-polymerized polydopamine-coated recycled PLA filament used in 3D printing. J. Appl. Surf. Sci. 2018, 441, 381–387. [Google Scholar] [CrossRef]

- Kováčová, M.; Kozakovičová, J.; Procházka, M.; Janigová, I.; Vysopal, M.; Černičková, I.; Krajčovič, J.; Špitalský, Z. Novel Hybrid PETG Composites for 3D Printing. Appl. Sci. 2020, 10, 3062. [Google Scholar] [CrossRef]

- Mägi, P.; Krumme, A.; Pohlak, M. Recycling of PA-12 in Additive Manufacturing and the Improvement of its Mechanical Properties. Key Eng. Mater. 2016, 674, 9–14. [Google Scholar] [CrossRef]

- Gaikwad, V.; Ghose, A.; Cholake, S.; Rawal, A.; Iwato, M.; Sahajwalla, V. Transformation of E-Waste Plastics into Sustainable Filaments for 3D Printing. ACS Sustain. Chem. Eng. 2018, 6, 14432–14440. [Google Scholar] [CrossRef]

| Advantages | Describe |

|---|---|

| Manufacturing complex items without increasing costs | In traditional manufacturing, the more complex the shape of the object, the more expensive it is to manufacture. For 3D printers, the cost of manufacturing complex-shaped objects does not increase. Making a gorgeous complex-shaped object does not consume more time, skill, or cost than printing a simple cube. |

| Product diversity | A 3D printer can print many shapes. Traditional manufacturing equipment has fewer features and makes a limited variety of shapes. |

| Human resource | A 3D printer requires only different digital design blueprints and a new batch of raw materials and do not need specialized staff. |

| No assembly required | 3D printing enables parts to be molded in an integrated manner. Traditional mass production is based on assembly lines, and in modern factories, machines produce identical parts and then are assembled by robots or workers (even across continents). |

| Deliver immediately | 3D printers can print on demand. Just-in-time production reduces a company’s inventory, and companies can use 3D printers to create special or customized products to meet customer needs based on customer orders. |

| Small footprint, easy to carry | In terms of manufacturing space per unit, 3D printers have greater manufacturing capabilities than traditional manufacturing machines. The machine can move freely, which makes them suitable for home or office use. |

| Infinite combinations of materials | Traditional manufacturing machines cannot easily fuse multiple raw materials during the cutting or mold forming process, but 3D printing can do it. |

| Methods | Processing | Material Requirements |

|---|---|---|

| SLA | Cure the polymer by light. | Viscosity, flexibility, moisture resistance, and fracture energy of the material after molding. |

| LOM | Laminate the material and cut the sheet. | Need to have high heat resistance, high hardness, mechanical properties, etc. |

| FDM | Melt the material in the apparatus and spray the melt. | Viscosity and melting point. |

| SLS | Sinter the powder, layer by layer, to form the products. | Need powder material. |

| 3DP | Bond the sprayed powder. | Gypsum. |

| Material | Material Requirements | Advantages | Disadvantages |

|---|---|---|---|

| 1. ABS 2. PLA 3. PCL 4. PA 5. PC, etc. | Good processing performance; material performance should be suitable for the occasions. | A wide range of products | More expensive, some other properties are sacrificed to ensure processing performance [24] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Li, T.; Mohideen, M.M.; Hu, P.; Gupta, R.; Ramakrishna, S.; Liu, Y. Realization of Circular Economy of 3D Printed Plastics: A Review. Polymers 2021, 13, 744. https://doi.org/10.3390/polym13050744

Zhu C, Li T, Mohideen MM, Hu P, Gupta R, Ramakrishna S, Liu Y. Realization of Circular Economy of 3D Printed Plastics: A Review. Polymers. 2021; 13(5):744. https://doi.org/10.3390/polym13050744

Chicago/Turabian StyleZhu, Caihan, Tianya Li, Mohamedazeem M. Mohideen, Ping Hu, Ramesh Gupta, Seeram Ramakrishna, and Yong Liu. 2021. "Realization of Circular Economy of 3D Printed Plastics: A Review" Polymers 13, no. 5: 744. https://doi.org/10.3390/polym13050744

APA StyleZhu, C., Li, T., Mohideen, M. M., Hu, P., Gupta, R., Ramakrishna, S., & Liu, Y. (2021). Realization of Circular Economy of 3D Printed Plastics: A Review. Polymers, 13(5), 744. https://doi.org/10.3390/polym13050744