1. Introduction

The accuracy of the hyperelastic constitutive model of rubber materials has an important influence on the mechanical analysis and calculation accuracy of rubber structure. The mechanical properties of rubber can be significantly affected by the change of temperature [

1]. Therefore, it is particularly important to screen or propose models that can accurately characterize the mechanical properties of rubber at different temperatures and can be easily applied to the finite element analysis software. So far, the understanding and characterization of the mechanical behavior of rubber materials have been greatly developed. At the same time, many constitutive models have been developed for rubber materials and a lot of experimental data have been obtained [

2,

3]. Different hyperelastic models have different capabilities to predict the complex deformation behavior of rubber materials. Seibert et al. discussed the predictive ability of six hyperelastic models to test data [

4]. Steinmann et al. investigated the fitting ability of 14 hyperelastic models to test data under different deformation states [

5]. Hohenberger et al. studied the constitutive model for both low and high strain non-linearities in highly filled elastomers and implementation [

6]. Ding made a theoretical summary on how to choose the model based on the analysis of uniaxial stress–strain curves [

7]. However, most of these studies focused on examining the hyperelastic mechanical properties of rubber materials at room temperature and in large deformation range (strain exceeding 300%) and did not discuss the selection of models for rubber experimental data at different temperatures. Although most of the rubber components are in the medium deformation range (strain less than 150%), there are relatively few studies on the temperature dependence of the mechanical behavior of filled rubber in the medium deformation range.

In summary, there are few systematic studies on the mechanical properties and temperature dependence of filled rubber, which is difficult to meet the production and design requirements at this stage. Therefore, in order to study the mechanical properties of rubber more accurately, it is necessary to conduct the experimental tests on the temperature-dependent mechanical properties of the filled rubber in a larger deformation range, and to investigate the ability of various rubber constitutive models to characterize the experimental data. It is very important to find or establish a constitutive model that can accurately describe the mechanical characteristics of filled rubber under various deformation states, and to study the ability of the model to describe the temperature dependence of the rubber compound in the medium deformation range.

The main purpose of this paper is to explore the law of hyperelastic temperature dependence of filled rubber under certain deformation, investigate the ability of constitutive models to characterize the temperature dependence of rubber hyperelasticity, reveal the internal laws of temperature dependence of rubber mechanical properties through material parameters, propose a more accurate constitutive model, and study the ability of constitutive models to predict the stress–strain behavior of different deformation states.

4. Experiment Results

The deformation of rubber is generally less than 100% in terms of engineering strain, and 150% strain can be applied to most working conditions. Thus, in the uniaxial tensile test, 150% strain was used to characterize the mechanical properties of rubber materials.

In this section, the nominal stress–strain curve and the Mooney curve were used to study the nonlinear characteristics of the mechanical behavior of rubber compound at different temperatures. The horizontal axis of Mooney curve is the reciprocal of the stretch ratio, i.e.,

, and the vertical axis is “reduced stress

”, where

is the corresponding nominal stress [

29].

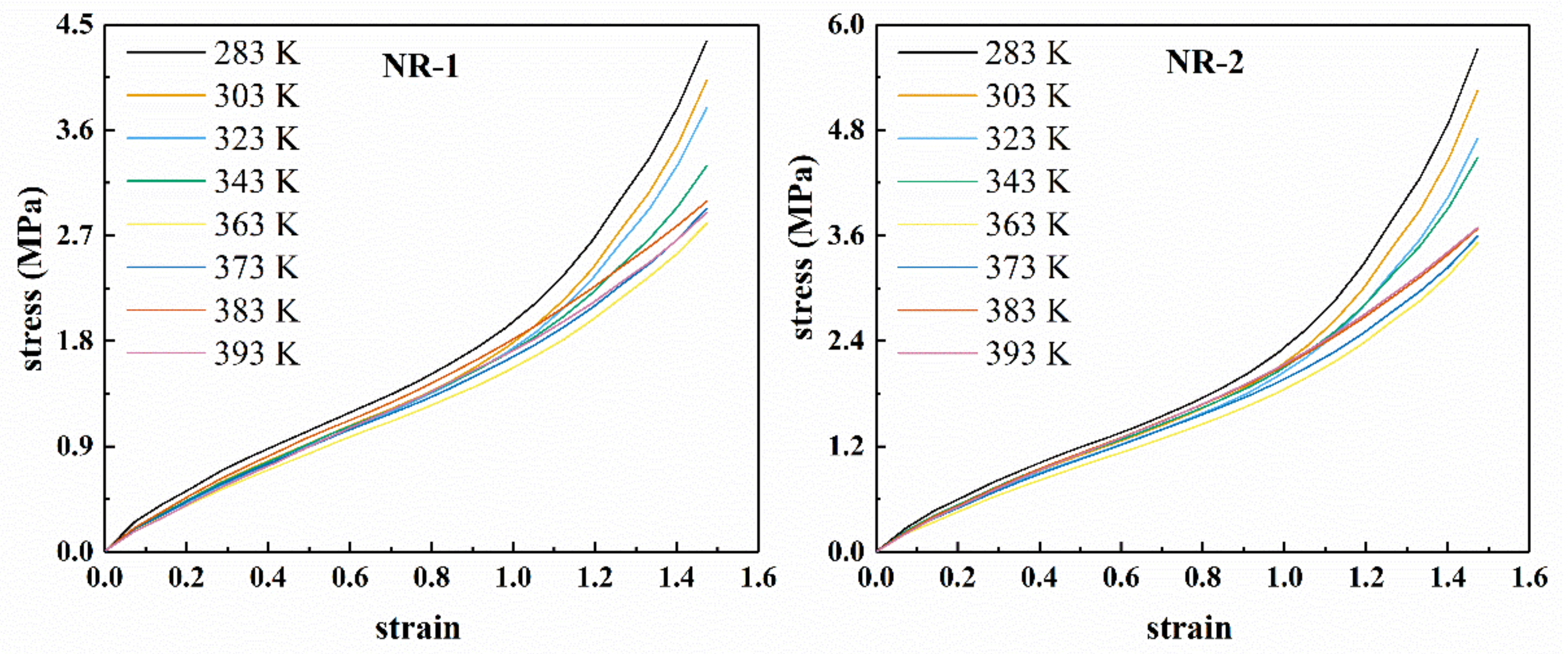

Figure 1 shows the uniaxial tensile nominal stress–strain curves of two types of CB filled rubber at different temperatures. Figure 3 shows the corresponding Mooney curves. Due to the difference in the properties of the two kinds of filled rubber, the temperature range of the Mooney curve varies with the rubber compound.

Figure 2 shows the relationship between the stress and temperature of the two types of rubber under constant strains. From

Figure 1, it can be seen that all the nominal stress–strain curves of filled rubber at different temperatures exhibit obvious “S-shape” non-linear characteristics, that is, the mechanical behavior of filled rubber still maintains highly monotonic nonlinearity, but the non-linear degree of the stress–strain curves does not change with the temperature. According to

Figure 1 and

Figure 2, unlike the natural vulcanized rubber without carbon black filling [

29,

30,

31,

32], under constant strain, the stress of carbon black filled rubber varies nonlinearly with the increase of temperature. When the temperature increased, the overall stress response of the filled compound changed with temperature in a more complex pattern. In the range of 283 K–363 K, the overall stress–strain curve of the rubber decreased with the increase of temperature. Thus, in this temperature range, the rubber material became softer with the temperature. When the temperature exceeded 363 K, the overall stress–strain curve of the rubber compound was higher than the 363 K’s, that is, with the increase of temperature, the modulus stiffness of the rubber compound increased and the rubber became harder. Combined with

Figure 1 and

Figure 2, the variation of stress is relatively disorderly around 393 K, and the stress at constant stretch has a downward tendency again. It appears that at constant stretch, the stress at 393 K is lower than that at 383 K. In the entire temperature range, the constant elongation stress showed a highly nonlinear change with temperature. Considering that the filling of carbon black particles aggravated the viscoelastic response of the rubber compound [

33,

34,

35], the nonlinearity of the stress-temperature relationship of the filled rubber was much more severe than that of the natural vulcanized rubber.

According to

Figure 3, temperature has significant effect on the reduced stress of filled rubber. From

Figure 3, as the temperature increases, the initial modulus of the rubber first decreases, and then increases after the temperature reaches 363 K. The absolute value of the slope and the reduced stress of the Mooney plot increased with the increase of the tensile ratio

at larger stretches(

), which suggested that the deviation from Gaussian behavior was due to the interactions or constraints of neighboring chains. In addition, the “up-turn” indicated the non-Gaussian regime of chain stretch. The Mooney plot of NR-1 showed an overall upward trend at

, and the reduced stress gradually decreased with the increase of the tensile ratio

, which supported the Mooney–Rivlin model [

2]. However, NR-2 showed a downward trend at

. At

, the Mooney plot showed a straight line with a slope of zero, which indicated that the material obeyed Gaussian statistics.

In conclusion, because the interaction between carbon black particles and rubber matrix was obviously affected by temperature, the filled rubber exhibited a more complex temperature-dependent mechanical behavior than pure rubber.

5. Analysis and Evaluation of the Ability of Some Hyperelastic Models to Characterize Temperature Dependence

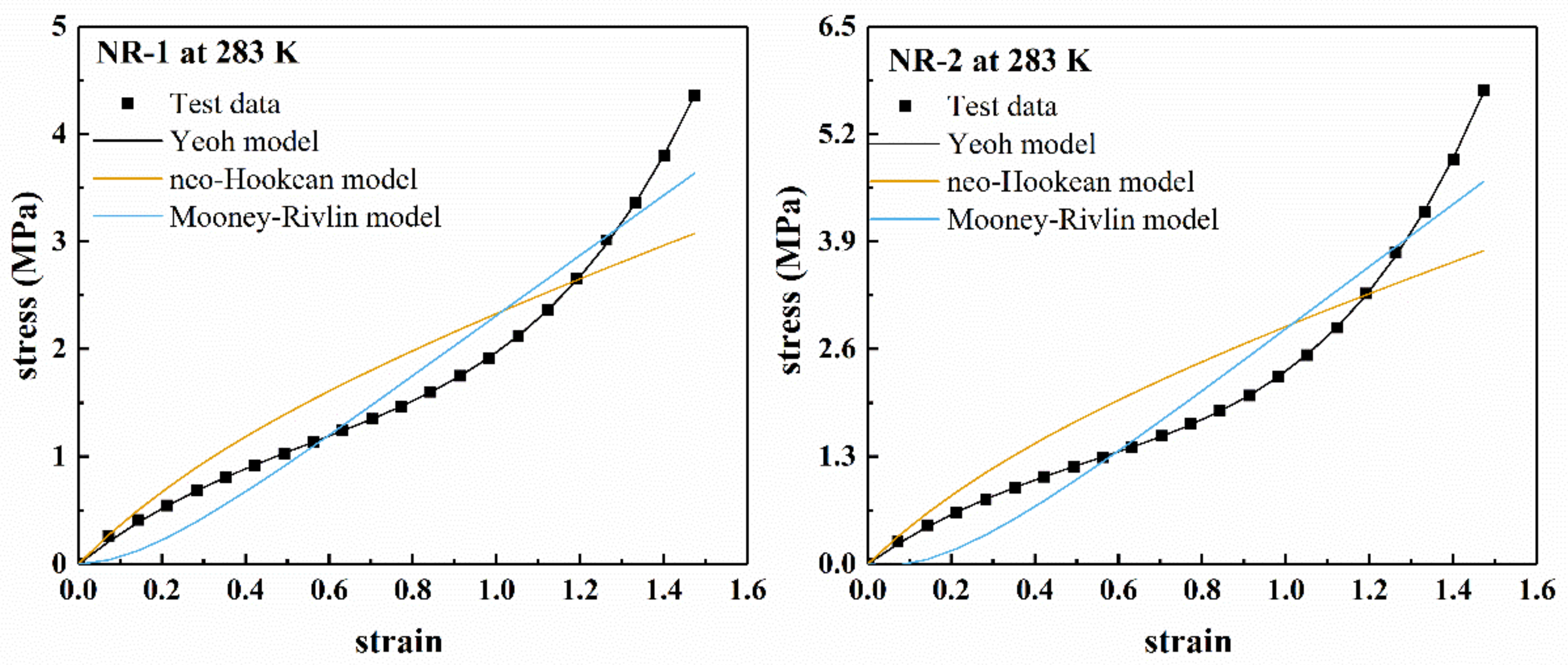

Figure 4 shows the fitting results of several polynomial models for the uniaxial stretching of rubber materials NR-1 and NR-2 at 283 K in a larger deformation range (nominal strain

ε < 1.5).

Figure 5 shows the fitting results of Ogden model for uniaxial tension. It can be seen from

Figure 4 that the neo-Hookean model and Mooney–Rivlin model cannot fit the “S-shape” characteristics of the stress–strain curve under larger deformation, and there are obvious deviations between the fitting results and the uniaxial tensile test data. Therefore, the neo-Hookean model and Mooney–Rivlin model cannot accurately characterize the nonlinear change of material stiffness under larger deformation. The Yeoh model has better fitting results.

It can be found from

Figure 5 that for the experimental data of NR-1 at 283 K, when

n = 1, the Ogden model has poor fitting results. When

n = 2 and

n = 3, the fitting curves overlap, and the model is in good agreement with the experimental data. For NR-2 at 283 K, when

n = 1 and

n = 2, the fitting curves of Ogden model overlap. Only when

n = 3, the fitting curve can well describe the experimental data. The results show that when

n = 2, the ability of the model to describe experimental data was unstable.

Therefore, the fitting ability of Ogden model to data increased with the increase of the value of n. However, the increase of n led to the increase of model parameters, which increased the complexity of the model. For the test materials in this paper, n = 3 was the most appropriate.

In order to evaluate the goodness of fit of the eight-chain model and the improved eight-chain model, we calculated the Total Sum of Squares (TSS) and Residual Sum of Squares (RSS), and obtained the coefficient of determination .

where

is the experimental value,

is the average value of

,

is the model fitting value, and

is the number of experimental data points participating in the fitting. The larger the

, the higher the overall goodness of the model.

Figure 6 shows the fitting results of the eight-chain model and the improved eight-chain model. The residuals of the fitting results are shown in

Figure 7. The values of

of both models are listed in

Table 2. From

Table 2, it can be seen that the improved eight-chain model provides a better fit for both types of rubber than the eight-chain model. From

Figure 6 and

Figure 7, it can be seen that although the eight-chain model can reflect the main characteristics of the mechanical behavior of the rubber to a certain extent, there is still a significant deviation between the fitting results and the experimental data. In the entire deformation range, the fitting result of the improved eight-chain model is better than that of the eight-chain model. In summary, the improved eight-chain model has a better fitting effect.

In summary, Yeoh model, Ogden model (n = 3), and the improved eight-chain model are excellent in describing the data. Subsequently, the following sections will focus on evaluating the capability of Yeoh model, Ogden model (n = 3) and improved eight-chain model to characterize the temperature dependence.

It can be seen from

Figure 8 that within the range of experimental data (

ε < 1.5), there is almost no difference between the fitting curves of the two models, which demonstrates that both models can reasonably describe the experimental data within the range. In addition, the “S shape” of the experimental curve is also well characterized in the fitting curves. For the prediction curves beyond the range of experimental data (

ε > 1.5), the two models only have large differences at 303 K and 323 K, but the shapes of the prediction curves are roughly the same. Thus, it is impossible to judge the pros and cons of the prediction curves of the two models. At other temperatures, the prediction curves of the two models are basically the same. However, using Ogden model (

n = 3), the parameters of the model were extremely difficult to converge, and the calculation time was long, which may cause inconvenience in the application of the model.

The fitting parameters of Yeoh model for NR-1 and NR-2 experimental data at different temperatures are listed in

Table 3. The following relationship was obtained by fitting the experimental data.

Figure 9 shows the relationship of Yeoh model parameters with temperature and the fitting curve of parameters according to Equation (15). As shown in

Figure 9, the trend of Yeoh model parameter

with temperature is similar to the stress-temperature curve, that is, as the temperature increases, the parameter value first decreases and then increases, and the inflection point is between 353 K and 373 K. In conclusion,

varies approximately as a quadratic function with temperature, and has a certain temperature dependence. The parameters

and

almost change linearly with temperature.

Figure 10 and

Table 4 show the relationship between the parameters of Ogden model (

n = 3) and temperature. As can be seen from the diagram, the parameters of Ogden model have no law with the change of temperature, so it can be said that the parameters have no temperature dependence.

In summary, Yeoh model and Ogden model (n = 3) have good ability to describe the experimental results at different temperatures and to predict beyond the range of experimental data. However, as mentioned earlier, the Yeoh and Ogden model parameters are empirical and lack physical meaning. So, it is difficult to ensure that the two models can correctly describe the nonlinear characteristics of rubber under various deformation states only by using the model parameters determined by a single deformation form. Moreover, the Ogden model (n = 3) has too many model parameters and poor fitting convergence.

Figure 11 shows the fitting results of the improved eight-chain model for the uniaxial tension of the filled rubber NR-1, and

Figure 12 shows the Mooney curve of the model. From

Figure 11, it can be seen that the improved eight-chain model can accurately describe the uniaxial tensile mechanical behavior of the rubber NR-1 at different temperatures and can reasonably reflect the “S shape” of stress–strain curve of the filled rubber in the studied deformation range.

Figure 12 shows that when

, the improved eight-chain model can reasonably describe the Mooney curve of the rubber at different temperatures; however, when

, there is a larger difference between the fitting curve of the improved eight-chain model and the Mooney curve, and the reduced stress of the test data is obviously larger than the fitting value. This phenomenon is due to the fact that in the early stage of tension, the stress is relatively small, and the equipment error is relatively large. Therefore, in the early stage of tension, the test stress was larger than the actual stress, and the improved eight-chain model corrected the equipment error to a certain extent. After model correction, the curve in

Figure 12 shows linear behavior in the small to moderate stretch range, and an upward trend in a larger stretch range.

Table 5 lists the values of the fitting parameters of the improved eight-chain model according to the test data of the filling rubber NR-1 at different temperatures.

Figure 13 shows the variation trend of the four material parameters of the improved eight-chain model with temperature. From

Figure 13a, the changes of parameters

and

are approximately a quadratic function of temperature, and the shape and trend of the curves of the two parameters are approximately the same, which shows that the physical properties of the rubber compound also vary regularly with temperature. According to

Figure 13b, it is found that the parameter

changes approximately linearly with temperature, and the parameter

changes exponentially with temperature. It can be concluded that the parameters of the improved eight-chain model have the law of temperature dependence.

6. Analysis and Evaluation of the Predictive Ability of the Hyperelastic Model in Various Deformation States

If only uniaxial tension data is used, a set of coefficients can be obtained through each constitutive model. After the coefficients are determined, the constitutive model can predict biaxial tension and pure shear curves. According to the conclusions of the previous section, the Yeoh model and the improved eight-chain model were selected to evaluate the predictive ability of the experimental data.

Based on the data in Reference [

36], the fitting results of the improved eight-chain model and the Yeoh model for uniaxial stretching of a certain filled rubber material as well as the prediction results under pure shear and biaxial tension deformation were obtained, as shown in

Figure 14.

Table 6 lists the model fitting parameters and correlation coefficient

R corresponding to uniaxial tension. It can be seen from

Figure 14 and

Table 6 that both models can well characterize the stress–strain relationship under uniaxial tension. In addition, when the pure shear (

ε < 0.2) and biaxial tension (

ε < 0.6) are in a small deformation range, the predictions of the two models are very accurate. However, under a larger deformation, the prediction results of the two models for pure shear (

ε > 0.6) and biaxial tension (

ε > 0.2) have deviation from the test results. However, in a larger deformation range, the improved eight-chain model still has better predictive ability than the Yeoh model.

Figure 15a shows the stress–strain curve on the Przybylo and Arruda compression test results [

37], and the Yeoh and improved eight-chain models were used to fit the experimental data. The fitting results are also shown in

Figure 15a. The corresponding fitting coefficients and correlation coefficients

R are listed in

Table 7. From

Figure 15a and

Table 7, it can be found that both models can accurately reproduce the uniaxial compression data. When the uniaxial compression analysis of each model was extended beyond the characteristic range, the Yeoh model failed to predict the expected response, as shown in

Figure 15b, which was due to the fact that as the compressive stretch increased, the nominal stress had a smaller and smaller negative value. The constants in

Table 7 were used to predict uniaxial stretching, and the results are shown in

Figure 15b. The predicted tensile results were similar under moderate stretches (

ε < 1.5) for both models, but varied substantially under large stretches (

ε > 1.5), only the improved eight-chain model can reasonably predict the actual physical response of tension, the Yeoh model become unstable in tension and predict unrealistic responses. This result was due to the fact that the Drucker’s stability of the Yeoh model was not considered [

38]. However, considering the stability will sacrifice the fitting accuracy of the model. The improved eight-chain model is extended from the eight-chain model, so the parameters have inherent stability. Therefore, from this perspective, the improved eight-chain model is superior to the Yeoh model.

9. Conclusions

(1) The phenomenological model and the molecular chain model of statistical mechanics are theoretically summarized. By combining the advantages of exponential function to describe the hyperelastic behavior of rubber, the eight-chain model was modified, and an improved eight-chain model was proposed.

(2) The temperature-dependent laws of the mechanical behavior of the filled rubber in a larger deformation range were summarized. When the temperature increased in the range of 283 K to 363 K, the uniaxial tensile modulus of the rubber decreased accordingly. When the temperature was higher than 363 K, the uniaxial tensile stress–strain curve of the rubber went up as a whole, the modulus of the rubber compound increased with the increase of temperature, and the rubber compound became hard. At 393 K, the mechanical state of rubber was no longer stable, and the curve had a downward trend, that is, the rubber compound became soft again. Compared with natural rubber, the mechanical properties of filled rubber showed more complex temperature dependence.

(3) Based on the uniaxial tensile data at different temperatures, the ability of several classical hyperelastic constitutive models to describe temperature dependence was evaluated. The results showed that the improved eight-chain model can accurately describe the uniaxial tensile mechanical behavior of two rubber compounds at different temperatures and can reasonably reflect the non-linear changes of the stress–strain curves at different temperatures. The Yeoh and Ogden models also had good ability to describe temperature dependence. However, although the higher-order Ogden model (n = 3) had good fitting effect, it contained too many parameters and the fitting convergence was difficult. On the contrary, the low-order Ogden model (n = 1, n = 2) had poor ability to describe data. The parameters of the Yeoh model are empirical, and if the parameters of the model are only determined by a single deformation state, it is difficult to ensure that the model can correctly describe the nonlinear characteristics of rubber under various deformation states. Compared with the improved eight-chain model, the polynomial model and the eight-chain model had more challenges to accurately reflect the nonlinear elastic mechanical properties of rubber compound at different temperatures.

(4) The improved eight-chain model proposed and developed in this paper can accurately describe the deformation state of the filled rubber in the entire deformation range. Another advantage of the improved eight-chain model is that it is based on the eight-chain model, so its parameters and prediction curves inherit the inherent stability of the eight-chain model. In addition, the improved eight-chain model had high practicality because only one test was required to determine the model parameters of the rubber, and then the mechanical response of rubber under other strain states can be fully characterized by the model.

(5) Finally, the finite element software ABAQUS was used to simulate the uniaxial tension of rubber specimens, and the simulation results were compared with corresponding test data to verify the reliability of material parameters. The results showed that the constitutive model proposed in this paper can effectively characterize the static mechanical properties of carbon black filled rubber and can be easily embedded into the existing finite element software. It has the characteristics of few material parameters, accurate results, strong engineering practicability, etc.