A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites

Abstract

1. Introduction

2. Natural Fibres

2.1. Natural Fibre Polymer Composite (NFPC)

2.2. Woven Natural Fibre Reinforced Polymer Composite

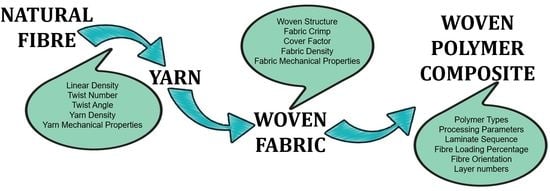

3. Factors Influencing Woven Polymer Composites Properties

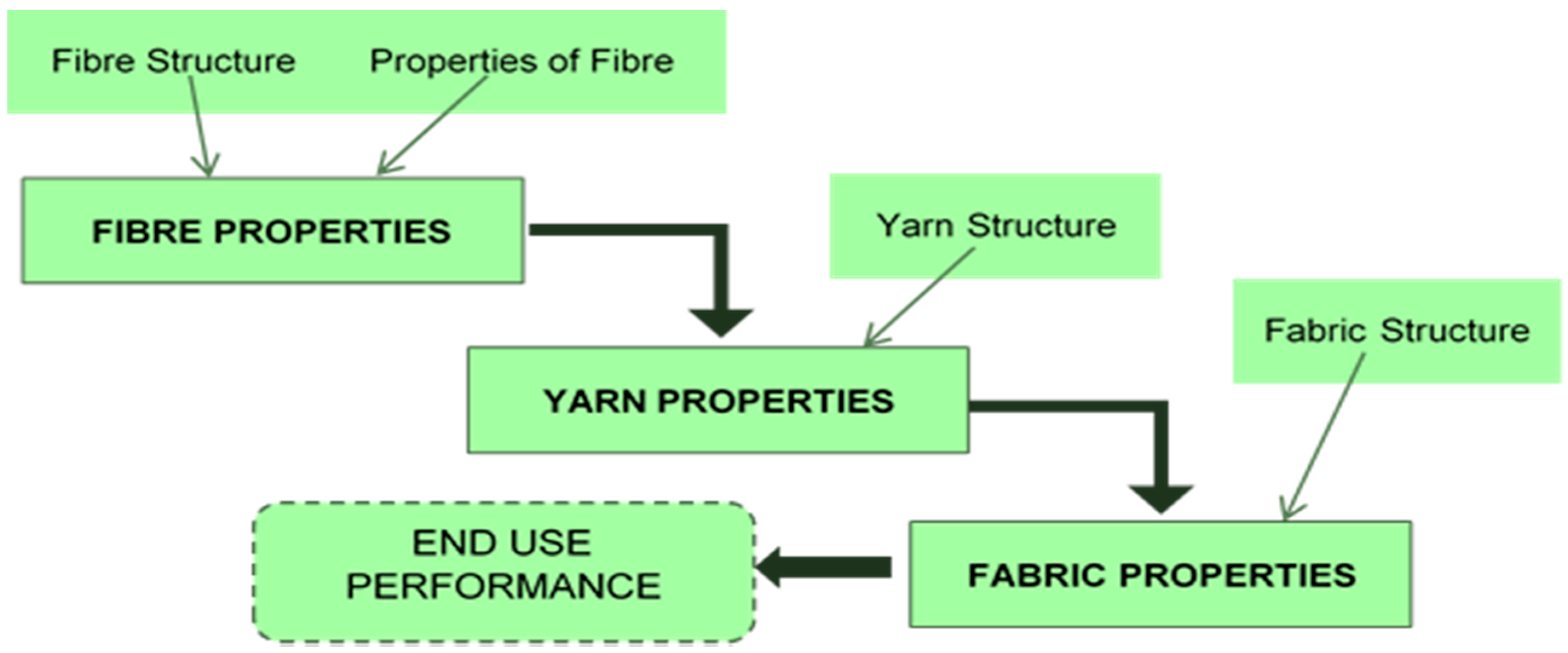

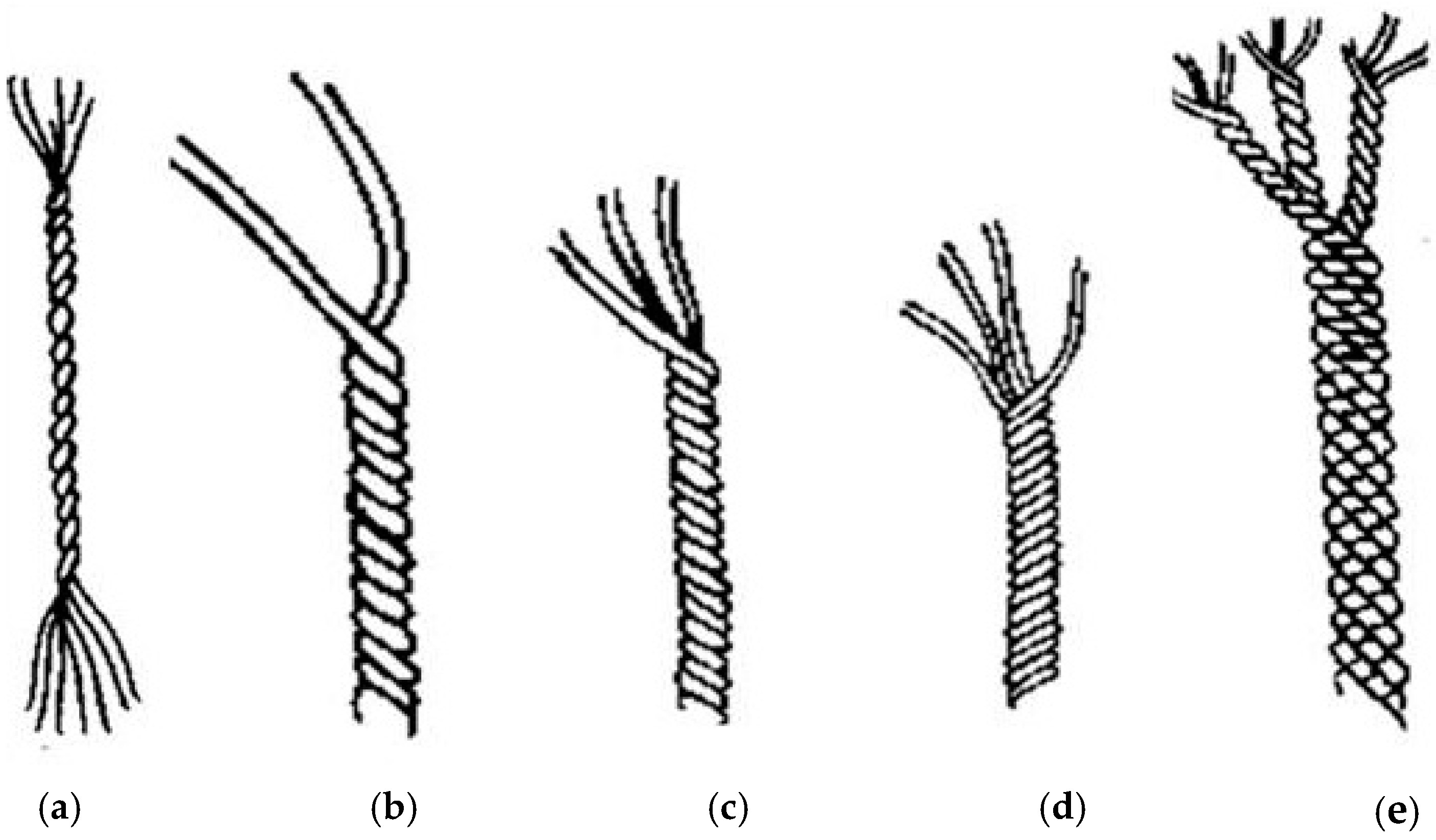

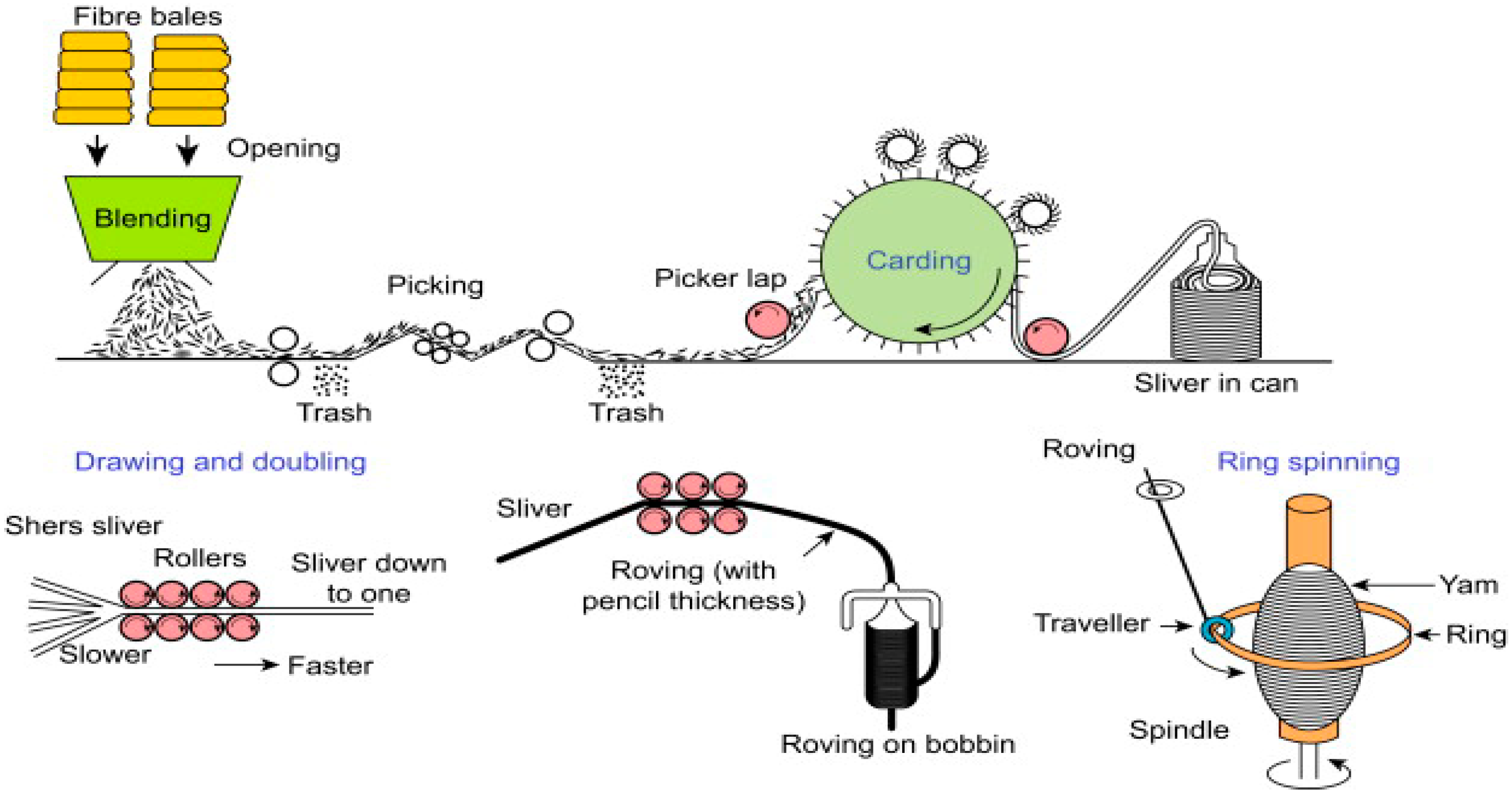

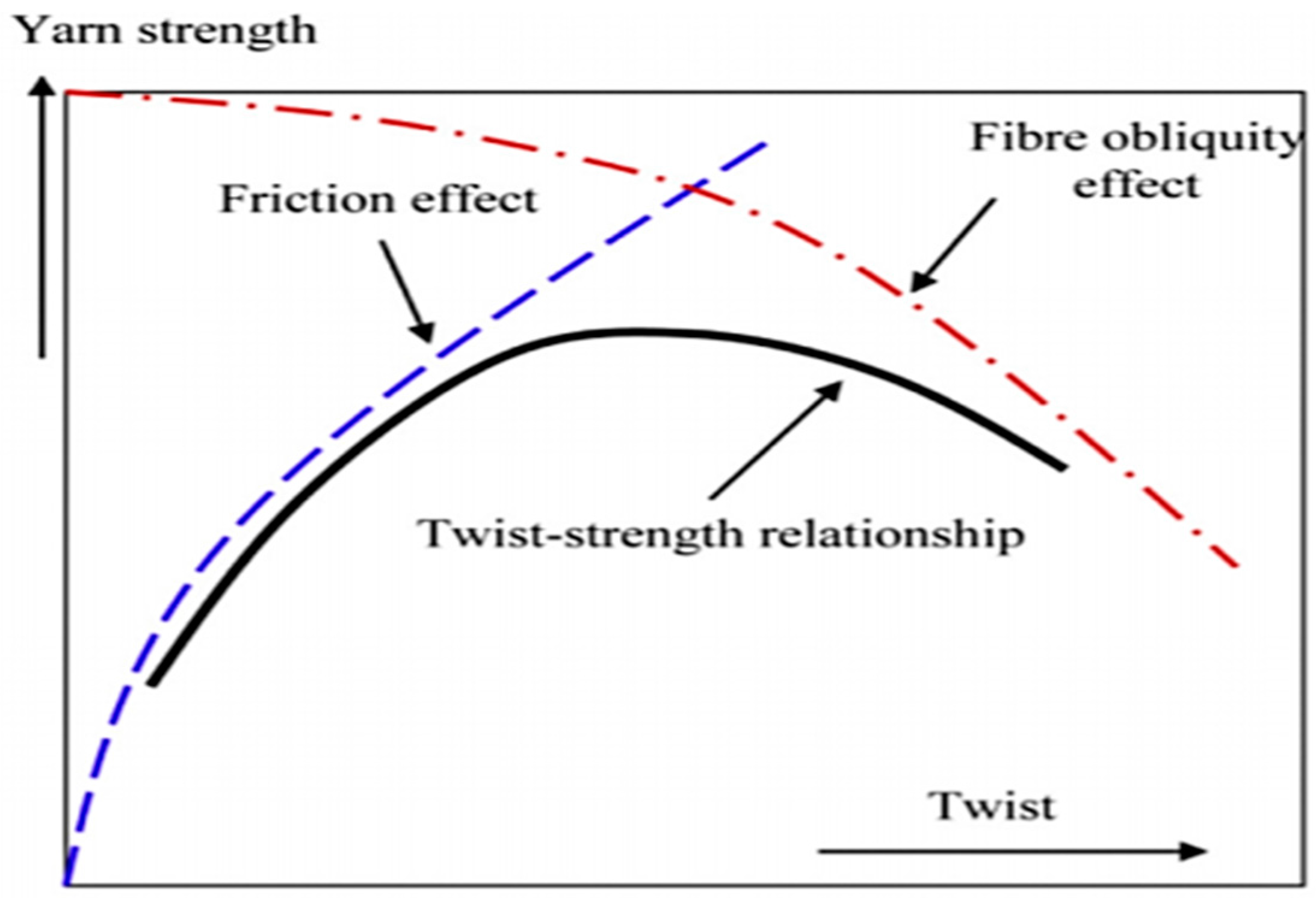

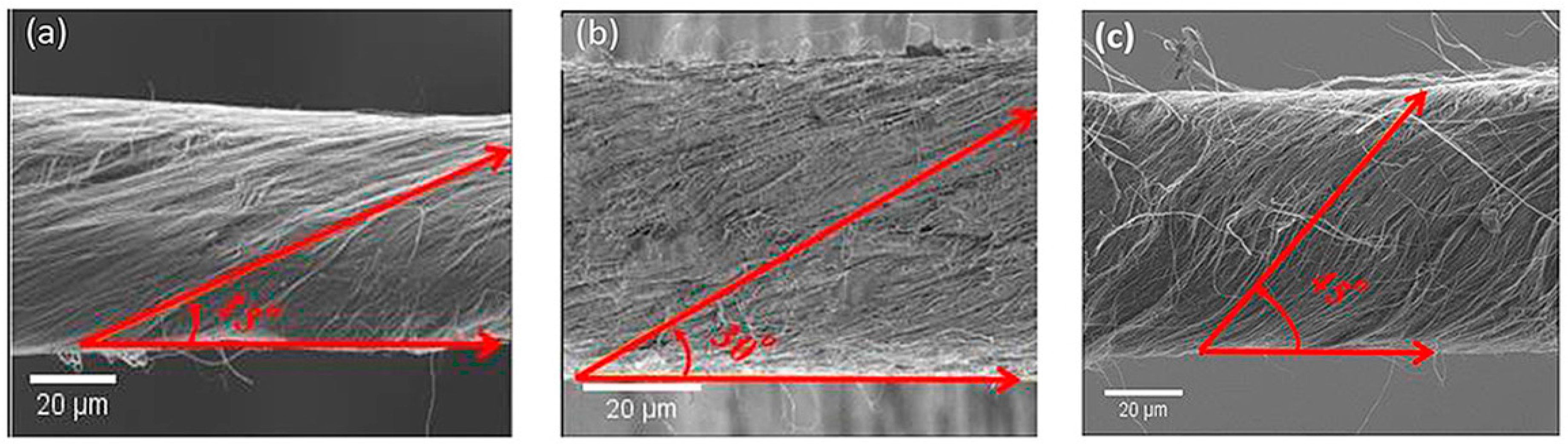

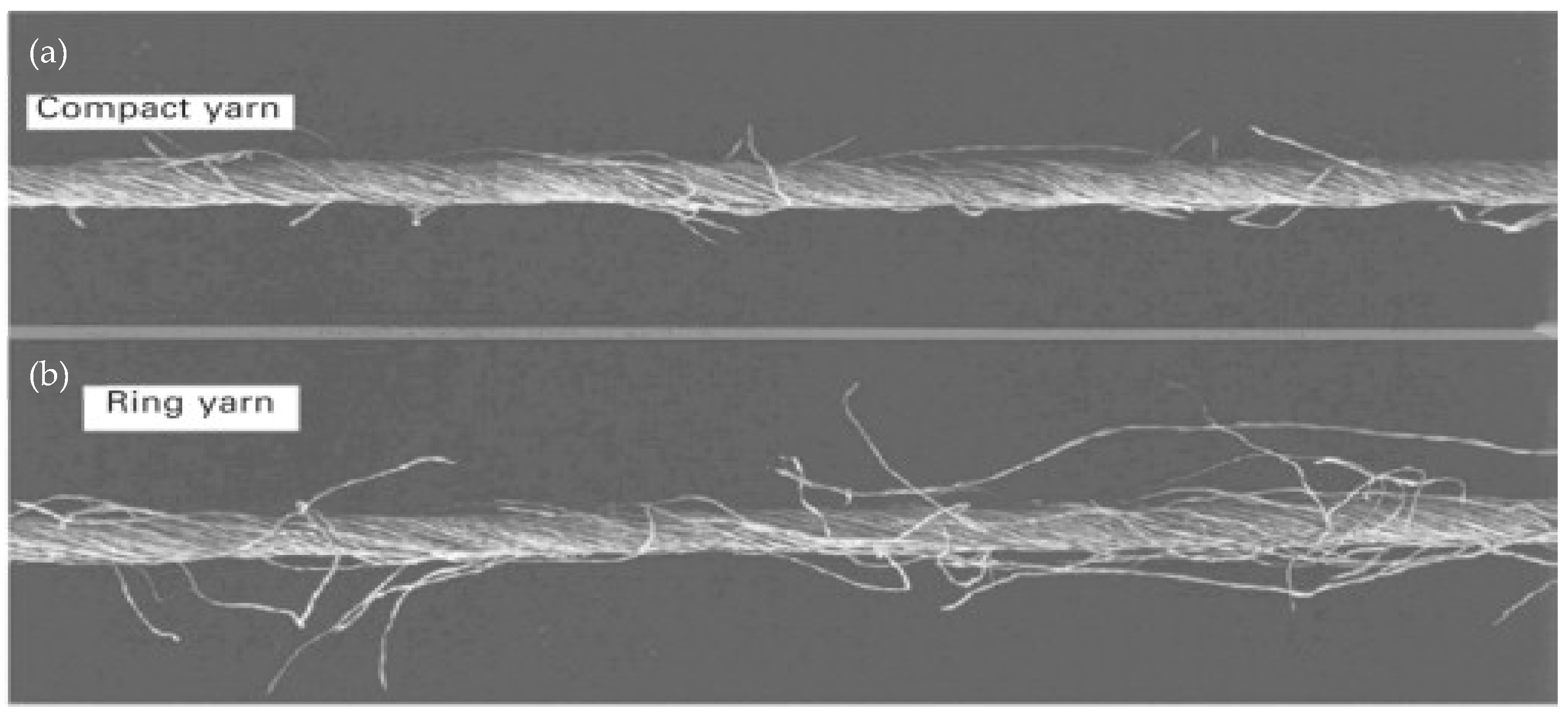

3.1. Yarn Properties

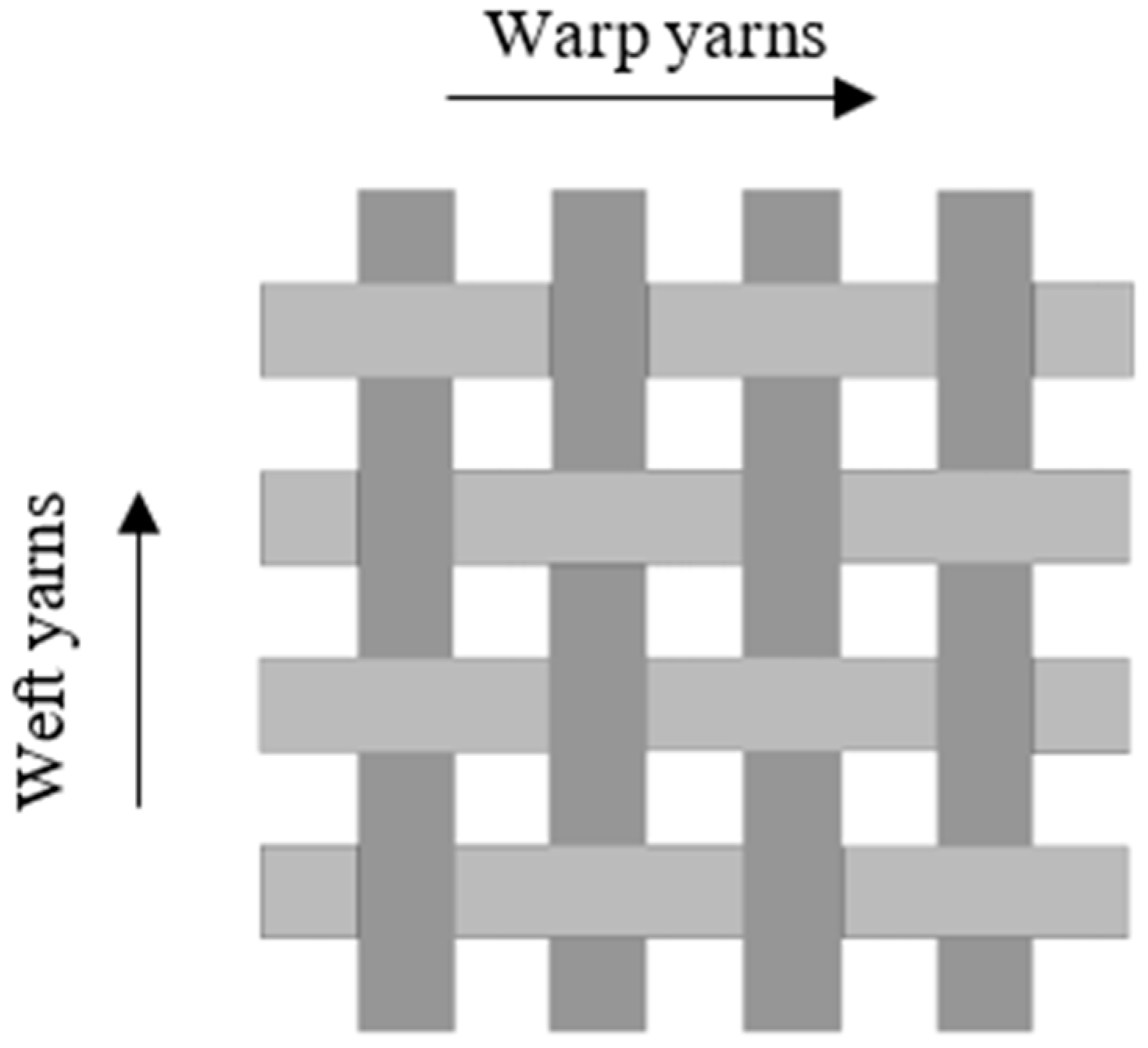

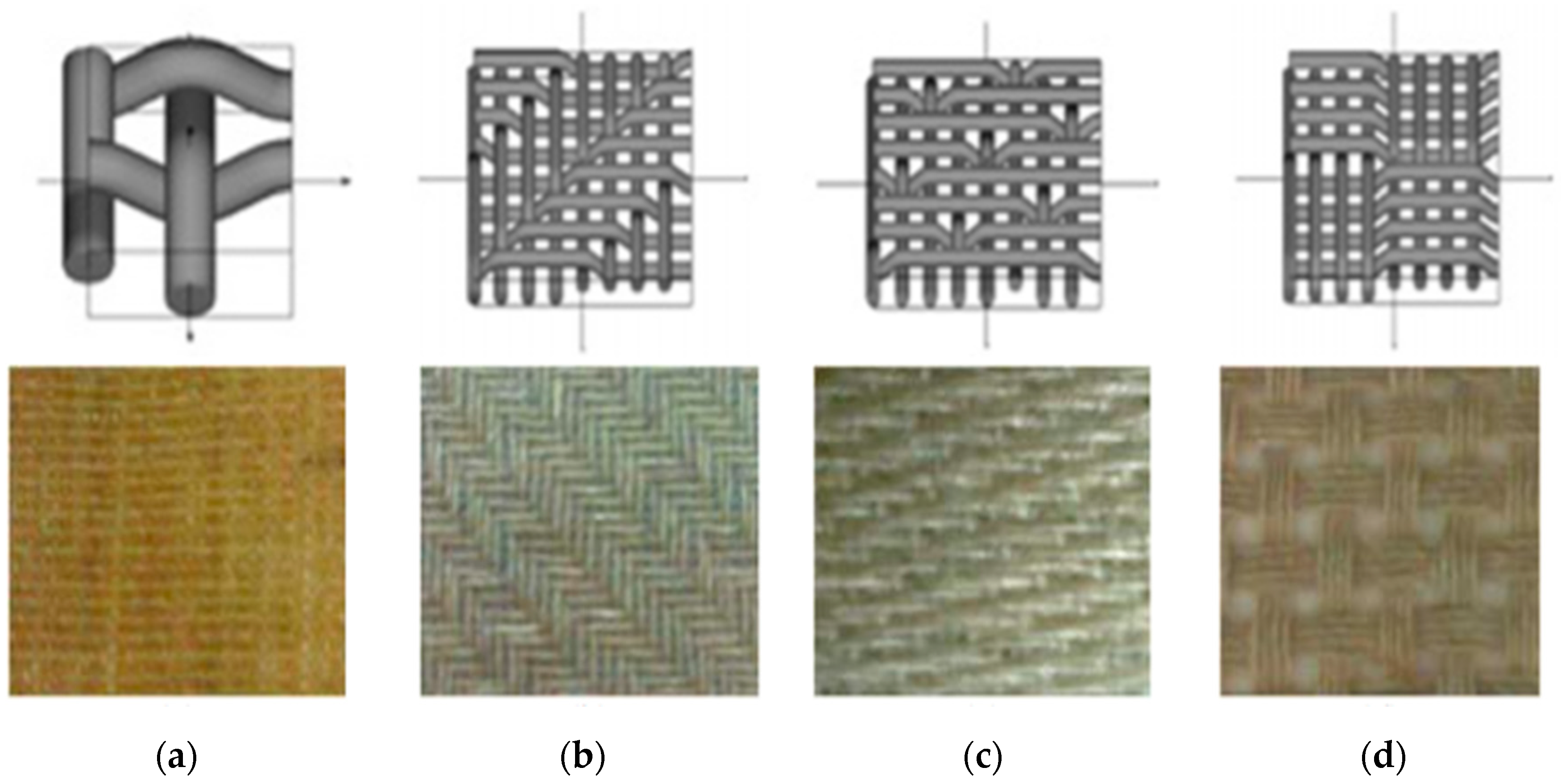

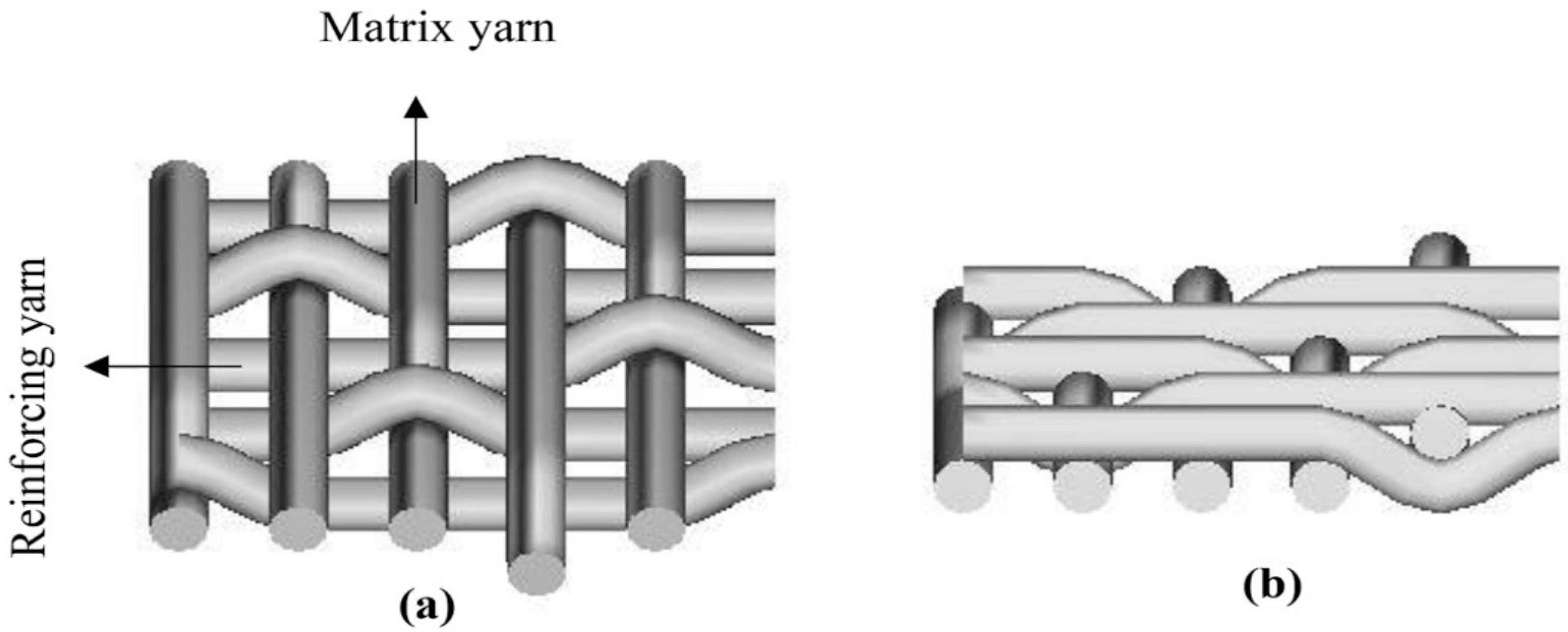

3.2. Fabric Properties

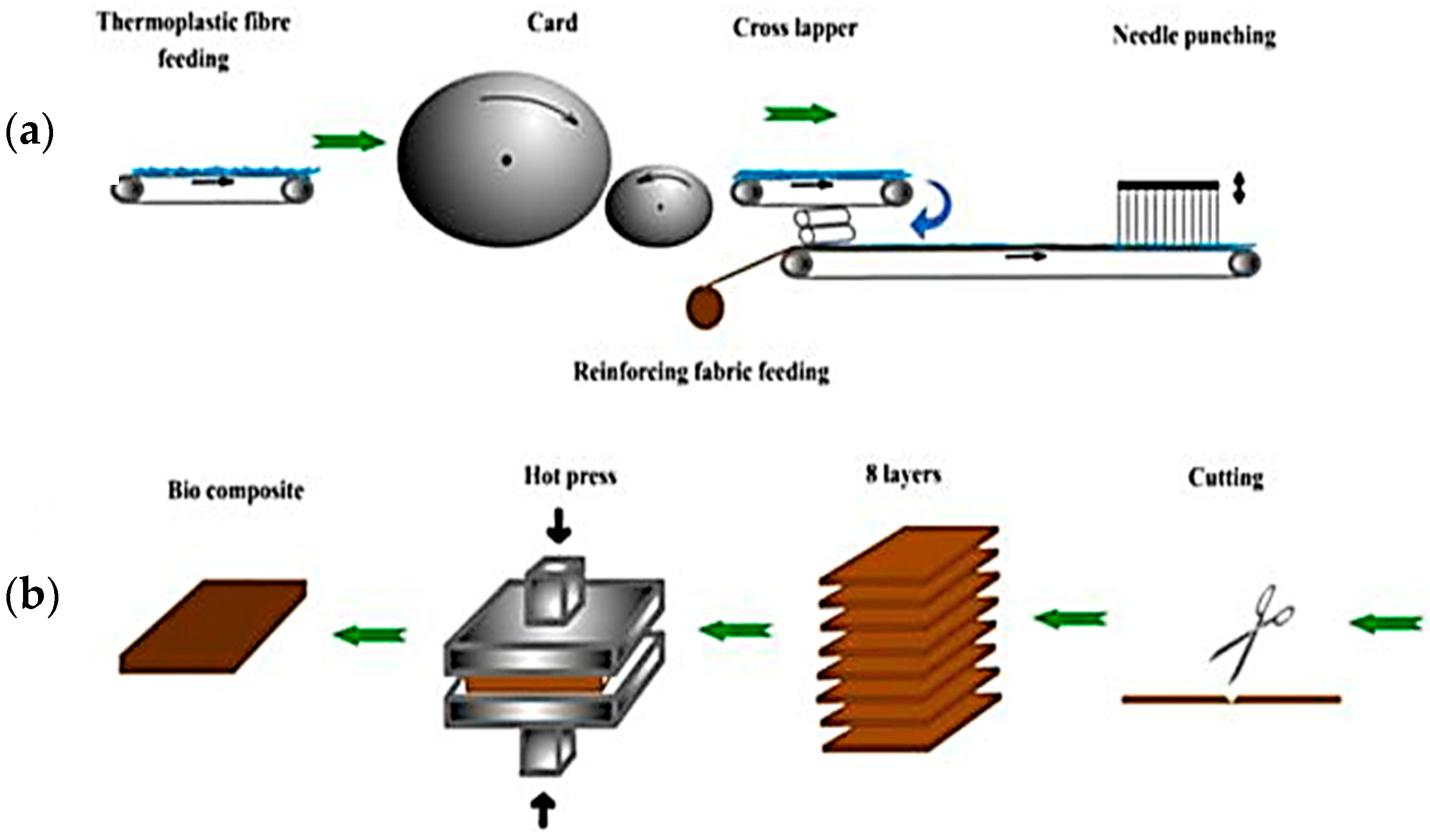

3.3. Composites and Manufacturing Parameters

4. Properties of Woven Natural Fibre Polymer Composites

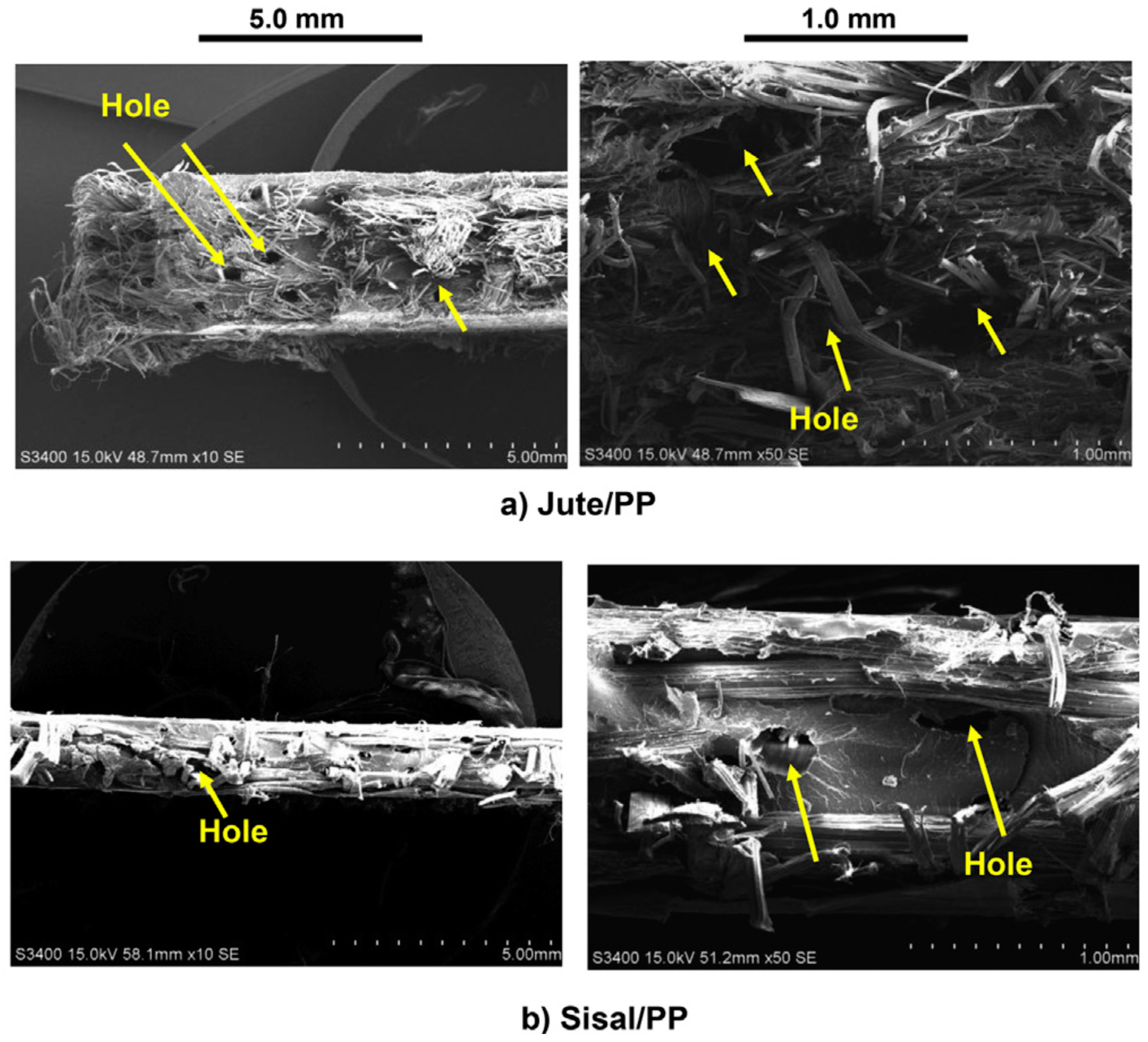

4.1. Woven Polymer Polypropylene (PP) Composites

4.2. Woven Polymer Polylacticacid (PLA) Composites

4.3. Woven Polymer Epoxy Composites

4.4. Woven Polymer Polyester (PE) Composites

5. Applications of Woven Natural Fibre Polymer Composites

6. Challenges and Future Perspective on Woven Natural Fibre Composites

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Atikah, M.S.N.; Ibrahim, R.; Dele-Afolabi, T.T.; Hazrol, M.D. Introduction to Biofiller-Reinforced Degradable Polymer Composites. In Biofiller-Reinforced Biodegradable Polymer Composites; Jumaidin, R., Sapuan, S.M., Ismail, H., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 1–23. [Google Scholar]

- Sari, N.H.; Pruncu, C.I.; Sapuan, S.M.; Ilyas, R.A.; Catur, A.D.; Suteja, S.; Sutaryono, Y.A.; Pullen, G. The effect of water immersion and fibre content on properties of corn husk fibres reinforced thermoset polyester composite. Polym. Test. 2020, 91, 106751. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical properties of longitudinal basalt/woven-glass-fiber-reinforced unsaturated polyester-resin hybrid composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M. The Preparation Methods and Processing of Natural Fibre Bio-polymer Composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M. Biopolymers and Biocomposites: Chemistry and Technology. Curr. Anal. Chem. 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Shaw, A.; Sriramula, S.; Gosling, P.D.; Chryssanthopoulos, M.K. A critical reliability evaluation of fibre reinforced composite materials based on probabilistic micro and macro-mechanical analysis. Compos. Part B Eng. 2010, 41, 446–453. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Dele-afolabi, T.T.; Hanim, M.A.A.; Calin, R.; Ilyas, R.A. Microelectronics Reliability Microstructure evolution and hardness of MWCNT-reinforced Sn-5Sb/Cu composite solder joints under different thermal aging conditions. Microelectron. Reliab. 2020, 110, 113681. [Google Scholar] [CrossRef]

- Ilie, N.; Hickel, R. Macro-, micro- and nano-mechanical investigations on silorane and methacrylate-based composites. Dent. Mater. 2009, 25, 810–819. [Google Scholar] [CrossRef]

- Atikah, M.S.N.; Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Ibrahim, R.; Atiqah, A.; Ansari, M.N.M.; Jumaidin, R. Degradation and physical properties of sugar palm starch/sugar palm nanofibrillated cellulose bionanocomposite. Polimery 2019, 64, 680–689. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial activities of starch-based biopolymers and biocomposites incorporated with plant essential oils: A review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef]

- Syafri, E.; Sudirman; Mashadi; Yulianti, E.; Deswita; Asrofi, M.; Abral, H.; Sapuan, S.M.; Ilyas, R.A.; Fudholi, A. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Abral, H.; Atmajaya, A.; Mahardika, M.; Hafizulhaq, F.; Kadriadi; Handayani, D.; Sapuan, S.M.; Ilyas, R.A. Effect of ultrasonication duration of polyvinyl alcohol (PVA) gel on characterizations of PVA film. J. Mater. Res. Technol. 2020, 9, 2477–2486. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose Reinforced Thermoplastic Starch (TPS), Polylactic Acid (PLA), and Polybutylene Succinate (PBS) for Food Packaging Applications. Front. Chem. 2020, 8, 1–12. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Tahir, P.M.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Khalil HPS, A. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers 2021, 13, 116. [Google Scholar] [CrossRef] [PubMed]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Liu, D.; McDaid, A.; Aw, K.; Xie, S.Q. Position control of an Ionic Polymer Metal Composite actuated rotary joint using Iterative Feedback Tuning. Mechatronics 2011, 21, 315–328. [Google Scholar] [CrossRef]

- Zhao, K.; Xue, S.; Zhang, P.; Tian, Y.; Li, P. Application of Natural Plant Fibers in Cement-Based Composites and the Influence on Mechanical Properties and Mass Transport. Materials 2019, 12, 3498. [Google Scholar] [CrossRef]

- Akubueze, E.U.; Ezeanyanaso, C.S.; Muniru, S.O.; Igwe, C.C.; Nwauzor, G.O.; Ugoh, U.; Nwaze, I.O.; Mafe, O.; Nwaeche, F.C. Reinforcement of Plaster of Paris (POP) for Suspended Ceilings Applications Using Kenaf Bast Fibre. Curr. J. Appl. Sci. Technol. 2019, 1–6. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Kim, Y.K.; Chalivendra, V. Natural fibre composites (NFCs) for construction and automotive industries. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 469–498. ISBN 9780128187821. [Google Scholar]

- Hariprasad, K.; Ravichandran, K.; Jayaseelan, V.; Muthuramalingam, T. Acoustic and mechanical characterisation of polypropylene composites reinforced by natural fibres for automotive applications. J. Mater. Res. Technol. 2020, 9, 14029–14035. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Norizan, M.N.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; Ishak, M.R.; Zainudin, E.S.; Izwan, S.; Azammi, A.M.N.; et al. Potential of natural fibre composites for transport industry: A review. In Proceedings of the Prosiding Seminar Enau Kebangsaan 2019, Bahau, Malaysia, 1 April 2019; pp. 2–11. [Google Scholar]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 1–6. [Google Scholar] [CrossRef]

- Mazani, N.; Sapuan, S.M.; Sanyang, M.L.; Atiqah, A.; Ilyas, R.A. Design and Fabrication of a Shoe Shelf from Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Ariffin, H., Sapuan, S.M., Hassan, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 315–332. ISBN 9780128163542. [Google Scholar]

- Sanyang, M.L.; Ilyas, R.A.; Sapuan, S.M.; Jumaidin, R. Sugar palm starch-based composites for packaging applications. In Bionanocomposites for Packaging Applications; Jawaid, M., Swain, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 125–147. ISBN 9783319673196. [Google Scholar]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Measurement of ballistic impact properties of woven kenaf-aramid hybrid composites. Meas. J. Int. Meas. Confed. 2016, 77, 335–343. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.C.; Nascimento, L.F.C.; da Luz, F.S.; da Silva, L.C.; dos Santos, J.L.; da Costa Garcia Filho, F.; de Assis, F.S.; Lima, É.P.; et al. Natural Fibers Reinforced Polymer Composites Applied in Ballistic Multilayered Armor for Personal Protection—An Overview. In Minerals, Metals and Materials Series; Springer: Berlin/Heidelberg, Germany, 2019; pp. 33–47. ISBN 9783030103828. [Google Scholar]

- Pereira, A.C.; De Assis, F.S.; Filho, F.D.C.G.; Oliveira, M.S.; Demosthenes, L.C.D.C.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance of multilayered armor with intermediate polyester composite reinforced with fique natural fabric and fibers. J. Mater. Res. Technol. 2019, 8, 4221–4226. [Google Scholar] [CrossRef]

- Sharip, N.S.; Yasim-Anuar, T.A.T.; Norrrahim, M.N.F.; Sharip, N.S.; Shazleen, S.S.; Nurazzi, N.M.; Sapuan, S.M.; Ilyas, R.A. A Review on Nanocellulose Composites in Biomedical Application. In Composites in Biomedical Applications; Sapuan, S.M., Nukman, Y., Osman, N.A.A., Ilyas, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 162–189. ISBN 9780367271688. [Google Scholar]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Ilyas, R.A.; Mohd Nurazzi, N. A Review of Biocomposites in Biomedical Application. In Composites in Biomedical Applications; Sapuan, S.M., Nukman, Y., Osman, N.A.A., Ilyas, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 31–48. ISBN 9780367271688. [Google Scholar]

- Morris, R.H.; Geraldi, N.R.; Stafford, J.L.; Spicer, A.; Hall, J.; Bradley, C.; Newton, M.I. Woven Natural Fibre Reinforced Composite Materials for Medical Imaging. Materials 2020, 13, 1684. [Google Scholar] [CrossRef] [PubMed]

- Jumaidin, R.; Khiruddin, M.A.A.; Asyul Sutan Saidi, Z.; Salit, M.S.; Ilyas, R.A. Effect of cogon grass fibre on the thermal, mechanical and biodegradation properties of thermoplastic cassava starch biocomposite. Int. J. Biol. Macromol. 2020, 146, 746–755. [Google Scholar] [CrossRef]

- Jumaidin, R.; Saidi, Z.A.S.; Ilyas, R.A.; Ahmad, M.N.; Wahid, M.K.; Yaakob, M.Y.; Maidin, N.A.; Rahman, M.H.A.; Osman, M.H. Characteristics of Cogon Grass Fibre Reinforced Thermoplastic Cassava Starch Biocomposite: Water Absorption and Physical Properties. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 62, 43–52. [Google Scholar]

- Jumaidin, R.; Ilyas, R.A.; Saiful, M.; Hussin, F.; Mastura, M.T. Water Transport and Physical Properties of Sugarcane Bagasse Fibre Reinforced Thermoplastic Potato Starch Biocomposite. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 61, 273–281. [Google Scholar]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 1–14. [Google Scholar] [CrossRef]

- Mohamad, N.; Abd-Talib, N.; Kelly Yong, T.-L. Furfural production from oil palm frond (OPF) under subcritical ethanol conditions. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Kumar, T.S.M.; Chandrasekar, M.; Senthilkumar, K.; Ilyas, R.A.; Sapuan, S.M.; Hariram, N.; Rajulu, A.V.; Rajini, N.; Siengchin, S. Characterization, Thermal and Antimicrobial Properties of Hybrid Cellulose Nanocomposite Films with in-Situ Generated Copper Nanoparticles in Tamarindus indica Nut Powder. J. Polym. Environ. 2020, 1–10. [Google Scholar] [CrossRef]

- Lee, S.H.; Zaidon, A.; Rasdianah, D.; Lum, W.C.; Aisyah, H.A. Alteration in colour and fungal resistance of thermally treated oil palm trunk and rubberwood particleboard using palm oil. J. Oil Palm Res. 2020. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. eXPRESS Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- De Aguiar, J.; Bondancia, T.J.; Claro, P.I.C.; Mattoso, L.H.C.; Farinas, C.S.; Marconcini, J.M. Enzymatic deconstruction of sugarcane bagasse and straw to obtain cellulose nanomaterials. ACS Sustain. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N.; Mohd Nurazzi, N.; Atiqah, A.; Ansari, M.N.M.; et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Hazrol, M.D.; Sapuan, S.M.; Ilyas, R.A.; Othman, M.L.; Sherwani, S.F.K. Electrical properties of sugar palm nanocrystalline cellulose reinforced sugar palm starch nanocomposites. Polimery 2020, 65, 363–370. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Water transport properties of bio-nanocomposites reinforced by sugar palm (arenga pinnata) nanofibrillated cellulose. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 51, 234–246. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atiqah, A.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Nurazzi, N.M.; Atikah, M.S.N.; Ansari, M.N.M.; et al. Sugar palm (Arenga pinnata [Wurmb.] Merr) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym. Compos. 2020, 41, 459–467. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atiqah, A.; Atikah, M.S.N.; Syafri, E.; Asrofi, M.; et al. Thermal, Biodegradability and Water Barrier Properties of Bio-Nanocomposites Based on Plasticised Sugar Palm Starch and Nanofibrillated Celluloses from Sugar Palm Fibres. J. Biobased Mater. Bioenergy 2020, 14, 234–248. [Google Scholar] [CrossRef]

- Asrofi, M.; Sujito; Syafri, E.; Sapuan, S.M.; Ilyas, R.A. Improvement of Biocomposite Properties Based Tapioca Starch and Sugarcane Bagasse Cellulose Nanofibers. Key Eng. Mater. 2020, 849, 96–101. [Google Scholar] [CrossRef]

- Asrofi, M.; Sapuan, S.M.; Ilyas, R.A.; Ramesh, M. Characteristic of composite bioplastics from tapioca starch and sugarcane bagasse fiber: Effect of time duration of ultrasonication (Bath-Type). Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S. Exploring the applicability of natural fibers for the development of biocomposites. Express Polym. Lett. 2021, 15, 193. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Rafiqah, S.A.; Aisyah, H.A.; Nurazzi, N.M.; Norrrahim, M.N.F. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2021, 91, 152–167. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Effect of delignification on the physical, thermal, chemical, and structural properties of sugar palm fibre. BioResources 2017, 12, 8734–8754. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Bodros, E.; Baley, C. Study of the tensile properties of stinging nettle fibres (Urtica dioica). Mater. Lett. 2008, 62, 2143–2145. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers-An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part 1—Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Bourmaud, A.; Le Duigou, A.; Biocomposites, C.B. Mechanical performance of flax-based biocomposites. In Biocomposites, Design and Mechanical Performance; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Faruk, O.; Bledzki, A.; Fink, H.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. In Progress in Polymer Science; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Chattopadhyay, S.K.; Singh, S.; Pramanik, N.; Niyogi, U.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Biodegradability studies on natural fibers reinforced polypropylene composites. J. Appl. Polym. Sci. 2011, 121, 2226–2232. [Google Scholar] [CrossRef]

- Everitt, N.M.; Aboulkhair, N.T.; Clifford, M.J. Looking for Links between Natural Fibres’ Structures and Their Physical Properties. Conf. Pap. Mater. Sci. 2013, 2013, 141204. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H.; Liu, M. A Comprehensive Review on Bast Fibre Retting Process for Optimal Performance in Fibre-Reinforced Polymer Composites. Adv. Mater. Sci. Eng. 2020, 2020, 6074063. [Google Scholar] [CrossRef]

- Bennett, S.J.; Snell, R.; Wright, D. Effect of variety, seed rate and time of cutting on fibre yield of dew-retted hemp. Ind. Crops Prod. 2006, 24, 79–86. [Google Scholar] [CrossRef]

- Viel, Q.; Esposito, A.; Saiter, J.-M.; Santulli, C.; Turner, J. Interfacial Characterization by Pull-Out Test of Bamboo Fibers Embedded in Poly(Lactic Acid). Fibers 2018, 6, 7. [Google Scholar] [CrossRef]

- Panigrahi, S.; Kushwaha, R.L.; Rahman, A. Impact of fibre diameter on mechanical properties of flax based composite. In Proceedings of the 2012 ASABE Annual International Meeting, Dallas, TX, USA, 29 July–1 August 2012. [Google Scholar]

- Abdul Khalil, H.P.S.P.S.; Yusra, A.F.I.F.I.; Bhat, A.H.H.; Jawaid, M. Cell wall ultrastructure, anatomy, lignin distribution, and chemical composition of Malaysian cultivated kenaf fiber. Ind. Crops Prod. 2010, 31, 113–121. [Google Scholar] [CrossRef]

- Lee, C.H.; Sapuan, S.M.; Hassan, M.R. Mechanical and thermal properties of kenaf fiber reinforced polypropylene/magnesium hydroxide composites. J. Eng. Fiber. Fabr. 2017, 12, 50–58. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.A.; Ponnamma, D.; El-Samak, A.A. Polymers to Improve the World and Lifestyle: Physical, Mechanical, and Chemical Needs. In Polymer Science and Innovative Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–19. [Google Scholar]

- Ahmed, K.S.; Vijayarangan, S.; Kumar, A. Low velocity impact damage characterization of woven jute-glass fabric reinforced isothalic polyester hybrid composites. J. Reinf. Plast. Compos. 2007, 26, 959–976. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Dhakal, H.N. Green-composites: Ecofriendly and Sustainability. Appl. Sci. Eng. Prog. 2020, 13. [Google Scholar] [CrossRef]

- Liu, Q.; Hughes, M. The fracture behaviour and toughness of woven flax fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1644–1652. [Google Scholar] [CrossRef]

- Rashid, A.H.A.; Ahmad, R.; Jaafar, M.; Roslan, M.N.; Ariffin, S. Mechanical properties evaluation of woven coir and kevlar reinforced epoxy composites. Adv. Mater. Res. 2011, 277, 36–42. [Google Scholar] [CrossRef]

- Me, R.C.; Cipta, A.; Ibrahim, R.; Tahir, P.M. Natural based biocomposite material for prosthetic socket fabrication. Alam Cipta 2012, 5, 27–34. [Google Scholar]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and thermal behavior of woven hemp fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Wahab, M.; Rejab, M.; Saiman, M.P. Analysis of mechanical properties for 2D woven kenaf composite. In Applied Mechanics and Materials; Trans Tech Publication: Freienbach, Switzerland, 2014. [Google Scholar] [CrossRef]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: Effect of woven fabric and random orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Characterization of thermoplastic natural fibre composites made from woven hybrid yarn prepregs with different weave pattern. Compos. Part A Appl. Sci. Manuf. 2015, 76, 154–161. [Google Scholar] [CrossRef]

- Monteiro, S.; Milanezi, T.; Louro, L.; Lima, É.P., Jr.; Braga, F.O.; Gomes, A.V.; Drelich, J.W. Novel ballistic ramie fabric composite competing with KevlarTM fabric in multilayered armor. Mater. Des. 2016, 96, 263–269. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf–aramid hybrid laminated composites. Mater. Des. 2015, 67, 173–179. [Google Scholar] [CrossRef]

- Abdellaoui, H.; Bensalah, H.; Echaabi, J.; Bouhfid, R.; Qaiss, A. Fabrication, characterization and modelling of laminated composites based on woven jute fibres reinforced epoxy resin. Mater. Des. 2015, 68, 104–113. [Google Scholar] [CrossRef]

- Salman, S.D.; Sharba, M.J.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Cardona, F. Physical, Mechanical, and Morphological Properties of Woven Kenaf/Polymer Composites Produced Using a Vacuum Infusion Technique. Int. J. Polym. Sci. 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Khan, G.M.A.; Terano, M.; Gafur, M.A.; Alam, M.S. Studies on the mechanical properties of woven jute fabric reinforced poly(L-lactic acid) composites. J. King Saud Univ. Eng. Sci. 2016, 28, 69–74. [Google Scholar] [CrossRef]

- Sivakumar, D.; Ng, L.F.; Lau, S.M.; Lim, K.T. Fatigue Life Behaviour of Glass/Kenaf Woven-Ply Polymer Hybrid Biocomposites. J. Polym. Environ. 2018, 26, 499–507. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Khalina, A.; Sapuan, S.M.; Wahab, M.S.; Berkalp, O.B.; Lee, C.H.; Lee, S.H. Effects of Fabric Counts and Weave Designs on the Properties of Laminated Woven Kenaf/Carbon Fibre Reinforced Epoxy Hybrid Composites. Polymers 2018, 10, 1320. [Google Scholar] [CrossRef] [PubMed]

- Kandola, B.K.; Mistik, S.I.; Pornwannachai, W.; Anand, S.C. Natural fibre-reinforced thermoplastic composites from woven-nonwoven textile preforms: Mechanical and fire performance study. Compos. Part B Eng. 2018, 153, 456–464. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.Q.N.; Teo, W.S.; Tay, T.E.; Lee, H.P. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S.; et al. Thermal Properties of Woven Kenaf/Carbon Fibre-Reinforced Epoxy Hybrid Composite Panels. Int. J. Polym. Sci. 2019, 2019, 1–8. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Pac, M.J.; Ayad, R. Mode-I interlaminar fracture toughness of flax, glass and hybrid flax-glass fibre woven composites: Failure mechanism evaluation using acoustic emission analysis. Polym. Test. 2019, 75, 246–253. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Yaakob, M.Y.; Husin, M.A.; Abdullah, A.; Mohamed, K.A.; Khim, A.S.; Chuok Fang, M.L.; Sihombing, H. Effect of Stitching Patterns on Tensile Strength of Kenaf Woven Fabric Composites. Int. J. Integr. Eng. 2019, 11, 70–79. [Google Scholar] [CrossRef]

- Mohamad Hamdan, M.H.; Siregar, J.P.; Thomas, S.; Jacob, M.J.; Jaafar, J.; Tezara, C. Mechanical performance of hybrid woven jute–roselle-reinforced polyester composites. Polym. Polym. Compos. 2019, 27, 407–418. [Google Scholar] [CrossRef]

- Arulmurugan, M.; Prabu, K.; Rajamurugan, G.; Selvakumar, A.S. Impact of BaSO4 filler on woven Aloevera/Hemp hybrid composite: Dynamic mechanical analysis. Mater. Res. Express 2019, 6, 045309. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Amjad, A.; Anjang, A.; Md Akil, H.; Zainol Abidin, M.S. Effect of comingling techniques on mechanical properties of natural fibre reinforced cross-ply thermoplastic composites. Compos. Part B Eng. 2019, 177, 107279. [Google Scholar] [CrossRef]

- Mobarak Hossain, M.; Datta, E.; Rahman, S. A Review on Different Factors of Woven Fabrics’ Strength Prediction. Sci. Res. 2016, 4, 88–97. [Google Scholar] [CrossRef]

- Sanjay, M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Xia, Z.; Xu, W. A review of ring staple yarn spinning method development and its trend prediction. J. Nat. Fibers. 2013, 10, 62–81. [Google Scholar] [CrossRef]

- Grosberg, P.; Iype, C. Yarn Production, Theoretical Aspect; The Textile Institute: Manchester, UK, 1999; pp. 99–113. [Google Scholar]

- Booth, J.E. Textile Mathematics; The Textile Institute: Manchester, UK, 1975; Volume 2, p. 333. [Google Scholar]

- Alagirusamy, R.; Das, A. Conversion of Fibre to Yarn. In Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2015; pp. 159–189. [Google Scholar] [CrossRef]

- Ngai, T. Carbon-carbon composite. In Handbook of Composite Reinforcements; Lee, S.M., Ed.; Wiley-VCH: Weinheim, Germany, 1993; pp. 41–70. [Google Scholar]

- Saiman, M.; Bin Wahab, M.S.; Wahit, M.U. The effect of yarn linear density on mechanical properties of plain Woven Kenaf reinforced unsaturated polyester composite. In Applied Mechanics and Materials; Trans Tech Publication: Freienbach, Switzerland, 2014. [Google Scholar]

- Madsen, B.; Hoffmeyer, P.; Thomsen, A.B.; Lilholt, H. Hemp yarn reinforced composites–I. Yarn characteristics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2194–2203. [Google Scholar] [CrossRef]

- Miao, M. The role of twist in dry spun carbon nanotube yarns. Carbon 2016, 96, 819–826. [Google Scholar] [CrossRef]

- Anike, J.C.; Belay, K.; Abot, J.L. Effect of twist on the electromechanical properties of carbon nanotube yarns. Carbon 2019, 142, 491–503. [Google Scholar] [CrossRef]

- Realff, M.L.; Boyce, M.C.; Backer, S. A Micromechanical Model of the Tensile Behavior of Woven Fabric. Text. Res. J. 1997, 67, 445–459. [Google Scholar] [CrossRef]

- Taylor, H.M. 9—Tensile and tearing strength of cotton cloths. J. Text. Inst. Trans. 1959, 50, T161–T188. [Google Scholar] [CrossRef]

- Goutianos, S.; Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of Flax Fibre based Textile Reinforcements for Composite Applications. App. Comp. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Licence, P.; Clifford, M.J. Hydroxyethylcellulose surface treatment of natural fibres: The new “twist” in yarn preparation and optimization for composites applicability. J. Mater. Sci. 2012, 47, 2700–2711. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W. Interfacial characteristics of sisal fiber and polymeric matrices. J. Adhes. 2006, 82, 527–554. [Google Scholar] [CrossRef]

- Omeroglu, S.; Karaca, E.; Becerir, B. Comparison of Bending, Drapability and Crease Recovery Behaviors of Woven Fabrics Produced from Polyester Fibers Having Different Cross-sectional Shapes. Text. Res. J. Artic. Text. Res. J. 2010, 80, 1180–1190. [Google Scholar] [CrossRef]

- Morton, W.E.; Hearle, J.W.S. Fibre fineness and transverse dimensions. In Physical Properties of Textile Fibres; Morton, W., Hearle, J., Eds.; Elsevier: London, UK, 2008; pp. 97–133. [Google Scholar]

- Bauer-Kurz, I. Fiber Crimp and Crimp Stability in Nonwoven Fabric Processes. Ph.D. Thesis, North Carolna State University, Raleigh, NC, USA, 2000. [Google Scholar]

- Chen, X. Modelling and Predicting Textile Behaviour, 1st ed.; Chen, X., Ed.; Woodhead Publishing Series in Textiles: Number 94; Woodhead Publishing: Oxford, UK, 2009. [Google Scholar]

- Messiry, M.E. Theoretical analysis of natural fiber volume fraction of reinforced composites. Alex. Eng. J. 2013, 52, 301–306. [Google Scholar] [CrossRef]

- Cheng, K.P.S.; Yu, C. A Study of Compact Spun Yarns. Text. Res. J. 2003, 73, 345–349. [Google Scholar] [CrossRef]

- Stalder, H. Ring spinning advance. Text. Asia 2000, 31, 43–46. [Google Scholar]

- Basal, G. The Structure and Properties of Vortex and Compact Spun Yarns. Ph.D. Thesis, North Carolna State University, Raleigh, NC, USA, 2003. [Google Scholar]

- El-Sayed, M.A.M.; Sanad, S.H. Compact spinning technology. In Advances in Yarn Spinning Technology; Elsevier: Amsterdam, The Netherlands, 2010; pp. 237–260. ISBN 9781845694449. [Google Scholar]

- Pan, N. Theoretical Determination of the Optimal Fiber Volume Fraction and Fiber-Matrix Property Compatibility of Short Fiber Composites. Polym. Compos. 1993, 14, 85–93. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Rashid, A.H.A.; Seang, C.T.; Ahmad, R.; Mustapha, M.J. Impact and flexural properties of imbalance plain woven coir and kenaf composite. Appl. Mech. Mater. 2013, 271, 81–85. [Google Scholar] [CrossRef]

- Kim, J.; Sham, M.L. Impact and delamination failure of woven-fabric composites. Compos. Sci. Technol. 2000, 60, 745–761. [Google Scholar] [CrossRef]

- Kelly, A. Very stiff fibres woven into engineering’s future: A long-term perspective. J. Mater. Sci. 2008, 43, 6578–6585. [Google Scholar] [CrossRef]

- Samivel, P. Mechanical behavior of stacking sequence in kenaf and bananafiber reinforced -Polyester laminate. Mech. Behav. Stacking Seq. Kenaf Banan. Reinf. Polyest. Laminate 2013, 3, 32–65. [Google Scholar]

- Othman, Z.; Saiman, M.P.; Hamid, M.F.A.; Talibin, M.N. The application of 2D woven kenaf reinforced unsaturated polyester composite in automotive interiors. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012032. [Google Scholar] [CrossRef]

- Alias, A.H.; Tahir, P.M.; Abdan, K.; Sapuan, M.S.; Wahab, M.S.; Saiman, M.P. Evaluation of kenaf yarn properties as affected by different linear densities for woven fabric laminated composite production. Sains Malays. 2018, 47, 1853–1860. [Google Scholar] [CrossRef]

- Saiman, M.; Wahab, M.; Wahit, M.U. The effect of fabric weave on the tensile strength of woven kenaf reinforced unsaturated polyester composite. In Proceedings of the International Colloquium in Textile Engineering, Fashion, Apparel and Design 2014 (ICTEFAD 2014); Springer: Singapore, 2014. [Google Scholar]

- Ferdous, N.; Rahman, M.; Kabir, R.B.; Ahmed, A.E. A comparative study on tensile strength of different weave structures. Int. J. Sci. Res. Eng. Technol. 2014, 3, 1307–1313. [Google Scholar]

- Maqsood, M.; Hussain, T.; Nawab, Y.; Shaker, K.; Umair, M. Prediction of warp and weft yarn crimp in cotton woven fabrics. J. Text. Inst. 2015, 106, 1180–1189. [Google Scholar] [CrossRef]

- Causa, A.; Netravali, A. Characterization and measurement of textile fabric properties. In Structure and Mechanics of Textile Fibre Assemblies; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Peerzada, M.H.; Abbasi, S.A.; Khatri, A. Effect of weave structure on tensile strength and yarn crimp of three-dimensional fibre woven fabric. Sci. Int. 2012, 24, 1–10. [Google Scholar]

- Ramaswamy, G.N.; Easter, E.P. Durability and Aesthetic Properties of Kenaf/Cotton Blend Fabrics. Text. Res. J. 1997, 67, 803–808. [Google Scholar] [CrossRef]

- Banerjee, P.K.; Mishra, S.; Ramkumar, T. Effect of sett and construction on uniaxial tensile properties of woven fabrics. J. Eng. Fiber. Fabr. 2010, 5, 8–21. [Google Scholar] [CrossRef]

- Tàpias, M.; Ralló, M.; Escofet, J. Automatic measurements of partial cover factors and yarn diameters in fabrics using image processing. Text. Rer. J. 2011, 81, 173–186. [Google Scholar] [CrossRef]

- Gandhi, K.L.; Sondhelm, W.S. Technical fabric structures—1. Woven fabrics. In Handbook of Technical Textiles; Anand, S.C., Horrocks, A.R., Eds.; Elsevier: Oxford, UK, 2016; pp. 63–106. [Google Scholar]

- Milašius, V. An integrated structure factor for woven fabrics part I: Estimation of the weave. J. Text. Inst. 2000, 91, 268–276. [Google Scholar] [CrossRef]

- Milašius, V.; Milašius, R.; Kumpikaité, E.; Olšauskiené, A. Influence of fabric structure on some technological and end-use properties. Fibres Text. East. Eur. 2003, 2, 48–51. [Google Scholar]

- Derbali, I.; Terekhina, S.; Guillaumat, L.; Ouagne, P. Rapid manufacturing of woven comingled flax/polypropylene composite structures. Int. J. Mater. Form. 2019, 12, 927–942. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Atikah, M.S.N.; Atiqah, A.; Ansari, M.N.M.; Norrrahim, M.N.F. Production, Processes and Modification of Nanocrystalline Cellulose from Agro-Waste: A Review. In Nanocrystalline Materials; IntechOpen: London, UK, 2019; pp. 3–32. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Asrofi, M.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensive approach from macro to nano scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Jordan, W.; Chester, P. Improving the Properties of Banana Fiber Reinforced Polymeric Composites by Treating the Fibers. Procedia Eng. 2017, 200, 283–289. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): Effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int. J. Biol. Macromol. 2019, 123, 379–388. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Pratama, A.B.; Fajri, N.; Sapuan, S.M.; Ilyas, R.A. Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocoll. 2020, 98, 105266. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E.S. Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Sapuan, S.M.; Ilyas, R.A. Highly transparent and antimicrobial PVA based bionanocomposites reinforced by ginger nanofiber. Polym. Test. 2019, 106186. [Google Scholar] [CrossRef]

- Arulmurugan, M.; Selvakumar, A.S.; Prabu, K.; Rajamurugan, G. Effect of barium sulphate on mechanical, DMA and thermal behaviour of woven aloevera/flax hybrid composites. Bull. Mater. Sci. 2020, 43, 58. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Rajeswari, N.; Vishvak, R. Influence of sequential positioning of fibre mats in enhancing the properties of natural fibre mat hybrid composite. Mater. Today Proc. 2020, 28, 1144–1148. [Google Scholar] [CrossRef]

- Torres, J.; Vandi, L.; Veidt, M.; Heitzmann, M.T. The mechanical properties of natural fibre composite laminates: A statistical study. Compos. Part A Appl. Sci. Manuf. 2017, 98, 99–104. [Google Scholar] [CrossRef]

- Yallew, T.B.; Kassegn, E.; Aregawi, S.; Gebresias, A. Study on effect of process parameters on tensile properties of compression molded natural fiber reinforced polymer composites. SN Appl. Sci. 2020, 2, 338. [Google Scholar] [CrossRef]

- Yallew, T.B.; Kumar, P.; Singh, I. Sliding Wear Properties of Jute Fabric Reinforced Polypropylene Composites. Procedia Eng. 2014, 97, 402–411. [Google Scholar] [CrossRef]

- Akonda, M.H.; Shah, D.U.; Gong, R.H. Natural fibre thermoplastic tapes to enhance reinforcing effects in composite structures. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105822. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Anjang, A.; Md Akil, H.; Zainol Abidin, M.S. Effect of fabric architecture on the shear and impact properties of natural fibre reinforced composites. Compos. Part B Eng. 2020, 195, 108069. [Google Scholar] [CrossRef]

- Azammi, A.M.N.; Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Atikah, M.S.N.; Asrofi, M.; Atiqah, A. Characterization studies of biopolymeric matrix and cellulose fibres based composites related to functionalized fibre-matrix interface. In Interfaces in Particle and Fibre Reinforced Composites-From Macro to Nano Scales; Woodhead Publishing: London, UK, 2019; pp. 1–68. ISBN 9780081026656. [Google Scholar]

- Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D.; Hossain, M.; Haafiz, M.K.; Khalil, H.P.S.A. Disposal Options of Bamboo Fabric-Reinforced Poly(Lactic) Acid Composites for Sustainable Packaging: Biodegradability and Recyclability. Polymers 2015, 7, 1476–1496. [Google Scholar] [CrossRef]

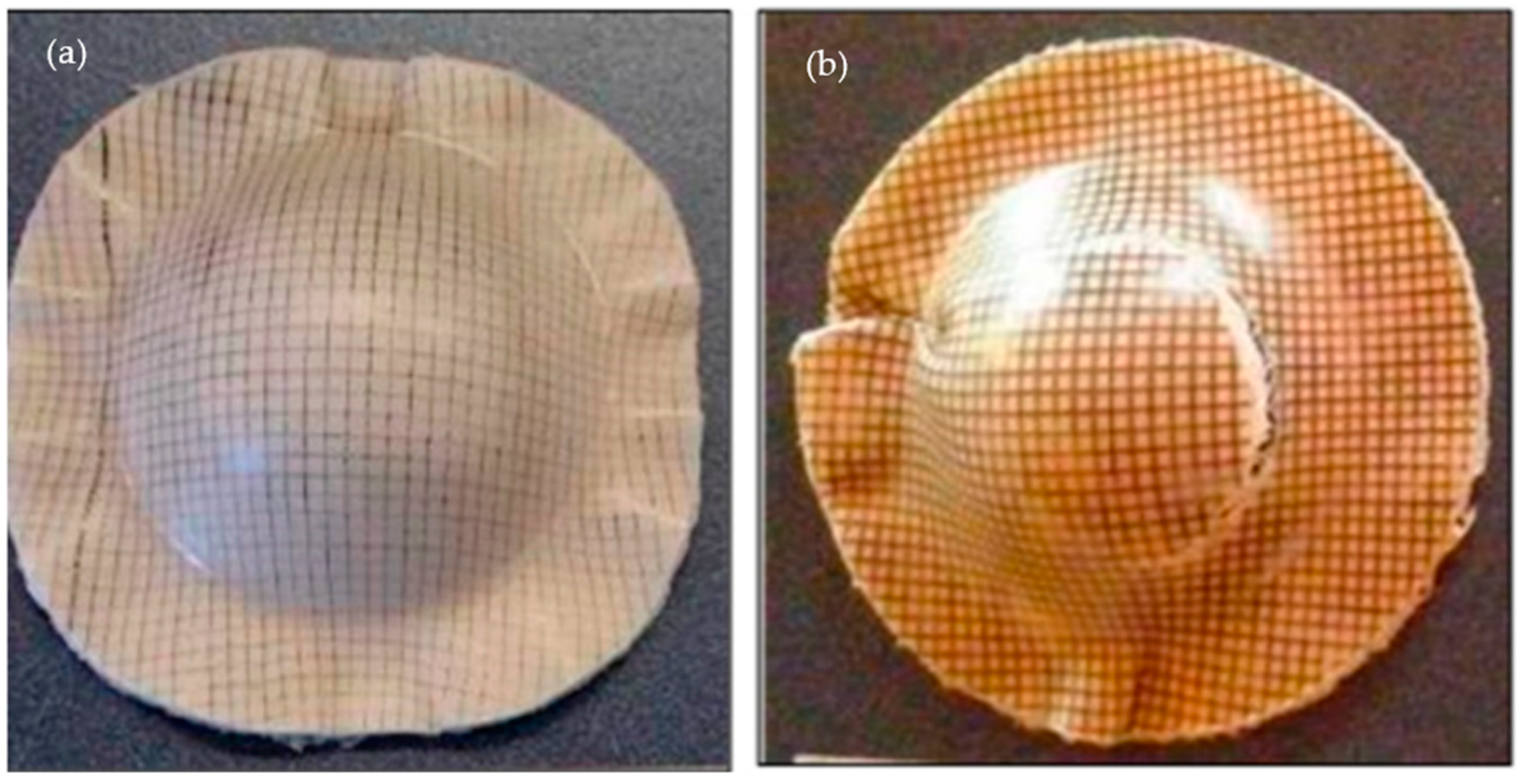

- Fazita, M.R.N.; Jayaraman, K.; Bhattacharyya, D. Formability Analysis of Bamboo Fabric Reinforced Poly (Lactic) Acid Composites. Materials 2016, 9, 539. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Maleque, M.A. Design and fabrication of natural woven fabric reinforced epoxy composite for household telephone stand. Mater. Des. 2005, 26, 65–71. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Leenie, A.; Harimi, M.; Beng, Y.K. Mechanical properties of woven banana fibre reinforced epoxy composites. Mater. Des. 2006, 27, 689–693. [Google Scholar] [CrossRef]

- De Vasconcellos, D.S.; Sarasini, F.; Touchard, F.; Pucci, M.; Santulli, C.; Tirillò, J.; Sorrentino, L.; de Vasconcellos, D.S.; Sarasini, F.; Touchard, F.; et al. Influence of low velocity impact on fatigue behaviour of woven hemp fibre reinforced epoxy composites. Compos. Part B Eng. 2014, 66, 46–57. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Sy, B.L.; Bougherara, H.; Zdero, R. Impact properties of a new hybrid composite material made from woven carbon fibres plus flax fibres in an epoxy matrix. Compos. Struct. 2019, 208, 346–356. [Google Scholar] [CrossRef]

- Palani Kumar, K.; Shadrach Jeya Sekaran, A.; Pitchandi, K. Investigation on mechanical properties of woven alovera/sisal/kenaf fibres and their hybrid composites. Bull. Mater. Sci. 2017, 40, 117–128. [Google Scholar] [CrossRef]

- Pothan, L.A.; Oommen, Z.; Thomas, S. Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 283–293. [Google Scholar] [CrossRef]

- Dalbehera, S.; Acharya, S.K. Effect of Cenosphere Addition on Erosive Wear Behaviour of Jute-glass Reinforced Composite Using Taguchi Experimental Design. Mater. Today Proc. 2015, 2, 2389–2398. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.A.; Jawaid, M.; Iqbal, M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part B Eng. 2014, 56. [Google Scholar] [CrossRef]

- Hamdan, M.H.M.; Siregar, J.P.; Cionita, T.; Jaafar, J.; Efriyohadi, A.; Junid, R.; Kholil, A. Water absorption behaviour on the mechanical properties of woven hybrid reinforced polyester composites. Int. J. Adv. Manuf. Technol. 2019, 104, 1075–1086. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S.; Rajput, C. Mechanical behavior of isothalic polyester-based untreated woven jute and glass fabric hybrid composites. J. Reinf. Plast. Compos. 2006, 25, 1549–1569. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S. Tensile, flexural and interlaminar shear properties of woven jute and jute-glass fabric reinforced polyester composites. J. Mater. Process. Technol. 2008, 207, 330–335. [Google Scholar] [CrossRef]

- Khalid, S.N.A.; Ismail, A.E.; Zainulabidin, M.H.; Tajul Arifin, A.M.; Hassan, M.F.; Ibrahim, M.R.; Rahim, M.Z. Mechanical performances of twill kenaf woven fiber reinforced polyester composites. Int. J. Integr. Eng. 2018, 10, 49–59. [Google Scholar] [CrossRef]

- Shahroze, R.M.; Ishak, M.R.; Salit, M.S.; Leman, Z.; Asim, M.; Chandrasekar, M. Effect of Organo-Modified Nanoclay on the Mechanical Properties of Sugar Palm Fiber-reinforced Polyester Composites. BioResources 2018, 13, 7430–7444. [Google Scholar] [CrossRef]

- Ahmed, K.; Vijayarangan, S.; Naidu, A.C.B. Elastic properties, notched strength and fracture criterion in untreated woven jute–glass fabric reinforced polyester hybrid composites. Mater. Des. 2007, 28, 2287–2294. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Khalina, A.; Sapuan, S.M.; Dayang Laila, A.H.A.M.; Rahmah, M.; Hanafee, Z. A Review: Fibres, Polymer Matrices and Composites. Pertanika J. Sci. Technol. 2017, 25, 1085–1102. [Google Scholar]

- Manap, N.; Jumahat, A.; Abd Rahman, N.; Ain Abd Rahman, N. NaOH treated Kenaf/Glass hybrid composite: The effects of nanosilica on longitudinal and transverse tensile properties. J. Phys. Conf. Ser. 2020, 1432, 12046. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Senthamaraikannan, P.; Kathiresan, M.; Saibalaji, M.A.; Yogesha, B. The Hybrid Effect of Jute/Kenaf/E-Glass Woven Fabric Epoxy Composites for Medium Load Applications: Impact, Inter-Laminar Strength, and Failure Surface Characterization. J. Nat. Fibers 2019, 16, 600–612. [Google Scholar] [CrossRef]

- Yusof, N.S.B.; Sapuan, S.M.; Sultan, M.T.H.; Jawaid, M. Conceptual design of oil palm fibre reinforced polymer hybrid composite automotive crash box using integrated approach. J. Cent. South Univ. 2020, 27, 64–75. [Google Scholar] [CrossRef]

- Amir, S.; Sultan, M.; Jawaid, M.; Safri, S.N.; Shah, A.U.; Yusof, M.R.; Naveen, J.; Mohd, S.; Salleh, K.A.; Saba, N. Effects of layering sequence and gamma radiation on mechanical properties and morphology of Kevlar/oil palm EFB/epoxy hybrid composites. J. Mater. Res. Technol. 2019, 8, 5362–5373. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Norizan, M.N.; Abdan, K.; Ilyas, R.A. Effect of water absorption on treated sugar palm yarn fibre/glass fibre hybrid composites. In Proceedings of the Prosiding Seminar Enau Kebangsaan 2019, Bahau, Malaysia, 1 April 2019; pp. 78–81. [Google Scholar]

- Zin, M.H.; Abdan, K.; Norizan, M.N. The effect of different fiber loading on flexural and thermal properties of banana/pineapple leaf (PALF)/glass hybrid composite. In Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–17. [Google Scholar]

- Srinivasan, V.; Rajendra Boopathy, S.; Sangeetha, D.; Vijaya Ramnath, B. Evaluation of mechanical and thermal properties of banana–flax based natural fibre composite. Mater. Des. 2014, 60, 620–627. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Development of PALF/Glass and COIR/Glass Fiber Reinforced Hybrid Epoxy Composites. J. Mater. Sci. Surf. Eng. 2018. [Google Scholar] [CrossRef]

- Uma Devi, L.; Bhagawan, S.S.; Thomas, S. Dynamic mechanical analysis of pineapple leaf/glass hybrid fiber reinforced polyester composites. Polym. Compos. 2010, 31, 956–965. [Google Scholar] [CrossRef]

- Morye, S.S.; Wool, R.P. Mechanical properties of glass/flax hybrid composites based on a novel modified soybean oil matrix material. Polym. Compos. 2005, 26, 407–416. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical behavior of carbon/flax hybrid composites for structural applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Studies on the water absorption properties of short hemp-glass fiber hybrid polypropylene composites. J. Compos. Mater. 2007, 41, 1871–1883. [Google Scholar] [CrossRef]

- La Rosa, A.; Cozzo, G.; Latteri, A.; Recca, A.; Björklund, A.; Parrinello, E.; Cicala, G. Life cycle assessment of a novel hybrid glass-hemp/thermoset composite. J. Clean. Prod. 2013, 44, 69–76. [Google Scholar] [CrossRef]

- Amico, S.C.; Angrizani, C.C.; Drummond, M.L. Influence of the Stacking Sequence on the Mechanical Properties of Glass/Sisal Hybrid Composites. J. Reinf. Plast. Compos. 2010, 29, 179–189. [Google Scholar] [CrossRef]

- Idicula, M.; Malhotra, S.K.; Joseph, K.; Thomas, S. Dynamic mechanical analysis of randomly oriented intimately mixed short banana/sisal hybrid fibre reinforced polyester composites. Compos. Sci. Technol. 2005, 65, 1077–1087. [Google Scholar] [CrossRef]

- Hamouda, T.; Hassanin, A.H.; Kilic, A.; Candan, Z.; Safa Bodur, M. Hybrid composites from coir fibers reinforced with woven glass fabrics: Physical and mechanical evaluation. Polym. Compos. 2017, 38, 2212–2220. [Google Scholar] [CrossRef]

- Saw, S.K.; Sarkhel, G.; Choudhury, A. Preparation and characterization of chemically modified Jute-Coir hybrid fiber reinforced epoxy novolac composites. J. Appl. Polym. Sci. 2012, 125, 3038–3049. [Google Scholar] [CrossRef]

- Clark, R.A.; Ansell, M.P. Jute and glass fibre hybrid laminates. J. Mater. Sci. 1986, 21, 269–276. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Comparative evaluation on properties of hybrid glass fiber-sisal/jute reinforced epoxy composites. Procedia Eng. 2013, 51, 745–750. [Google Scholar] [CrossRef]

- Richard, B.D.; Wahi, A.; Nani, R.; Lling, E.; Osman, S.; Ali, D.S.H. Effect of fiber loading on the flexural and tensile strength of oil palm frond fiber reinforced polymer composite. Int. J. Integr. Eng. 2019, 11, 122–128. [Google Scholar] [CrossRef]

- Islam, M.; Gupta, A.; Rivai, M.; Beg, M. Characterization of microwave-treated oil palm empty fruit bunch/glass fibre/polypropylene composites. J. Thermoplast. Compos. Mater. 2017, 30, 986–1002. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Salit, M.S.; Mohamed, R. Physical, mechanical and thermal properties of sugar palm yarn fibre loading on reinforced unsaturated polyester composites. J. Phys. Sci. 2017. [Google Scholar] [CrossRef]

- Baihaqi, N.M.Z.N.; Khalina, A.; Nurazzi, N.M.; Aisyah, H.A.; Sapuan, S.M.; Ilyas, R.A. Effect of fiber content and their hybridization on bending and torsional strength of hybrid epoxy composites reinforced with carbon and sugar palm fibers. Polimery 2021, 66, 36–43. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Tholibon, D.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites. Polymers 2020, 12, 1643. [Google Scholar] [CrossRef]

- Chung, T.-J.; Park, J.-W.; Lee, H.-J.; Kwon, H.-J.; Kim, H.-J.; Lee, Y.-K.; Tai Yin Tze, W. The improvement of mechanical properties, thermal stability, and water absorption resistance of an eco-friendly PLA/Kenaf biocomposite using acetylation. Appl. Sci. 2018, 8, 376. [Google Scholar] [CrossRef]

- Zin, M.H.; Abdan, K.; Norizan, M.N.; Mazlan, N. The effects of alkali treatment on the mechanical and chemical properties of banana fibre and adhesion to epoxy resin. Pertanika J. Sci. Technol. 2018, 26, 161–176. [Google Scholar]

- Karthick, R.; Adithya, K.; Hariharaprasath, C.; Abhishek, V. Evaluation of mechanical behavior of banana fibre reinforced hybrid epoxy composites. Mater. Today Proc. 2018, 5, 12814–12820. [Google Scholar] [CrossRef]

- Glória, G.O.; Teles, M.C.A.; Neves, A.C.C.; Vieira, C.M.F.; Lopes, F.P.D.; de Gomes, M.A.; Margem, F.M.; Monteiro, S.N. Bending test in epoxy composites reinforced with continuous and aligned PALF fibers. J. Mater. Res. Technol. 2017, 6, 411–416. [Google Scholar] [CrossRef]

- Doddi, P.R.V.; Chanamala, R.; Dora, S.P. Effect of fiber orientation on dynamic mechanical properties of PALF hybridized with basalt reinforced epoxy composites. Mater. Res. Express 2020, 7, 015329. [Google Scholar] [CrossRef]

- Ravandi, M.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. Low velocity impact performance of stitched flax/epoxy composite laminates. Compos. Part B Eng. 2017, 117, 89–100. [Google Scholar] [CrossRef]

- Barouni, A.K.; Dhakal, H.N. Damage investigation and assessment due to low-velocity impact on flax/glass hybrid composite plates. Compos. Struct. 2019, 226, 111224. [Google Scholar] [CrossRef]

- Haghighatnia, T.; Abbasian, A.; Morshedian, J. Hemp fiber reinforced thermoplastic polyurethane composite: An investigation in mechanical properties. Ind. Crops Prod. 2017, 108, 853–863. [Google Scholar] [CrossRef]

- Gupta, M.K.; Gond, R.K.; Bharti, A. Effects of treatments on the properties of polyester based hemp composite. Indian J. Fibre Text. Res. 2018, 43, 313–319. [Google Scholar]

- Rana, S.S.; Gupta, M.K.; Srivastava, R.K. Effect of variation in frequencies on dynamic mechanical properties of short sisal fibre reinforced epoxy composite. Mater. Today Proc. 2017, 4, 3387–3396. [Google Scholar] [CrossRef]

- Wang, H.; Memon, H.; Hassan, E.A.M.; Miah, M.S.; Ali, M.A. Effect of Jute Fiber Modification on Mechanical Properties of Jute Fiber Composite. Materials 2019, 12, 1226. [Google Scholar] [CrossRef]

- Reddy, K.S.; Singla, H. Optimization of woven jute/glass fibre-reinforced polyester hybrid composite solar parabolic trough collector. IOP Conf. Ser. Mater. Sci. Eng. 2017, 222, 012016. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Valenza, A. Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Meysam, S.; Rostami, R.; Ismail, M.; Razak, A.; Ezekiel, B. Woven hybrid Biocomposite: Mechanical properties of woven kenaf bast fibre/oil palm empty fruit bunches hybrid reinforced poly hydroxybutyrate biocomposite as non-structural building materials. Constr. Build. Mater. 2017, 154, 155–166. [Google Scholar] [CrossRef]

- Zhang, Y.; Mao, T.; Wu, H.; Cheng, L.; Zheng, L. Carbon Nanotubes Grown on Flax Fabric as Hierarchical All-Carbon Flexible Electrodes for Supercapacitors. Adv. Mater. Interfaces 2017, 4, 1601123. [Google Scholar] [CrossRef]

- Kalagi, G.R.; Patil, R.; Nayak, N. Experimental Study on Mechanical Properties of Natural Fiber Reinforced Polymer Composite Materials for Wind Turbine Blades. Mater. Today Proc. 2018, 5, 2588–2596. [Google Scholar] [CrossRef]

- Macha, I.J.; Muna, M.M.; Magere, J.L. In vitro study and characterization of cotton fabric PLA composite as a slow antibiotic delivery device for biomedical applications. J. Drug Deliv. Sci. Technol. 2018, 43, 172–177. [Google Scholar] [CrossRef]

- Scarponi, C.; Messano, M. Comparative evaluation between E-Glass and hemp fiber composites application in rotorcraft interiors. Comp. Part B Eng. 2015, 69, 542–549. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Khalina, A.; Sapuan, S.M.; Rahmah, M. Development of sugar palm yarn/glass fibre reinforced unsaturated polyester hybrid composites. Mater. Res. Express 2018, 5, 045308. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Ilyas, R.A.; Biofibers, S.P. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 2020, 65, 34–43. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Bachtiar, D. Mechanical properties of sugar palm fibre reinforced high impact polystyrene composites. Proc. Chem. 2012, 4, 101–106. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Salit, M.S.; Mohamed, R. The effect of alkaline treatment on the mechanical properties of treated sugar palm yarn fibre reinforced unsaturated polyester composites reinforced with different fibre loadings of sugar palm fibre. Sains Malaysiana 2018. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2019. [Google Scholar] [CrossRef]

- Scida, D.; Aboura, Z.; Benzeggagh, M.L.; Bocherens, E. A micromechanics model for 3D elasticity and failure of woven-fibre composite materials. Compos. Sci. Technol. 1999, 59, 505–517. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef]

- Witayakran, S.; Smitthipong, W.; Wangpradid, R.; Chollakup, R.; Clouston, P.L. Natural Fiber Composites: Review of Recent Automotive Trends. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 166–174. [Google Scholar]

- Bagheri, Z.S.; El Sawi, I.; Schemitsch, E.H.; Zdero, R.; Bougherara, H. Biomechanical properties of an advanced new carbon/flax/epoxy composite material for bone plate applications. J. Mech. Behav. Biomed. Mater. 2013, 20, 398–406. [Google Scholar] [CrossRef]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A Appl. Sci. Manuf. 2016, 83, 193–205. [Google Scholar] [CrossRef]

- Wambua, P.; Vangrimde, B.; Lomov, S.; Verpoest, I. The response of natural fibre composites to ballistic impact by fragment simulating projectiles. Compos. Struct. 2007, 77, 232–240. [Google Scholar] [CrossRef]

- Radif, Z.S.; Ali, A.; Abdan, K. Development of a Green Combat Armour from Rame-Kevlar-Polyester Composite. Pertanika J. Sci. Technol. 2011, 19, 339–348. [Google Scholar]

- Luz, F.S.D.; Junior, E.P.L.; Louro, L.H.L.; Monteiro, S.N. Ballistic test of multilayered armor with intermediate epoxy composite reinforced with jute fabric. Mater. Res. 2015, 18, 170–177. [Google Scholar] [CrossRef]

- Tausif, M.; Ahmad, F.; Hussain, U.; Basit, A.; Hussain, T. A comparative study of mechanical and comfort properties of bamboo viscose as an eco-friendly alternative to conventional cotton fibre in polyester blended knitted fabrics. J. Clean. Prod. 2015, 89, 110–115. [Google Scholar] [CrossRef]

- Mott, S. Five Forms of Thermoset Processing. Available online: https://blog.mar-bal.com/blog/five-forms-of-thermoset-processing (accessed on 13 January 2021).

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A review of 3D and 4D printing of natural fibre biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Aravind Kumar, D.; Gokul Raj, G.; Shivaani, G.; Sreehari, V.M. Structural analysis of aircraft wings made of natural fiber reinforced composites. Int. J. Mech. Eng. Technol. 2018, 9, 1262–1268. [Google Scholar]

- Lee, C.H.; Salit, M.S.; Hassan, M.R. A Review of the Flammability Factors of Kenaf and Allied Fibre Reinforced Polymer Composites. Adv. Mater. Sci. Eng. 2014, 2014, 514036. [Google Scholar] [CrossRef]

| Fibre | Density | Young’s Modulus (GPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| Sugar palm | 1.5 | 10.4 | 421.4 | 9.8 |

| Bamboo | 0.6–1.1 | 11–17 | 140–230 | - |

| Cotton | 1.5–1.6 | 5.5–12.6 | 287–597 | 7–8 |

| Flax | 1.54 | 27–85 | 345–2000 | 1–4 |

| Hemp | 1.47 | 17–70 | 368–800 | 1.6 |

| Jute | 1.44 | 10–30 | 393–773 | 1.5–1.8 |

| Kenaf | 1.2 | 14–53 | 240–930 | 1.6 |

| Ramie | 1.5–1.56 | 27–128 | 400–1000 | 1–4 |

| Fibre Types * | Matrix Type | Key Findings | Ref. |

|---|---|---|---|

| Woven jute: glass fibre (43:0, 35:8, 25:16, 17:25) | Polyester (PE) | Woven jute laminates had poorer damage resistance and tolerance capability than jute/glass hybrid laminates, but better in damage tolerance capability. The optimum ratio of the hybrid laminate was 25:16, that increased the damage tolerance capability. | [71] |

| Woven flax (31–39%) | Epoxy | The addition of woven flax improved the fracture toughness of the composites and the strength of the fracture depended significantly on the directions (warp or weft) of the composite being tested. | [73] |

| Plain woven coir and kevlar | Epoxy | Woven hybrid coir/Kevlar composite had flexural strength and impact strength nearest to the properties of woven Kevlar composite. | [74] |

| Woven kenaf fibre | Glass, nylon fibre | The incorporation of kenaf woven as one of the layers in the existing laminated composite structure in making prosthetic leg sockets resulted in the improvement in the impact, tensile and flexural strength. | [75] |

| Plain and twill hemp fabric (6%—1 layer and 20% —three layers) | Polylactic acid (PLA) | Composites incorporated with twill hemp fabrics showed better mechanical, thermal, and viscoelastic behaviours than plain hemp fabric composites. Improvement of the twill hemp in the composite was due to the dimensional properties and weave structures of the twill fabrics. | [76] |

| Kenaf fabric | Epoxy | Yarn size and weave pattern influenced the porosity, unit cell, weft crimp, and warp crimp. The mechanical properties of woven kenaf composite depended on the crimp and porosity. | [77] |

| Woven banana and kenaf (40%) | Polyester (PE) | Plain fabric improved the tensile properties of the composite compared to twill fabric composite and randomly oriented composites. | [78] |

| Hemp woven fabric (30%) | Polylactic acid (PLA) | Composite from satin fabric had significantly lowest porosities and better mechanical properties than the composites made from the wound hybrid yarn and basket fabric. | [79] |

| Ramie fabric (30%) | Epoxy | Ballistic tests revealed that 30 vol% of ramie fabric composites had a better performance than Kevlar as a ceramic front backing plate in multilayered ballistic armour systems with more cost-saving (~95%) of the total multilayered armour. | [80] |

| Woven kenaf: Kevlar fabric (42–43: 60–62) | Epoxy | Hybrid composite with kenaf fabric as skin layers exhibited higher impact properties compared with samples with Kevlar as skin layers. | [81] |

| Woven jute (41%) | Epoxy | The mechanical behaviour of woven jute laminated composite was improved by increasing the number of layers, with a maximum number of layers of 5 at 0° fibre and cutting direction. | [82] |

| Woven kenaf (35%) | Epoxy, unsaturated polyester and vinyl ester. | Plain woven kenaf composite possessed good mechanical strength. Tensile, flexural and impact strengths of the woven kenaf/epoxy composite were superior to those of the other polymers. | [83] |

| Jute fabric | Poly (L-lactic acid) (PLLA) | Woven jute fabric composites in warp and weft directions presented superior mechanical properties than non-woven jute fabric composites. | [84] |

| Kenaf fabric: glass fibre (6.8–15.2: 8.8–20.4) | Polypropylene (PP) and epoxy | Fatigue strength of laminated kenaf fabric and glass fibre reinforced with polypropylene demonstrated greater performance compared to composites reinforced with epoxy. | [85] |

| Woven kenaf: carbon fibre (16–20: 12) | Epoxy | Weave design and fabric count of kenaf fabrics played important roles in determining the final laminated composite properties. The findings showed that plain fabric was more suited to achieving high tensile and impact strengths than satin fabric. | [86] |

| Plain woven jute (39–42%), plain woven sisal (34–41%) and glass fabrics (72–74%) | Polypropylene (PP) and polylactic acid (PLA) | The PLA composite tensile and flexural modulus were superior to the PP composites. Compared to jute composites, sisal composite has higher tensile and flexural modulus. | [87] |

| Flax fabrics: carbon fabric (28–31: 8–15) | Epoxy | There were noteworthy improvements in the strength and stiffness of various interlayer flax-carbon hybrid configurations at low carbon volume fractions. | [88] |

| Kenaf fabric and carbon fibre (16–20%) | Epoxy | Hybrid composite with higher kenaf fibre content (higher fabric count) showed better thermal stability whilst pure carbon fibre composite had the highest thermal stability. The DSC data revealed that the temperature of decomposition increased with the presence of woven kenaf. | [89] |

| Woven flax: glass fibre (0.26–0.4: 0.14–0.5) | Epoxy | Hybridization of flax fabric in composites with glass fibre showed good resistance to better interlaminar fracture toughness. | [90] |

| Woven bamboo and kenaf mat (40%) | Epoxy | The optimum weight ratio of hybridization bamboo mat and woven kenaf for good thermomechanical and dynamical mechanical properties of hybrid composites is 50:50. | [91] |

| Woven kenaf | Epoxy | Adding stitches on the woven kenaf structure gave a better performance in specific strength while stitching patterns and stitching angle gave significant impact to woven stitch kenaf composite performance when compared to unstitched ones. | [92] |

| Woven jute, ramie and roselle | Polyester | Various types of woven fabric used in the hybrid composite showed various mechanical properties. Better tensile and flexural properties of the composite were provided by the hybridization of woven jute and ramie. In the meantime, hybrid woven jute and roselle developed superior properties of composite impacts. | [93] |

| Woven aloe vera and flax | Epoxy | The physical properties and woven pattern of the aloe vera fibre improved the toughness properties of the composite. The chemical treatment of aloe vera fibre by using barium sulphate (BaSO4) was found to increase the thermal stability of the composite. | [94] |

| Jute, hemp and flax fabrics (47%) | Polypropylene (PP) | The effect of the fabric architecture, i.e., woven, woven commingled and knitted commingle of jute, hemp, and flax on the composite properties were investigated. The results showed composite from jute knitted commingled fabric composite exhibited 20% and 29% higher strengths compared to their woven and woven commingled composite. | [95] |

| Properties | Weave Structure | ||

|---|---|---|---|

| Plain | Twill | Satin | |

| Good Stability | **** | *** | ** |

| Good Drape | ** | **** | ***** |

| Low Porosity | *** | **** | ***** |

| Low Crimp | ** | *** | ***** |

| Balance | **** | **** | ** |

| Fibre Types | Matrix Type | Properties Remark | Ref. |

|---|---|---|---|

| Oil palm frond | Urea Formaldehyde | Composite with 50% of fibre showed higher flexural strength, modulus of electricity (MOE), and tensile strength of 1.43 MPa, 1248 MPa and 3.8 MPa, respectively. | [195] |

| Oil palm EFB | Polypropylene | Microwave-treated fibre-based composites showed improved mechanical and thermal properties. EFB fibres treated at 90 °C for 90 min were found to be suitable for better reinforcement into the composite in terms of mechanical, thermal, and crystalline properties. Moreover, onset degradation temperature and water absorption properties were also found to be changed apparently due to treatment. | [196] |

| Sugar palm | Unsaturated polyester | Increasing trends in the tensile strength, tensile modulus, flexural strength, and flexural modulus were shown in sugar palm yarn loadings of up to 30 wt%. However, maximum impact strength was achieved at 40 wt% of sugar palm fibre yarn loadings. Elongation at break increased with the increment of sugar palm yarn loading up to 50 wt%. The thermal stability of the composite decreased in accordance with onset and maximum temperatures, while the percentage of residue increased for higher fibre loadings | [197] |

| Sugar palm | Epoxy | Increasing flexural and torsion properties of the non-hybrid composite at fibre loading of 15 wt% were 7.40% and 75.61%, respectively. For hybrid composites, the experimental results revealed the highest flexural and torsion properties that was achieved at the ratio of 85/15 reinforcement and 60/40 for the fibre ratio of hybrid sugar palm yarn/carbon fibre-reinforced composites. The different ratio between matrix and reinforcement had a significant effect on the performance of sugar palm composites. | [198] |

| Kenaf | Epoxy | The kenaf composite was found to withstand a maximal temperature of 120 °C. The tensile and flexural strengths of the aligned kenaf composites (50 and 90 MPa, respectively) were three times higher than those of the commercialized Product T (between 39 and 30.5 MPa, respectively) at a temperature range of 90 to 120 °C. | [199] |

| Kenaf | Polylactic acid (PLA) | The acetylation treatment was effective for improving the performance of PLA/kenaf composites. This behaviour was found to relate to the surface cleaning of acetylated kanaf, in addition to the efficient modification of the hydrophilic characteristics of kenaf. | [200] |

| Banana fibre | Epoxy | The mechanical analysis indicated that 6% NaOH treatment with a two-hour immersion time gave the highest tensile strength. It was found that 6% NaOH treatment with a two-hour immersion yielded the highest interfacial shear stress of 3.96 MPa. The TGA analysis implied that alkaline treatment improved the thermal and heat resistivity of the fibre. | [201] |

| Banana fibre | Epoxy | The best mechanical performance was achieved in the composite specimen of 10 mm fibre length and 15% fibre loading. | [202] |

| PALF | Epoxy | The continuous and aligned fibres significantly increased flexural strength. Revealed by Weibull statistics, the PALF reinforcement, above 10–30 vol%, followed a linear increase to a value of flexural strength around 120 MPa. | [203] |

| PALF | Epoxy | It was found that the change in fibre orientations will have a great influence on storage modulus and loss tangent along with other mechanical properties investigated in this study, as the evidence from the table that maximum variance in storage modulus at frequencies of 0.1, 1 and 10 Hz were approximately 3.86, 4.26 and 4.23 GPa, respectively and the corresponding variance in loss factor values were 0.16, 0.12, and 0.09, respectively. | [204] |

| Flax | Epoxy | The unstitched and stitched flax composites showed that while delamination was not the predominant damage mode in both laminates, stitching did facilitate the propagation of in-plane cracks. The findings revealed that stitching with thicker yarn (flax) led to a lower ratio of absorbed energy per area of damage as well as the energy absorbed for full penetration. | [205] |

| Flax | Vinyl ester | The results at two different impact energies (25 J and 50 J) confirmed the fact that the flax specimens can absorb more energy during the impact event, but they tended to show greater damage extension at lower energy levels compared to the glass/flax specimens. The hybridisation of the flax reinforced natural fibre composite revealed a much higher impact performance, exhibiting greater perforation and penetration resistance with the benefits of having a lower environmental impact than glass fibre laminates without hybridisation. | [206] |

| Hemp | Polyurethane (PU) | Increasing fibre volume content to 40%, flexural strength enhanced 193.24%. Additionally, 15 mm hemp fibre was found to be the optimum fibre length, where flexural strength at 40% fibre volume was further increased to 274.3%. | [207] |

| Hemp | Unsaturated polyester | The results suggested a significant effect of chemical treatment in terms of increasing mechanical and dynamic mechanical properties and decreasing in water absorption properties. The benzoylation treatment showed a better impact among all three chemical treatments (benzoylation, alkali treatment, and sodium bicarbonate). | [208] |

| Sisal | Epoxy | The results indicated that storage modulus and loss modulus were found to be high for the composite having 15 mm length of fibres. | [209] |

| Jute | Epoxy | Composites prepared from chemically treated (acid pretreatment, alkali pretreatment, and scouring) jute fibres were found to be better than the raw jute composites in terms of tensile strength, elongation at break, void fraction, and interfacial adhesion. The findings suggested the chemical treatment of jute fibres could enable better matrix–fibre adhesion due to improvement in interfacial bonding with polymer matrix, which consequently improved the tensile properties of the composites. | [210] |

| Fibres | Reinforcement | Applications | Ref. |

|---|---|---|---|

| Bamboo fabric | Polylactic acid | Packaging | [158,159] |

| Woven jute and glass fibre | Polyester | Solar parabolic trough collector | [211] |

| Twill weave woven flax fabric | Polypropylene | Marine composite | [212] |

| Woven kenaf bast and oil palm EFB | Polyhydroxybutyrate (PHB) | Construction and building materials | [213] |

| Flax fabric | Carbon nanotubes | Supercapacitor electrode | [214] |

| Sisal fabric, flax fabric and glass fibre | Epoxy | Wind turbine blades | [215] |

| Woven cotton fabric | Polylactic acid | Antibiotic delivery device | [216] |

| Plain hemp fabric | Epoxy | Electronic racks | [217] |

| Woven kenaf and Kevlar fabric | Epoxy | Ballistic armour materials | [27,81] |

| Sugar palm yarn | Polyester | Automotive component | [198,218,219,220,221,222] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers 2021, 13, 471. https://doi.org/10.3390/polym13030471

Aisyah HA, Paridah MT, Sapuan SM, Ilyas RA, Khalina A, Nurazzi NM, Lee SH, Lee CH. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers. 2021; 13(3):471. https://doi.org/10.3390/polym13030471

Chicago/Turabian StyleAisyah, H. A., M. T. Paridah, S. M. Sapuan, R. A. Ilyas, A. Khalina, N. M. Nurazzi, S. H. Lee, and C. H. Lee. 2021. "A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites" Polymers 13, no. 3: 471. https://doi.org/10.3390/polym13030471

APA StyleAisyah, H. A., Paridah, M. T., Sapuan, S. M., Ilyas, R. A., Khalina, A., Nurazzi, N. M., Lee, S. H., & Lee, C. H. (2021). A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers, 13(3), 471. https://doi.org/10.3390/polym13030471