The Effect of Stacking Sequence on Fatigue Behaviour of Hybrid Pineapple Leaf Fibre/Carbon-Fibre-Reinforced Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Fabrication Method

2.3. Evaluation Methods

2.3.1. Void Content

2.3.2. Tensile Strength

2.3.3. Fatigue Test

2.3.4. Scanning Electron Microscopy (SEM)

3. Results

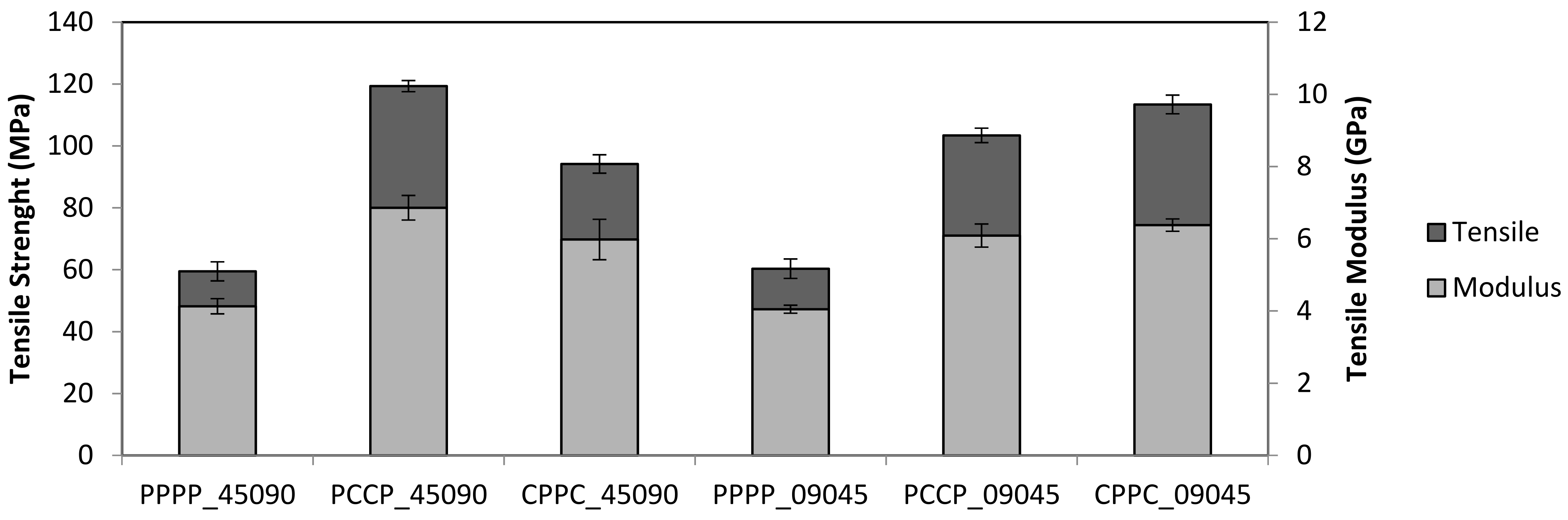

3.1. Void Content and Tensile Properties

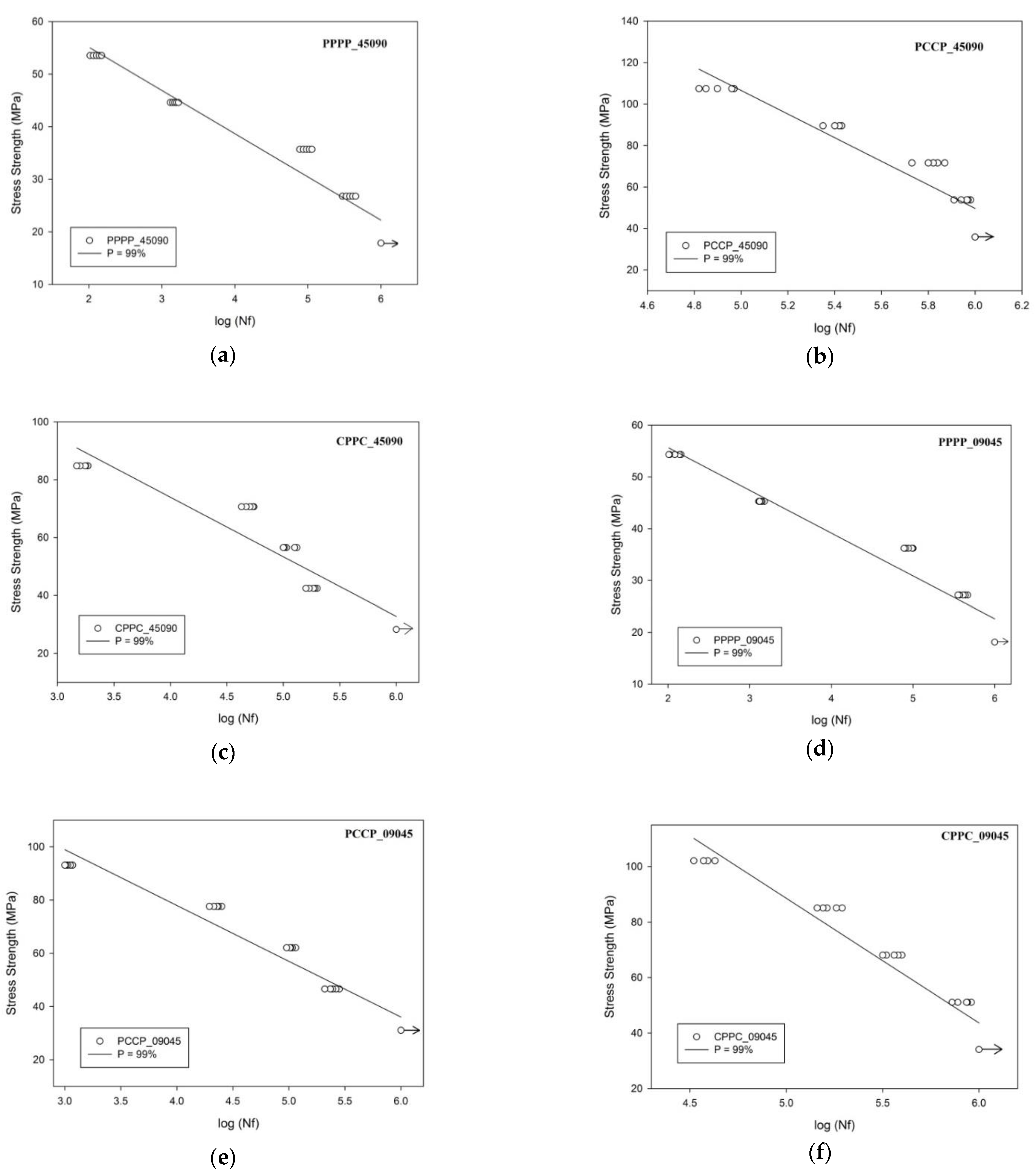

3.2. Wöhler Curves

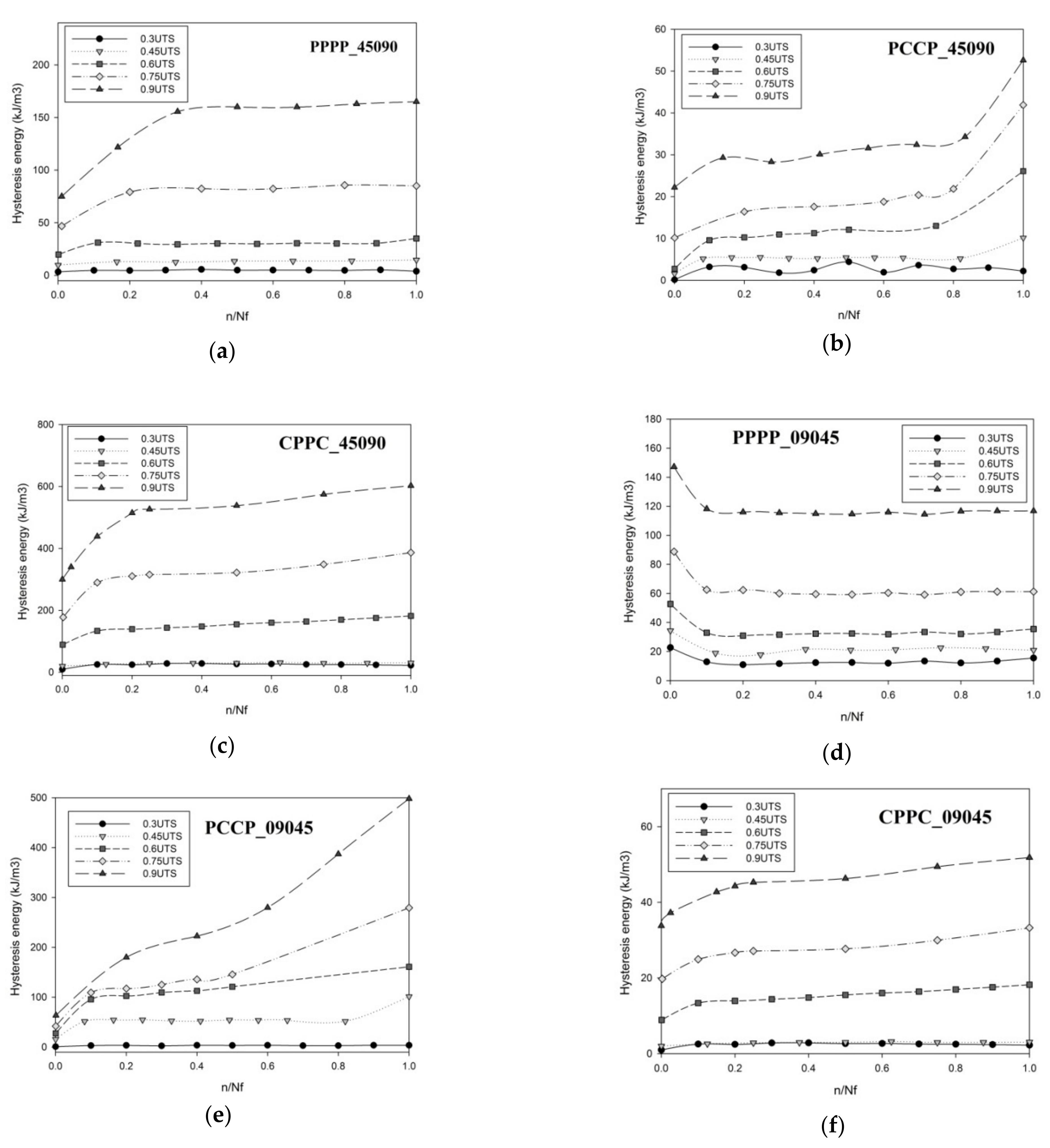

3.3. Hysteresis Energy

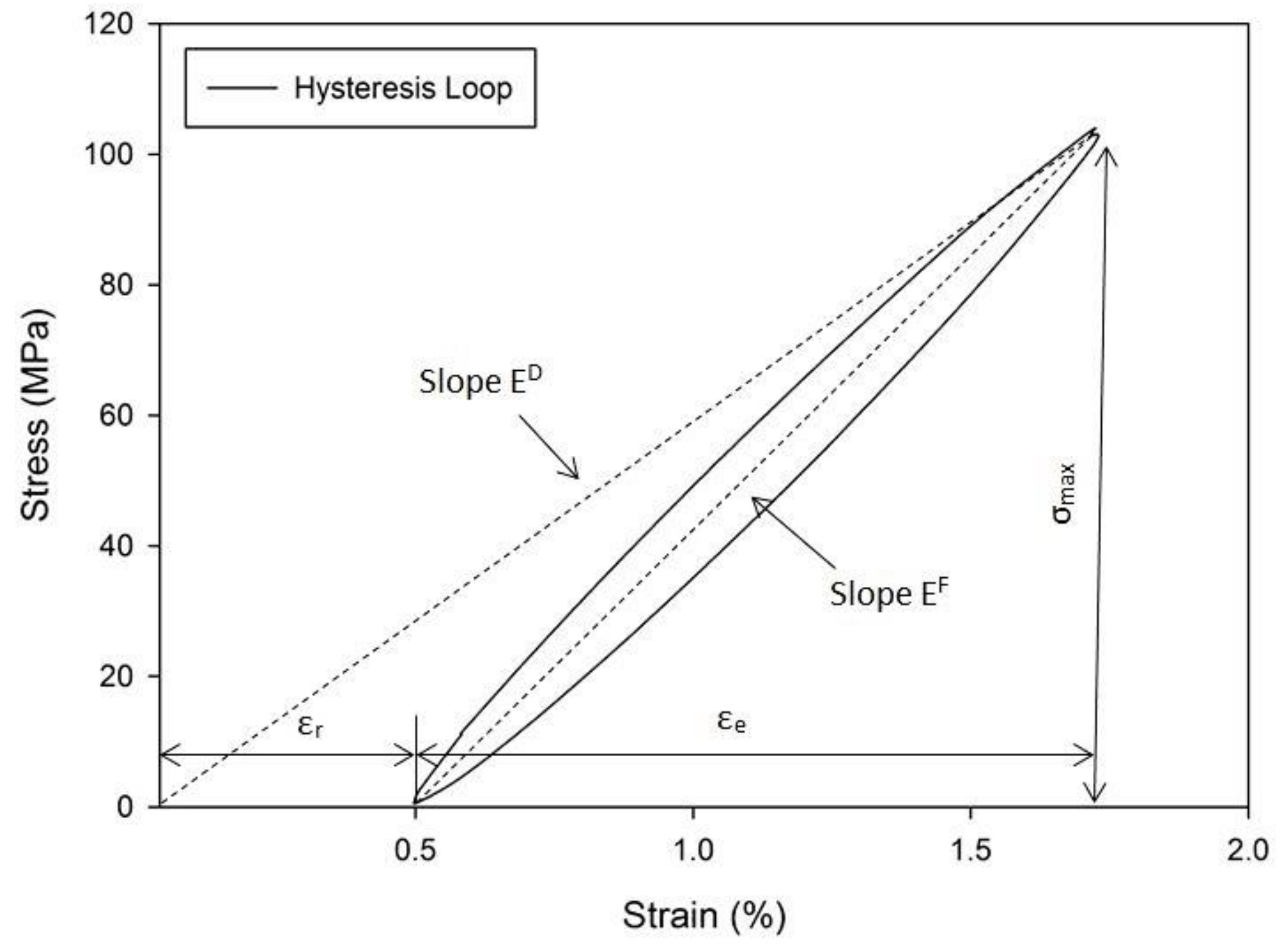

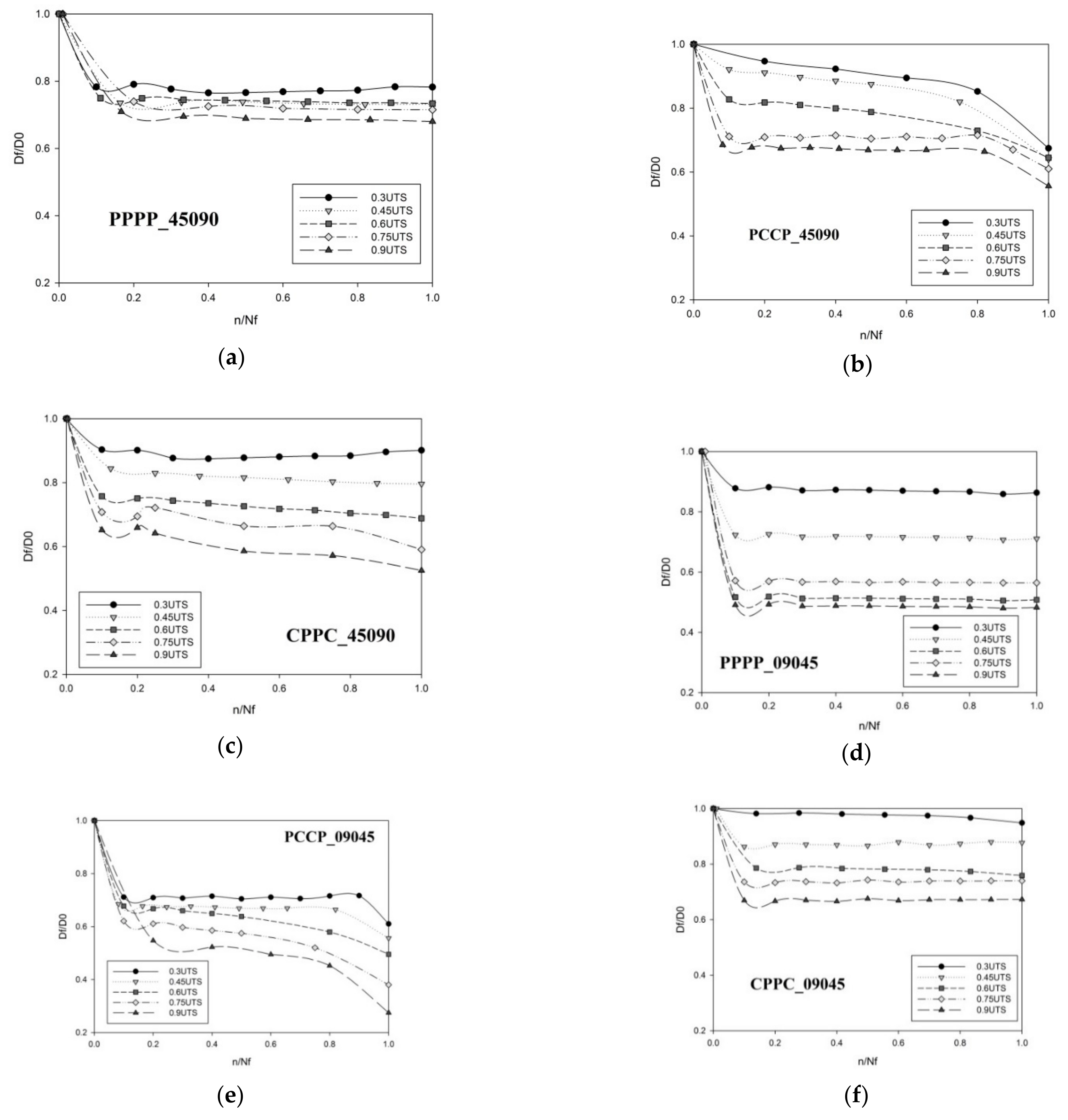

3.4. Stiffness Evolution

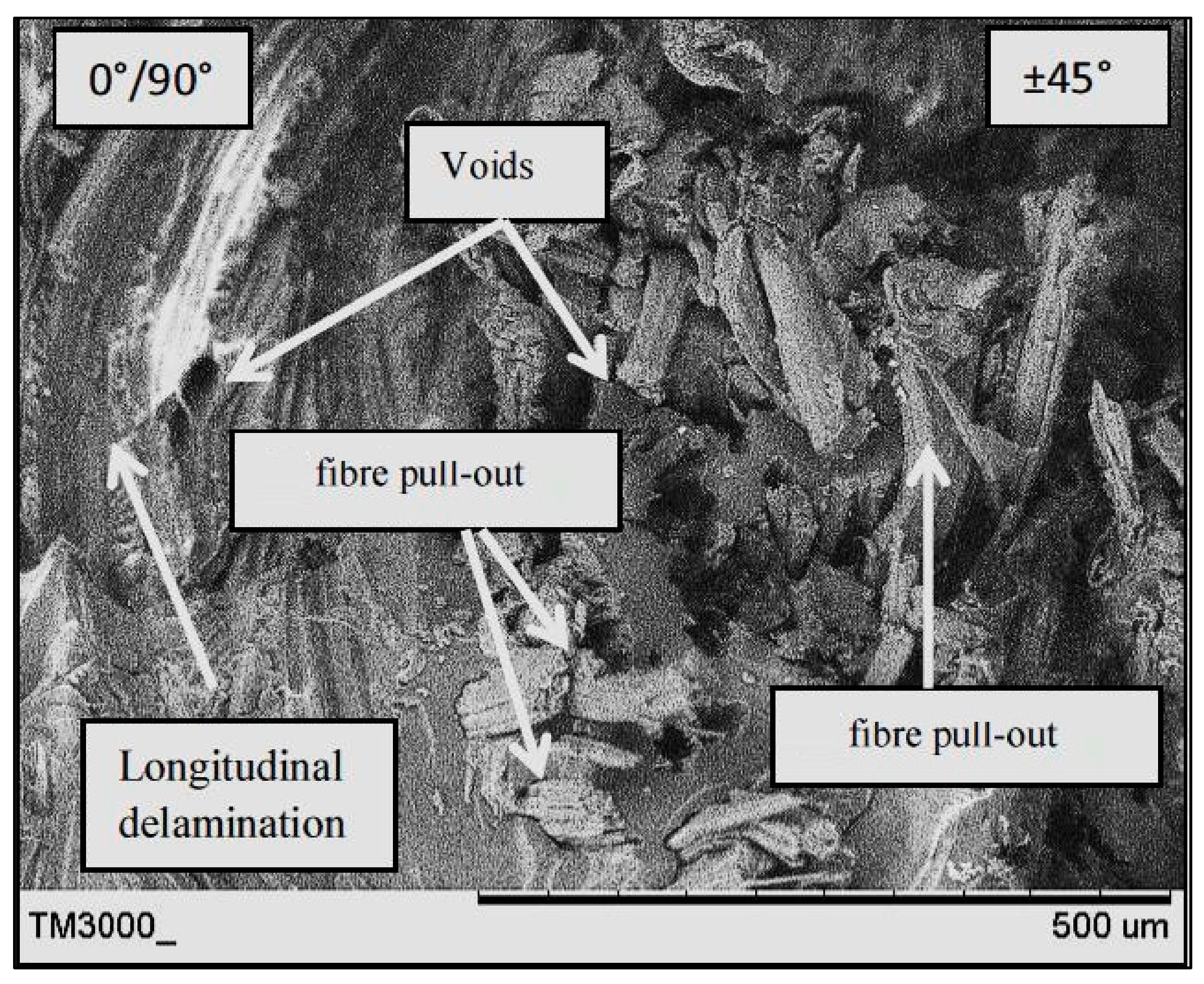

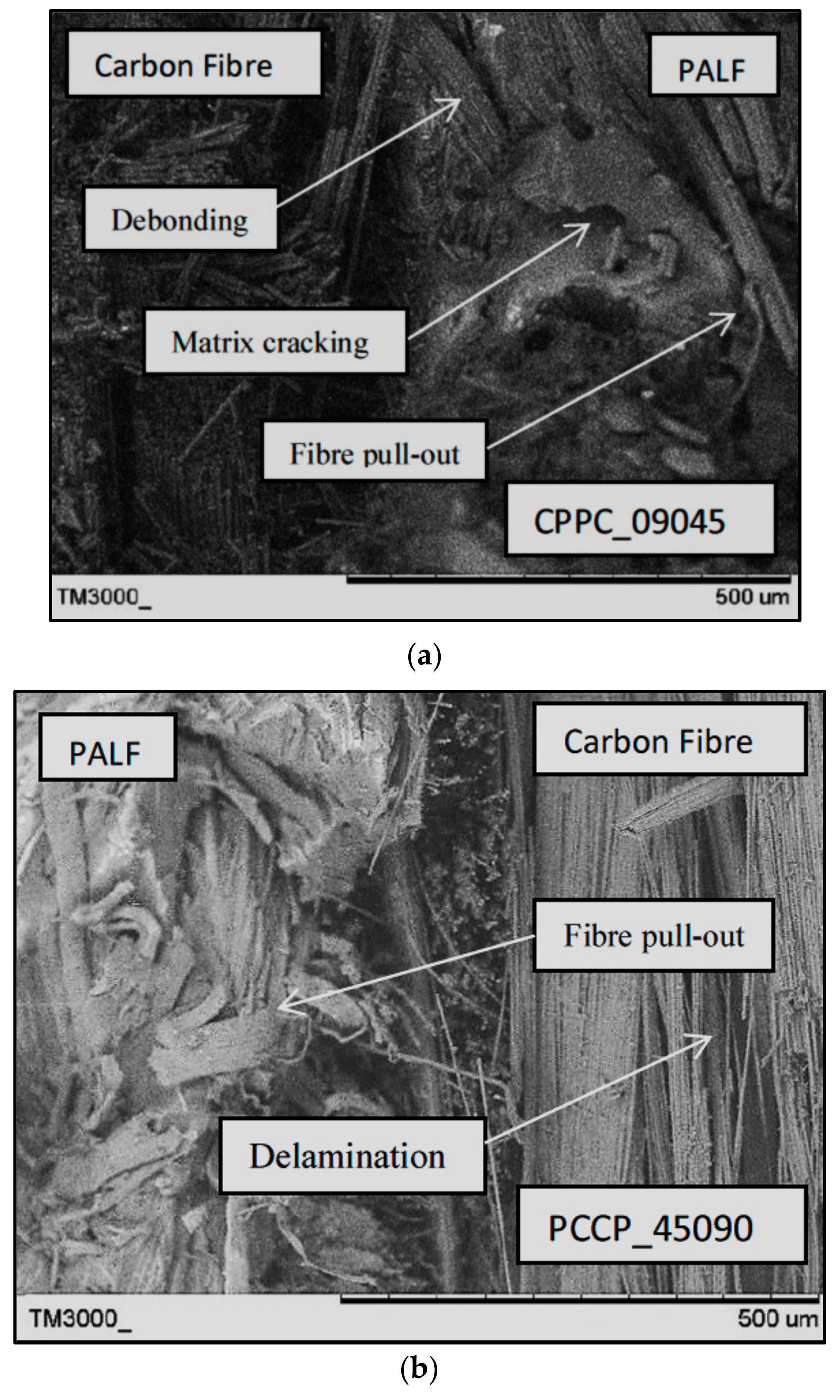

3.5. Damage Mechanism

4. Conclusions

- PCCP_45090 recorded the maximum tensile strength and modulus. This is because the carbon ply direction was aligned with the loading direction. The carbon ply is an internal layer which promises good adhesion between the matrix. The superior properties of the carbon fibre dominated the overall tensile properties of the laminate.

- The fatigue response investigation indicated that PCCP_45090 and CPPC_09045 yielded higher useful lives than the other laminates, especially when the laminates are subjected to high-intensity stress levels. The normalised stress against the number of cycles showed that the stacking sequence of different ply orientations significantly affected the fatigue behaviour, as compared to the stacking sequences of the material. The stacking sequences of the laminates significantly affected the hysteresis energy evolution. The hysteresis energy tended to follow the ply orientation of the carbon fibre, with higher hysteresis energy being exhibited for the laminates with the carbon ply off-axis to the load direction. The measured stiffness evaluation exhibited a considerable effect when the carbon ply was oriented at ± 45°.

- Morphological analyses indicated that the laminates which failed under fatigue testing failed in the typical modes of fibre pull-out, fibre breakage, delamination, debonding, and matrix cracking. Failure during fatigue was initiated from the external layer, as shown by fibre pull-out, matrix cracking, and fibre breakage. When the external layer was a carbon ply, delamination was the primary failure mode.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Ng, L.F.; Malingam, S.D.; Subramaniam, K.; Selamat, M.; Juan, W. The Investigation of the Tensile and Quasi-Static Indentation Properties of Pineapple Leaf/Kevlar Fibre Reinforced Hybrid Composites. Def. ST Tech. Bull. 2020, 13, 117–129. [Google Scholar]

- Varvani-Farahani, A.; Shirazi, A. A Fatigue Damage Model for (0/90) FRP Composites based on Stiffness Degradation of 0° and 90° Composite Plies. J. Reinf. Plast. Compos. 2007, 26, 1319–1336. [Google Scholar] [CrossRef]

- Philippidis, T.P.; Vassilopoulos, A. Life prediction methodology for GFRP laminates under spectrum loading. Compos. Part A Appl. Sci. Manuf. 2004, 35, 657–666. [Google Scholar] [CrossRef]

- Petermann, J.; Schulte, K. The effects of creep and fatigue stress ratio on the long-term behaviour of angle-ply CFRP. Compos. Struct. 2002, 57, 205–210. [Google Scholar] [CrossRef]

- Movahedi-Rad, A.V.; Keller, T.; Vassilopoulos, A.P. Fatigue damage in angle-ply GFRP laminates under tension-tension fatigue. Int. J. Fatigue 2018, 109, 60–69. [Google Scholar] [CrossRef]

- Savvilotidou, M.; Keller, T.; Vassilopoulos, A.P. Fatigue performance of a cold-curing structural epoxy adhesive subjected to moist environments. Int. J. Fatigue 2017, 103, 405–414. [Google Scholar] [CrossRef]

- Benaarbia, A.; Chrysochoos, A.; Robert, G. Thermomechanical behavior of PA6.6 composites subjected to low cycle fatigue. Compos. Part B Eng. 2015, 76, 52–64. [Google Scholar] [CrossRef] [Green Version]

- Sharba, M.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Hanim, M.A.A. Partial Replacement of Glass Fiber by Woven Kenaf in Hybrid Composites and its Effect on Monotonic and Fatigue Properties. Bioresources 2015, 11, 2665–2683. [Google Scholar] [CrossRef] [Green Version]

- Sivakumar, D.; Ng, L.F.; Lau, S.M.; Lim, K.T. Fatigue Life Behaviour of Glass/Kenaf Woven-Ply Polymer Hybrid Biocomposites. J. Polym. Environ. 2017, 26, 499–507. [Google Scholar] [CrossRef]

- Salman, S.D.; Sharba, M.J.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Cardona, F. Tension-Compression Fatigue Behavior of Plain Woven Kenaf/Kevlar Hybrid Composites. Bioresources 2016, 11, 3575–3586. [Google Scholar] [CrossRef]

- Marin, J.C.; Justo, J.; París, F.; Cañas, J. The effect of frequency on tension-tension fatigue behavior of unidirectional and woven fabric graphite-epoxy composites. Mech. Adv. Mater. Struct. 2019, 26, 1430–1436. [Google Scholar] [CrossRef]

- Yang, B.; Lei, H.; Zhao, Y.; Xing, G.; Zhang, H. Quasi-Symmetric Transfer Behavior in an Asymmetric Two-Strand Tundish with Different Turbulence Inhibitor. Metals 2019, 9, 855. [Google Scholar] [CrossRef] [Green Version]

- Nopparut, A.; Amornsakchai, T. Influence of pineapple leaf fiber and it’s surface treatment on molecular orientation in, and mechanical properties of, injection molded nylon composites. Polym. Test. 2016, 52, 141–149. [Google Scholar] [CrossRef]

- Najeeb, M.; Sultan, M.; Andou, Y.; Shah, A.; Eksiler, K.; Jawaid, M.; Ariffin, A. Characterization of silane treated Malaysian Yankee Pineapple AC6 leaf fiber (PALF) towards industrial applications. J. Mater. Res. Technol. 2020, 9, 3128–3139. [Google Scholar] [CrossRef]

- Salleh, Z.; Taib, Y.; Hyie, K.M.; Mihat, M.; Berhan, M.; Ghani, M. Fracture Toughness Investigation on Long Kenaf/Woven Glass Hybrid Composite Due To Water Absorption Effect. Procedia Eng. 2012, 41, 1667–1673. [Google Scholar] [CrossRef] [Green Version]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. Part B Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Jeon, Y.-P.; Alway-Cooper, R.; Morales, M.; Ogale, A.A. Chapter 2.8—Carbon Fibers. In Handbook of Advanced Ceramics, 2nd ed.; Somiya, S., Ed.; Academic Press: Oxford, UK, 2013; pp. 143–154. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Hakeem, K.; Paridah, M.; Khalina, A.; Alothman, O. Potential of bioenergy production from industrial kenaf (Hibiscus cannabinus L.) based on Malaysian perspective. Renew. Sustain. Energy Rev. 2015, 42, 446–459. [Google Scholar] [CrossRef]

- Ahmad, M.; Majid, M.S.A.; Ridzuan, M.; Mazlee, M.; Gibson, A. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef] [Green Version]

- Borrego, L.; Costa, J.; Ferreira, J.; Silva, H. Fatigue behaviour of glass fibre reinforced epoxy composites enhanced with nanoparticles. Compos. Part B Eng. 2014, 62, 65–72. [Google Scholar] [CrossRef]

- Sharba, M.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Hanim, M.A.A. Effects of Kenaf Fiber Orientation on Mechanical Properties and Fatigue Life of Glass/Kenaf Hybrid Composites. Bioresources 2015, 11, 1448–1465. [Google Scholar] [CrossRef] [Green Version]

- Roundi, W.; EL Mahi, A.; El Gharad, A.; Rebière, J.-L. Experimental and numerical investigation of the effects of stacking sequence and stress ratio on fatigue damage of glass/epoxy composites. Compos. Part B Eng. 2017, 109, 64–71. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.B.; Guillaumat, L. Properties evolution of flax/epoxy composites under fatigue loading. Int. J. Fatigue 2014, 63, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Boey, F.; Lye, S. Void reduction in autoclave processing of thermoset composites: Part 1: High pressure effects on void reduction. Composite 1992, 23, 261–265. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Hashim, M.; Majid, M.A.; Kasim, M.; Sultan, M. The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites. Polymers 2021, 13, 455. [Google Scholar] [CrossRef]

- Srivathsan, A.; Vijayaram, B.; Ramesh, R. Gokuldass Investigation on Mechanical Behavior of Woven Fabric Glass/Kevlar Hybrid Composite Laminates Made of Varying Fibre Inplane Orientation And Stacking Sequence. Mater. Today Proc. 2017, 4, 8928–8937. [Google Scholar] [CrossRef]

- Sezgin, H.; Berkalp, O.B. The effect of hybridization on significant characteristics of jute/glass and jute/carbon-reinforced composites. J. Ind. Text. 2017, 47, 283–296. [Google Scholar] [CrossRef]

- Hossain, R.M.; Islam, A.; Van Vuure, A.W.; Ignaas, V. Effect of Fiber Orientation on the Tensile Properties of Jute Epoxy Laminated Composite. J. Sci. Res. 2012, 5, 43–54. [Google Scholar] [CrossRef]

- Liu, W.; Misra, M.; Askeland, P.; Drzal, L.T.; Mohanty, A.K. ‘Green’ composites from soy based plastic and pineapple leaf fiber: Fabrication and properties evaluation. Polymers 2005, 46, 2710–2721. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Dadej, K.; Bieniaś, J. On fatigue stress-cycle curves of carbon, glass and hybrid carbon/glass-reinforced fibre metal laminates. Int. J. Fatigue 2020, 140, 105843. [Google Scholar] [CrossRef]

- Seghini, M.C.; Touchard, F.; Sarasini, F.; Chocinski–Arnault, L.; Ricciardi, M.R.; Antonucci, V.; Tirillò, J. Fatigue behaviour of flax-basalt/epoxy hybrid composites in comparison with non-hybrid composites. Int. J. Fatigue 2020, 139, 105800. [Google Scholar] [CrossRef]

- Katerelos, D.G.; McCartney, L.N.; Galiotis, C. Effect of Off—Axis Matrix Cracking on Stiffness of Symmetric Angle-Ply Composite Laminates. Int. J. Fract. 2006, 139, 529–536. [Google Scholar] [CrossRef]

- Hung, P.-Y.; Lau, K.-T.; Cheng, L.-K.; Leng, J.; Hui, D. Impact response of hybrid carbon/glass fibre reinforced polymer composites designed for engineering applications. Compos. Part B Eng. 2018, 133, 86–90. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Nayak, R.K. Improvement of mechanical properties of hybrid composites through interply rearrangement of glass and carbon woven fabrics for marine application. Compos. Part B Eng. 2019, 168, 467–475. [Google Scholar] [CrossRef]

- Singh, K.K.; Alam Ansari, T.; Azam, S. Fatigue life and damage evolution in woven GFRP angle ply laminates. Int. J. Fatigue 2021, 142, 105964. [Google Scholar] [CrossRef]

- Vasiukov, D.; Panier, S.; Hachemi, A. Direct method for life prediction of fibre reinforced polymer composites based on kinematic of damage potential. Int. J. Fatigue 2015, 70, 289–296. [Google Scholar] [CrossRef]

- Ribeiro, F.; Sena-Cruz, J.; Vassilopoulos, A.P. Tension-tension fatigue behavior of hybrid glass/carbon and carbon/carbon composites. Int. J. Fatigue 2021, 146, 106143. [Google Scholar] [CrossRef]

- Bellini, C.; Sorrentino, L. Analysis of cure induced deformation of CFRP U-shaped laminates. Compos. Struct. 2018, 197, 1–9. [Google Scholar] [CrossRef]

- Yang, J.; Jones, D.; Yang, S.; Meskini, A. A Stiffness Degradation Model for Graphite/Epoxy Laminates. J. Compos. Mater. 1990, 24, 753–769. [Google Scholar] [CrossRef]

- Manjunatha, C.; Sprenger, S.; Taylor, A.; Kinloch, A. The Tensile Fatigue Behavior of a Glass-fiber Reinforced Plastic Composite Using a Hybrid-toughened Epoxy Matrix. J. Compos. Mater. 2010, 44, 2095–2109. [Google Scholar] [CrossRef] [Green Version]

- Dassios, K.G. A Review of the Pull-Out Mechanism in the Fracture of Brittle-Matrix Fibre-Reinforced Composites. Adv. Compos. Lett. 2007, 16, 161. [Google Scholar] [CrossRef] [Green Version]

- Reifsnider, K.L.; Schulte, K.; Duke, J.C. Long-Term Fatigue Behavior of Composite Materials. In Long-Term Behavior Composites; O’Brien, T.K., Ed.; ASTM International: West Conshohocken, PA, USA, 1983; pp. 136–159. [Google Scholar] [CrossRef]

| Property | Epoxy | Fibre | |

|---|---|---|---|

| PALF | Carbon Fibre | ||

| Tensile strength (MPa) | 45 | 148.44 | 3530 |

| Tensile modulus (GPa) | 1.75 | 10.46 | 230 |

| Strain at failure (%) | 6 | 1.05 | 1.5 |

| Reference | [17] | [18] | [19] |

| Composition | Percentage (%) |

|---|---|

| Cellulose | 47.74 |

| Hemicellulose | 15.98 |

| Lignin | 2.44 |

| Orientation | Layering Sequence (Number of Layers) | Notation | |

|---|---|---|---|

| External | Internal | ||

| [± 45°2, 0°/90°2]s | PALF (8) | PPPP_45090 | |

| PALF (4) | Carbon (4) | PCCP_45090 | |

| Carbon (4) | PALF (4) | CPPC_45090 | |

| [0°/90°2, ± 45°2]s | PALF (8) | PPPP_09045 | |

| PALF (4) | Carbon (4) | PCCP_09045 | |

| Carbon (4) | PALF (4) | CPPC_09045 | |

| Laminate | Void Content (%) |

|---|---|

| PPPP_45090 | 2.63 (± 0.85) |

| PCCP_45090 | 2.02 (± 0.55) |

| CPPC_45090 | 2.23 (± 0.53) |

| PPPP_09045 | 2.53 (± 0.76) |

| PCCP_09045 | 2.03 (± 0.41) |

| CPPC_09045 | 1.53 (± 0.32) |

| Laminates | 0.9 UTS | 0.75 UTS | 0.6 UTS | 0.45 UTS | 0.3 UTS |

|---|---|---|---|---|---|

| PPPP_45090 | 127 (± 16) | 1495 (± 122) | 95,391 (± 9160) | 372,791 (± 44,672) | > 1 × 106 |

| PCCP_45090 | 80,109 (± 8157) | 253,994 (± 18,290) | 652,772 (± 79,452) | 898,846 (± 82,191) | > 1 × 106 |

| CPPC_45090 | 1693 (± 60) | 49,758 (± 3967) | 113,350 (± 14,008) | 180,579 (± 16,328) | > 1 × 106 |

| PPPP_09045 | 122 (± 15) | 1380 (± 97) | 88,924 (± 8,130) | 408,251 (± 44,507) | > 1 × 106 |

| PCCP_09045 | 1076 (± 62) | 22,458 (± 1,943) | 104,638 (± 7,392) | 209,154 (± 42,153) | > 1 × 106 |

| CPPC_09045 | 38,948 (± 3,675) | 167,822 (± 18,672) | 357,677 (± 30,992) | 829,277 (± 69,979) | > 1 × 106 |

| A | B | s | R | |

|---|---|---|---|---|

| PPPP_45090 | 7.8344 | 0.1216 | 0.433 | 0.9696 |

| PCCP_45090 | 6.3915 | 0.0364 | 0.869 | 0.9175 |

| CPPC_45090 | 4.5662 | 0.0486 | 1.5128 | 0.9431 |

| PPPP_09045 | 7.8736 | 0.1209 | 0.4301 | 0.9703 |

| PCCP_09045 | 5.5684 | 0.0477 | 1.0747 | 0.9711 |

| CPPC_09045 | 6.9463 | 0.0436 | 1.3128 | 0.9640 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashim, M.K.R.; Majid, M.S.A.; Jamir, M.R.M.; Kasim, F.H.; Sultan, M.T.H.; Shah, A.U.M.; Ahmad, K.A.; Basri, A.A. The Effect of Stacking Sequence on Fatigue Behaviour of Hybrid Pineapple Leaf Fibre/Carbon-Fibre-Reinforced Epoxy Composites. Polymers 2021, 13, 3936. https://doi.org/10.3390/polym13223936

Hashim MKR, Majid MSA, Jamir MRM, Kasim FH, Sultan MTH, Shah AUM, Ahmad KA, Basri AA. The Effect of Stacking Sequence on Fatigue Behaviour of Hybrid Pineapple Leaf Fibre/Carbon-Fibre-Reinforced Epoxy Composites. Polymers. 2021; 13(22):3936. https://doi.org/10.3390/polym13223936

Chicago/Turabian StyleHashim, Mohd Khairul Rabani, Mohd Shukry Abdul Majid, Mohd Ridzuan Mohd Jamir, Farizul Hafiz Kasim, Mohamed Thariq Hameed Sultan, Ain Umaira Md Shah, Kamarul Arifin Ahmad, and Adi Azriff Basri. 2021. "The Effect of Stacking Sequence on Fatigue Behaviour of Hybrid Pineapple Leaf Fibre/Carbon-Fibre-Reinforced Epoxy Composites" Polymers 13, no. 22: 3936. https://doi.org/10.3390/polym13223936

APA StyleHashim, M. K. R., Majid, M. S. A., Jamir, M. R. M., Kasim, F. H., Sultan, M. T. H., Shah, A. U. M., Ahmad, K. A., & Basri, A. A. (2021). The Effect of Stacking Sequence on Fatigue Behaviour of Hybrid Pineapple Leaf Fibre/Carbon-Fibre-Reinforced Epoxy Composites. Polymers, 13(22), 3936. https://doi.org/10.3390/polym13223936