A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives

Abstract

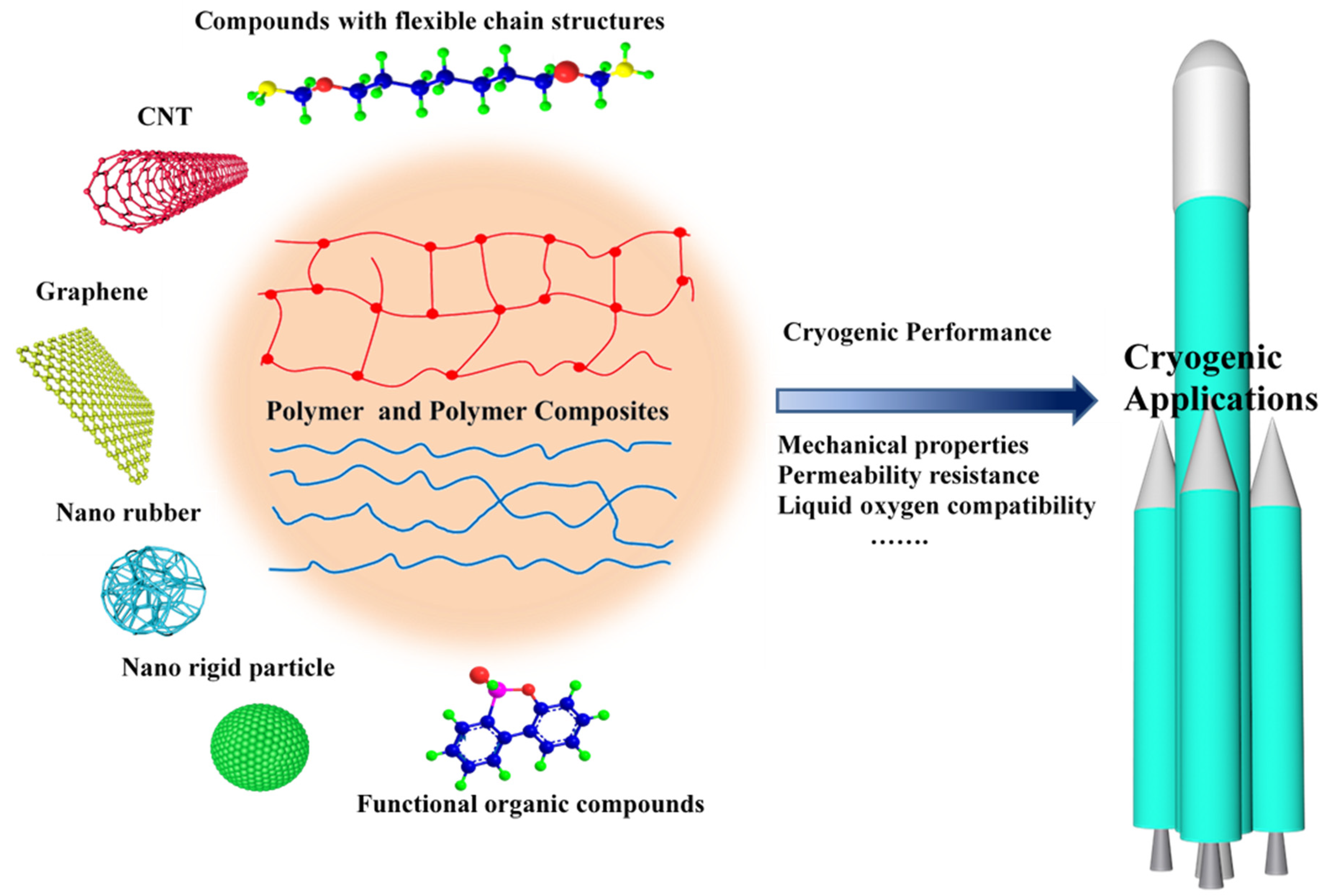

1. Introduction

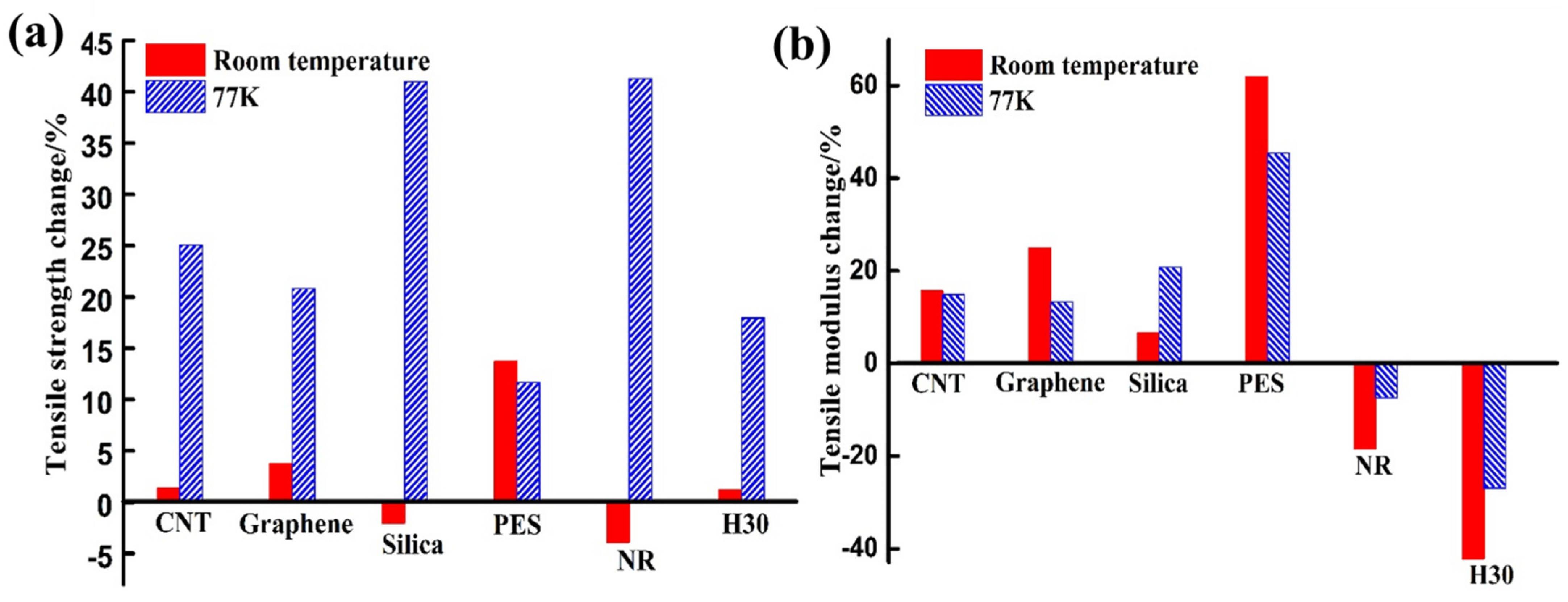

2. The Research Development of Thermoset Polymer for Cryogenic Application

2.1. Enhancing the Cryogenic Performance of Thermoset Polymer by Introducing the Rigid Nanomaterial

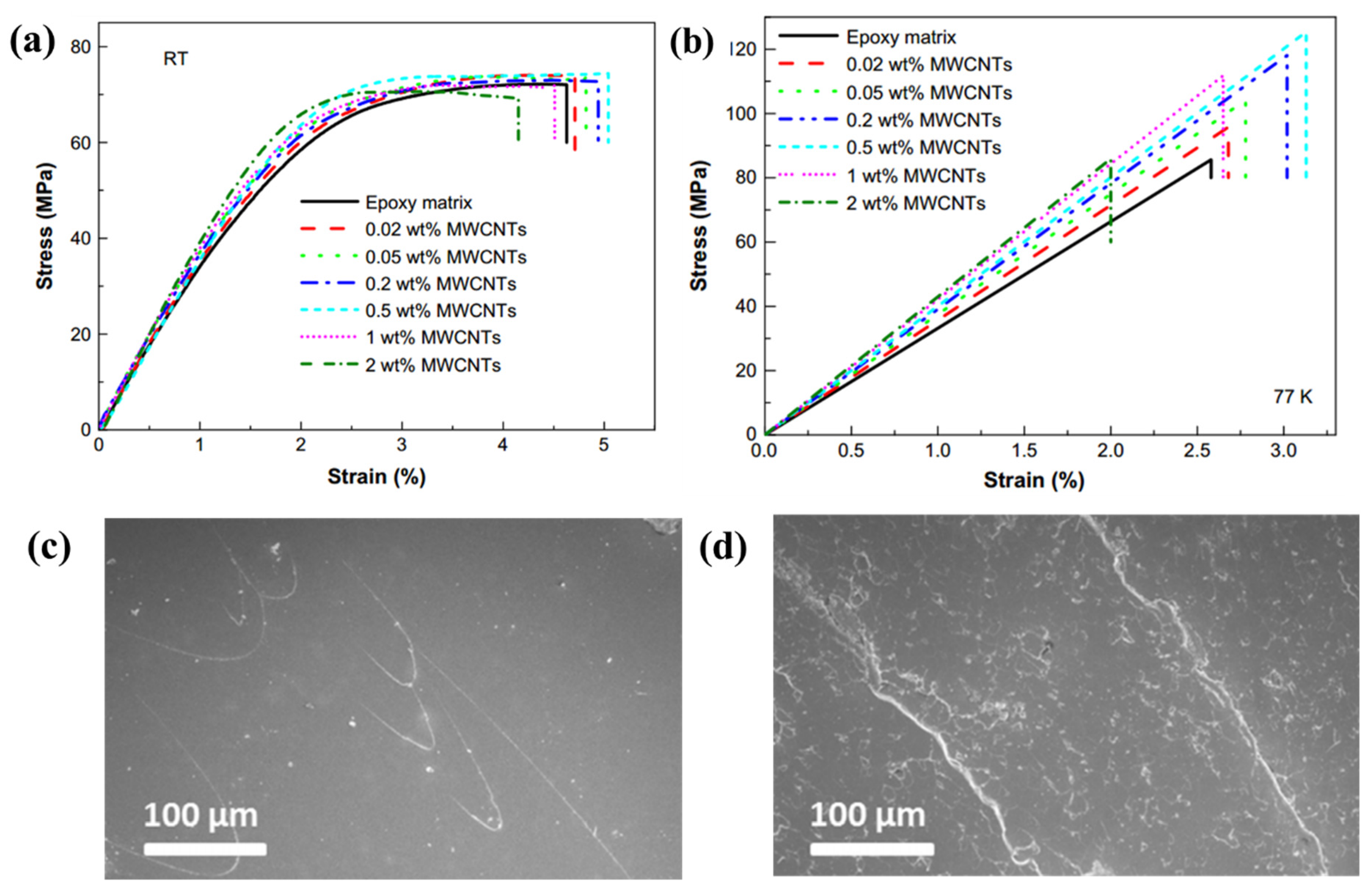

2.1.1. Carbon Nanotubes

2.1.2. Graphene

2.1.3. Other Inorganic Nanomaterials

2.2. Enhancing the Cryogenic Performance of Thermoset Polymer by Introducing the Soft Organic Modifiers

2.2.1. Thermoplastic Polymer

2.2.2. Rubber

2.3. Enhancing the Cryogenic Performance of Thermoset Polymer by Decreasing the Crosslink Density

3. The Research Development of Thermoplastic Polymer for Cryogenic Application

3.1. The Cryogenic Performance of Pristine Thermoplastic Polymer

3.2. The Cryogenic Performance of Modified Thermoplastic Polymer

4. The Research Development of the Polymer for Liquid Oxygen Application

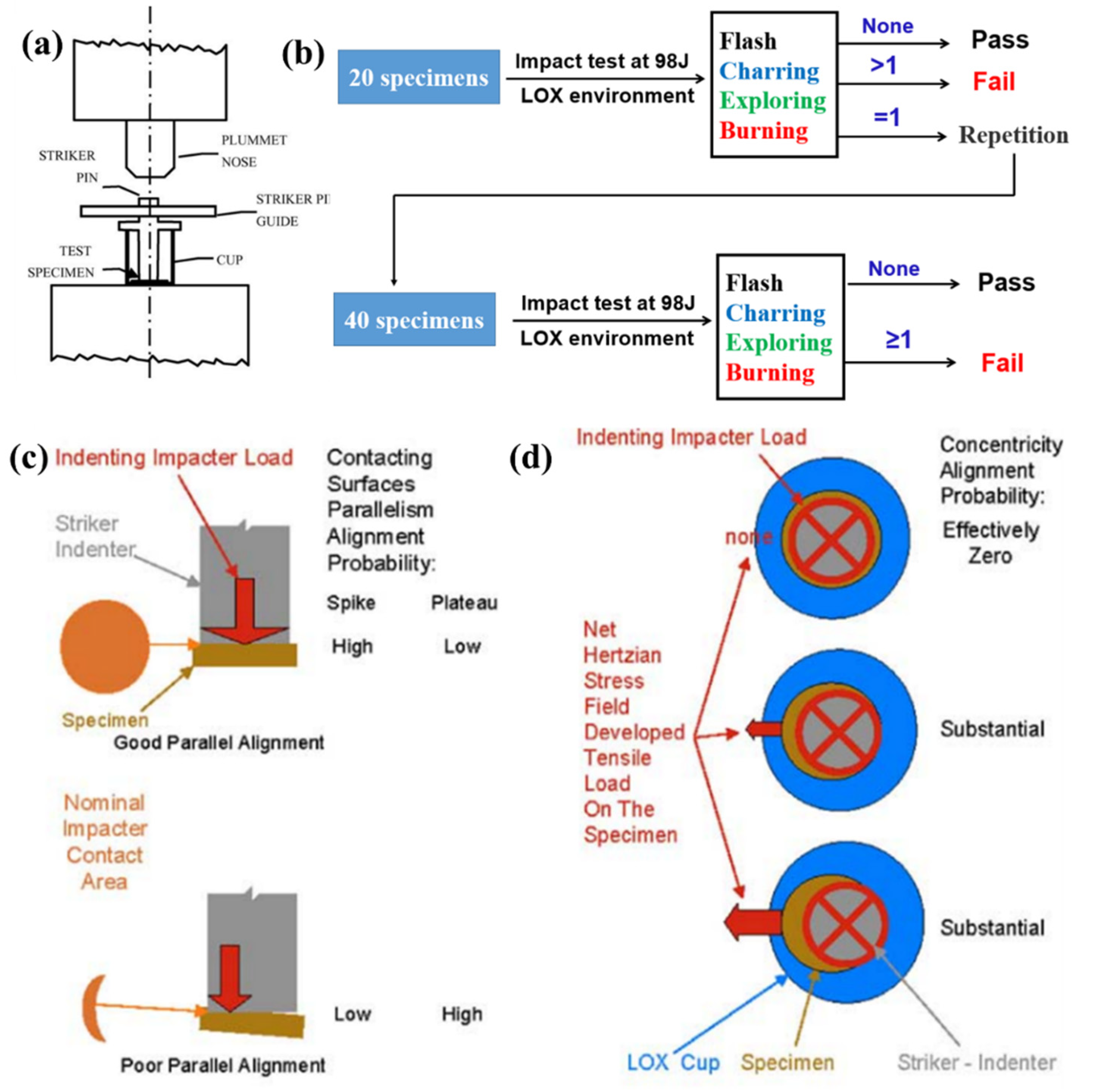

4.1. The Acceptance-Testing Method of Materials Used in the Liquid Oxygen Environment

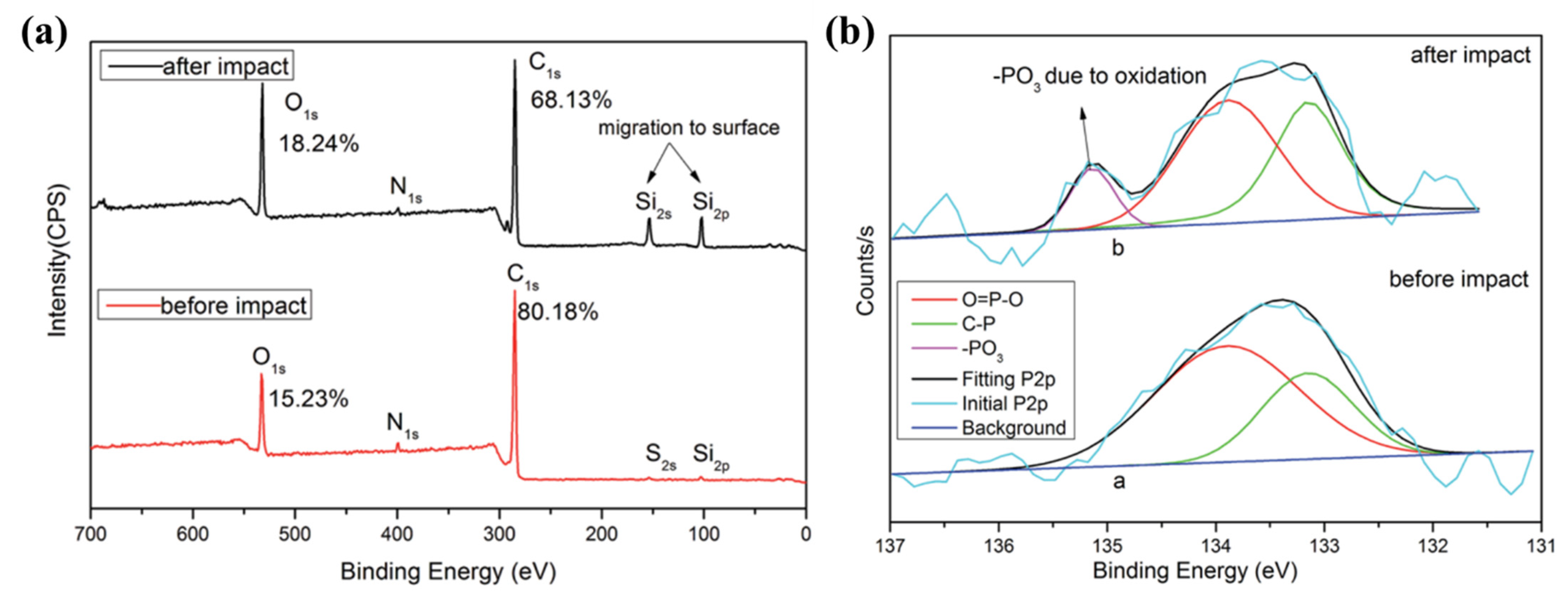

4.2. Research Progress in Liquid Oxygen Compatibility of Polymers

5. Summary and Perspectives

- Compared with thermosetting or general used thermoplastic polymers, the high-performance engineering thermoplastic polymers have more potential for cryogenic application due to their prominent comprehensive properties (strength, toughness, flame retardancy and recyclable performance). However, the research of high-performance engineering plastic for cryogenic use are seldomly reported. With the development of energy and aerospace, more attention should be paid on the study of high-performance engineering thermoplastic and its composites for cryogenic application.

- The damage evolution and fracture mechanism and the LOX compatibility mechanism of polymer and its composites at cryogenic temperature need to be studied further. A deep understanding of the cryogenic performance of polymer and its composites would help researchers to find more effective ways to obtain suitable material.

- During the cryogenic performance test process of the material, several cryogenic media such as LHe, LN2, and LOX are necessary to provide the cryogenic test environment. Because these cryogenic liquid fluids are extremely volatile, it would take a lot of time and liquids to test the cryogenic performance of the material. Thus, it will be meaningful and interesting to find out the relationship between room temperature performance and cryogenic temperature performance of polymer and its composites or construct the prediction model based on the data of the report to predict the cryogenic performance polymer.

- The present reports mainly focused on the effectiveness of the methods to improve the cryogenic performance such as mechanical properties, LOX compatibility and impermeability of polymer and its composites. However, the processability of the modified polymer such as viscosity and pot life, which are essential for practical applications, is not included. Future work is required to provide greater insight into the processability of material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bostock, T.D.; Scurlock, R.G. Introduction. Low-Loss Storage and Handling of Cryogenic Liquids: The Application of Cryogenic Fluid Dynamics; Springer International Publishing: Cham, Switzerland, 2019; pp. 1–11. [Google Scholar]

- Zohuri, B. Physics of Cryogenics—An Ultralow Temperature Phenomenon; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Yano, O.; Yamaoka, H. Cryogenic properties of polymers. Prog. Polym. Sci. 1995, 20, 585–613. [Google Scholar] [CrossRef]

- Irving, S.P.E.; Soutis, C. Polymer Composites in the Aerospace Industry; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Johnson, T.F.; Sleight, D.W.; Martin, R.A. Structures and Design Phase I Summary for the NASA Composite Cryotank Technology Demonstration Project. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013. [Google Scholar] [CrossRef]

- Sippel, M.; Kopp, A.; Sinkó, K.; Mattsson, D. Advanced Hypersonic Cryo-Tanks Research in CHATT. In Proceedings of the 18th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Tours, France, 24–28 September 2012. [Google Scholar] [CrossRef]

- McCarville, D.A.; Guzman, J.C.; Dillon, A.K.; Jackson, J.R.; Birkland, J.O. 3.5 Design, Manufacture and Test of Cryotank Components; Elsevier: Amsterdam, The Netherlands, 2018; pp. 153–179. [Google Scholar]

- Space Exploration Technologies Corp. Capabilities and Services. Available online: https://www.spacex.com/media/Capabilities&Services (accessed on 14 October 2020).

- Achary, D.; Biggs, R.; Bouvier, C.; McBain, M.; Lee, W. Composite Development & Applications for Cryogenic Tankage. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Austin, TX, USA, 18–21 April 2005. [Google Scholar] [CrossRef]

- Grayson, G.; Cook, L. Performance characteristics of the DC-XA liquid oxygen propellant-acquisition system. In Proceedings of the 32nd Joint Propulsion Conference and Exhibit, Lake Buena vista, FL, USA, 1–3 July 1996. [Google Scholar] [CrossRef]

- Glaessgen, E.H.; Reeder, J.R.; Sleight, D.W.; Wang, J.T.; Raju, I.S.; Harris, C.E. Debonding Failure of Sandwich-Composite Cryogenic Fuel Tank with Internal Core Pressure. J. Spacecr. Rocket. 2005, 42, 613–627. [Google Scholar] [CrossRef]

- Space. SpaceX Tests Huge Fuel Tank for Mars Colony Spaceship. Available online: https://www.space.com/34759-spacex-mars-spaceship-fuel-tank-test.html (accessed on 14 October 2020).

- Pavlick, M.; Johnson, W.; Jensen, B.; Weiser, E. Evaluation of mechanical properties of advanced polymers for composite cryotank applications. Compos. Part A Appl. Sci. Manuf. 2009, 40, 359–367. [Google Scholar] [CrossRef]

- Callaghan, M. Use of resin composites for cryogenic tankage. Cryogenics 1991, 31, 282–287. [Google Scholar] [CrossRef]

- Mayes, J.S.; Nickerson, S.; Welsh, J. Multiscale Approach to the Effects of Cryogenic Environments on Polymer Matrix Composites. In Proceedings of the 45th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Palm Springs, CA, USA, 19–22 April 2004. [Google Scholar] [CrossRef]

- Bechel, V.; Arnold, F. Permeability of polymer composites for cryogenic applications. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, RI, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Robinson, M.; Stoltzfus, J.; Owens, T. Composite material compatibility with liquid oxygen. In Proceedings of the 38th Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 7–10 April 1997. [Google Scholar] [CrossRef]

- Naebe, M.; Abolhasani, M.M.; Khayyam, H.; Amini, A.; Fox, B. Crack Damage in Polymers and Composites: A Review. Polym. Rev. 2016, 56, 31–69. [Google Scholar] [CrossRef]

- Sumikawa, M.; Shindo, Y.; Takeda, T.; Narita, F.; Takano, S.; Sanada, K. Analysis of Mode I Interlaminar Fracture and Damage Behavior of GFRP Woven Laminates at Cryogenic Temperatures. J. Compos. Mater. 2005, 39, 2053–2066. [Google Scholar] [CrossRef]

- Shindo, Y.; Sato, T.; Narita, F.; Sanada, K. Mode II Interlaminar Fracture and Damage Evaluation of GFRP Woven Laminates at Cryogenic Temperatures using the 4ENF Specimen. J. Compos. Mater. 2008, 42, 1089–1101. [Google Scholar] [CrossRef]

- Miura, M.; Shindo, Y.; Narita, F.; Watanabe, S.; Suzuki, M. Mode III fatigue delamination growth of glass fiber reinforced polymer woven laminates at cryogenic temperatures. Cryogenics 2009, 49, 407–412. [Google Scholar] [CrossRef]

- Shindo, Y.; Takahashi, S.; Takeda, T.; Narita, F.; Watanabe, S. Mixed-mode interlaminar fracture and damage characterization in woven fabric-reinforced glass/epoxy composite laminates at cryogenic temperatures using the finite element and improved test methods. Eng. Fract. Mech. 2008, 75, 5101–5112. [Google Scholar] [CrossRef]

- Choi, S.; Sankar, B.V. Micromechanical Analysis of Composite Laminates at Cryogenic Temperatures. J. Compos. Mater. 2005, 40, 1077–1091. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.; Xu, H.; Wu, Z. Prediction on residual stresses of carbon/epoxy composite at cryogenic temperature. Polym. Compos. 2019, 40, 3412–3420. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Narita, F. Three-dimensional thermoelastic analysis of cracked plain weave glass/epoxy composites at cryogenic temperatures. Compos. Sci. Technol. 2004, 64, 2353–2362. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Chruściel, J.J.; Leśniak, E. Modification of epoxy resins with functional silanes, polysiloxanes, silsesquioxanes, silica and silicates. Prog. Polym. Sci. 2015, 41, 67–121. [Google Scholar] [CrossRef]

- Bagheri, R.; Marouf, B.T.; Pearson, R.A. Rubber-Toughened Epoxies: A Critical Review. Polym. Rev. 2009, 49, 201–225. [Google Scholar] [CrossRef]

- Vidil, T.; Tournilhac, F.; Musso, S.; Robisson, A.; Leibler, L. Control of reactions and network structures of epoxy thermosets. Prog. Polym. Sci. 2016, 62, 126–179. [Google Scholar] [CrossRef]

- Marouf, B.T.; Mai, Y.-W.; Bagheri, R.; Pearson, R.A. Toughening of Epoxy Nanocomposites: Nano and Hybrid Effects. Polym. Rev. 2016, 56, 70–112. [Google Scholar] [CrossRef]

- Fallahi, H.; Taheri-Behrooz, F.; Asadi, A. Nonlinear Mechanical Response of Polymer Matrix Composites: A Review. Polym. Rev. 2019, 60, 42–85. [Google Scholar] [CrossRef]

- Jesson, D.A.; Watts, J.F. The Interface and Interphase in Polymer Matrix Composites: Effect on Mechanical Properties and Methods for Identification. Polym. Rev. 2012, 52, 321–354. [Google Scholar] [CrossRef]

- Biron, M.; Marichal, O. Thermoplastics and Thermoplastic Composites; William Andrew: Waltham, MA, USA, 2013. [Google Scholar]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Dodiuk, H.; Goodman, S.H. Handbook of Thermoset Plastics; William Andrew: Waltham, MA, USA, 2014. [Google Scholar]

- Capricho, J.C.; Fox, B.L.; Hameed, N. Multifunctionality in Epoxy Resins. Polym. Rev. 2019, 60, 1–41. [Google Scholar] [CrossRef]

- Chen, Z.-K.; Yang, J.-P.; Ni, Q.-Q.; Fu, S.-Y.; Huang, Y.-G. Reinforcement of epoxy resins with multi-walled carbon nanotubes for enhancing cryogenic mechanical properties. Polymer 2009, 50, 4753–4759. [Google Scholar] [CrossRef]

- Jia, L.; Qi, P.; Shi, K.; Liu, X.; Ma, W.; Lin, S.; Zhang, F.; Jia, X.; Cai, Q.; Yang, X. High performance epoxy-based composites for cryogenic use: A approach based on synergetic strengthening effects of epoxy grafted polyurethane and MWCNTs-NH2. Compos. Sci. Technol. 2019, 184, 107865. [Google Scholar] [CrossRef]

- Yi, X.F.; Mishra, A.K.; Kim, N.H.; Ku, B.-C.; Lee, J.H. Synergistic effects of oxidized CNTs and reactive oligomer on the fracture toughness and mechanical properties of epoxy. Compos. Part A Appl. Sci. Manuf. 2013, 49, 58–67. [Google Scholar] [CrossRef]

- Shen, X.-J.; Liu, Y.; Xiao, H.-M.; Feng, Q.-P.; Yu, Z.-Z.; Fu, S.-Y. The reinforcing effect of graphene nanosheets on the cryogenic mechanical properties of epoxy resins. Compos. Sci. Technol. 2012, 72, 1581–1587. [Google Scholar] [CrossRef]

- Hussein, A.; Sarkar, S.; Lee, K.; Kim, B. Cryogenic fracture behavior of epoxy reinforced by a novel graphene oxide/poly(p-phenylenediamine) hybrid. Compos. Part B Eng. 2017, 129, 133–142. [Google Scholar] [CrossRef]

- Lee, J.K.; Song, S.; Kim, B. Functionalized graphene sheets-epoxy based nanocomposite for cryotank composite application. Polym. Compos. 2012, 33, 1263–1273. [Google Scholar] [CrossRef]

- Prusty, R.K.; Rathore, D.K.; Sahoo, S.; Parida, V.; Ray, B.C. Mechanical behaviour of graphene oxide embedded epoxy nanocomposite at sub- and above- zero temperature environments. Compos. Commun. 2017, 3, 47–50. [Google Scholar] [CrossRef]

- He, Y.; Chen, Q.; Yang, S.; Lu, C.; Feng, M.; Jiang, Y.; Cao, G.; Zhang, J.; Liu, C. Micro-crack behavior of carbon fiber reinforced Fe3O4/graphene oxide modified epoxy composites for cryogenic application. Compos. Part A Appl. Sci. Manuf. 2018, 108, 12–22. [Google Scholar] [CrossRef]

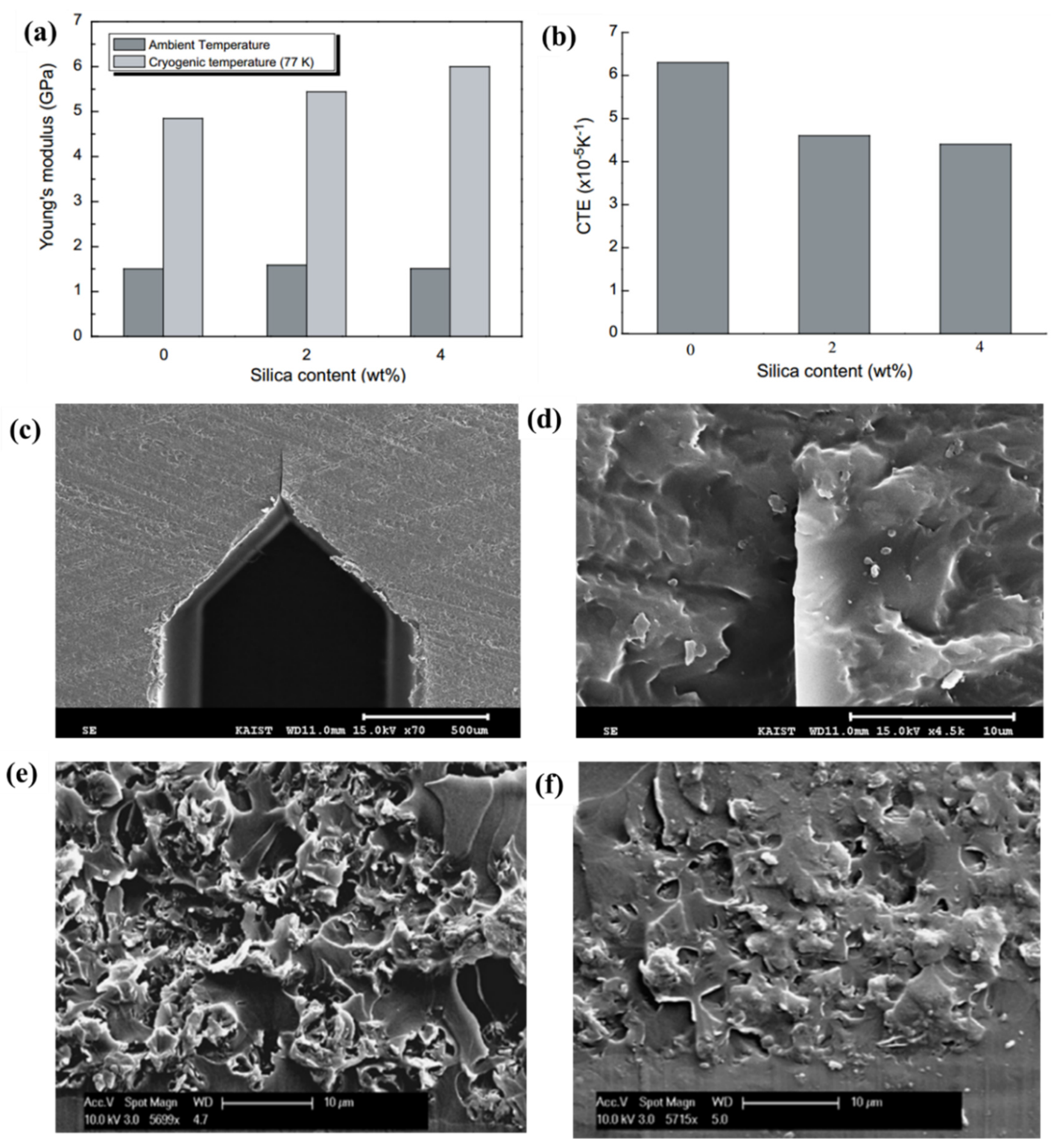

- Huang, C.; Fu, S.; Zhang, Y.; Lauke, B.; Li, L.; Ye, L. Cryogenic properties of SiO2/epoxy nanocomposites. Cryogenics 2005, 45, 450–454. [Google Scholar] [CrossRef]

- Hu, C.; Sun, Y.; Yu, J.; Huo, J. Simultaneously enhanced cryogenic mechanical behaviors of cyanate ester/epoxy resins by poly(ethylene oxide)-co -poly(propylene oxide)-co -poly(ethylene oxide) (PEO-PPO-PEO) block copolymer and clay. Polym. Compos. 2017, 38, 2237–2247. [Google Scholar] [CrossRef]

- Wang, H.; Sun, T.; Peng, C.; Wu, Z. Effect of different silane coupling agents on cryogenic properties of silica-reinforced epoxy composites. High Perform. Polym. 2018, 30, 24–37. [Google Scholar] [CrossRef]

- Yang, G.; Zheng, B.; Yang, J.-P.; Xu, G.-S.; Fu, S. Preparation and cryogenic mechanical properties of epoxy resins modified by poly(ethersulfone). J. Polym. Sci. Part A Polym. Chem. 2007, 46, 612–624. [Google Scholar] [CrossRef]

- He, Y.-X.; Li, Q.; Kuila, T.; Kim, N.H.; Jiang, T.; Lau, K.-T.; Lee, J.H. Micro-crack behavior of carbon fiber reinforced thermoplastic modified epoxy composites for cryogenic applications. Compos. Part B Eng. 2013, 44, 533–539. [Google Scholar] [CrossRef]

- Wu, T.; Liu, Y.; Li, N.; Huang, G.-W.; Qu, C.-B.; Xiao, H.-M. Cryogenic mechanical properties of epoxy resin toughened by hydroxyl-terminated polyurethane. Polym. Test. 2019, 74, 45–56. [Google Scholar] [CrossRef]

- Li, S.; Chen, D.; Yuan, Y.; Gao, C.; Cui, Y.; Wang, H.; Liu, X.; Liu, M.; Wu, Z. Influence of flexible molecular structure on the cryogenic mechanical properties of epoxy matrix and carbon fiber/epoxy composite laminate. Mater. Des. 2020, 195, 109028. [Google Scholar] [CrossRef]

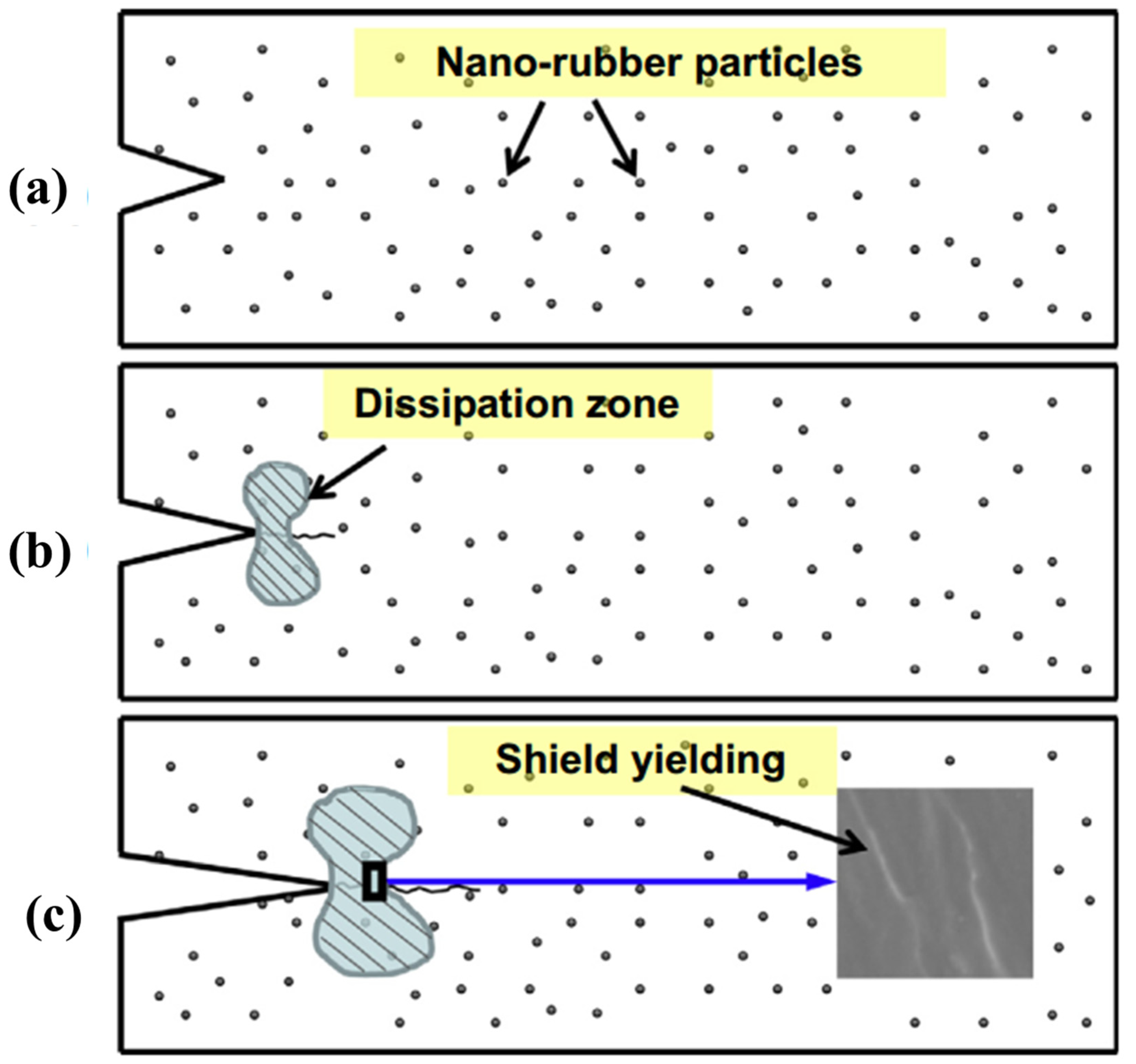

- Zhao, Y.; Chen, Z.-K.; Liu, Y.; Xiao, H.-M.; Feng, Q.; Fu, S.-Y. Simultaneously enhanced cryogenic tensile strength and fracture toughness of epoxy resins by carboxylic nitrile-butadiene nano-rubber. Compos. Part A Appl. Sci. Manuf. 2013, 55, 178–187. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, B.; Chen, J. Properties of impregnation resin added to multifunctional epoxy at cryogenic temperature. J. Appl. Polym. Sci. 2003, 89, 1385–1389. [Google Scholar] [CrossRef]

- Yang, J.-P.; Chen, Z.-K.; Yang, G.; Fu, S.; Ye, L. Simultaneous improvements in the cryogenic tensile strength, ductility and impact strength of epoxy resins by a hyperbranched polymer. Polymer 2008, 49, 3168–3175. [Google Scholar] [CrossRef]

- Byrne, M.T.; Gun’Ko, Y.K. Recent Advances in Research on Carbon Nanotube-Polymer Composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef]

- Rahmat, M.; Hubert, P. Carbon nanotube–polymer interactions in nanocomposites: A review. Compos. Sci. Technol. 2011, 72, 72–84. [Google Scholar] [CrossRef]

- Chen, J.; Yan, L.; Song, W.; Xu, D. Interfacial characteristics of carbon nanotube-polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 149–169. [Google Scholar] [CrossRef]

- Liu, S.; Chevali, V.S.; Xu, Z.; Hui, D.; Wang, H. A review of extending performance of epoxy resins using carbon nanomaterials. Compos. Part B Eng. 2018, 136, 197–214. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Li, Z.; Liu, M.; Kinloch, I.A.; Young, R.J. Mechanisms of mechanical reinforcement by graphene and carbon nanotubes in polymer nanocomposites. Nanoscale 2020, 12, 2228–2267. [Google Scholar] [CrossRef]

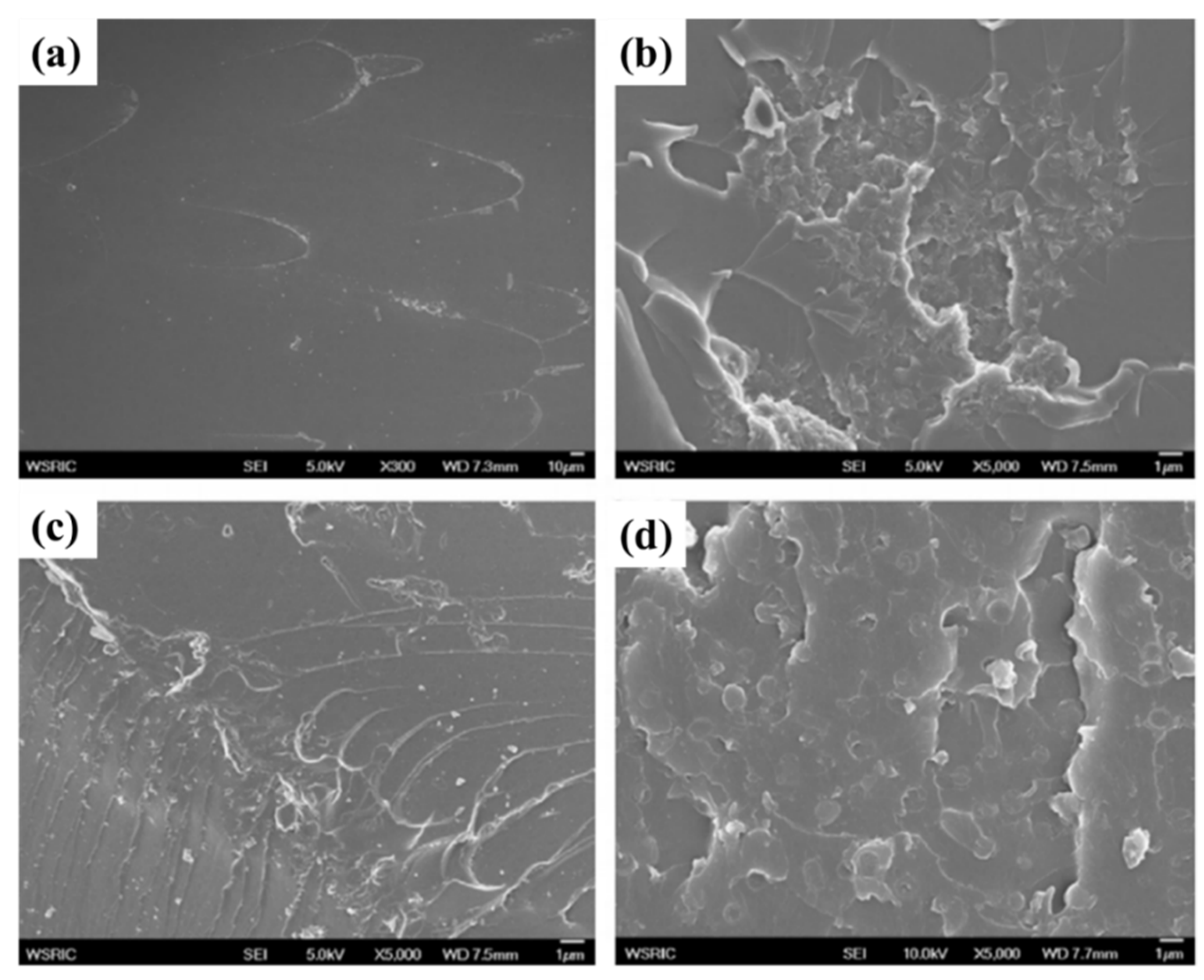

- Kim, M.-G.; Moon, J.-B.; Kim, C.-G. Effect of CNT functionalization on crack resistance of a carbon/epoxy composite at a cryogenic temperature. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1620–1627. [Google Scholar] [CrossRef]

- Prusty, R.K.; Rathore, D.K.; Ray, B.C. Evaluation of the role of functionalized CNT in glass fiber/epoxy composite at above- and sub-zero temperatures: Emphasizing interfacial microstructures. Compos. Part A Appl. Sci. Manuf. 2017, 101, 215–226. [Google Scholar] [CrossRef]

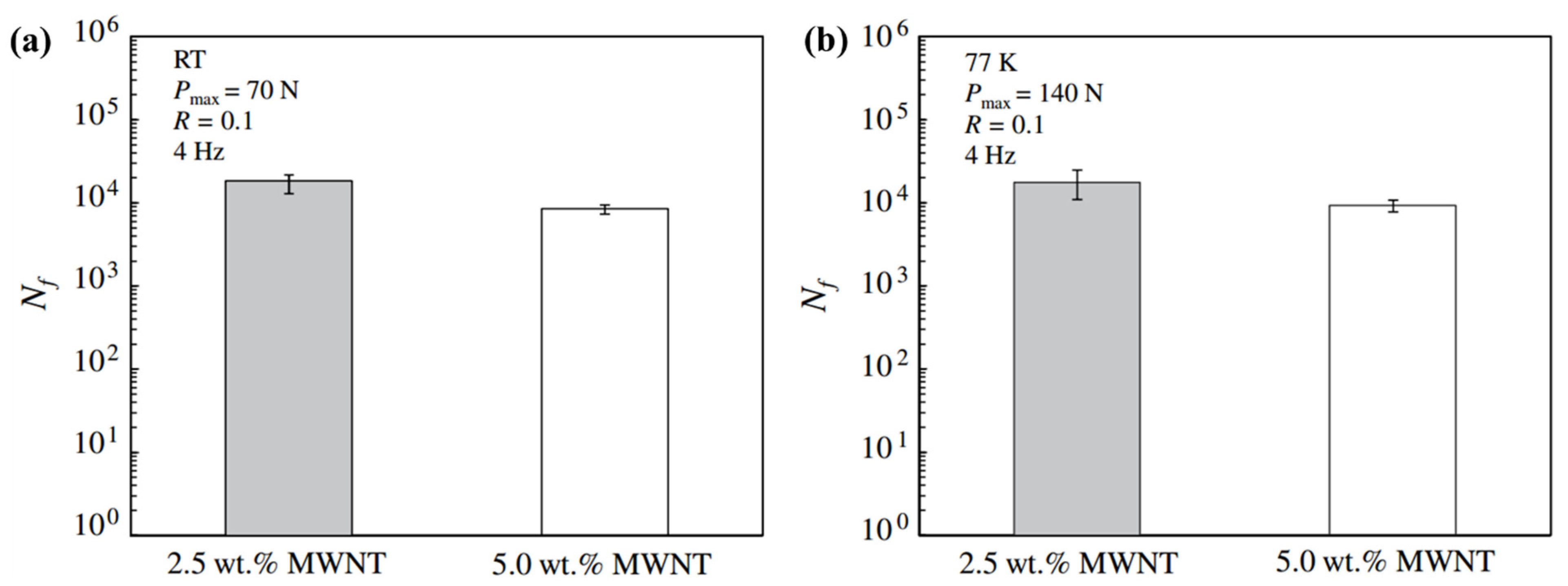

- Takeda, T.; Fan, W.; Feng, Q.-P.; Fu, S.-Y.; Narita, F.; Shindo, Y. Cryogenic mechanical properties of woven glass/epoxy composites modified with multi-walled carbon nanotube and n-butyl glycidyl ether under tensile static and cyclic loadings. Cryogenics 2013, 58, 33–37. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.-P.; Xiao, H.-M.; Qu, C.-B.; Feng, Q.; Fu, S.; Shindo, Y. Role of matrix modification on interlaminar shear strength of glass fibre/epoxy composites. Compos. Part B Eng. 2012, 43, 95–98. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Long, M.; Wang, P.; Fang, H.; Hu, W. Progress, Challenges, and Opportunities for 2D Material Based Photodetectors. Adv. Funct. Mater. 2019, 29, 1803807. [Google Scholar] [CrossRef]

- Wang, X.; Jin, J.; Song, M. An investigation of the mechanism of graphene toughening epoxy. Carbon 2013, 65, 324–333. [Google Scholar] [CrossRef]

- Mohan, V.B.; Lau, K.-T.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: A review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer Nanocomposites—A Comparison between Carbon Nanotubes, Graphene, and Clay as Nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Su, Q.; Pang, S.; Alijani, V.; Li, C.; Feng, X.; Müllen, K. Composites of Graphene with Large Aromatic Molecules. Adv. Mater. 2009, 21, 3191–3195. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Francis, R.; Joy, N.; Aparna, E.P.; Vijayan, R. Polymer Grafted Inorganic Nanoparticles, Preparation, Properties, and Applications: A Review. Polym. Rev. 2014, 54, 268–347. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Nikafshar, S.; Preyeswary, K.C.; Naebe, M. A technical review on epoxy-clay nanocomposites: Structure, properties, and their applications in fiber reinforced composites. Compos. Part B Eng. 2018, 135, 1–24. [Google Scholar] [CrossRef]

- Kaya, G.G.; Deveci, H. Synergistic effects of silica aerogels/xerogels on properties of polymer composites: A review. J. Ind. Eng. Chem. 2020, 89, 13–27. [Google Scholar] [CrossRef]

- Luo, H.; Ding, J.; Huang, Z.; Yang, T. Investigation of properties of nano-silica modified epoxy resin films and composites using RFI technology. Compos. Part B Eng. 2018, 155, 288–298. [Google Scholar] [CrossRef]

- Azimi, R.; Roghani-Mamaqani, H.; Gholipour-Mahmoudalilou, M. Grafting poly (amidoamine) dendrimer-modified silica nanoparticles to graphene oxide for preparation of a composite and curing agent for epoxy resin. Polymer 2017, 126, 152–161. [Google Scholar] [CrossRef]

- Withers, G.; Yu, Y.; Khabashesku, V.; Cercone, L.; Hadjiev, V.G.; Souza, J.; Davis, D. Improved mechanical properties of an epoxy glass–fiber composite reinforced with surface organomodified nanoclays. Compos. Part B Eng. 2015, 72, 175–182. [Google Scholar] [CrossRef]

- Tatar, A.C.; Kaybal, H.B.; Ulus, H.; Demir, O.; Avcı, A. Erbakan University Evaluation of low-velocity impact behavior of epoxy nanocomposite laminates modified with SiO2 nanoparticles at cryogenic temperatures. Res. Eng. Struct. Mater. 2019, 5, 115–125. [Google Scholar] [CrossRef]

- Scatteia, L.; Lenzi, F.; Totaro, G.; Cantoni, S.; Franceschi, M. Composite and Nanocomposite Materials Evaluation and Assessment for Cryogenic Propellant Storage. In Proceedings of the AIAA/CIRA 13th International Space Planes and Hypersonics Systems and Technologies Conference, Capua, Italy, 16–20 May 2005. [Google Scholar] [CrossRef]

- Miller, S.G.; Meador, M.A. Polymer- Layered silicate nanocomposites for cryotank Applications. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007. [Google Scholar] [CrossRef]

- Ma, H.-L.; Zhang, X.; Lau, K.-T.; Shi, S.-Q. Effect of nanoclay concentration on the lap joint shear performance of nanoclay/epoxy adhesive at cryogenic condition. J. Compos. Mater. 2018, 52, 2477–2482. [Google Scholar] [CrossRef]

- Kim, B.C.; Park, S.W.; Gil Lee, D. Fracture toughness of the nano-particle reinforced epoxy composite. Compos. Struct. 2008, 86, 69–77. [Google Scholar] [CrossRef]

- Timmerman, J.F.; Hayes, B.S.; Seferis, J.C. Nanoclay reinforcement effects on the cryogenic microcracking of carbon fiber/epoxy composites. Compos. Sci. Technol. 2002, 62, 1249–1258. [Google Scholar] [CrossRef]

- Farooq, U.; Teuwen, J.; Dransfeld, C. Toughening of Epoxy Systems with Interpenetrating Polymer Network (IPN): A Review. Polymer 2020, 12, 1908. [Google Scholar] [CrossRef]

- Deng, S.; Djukic, L.; Paton, R.; Ye, L. Thermoplastic–epoxy interactions and their potential applications in joining composite structures—A review. Compos. Part A Appl. Sci. Manuf. 2015, 68, 121–132. [Google Scholar] [CrossRef]

- Nishijima, S.; Honda, Y.; Tagawa, S.; Okada, T. Study of epoxy resin for cryogenic use by positron annihilation method. J. Radioanal. Nucl. Chem. 1996, 211, 93–101. [Google Scholar] [CrossRef]

- Cheng, X.; Wu, Q.; Morgan, S.E.; Wiggins, J. Morphologies and mechanical properties of polyethersulfone modified epoxy blends through multifunctional epoxy composition. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Rider, A.N.; Yeo, E.; Gopalakrishna, J.; Thostenson, E.T.; Brack, N. Hierarchical composites with high-volume fractions of carbon nanotubes: Influence of plasma surface treatment and thermoplastic nanophase-modified epoxy. Carbon 2015, 94, 971–981. [Google Scholar] [CrossRef]

- Augustine, D.; Vijayalakshmi, K.; Sadhana, R.; Mathew, D.; Nair, C.P.R. Hydroxyl terminated PEEK-toughened epoxy-amino novolac phthalonitrile blends—Synthesis, cure studies and adhesive properties. Polymer 2014, 55, 6006–6016. [Google Scholar] [CrossRef]

- Zhang, Y.; Hasegawa, K.; Kamo, S.; Takagi, K.; Takahara, A. Enhanced adhesion effect of epoxy resin on carbon fiber-reinforced Poly(etheretherketone) via surface initiated photopolymerization of glycidyl methacrylate. Polymer 2020, 209, 123036. [Google Scholar] [CrossRef]

- Bakar, M.; Kobusińska, J.; Szczerba, J. Mechanical properties of epoxy resin modified with polycarbonate and reactive polybutadiene. J. Appl. Polym. Sci. 2007, 106, 2892–2897. [Google Scholar] [CrossRef]

- Tang, L.-C.; Zhang, H.; Sprenger, S.; Ye, L.; Zhang, Z. Fracture mechanisms of epoxy-based ternary composites filled with rigid-soft particles. Compos. Sci. Technol. 2012, 72, 558–565. [Google Scholar] [CrossRef]

- Arias, M.L.; Frontini, P.M.; Williams, R.J. Analysis of the damage zone around the crack tip for two rubber-modified epoxy matrices exhibiting different toughenability. Polymer 2003, 44, 1537–1546. [Google Scholar] [CrossRef]

- Reddy, K.C.; Bharathiraja, G.; Jayakumar, V. Mode I fracture toughness analysis of rubber particulate epoxy composite. Mater. Today Proc. 2020, 22, 759–761. [Google Scholar] [CrossRef]

- Zhang, L.; Chao, M.; Hui, D.; Liu, J.; Zheng, J.; Lei, W.; Zhou, X.; Wang, R.; Zhang, L. Enhanced interfacial interaction and excellent performance of silica/epoxy group-functionalized styrene-butadiene rubber (SBR) nanocomposites without any coupling agent. Compos. Part B Eng. 2017, 114, 356–364. [Google Scholar] [CrossRef]

- Yang, B.; Wang, W.; Huang, J. Synergic effects of poly(vinyl butyral) on toughening epoxies by nanostructured rubbers. Polymer 2015, 77, 129–142. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Jiang, L.; Qiao, J. Advances in toughened polymer materials by structured rubber particles. Prog. Polym. Sci. 2019, 98, 101160. [Google Scholar] [CrossRef]

- Nobelen, M.; Hayes, B.S.; Seferis, J.C. Influence of elastomer distribution on the cryogenic microcracking of carbon fiber/epoxy composites. J. Appl. Polym. Sci. 2003, 90, 2268–2275. [Google Scholar] [CrossRef]

- Nobelen, M.; Hayes, B.S.; Seferis, J.C. Cryogenic microcracking of rubber toughened composites. Polym. Compos. 2010, 24, 723–730. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Valavala, P.K.; Clancy, T.C.; Wise, K.E.; Odegard, G.M. Molecular modeling of crosslinked epoxy polymers: The effect of crosslink density on thermomechanical properties. Polymer 2011, 52, 2445–2452. [Google Scholar] [CrossRef]

- Park, H.; Kim, B.; Choi, J.; Cho, M. Influences of the molecular structures of curing agents on the inelastic-deformation mechanisms in highly-crosslinked epoxy polymers. Polymer 2018, 136, 128–142. [Google Scholar] [CrossRef]

- Kim, B.; Choi, J.; Yu, S.; Yang, S.; Cho, M. Influence of crosslink ratio on the thermomechanical properties of polymer nanocomposites and interphase: A molecular dynamics simulation. In Proceedings of the 55th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar] [CrossRef][Green Version]

- Heba, F.; Mouzali, M.; Abadie, M.J.M. Effect of the crosslinking degree on curing kinetics of an epoxy-acid copolymer system. J. Appl. Polym. Sci. 2003, 90, 2834–2839. [Google Scholar] [CrossRef]

- Nishijima, S.; Honda, Y.; Okada, T. Application of the positron annihilation method for evaluation of organic materials for cryogenic use. Cryogenics 1995, 35, 779–781. [Google Scholar] [CrossRef]

- Sawa, F.; Nishijima, S.; Okada, T. Molecular design of an epoxy for cryogenic temperatures. Cryogenics 1995, 35, 767–769. [Google Scholar] [CrossRef]

- Ueki, T.; Nishijima, S.; Izumi, Y. Designing of epoxy resin systems for cryogenic use. Cryogenics 2005, 45, 141–148. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Yuan, Y.; Liu, X.; Sun, T.; Wu, Z. Study of the epoxy/amine equivalent ratio on thermal properties, cryogenic mechanical properties, and liquid oxygen compatibility of the bisphenol A epoxy resin containing phosphorus. High Perform. Polym. 2020, 32, 429–443. [Google Scholar] [CrossRef]

- Yang, G.; Fu, S.-Y.; Yang, J.-P. Preparation and mechanical properties of modified epoxy resins with flexible diamines. Polymer 2007, 48, 302–310. [Google Scholar] [CrossRef]

- Chen, Z.-K.; Yang, G.; Yang, J.-P.; Fu, S.; Ye, L.; Huang, Y.-G. Simultaneously increasing cryogenic strength, ductility and impact resistance of epoxy resins modified by n-butyl glycidyl ether. Polymer 2009, 50, 1316–1323. [Google Scholar] [CrossRef]

- Feng, Q.; Yang, J.; Liu, Y.; Xiao, H.; Fu, S. Simultaneously Enhanced Cryogenic Tensile Strength, Ductility and Impact Resistance of Epoxy Resins by Polyethylene Glycol. J. Mater. Sci. Technol. 2014, 30, 90–96. [Google Scholar] [CrossRef]

- Li, S.; Chen, D.; Gao, C.; Yuan, Y.; Wang, H.; Liu, X.; Hu, B.; Ma, J.; Liu, M.; Wu, Z. Epoxy-functionalized polysiloxane/Nano-SiO2 synergistic reinforcement in cryogenic mechanical properties of epoxy and carbon fiber reinforced epoxy laminate. Compos. Sci. Technol. 2020, 198, 108292. [Google Scholar] [CrossRef]

- Tsai, L.D.; Hwang, M.R. Thermoplastic and Thermosetting Polymers and Composites; Nova Science Publishers: New York, NY, USA, 2011. [Google Scholar]

- Miche, B. Thermoplastics and Thermoplastic Composites; Elsevier Science & Technology: Oxford, UK, 2013. [Google Scholar]

- Boisse, P. Advances in Composites Manufacturing and Process Design; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Rajan, S.; Sutton, M.A.; Sockalingam, S.; McMakin, W.; Gurdal, Z.; Kidane, A. Simulations and experiments for automated fiber placement of prepreg slit tape: Wrinkle formation and fundamental observations. Compos. Part B Eng. 2020, 201, 108287. [Google Scholar] [CrossRef]

- He, K.; Nie, H.; Yan, C. The Intelligent Composite Panels Manufacturing Technology Based on Tape-laying Automatic System. Procedia CIRP 2016, 56, 610–613. [Google Scholar] [CrossRef][Green Version]

- Dhinakaran, V.; Surendar, K.; Riyaz, M.H.; Ravichandran, M. Review on study of thermosetting and thermoplastic materials in the automated fiber placement process. Mater. Today Proc. 2020, 27, 812–815. [Google Scholar] [CrossRef]

- Ahlborn, K. Cryogenic mechanical response of carbon fibre reinforced plastics with thermoplastic matrices to quasi-static loads. Cryogenics 1991, 31, 252–256. [Google Scholar] [CrossRef]

- Thiruchitrambalam, M.; Kumar, D.B.; Shanmugam, D.; Jawaid, M. A review on PEEK composites—Manufacturing methods, properties and applications. Mater. Today Proc. 2020, 33, 1085–1092. [Google Scholar] [CrossRef]

- Becker, R.; Nettles, A.; Bucinell, R.; Langone, R.; Mondo, J. Fabrication of a peek/graphite composite cryogenic fuel line. In Proceedings of the 6th International SAMPE Symposium and Exhibition, Long Beach, CA, USA, 6–10 May 2001. [Google Scholar]

- Flanagan, M.; Grogan, D.; Goggins, J.; Appel, S.; Doyle, K.; Leen, S.B.; Brádaigh, C.M.Ó. Permeability of carbon fibre PEEK composites for cryogenic storage tanks of future space launchers. Compos. Part A Appl. Sci. Manuf. 2017, 101, 173–184. [Google Scholar] [CrossRef]

- Grogan, D.; Leen, S.; Semprimoschnig, C.; Brádaigh, C.M.Ó. Damage characterisation of cryogenically cycled carbon fibre/PEEK laminates. Compos. Part A Appl. Sci. Manuf. 2014, 66, 237–250. [Google Scholar] [CrossRef]

- Grogan, D.; Brádaigh, C.Ó.; McGarry, J.; Leen, S. Damage and permeability in tape-laid thermoplastic composite cryogenic tanks. Compos. Part. A Appl. Sci. Manuf. 2015, 78, 390–402. [Google Scholar] [CrossRef]

- Whitley, K.; Gates, T. Thermal/Mechanical Response and Damage Growth in Polymeric Composites at Cryogenic Temperatures. In Proceedings of the 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Denver, CO, USA, 22–25 April 2002. [Google Scholar] [CrossRef]

- Li, F.; Liu, Y.; Qu, C.-B.; Xiao, H.-M.; Hua, Y.; Sui, G.-X.; Fu, S.-Y. Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating. Polymer 2015, 59, 155–165. [Google Scholar] [CrossRef]

- Li, F.; Hua, Y.; Qu, C.-B.; Xiao, H.-M.; Fu, S. Greatly enhanced cryogenic mechanical properties of short carbon fiber/polyethersulfone composites by graphene oxide coating. Compos. Part A Appl. Sci. Manuf. 2016, 89, 47–55. [Google Scholar] [CrossRef]

- Hartwig, G.; Hübner, R.; Knaak, S. Fatigue Behavior of Polymers and Composites at Cryogenic Temperatures. Adv. Cryog. Eng. Mater. 1996, 155–159. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Narita, F.; Sanada, K. Stress Intensity Factors for Woven Glass/Epoxy Laminates with Cracks at Cryogenic Temperatures. Mech. Adv. Mater. Struct. 2004, 11, 109–132. [Google Scholar] [CrossRef]

- Paarmann, M.; Sander, M. Analytical determination of stress intensity factors in thick walled thermally loaded components. Eng. Fract. Mech. 2020, 235, 107125. [Google Scholar] [CrossRef]

- Sajith, S.; Murthy, K.; Robi, P. Estimation of stress intensity factors from crack flank displacements. Mater. Today Proc. 2020, 24, 887–894. [Google Scholar] [CrossRef]

- Kahn, H.; Chen, L.; Ballarini, R.; Heuer, A. Mechanical fatigue of polysilicon: Effects of mean stress and stress amplitude. ACTA Mater. 2006, 54, 667–678. [Google Scholar] [CrossRef]

- Weiss, K.-P.; Bagrets, N.; Lange, C.; Goldacker, W.; Wohlgemuth, J. Thermal and mechanical properties of selected 3D printed thermoplastics in the cryogenic temperature regime. IOP Conf. Ser. Mater. Sci. Eng. 2015, 102, 012022. [Google Scholar] [CrossRef]

- Atli-Veltin, B. Cryogenic performance of single polymer polypropylene composites. Cryogenics 2018, 90, 86–95. [Google Scholar] [CrossRef]

- Takeda, T.; Narita, F.; Kuronuma, Y.; Shindo, Y. Numerical and experimental study on the response of multi-walled carbon nanotube/polymer composites under compressive loading. Int. J. Mater. Struct. Integr. 2013, 7, 4–21. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Wei, Z.; Kuronuma, Y.; Narita, F. Fatigue failure and electrical resistance behaviors of carbon nanotube-based polymer composites under uniaxial tension–tension loading in a cryogenic environment. J. Compos. Mater. 2014, 49, 457–463. [Google Scholar] [CrossRef]

- Wei, Z.; Takeda, T.; Narita, F.; Shindo, Y. Flexural fatigue performance and electrical resistance response of carbon nanotube-based polymer composites at cryogenic temperatures. Cryogenics 2014, 59, 44–48. [Google Scholar] [CrossRef]

- Bahceli, G. Cryogenic Properties of CNT Reinforced UHMWPE Laminated Composites. In Proceedings of the AIAA SciTech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar] [CrossRef]

- Clark, A.F.; Hust, J.G. A Review of the Compatibility of Structural Materials with Oxygen. AIAA J. 1974, 12, 441–454. [Google Scholar] [CrossRef]

- Kim, R.; Lee, W.; Camping, J.; Bowman, K. Impact Reaction of Composites in Liquid Oxygen. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Austin, TX, USA, 18–21 April 2005. [Google Scholar] [CrossRef]

- Livingstona, R.A.; Schweitzer, J.S.; Parsons, A.M.; Arens, E.E. Feasibility Study for Measurement of Insulation Compaction in the Cryogenic Rocket Fuel Storage Tanks at Kennedy Space Center by Fast/Thermal Neutron Techniques. AIP Conf. Proc. 2014, 1581, 1832–1839. [Google Scholar] [CrossRef]

- Dean, S.; Gerzeski, R. Hertzian Fracture, Kinetic Friction and the Mechanical Impact LOX Compatibility Testing of Polymers and Polymer Matrix Composites. J. ASTM Int. 2006, 3, 100549. [Google Scholar] [CrossRef]

- Dean, S.W.; Gerzeski, R. Fractography of ASTM D2512 Tested Polymeric Isotropic Material Residuals Generated External to the Impacting Indenter. J. ASTM Int. 2010, 7. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Gerzeski, R. LOX Compatible Toughened Bismaleimide Matrix Thermally Conductive Fiber Composites Part II: ASTM D2512 Specimen Fabrication, Cleaning and Testing. J. Test. Eval. 2008, 36. [Google Scholar] [CrossRef]

- Wang, G.; Li, X.; Yan, R.; Xing, S. The study on compatibility of polymer matrix resins with liquid oxygen. Mater. Sci. Eng. B 2006, 132, 70–73. [Google Scholar] [CrossRef]

- Clippinger, D.; Morris, G. Impact Sensitivity of Organic Materials on Exposure to Liquid Oxygen. Aircr. Eng. Aerosp. Technol. 1959, 31, 204–205. [Google Scholar] [CrossRef]

- Hoggatt, J.T. Compatibility of Polymeric Films with Liquid Oxygen; NASA CR-72I34; National Aeronautics and Space Administration Office of Scientific and Technical Information: Washington, DC, USA, 1967.

- Wu, Z.; Gao, F.; Yan, J.; Wang, Z. Damage mechanism of polyphenylene sulfide resin in liquid oxygen. Iran. Polym. J. 2012, 21, 185–190. [Google Scholar] [CrossRef]

- Wu, Z.; Li, J.; Chen, Y.; Wang, Z.; Li, S. Effect of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide on liquid oxygen compatibility of bisphenol a epoxy resin. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Wu, Z.; Wang, Z. The effect of 10-(2,5-dihydroxyphenyl)-9, 10-dihydro-9-oxa-10-phosphaphenanthrene- 10-oxide on liquid oxygen compatibility and cryogenic mechanical properties of epoxy resins. High. Perform. Polym. 2016, 28, 820–830. [Google Scholar] [CrossRef]

- Wu, Z.; Li, J.; Wang, Z. Liquid oxygen compatibility and thermal stability of bisphenol A and bisphenol F epoxy resins modified by DOPO. Polym. Adv. Technol. 2015, 26, 153–159. [Google Scholar] [CrossRef]

- Wu, Z.; Li, S.; Liu, M.; Wang, Z.; Li, J. Synthesis and characterization of a liquid oxygen-compatible epoxy resin. High. Perform. Polym. 2014, 27, 74–84. [Google Scholar] [CrossRef]

- Wu, Z.; Li, S.; Liu, M.; Wang, Z.; Liu, X. Liquid oxygen compatible epoxy resin: Modification and characterization. RSC Adv. 2015, 5, 11325–11333. [Google Scholar] [CrossRef]

- Peng, C.; Li, J.; Wu, Z.; Peng, W.; Zhou, D. Investigating into the liquid oxygen compatibility of a modified epoxy resin containing silicon/phosphorus and its mechanical behavior at cryogenic temperature. RSC Adv. 2016, 6, 38300–38309. [Google Scholar] [CrossRef]

- Wang, H.; Peng, C.; Li, S.; Liu, X.; Wu, Z. Improvement of the liquid oxygen compatibility of epoxy via the addition of surface-modified boehmite. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Peng, C.; Gao, C.; Yuan, Y.; Wu, Z.; Zhou, D. Synthesis and application of a benzoxazine-type phosphorus-containing monomer on epoxy/benzoxazine copolymer: Thermal stability and compatibility with liquid oxygen. Polym. Degrad. Stab. 2018, 157, 131–142. [Google Scholar] [CrossRef]

- Lyu, Y.; Ishida, H. Natural-sourced benzoxazine resins, homopolymers, blends and composites: A review of their synthesis, manufacturing and applications. Prog. Polym. Sci. 2019, 99, 101168. [Google Scholar] [CrossRef]

- Sini, N.; Bijwe, J.; Varma, I.K. Thermal behaviour of bis-benzoxazines derived from renewable feed stock ‘vanillin’. Polym. Degrad. Stab. 2014, 109, 270–277. [Google Scholar] [CrossRef]

| Resin System 1 | Modifier 1 | Content | Temperature | Mechanical Properties | Ref. |

|---|---|---|---|---|---|

| DGEBF/DETDA | MWCNTS | 0.5 wt% | 77 K | Tensile strength: 119.35 MPa Tensile modulus: 5.26 GPa Tensile fracture strain: 3.20% Impact strength: 35.56 KJ/m2 | [37] |

| DGEBA/EP-PU/DETDA | MWCNTS-NH2 | 0.2 wt% | 77 K | Tensile strength: 120 MPa Tensile modulus: 7.0 GPa Flexural strength: 275 MPa Flexural modulus: 8.0 GPa Impact strength: 32 KJ/m2 Fracture toughness: 3.25 MPa·m1/2 | [38] |

| DGEBA/15 wt% Oligomer/D-230 | O-CNTs | 0.5 wt% | 77 K | Tensile strength: 91.7 MPa Tensile modulus: 3.6 GPa Impact strength: 46 KJ/m2 | [39] |

| DEGBA/DETDA | Graphene | 0.1 wt% | 77 K | Tensile strength: 140.0 MPa Tensile modulus: 7.0 GPa Impact strength: 21.9 KJ/m2 | [40] |

| DGEBA/DETA | GO-PDA | 1 wt% | 150 K | Tensile strength: 70 MPa Tensile modulus: 3.29 GPa Tensile fracture strain: 2.50% GIC: 666.32 J/m2 KIC: 1.58 MN/m3/2 | [41] |

| DGEBA/diluent/D-230 | FGSs | 1.6 wt% | 143 K | Tensile strength: 82.91 MPa Tensile modulus: 5.54 GPa Tensile fracture strain: 1.65% | [42] |

| DGEBA/TETA | GO | 0.2 wt% | 193 K | Tensile strength: 150 MPa Tensile modulus: 4.7 GPa Tensile fracture strain: 3.7% | [43] |

| DGEBA/D-230 | Fe3O4/GO | 0.5 wt% | 77 K | Tensile strength: 96.4 MPa Tensile modulus: 5.9 GPa Tensile fracture strain: 19.5% Impact strength: 44.2 MPa KIC: 2.1 MN/m3/2 | [44] |

| DGEBF/DETD | SiO2 | 4 wt% | 77 K | Tensile strength: 77.63 MPa Tensile modulus: 4.62 GPa Tensile fracture strain: 2.2% | [45] |

| DGEBA/BCE/BCP | Nano-clay | 3 wt% | 77 K | Tensile strength: 169 MPa Tensile modulus: 5.5 GPa Tensile fracture strain: 2.2% | [46] |

| DGEBA/DDM | KH560-modified silica | 1 wt% | 90 K | Tensile strength: 169 MPa Tensile modulus: 9.0 GPa Tensile fracture strain: 2.5% | [47] |

| DGEBF/DETD | PES | 20 phr | 77 K | Tensile strength: 86.64 MPa Tensile modulus: 4.32 GPa Tensile fracture strain: 2.87% | [48] |

| DGEBA/D-230 | PBT/PEI/PC | 1.5 wt% | 77 K | Impact strength: 34.5 KJ/m2(PBT) Impact strength: 39.8 KJ/m2(PEI) Impact strength: 36.01 KJ/m2(PC) | [49] |

| DGEBA/DETDA | HTPU | 5 phr | 77 K | Tensile strength: 161.67 MPa Tensile modulus: 6.89 GPa Tensile fracture strain: 2.58% Impact strength: 30 KJ/m2 | [50] |

| DGEBF/DDM | EPSE | 5 wt% | 90 K | Tensile strength: 210 MPa Tensile fracture strain: 3% | [51] |

| DGEBF/DDM | EPSE | 5–8 wt% | 77 K | KIC: 2.35 MN/m3/2 (5 wt%) KIC: 2.6 MN/m3/2 (8 wt%) | [52] |

| DGEBF/DETD | NR | 15 phr | 77 K | Tensile strength: 129.98 MPa Tensile modulus: 4.13 GPa Tensile fracture strain: 3.15% KIC: 2.2 MN/m3/2 | [53] |

| DGEBA/NA/A-178 | HK021 | 80 phr | 77 K | LSS: 9.7Mpa | [54] |

| DGEBF/MeTHPA | H30 | 10 wt% | 77 K | Tensile strength: 115.6 MPa Tensile modulus: 3.8 GPa Tensile fracture strain: 3.1% Impact strength: 32 KJ/m2 | [55] |

| Resin System 1 | Modifier 1 | Contents | Thermal Stability | Mechanical Properties | Ref. |

|---|---|---|---|---|---|

| DGEBA/DOPO/DDS | DOPO | 7.7 phr | T(10%): 381 °C | - | [141] |

| DGEBA/ODOPB/DDM | ODOPB | 18.6 phr | T(5%): 393 °C T(50%): 531 °C | Tensile strength: 148.9 MPa (90 K) Tensile fracture strain:2.27% (90 K) KIC = 1.58 MN/m3/2 (77 K) | [152] |

| DGEBA/TBBPA/DDM | TBBPA | 20.5 phr | T(5%): 365 °C | Tensile strength:86.37 MPa (77 K) KIC = 1.63 MN/m3/2 (77 K) | [154] |

| DGEBA/AlOOH−DOPO−GPTS/ DDM | AlOOH−DOPO−GPTS | 20 wt% | T(5%): 367.8 °C T(10%): 380.3 °C | Tensile strength: 126 MPa (90 K) Tensile fracture strain:1.57% (90 K) | [157] |

| EP/PBA/BA | PBA/BA | 24 wt%/34.3 wt% | T(5%): 351.2 °C T(50%): 533.7 °C | - | [158] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Li, J.; Yuan, Y.; Gao, C.; Cui, Y.; Li, S.; Liu, X.; Wang, H.; Peng, C.; Wu, Z. A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polymers 2021, 13, 320. https://doi.org/10.3390/polym13030320

Chen D, Li J, Yuan Y, Gao C, Cui Y, Li S, Liu X, Wang H, Peng C, Wu Z. A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polymers. 2021; 13(3):320. https://doi.org/10.3390/polym13030320

Chicago/Turabian StyleChen, Duo, Juanzi Li, Yuhuan Yuan, Chang Gao, Yunguang Cui, Shichao Li, Xin Liu, Hongyu Wang, Cong Peng, and Zhanjun Wu. 2021. "A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives" Polymers 13, no. 3: 320. https://doi.org/10.3390/polym13030320

APA StyleChen, D., Li, J., Yuan, Y., Gao, C., Cui, Y., Li, S., Liu, X., Wang, H., Peng, C., & Wu, Z. (2021). A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polymers, 13(3), 320. https://doi.org/10.3390/polym13030320