Effect of Strain Rate and Silica Filler Content on the Compressive Behavior of RTM6 Epoxy-Based Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Matrix Material

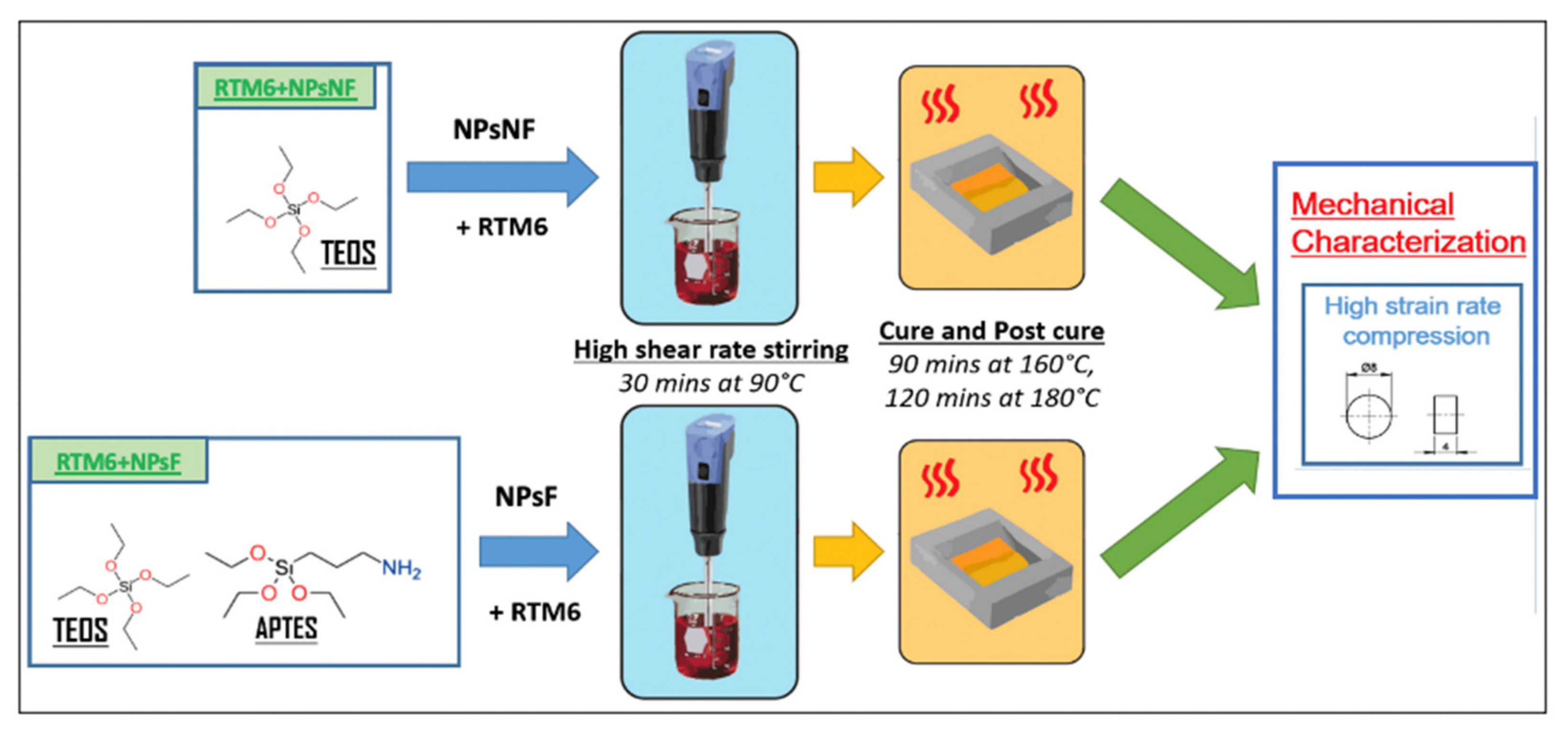

2.2. Nanoparticles Synthesis and Nanocomposite Preparation

2.3. Dynamic Mechanical Analysis

2.4. Quasi-Static Testing

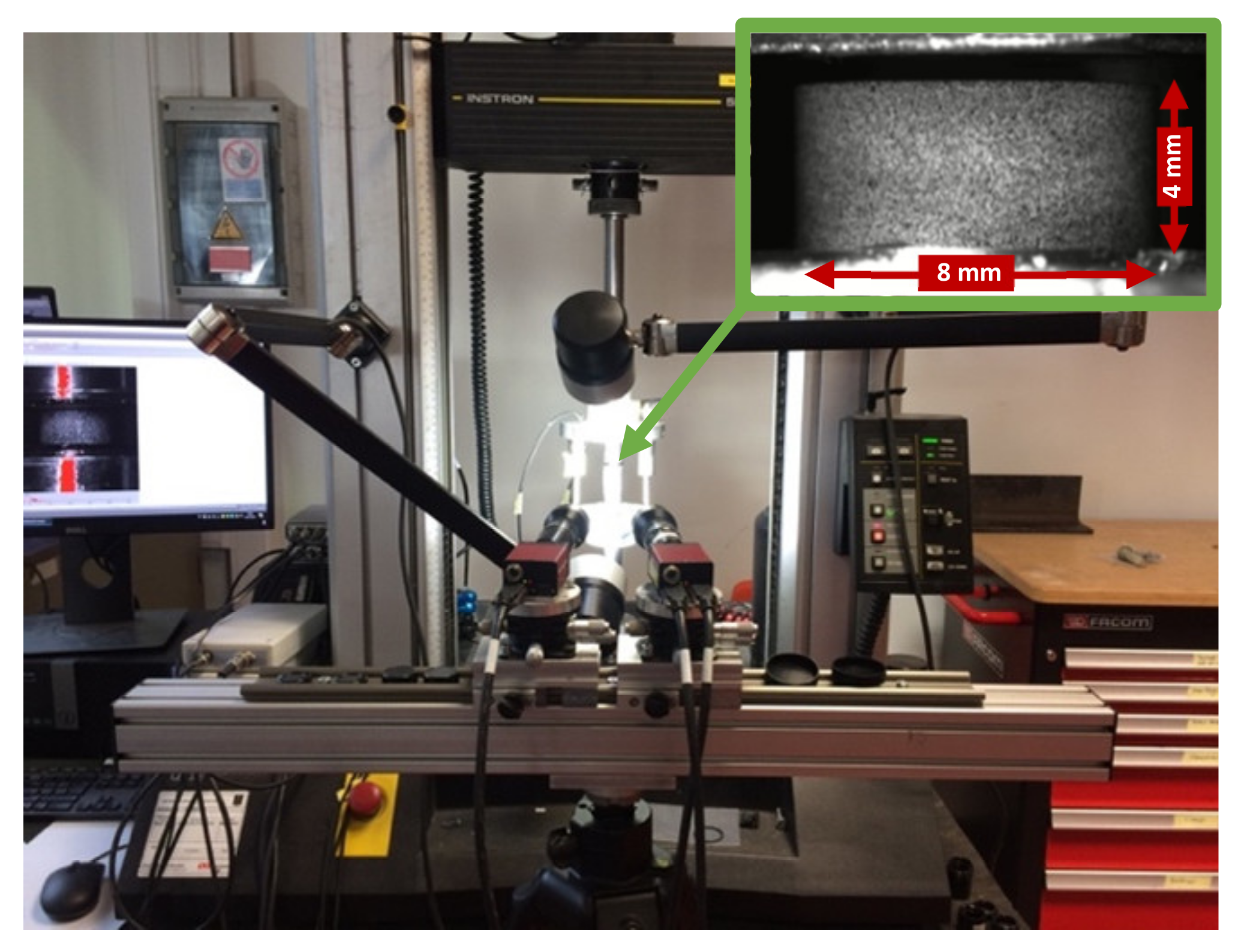

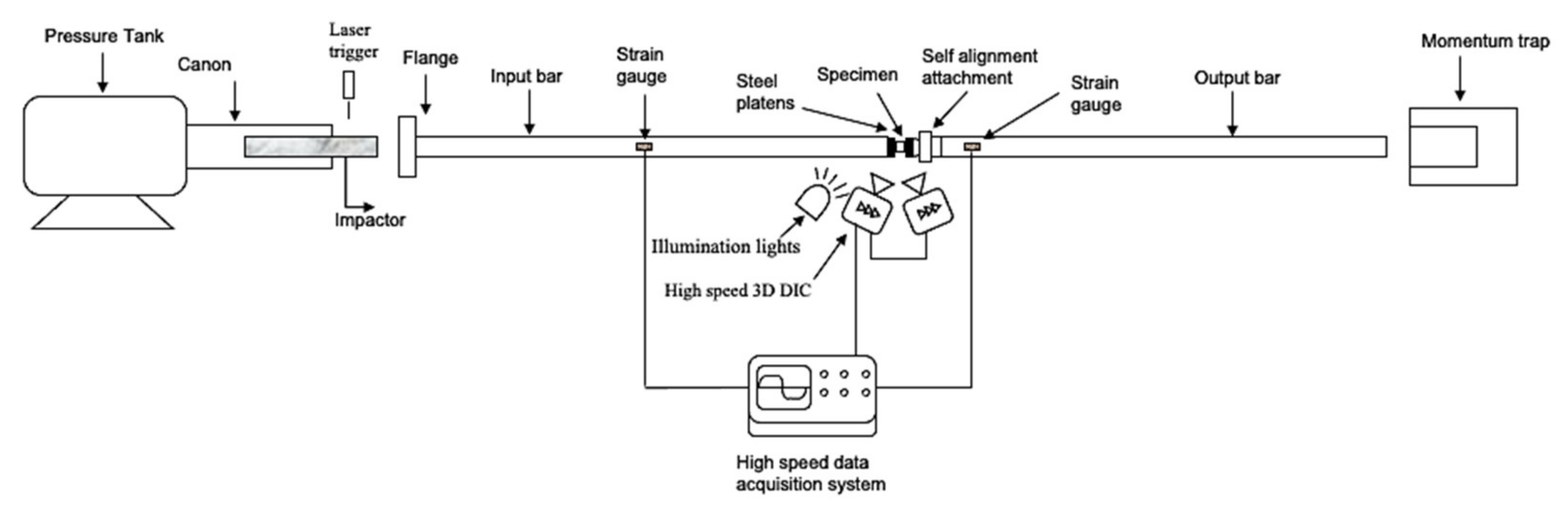

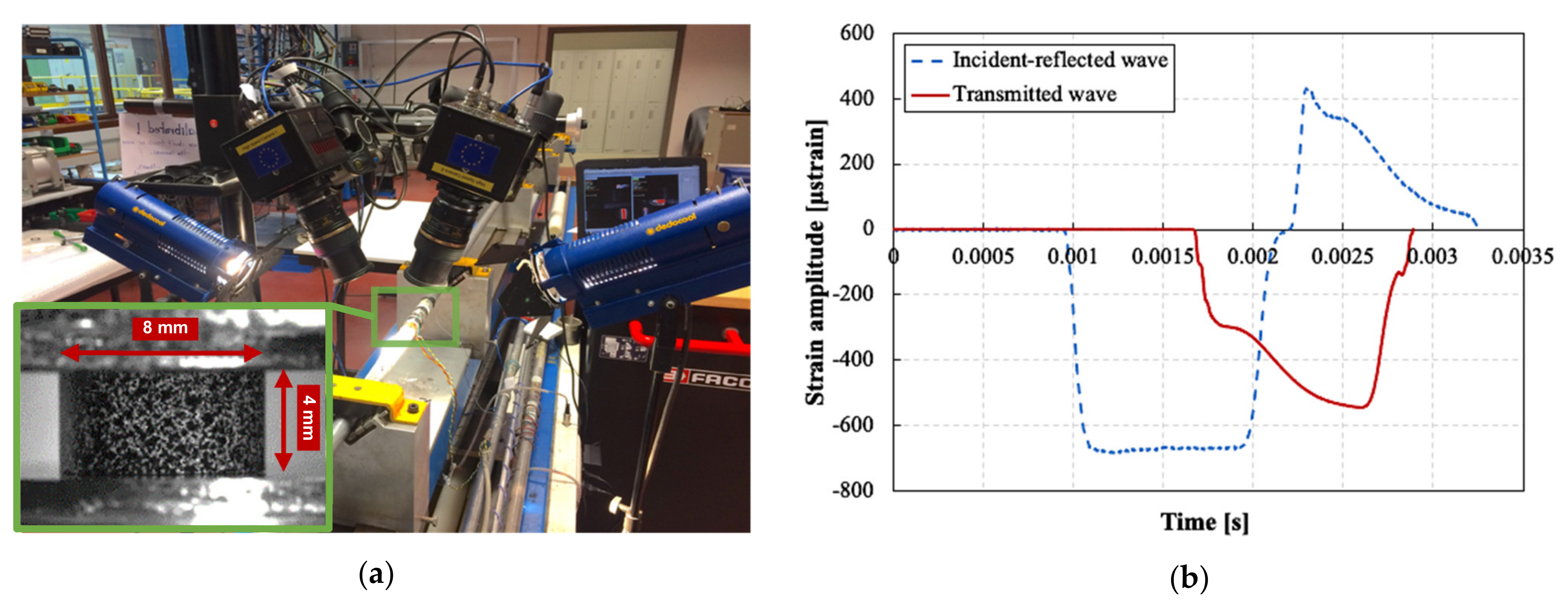

2.5. High Strain Rate Testing

2.6. DIC Data Reduction and Processing Parameters

3. Results and Discussion

3.1. Dynamic Mechanical Analysis

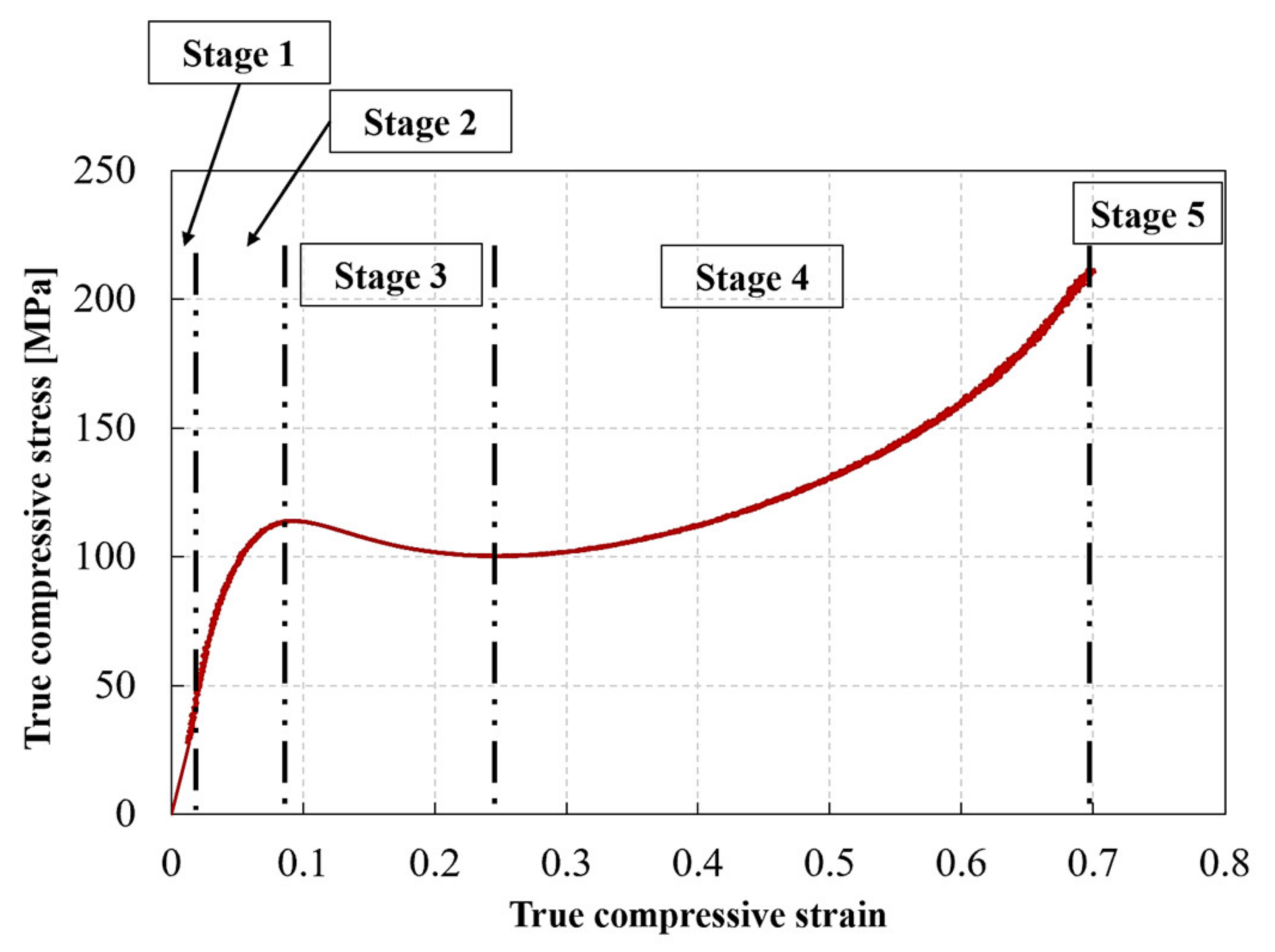

3.2. Compressive Stress-Strain Response of RTM6 Epoxy Nanocomposites at Different Strain Rates

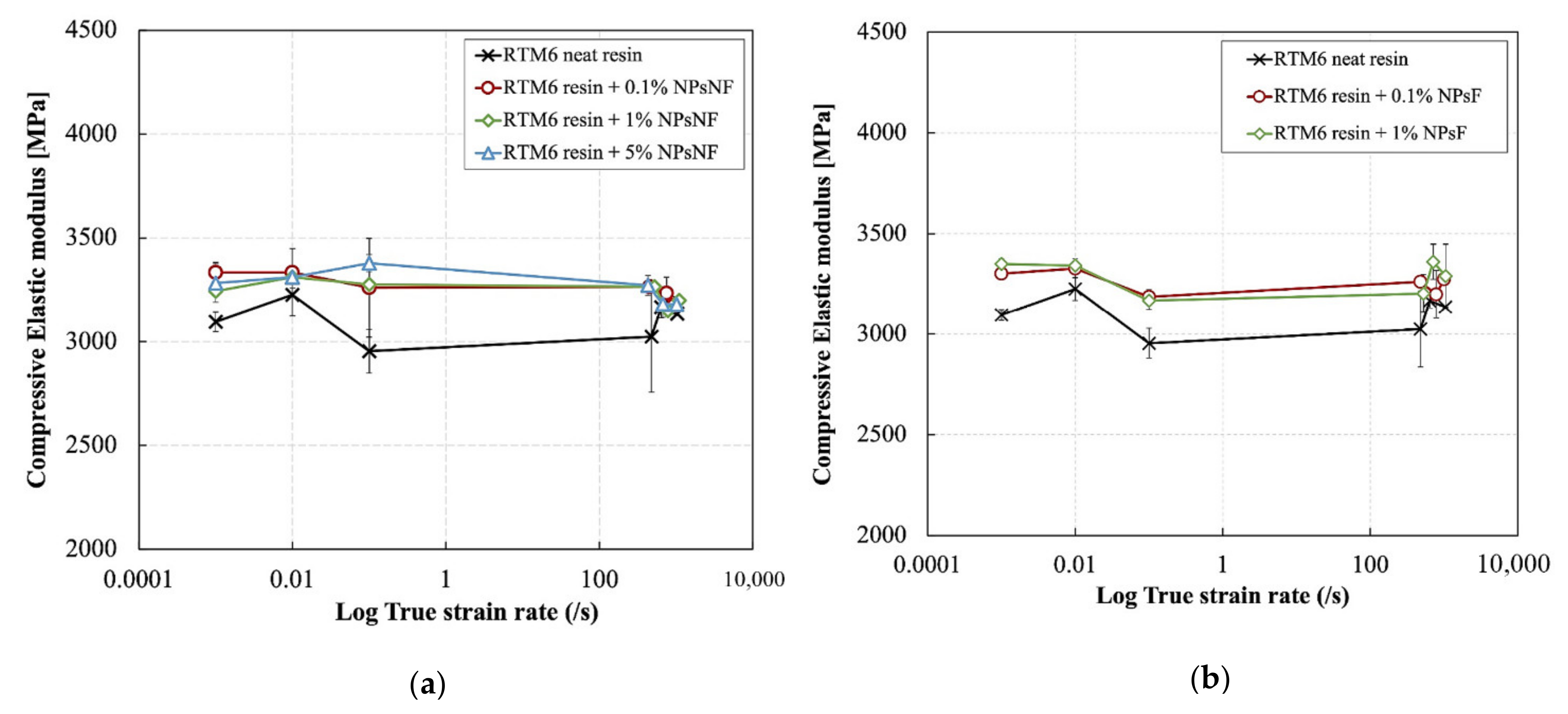

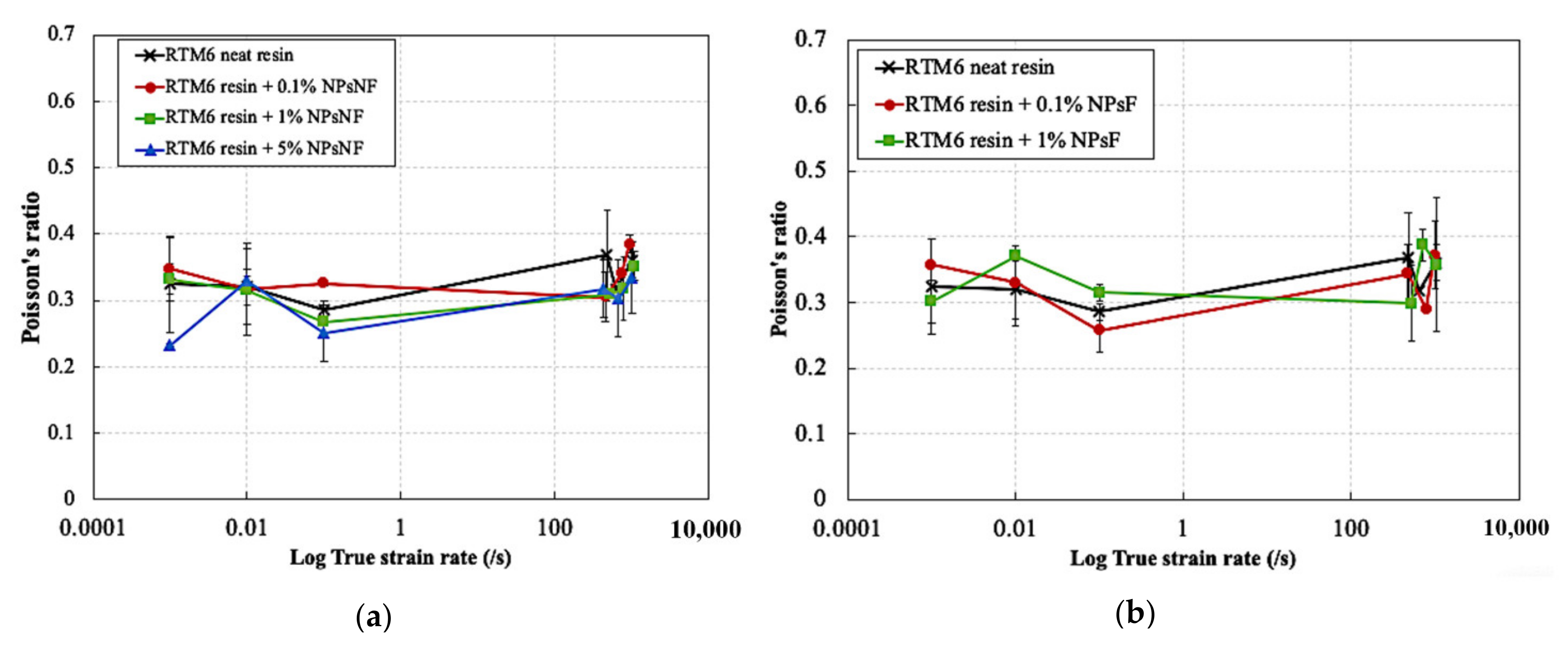

3.3. Effect of Strain Rate and Weight Content on the Elastic Modulus and Poisson’s Ratio of the Silica Nanoparticles Filled RTM6 Epoxy Resin

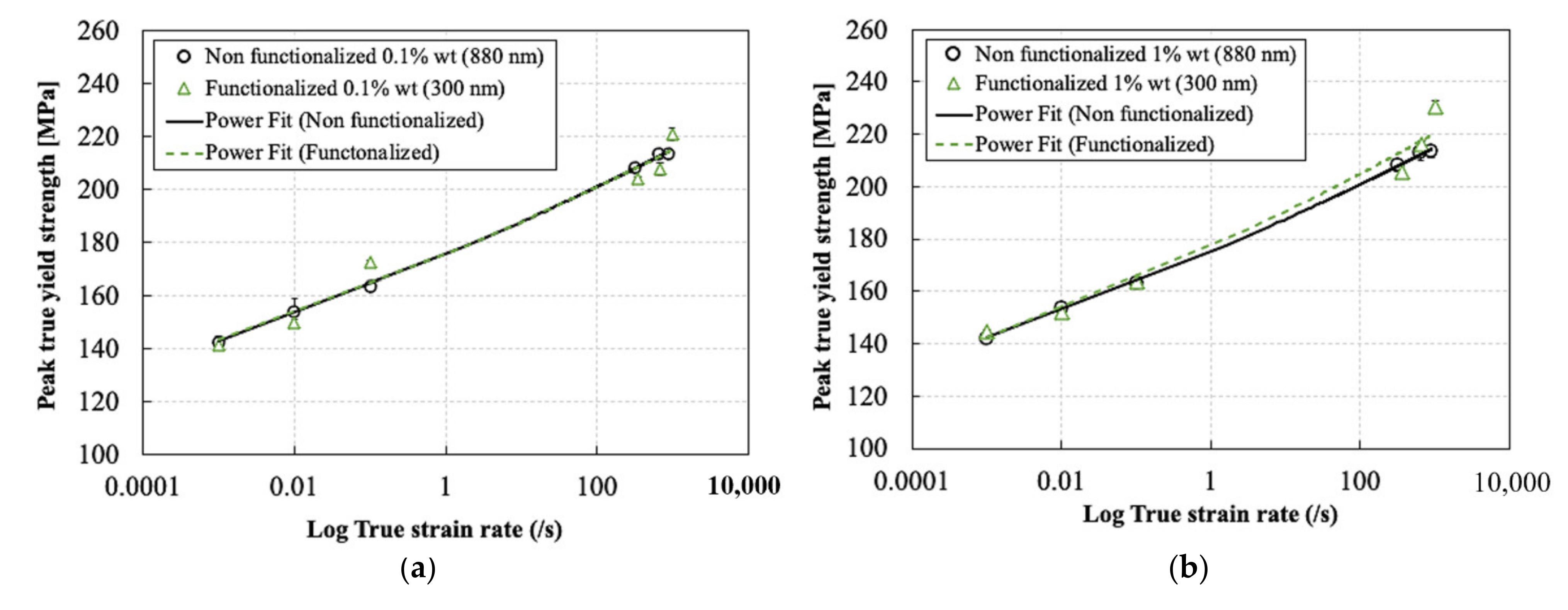

3.4. Effect of Strain Rate and Weight Content on the Peak Yield Strength of the Silica Nanoparticle-Filled RTM6 Epoxy Resin

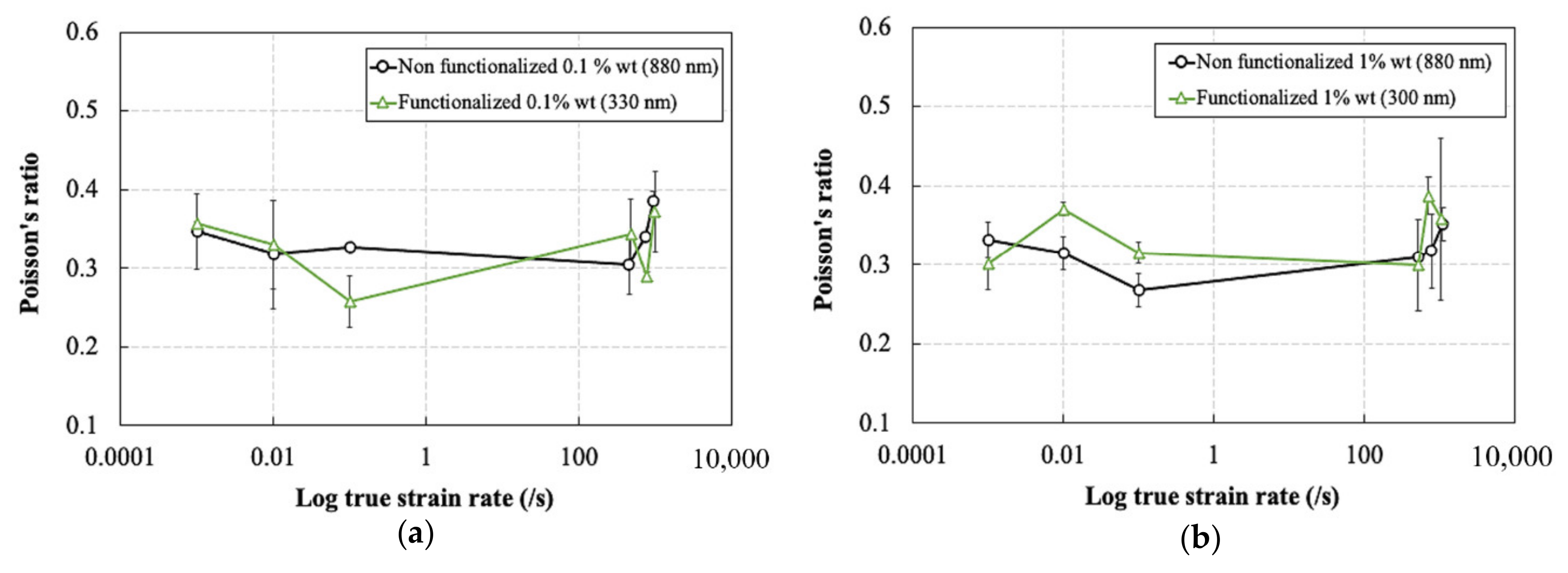

3.5. Effect of the Silica Nanoparticles Size and Surface Functionalization of on the Elastic Modulus, Poisson’s Ratio and Peak Yield Strength of RTM6 Epoxy Nanocomposite

4. Conclusions

- The tested RTM6 neat and nanoparticle filled resins were all strain rate-sensitive in compression. All materials showed an increase in strength with increasing strain rates for all the weight percentages and sizes of the fillers.

- The elastic modulus and Poisson’s ratio of the tested epoxy nanocomposites were independent of the strain rate and showed a nearly constant behavior at different strain rates for all weight percentages and sizes of the particles. However, the true peak yield strength showed an increase with increasing strain rates for all weight percentages and sizes of the particles used.

- The addition of silica nanoparticles to the RTM6 epoxy resin generally improved both its elastic modulus and its peak yield strength at different strain rates for all the weight percentages of the particles. Increasing the weight percentage of both types the silica nanoparticles from 0.1% to 5% did not yield any improvement in the elastic modulus and the Poisson’s ratio but led to a slight increase in the peak yield strength. Additionally, it was found that the improvement in the peak yield strength due to the addition of silica nanoparticles was more prominent in the quasi-static strain rate regime compared to the high strain rate regime.

- The dynamic mechanical analysis showed an increase in the storage modulus and a marginal increase in the glass transition temperature of the resin by the addition of silica nanoparticles of different weight percentages.

- The sizes of the silica nanoparticles used (300 nm and 880 nm) did not significantly affect the compressive properties of the RTM6 epoxy resin, regardless of the weight percentages of the particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mallick, P.K. Composites Engineering Handbook, 1st ed.; Mallick, P.K., Ed.; CRC Press: Boca Raton, FL, USA, 1997; ISBN 9780429175497. [Google Scholar]

- Domun, N.; Hadavinia, H.; Zhang, T.; Liaghat, G.; Vahid, S.; Spacie, C.; Paton, K.R.; Sainsbury, T. Improving the fracture toughness properties of epoxy using graphene nanoplatelets at low filler content. Nanocomposites 2017, 3, 85–96. [Google Scholar] [CrossRef]

- Duan, Z.; He, H.; Liang, W.; Wang, Z.; He, L.; Zhang, X. Tensile, quasistatic and dynamic fracture properties of nano-Al2O3-modified epoxy resin. Materials 2018, 11, 905. [Google Scholar] [CrossRef] [Green Version]

- Naik, N.K.; Pandya, K.S.; Kavala, V.R.; Zhang, W.; Koratkar, N.A. Alumina nanoparticle filled epoxy resin: High strain rate compressive behavior. Polym. Eng. Sci. 2014, 54, 2896–2901. [Google Scholar] [CrossRef]

- Gurusideswar, S.; Velmurugan, R.; Gupta, N.K. High strain rate sensitivity of epoxy/clay nanocomposites using non-contact strain measurement. Polymer 2016, 86, 197–207. [Google Scholar] [CrossRef]

- Sprenger, S. Epoxy resins modified with elastomers and surface-modified silica nanoparticles. Polymer 2013, 54, 4790–4797. [Google Scholar] [CrossRef] [Green Version]

- Kausar, A. Rubber toughened epoxy-based nanocomposite: A promising pathway toward advanced materials. J. Macromol. Sci. Part A 2020. [Google Scholar] [CrossRef]

- Bie, B.X.; Han, J.H.; Lu, L.; Zhou, X.M.; Qi, M.L.; Zhang, Z.; Luo, S.N. Dynamic fracture of carbon nanotube/epoxy composites under high strain-rate loading. Compos. Part A Appl. Sci. Manuf. 2015, 68, 282–288. [Google Scholar] [CrossRef]

- Gómez-Del Río, T.; Rodríguez, J.; Pearson, R.A. Compressive properties of nanoparticle modified epoxy resin at different strain rates. Compos. Part B Eng. 2014, 57, 173–179. [Google Scholar] [CrossRef]

- Buonocore, G.G.; Schiavo, L.; Attianese, I.; Borriello, A. Hyperbranched polymers as modifiers of epoxy adhesives. Compos. Part B Eng. 2013, 53, 187–192. [Google Scholar] [CrossRef]

- Zotti, A.; Elmahdy, A.; Zuppolini, S.; Borriello, A.; Verleysen, P.; Zarrelli, M. Aromatic hyperbranched polyester/RTM6 epoxy resin for extreme dynamic loading aeronautical applications. Nanomaterials 2020, 10, 188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boogh, L.; Pettersson, B.; Månson, J.A.E. Dendritic hyperbranched polymers as tougheners for epoxy resins. Polymer 1999, 40, 2249–2261. [Google Scholar] [CrossRef]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Eger, C.; Sprenger, S.; Egan, D. The effect of silica nano particles and rubber particles on the toughness of multiphase thermosetting epoxy polymers. J. Mater. Sci. 2005, 40, 5083–5086. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S. The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.L.; Pearson, R.A. Toughening mechanisms in epoxy-silica nanocomposites (ESNs). Polymer 2009, 50, 4895–4905. [Google Scholar] [CrossRef]

- Linec, M.; Mušič, B. The effects of silica-based fillers on the properties of epoxy molding compounds. Materials 2019, 12, 1811. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bondioli, F.; Darecchio, M.E.; Luyt, A.S.; Messori, M. Epoxy resin modified with in situ generated metal oxides by means of sol-gel process. J. Appl. Polym. Sci. 2011, 122, 1792–1799. [Google Scholar] [CrossRef]

- Aliofkhazraei, M. Handbook of Nanoparticles; Springer International Publishing: Cham, Switzerland, 2015; ISBN 9783319153384. [Google Scholar]

- Chen, C.; Justice, R.S.; Schaefer, D.W.; Baur, J.W. Highly dispersed nanosilica-epoxy resins with enhanced mechanical properties. Polymer 2008, 49, 3805–3815. [Google Scholar] [CrossRef]

- Jumahat, A.; Soutis, C.; Jones, F.R.; Hodzic, A. Effect of silica nanoparticles on compressive properties of an epoxy polymer. J. Mater. Sci. 2010, 45, 5973–5983. [Google Scholar] [CrossRef] [Green Version]

- Kothmann, M.H.; Bakis, G.; Zeiler, R.; Ziadeh, M.; Breu, J.; Altstädt, V. Fatigue crack growth behaviour of epoxy nanocomposites—Influence of particle geometry. Superconductivity 2017, 247, 23–32. [Google Scholar]

- Tian, Y.; Zhang, H.; Zhang, Z. Influence of nanoparticles on the interfacial properties of fiber-reinforced-epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 1–8. [Google Scholar] [CrossRef]

- Rahman, I.A.; Padavettan, V. Synthesis of silica nanoparticles by Sol-Gel: Size-dependent properties, surface modification, and applications in silica-polymer nanocompositesa review. J. Nanomater. 2012, 2012, 132424. [Google Scholar] [CrossRef] [Green Version]

- Macan, J.; Paljar, K.; Burmas, B.; Špehar, G.; Leskovac, M.; Gajović, A. Epoxy-matrix composites filled with surface-modified SiO2 nanoparticles. J. Therm. Anal. Calorim. 2017, 127, 399–408. [Google Scholar] [CrossRef]

- León, L.M.; Laza, M.; Puchol, V.; Torrens, F.; Abad, C.; Campos, A. Dynamic mechanical measurements of epoxy matrix-silica nanocomposites ii. Polym. Polym. Compos. 2009, 17, 313–324. [Google Scholar] [CrossRef]

- Kamran-Pirzaman, A.; Rostamian, Y.; Babatabar, S. Surface improvement effect of silica nanoparticles on epoxy nanocomposites mechanical and physical properties, and curing kinetic. J. Polym. Res. 2020, 27, 13. [Google Scholar] [CrossRef]

- Kang, S.; Hong, S.I.; Choe, C.R.; Park, M.; Rim, S.; Kim, J. Preparation and characterization of epoxy composites filled with functionalized nanosilica particles obtained via sol-gel process. Polymer 2001, 42, 879–887. [Google Scholar] [CrossRef]

- Dittanet, P.; Pearson, R.A. Effect of silica nanoparticle size on toughening mechanisms of filled epoxy. Polymer 2012, 53, 1890–1905. [Google Scholar] [CrossRef]

- Bondioli, F.; Cannillo, V.; Fabbri, E.; Messori, M. Epoxy-silica nanocomposites: Preparation, experimental characterization, and modeling. J. Appl. Polym. Sci. 2005, 97, 2382–2386. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Z.; Moon, K.S.; Wong, C.P. Glass transition and relaxation behavior of epoxy nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 3849–3858. [Google Scholar] [CrossRef]

- Miao, Y.G.; Liu, H.Y.; Suo, T.; Mai, Y.W.; Xie, F.Q.; Li, Y.L. Effects of strain rate on mechanical properties of nanosilica/epoxy. Compos. Part B Eng. 2016, 96, 119–124. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, H.; Zhao, J.; Li, T.; Bie, B.X.; Luo, S.N.; Zhang, Z. High strain rate compression of epoxy based nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 62–70. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Y. Quasi-static/dynamic response of SiO2-epoxy nanocomposites. Mater. Sci. Eng. A 2007, 458, 330–335. [Google Scholar] [CrossRef]

- Ma, P.; Jiang, G.; Li, Y.; Zhong, W. The impact compression behaviors of silica nanoparticles—Epoxy composites. J. Text. Sci. Technol. 2015, 01, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Sekiguchi, Y. Effects of mixed micro and nano silica particles on the dynamic compressive performances of epoxy adhesive. Appl. Adhes. Sci. 2017, 5, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Fang, M.; Volotinen, T.T.; Kulkarni, S.K.; Belova, L.; Rao, K.V. Effect of embedding Fe3O4 nanoparticles in silica spheres on the optical transmission properties of three-dimensional magnetic photonic crystals. J. Appl. Phys. 2010, 108, 103501. [Google Scholar] [CrossRef]

- Zotti, A.; Zuppolini, S.; Borriello, A.; Zarrelli, M. Thermal properties and fracture toughness of epoxy nanocomposites loaded with hyperbranched-polymers-based core/shell nanoparticles. Nanomaterials 2019, 9, 418. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jerabek, M.; Major, Z.; Lang, R.W. Uniaxial compression testing of polymeric materials. Polym. Test. 2010, 29, 302–309. [Google Scholar] [CrossRef]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. Sect. B 1949, 62, 676–700. [Google Scholar] [CrossRef]

- Gorham, D.A. The effect of specimen dimensions on high strain rate compression measurements of copper. J. Phys. D Appl. Phys. 1991, 24, 1489–1492. [Google Scholar] [CrossRef]

- Gerlach, R.; Siviour, C.R.; Petrinic, N.; Wiegand, J. Experimental characterisation and constitutive modelling of RTM-6 resin under impact loading. Polymer 2008, 49, 2728–2737. [Google Scholar] [CrossRef]

- Miao, Y.G.; Li, Y.L.; Liu, H.Y.; Deng, Q.; Shen, L.; Mai, Y.W.; Guo, Y.Z.; Suo, T.; Hu, H.T.; Xie, F.Q.; et al. Determination of dynamic elastic modulus of polymeric materials using vertical split Hopkinson pressure bar. Int. J. Mech. Sci. 2016, 108–109, 188–196. [Google Scholar] [CrossRef]

- Sperandio, C.; Laachachi, A.; Ruch, D.; Poilâne, C.; Bourson, P.; Salvestrini, J.P.; Ahzi, S. Use of functionalized nanosilica to improve thermo-mechanical properties of epoxy adhesive joint bonding aluminium substrates. J. Nanosci. Nanotechnol. 2010, 10, 2844–2849. [Google Scholar] [CrossRef] [PubMed]

- Morelle, X.P.; Chevalier, J.; Bailly, C.; Pardoen, T.; Lani, F. Mechanical characterization and modeling of the deformation and failure of the highly crosslinked RTM6 epoxy resin. Mech. Time Depend. Mater. 2017, 21, 419–454. [Google Scholar] [CrossRef]

- Tamrakar, S.; Ganesh, R.; Sockalingam, S.; Haque, B.Z.; Gillespie, J.W. Strain rate-dependent large deformation inelastic behavior of an epoxy resin. J. Compos. Mater. 2020, 54, 71–87. [Google Scholar] [CrossRef]

- Chen, L.P.; Yee, A.F.; Moskala, E.J. The molecular basis for the relationship between the secondary relaxation and mechanical properties of a series of polyester copolymer glasses. Macromolecules 1999, 32, 5944–5955. [Google Scholar] [CrossRef]

- Rose, S.; Dizeux, A.; Narita, T.; Hourdet, D.; Marcellan, A. Time dependence of dissipative and recovery processes in nanohybrid hydrogels. Macromolecules 2013, 46, 4095–4104. [Google Scholar] [CrossRef]

- Pan, Z.; Sun, B.; Shim, V.P.W.; Gu, B. Transient heat generation and thermo-mechanical response of epoxy resin under adiabatic impact compressions. Int. J. Heat Mass Transf. 2016, 95, 874–889. [Google Scholar] [CrossRef] [Green Version]

- Gómez-del Río, T.; Rodríguez, J. Compression yielding of epoxy: Strain rate and temperature effect. Mater. Des. 2012, 35, 369–373. [Google Scholar] [CrossRef]

| Sample | Matrix | Filler | Filler Content [%] |

|---|---|---|---|

| RTM6 neat resin | RTM6 | - | 0 |

| RTM6 + 0.1 wt% NPsNF | RTM6 | NPsNF | 0.1 |

| RTM6 + 1 wt% NPsNF | RTM6 | NPsNF | 1 |

| RTM6 + 5 wt% NPsNF | RTM6 | NPsNF | 5 |

| RTM6 + 0.1 wt% NPsF | RTM6 | NPsF | 0.1 |

| RTM6 + 1 wt% NPsF | RTM6 | NPsF | 1 |

| Parameter | Value |

|---|---|

| Correlation criterion | Zero normalized sum of square differences (ZNSSD) |

| Interpolation order | Bi-cubic spline |

| Shape function | Affine |

| Subset size (pixels x pixels) | 55 × 55 (quasi-static) and 21 × 21 (high strain rate) |

| Step size (pixels) | 10 |

| Strain window | 15 |

| Sample Type | Storage Modulus at 40 °C (MPa) | Storage Modulus at 250 °C (MPa) | Glass Transition Temperature (°C) | ||

|---|---|---|---|---|---|

| Mean | Std. Dev | Mean | Std. Dev | ||

| RTM6 neat resin | 3023 | ±23 | 38.4 | ±2.1 | 226.6 ± 0.2 |

| RTM6 + 0.1 wt% NPsNF | 3047 | ±43 | 38.8 | ±1.8 | 225.7 ± 0.3 |

| RTM6 + 1 wt% NPsNF | 3093 | ±17 | 39.4 | ±1.7 | 229.0 ± 0.2 |

| RTM6 + 5 wt% NPsNF | 3375 | ±33 | 44.5 | ±2.4 | 229.4 ± 0.4 |

| RTM6 + 0.1 wt% NPsF | 3123 | ±56 | 39.9 | ±6.2 | 226.0 ± 0.3 |

| RTM6 + 1 wt% NPsF | 3243 | ±31 | 41.0 | ±3.1 | 228.3 ± 0.4 |

| Material Condition | Achieved True Strain Rates for Elastic Modulus and Poisson’s Ratio (s−1) | Elastic Modulus (MPa) | Poisson’s Ratio | Achieved True Strain Rates for Peak Yield Strength (s−1) | True Peak Yield Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Mean | Std. Dev. | Mean | Std. Dev. | Mean | Std. Dev. | |||

| RTM6 neat resin | 0.001 | 3095.653 | 46.804 | 0.3243 | 0.1256 | 0.001 | 136.403 | 6.2101 |

| 0.01 | 3225.250 | 100.59 | 0.3208 | 0.0985 | 0.01 | 145.318 | 4.2153 | |

| 0.1 | 2953.969 | 105.521 | 0.2861 | 0.0178 | 0.1 | 155.196 | 7.8117 | |

| 478.638 | 3024.542 | 267.920 | 0.3683 | 0.09698 | 365.760 | 204.840 | 8.2448 | |

| 638.877 | 3166.459 | 52.097 | 0.3174 | 0.0017 | 527.334 | 211.603 | 11.305 | |

| 1034.972 | 3135.218 | 9.455 | 0.3608 | 0.0375 | 1017.751 | 212.295 | 1.774 | |

| RTM6 + 0.1% NPsNF | 0.001 | 3332.913 | 69.506 | 0.3471 | 0.0675 | 0.001 | 142.063 | 3.574 |

| 0.01 | 3333.440 | 162.954 | 0.3175 | 0.0978 | 0.01 | 153.812 | 7.4526 | |

| 0.1 | 3259.936 | 336.447 | 0.3259 | 0.0045 | 0.1 | 163.187 | 1.1321 | |

| 454.339 | 3264.105 | 1.148 | 0.3046 | 0.0531 | 318.821 | 207.955 | 0.994 | |

| 750.6 | 3233.544 | 109.158 | 0.3398 | 0.0073 | 640.054 | 213.176 | 0.717 | |

| 946.35 | 3174.352 | 58.153 | 0.3846 | 0.0189 | 891 | 213.292 | 0.9457 | |

| RTM6 + 1% NPsNF | 0.001 | 3243.419 | 5.8576 | 0.3318 | 0.0325 | 0.001 | 146.242 | 0.873 |

| 0.01 | 3310.858 | 26.257 | 0.3147 | 0.2677 | 0.01 | 152.376 | 0.0631 | |

| 0.1 | 3275.084 | 65.296 | 0.2677 | 0.0300 | 0.1 | 164.471 | 0.1899 | |

| 520.731 | 3264.376 | 79.535 | 0.3090 | 0.0013 | 369.592 | 208.867 | 3.8367 | |

| 786.096 | 3150.037 | 28.658 | 0.3172 | 0.0675 | 737.255 | 220.455 | 5.8581 | |

| 1093.333 | 3198.981 | 44.3911 | 0.3516 | 0.0306 | 1089.456 | 219.829 | 3.6738 | |

| RTM6 + 5% NPsNF | 0.001 | 3282.311 | 53.296 | 0.2324 | 0.0038 | 0.001 | 139.690 | 6.1066 |

| 0.01 | 3310.217 | 130.112 | 0.3299 | 0.0240 | 0.01 | 153.717 | 1.6009 | |

| 0.1 | 3378.446 | 73.952 | 0.2516 | 0.0597 | 0.1 | 170.631 | 0.4492 | |

| 431.035 | 3270.771 | 70.508 | 0.3174 | 0.0607 | 285.279 | 209.522 | 2.3349 | |

| 670.14 | 3180.850 | 83.435 | 0.3031 | 0.0809 | 596.957 | 214.067 | 0.5062 | |

| 1015.2 | 3179.854 | 107.427 | 0.3341 | 0.0766 | 1003.242 | 222.986 | 2.6408 | |

| RTM6 + 0.1% NPsF | 0.001 | 3301.023 | 3.642 | 0.3573 | 0.0028 | 0.001 | 141.454 | 2.6183 |

| 0.01 | 3327.148 | 66.729 | 0.3300 | 0.0792 | 0.01 | 149.692 | 1.6139 | |

| 0.1 | 3186.456 | 50.550 | 0.2572 | 0.0465 | 0.1 | 172.510 | 0.6441 | |

| 476.222 | 3261.809 | 25.714 | 0.3439 | 0.0621 | 342.424 | 203.886 | 1.0950 | |

| 782.692 | 3198.150 | 205.811 | 0.2900 | 0.0068 | 683.038 | 207.785 | 3.3535 | |

| 991.71 | 3273.225 | 45.430 | 0.3723 | 0.072 | 982.414 | 220.873 | 3.3542 | |

| RTM6 + 1% NPsF | 0.001 | 3349.470 | 36.207 | 0.3013 | 0.0457 | 0.001 | 144.687 | 0.9358 |

| 0.01 | 3342.377 | 10.823 | 0.3707 | 0.0112 | 0.01 | 152.181 | 3.4609 | |

| 0.1 | 3166.964 | 60.340 | 0.3152 | 0.0189 | 0.1 | 163.443 | 3.0203 | |

| 524.656 | 3202.538 | 132.026 | 0.2990 | 0.0818 | 355.420 | 205.585 | 1.7706 | |

| 711.72 | 3360.668 | 122.428 | 0.3875 | 0.0334 | 656.1 | 215.882 | 2.0841 | |

| 1048.6 | 3290.045 | 222.304 | 0.3576 | 0.1438 | 1004.4 | 230.579 | 3.1928 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmahdy, A.; Zotti, A.; Zuppolini, S.; Zarrelli, M.; Borriello, A.; Verleysen, P. Effect of Strain Rate and Silica Filler Content on the Compressive Behavior of RTM6 Epoxy-Based Nanocomposites. Polymers 2021, 13, 3735. https://doi.org/10.3390/polym13213735

Elmahdy A, Zotti A, Zuppolini S, Zarrelli M, Borriello A, Verleysen P. Effect of Strain Rate and Silica Filler Content on the Compressive Behavior of RTM6 Epoxy-Based Nanocomposites. Polymers. 2021; 13(21):3735. https://doi.org/10.3390/polym13213735

Chicago/Turabian StyleElmahdy, Ahmed, Aldobenedetto Zotti, Simona Zuppolini, Mauro Zarrelli, Anna Borriello, and Patricia Verleysen. 2021. "Effect of Strain Rate and Silica Filler Content on the Compressive Behavior of RTM6 Epoxy-Based Nanocomposites" Polymers 13, no. 21: 3735. https://doi.org/10.3390/polym13213735

APA StyleElmahdy, A., Zotti, A., Zuppolini, S., Zarrelli, M., Borriello, A., & Verleysen, P. (2021). Effect of Strain Rate and Silica Filler Content on the Compressive Behavior of RTM6 Epoxy-Based Nanocomposites. Polymers, 13(21), 3735. https://doi.org/10.3390/polym13213735