Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites

Abstract

1. Introduction

2. Experimentation

2.1. Materials

2.2. Methods

2.2.1. Extraction of MCC from Bamboo Fiber

2.2.2. Fabricated of MCC Reinforced PLA/PBS Composites

2.3. Characterization and Testing

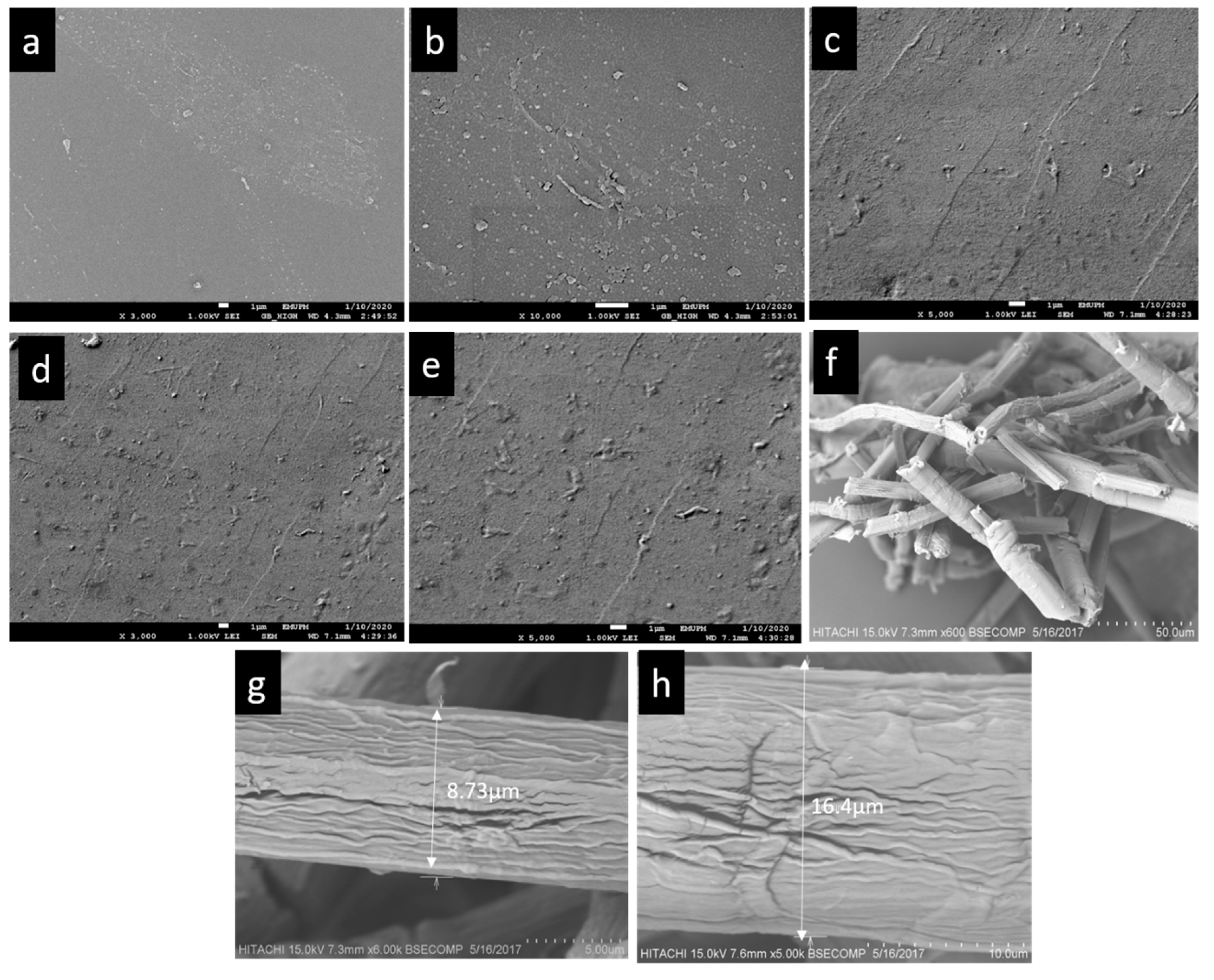

2.3.1. Field Emission Scanning Electron Microscopy (FESEM)

2.3.2. Scanning Electron Microscopy (SEM)

2.3.3. X-ray Diffraction (XRD)

2.3.4. Fourier Transform Infrared Spectroscope (FTIR)

2.3.5. Thermal Characterization

2.3.6. Tensile Properties

3. Results and Discussions

3.1. FESEM

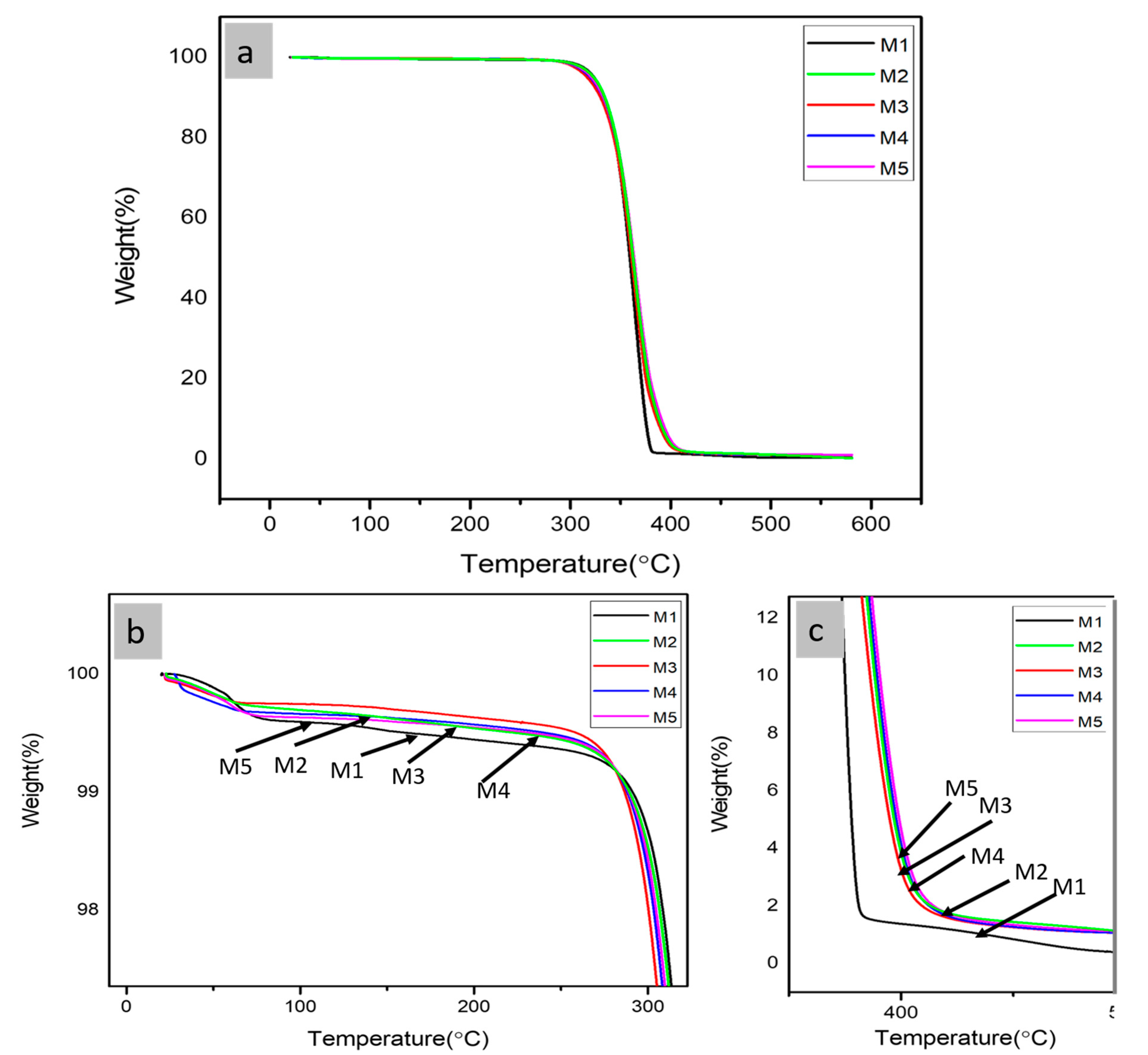

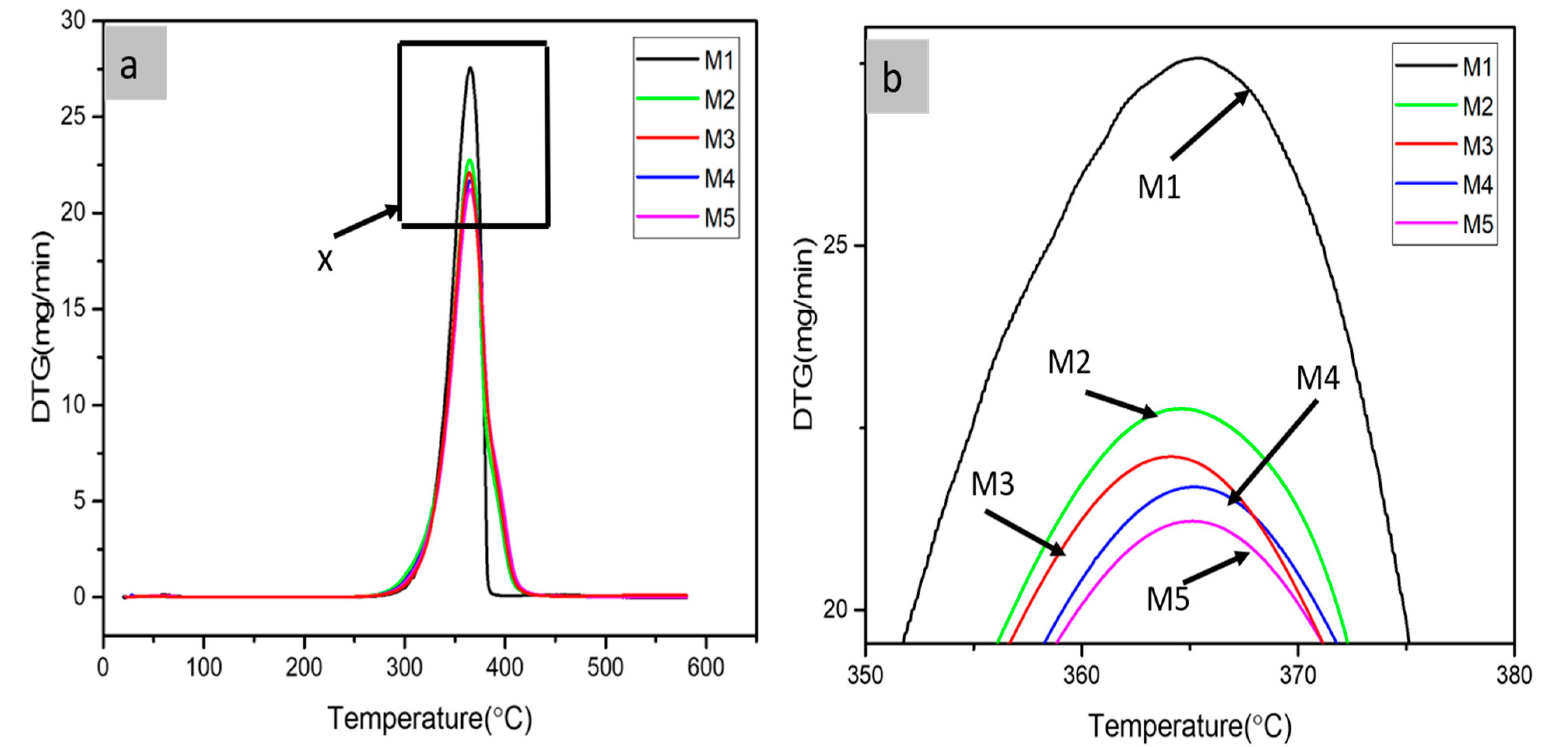

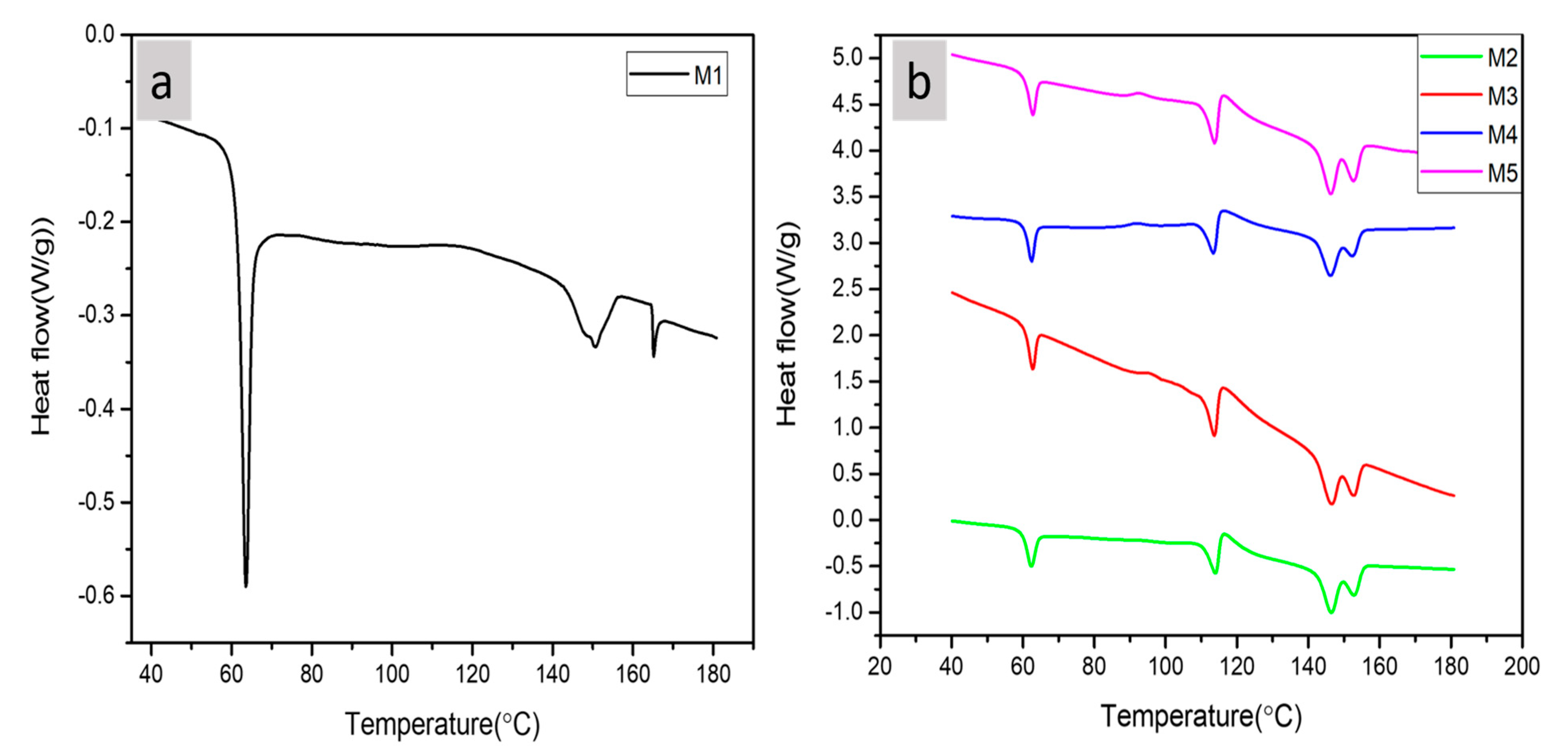

3.2. Thermal Properties

3.3. X-ray Diffractometry (XRD)

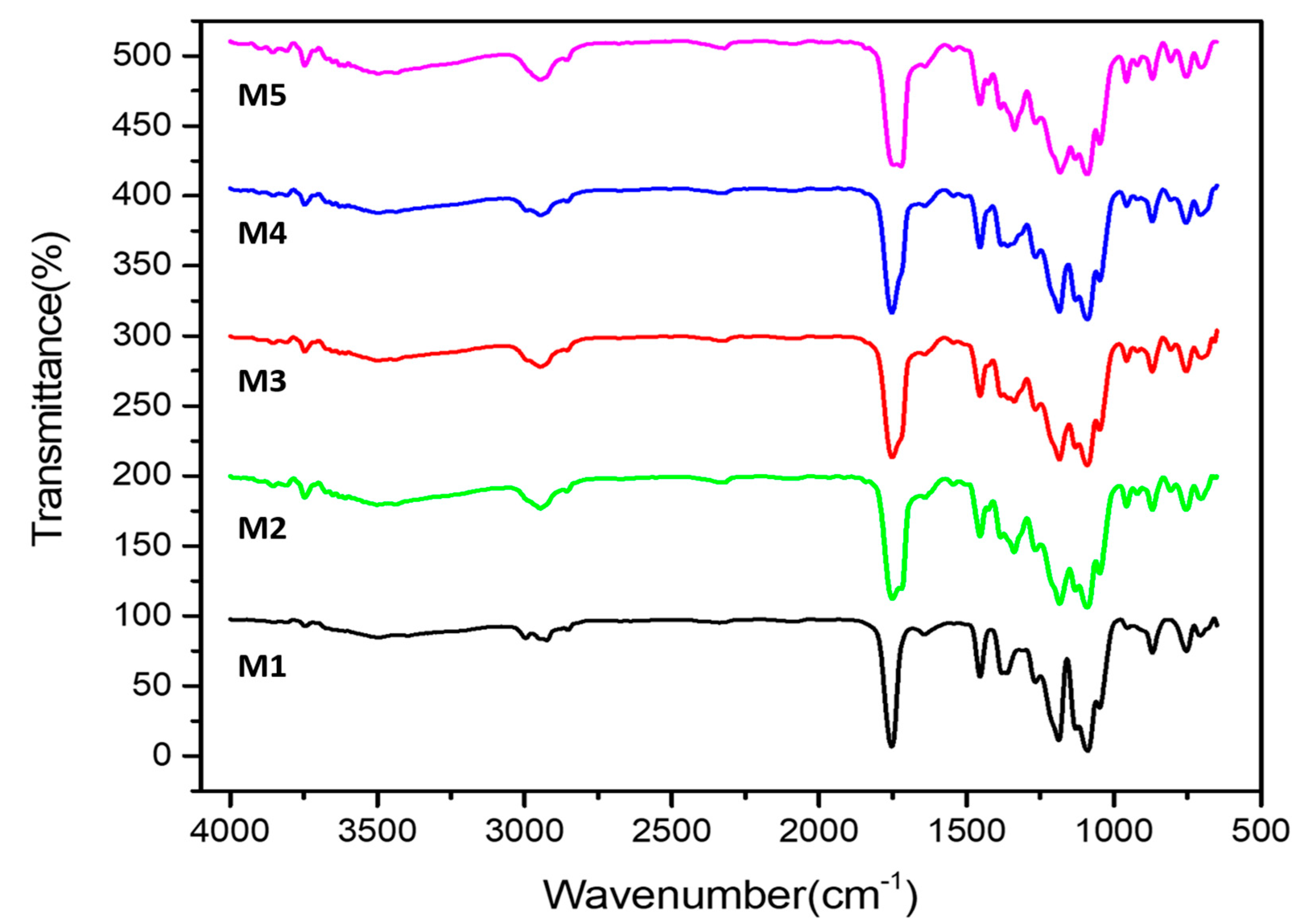

3.4. Fourier Transform Infrared Spectra (FTIR)

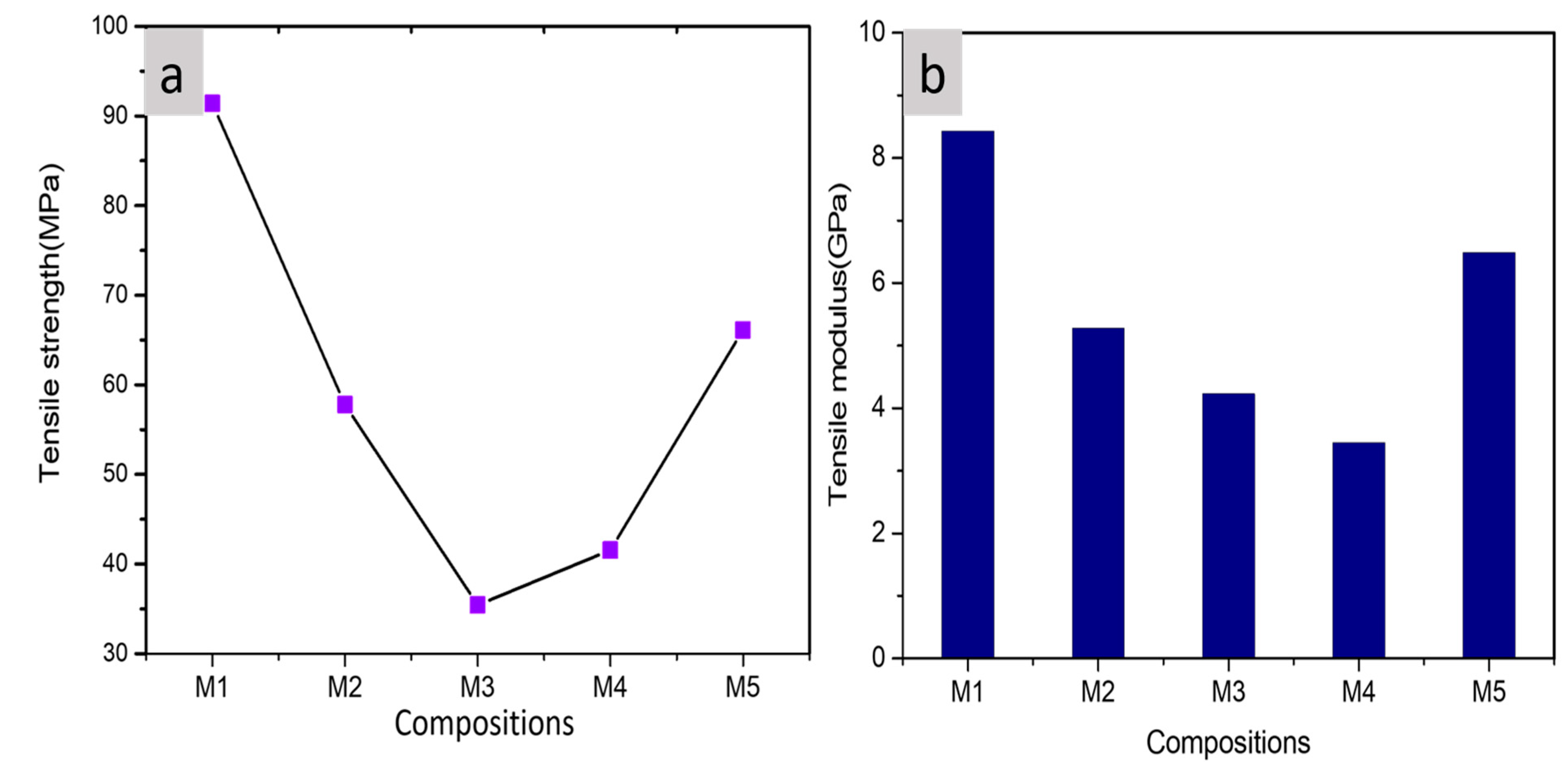

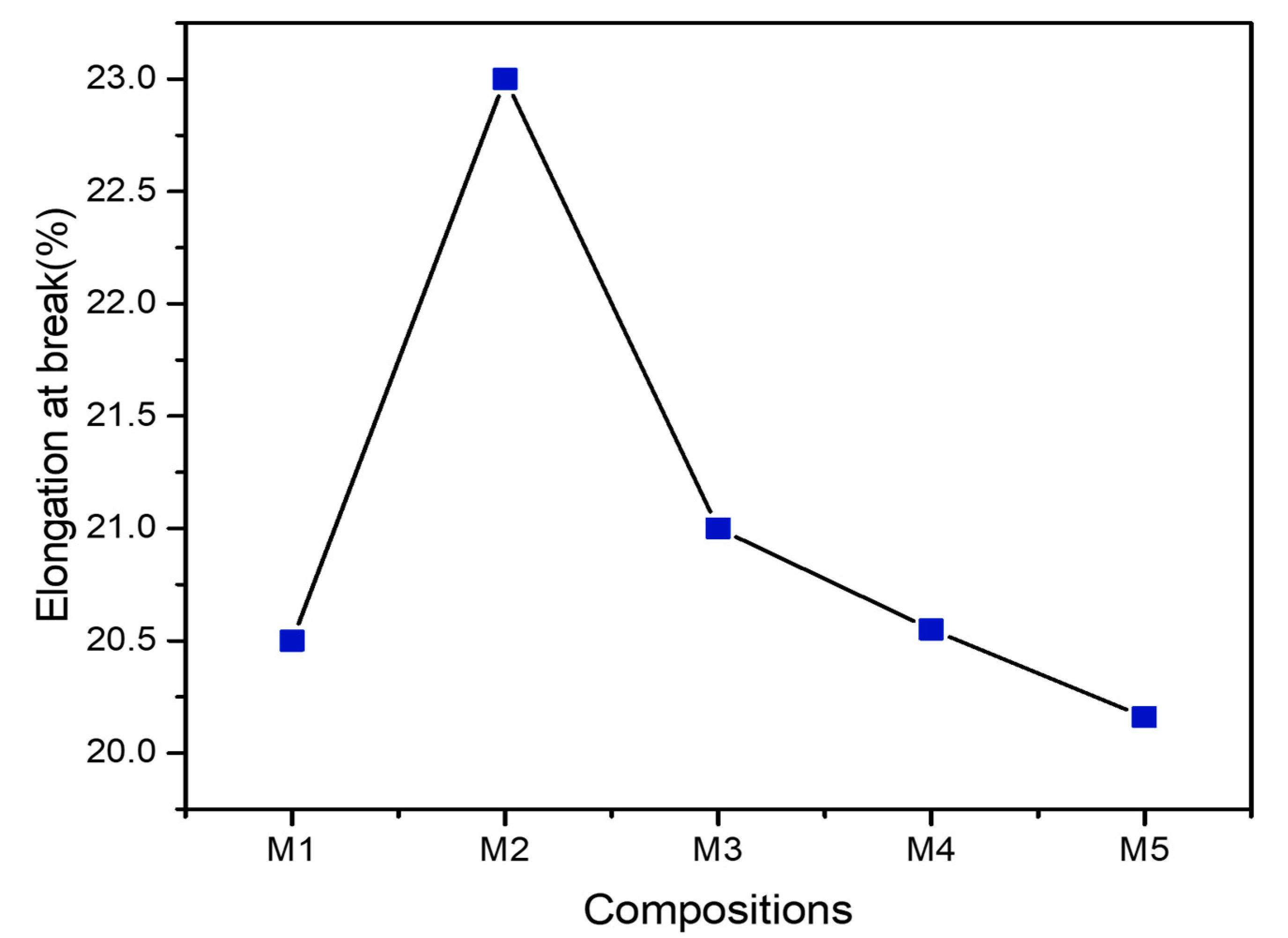

3.5. Tensile Properties

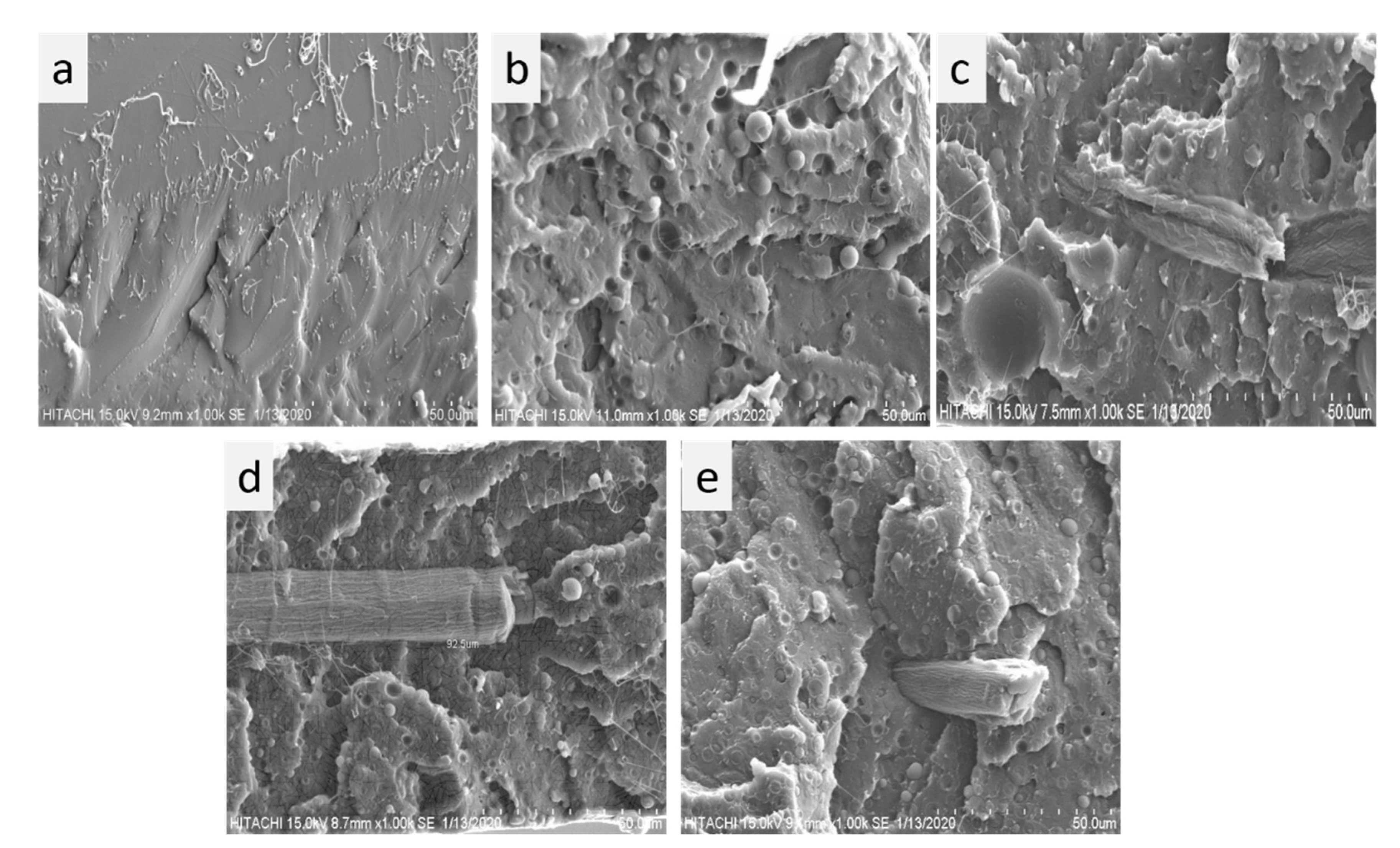

3.6. SEM Analysis of Fractured Surfaces

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, Q.; Hanna, M.A. Rheological properties of amorphous and semicrystalline polylactic acid polymers. Ind. Crop. Prod. 1999, 10, 47–53. [Google Scholar] [CrossRef]

- Ogata, N.; Jimenez, G.; Kawai, H.; Ogihara, T. Structure and thermal/mechanical properties of poly(l-lactide)-clay blend. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 389–396. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Processing and characterization of plasticized PLA/PHB blends for biodegradable multiphase systems. Express Polym. Lett. 2015, 9, 583–596. [Google Scholar] [CrossRef]

- Bai, H.; Huang, C.; Xiu, H.; Gao, Y.; Zhang, Q.; Fu, Q. Toughening of poly(l-lactide) with poly(ε-caprolactone): Combined effects of matrix crystallization and impact modifier particle size. Polymer 2013, 54, 5257–5266. [Google Scholar] [CrossRef]

- Mittal, V.; Akhtar, T.; Matsko, N. Mechanical, Thermal, Rheological and Morphological Properties of Binary and Ternary Blends of PLA, TPS and PCL. Macromol. Mater. Eng. 2015, 300, 423–435. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) blends for packaging application. Korea Aust. Rheol. J. 2007, 19, 125–131. [Google Scholar]

- Liu, X.; Dever, M.; Fair, N.; Polymer, R.B.-J.U. Thermal and Nechanical Properties of Poly (Lactic Acid) and Poly (Ethylene/Butylene Succinate) Blends; Springer: Berlin, Germany, 1997; Volume 5, pp. 225–235. [Google Scholar]

- Yokohara, T.; Yamaguchi, M. Structure and properties for biomass-based polyester blends of PLA and PBS. Eur. Polym. J. 2008, 44, 677–685. [Google Scholar] [CrossRef]

- Homklin, R.; Hongsriphan, N. Mechanical and Thermal Properties of PLA/PBS Co-continuous Blends Adding Nucleating Agent. Energy Procedia 2013, 34, 871–879. [Google Scholar] [CrossRef]

- Lin, N.; Huang, J.; Chang, P.R.; Feng, J.; Yu, J. Surface acetylation of cellulose nanocrystal and its reinforcing function in poly(lactic acid). Carbohydr. Polym. 2011, 83, 1834–1842. [Google Scholar] [CrossRef]

- Lu, T.; Liu, S.; Jiang, M.; Xu, X.; Wang, Y.; Gou, J.; Hui, D.; Chen, X. Effects of modifications of bamboo cellulose fibers on the improved mechanical properties of cellulose reinforced poly(lactic acid) composites. Compos. Part B Eng. 2014, 62, 191–197. [Google Scholar] [CrossRef]

- Haldar, D.; Purkait, M. Micro and nanocrystalline cellulose derivatives of lignocellulosic biomass: A review on synthesis, applications and advancements. Carbohydr. Polym. 2020, 250. [Google Scholar] [CrossRef] [PubMed]

- Das, K.; Ray, D.; Bandyopadhyay, N.R.; Sengupta, S. Study of the Properties of Microcrystalline Cellulose Particles from Different Renewable Resources by XRD, FTIR, Nanoindentation, TGA and SEM. J. Polym. Environ. 2010, 18, 355–363. [Google Scholar] [CrossRef]

- Elsakhawy, M.; Hassan, M. Physical and mechanical properties of microcrystalline cellulose prepared from agricultural residues. Carbohydr. Polym. 2007, 67, 1–10. [Google Scholar] [CrossRef]

- Jahan, M.S.; Saeed, A.; He, Z.; Ni, Y. Jute as raw material for the preparation of microcrystalline cellulose. Cellular 2010, 18, 451–459. [Google Scholar] [CrossRef]

- Courgneau, C.; Domenek, S.; Guinault, A.; Avérous, L.; Ducruet, V. Analysis of the Structure-Properties Relationships of Different Multiphase Systems Based on Plasticized Poly(Lactic Acid). J. Polym. Environ. 2011, 19, 362–371. [Google Scholar] [CrossRef]

- Shih, Y.-F.; Wang, T.Y.; Jeng, R.J.; Wu, J.Y.; Teng, C.C. Biodegradable nanocomposites based on poly(butylene succinate)/organoclay. J. Polym. Environ. 2007, 15, 151–158. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Hua, K.; Duan, C.; Zhang, W.; Ji, J.-H.; Yang, X. Enhanced mechanical properties and degradability of poly(butylene succinate) and poly(lactic acid) blends. Iran. Polym. J. 2013, 22, 267–275. [Google Scholar] [CrossRef]

- Rico, M.; Rodríguez-Llamazares, S.; Barral, L.; Bouza, R.; Montero, B. Processing and characterization of polyols plasticized-starch reinforced with microcrystalline cellulose. Carbohydr. Polym. 2016, 149, 83–93. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Chen, H.M.; Yang, G.; Zheng, X.; Zhou, S. Water-induced shape-memory poly(d,l-lactide)/microcrystalline cellulose composites. Carbohydr. Polym. 2014, 104, 101–108. [Google Scholar] [CrossRef]

- Cao, Z.; Lu, Y.; Zhang, C.; Zhang, Q.; Zhou, A.; Hu, Y.; Wu, D.; Tao, G.; Gong, F.; Ma, W.; et al. Effects of the chain-extender content on the structure and performance of poly(lactic acid)-poly(butylene succinate)-microcrystalline cellulose composites. J. Appl. Polym. Sci. 2017, 134, 1–8. [Google Scholar] [CrossRef]

- Amado, C.M.; Minahk, C.J.; Cilli, E.; Oliveira, R.G.; Dupuy, F.G. Bacteriocin enterocin CRL35 is a modular peptide that induces non-bilayer states in bacterial model membranes. Biochim. Biophys. Acta (BBA) Biomembr. 2020, 1862. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Karim, Z.; Abdullah, L.C. Morphological, Physiochemical and Thermal Properties of Microcrystalline Cellulose (MCC) Extracted from Bamboo Fiber. Molecules 2020, 25, 2824. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Zhang, J.; Wolcott, M.P. Comparison of polylactide/nano-sized calcium carbonate and polylactide/montmorillonite composites: Reinforcing effects and toughening mechanisms. Polymer 2007, 48, 7632–7644. [Google Scholar] [CrossRef]

- Hassan, E.A.; Elarabi, S.E.; Wei, Y.; Yu, M. Biodegradable poly (lactic acid)/poly (butylene succinate) fibers with high elongation for health care products. Text. Res. J. 2017, 88, 1735–1744. [Google Scholar] [CrossRef]

- Thiangtham, S.; Runt, J.; Saito, N.; Manuspiya, H. Fabrication of biocomposite membrane with microcrystalline cellulose (MCC) extracted from sugarcane bagasse by phase inversion method. Cellular 2019, 27, 1367–1384. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, J.; Ye, H.-M.; Dong, Y.; Zhou, Q. Combined effect of cellulose nanocrystals and poly(butylene succinate) on poly(lactic acid) crystallization: The role of interfacial affinity. Carbohydr. Polym. 2018, 179, 79–85. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Pimpan, V.; Chuayjuljit, S.; Leejarkpai, T. Biodegradable Plastics Prepared from Poly(lactic acid), Poly(butylene succinate) and Microcrystalline Cellulose Extracted from Waste-Cotton Fabric with a Chain Extender. J. Polym. Environ. 2015, 23, 114–125. [Google Scholar] [CrossRef]

- Xiuju, Z.; Juncai, S.; Huajun, Y.; Zhidan, L.; Shaozao, T. Mechanical Properties, Morphology, Thermal Performance, Crystallization Behavior, and Kinetics of PP/Microcrystal Cellulose Composites Compatibilized by Two Different Compatibilizers. J. Thermoplast. Compos. Mater. 2011, 24, 735–754. [Google Scholar] [CrossRef]

- Baskaran, R.; Selvasekarapandian, S.; Kuwata, N.; Kawamura, J.; Hattori, T. Conductivity and thermal studies of blend polymer electrolytes based on PVAc–PMMA. Solid State Ionics 2006, 177, 2679–2682. [Google Scholar] [CrossRef]

- Mandal, A.; Chakrabarty, D. Studies on the mechanical, thermal, morphological and barrier properties of nanocomposites based on poly(vinyl alcohol) and nanocellulose from sugarcane bagasse. J. Ind. Eng. Chem. 2014, 20, 462–473. [Google Scholar] [CrossRef]

- Robeson, L.M. Fundamentals of Polymer Blends. Polym. Blends 2007, 11–64. [Google Scholar] [CrossRef]

- Diani, J.; Gall, K. Toughening modification of PLLA/PBS blendsviai in situ compatibilization. Polym. Eng. Sci. 2009, 26–33. [Google Scholar] [CrossRef]

- Ji, D.; Liu, Z.; Lan, X.; Wu, F.; Xie, B.; Yang, M. Morphology, rheology, crystallization behavior, and mechanical properties of poly(lactic acid)/poly(butylene succinate)/dicumyl peroxide reactive blends. J. Appl. Polym. Sci. 2013, 131, 1–8. [Google Scholar] [CrossRef]

- Silverajah, V.S.G.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Abu Hassan, H.; Woei, C.B. A Comparative Study on the Mechanical, Thermal and Morphological Characterization of Poly(lactic acid)/Epoxidized Palm Oil Blend. Int. J. Mol. Sci. 2012, 13, 5878–5898. [Google Scholar] [CrossRef]

- Li, L.; Song, G.; Tang, G. Novel Biodegradable Polylactide/Poly(butylene succinate) Composites via Cross-Linking with Methylene Diphenyl Diisocyanate. Polym. Technol. Eng. 2013, 52, 1183–1187. [Google Scholar] [CrossRef]

- Yeh, J.; Tsou, C.-H.; Li, Y.-M.; Xiao, H.-W.; Wu, C.-S.; Chai, W.-L.; Lai, Y.-C.; Wang, C.-K. The compatible and mechanical properties of biodegradable poly(Lactic Acid)/ethylene glycidyl methacrylate copolymer blends. J. Polym. Res. 2012, 19. [Google Scholar] [CrossRef]

- Zheng, M.; Luo, X. Phase Structure and Properties of Toughened Poly(L-Lactic Acid)/Glycidyl Methacrylate Grafted Poly(Ethylene Octane) Blends Adjusted by the Stereocomplex. Polym. Technol. Eng. 2013, 52, 1250–1258. [Google Scholar] [CrossRef]

- Zou, H.; Yi, C.; Wang, L.; Xu, W. Crystallization, hydrolytic degradation, and mechanical properties of poly (trimethylene terephthalate)/poly(lactic acid) blends. Polym. Bull. 2009, 64, 471–481. [Google Scholar] [CrossRef]

- Park, J.W.; Im, S.S. Phase behavior and morphology in blends of poly(L-lactic acid) and poly(butylene succinate). J. Appl. Polym. Sci. 2002, 86, 647–655. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Song, Z.H.; Leejarkpai, T.; Chuayjuljit, S. Use of Microcrystalline Cellulose Prepared from Cotton Fabric Waste to Prepare Poly(butylene succinate) Composites. Adv. Mater. Res. 2011, 356–360, 430–434. [Google Scholar] [CrossRef]

- Pamuła, E.; Błażewicz, M.; Paluszkiewicz, C.; Dobrzyński, P. FTIR study of degradation products of aliphatic polyesters–carbon fibres composites. J. Mol. Struct. 2001, 596, 69–75. [Google Scholar] [CrossRef]

- Kemala, T.; Budianto, E.; Soegiyono, B. Preparation and characterization of microspheres based on blend of poly(lactic acid) and poly(ɛ-caprolactone) with poly(vinyl alcohol) as emulsifier. Arab. J. Chem. 2012, 5, 103–108. [Google Scholar] [CrossRef]

- Qu, P.; Gao, Y.; Wu, G.F.; Zhang, L.P. Nanocomposites of Poly(lactic acid) reinforced with cellulose nanofibrils. BioResources 2010, 5, 1811–1823. [Google Scholar] [CrossRef]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Leejarkpai, T.; Kashima, D.P.; Chuayjuljit, S. Poly(Lactic Acid)/Poly(Butylene Succinate) Blends Filled with Epoxy Functionalised Polymeric Chain Extender. Adv. Mater. Res. 2013, 664, 644–648. [Google Scholar] [CrossRef]

- Thoorens, G.; Krier, F.; Leclercq, B.; Carlin, B.; Pestieau, A. Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review. Int. J. Pharm. 2014, 473, 64–72. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Luz, S.; Gonçalves, A.R.; Del’Arco, A. Mechanical behavior and microstructural analysis of sugarcane bagasse fibers reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1455–1461. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Effect of Clay on Thermal, Mechanical and Gas Barrier Properties of Biodegradable Poly(lactic acid)/Poly(butylene succinate) (PLA/PBS) Nanocomposites. Int. Polym. Process. 2010, 25, 5–14. [Google Scholar] [CrossRef]

- Shibata, M.; Inoue, Y.; Miyoshi, M. Mechanical properties, morphology, and crystallization behavior of blends of poly(l-lactide) with poly (butylene succinate-co-l-lactate) and poly (butylene succinate). Polymer 2006, 47, 3557–3564. [Google Scholar] [CrossRef]

- Wang, Y.-P.; Xiao, Y.-J.; Duan, J.; Yang, J.-H.; Wang, Y.; Zhang, C.-L. Accelerated hydrolytic degradation of poly(lactic acid) achieved by adding poly(butylene succinate). Polym. Bull. 2015, 73, 1067–1083. [Google Scholar] [CrossRef]

| S.No | Composite | PLA (wt%) | PBS (wt%) | MCC |

|---|---|---|---|---|

| 1. | M1 | 100 | 0 | 0 |

| 2. | M2 | 80 | 20 | 0 |

| 3. | M3 | 80 | 20 | 0.5 |

| 4. | M4 | 80 | 20 | 1 |

| 5. | M5 | 80 | 20 | 1.5 |

| Process | Parameters | |||

|---|---|---|---|---|

| Temperature (°C) | Pressure (MPa) | Time (min) | Speed (rpm) | |

| Melt mixing | 180 | - | 15 | 60 |

| Hot pressing | 180 | 150 | 3 | - |

| Samples | Ti a (°C) | T50 b% (°C) | Tmax c (°C) | Tf d (°C) | Wi e (°C) | Wmax f (%) | Wfinal g (%) | Wresidue h (%) |

|---|---|---|---|---|---|---|---|---|

| M1 | 284.81 | 359.42 | 365.24 | 386.09 | 98.9 | 27.57 | 1.698 | 0.372 |

| M2 | 286.66 | 361.197 | 365.72 | 416.72 | 98.95 | 22.76 | 2.131 | 1.044 |

| M3 | 288.12 | 362.96 | 365.10 | 417.74 | 97.65 | 22.04 | 2.221 | 1.046 |

| M4 | 289.22 | 363.11 | 366.50 | 419.65 | 96.43 | 21.65 | 2.163 | 1.064 |

| M5 | 289.45 | 362.48 | 366.72 | 420.67 | 95.88 | 21.21 | 2.056 | 1.099 |

| Sample | Tg (°C) | Tm (°C) | ΔH (J/g) | Tm1 (°C) | ΔH (J/g) | Tm2 (°C) | ΔH (J/g) |

|---|---|---|---|---|---|---|---|

| M1 | 64 | - | - | 151 | 2.81 | 165.14 | 0.32 |

| M2 | 62 | 113.94 | 6.47 | 146.21 | 6.58 | 152.89 | 4.28 |

| M3 | 63 | 113.60 | 10.68 | 146.23 | 6.74 | 152.73 | 5.29 |

| M4 | 63.10 | 113.51 | 10.62 | 146.33 | 7.77 | 152.84 | 2.41 |

| M5 | 63.24 | 113.56 | 9.34 | 146.01 | 8.27 | 152.68 | 5.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasheed, M.; Jawaid, M.; Parveez, B.; Hussain Bhat, A.; Alamery, S. Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites. Polymers 2021, 13, 465. https://doi.org/10.3390/polym13030465

Rasheed M, Jawaid M, Parveez B, Hussain Bhat A, Alamery S. Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites. Polymers. 2021; 13(3):465. https://doi.org/10.3390/polym13030465

Chicago/Turabian StyleRasheed, Masrat, Mohammad Jawaid, Bisma Parveez, Aamir Hussain Bhat, and Salman Alamery. 2021. "Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites" Polymers 13, no. 3: 465. https://doi.org/10.3390/polym13030465

APA StyleRasheed, M., Jawaid, M., Parveez, B., Hussain Bhat, A., & Alamery, S. (2021). Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites. Polymers, 13(3), 465. https://doi.org/10.3390/polym13030465