Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O

Abstract

:1. Introduction

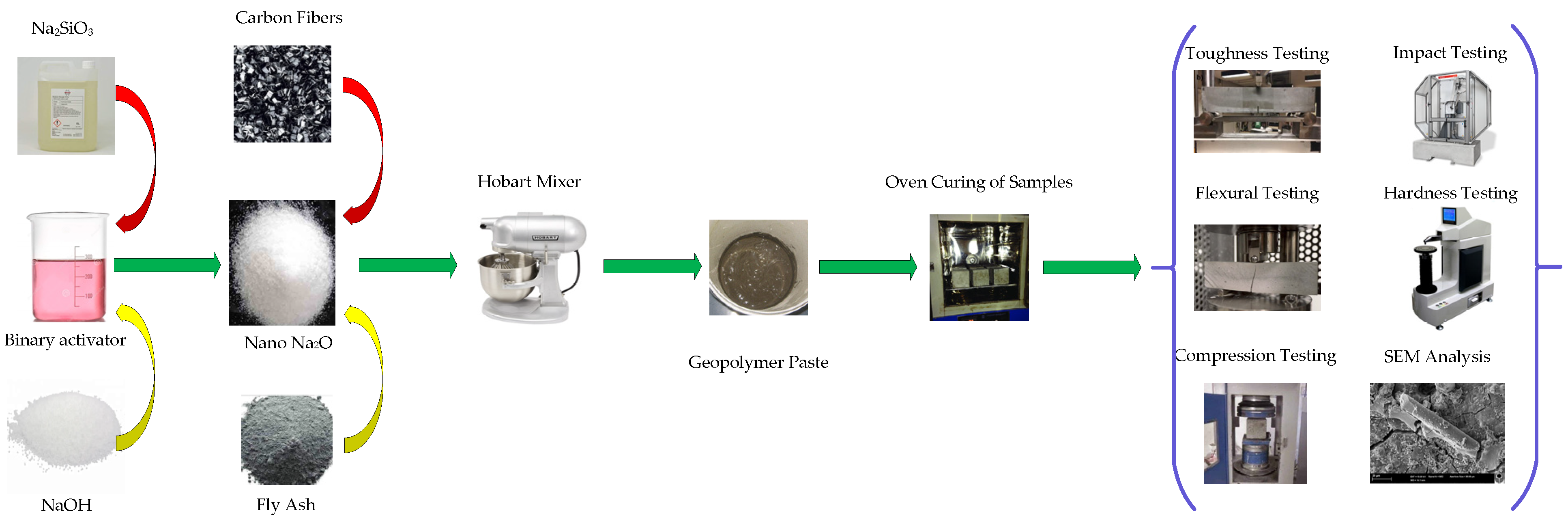

2. Experimental Setup

2.1. Materials and Methods

2.2. Sample Preparation and Curing

2.3. Testing Procedures of Samples

2.3.1. COS Test

2.3.2. FLS Test

2.3.3. FRT Test

2.3.4. HAD Test

2.3.5. IMS Test

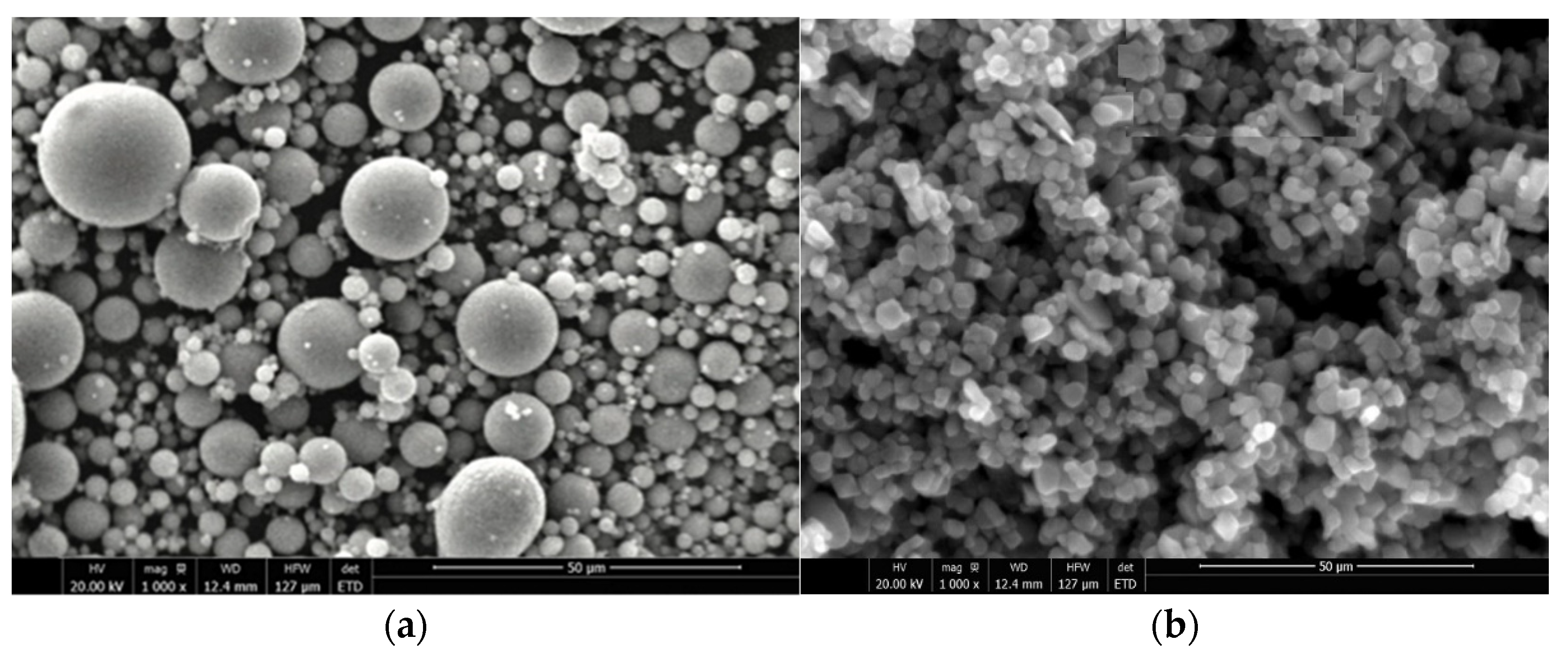

2.3.6. Microstructural Analysis through SEM

3. Discussion of Results

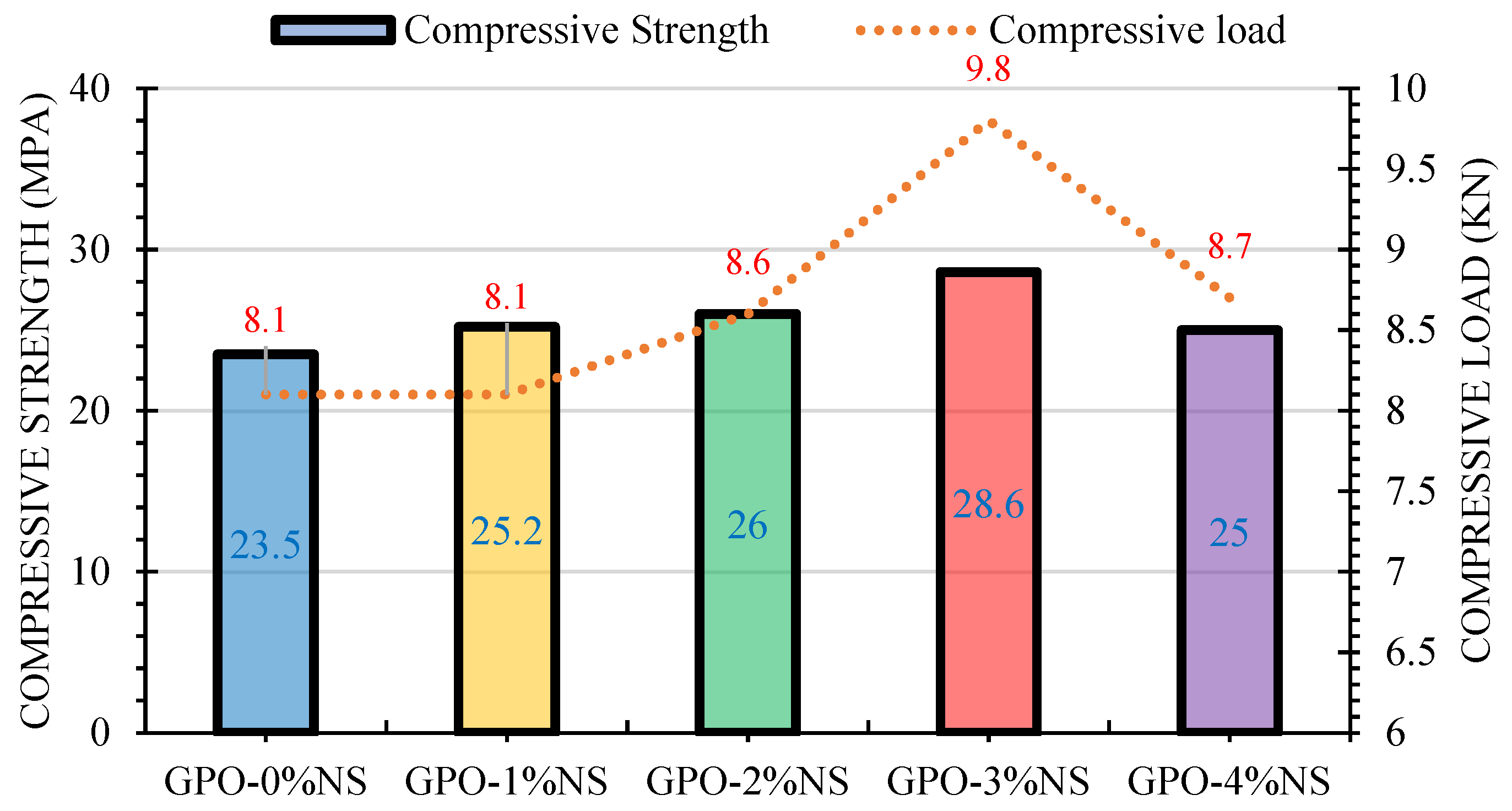

3.1. Compressive Strength

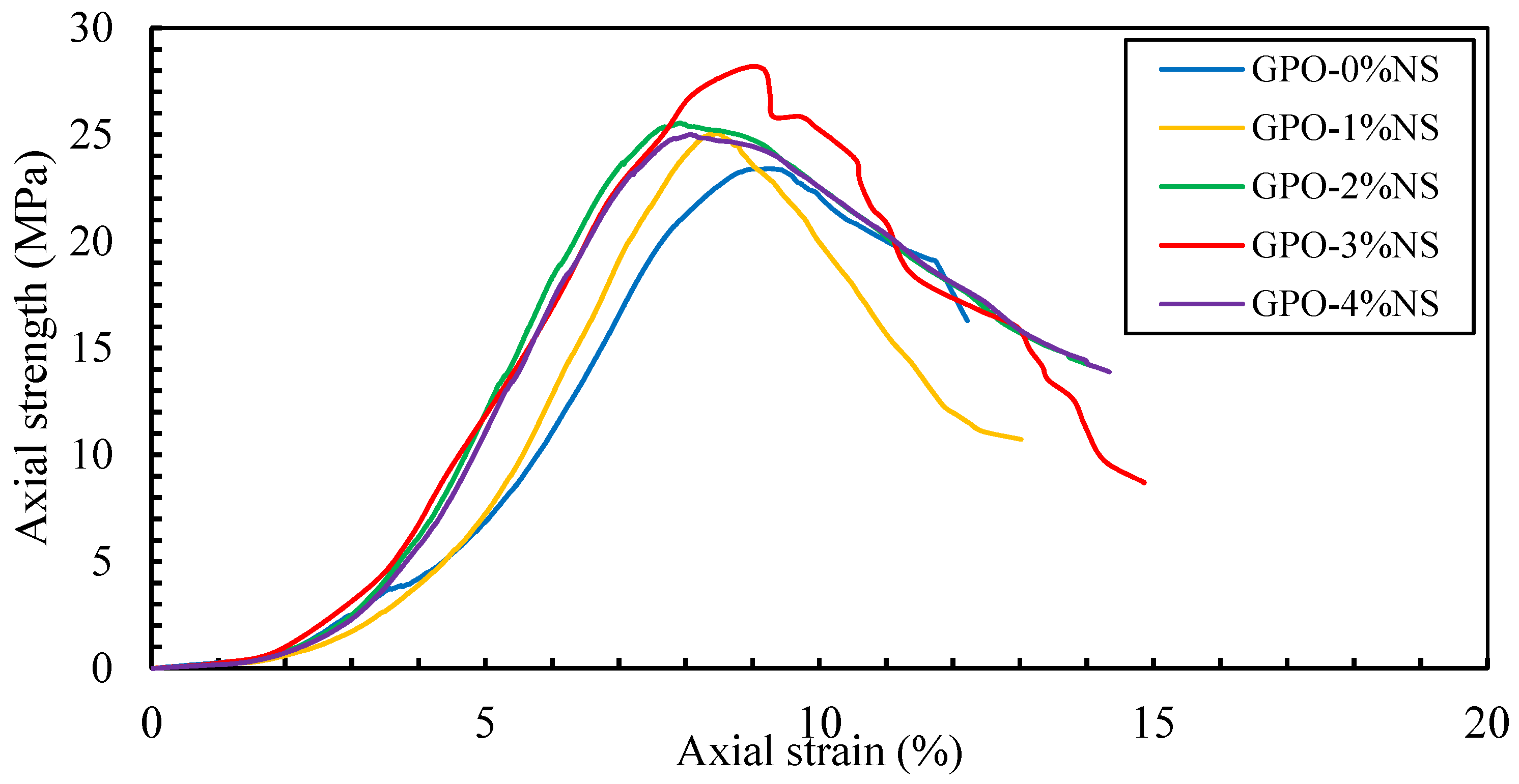

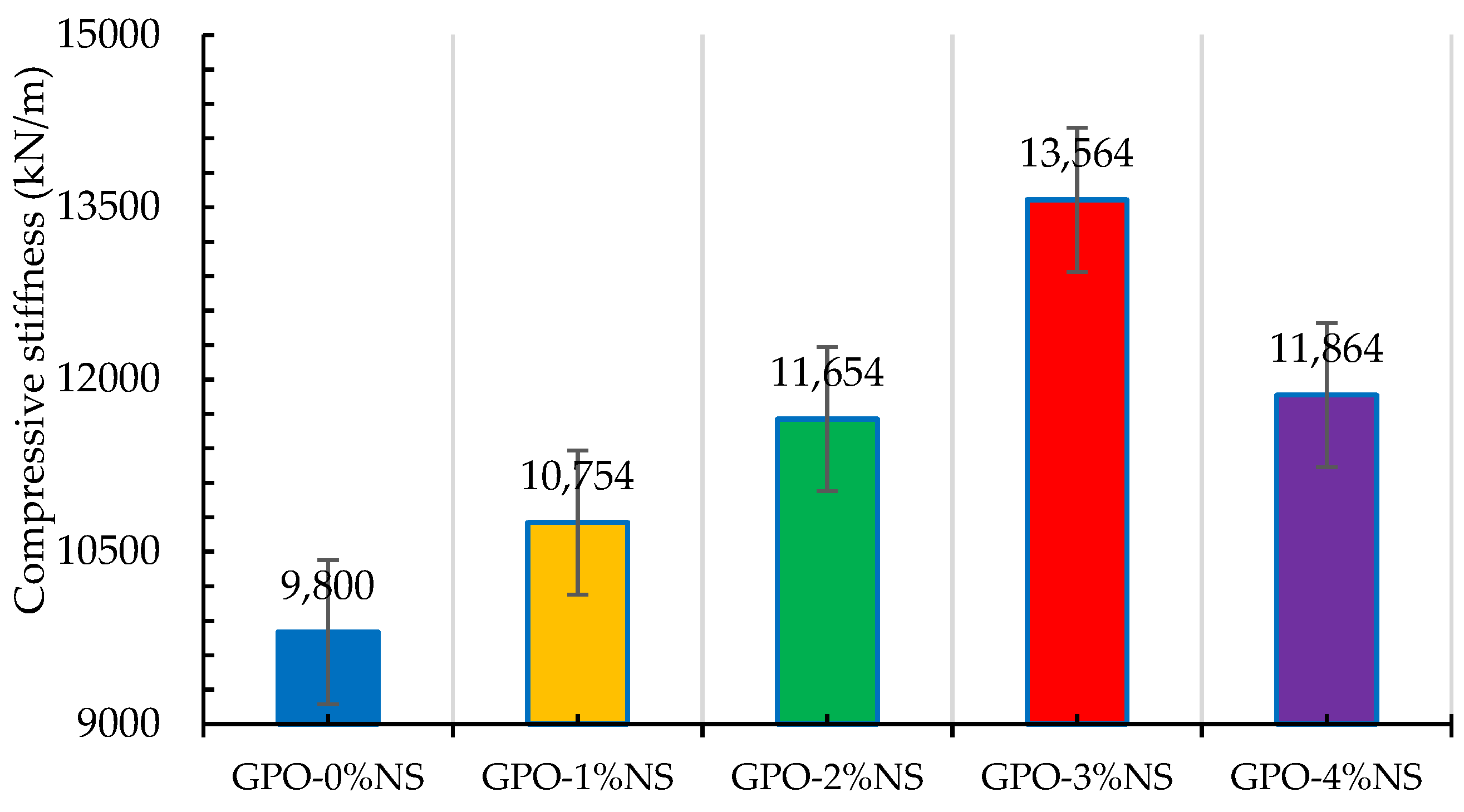

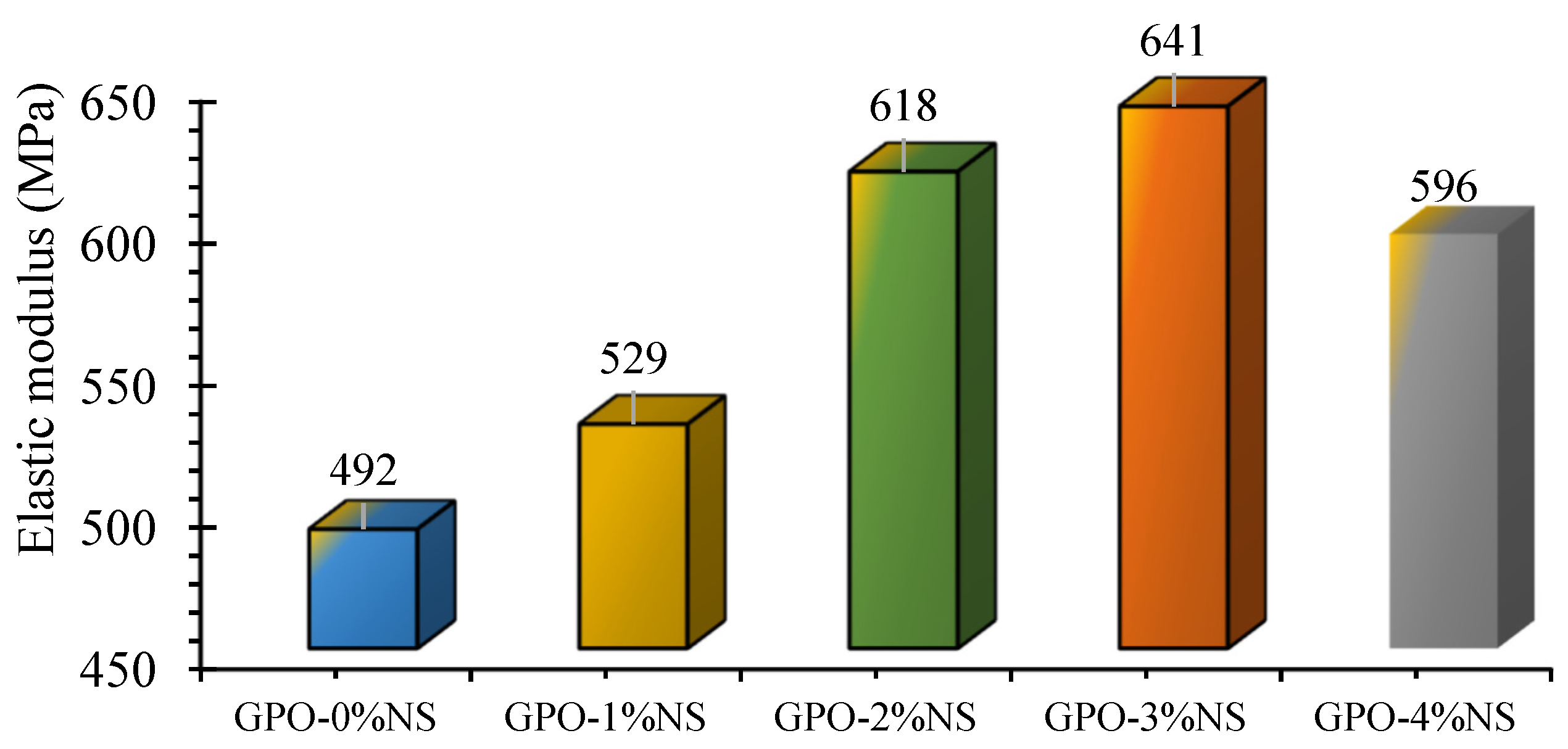

3.2. Compressive Stress–Strain Behavior

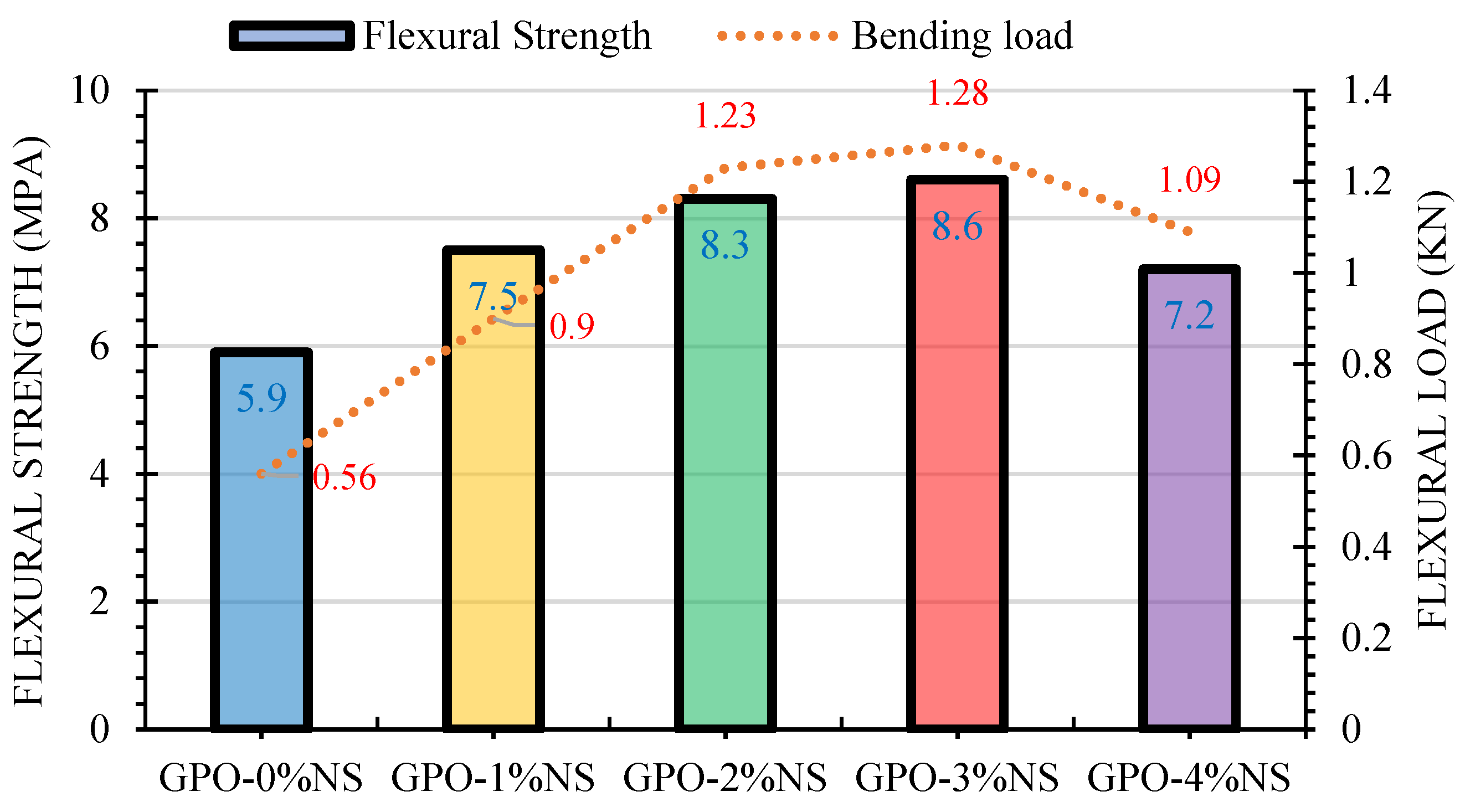

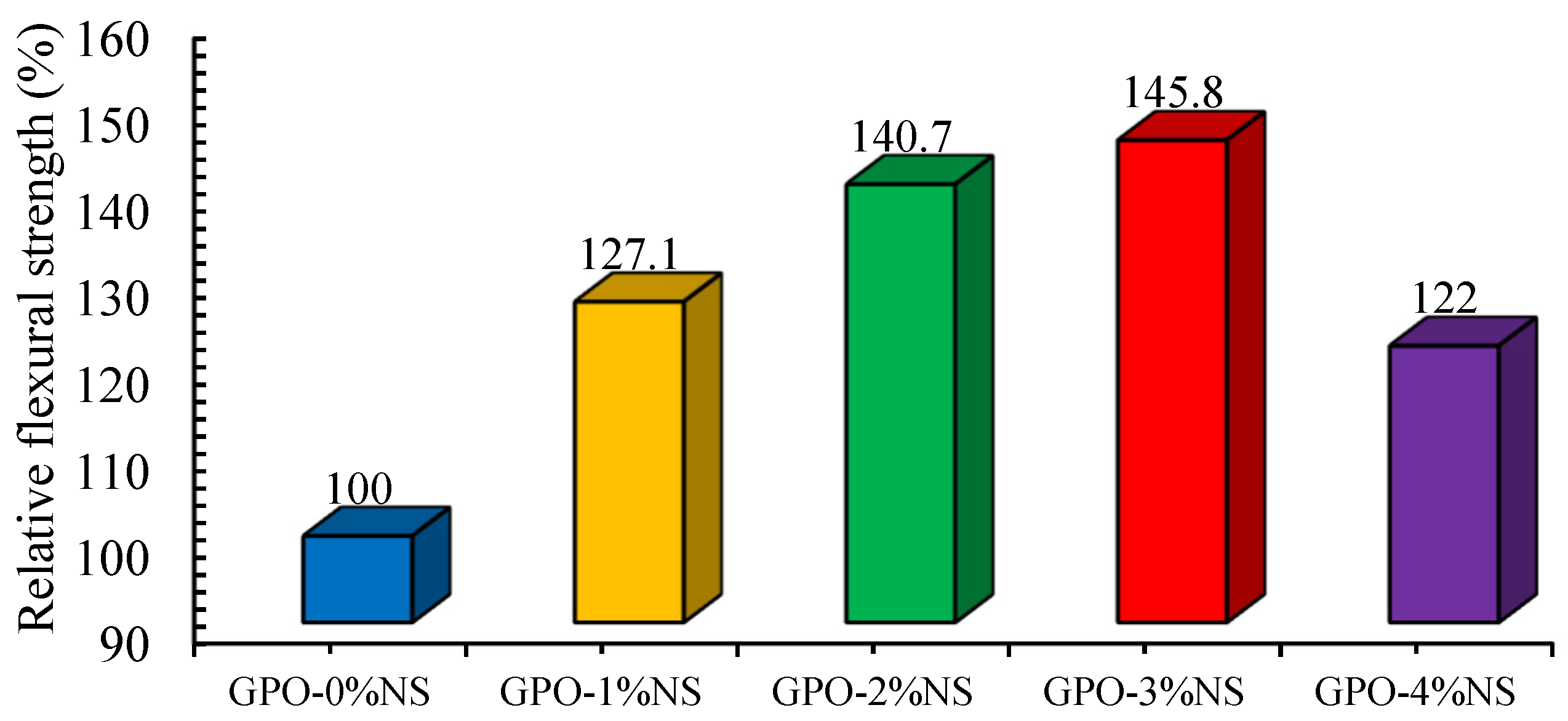

3.3. Flexural Strength

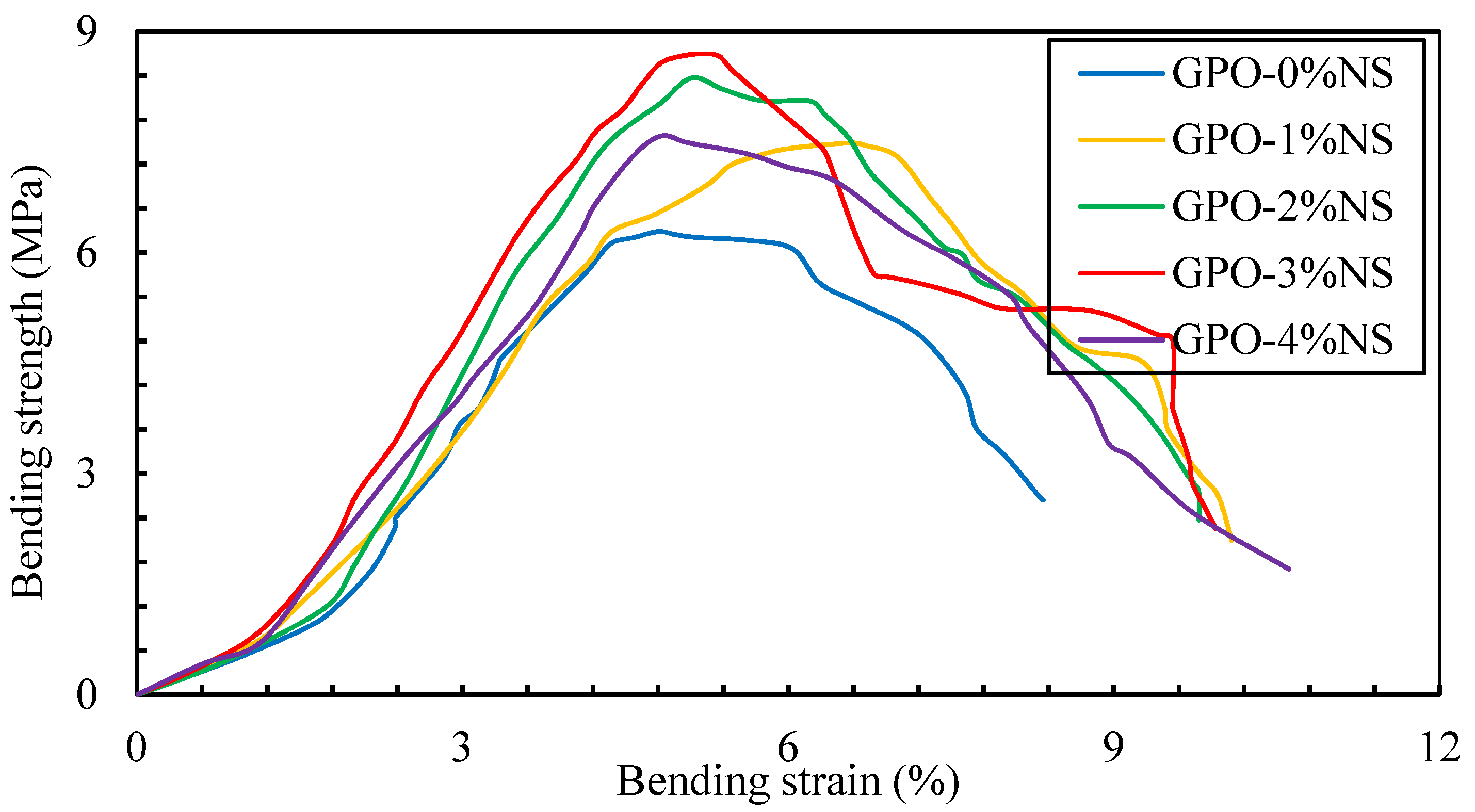

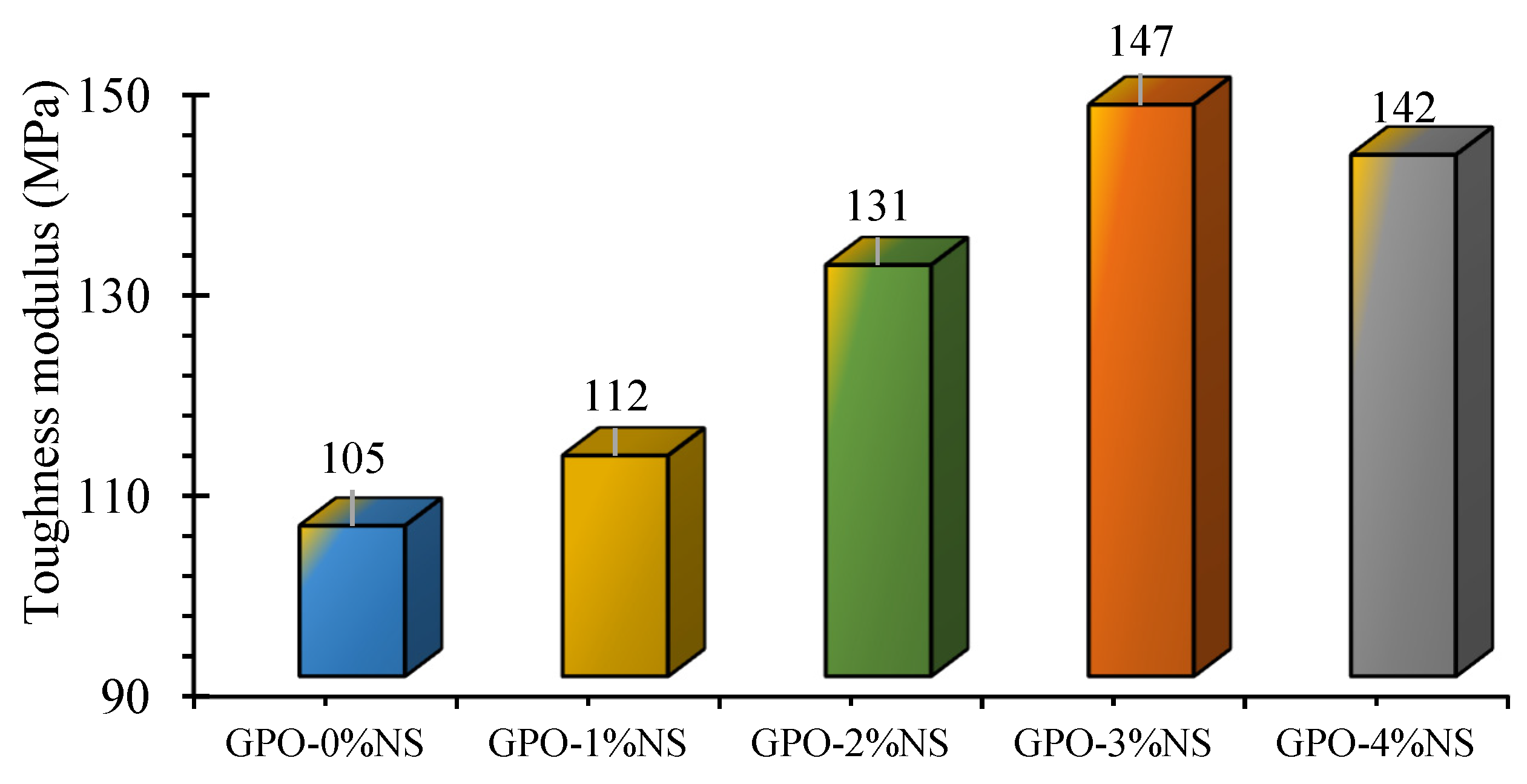

3.4. Bending Stress–Strain Behavior

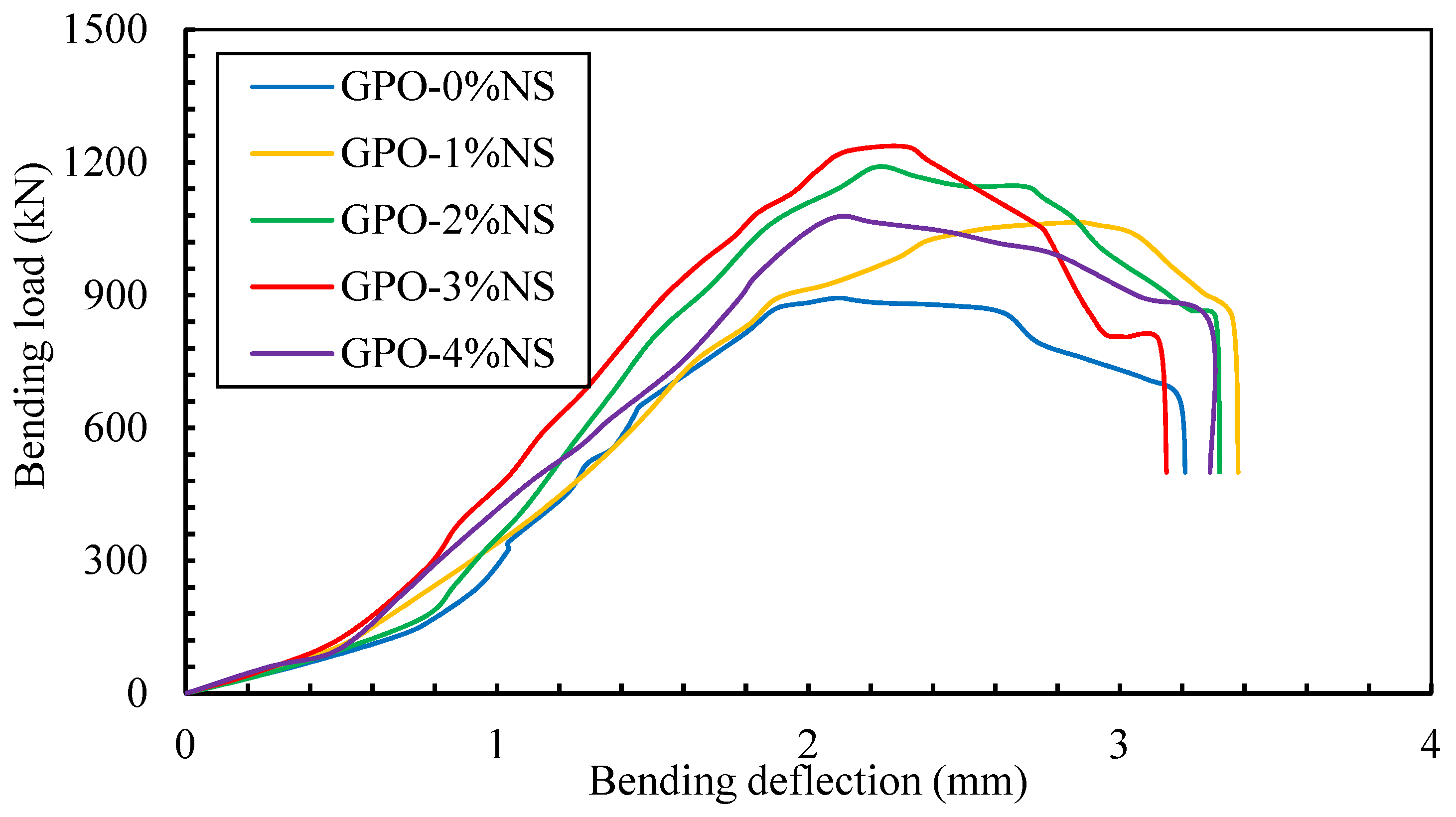

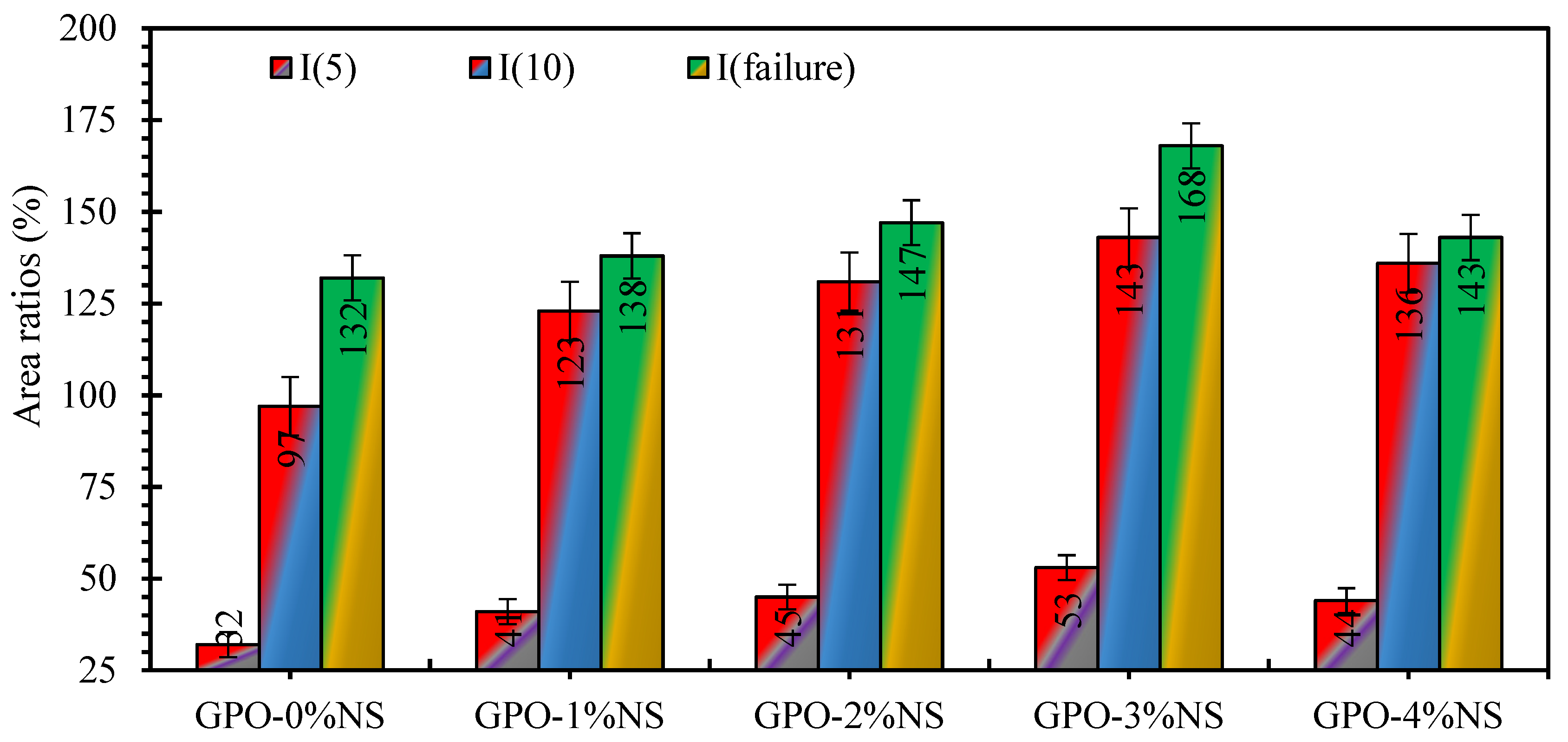

3.5. Flexural Load–Deflection Curves and Toughness Indices

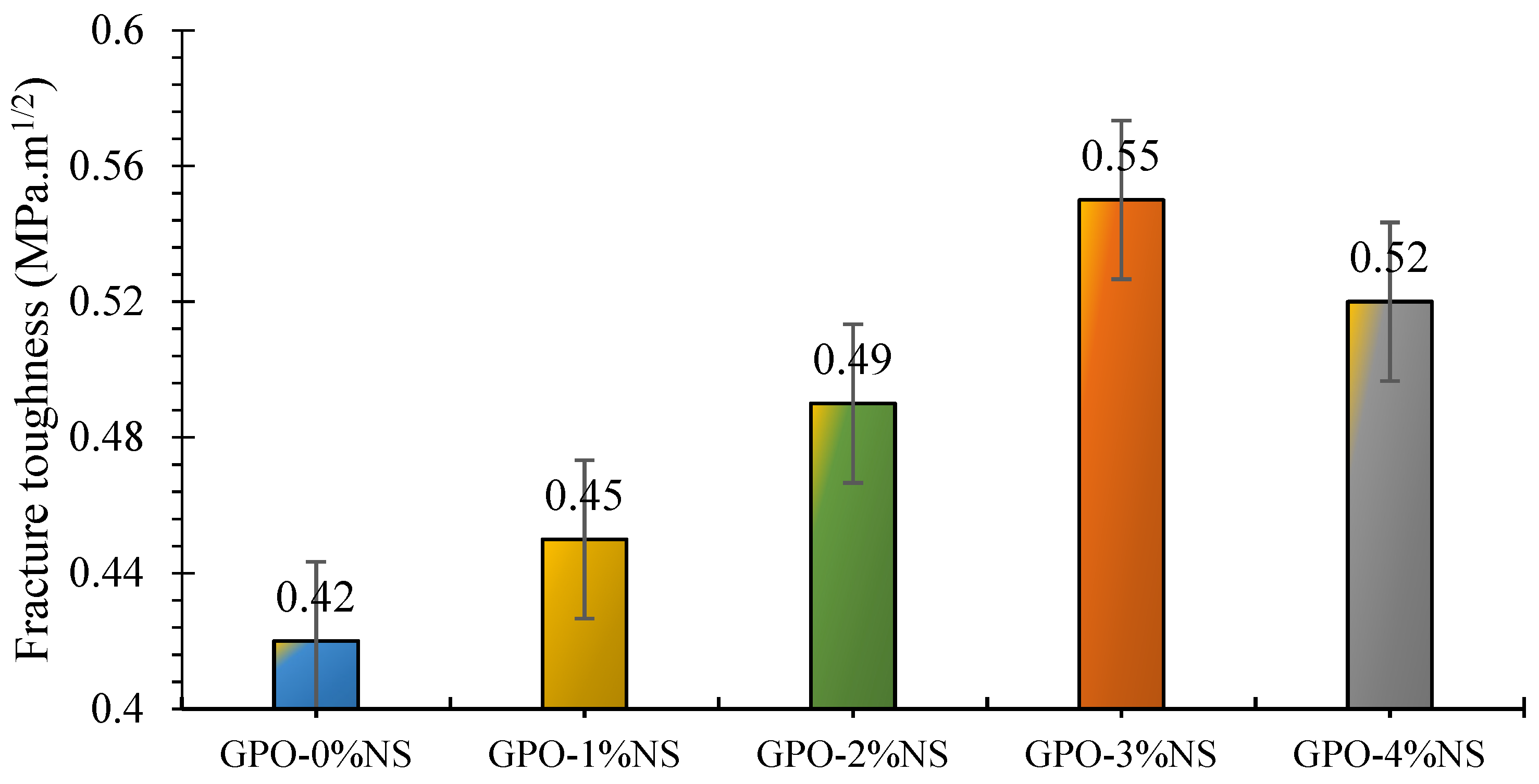

3.6. Fracture Toughness

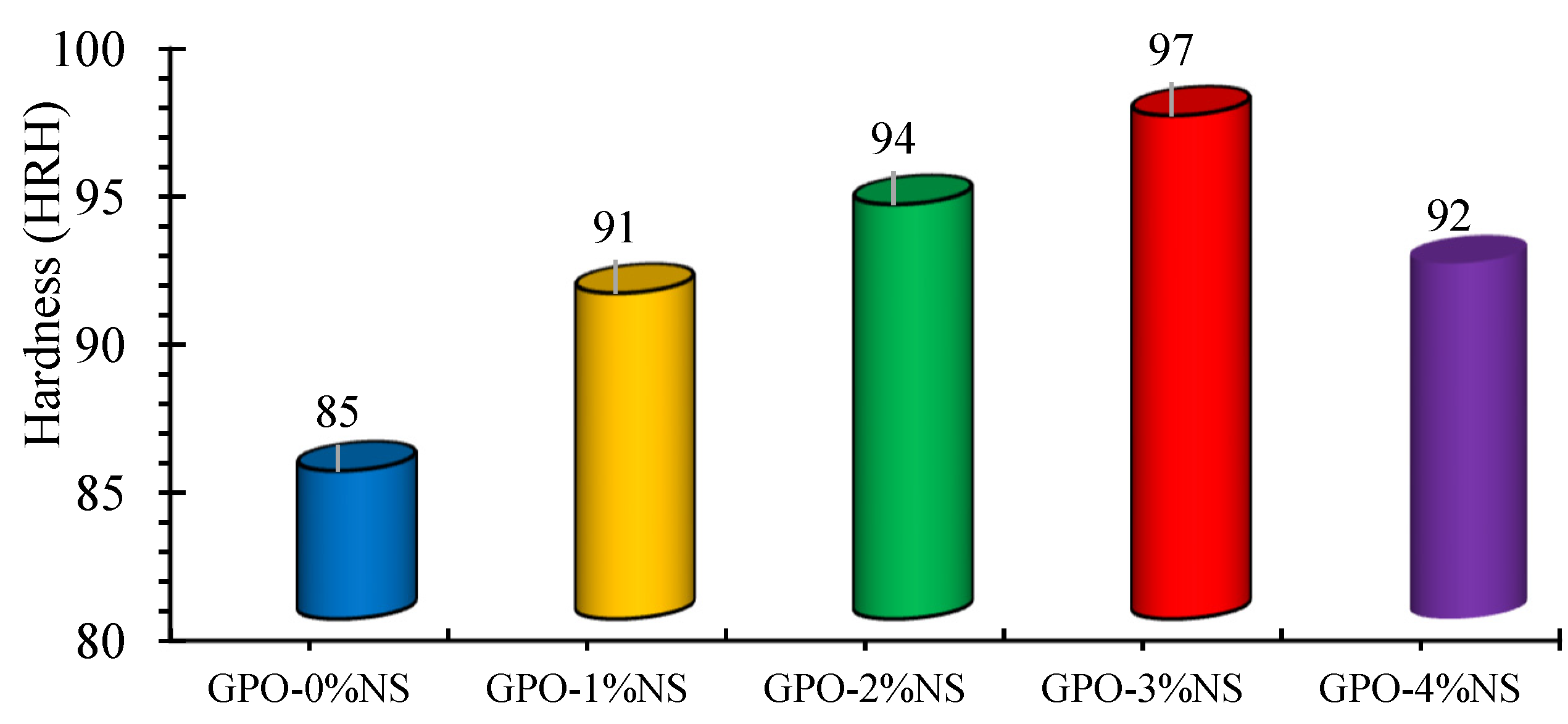

3.7. Hardness

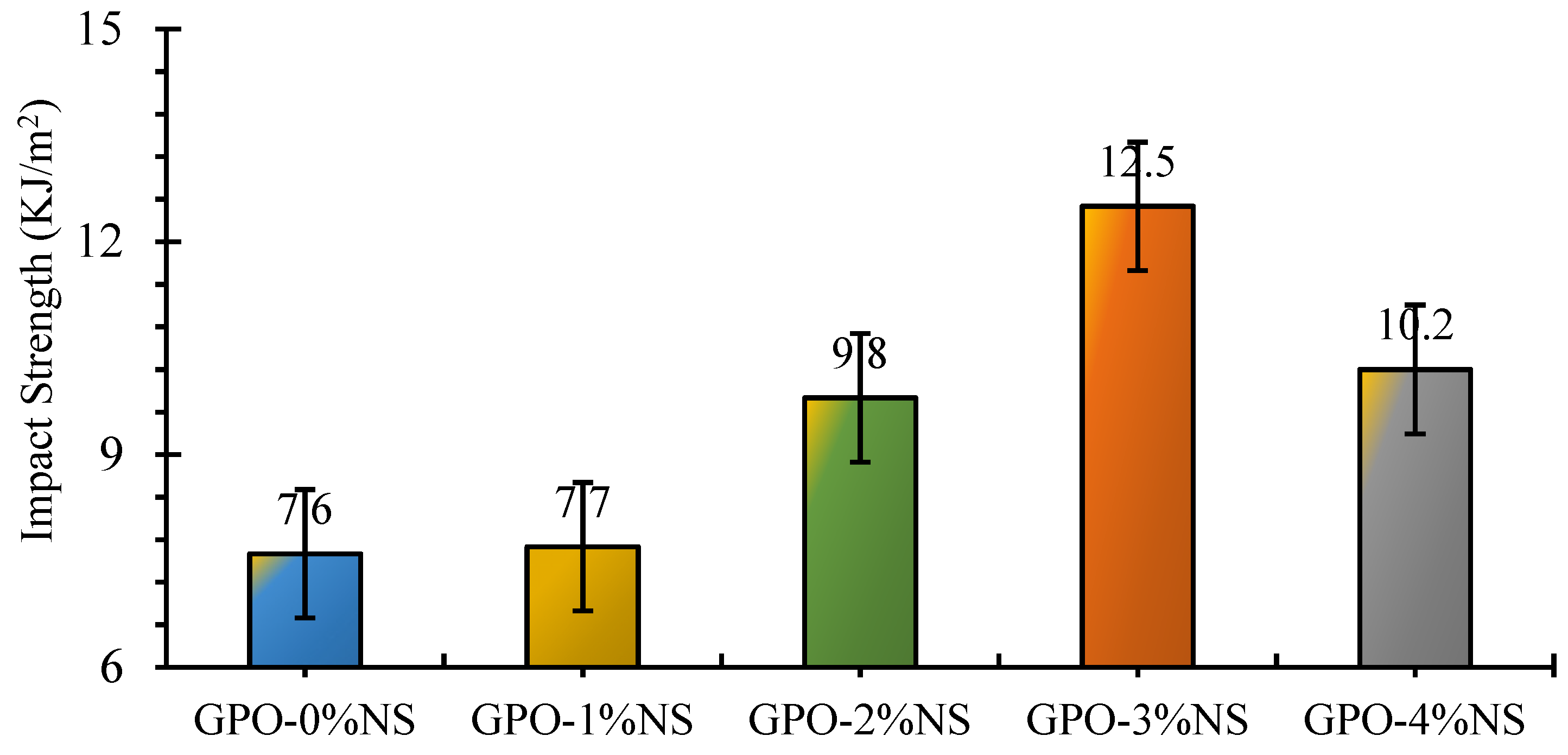

3.8. Impact Strength

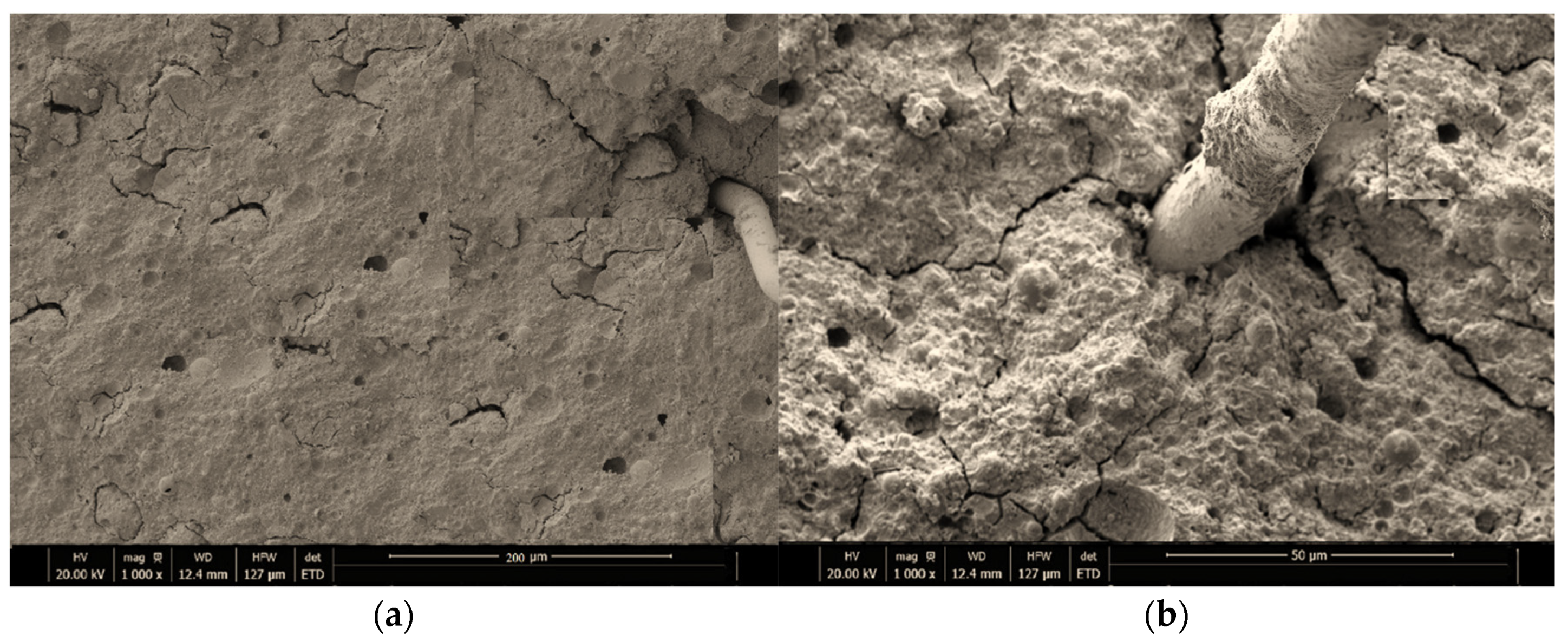

3.9. Microstructural Assessment

4. Summary and Conclusions

- (1)

- We obtained the maximum COS value of carbon-fiber-reinforced GPO pastes, 22% in comparison to the GPO paste without NS, with 3% NS. This improvement may have resulted from the blocking of nanovoids and microvoids caused by the inclusion of NS, as well as the increased speed of the polymerization reaction.

- (2)

- At 3% NS, the FLS was 46% higher than that of the control blend, possibly because of the expedient impact of the polymerization response cycle and the refinement of the microstructure with the NS particles. This may have prompted the densification of the composite lattice. At 3% NS, we recorded the best improvements of toughness.

- (3)

- At 3% NS, the FRT was raised by 31% in comparison to the control sample, possibly due to the filling property of the nanoparticles and the existence of carbon fibers, as a which moved the interior loads in the lattice and prompted improvements in protection against break initiation.

- (4)

- Following the addition of NS, the IMS of the pastes improved (with 3% NS showing the maximum value of 64% greater than that of the control mix), possibly due to nanoparticles within the GPO pastes. These nanoparticles increased the bond strength between the reinforcing fibers and matrix, and they aided in cracking resistance via the creation of a solid and dense matrix.

- (5)

- The SEM micrographs showed that the appearance of denser structure following the addition of NS, which filled nanovoids between fly ash particles. The SEM micrographs also revealed strong holding between the GPO and carbon fibers, possibly because of the refinement and densification of the composite mixes caused by NS. Therefore, for sustainable development in the construction industry, the mechanical efficacy of carbon-fiber-reinforced GPO composite pastes can be enhanced through NS.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, K.S. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Provis, L.J.; Palomo, A.; Shi, A.C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Flower, J.D.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, C.; Zhao, J.; Liu, F.; Fang, C. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 2020, 247, 118540. [Google Scholar] [CrossRef]

- Ali, N.; Canpolat, O.; Aygörmez, Y.; Al-Mashhadani, M.M. Evaluation of the 12–24 mm basalt fibers and boron waste on reinforced metakaolin-based geopolymer. Constr. Build. Mater. 2020, 251, 118976. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Properties of low-calcium fly ash based geopolymer concrete incorporating OPC as partial replacement of fly ash. Constr. Build. Mater. 2017, 150, 792–807. [Google Scholar] [CrossRef]

- Patel, Y.J.; Shah, N. Development of self-compacting geopolymer concrete as a sustainable construction material. Sustain. Environ. Res. 2018, 28, 412–421. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Adesina, A. Efficacy and sustainability overview of alkali-activated self-compacting concrete. Waste Dispos. Sustain. Energy 2020, 2, 1–11. [Google Scholar] [CrossRef]

- Norton, M.G.; Provis, J.L. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; He, Z. Mechanical and fracture properties of geopolymer concrete with basalt fiber by means of digital image correlation. Theor. Appl. Fract. Mech. 2021, 112, 102909. [Google Scholar] [CrossRef]

- Pham, T.M. Enhanced properties of high-silica rice husk ash-based geopolymer paste by incorporating basalt fibers. Constr. Build. Mater. 2020, 245, 118422. [Google Scholar] [CrossRef]

- Timakul, P.; Rattanaprasit, W.; Aungkavattana, P. Improving compressive strength of fly ash-based geopolymer composites by basalt fibers inclusion. Ceram. Int. 2016, 42, 6288–6295. [Google Scholar] [CrossRef]

- Ren, D.; Yan, C.; Duan, P.; Zhang, Z.; Li, L.; Yan, Z. Durability efficacys of wollastonite, tremolite and basalt fiber-reinforced metakaolin geopolymer composites under sulfate and chloride attack. Constr. Build. Mater. 2017, 134, 56–66. [Google Scholar] [CrossRef]

- Punurai, W.; Kroehong, W.; Saptamongkol, A.; Chindaprasirt, P. Mechanical properties, microstructure and drying shrinkage of hybrid fly ash-basalt fiber geopolymer paste. Constr. Build. Mater. 2018, 186, 62–70. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef]

- Adesina, A. Durability enhancement of concrete by means of nanomaterials: An overview. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2019. [Google Scholar] [CrossRef]

- Adesina, A. Nanomaterials in cementitious composites: Review of durability efficacy. J. Build. Pathol. Rehabil. 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of fly ash/slag based self-compacting geopolymer concrete by means of nano-silica and steel fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Kaze, C.R.; Jindal, B.B.; Subaer, S.; Shaikh, F.; Alraddadi, S. Characterization and properties of geopolymer nanocomposites with different contents of nano-CaCO3. Constr. Build. Mater. 2020, 252, 119137. [Google Scholar] [CrossRef]

- Tanzadeh, J. Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials. Constr. Build. Mater. 2020, 232, 117211. [Google Scholar] [CrossRef]

- Guler, S.; Türkmenoğlu, Z.F.; Ashour, A. Efficacy of single and hybrid nanoparticles added concrete at ambient and elevated temperatures. Constr. Build. Mater. 2020, 250, 118847. [Google Scholar] [CrossRef]

- Mustakim, S.M.; Das, S.K.; Mishra, J.; Aftab, A.; Alomayri, T.S.; Assaedi, H.S.; Kaze, C.R. Improvement in fresh, mechanical and microstructural properties of fly ash-blast furnace slag based geopolymer concrete by inclusion of nano and micro silica. Silicon 2021, 13, 2415–2428. [Google Scholar] [CrossRef]

- Al Bakri, A.M.; Kamarudin, H.; Bnhussain, M.; Liyana, J.; Ghazali, C.M.R. Nano geopolymer for sustainable concrete by means of fly ash synthesized by high energy ball milling. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2013. [Google Scholar] [CrossRef]

- Tuntachon, S.; Kamwilaisak, K.; Somdee, T.; Mongkoltanaruk, W.; Sata, V.; Boonserm, K.; Wongsa, A.; Chindaprasirt, P. Resistance to algae and fungi formation of high calcium fly ash geopolymer paste containing TiO2. J. Build. Eng. 2019, 25, 100817. [Google Scholar] [CrossRef]

- Sastry, K.G.K.; Sahitya, P.; Ravitheja, A. Influence of nano TiO2 on strength and durability properties of geopolymer concrete. Mater. Today Proc. 2021, 45, 1017–1025. [Google Scholar] [CrossRef]

- ASTMC618-19. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D695-15. Standard Test Method for Compressive Properties of Rigid Plastics; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C78M-21. Standard Test Method for Flexural Strength of Concrete (By means of Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- Low, I.M.; McGrath, M.; Lawrence, D.; Schmidt, P.; Lane, J.; Latella, B.A.; Sim, K.S. Mechanical and fracture properties of cellulose-fibre-reinforced epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 963–974. [Google Scholar] [CrossRef]

- ASTM D785-08(2015). Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Saini, G.; Vattipalli, U. Assessing properties of alkali activated GGBS based self-compacting geopolymer concrete by means of nano-silica. Case Stud. Constr. Mater. 2020, 12, e00352. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Alomayri, T. Experimental study of the microstructural and mechanical properties of geopolymer paste with nano material (Al2O3). J. Build. Eng. 2019, 25, 100788. [Google Scholar] [CrossRef]

- Assaedi, H. The role of nano-CaCO3 in the mechanical efficacy of polyvinyl alcohol fibre-reinforced geopolymer composites. Compos. Interfaces 2021, 28, 527–542. [Google Scholar] [CrossRef]

- Shaikh, F.; Shafaei, Y.; Sarker, P. Effect of nano and micro-silica on bond behaviour of steel and polypropylene fibres in high volume fly ash mortar. Constr. Build. Mater. 2016, 115, 690–698. [Google Scholar] [CrossRef] [Green Version]

- Yip, C.K.; Lukey, G.; van Deventer, J.S. The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem. Concr. Res. 2005, 35, 1688–1697. [Google Scholar] [CrossRef]

- Yip, C.K.; Lukey, G.C.; Provis, J.L.; Van Deventer, J.S. Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 2008, 38, 554–564. [Google Scholar] [CrossRef]

| Compound | Composition (%) | Compound | Composition (%) |

|---|---|---|---|

| SiO2 | 62.5 | Na2O | 0.82 |

| Al2O3 | 27.2 | MgO | 0.64 |

| CaO | 2.56 | SO3 | 0.12 |

| Fe2O3 | 3.03 | P2O5 | 0.11 |

| K2O | 1.81 | LOI | 1.42 |

| Property | Value | Property | Value |

|---|---|---|---|

| pH | 12.0 | Appearance | White crystalline powder |

| Average size | 20 nm | Type | Crystalline |

| Purity | 99.9 % | Density | 2.28 g/cm3 |

| Compound/Feature | Quantity | Compound/Feature | Quantity |

|---|---|---|---|

| Tensile strength | 4000 MPa | Elastic modulus | 242 GPa |

| Nominal length | 12 mm | Nominal diameter | 7 μm |

| Density | 1.81 g/cc | Aspect ratio | 1715 |

| Geopolymer Mix | GPO-0%NS | GPO-1%NS | GPO-2%NS | GPO-3%NS | GPO-4%NS |

|---|---|---|---|---|---|

| Sodium hydroxide (kg) | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 |

| Fly ash (kg) | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 |

| Micro carbon fibers (wt.%) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sodium silicate (kg) | 0.58 | 0.58 | 0.58 | 0.58 | 0.58 |

| NS (kg) | 0 | 0.01 | 0.02 | 0.03 | 0.04 |

| NS (wt.%) | 0 | 1.0 | 2.0 | 3.0 | 4.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashedi, A.; Marzouki, R.; Raza, A.; Rawi, N.F.M.; Naveen, J. Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O. Polymers 2021, 13, 3852. https://doi.org/10.3390/polym13213852

Rashedi A, Marzouki R, Raza A, Rawi NFM, Naveen J. Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O. Polymers. 2021; 13(21):3852. https://doi.org/10.3390/polym13213852

Chicago/Turabian StyleRashedi, Ahmad, Riadh Marzouki, Ali Raza, Nurul Fazita Mohammad Rawi, and J. Naveen. 2021. "Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O" Polymers 13, no. 21: 3852. https://doi.org/10.3390/polym13213852

APA StyleRashedi, A., Marzouki, R., Raza, A., Rawi, N. F. M., & Naveen, J. (2021). Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O. Polymers, 13(21), 3852. https://doi.org/10.3390/polym13213852