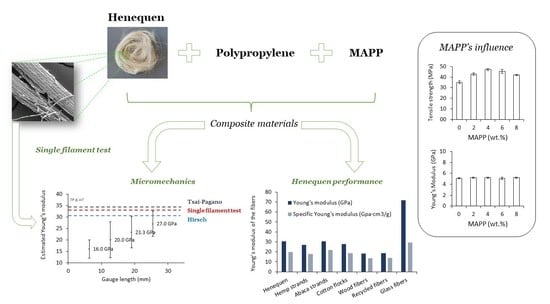

Effective Young’s Modulus Estimation of Natural Fibers through Micromechanical Models: The Case of Henequen Fibers Reinforced-PP Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Composite Materials

2.2.2. Injection Molding of Standard Specimens and Mechanical Characterization

2.2.3. Morphological Analysis of the Fibers

2.2.4. Scanning Electron Microscopy

2.2.5. Single Filament Test

3. Results and Discussion

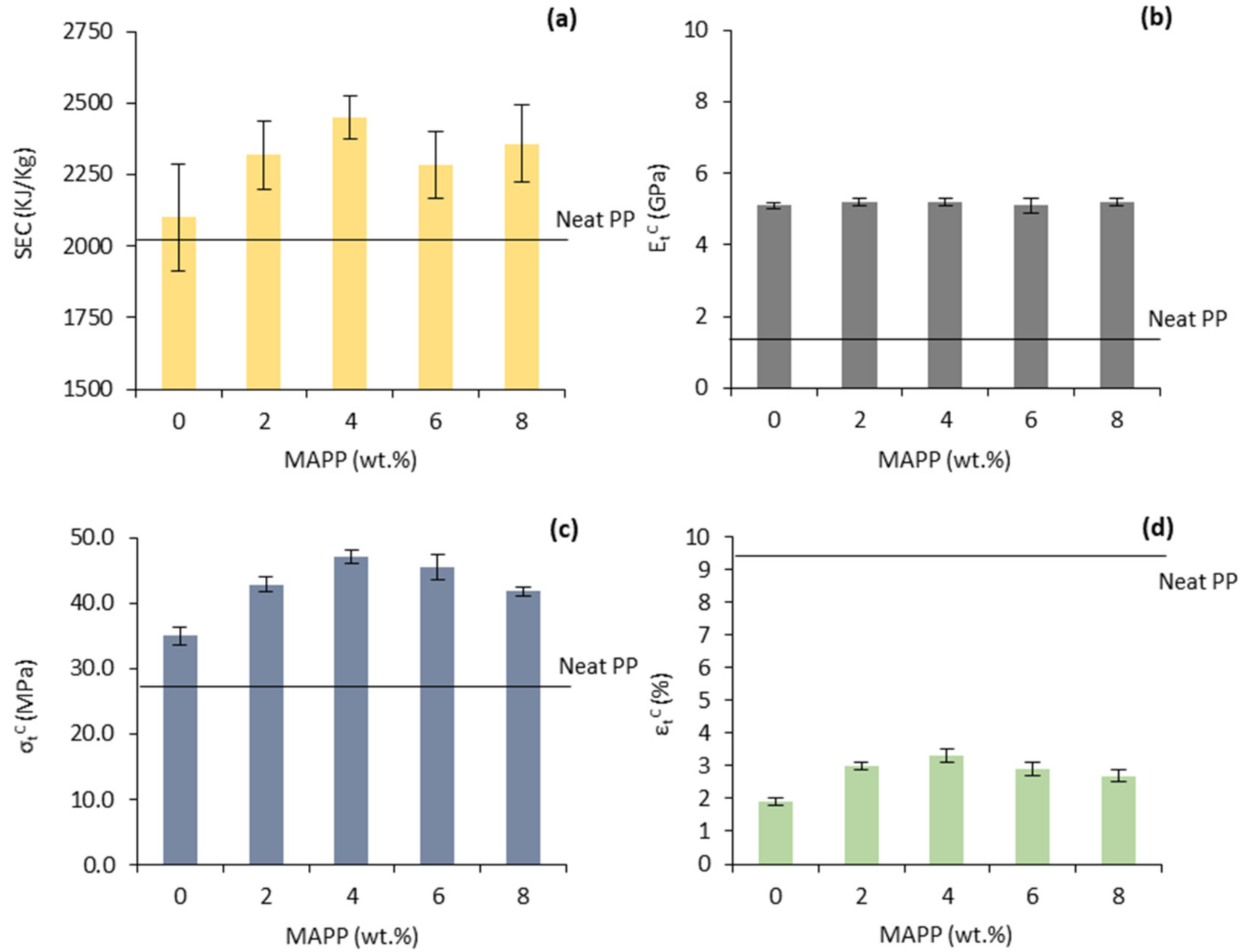

3.1. Coupling Agent Optimization

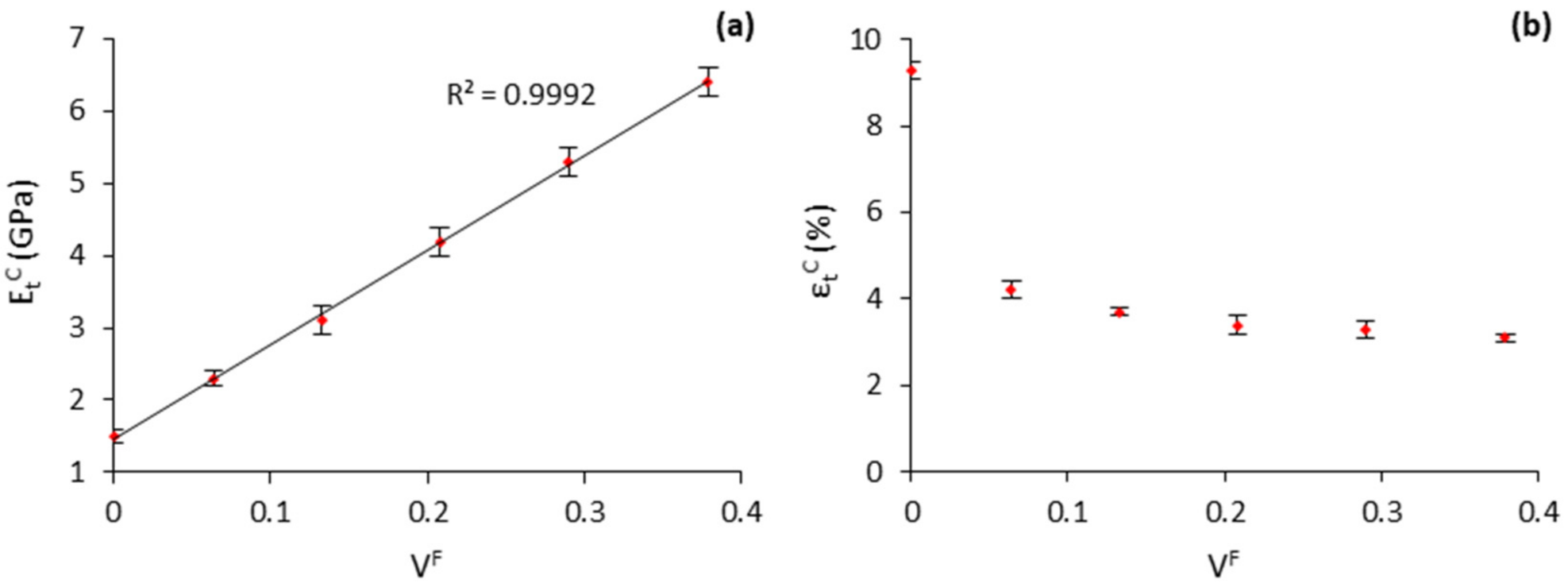

3.2. Analysis of the Young’s Modulus

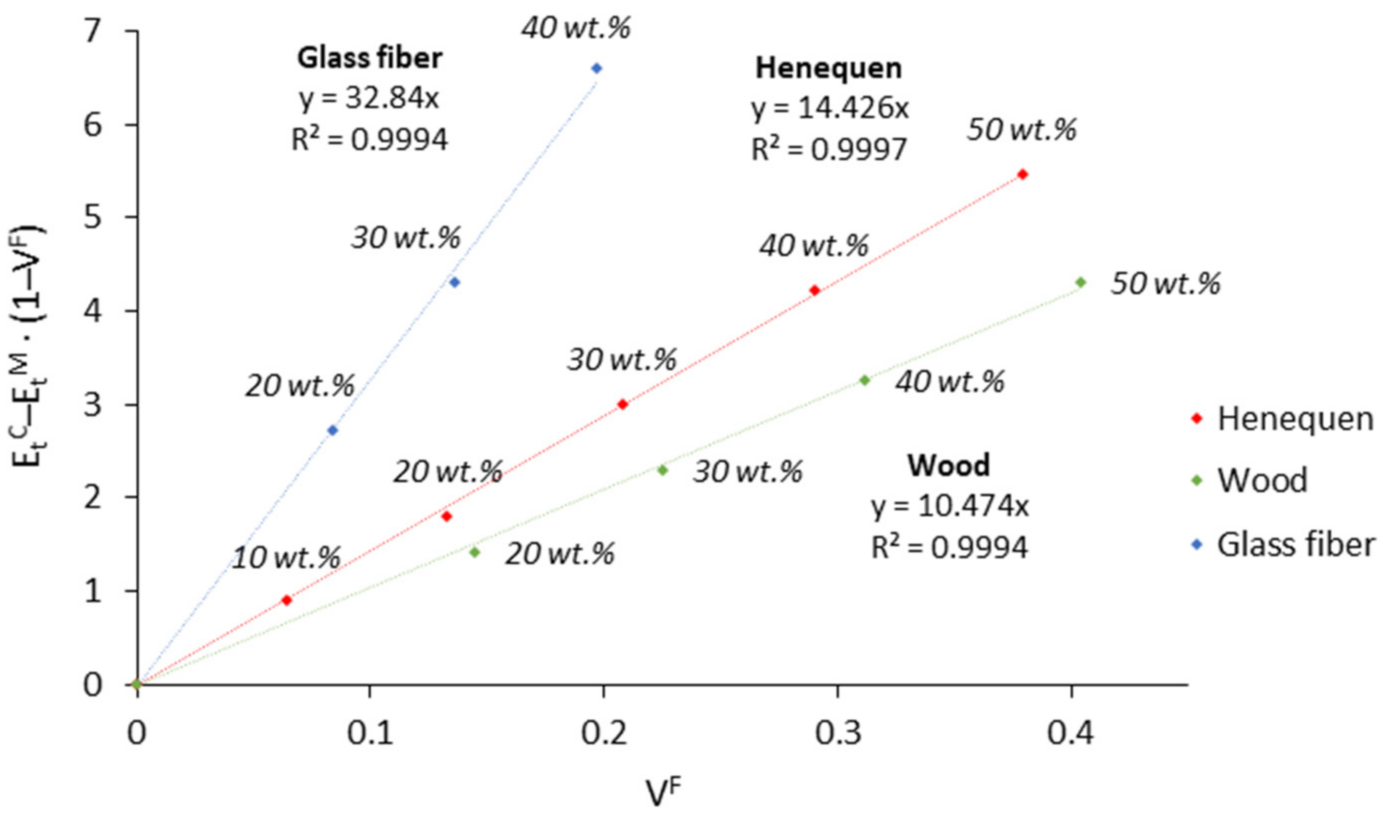

3.3. Fiber Contribution to the Young’s Modulus

3.4. Estimation of the Intrinsic Young’s Modulus of Henequen Fibers

3.5. Modulus Efficiency, Length, and Orientations Factors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Fitzgerald, A.; Proud, W.; Kandemir, A.; Murphy, R.J.; Jesson, D.A.; Trask, R.S.; Hamerton, I.; Longana, M.L. A life cycle engineering perspective on biocomposites as a solution for a sustainable recovery. Sustainability 2021, 13, 1160. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of Natural Fiber-Reinforced Plastics (NFRP) Based on Biobased Polyethylene and Waste Fibers From Posidonia oceanica Seaweed. Polym. Polym. Compos. 2008, 36, 1378–1385. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Xu, A.; Wang, Y.; Gao, J.; Wang, J. Facile fabrication of a homogeneous cellulose/polylactic acid composite film with improved biocompatibility, biodegradability and mechanical properties. Green Chem. 2019, 21, 4449–4456. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Vilaseca, F.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M.; Tarrés, Q. Stiffening potential of lignocellulosic fibers in fully biobased composites: The case of abaca strands, spruce tmp fibers, recycled fibers from onp and barley tmp fibers. Polymers 2021, 13, 619. [Google Scholar] [CrossRef] [PubMed]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Karmaker, A.C.; Hoffmann, A.; Hinrichsen, G. Influence of water uptake on the mechanical properties of jute fiber-reinforced polypropylene. J. Appl. Polym. Sci. 1994, 54, 1803–1807. [Google Scholar] [CrossRef]

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholz, L.; Essel, R.; Breitmayer, E.; Barth, M. WPC/NFC Market Study 2014-10 (Update 2015-06): Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC): European and Global Markets 2012 and Future Trends in Automotive and Construction. Bio-Based Eu/Mark. 2015, 6, 1–14. [Google Scholar]

- Bledzki, A.K.; Gassan, J.; Theis, S. Wood-filled thermoplastic composites. Mech. Compos. Mater. 1998, 34, 563–568. [Google Scholar] [CrossRef]

- Gironès, J.; Lopez, J.P.; Vilaseca, F.; Bayer, R.; Herrera-Franco, P.J.; Mutjé, P. Biocomposites from Musa textilis and polypropylene: Evaluation of flexural properties and impact strength. Compos. Sci. Technol. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Serra, A.; Tarrés, Q.; Llop, M.; Reixach, R.; Mutjé, P.; Espinach, F.X. Recycling dyed cotton textile byproduct fibers as polypropylene reinforcement. Text. Res. J. 2019, 89, 2113–2125. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Kärki, T. The Effects of the Substitution of Wood Fiberwith Agro-based Fiber (Barley Straw) on the Properties of Natural Fiber/Polypropylene Composites. In MATEC Web of Conferences; EDP Sciences: Perak, Malaysia, 2015; Volume 30, p. 1014. [Google Scholar]

- Reixach, R.; Espinach, F.X.; Arbat, G.; Julián, F.; Delgado-Aguilar, M.; Puig, J.; Mutjé, P. Tensile properties of polypropylene composites reinforced with mechanical, thermomechanical, and chemi-thermomechanical pulps from orange pruning. BioResources 2015, 10, 4544–4556. [Google Scholar] [CrossRef] [Green Version]

- Delgado-Aguilar, M.; González, I.; Pèlach, M.A.; De La Fuente, E.; Negro, C.; Mutjé, P. Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 2015, 22, 789–802. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowell, R.M. Recycled Newspaper Fibers as Reinforcing Fillers in Thermoplastics: Part I-Analysis of Tensile and Impact Properties in Polypropylene. J. Reinf. Plast. Compos. 1994, 13, 54–67. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications; Springer: Berlin/Heidelberg, Germany, 2020; Volume 55, ISBN 1085301903990. [Google Scholar]

- Fajardo Cabrera de Lima, L.D.P.; Chamorro Rodríguez, C.D.; Mina Hernandez, J.H. Use of Organic Acids in Bamboo Fiber-Reinforced Polypropylene Composites: Mechanical Properties and Interfacial Morphology. Polymers 2021, 13, 2007. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface modification of natural fibers: A review. Procedia Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Zabihzadeh, S.M.; Ebrahimi, G.; Enayati, A.A. Effect of Compatibilizer on Mechanical, Morphological, and Thermal Properties of Chemimechanical Pulp-reinforced PP Composites. J. Thermoplast. Compos. Mater. 2011, 24, 221–231. [Google Scholar] [CrossRef]

- Pimenta, M.T.B.; Carvalho, A.J.F.; Vilaseca, F.; Girones, J.; López, J.P.; Mutjé, P.; Curvelo, A.A.S. Soda-treated sisal/polypropylene composites. J. Polym. Environ. 2008, 16, 35–39. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Yotinwattanakumtorn, C.; Thongpin, C. Influence of type and concentration of maleic anhydride grafted polypropylene and impact modifiers on mechanical properties of PP/wood sawdust composites. J. Appl. Polym. Sci. 2005, 97, 475–484. [Google Scholar] [CrossRef]

- Silva, N.G.; Cortat, L.I.; Mulinari, D.R. Effect of Alkaline Treatment and Coupling Agent on Thermal and Mechanical Properties of Macadamia Nutshell Residues Based PP Composites. J. Polym. Environ. 2021, 29, 3271–3287. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, L.; Panigrahi, S.; Opoku, A. The effect of fiber pretreatment and compatibilizer on mechanical and physical properties of flax fiber-polypropylene composites. J. Polym. Environ. 2008, 16, 74–82. [Google Scholar] [CrossRef]

- Nayak, S.K.; Dixit, G.; Appukuttan, K.K. Sisal fiber (SF) reinforced recycled polypropylene (RPP) composites. Int. J. Plast. Technol. 2012, 16, 150–165. [Google Scholar] [CrossRef]

- Neagu, R.C.; Gamstedt, E.K.; Berthold, F. Stiffness contribution of various wood fibers to composite materials. J. Compos. Mater. 2006, 40, 663–699. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Delgado-Aguilar, M.; Duran, J.; Mutjé, P. Stiffness of bio-based polyamide 11 reinforced with softwood stone ground-wood fibres as an alternative to polypropylene-glass fibre composites. Eur. Polym. J. 2016, 84, 481–489. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the elastic modulus of natural fibre reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1660–1671. [Google Scholar] [CrossRef]

- Rodriguez, M.; Rodriguez, A.; Bayer, J.; Vilaseca, F.; Girones, J.; Mutje, P. Determination of corn stalk fibers’ strength through modeling of the mechanical properties of its composites. BioResources 2010, 5, 2535–2546. [Google Scholar]

- Schmachtenberg, E.; Brandt, M. Mechanical design of injection moulded parts made of short-fibre reinforced thermoplastics by means of integrative simulation. J. Polym. Eng. 2006, 26, 179–196. [Google Scholar] [CrossRef]

- Shah, D.U.; Nag, R.K.; Clifford, M.J. Why do we observe significant differences between measured and “back-calculated” properties of natural fibres? Cellulose 2016, 23, 1481–1490. [Google Scholar] [CrossRef] [Green Version]

- Tarrés, Q.; Vilaseca, F.; Herrera-Franco, P.J.; Espinach, F.X.; Delgado-Aguilar, M.; Mutjé, P. Interface and micromechanical characterization of tensile strength of bio-based composites from polypropylene and henequen strands. Ind. Crops Prod. 2019, 132, 319–326. [Google Scholar] [CrossRef]

- Chihaoui, B.; Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Boufi, S.; Delgado-Aguilar, M. Effect of the fiber treatment on the stiffness of date palm fiber reinforced PP composites: Macro and micromechanical evaluation of the young’s modulus. Polymers 2020, 12, 1693. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, S.; Nayak, S.K.; Verma, S.K.; Tripathy, S.S. Effect of MAPP as a Coupling Agent on the Performance of Jute-PP Composites. J. Reinf. Plast. Compos. 2004, 23, 625–637. [Google Scholar] [CrossRef]

- Siregar, J.P.; Jaafar, J.; Cionita, T.; Jie, C.C.; Bachtiar, D.; Rejab, M.R.M.; Asmara, Y.P. The Effect of Maleic Anhydride Polyethylene on Mechanical Properties of Pineapple Leaf Fibre Reinforced Polylactic Acid Composites. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 101–112. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S. Sisal Glass Fiber Reinforced PP Hybrid Composites: Effect of MAPP on the Dynamic Mechanical and Thermal Properties. J. Reinf. Plast. Compos. 2010, 29, 1551–1568. [Google Scholar] [CrossRef]

- Brahmakumar, M.; Pavithran, C.; Pillai, R.M. Coconut fibre reinforced polyethylene composites: Effect of natural waxy surface layer of the fibre on fibre/matrix interfacial bonding and strength of composites. Compos. Sci. Technol. 2005, 65, 563–569. [Google Scholar] [CrossRef]

- Prasad, S.V.; Pavithran, C.; Rohatgi, P.K. Alkali treatment of coir fibres for coir-polyester composites. J. Mater. Sci. 1983, 18, 1443–1454. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; El Achaby, M.; Malha, M.; Bensalah, M.O.; Fassi-Fehri, O.; Bouhfid, R.; Benmoussa, K.; Qaiss, A. Mechanical and thermal properties of natural fibers reinforced polymer composites: Doum/low density polyethylene. Mater. Des. 2013, 43, 200–205. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Tresserras, J.; Pellicer, N.; Alcala, M.; Mutje, P. Study on the technical feasibility of replacing glass fibers by old newspaper recycled fibers as polypropylene reinforcement. J. Clean. Prod. 2014, 65, 489–496. [Google Scholar] [CrossRef]

- Thomason, J.L.; Rudeiros-Fernández, J.L. A review of the impact performance of natural fiber thermoplastic composites. Front. Mater. 2018, 5, 60. [Google Scholar] [CrossRef]

- Kandemir, A.; Longana, M.L.; Panzera, T.H.; del Pino, G.G.; Hamerton, I.; Eichhorn, S.J. Natural fibres as a sustainable reinforcement constituent in aligned discontinuous polymer composites produced by the HiPerDiF method. Materials 2021, 14, 1885. [Google Scholar] [CrossRef]

- López, J.P.; Mutjé, P.; Pèlach, M.À.; Mansouri, N.-E.; Boufi, S.; Vilaseca, F. Analysis of the tensile modulus of polypropylene composites reinforced with stone groundwood fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Hirsch, T.J. Modulus of Elasticity of Concrete Affected by Elastic Moduli of Cement Paste Matrix and Aggregate. J. Proc. 1962, 59, 427–452. [Google Scholar]

- Kalaprasad, G.; Joseph, K.; Thomas, S.; Pavithran, C. Theoretical modelling of tensile properties of short sisal fibre-reinforced low-density polyethylene composites. J. Mater. Sci. 1997, 32, 4261–4267. [Google Scholar] [CrossRef]

- Affdl, J.H.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Halpin, J.C. Effects of Environmental Factors on Composite Materials; Air Force Materials Lab: Wright-Patterson, OH, USA, 1969. [Google Scholar]

- Halpin, J.C.; Pagano, N.J. The Laminate Approximation for Randomly Oriented Fibrous Composites. J. Compos. Mater. 1969, 3, 720–724. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L.; Farrell, R.L. Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1165–1171. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Chawla, N.; de Toledo Filho, R.D. Tensile behavior of high performance natural (sisal) fibers. Compos. Sci. Technol. 2008, 68, 3438–3443. [Google Scholar] [CrossRef]

- Guimarães, J.R.; Chawla, K.K. Characteristics of the stiffness of a universal tensile testing apparatus. Metalurgia 1978, 34, 549. [Google Scholar]

- Pardini, L.C.; Manhani, L.G.B. Influence of the testing gage length on the strength, Young’s modulus and Weibull modulus of carbon fibres and glass fibres. Mater. Res. 2002, 5, 411–420. [Google Scholar] [CrossRef] [Green Version]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Krenchel, H. Fibre Reinforcement. In Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Jiménez, A.M.; Delgado-Aguilar, M.; Tarrés, Q.; Quintana, G.; Fullana-i-Palmer, P.; Mutjè, P.; Espinach, F.X. Sugarcane bagasse reinforced composites: Studies on the young’s modulus and macro and micro-mechanics. BioResources 2017, 12, 3618–3629. [Google Scholar] [CrossRef] [Green Version]

| Henequen (wt.%) | VF | (GPa) | (%) |

|---|---|---|---|

| 0 | 0 | 1.5 ± 0.1 | 9.3 ± 0.2 |

| 10 | 0.064 | 2.3 ± 0.1 | 4.2 ± 0.1 |

| 20 | 0.133 | 3.1 ± 0.1 | 3.7 ± 0.1 |

| 30 | 0.208 | 4.2 ± 0.2 | 3.4 ± 0.2 |

| 40 | 0.290 | 5.3 ± 0.1 | 3.3 ± 0.2 |

| 50 | 0.379 | 6.4 ± 0.1 | 3.1 ± 0.1 |

| Henequen (wt.%) | VF | lwF (µm) | dF (µm) | (GPa) | (GPa) |

|---|---|---|---|---|---|

| 10 | 0.064 | 826.3 ± 10.6 | 25.5 ± 0.1 | 30.5 | 36.5 |

| 20 | 0.133 | 784.2 ± 12.3 | 25.6 ± 0.1 | 29.1 | 33.4 |

| 30 | 0.208 | 741.9 ± 5.9 | 25.3 ± 0.2 | 31.3 | 36.1 |

| 40 | 0.290 | 708.1 ± 17.2 | 25.4 ± 0.2 | 31.3 | 34.8 |

| 50 | 0.379 | 674.3 ± 7.2 | 25.5 ± 0.1 | 30.5 | 32.0 |

| Mean value | 30.5 ± 0.9 | 34.6 ± 1.9 |

| Henequen (wt.%) | ηe | ηl | ηo |

|---|---|---|---|

| 10 | 0.46 | 0.88 | 0.52 |

| 20 | 0.46 | 0.89 | 0.52 |

| 30 | 0.46 | 0.90 | 0.52 |

| 40 | 0.47 | 0.91 | 0.51 |

| 50 | 0.47 | 0.92 | 0.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serra-Parareda, F.; Vilaseca, F.; Aguado, R.; Espinach, F.X.; Tarrés, Q.; Delgado-Aguilar, M. Effective Young’s Modulus Estimation of Natural Fibers through Micromechanical Models: The Case of Henequen Fibers Reinforced-PP Composites. Polymers 2021, 13, 3947. https://doi.org/10.3390/polym13223947

Serra-Parareda F, Vilaseca F, Aguado R, Espinach FX, Tarrés Q, Delgado-Aguilar M. Effective Young’s Modulus Estimation of Natural Fibers through Micromechanical Models: The Case of Henequen Fibers Reinforced-PP Composites. Polymers. 2021; 13(22):3947. https://doi.org/10.3390/polym13223947

Chicago/Turabian StyleSerra-Parareda, Ferran, Fabiola Vilaseca, Roberto Aguado, Francesc X. Espinach, Quim Tarrés, and Marc Delgado-Aguilar. 2021. "Effective Young’s Modulus Estimation of Natural Fibers through Micromechanical Models: The Case of Henequen Fibers Reinforced-PP Composites" Polymers 13, no. 22: 3947. https://doi.org/10.3390/polym13223947

APA StyleSerra-Parareda, F., Vilaseca, F., Aguado, R., Espinach, F. X., Tarrés, Q., & Delgado-Aguilar, M. (2021). Effective Young’s Modulus Estimation of Natural Fibers through Micromechanical Models: The Case of Henequen Fibers Reinforced-PP Composites. Polymers, 13(22), 3947. https://doi.org/10.3390/polym13223947