Study on Permeability Characteristics of Porous Transparent Gels Based on Synthetic Materials

Abstract

:1. Introduction

2. Experimental Study on the Permeability Characteristics of Transparent Soft Clay

2.1. Preparation of Transparent Clay

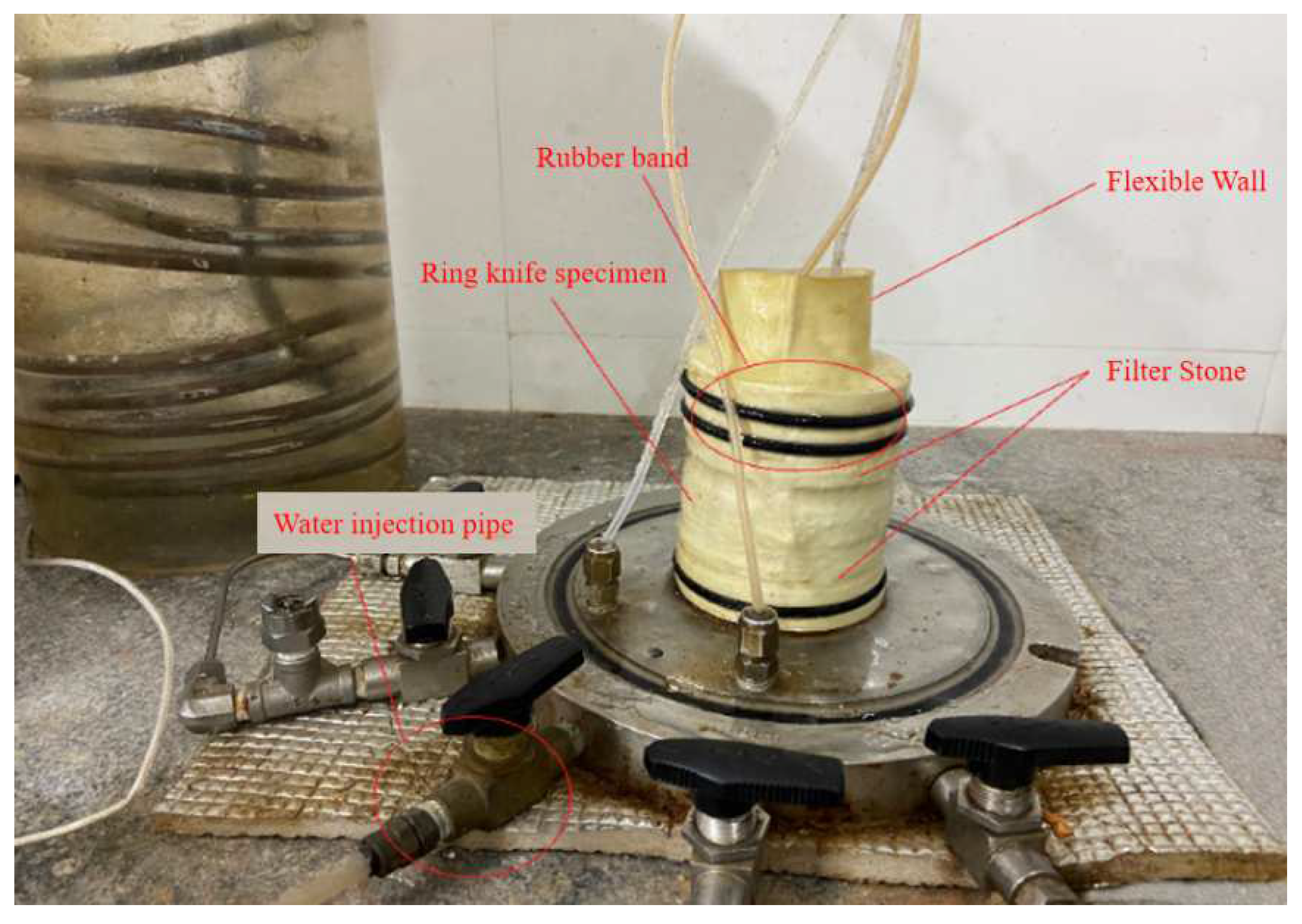

2.2. GDS Flexible Wall-Permeation Test

- (i)

- Introduction of the test instruments

- (ii)

- Test procedure

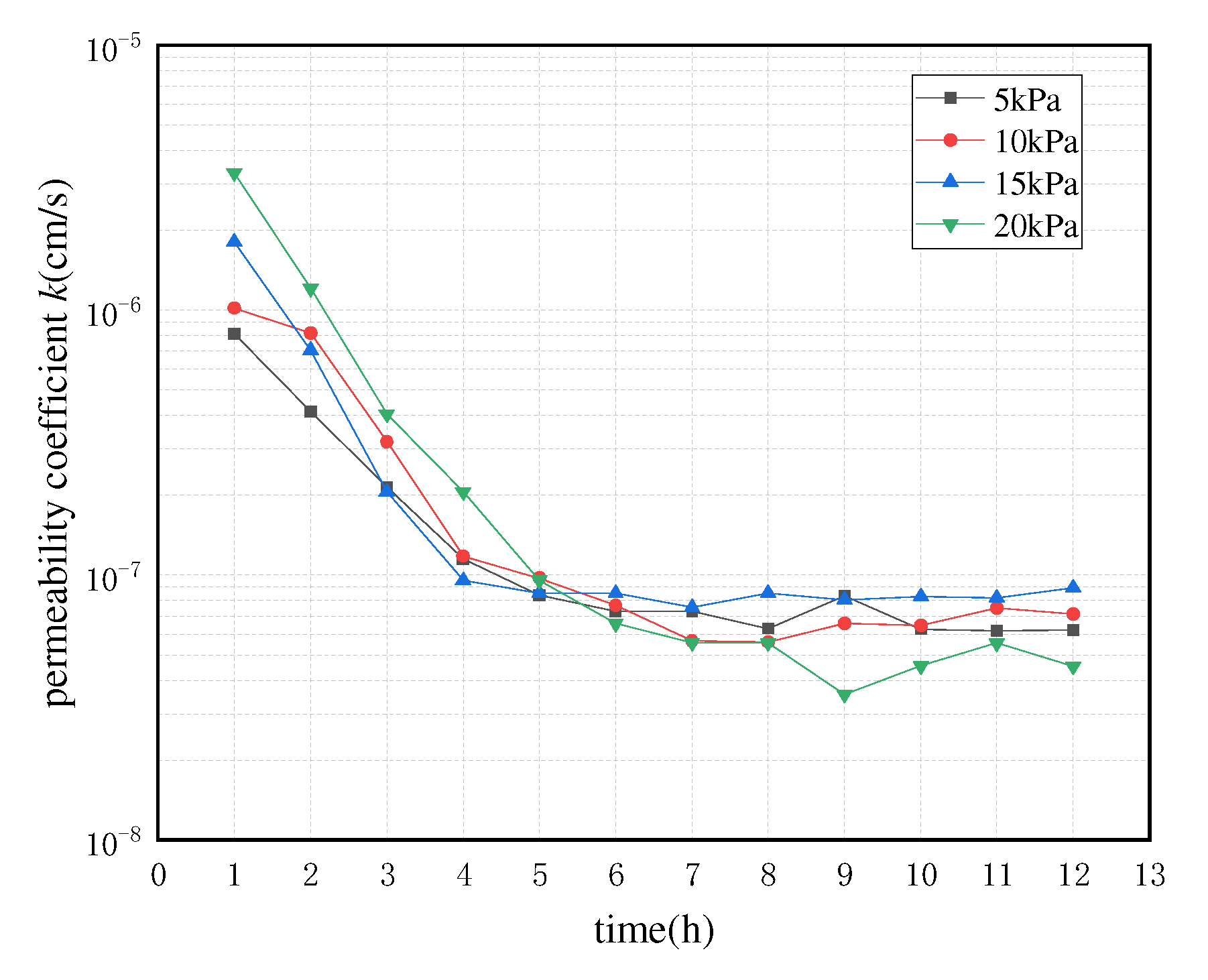

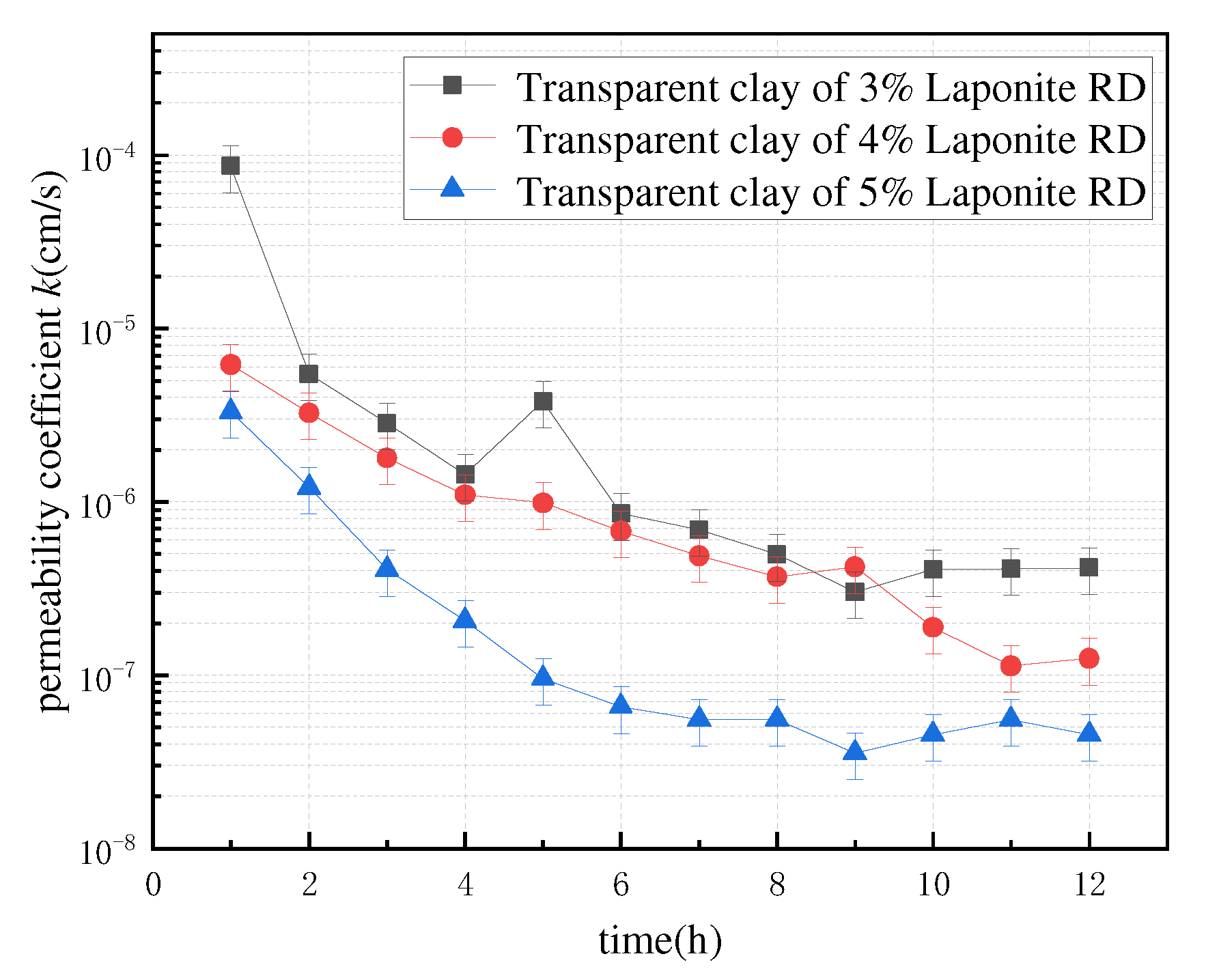

2.3. Test Results and Analysis

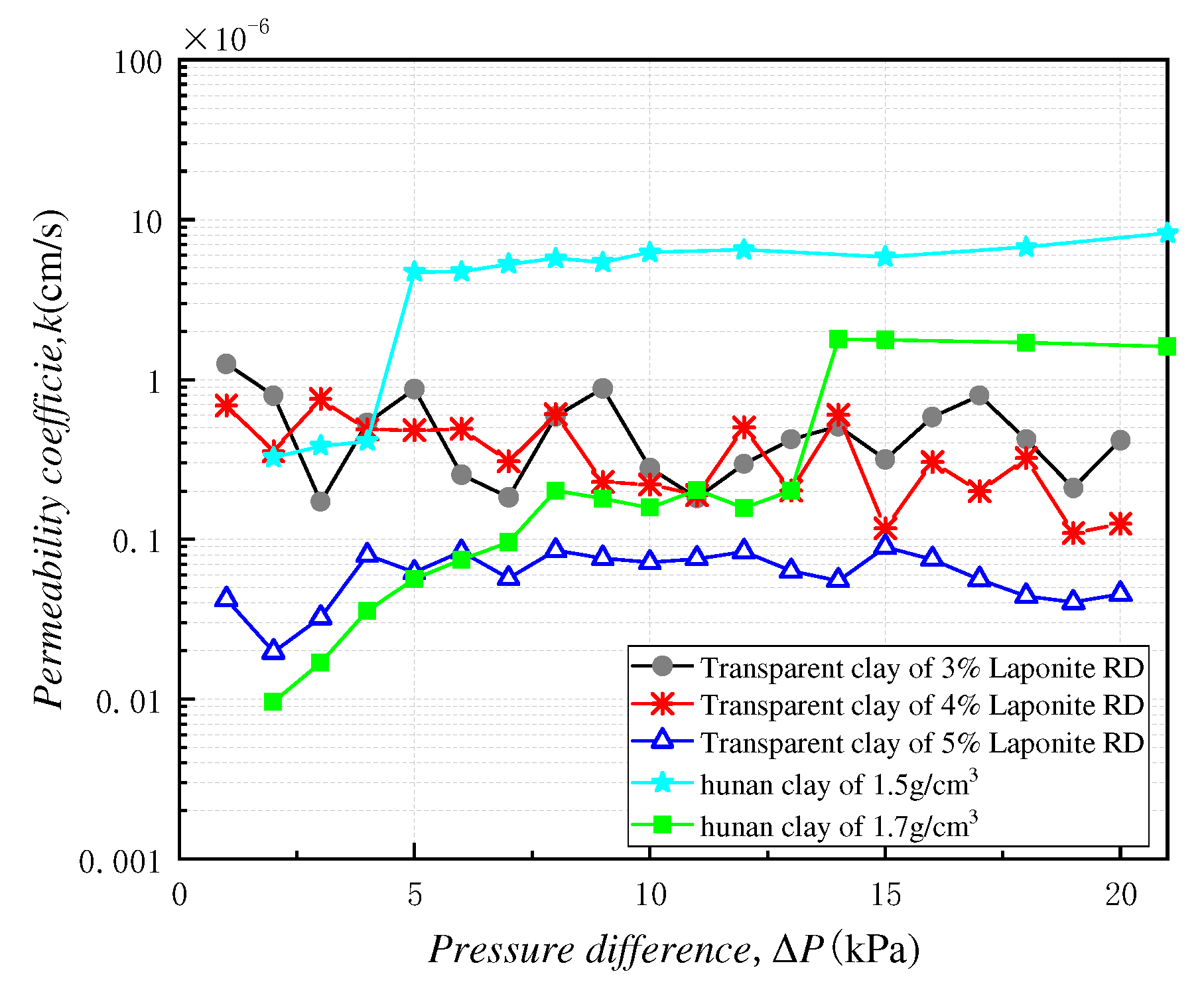

- The permeability coefficient of the transparent clay specimens after stabilization without a large range of change, and the overall trend remained stable. Greater Laporite RD content corresponded to smaller fluctuations of the permeability coefficient, i.e., the more stable the pore structure of the transparent clay specimens. This is due to the aggregate support of transparent clay being weak, and, when the amount of Laporite RD is small, the spatial network structure formed is looser, leaving more large pores within the transparent clay, such that the aggregate support structure is not stable enough, leading to a fluctuating permeability coefficient. In addition, the greater the Laporite RD content, the smaller the transparent clay permeability coefficient. This is due to the fact that more Laporite RD can produce more colloidal material to fill the pores, so, the overall porosity of the material is lower and the permeability coefficient is smaller.

- The permeability coefficient of Hunan clay showed a trend of rising first and then becoming constant with the change of permeability pressure difference. This is because when the permeability pressure difference is small, the film water, in the fine internal clay pores, cannot flow until it has reached the critical hydraulic gradient, whereupon can seepage occur. The transparent clay material does not have this phenomenon, essentially because the gel formed by Laporite RD and water is electrically neutral and cannot attract water molecules to form a bound-water film, as occurs with clay particles. When the permeability pressure difference reaches the critical hydraulic gradient, the permeability coefficient of clay changes by the same law as that of transparent clay, that is, it remains constant.

- The permeability coefficient of Hunan clay decreases with the increase of the dry density after stabilization.

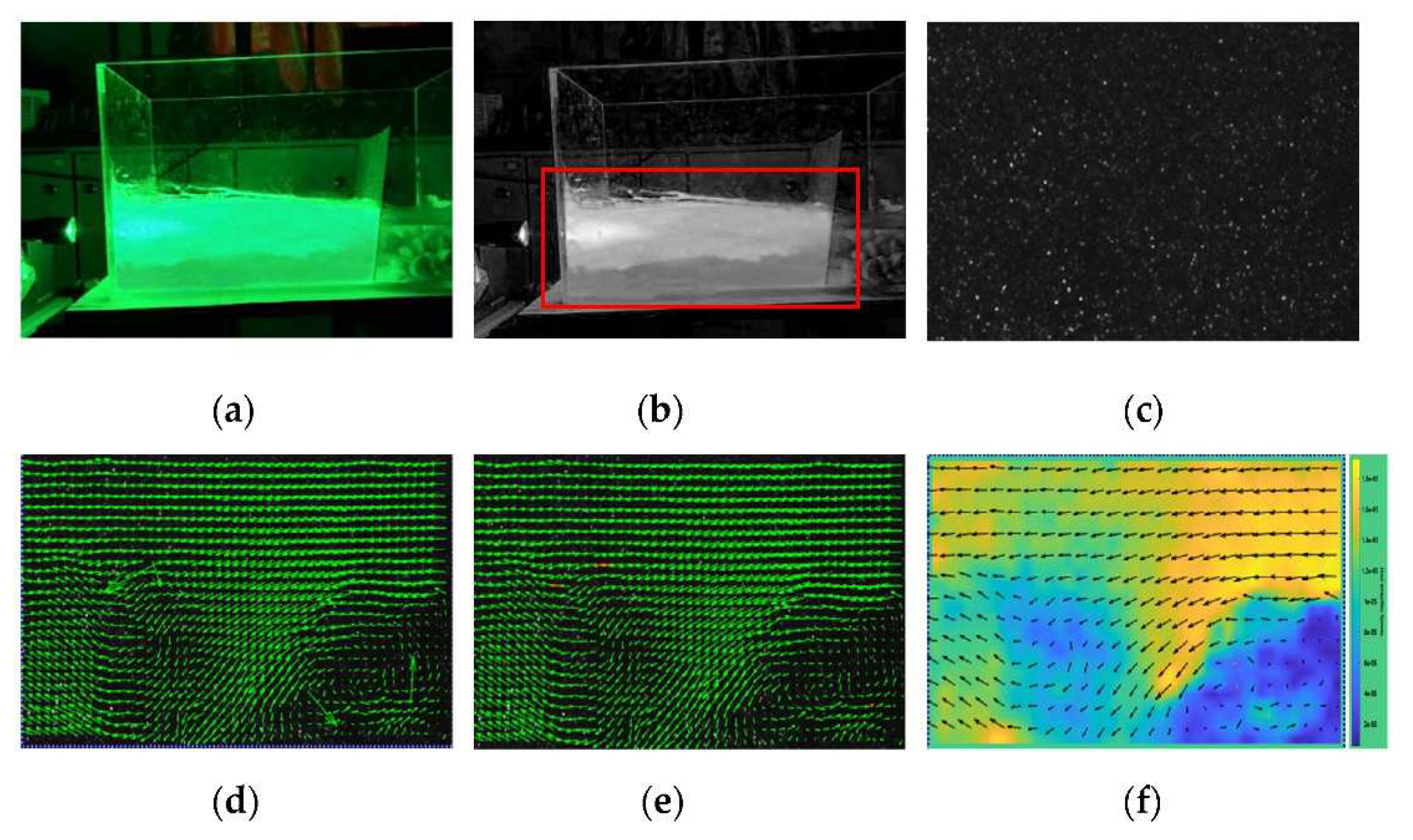

3. Seepage Observation Test of Transparent Clay

3.1. Test Equipment and Basic Principle

3.2. The Basic Principle of PIV Technology

3.3. Test Procedure

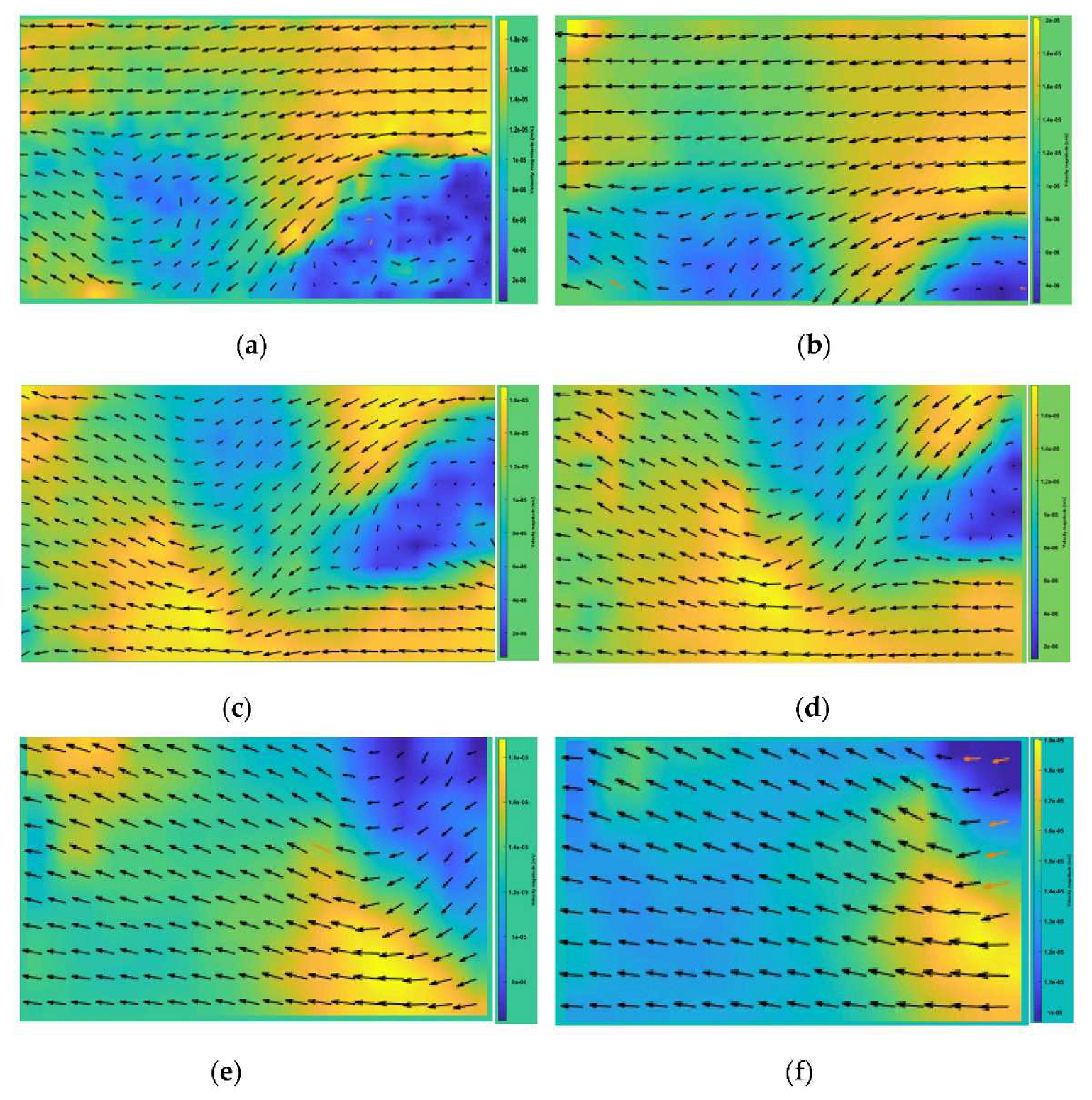

3.4. Permeation Velocity Distribution Pattern of Specimens with Different Mass Ratios

3.5. Flow Velocity Clouds of Specimen Sections with Different Mass Ratios

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhen, Z.; Li, J.; Zhou, J. Microscopic Roles of “Viscoelasticity” in HPMA polymer flooding for EOR. Transp. Porous Med. 2011, 86, 199–214. [Google Scholar] [CrossRef] [Green Version]

- Tao, G.; Yuan, J.; Chen, Q.; Peng, W.; Basack, S. Chemical stabilization of calcareous sand by polyurethane foam adhesive. Constr. Build. Mater. 2021, 295, 123609. [Google Scholar] [CrossRef]

- Qc, A.; Ry, A.; Yl, A.; Gt, A.; Sn, B. Cyclic stress-strain characteristics of calcareous sand improved by polyurethane foam adhesive. Transp. Geotech. 2021, 31, 100640. [Google Scholar]

- Roscoe, K. The determination of strains in soils by an X-ray method. Civ. Engng. Publ. Wks. Rev. 1963, 58, 873–876. [Google Scholar]

- Mandava, S.S.; Watson, A.T.; Edwards, C.M. NMR imaging of saturation during immiscible displacements. AIChE J. 1990, 36, 1680–1686. [Google Scholar] [CrossRef]

- Cai, G.Q.; Sheng, D.C.; Zhou, A.N.; Civil, S.O. Approach for predicting the relative coefficient of permeability of unsaturated soils with different initial void ratios. J. Rock Mech. Geotech. 2014, 36, 827–835, In Chinese. [Google Scholar] [CrossRef]

- Liu, H.Y.; Xia, Q.; Zhang, S.S.; Gang, L.U.; Wan, Y.; China, P. Evaluation on the Indefinability of Reservoir Leakage Amount Based on the Hydrogeological Parameters Sensitivities Analysis. Sci. Technol. Eng. 2017, 17, 32–38, In Chinese. [Google Scholar] [CrossRef]

- Xiao, B.Q.; Wang, W.; Zhang, X.; Long, G.; Fan, J.; Chen, H.; Deng, L. A novel fractal solution for permeability and kozeny-carman constant of fibrous porous media made up of solid particles and porous fibers. Powder Technol. 2019, 349, 92–98. [Google Scholar] [CrossRef]

- Iskander, M.; Bathurst, R.; Omidvar, M. Past, present, and future of transparent soils. Geotech. Test. J. 2015, 38, 557–573. [Google Scholar] [CrossRef]

- Allersma, H.; Hgb, A. Photo-elastic stress analysis and strains in simple shear. In Proceedings of the IUTAM Conference on Deformation and Failure of Granular Materials, Rotterdam, The Netherlands, 31 August–3 September 1982. [Google Scholar]

- Mannheimer, R. Slurries you can see through. Technol. Today 1990, 3, 2. [Google Scholar]

- Iskander, M.G.; Lai, J.; Oswald, C.J.; Mannheimer, R. Development of a transparent material to model the geotechnical properties of soils. Geotech. Test. J. 1994, 17, 425–433. [Google Scholar]

- Mannheimer, R.; Oswald, C. Development of transparent porous media with permeabilities and porosities comparable to soils, aquifers, and petroleum reservoirs. Groundwater 1993, 31, 781–788. [Google Scholar] [CrossRef]

- Gill, D.R.; Lehane, B.M. An optical technique for investigating soil displacement patterns. Geotech. Test. J. 2001, 24, 324–329. [Google Scholar] [CrossRef]

- Hird, C.; Ni, Q.; Guymer, I. Physical modelling of deformations around piling augers in clay. Geotechnique 2011, 61, 993–999. [Google Scholar] [CrossRef]

- Mckelvey, D.; Sivakumar, V.; Bell, A.; Graham, J. Modelling vibrated stone columns in soft clay. Geotech. Eng. 2004, 157, 137–149. [Google Scholar] [CrossRef]

- Black, J.A. Centrifuge modelling with transparent soil and laser aided imaging. Geotech. Test. J. 2015, 38, 631–644. [Google Scholar] [CrossRef] [Green Version]

- Sadek, S.; Iskander, M.G.; Liu, J. Accuracy of digital image correlation for measuring deformations in transparent media. J. Comput. Civ. Eng. 2003, 17, 88–96. [Google Scholar] [CrossRef]

- Iskander, M.G.; Sadek, S.; Liu, J. Optical measurement of deformation using transparent silica gel to model sand. Int. J. Phys. Model. GeoTECH 2002, 2, 13–26. [Google Scholar] [CrossRef]

- Zhao, H.; Ge, L. Investigation on the shear moduli and damping ratios of silica gel. Granul. Matter 2014, 16, 449–456. [Google Scholar] [CrossRef]

- Tabe, K.; Iskander, M.; Honma, S. Transparent aquabeads to visualize flow in porous material. Adv. Mater. Res. 2011, 239–242, 2602–2605. [Google Scholar] [CrossRef]

- Tabe, K. Aquabeads to Model the Geotechnical Behavior of Natural Soils. Ph.D. Thesis, Polytechnic Institute of New York University, New York, NY, USA, 2009. [Google Scholar]

- Tabe, K. Transparent aquabeads to model LNAPL ganglia migration through surfactant flushing. Geotech. Test. J. 2015, 38, 787–804. [Google Scholar] [CrossRef]

- Alvarez-Hernandez, E.M. The Influence of Cohesion on Sediment Movement in Channels of Circular Cross-Section; Newcastle University: Newcastle upon Tyne, UK, 1990. [Google Scholar]

- Gidley, I.; Grozic, J. Gas hydrate dissociation structures in submarine slopes. In Proceedings of the 4th Canadian Conference on Geohazards: From Causes to Management, Calgary, Canada, 20–24 May 2008. [Google Scholar]

- Wallace, J.F.; Rutherford, C.J. Geotechnical properties of LAPONITE RD®. Geotech. Test. J. 2015, 38, 574–587. [Google Scholar] [CrossRef]

- Beemer, R.D.; Aubeny, C. Digital image processing of drag embedment anchors in translucent silicate gel. In Proceedings of the GeoManitoba, Winnepeg, Canada, 30 September–3 October 2012. [Google Scholar]

- Dolinar, B. Predicting the hydraulic conductivity of saturated clays using plasticity-value correlations. Appl. Clay Sci. 2009, 45, 90–94. [Google Scholar] [CrossRef]

- Tavenas, F.; Leblond, P.; Jean, P.; Leroueil, S. The permeability of natural soft clays. Part Ⅰ: Methods of laboratory measurement. Can. Geotech. J. 1983, 20, 629–644. [Google Scholar] [CrossRef]

| Name of Soil Sample | Saturated Permeability Coefficient (×10−7 cm·s−1) | Data Source |

|---|---|---|

| Kga | 1.421–5.000 | reference [28] |

| Kga | 0.750–3.100 | reference [28] |

| Saz | 0.140–0.990 | reference [28] |

| Louiseville clay | 0.169–1.460 | reference [29] |

| Hunan clay | 16.100–82.200 | experimentally measured |

| Transparent clay A | 1.720–12.500 | experimentally measured |

| Transparent clay B | 1.090–7.520 | experimentally measured |

| Transparent clay C | 0.197–0.837 | experimentally measured |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, G.; Luo, Q.; Huang, S.; Li, Y.; Huang, Z.; Wu, Z.; Zhang, F.; Dong, H. Study on Permeability Characteristics of Porous Transparent Gels Based on Synthetic Materials. Polymers 2021, 13, 4009. https://doi.org/10.3390/polym13224009

Tao G, Luo Q, Huang S, Li Y, Huang Z, Wu Z, Zhang F, Dong H. Study on Permeability Characteristics of Porous Transparent Gels Based on Synthetic Materials. Polymers. 2021; 13(22):4009. https://doi.org/10.3390/polym13224009

Chicago/Turabian StyleTao, Gaoliang, Qingshi Luo, Shaoping Huang, Yi Li, Zhe Huang, Zhijia Wu, Fan Zhang, and Heming Dong. 2021. "Study on Permeability Characteristics of Porous Transparent Gels Based on Synthetic Materials" Polymers 13, no. 22: 4009. https://doi.org/10.3390/polym13224009

APA StyleTao, G., Luo, Q., Huang, S., Li, Y., Huang, Z., Wu, Z., Zhang, F., & Dong, H. (2021). Study on Permeability Characteristics of Porous Transparent Gels Based on Synthetic Materials. Polymers, 13(22), 4009. https://doi.org/10.3390/polym13224009