In some studies two types of elastomers were blended together in a 50:50 wt % ratio. In the case of these polymer blends, the articles are discussed in the section of the elastomer that was first in the publication order and only mentioned in the section of the other elastomer in the blend.

The properties that were typically looked at when investigating the effect of LDH on the properties of rubber include tensile strength (TS), elongation at break (EB) and modulus. The modulus values can be reported at different elongation values, typically at 100% elongation (M100), 200% elongation (M200) or 300% elongation (M300). Other properties that were looked at are the glass transition temperature (T) and the tan() peak height. The tan() peak height gives an indication of chain mobility.

5.1. Ethylene Propylene Diene Monomer Rubber (EPDM)

EPDM contains some double bonds on the side groups. It is resistant to ozone attack, oxidation and moisture, making it useful for applications where weather and heat resistance is required [

3]. EPDM can be crosslinked using sulphur vulcanisation and peroxide crosslinking [

51].

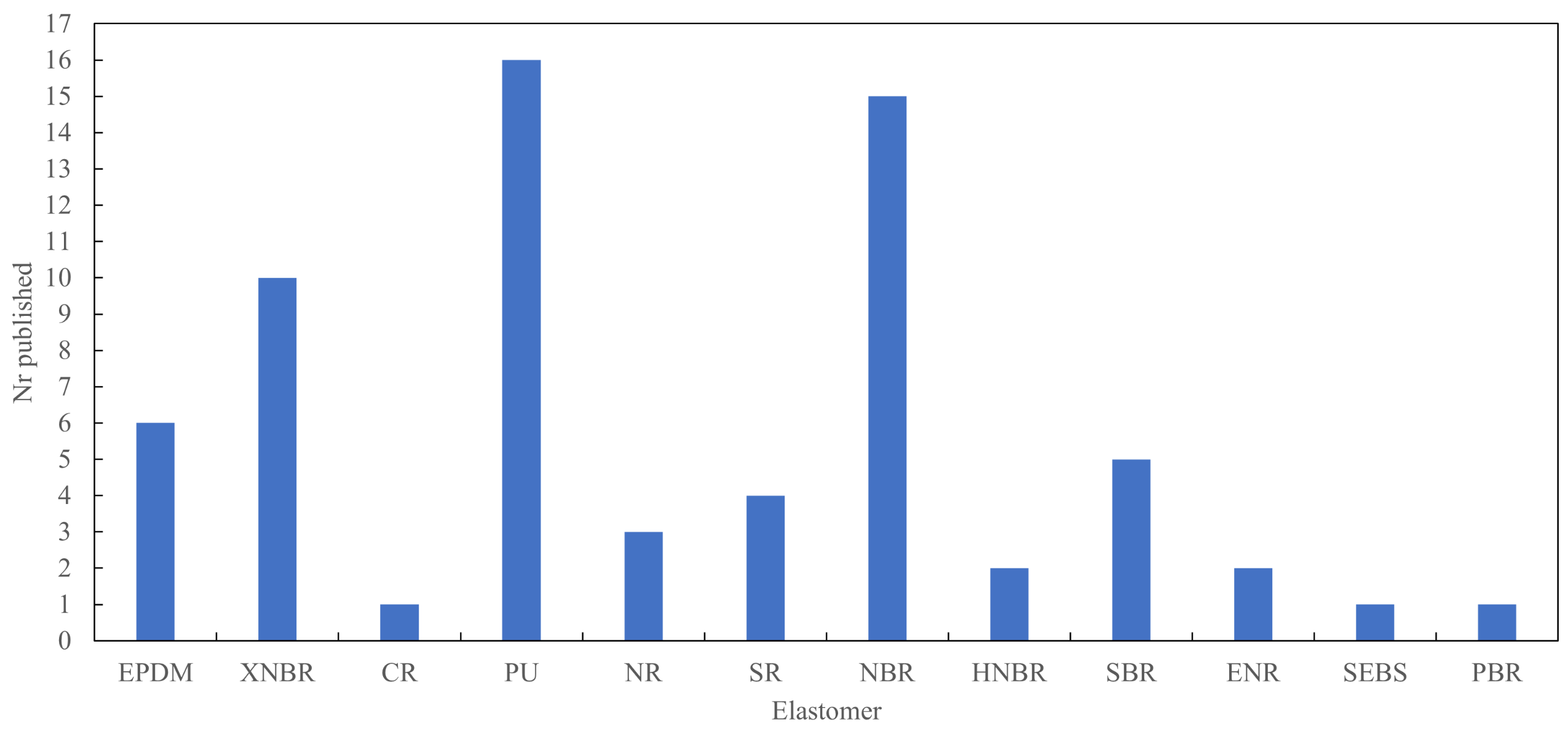

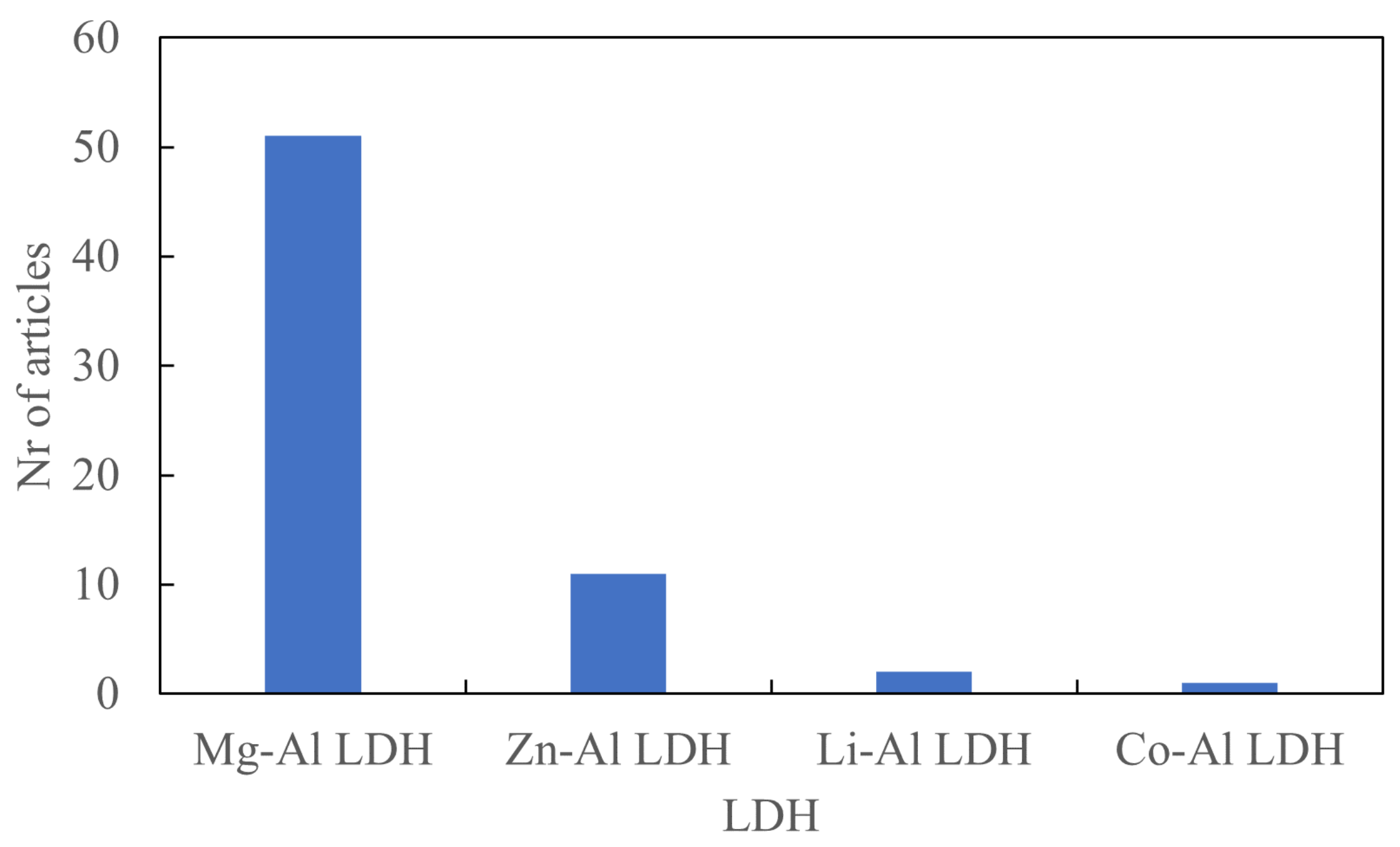

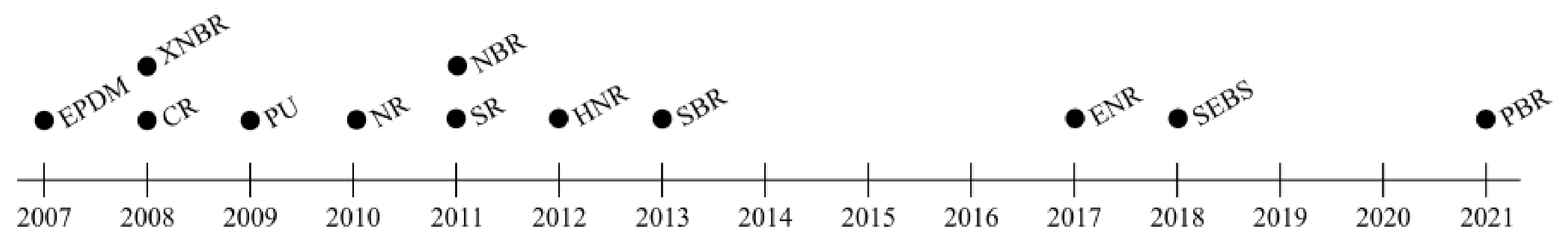

Of the 61 articles found during the literature search, 6 articles were on the use of LDH in EPDM. The first two articles were published in 2007 and then one per year was published in 2008, 2009, 2016 and 2020. Of the six articles, four used Mg-Al LDH and two used Zn-Al LDH. A total of five of the six LDHs were organically modified.

In two studies, Mg-Al LDH was modified with dodecyl sulphate (DS-LDH) and was added to EPDM at different loadings. The increase in interlayer spacing caused by the organic modification allowed the LDH layers to become partially exfoliated and the increased compatibility with EPDM, causing the LDH to be well dispersed [

52,

53]. The exfoliation of the LDH increased the polymer–filler interaction. Increasing the DS-LDH content increased the TS and EB of the composites. The interfacial interaction between the DS-LDH and EPDM allowed efficient stress transfer from the polymer, enhancing the TS and increasing the stiffness of the composite. The platelet orientation and chain slippage increased the EB. The dodecyl sulphate chain in the LDH may also have had a plasticising effect that increased EB. The modulus also increased due to the polymer–filler interaction and the sterically hindered LDH surface creating resistance. DS-LDH platelets altered the crack propagation in the EPDM because they acted as obstacles to crack propagation and caused cracks to branch off. At higher concentrations of LDH, the mechanical properties started to decrease again due to the presence of agglomerates. The thermal stability of the EPDM increased, reached a maximum and decreased again with increasing DS-LDH content This is similar to what was observed for the mechanical properties due to agglomeration. The exfoliated DS-LDH layers could act as barriers to volatile decomposition products and heat, improving thermal stability. T

was not affected by the addition of DS-LDH, which showed that the polymer chains did not become entangled around the LDH particles.

The effect of matrix polarity and functional groups on the dispersion of LDH, the polymer–filler interaction and the composite mechanical properties was investigated by Pradhan et al. [

13]. They compared EPDM, a non-polar rubber, to XNBR, a polar rubber with carboxyl functional groups that can interact with the hydroxyl groups on LDH. The XNBR results are discussed in detail in the section on XNBR. The Mg-Al LDH was modified with sodium 1-decanesulphonate (C10-LDH). EPDM did not interact with the C10-LDH during melt compounding and there was no intercalation or exfoliation observed. In EPDM, the C10-LDH was mostly present as individual particles and aggregates. The storage modulus of the EPDM composites decreased and then increased with increasing C10-LDH content. At low loadings the plasticising effect of the organic modifier dominated over the low reinforcing effect of the LDH due to poor polymer–filler interaction. At higher loadings the reinforcing effect of LDH increased and dominated over the plasticising effect. TS, modulus and EB increased with increasing C10-LDH content, similarly to what was observed by Acharya et al. [

52]. The tan(

) peak was not affected by the addition of C10-LDH, which showed that the interaction between the EPDM and C10-LDH was weak. Microvoids formed around the LDH particles, which also showed the interaction was weak. The formation of microvoids does, however, absorb energy during deformation which could help improve the mechanical properties of the composites.

Kuila et al. [

54] investigated the effect of dodecyl sulphate-modified Mg-Al LDH (DS-LDH) in a 50:50 wt % EVA/EPDM blend. The EVA used had a 45 wt % VA content. The DS-LDH was homogeneously distributed and exfoliated at low loadings, but agglomeration occurred at higher loadings. There was good interfacial interaction between DS-LDH and the polymer blend. The LDH hydroxyl groups could interact with the polar acetate groups in the EVA, which improved the polymer–filler compatibility and interaction. This caused the TS to increase as the DS-LDH concentration was increased. The EB was also improved due to the plasticising effect of the organic modifier, chain slippage and platelet orientation. The storage modulus was increased and the tan(

) peak was decreased by the polymer–filler interaction restricting chain movement and making the composite more stiff. The T

was unaffected by the DS-LDH. The thermal stability increased as the DS-LDH loading increased due to the barrier effect of the platelets and the char formation caused by the decomposition of the LDH. Agglomeration at higher loadings caused a decrease in thermal stability. Increasing the DS-LDH concentration first decreased and then increased the crosslink density. This may have been caused by the LDH platelets becoming more ordered and gradually adsorbing less of the peroxide crosslinker as the LDH content of the composite was increased. It can be concluded that the exfoliated DS-LDH platelets can act as a reinforcing filler and enhance the mechanical properties of the polymer blend, although agglomeration at higher LDH concentrations still poses a challenge.

Basu et al. [

55] reported successfully adding up to 100 phr (parts by weight per hundred resin) unmodified Zn-Al LDH to EPDM and found that crosslinking took place even in the absence of ZnO. The Zn ions of the LDH could therefore participate in the curing reaction. At 10 phr and above, the LDH was more efficient at curing the EPDM than ZnO. The TS and EB were increased compared to the ZnO-cured EPDM. The maximum increase was at 10 phr LDH before decreasing again. The modulus continued to increase with increasing LDH content. T

was also increased by adding LDH which shows that there is good interaction between the LDH and rubber despite the LDH being unmodified.

EPDM can be blended with polypropylene (PP) in the presence of LDH to form a dynamically vulcanised thermoplastic elastomer. Vol’fson and Nikiforov [

56] added stearate-modified Zn-Al LDH to a 60:40 weight ratio EPDM/PP blend. They found that the stearate modification improved compatibility between the LDH and polymer blend. Due to this the TS and EB were improved, although agglomeration decreased the mechanical properties at higher LDH loadings. The LDH also increased the thermal stability of the composites. The barrier effect of the LDH platelets, as well as the endothermic degradation of the LDH helped to form a char layer that prevented the diffusion of volatile degradation products and oxygen.

The effects of LDH on the mechanical properties on EPDM are summarised in

Table 1. The percentage change in each property compared to neat EPDM is shown. In some cases the data were only shown graphically and as such these percentages should only be used as an indication of the influence of LDH on the properties of the rubber and not as absolute values. In cases where multiple loadings of the same LDH were tested, the loading with the highest TS was used in reporting the mechanical properties. This method was used for summary tables for all sections where data were available. Due to the fact that experimental conditions varied from study to study, comparisons between results are difficult to make. The summary tables should therefore be viewed as a summary of work conducted so far rather than a direct comparison of results. The study by Acharya et al. [

53] was omitted as mechanical property values were not discussed. An approximation of the wt % loading of LDH in the study by Vol’fson and Nikiforov [

56] was made as limited data were available.

5.2. Carboxylated Nitrile Rubber (XNBR)

According to Thakur et al. [

57], XNBR is a terpolymer containing acrylonitrile, butadiene and monomers that have carboxyl groups such as acrylic acid and methacrylic acid. The pendant carboxyl groups can react with curing agents and provide additional curing sites. The carboxyl chains improve the intermolecular and intramolecular interactions between the chains, which leads to improved TS and loss of extension and recovery properties. While the mechanical properties of XNBR are good, the double bonds in the backbone of the rubber cause it to be sensitive to ozone and UV light [

58]. XNBR can be crosslinked using inorganic peroxides such as zinc peroxide [

47] and through ionic cluster crosslinking via metal oxides such as ZnO [

59]. A mixed system of zinc peroxide and sulphur accelerators can also be used [

60].

XNBR was used in 10 of the articles.

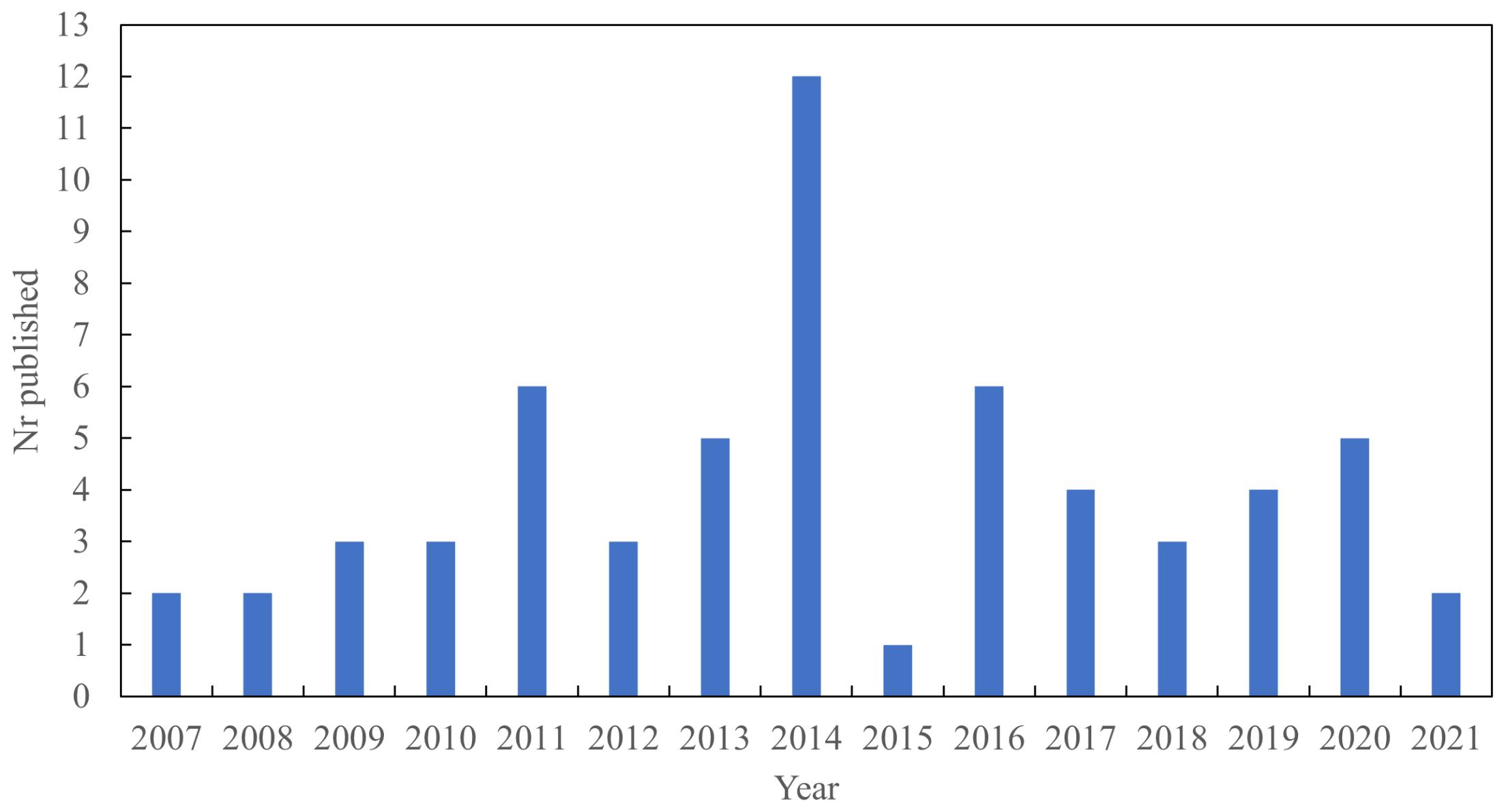

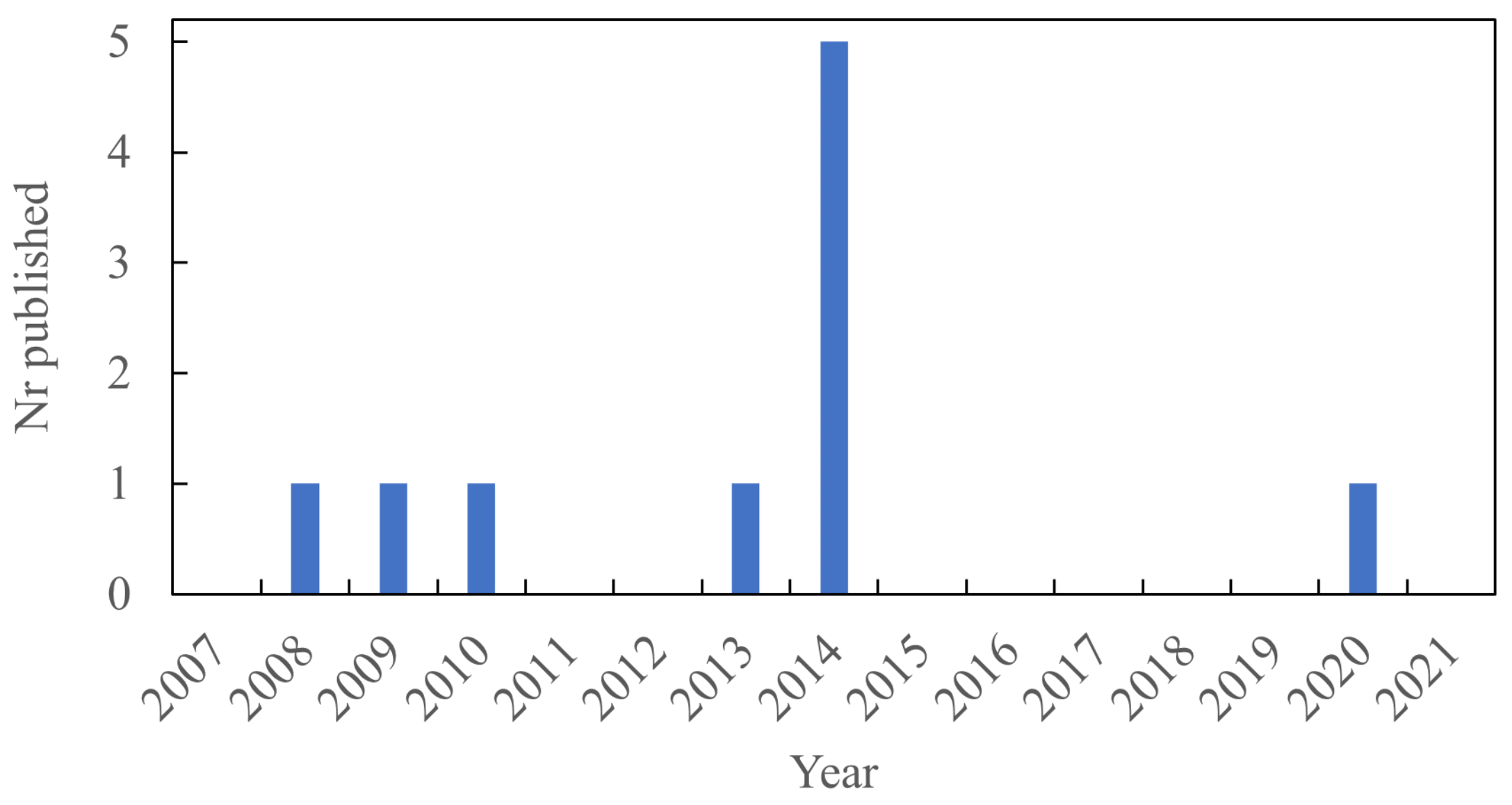

Figure 8 shows the distribution of papers published over the years. In the majority of these studies, unmodified Mg-Al LDH was used. One study used Zn-Al LDH and in two studies the LDH was modified with 1-decanesulphonate or 1-hexadecanesulphonate.

In the study conducted by Pradhan et al. [

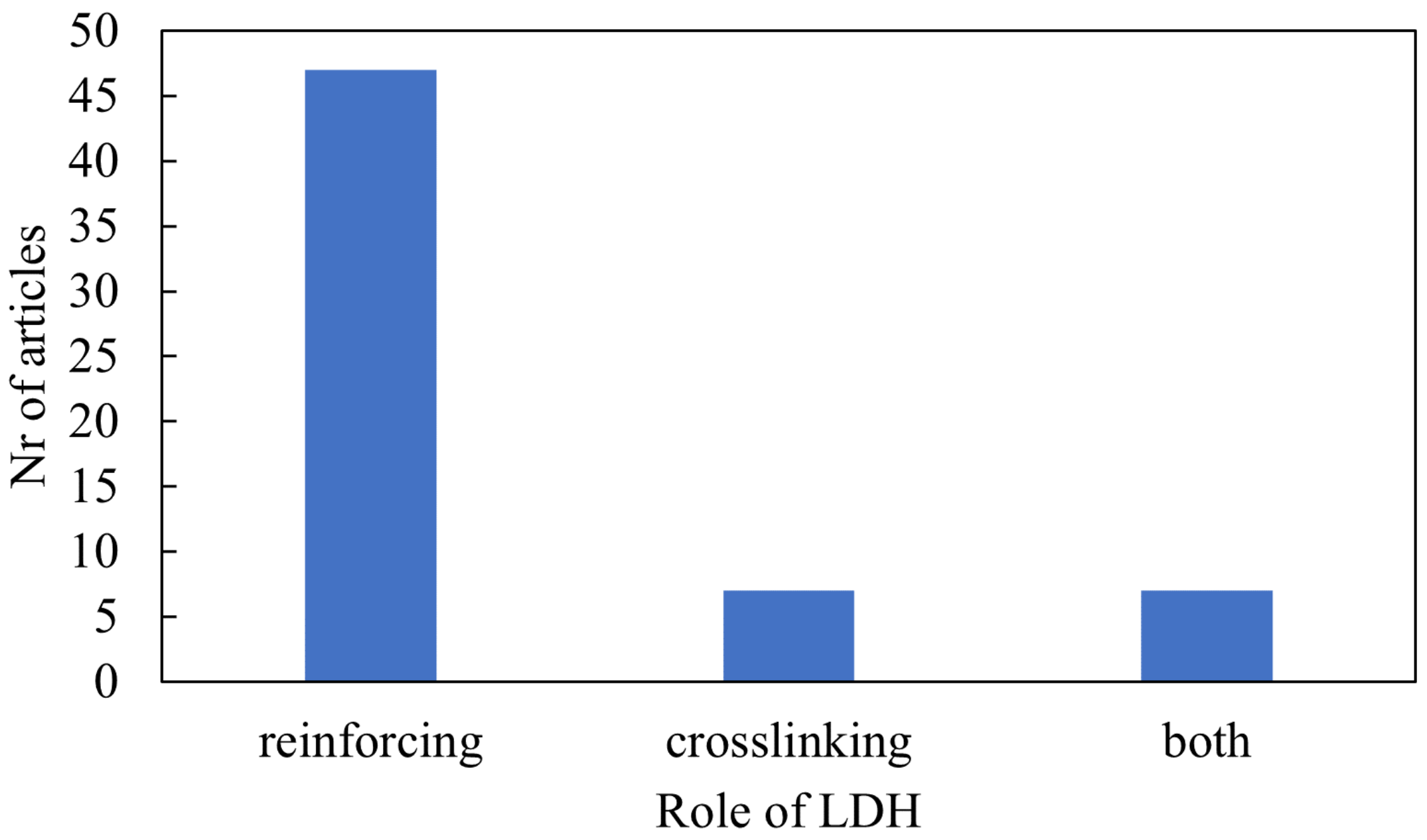

13] where XNBR was compared to EPDM, there was evidence that the 1-decanesulphonate-modified Mg-Al LDH (C10-LDH) interacted with XNBR during melt compounding. FTIR showed that reactions took place between the LDH hydroxyl groups and the XNBR carboxyl groups. XNBR chains were intercalated into the LDH interlayer. The polar nature of XNBR may have made the intercalation easier when compared to nonpolar EPDM. Exfoliation also occurred, most likely due to the strong interaction between the LDH and XNBR causing the LDH layers to be peeled apart during shear mixing. There was minimal agglomeration of C10-LDH particles in XNBR. The storage modulus and TS increased with increasing LDH content while EB decreased. This is due to the strong polymer–filler interaction. The C10-LDH increased the strain-induced crystallisation of XNBR, similar to what happens when conventional reinforcing fillers such as carbon black are used. The exfoliated particles had large surface areas and this, combined with the strong polymer–filler interaction, facilitated orientation of the XNBR chains and initiated crystallisation at lower strain. Additional crosslinks could also form due to the chemical interaction between the polar groups of the LDH and XNBR, showing that LDH can act as both a reinforcing filler and a crosslinking agent in XNBR.

Thakur et al. [

57] further investigated the effect of LDH on the cure and mechanical properties of XNBR composites containing ZnO. In order to minimise the effect of other interactions, no other crosslinking agents were added. The Mg-Al LDH was modified with sodium dodecylbenzenesulphonate (DBS-LDH). During melt compounding the organically modified LDH was shown to have greater interaction with XNBR than the unmodified LDH. While LDH has hydroxyl groups that can interact with the polar groups of XNBR, the organic modification further improved interaction by making it more hydrophobic and therefore more compatible with the hydrocarbon chains. The interlayer spacing of the LDH was also increased by the organic modifier, making it easier for polymer chains to intercalate into the LDH. The modified LDH was dispersed better in the rubber matrix than unmodified LDH and was also partially exfoliated, although there were still some agglomerates. The XNBR filled only with ZnO underwent self crosslinking through the formation of anhydride bridges. When unmodified and modified LDH was added to the XNBR, this self crosslinking was no longer observed. This indicated that the LDH may have suppressed the formation of anhydride linkages. LDH also suppressed the formation of ionic crosslinks between XNBR and ZnO. The authors suggested that this may be due to the hydroxyl groups of LDH forming coordination complexes with the zinc ions, leaving some of the carboxyl groups free in the XNBR. The organically modified LDH suppressed the ionic crosslinking to a lesser degree because the modifier prevented the LDH from entering into the coordination complex. The TS was significantly decreased by the unmodified and modified LDH due to the suppressed ionic crosslinking. The results of this work showed that LDH can interact with the crosslinking system and acts as an ionic crosslink inhibitor in XNBR. This negatively impacts the mechanical properties of the composites. Modification of the LDH reduced the inhibition but did not completely prevent the inhibition.

As shown previously, LDH can participate in the curing reactions and also affect the strain-induced crystallisation behaviour. Costa et al. [

59] investigated the influence of the organic modifier and dispersion of the LDH on the strain-induced crystallisation. Mg-Al LDH was modified with sodium 1-decanesulphonate (C10-LDH) and sodium 1-hexadecanesulphonate (C16-LDH). C16-LDH had a larger interlayer spacing than C10-LDH. As observed in previous work, the basic nature of LDH allowed it to be reactive to XNBR and participate in the crosslinking process. A very small amount of ZnO was added so that it would not significantly affect the crosslinking or interact with the organic modifiers of the LDH. The chemical interaction between the LDH and XNBR could be seen in the increase in TS of the composites. The type of modifier also had an influence on the properties of the XNBR. Before vulcanisation, C10-LDH was not dispersed as well as C16-LDH. During vulcanisation, while tactoids of both LDHs grew larger, no new C10-LDH tactoids formed while new C16-LDH tactoids formed, possibly due to exfoliated layers collapsing. This caused C16-LDH to be more poorly dispersed and have fewer exfoliated layers. While a larger interlayer spacing usually leads to more exfoliation and polymer chain intercalation, the changes during vulcanisation caused the opposite to occur. Both LDHs interacted with XNBR and caused an improvement in TS, but C10-LDH caused a greater improvement. The difference in TS was greater at higher concentrations of LDH. The C10-LDH increased strain-induced crystallisation while C16-LDH did not due to the large tactoids restricting chain movement and thus preventing the chains from aligning. The nature of the organic modifier on the can LDH therefore have a significant influence on the final properties of the XNBR composites.

Laskowska et al. [

61] investigated the effect of two ionic liquids (ILs) on the curing behaviour and mechanical properties of XNBR crosslinked with Mg-Al LDH, and NBR reinforced with silica and crosslinked using a sulphur cure system. The ILs used were hydrophilic 1-ethyl-3-methylimidazoliumthiocyanate (EMIM SCN) and hydrophobic 1-ethyl-3-methy-limidazolium bis(trifluoromethylsulfonyl)imide (EMIM TFSI). At 5 phr, EMIM SCN increased the stiffness and torque of both rubbers. At higher concentrations, the EMIM SCN reduced the torque. EMIM TFSI reduced the torque at all concentrations. This showed that the ILs had a negative effect on the formation of polar bonds between the LDH and XNBR as well as on the formation of covalent bonds in the NBR/SiO

composites. At 5 phr both ILs increased the rate of cure. The hydrophilic EMIM SCN was more effective because it better assisted in the dissolution and diffusion of crosslinking agents in the rubber. Further increasing the IL concentration decreased the rate of cure for both rubbers. Initially EMIM TFSI decreased the scorch time (t

) and optimum cure time (t

) but further increased the concentration decreased the rate of cure. EMIM SCN decreased the t

of the NBR/SiO

composites but not of the XNBR/LDH composites. A value of 5 phr EMIM SCN increased the modulus of both rubber composites but a further increase in IL concentration reduced the modulus. EMIM TFSI decreased the modulus at all concentrations. EMIM SCN increased the TS at 5 phr and then decreased the TS at higher concentrations for both rubbers. It decreased the EB at all concentrations. EMIM TSFI increased the TS and EB at all concentrations. At 5 phr both ILs increased the crosslink densities but the crosslink densities decreased with increasing IL content. EMIM SCN did not affect the T

of the XNBR composites and EMIM TFSI lowered the T

with increasing IL content due to a plasticising effect. In the case of NBR, EMIM SCN decreased the T

slightly with increasing IL content but EMIM TFSI did not have any effect. The plasticising effect may have been inhibited by the silica adsorbing the IL. This did not occur in the composites containing LDH. Hydrophobic EMIM TFSI improved dispersion of the LDH and silica. The authors speculate that this could be due to the fillers being coated in a layer of IL as well as adsorption of the IL, which decreased the polarity of the filler surfaces and increased compatibility with the rubber.

Marzec et al. [

62] continued the work on using ILs in XNBR crosslinked with Mg-Al LDH. They used two ILs, namely 1-butyl-3-methylimidazolium bis(trifluorome-thylsulfonyl)imide (BMIM TFSI) and 1-butyl-3-methylimidazolium tetrachloroaluminate (BMIM AlCl

) at various concentrations. The first is hydrophobic and the second is hydrophilic. BMIM AlCl

increased the crosslink rate and decreased the scorch time and optimum cure time even at a relatively high loading of 15 phr. BMIM TFSI did not seem to affect the curing characteristics of the XNBR. BMIM AlCl

also increased the crosslink density of the XNBR with increasing IL content while BMIM TFSI decreased it. This was due to the BMIM TFSI being adsorbed onto the LDH surface, decreasing the interactions between the LDH and rubber. BMIM AlCl

decreased TS and EB with increasing IL content and increased the modulus at 2.5 phr but decreased it again at higher concentrations of IL. This is due to the high crosslink density and reduced mobility of the polymer chains. On the other hand, the TS and EB of the BMIM TFSI composites increased, reached a maximum and then decreased with increasing IL content. All modulus values where BMIM TFSI was used were lower than for the neat XNBR/LDH composite. BMIM TFSI acted as a plasticising agent and did not affect the crosslink structure, which is why it had this effect on the mechanical properties. The plasticising effect also caused a decrease in the T

and the storage modulus. BMIM AlCl

did not affect the T

as much, although it did lower the T

somewhat.

This research group also compared the effect of EMIM TFSI, BMIM TFSI and 1-hexyl-3-methylimidazolium bis(trifluoro-methylsulfonyl)imide (HMIM TFSI) on the properties of XNBR cured with Mg-Al LDH [

63]. Adding ILs decreased the t

and t

values and increased the cure rate index (CRI) values compared to when no IL was used. The TFSI anions therefore accelerated the curing process. The amount and type of IL did not have a significant effect. HMIM TFSI had the greatest plasticising effect in the rubber because it has the longest alkyl chain, and decreased the viscosity of the uncured rubber. At low concentrations the EMIM TFSI and BMIM TFSI slightly increased EB and TS but as the IL concentration was increased the TS decreased. The plasticising effect of HMIM TFSI decreased the TS compared to neat XNBR/LDH at all concentrations. The ILs decreased the crosslink density of the rubber, which showed that they hindered the rubber–filler interactions that formed the ionic crosslinks. EMIM TFSI had the smallest negative impact on the properties. The T

was decreased by all three ILs due to their plasticising effect, and the decrease in T

was largest for the IL with the longest alkyl chain (HMIM TFSI).

Laskowska et al. [

58] continued their work on using unmodified Mg-Al LDH in XNBR and showed that LDH can be an effective ionic crosslinking agent for XNBR in the place of ZnO. They showed that ionic bonds formed when LDH was used without any ZnO present and that the crosslinking density increased with increasing LDH content. At low concentrations the LDH cure resulted in a lower crosslink density than ZnO, but the 10 phr LDH composite had a higher crosslink density than the 5 phr ZnO composite. The LDH-cured XNBR composites had lower scorch times and CRIs than ZnO-cured XNBR. Because the crosslink density increased with increasing LDH content and the XNBR and LDH had strong polar interactions, the T

, TS and storage modulus increased while EB decreased in comparison to neat XNBR. The ZnO-cured composite had lower EB and higher TS values than any of the LDH-cured composites but LDH improved the tear strength more than ZnO at higher loadings. An ionic transition, associated with the formation of ionic clusters, was observed for all the composites in the DMA results. The LDH composites had lower ionic transition temperatures than the ZnO composite. LDH can clearly be used as both a reinforcing filler and a crosslinking agent in XNBR.

Laskowska et al. [

64] found that the Mg content, aspect ratio and surface area of the LDH have an effect on the properties of XNBR. They added unmodified Mg-Al LDH with varying Mg:Al ratios and aspect ratios to XNBR and found that increasing the Mg content increased the cure efficiency, number of ionic bonds in the rubber, crosslink density, TS and storage modulus. A larger surface area and aspect ratio also increased the curing efficiency due to the increased interaction between the LDH and XNBR. This increased interaction also led to an increase in mechanical properties, although it also decreased EB. As shown previously, LDH can crosslink XNBR [

13], which is why the Mg content and interaction affects curing efficiency. Adding LDH to the XNBR increased the T

but the Mg:Al ratio and filler loading did not affect how much the T

was shifted.

In ionic elastomers such as XNBR, the ionic clusters formed during crosslinking affect the mechanical properties of the rubber. The clusters exist as a large number of ion pairs as well as hydrocarbons [

65]. ZnO can be used as an ionic activator but the use of ZnO results in scorchiness, poor flexibility and high compression set [

49]. Basu et al. [

17] compared Zn-Al LDH, ZnO and ZnCl

in metal oxide and sulphur cures and investigated the nature of the ionic interactions in XNBR. They found that in the metal oxide cure these Zn-containing compounds all formed crosslinks through forming coordination complexes. The ZnO-cured compound was the only one to show a second, high temperature transition. The authors proposed that the ZnO reacted with carboxylate groups and formed a three-dimensional polymeric network through formation of coordination complexes. The crosslinked network could then act as a separate phase with its own T

. The LDH and ZnCl

did not coordinate to form a polymeric network structure. In the sulphur cure, LDH was more efficient than ZnO at equivalent concentrations of Zn, resulting in higher crosslink density.

It was previously shown that the Mg:Al ratio influenced the properties of XNBR [

64] and the effect of the Mg:Al ratio and surface area of LDH on the properties of XNBR was further investigated by Lipińska et al. [

66]. In XNBR cured only with LDH, the optimal curing time and the onset curing temperature increased as the Al content of the LDH was increased. Increasing the surface area of the LDHs increased the availability of hydroxyl groups and cation sites, which increased the rate of cure. Curing could take place through polar interactions between XNBR and LDH as well as through the formation of ionic crosslinks between the LDH metal ions and carboxylic groups of XNBR. This is why an increased Mg content increased the curing efficiency through promoting the formation of the more ordered ionic phase. Increasing the Mg content of the LDH increased the polymer–filler interfacial interaction and decreased the filler–filler interactions.

Table 2 summarises the effect of the LDHs on the properties of XNBR. In cases where more than one loading was used, the loading that resulted in the highest TS was used as the point of comparison and where different types of LDHs were used, all types are shown in the table.

5.4. Polyurethane (PU)

PUs are polymers that have urethane groups and can thus form hydrogen bonds. PU elastomers are a subset of PU polymers. They have high chemical abrasion resistance and have good mechanical properties [

70]. PU elastomers have soft and hard segments. The soft segments provide most of the elastomeric properties and the hard segments provide tie points that act as crosslinks and as reinforcing fillers [

2]. PU can be crosslinked using peroxide crosslinking [

45].

There are 16 papers published on the effect of LDH on PU that fit the criteria of the systematic literature review.

Figure 9 shows the distribution of papers published.

Dodecyl sulphate-modified Mg-Al LDH (DS-LDH) was added to PU by Kotal et al. [

71] to investigate the effect of LDH on the properties of the rubber. The DS-LDH was intercalated and partially exfoliated in the polymer matrix. The hydroxyl groups of DS-LDH interacted with the polar groups of PU. This strong interfacial interaction and exfoliation enhanced stress transfer and increased the TS as the DS-LDH concentration was increased. The EB increased because of the the polymer chains becoming entangled as well as the synergy between chain slippage and DS-LDH platelet orientation. The DS-LDH particles acted as barriers to crack propagation, causing secondary cracks to form at the rubber/filler interface. During deformation, microvoids formed around the DS-LDH particles. The microvoid formation absorbed energy and enhanced the mechanical properties. DS-LDH also improved the thermal stability of PU. The mechanical properties and thermal stability increased, reached a maximum and then decreased as the DS-LDH concentration was increased. This is because agglomerates formed at higher concentrations of DS-LDH that weakened the polymer–filler interaction. Organically modified LDH can therefore be used to enhance the mechanical properties and thermal stability of PU, although when the LDH loading becomes too high the reinforcing and stabilising effect is reduced due to agglomeration.

Kotal et al. [

41] prepared 50:50 weight ratio PU/NBR blends containing Mg-Al LDH-modified with dodecyl sulphate (DS-LDH) at different loadings. Partial exfoliation and polymer chain intercalation took place, although agglomeration occurred at higher loadings of DS-LDH. The LDH hydroxyl groups could interact strongly with the polar groups of PU and NBR. This improved interfacial adhesion which, combined with good dispersion, enabled efficient stress transfer and increased the stiffness of the composites. This in turn improved the TS of the composites. EB was improved by the polymer chains becoming entangled around the DS-LDH platelets through chain slippage and platelet orientation. This improvement in mechanical properties was, however, only observed at the lowest loading of DS-LDH. As the DS-LDH loading was increased, the mechanical properties started to decrease. This was most likely caused by the presence of agglomerates at higher DS-LDH loadings that weakened the rubber–filler interaction and promoted crack growth. The storage and loss moduli increased, reached a maximum and then decreased again with increasing DS-LDH content. The increase in storage modulus was due to the strong rubber–filler interactions restricting polymer chain movement, while the increase in loss modulus was due to the dispersion and high aspect ratio of the DS-LDH platelets increasing the friction between the rubber and filler. The restricted chain movement also caused an increase in T

at lower LDH concentrations. DS-LDH also increased the thermal stability of the polymer blend, similarly to what has been observed in previous studies.

The effect of dodecyl sulphate-modified Mg-Al LDH (DS-LDH) on the properties of PU was investigated further by Kotal and Srivastava [

72], particularly the effect on shear and peel strength. At low loadings the LDH was partially exfoliated and at higher levels agglomeration occurred and dispersion was poor. Their previous work showed that the improvement in TS and EB reached an optimum [

71]. The DS-LDH made the composites more stiff, increasing the storage modulus. The T

was increased by adding DS-LDH due to the interaction between PU and LDH restricting polymer chain movement. The storage modulus and T

decreased again at higher loadings of LDH. The lap shear strength and peel strength were both increased by addition of DS-LDH. The adhesive strength of the PU was increased by the improved lap shear and peel strength as well as the strong interaction between the LDH and PU. At higher loadings of LDH the improvement in the properties was less due to the presence of agglomerates.

Kotal et al. [

73] did another study using PU, but modified the Mg-Al LDH with sodium stearate (St-LDH). At low loadings, the St-LDH layers were exfoliated, but at higher levels polymer chains intercalated into the St-LDH layers and distribution became inhomogeneous. The St-LDH hydroxyl groups underwent hydrogen bonding with the PU. The authors also predicted whether the mixing of LDH and PU is favourable by using the thermodynamic relationship in Equation (

1) for PU and St-LDH [

74].

The mixing of LDH and PU was determined to be favourable because the total change in Gibbs free energy, as given by Equation (

2), was negative at 8 wt % St-LDH.

The mechanical properties of PU were improved by the addition of St-LDH. The increase in TS and modulus were at a maximum at the lowest LDH loading and decreased with increasing LDH content. At the lowest loading, 1 wt % St-LDH, the exfoliation was best, which may explain why the reinforcement was best at this loading. The high degree of exfoliation and large aspect ratio of the LDH particles enhanced the interfacial interaction between the DS-LDH and PU via hydrogen bonding. As the St-LDH loading was increased, the filler–filler interaction became greater and agglomerates formed, thus decreasing the interaction between LDH and PU and lowering the TS. The high aspect ratio as well as the development of shear zones was most likely responsible for the increase in modulus. The EB was also increased by St-LDH. The increase reached a maximum at a higher concentration than the TS. The bonding between St-LDH and PU enabled the composite to resist breaking when it was extended, but the improvement in EB may also have been due to the stearate anion having a plasticising effect caused by its long alkyl chain. At higher loadings where the EB started to decrease, the agglomerated St-LDH particles restricted chain movement and thus the shear deformation of the PU was reduced. This led to a decrease in EB. In comparison to the previous work performed with DS-LDH [

71], the improvement in EB was larger for St-LDH. This may be because the stearate anion’s longer hydrocarbon chain gave the matrix more flexibility. This may also have caused the decrease in modulus values. The T

of the composites increased with increasing St-LDH content due to the restricted chain movement. The storage and loss moduli also increased with increasing St-LDH content due to increased friction between the filler and polymer as well as the restricted chain movement. This restricted mobility of the polymer chains at the polymer filler interface also reduced the height of the tan(

) peak and broadened it. St-LDH also proved to be a good thermal stabiliser for PU. The barrier effect of the exfoliated St-LDH layers as well as the endothermic decomposition of LDH helped to increase the thermal stability of the composite.

In the same year, Kotal and Srivastava [

75] found that organically modified Mg-Al LDH had a syngergistic effect with methylenediphenylene diisocyanate (MDI) and isophorone diisocyanate (IPDI) in PU. MDI and IPDI were successfully grafted into stearate and dodecyl sulphate-modified LDH (St-LDH and DS-LDH). The organic modification of the LDH increased the interlayer spacing of the LDH and allowed the MDI and IPDI to enter the interlayer and react with the hydroxyl groups of the LDH. The intercalation of MDI and IPDI did not occur when the LDH was unmodified, which showed the importance of increasing the interlayer spacing through organic modification. The modified MDI-LDH and IPDI-LDH were uniformly dispersed in the PU matrix and were exfoliated. The unmodified MDI-LDH and IPDI-LDH formed agglomerates. The MDI-St-LDH dispersed best and had the most exfoliation. There was also evidence of hydrogen bonding between the PU and modified and unmodified LDHs. The modified MDI-LDH and IPDI-LDH composites improved the TS more than unmodified MDI-LDH and IPDI-LDH or DS-LDH and St-LDH. This shows that the organic modifiers and MDI and IPDI have a synergistic effect. The stearate-modified MDI-LDH and IPDI-LDH composites had the largest increase in TS due to the chemical bonding between the isocyanate grafted St-LDH and PU. The MDI-grafted LDH composites had a smaller improvement in EB than their IPDI counterparts. The MDI-grafted LDHs restricted chain movement more than the IPDI-grafted LDHs, which increased the stiffness of the composite and decreased EB. The MDI-St-LDH composite had the highest crosslink density and the authors suggest that this is due to the MDI being more reactive than IPDI. All LDH composites had a higher thermal stability than neat PU but the greatest increase was in the MDI-St-LDH composite. This composite had good dispersion, which means the barrier effect of the LDH was effective. The T

of the composites containing MDI and IPDI grafted LDH increased. The stearate-modified MDI-LDH had the greatest increase in T

. The interaction between the filler and polymer restricted chain movement which increased the T

, showing that MDI-St-LDH had the best interaction with PU.

Guo et al. [

76] found that adding dodecyl sulphate-modified Co-Al LDH to PU improved the mechanical properties and improved the flame retardancy of the composite. At low loadings, the LDH was exfoliated in the polymer matrix. At higher LDH loadings intercalation of polymer chains into the LDH occurred. The exfoliation of the particles and strong interaction between LDH and PU enabled efficient stress transfer from the PU, which helped improve the mechanical properties. The large aspect ratio of the LDH particles also helped with elastic deformation. These factors increased the static adhesion strength and interfacial stiffness and improved the mechanical properties compared to neat PU. The well-dispersed LDH platelets caused small voids to form during strain. This void formation dissipated energy, which increased the amount of strain the composite could withstand and increase the mechanical properties. At higher LDH loadings, agglomeration decreased the mechanical properties. TGA data showed a reduction in thermal stability, possibly due to the Co-Al LDH catalyzing the degradation of the amide group in PU. However, the barrier effect of the LDH slowed the rate of thermo-oxidised degradation.

Kotal et al. [

77] further investigated the effect of stearate-modified LDH (St-LDH) on the properties of PU. They used in situ polymerisation to incorporate the St-LDH into the PU and then crosslinked the mixture. The PU chains were intercalated into the St-LDH, and the LDH layers were exfoliated and well dispersed, although agglomerates started to form at higher loadings. FTIR showed that hydrogen bonding occurred between the LDH and PU and that a urethane linkage formed between the -OH groups of LDH and the -NCO groups of the prepolymer. TS and EB were both increased by the addition of St-LDH. The increase in TS, EB and tensile modulus all reached a maximum at 3 wt % St-LDH before decreasing again due to agglomeration at higher loadings. The increase in mechanical properties occurred at a higher loading of St-LDH than in the previous study [

73]. The high surface area of the St-LDH particles, caused in part by exfoliation and hydrogen bonding, led to better polymer–filler interaction, which in turn improved the stress transfer efficiency from the PU and increased TS. The long hydrocarbon chain of the stearate anion had a plasticising effect, which increased EB. Chain slippage and platelet orientation may also have contributed. The tensile modulus was most likely improved due to the large aspect ratio and reinforcing effect of the LDH as well as the formation of shear zones during deformation. The strong interaction between St-LDH and PU also increased the storage modulus and lowered the tan(

) peak due to the polymer chain movement becoming restricted. At higher LDH loadings, the filler–filler interaction started to dominate over the filler–polymer interaction which decreased the storage modulus. The restricted polymer chain movement also increased T

, but at higher loadings of LDH T

decreased again due to the plasticising effect of the stearate anion dominating over the reinforcing effect. The barrier effect of the LDH particles also increased the thermal stability of the composites. This study shows that proper dispersion of the LDH in the rubber matrix plays an important role in how much the properties of the PU are improved and that stearate has a plasticising effect in PU.

PU can be used as a shape memory polymer that can maintain a temporary shape after deformation and be restored to its original shape after being exposed to a stimulus such as heat, water or light [

78]. The shape memory ability is related to the crystallinity of the soft segments in PU [

78]. Phua et al. [

79] used two sizes of polydopamine coated Mg-Al LDH (D-LDH), one large and one small, to enhance the mechanical and shape memory properties of polycaprolactone-based PU. The polydopamine coating improved the dispersion of LDH in the PU but agglomeration still occurred at higher concentrations of LDH. Uncoated LDH did not have any beneficial effects on the properties of PU. The D-LDH particles acted as nucleating agents due to the polydopamine coating forming hydrogen bonds with the PU hard segments. The large LDH particles negatively affected strain recovery because they connected hard segments to each other by passing through soft segments. Unlike uncoated LDH, the D-LDH promoted crystallisation on the soft and hard segments of PU, though the smaller LDH particles performed better. The enhanced crystallisation led to better shape memory properties because the stretched soft segment chains had restricted movement, preventing them from relaxing. The hard segment crystallisation and reinforcing effect of the LDH also enhanced stress recovery. The better interaction between the small LDH particles and PU led to more effective stress transfer and therefore better reinforcement. The presence of the coating enhanced the shape memory properties of PU. Particle size and LDH coating both affect the final properties of the composite.

Yu et al. [

80] investigated the effect of dodecyl sulphate-modified Mg-Al LDH (DS-LDH) and the presence of dangling chains on PU in a PU/PMMA blend. They found that increasing the LDH content increased the stiffness of the polymer. Chain mobility became more restricted as the free volume in the polymer was reduced by interaction between the LDH and polymer, increasing T

. The damping ability of the polymer blend was increased due to a synergistic effect between the dangling chains of the PU and the LDH. The dangling chains moved with the polymer backbone chain and increased resistance to motion and internal friction between the polymer, dangling chains and filler. The LDH itself also increased internal friction, increasing the damping ability. For this reason the composites with dangling chains had higher tan(

) values than the composites without dangling chains.

One of the methods that can be used to incorporate LDH into an elastomer such as PU is by using in situ polymerisation. Dispersion of the LDH elastomer affects the mechanical properties, as has been shown in many of the studies already discussed here. Carmo et al. [

81] used different methods of dispersing LDH into a PU prepolymer and investigated which method resulted in the best dispersion of the LDH. They used four dispersion sequences:

TBT: 30 min ultraturrax, 2 h ultrasound bath, 5 min ultraturrax;

TST: 30 min ultraturrax, 1 min sonication, 5 min ultraturrax;

T: 30 min ultraturrax;

B: 2 h ultrasound bath.

They found that the TBT, TST and T methods all promoted exfoliation and intercalation during polymerisation, and that the TBT method was best at promoting this. TBT and T resulted in the least filler–filler network formation, which lowered the Payne effect in these samples. This showed that these methods dispersed the LDH well and promoted polymer–filler interaction. All methods increased the T due to the polymer–filler interaction, with the T method increasing it the most. The LDH increased the storage modulus regardless of the dispersion method used. The storage modulus was lowest when the T method was used. This may have been due to the LDH hydroxyl groups interacting with the isocyanate groups and preventing them from participating in the polymerisation, ultimately reducing crosslink density. TBT reduced the amount of free isocyanate the most, meaning it caused the most intercalation into the LDH. The B method did not perform well in comparison to the other methods. Overall, the TBT method was most effective as it could destroy clusters and deagglomerate smaller particles.

Zhang et al. [

82] grafted

-aminopropyltriethoxysilane (APS) onto dodecyl sulphate-modified Mg-Al LDH (APS-DS-LDH) and added it to PU. Grafting APS onto DS-LDH improved the interfacial interaction between the filler and rubber. As the APS-DS-LDH content increased, the T

of the soft segments decreased. The authors stated that this was due to stronger interaction between the PU and APS-DS-LDH, contrary to what most other studies have observed. The general trend is that the T

is increased as interaction between the polymer and LDH is increased, restricting chain movement. This observation may be due to interaction between the modifier and polymer, although typically using dodecyl sulphate as a modifier does not decrease the T

. The strong interaction between the filler and polymer increased phase separation between the hard and soft segments of the PU. The damping properties of PU were increased because the internal friction between the polymer and filler increased with increasing APS-DS-LDH content. At higher levels the damping properties decreased again due to agglomeration causing filler–filler interaction to dominate over filler–polymer interaction and reducing the friction between APS-DS-LDH and PU. Hydrogen bonding occurred between the polar groups of the modified LDH and PU increased the interfacial interaction between the polymer and filler. This increased the TS. The strong interfacial interaction between APS-DS-LDH and PU combined with the plasticising effect of the dodecyl sulphate chain increased EB. The APS and dodecyl sulphate hydrocarbon chains increased the flexibility of the PU matrix which caused a decrease in the modulus. APS-DS-LDH also increased the thermal stability of PU.

Work had previously been done on the synergistic effect of carbon nanotubes (CNT) and LDH in silicon rubber [

83]. CNT and LDH both tend to form agglomerates in organophilic materials such as rubber [

84], limiting their usefulness. Roy et al. [

85] investigated the effect of combining Mg-Al LDH with organically modified CNT in a 50:50 wt % ratio PU/NBR blend. They found that at a low loading of 0.5 wt % filler, EB increased by 180% and TS improved by 171%. They modified CNT with sodium dodecyl sulphate and then mixed it with LDH to form a DS-CNT-LDH hybrid. The hybrid filler formed a three-dimensional network and the modified CNTs were uniformly distributed on the surface of the LDH platelets due to the interaction between the LDH and sulphate groups on the modified CNT. The hybrid filler was partially exfoliated in the rubber matrix and a filler network formed in the rubber. At higher filler concentrations, agglomeration started to occur. This decreased the mechanical properties by creating sites for failure initiation. The hybrid filler increased the storage modulus, TS and EB compared to the neat blend. This indicates that DS-CNT-LDH has a reinforcing effect caused by good dispersion and interaction between the rubber and filler that allows efficient stress transfer. The reinforcing effect was more pronounced at lower loadings due to less agglomeration than at higher loadings of DS-CNT-LDH. The polymer–filler interaction also restricted polymer chain mobility which caused an increase in T

and melting temperature (T

). The crystallisation temperature (T

) was increased due to the DS-CNT-LDH acting as a nucleating agent. The LDH and CNT, when tested individually, improved the mechanical properties of the rubber much less than when the two components were used together. This shows that the LDH and CNT had a syngergistic effect in the rubber.

Roy et al. [

86] also created hybrids with Zn-Al LDH and CNT and carbon nanofibers (CNF) by modifying the CNT and CNF with sodium dodecyl sulphate and then mixing them with the LDH. These were added to a 50:50 weight ratio PU/NBR blend. Both the CNT-LDH and CNF-LDH fillers formed uniformly distributed network structures at low loadings, but agglomeration occurred at higher loadings. Both hybrid fillers had a reinforcing effect in the rubber, improving TS and EB. A syngergistic effect between the LDH and modified CNT as well as between the LDH and CNF was observed because the individual components of the hybrids did not improve the mechanical properties as much as the hybrids did. CNT-LDH caused greater improvement in the mechanical properties than CNF-LDH and also increased the T

more, which shows that it has better interaction with the polymer than CNF-LDH.

Roy et al. [

87] did another study using a 50:50 weight ratio PU/NBR blend in which they made hybrids of dodecyl sulphate-modified CNF and Mg-Al LDH. The LDH particles had a high affinity towards the modified CNF and attached to the side walls of the CNF. The DS-CNF-LDH was partially exfoliated in the rubber matrix. There was strong interaction between DS-CNF-LDH and the rubber, which was reflected in the increase in storage modulus, loss modulus and T

, and the decrease in the tan(

) peak at lower filler concentrations. The strong interfacial interaction also increased TS and EB. The improvement in mechanical properties was higher for the hybrid than when the individual components were used. This is similar to what was observed previously [

85,

86].

Srivastava et al. [

88] compared the ability of MMT and Mg-Al LDH to improve the shape memory behaviour of PU. The MMT was better dispersed than the LDH. Both fillers had a nucleating effect in the soft segments of the PU, which caused crystallisation behaviour, although the MMT performed better. The good dispersion and better crystallisation when MMT was used caused the shape recovery efficiency of the MMT composite to be better. LDH increased the modulus of the PU more than MMT and decreased the TS but slightly less than MMT. The LDH decreased EB the most.

Multiple methods have been used so far to incorporate LDH into PU. Typically the LDH is organically modified and then mixed into the polymer via physical dispersion, solution blending [

72,

76] or in situ polymerisation [

77,

82]. In the case of solution blending, the LDH is synthesised, modified and then dispersed in tetrahydrofuran (THF). The PU is then added and the mixture is dried [

71]. In the case of in situ polymerisation, the LDH is synthesised and modified and then added to the prepolymer dissolved in THF and then crosslinked [

77]. Starukh et al. [

89] tried to simplify the process of incorporating LDH into PU by physically modifying the prepolymer linear macro diisocyanate (MDI). Mg-Al LDH was modified with dodecyl sulphate (DS-LDH) and dispersed in MDI diluted in THF. After this, the PU films were prepared using this MDI mixture. The LDH was partially exfoliated and hydrogen bonds most likely formed between MDI and LDH. The TS and EB were both significantly increased by adding the DS-LDH due to the interaction between the polar groups of the LDH and PU. The results were compared to the results of studies conducted with LDH incorporated using in situ polymerisation and physical dispersion and it was found that these results were comparable to when the other methods were used. A direct comparison with the same LDH loading, LDH type and modifier was not performed but this study showed that this method of incorporating LDH into PU is viable.

Table 4 summarises the effect of LDH on the properties of PU.

5.5. Natural Rubber (NR)

NR is usually tapped from the rubber tree,

Hevea brasiliensis, and makes up a significant portion of most tires, especially in high performance tires such as aeroplane tires [

90]. It can be crosslinked using sulphur vulcanisation or peroxide cure [

91]. It is typically reinforced using carbon black, although silica is also used [

92].

Three articles relevant to the literature review criteria have been published, one in 2010, one in 2013 and one in 2021. Zn-Al LDH was used in the first study and Mg-Al LDH was used in the other two. The modifiers used were dodecyl sulphate and hydrogenated fatty acid and in the third study IL was used together with LDH but the LDH was kept unmodified.

Adhha Abdullah et al. [

93] compared the effect of Zn-Al LDH modified with dodecyl sulphate (DS-Zn-Al LDH) to unmodified Zn-Al LDH on the properties of NR. They did not compare the results to NR containing no LDH. The NR chains did not intercalate into the unmodified LDH and the LDH was present as agglomerates in the rubber matrix. Organic modification increased the interlayer spacing of the LDH, which allowed NR chains to intercalate. The DS-Zn-Al LDH was also exfoliated in the NR. In the case of unmodified LDH, the TS decreased with increasing LDH content. The DS-Zn-Al LDH was better dispersed and intercalated, and had better interfacial interaction with the NR, which caused an increase in TS. The TS of the modified LDH composites was higher than for the DS-Zn-Al LDH composites at the same loading. Increasing the DS-Zn-Al LDH content improved the TS up to a maximum increase at 7 phr before decreasing again. The decrease in TS at higher loadings was most likely caused by the formation of agglomerates or poor dispersion. This work showed that organic modification improved the reinforcing properties of LDH due to increased compatibility, and created the possibility of exfoliation and intercalation of polymer chains into the LDH.

MMT is also a layered clay but is cationic, whereas LDH is anionic. Modified and unmodified MMT and Mg-Al LDH were added to a NR/cis-1,4-polybutadiene blend to determine the effect of the clays on the mechanical properties and curing behaviour of the rubber by Bottazzo et al. [

94]. They modified the LDH with a hydrogenated fatty acid (HFA-LDH) and the MMT with dimethyl dihydrogenated tallow quaternary ammonium and methyl tallow bis-2-hydroxyethyl quaternary ammonium. The organic modification of both clay types improved the interaction between the clay and rubber and increased crosslinking. Both modified and unmodified LDH increased the scorch time and CRI. This may be due to the LDH inactivating the vulcanisation agent partially, increasing the scorch time, and then acting as a catalyst and increasing the CRI. This behaviour may be due to the formation of coordination complexes between the LDH and ZnO, as discussed by Thakur et al. [

57]. The anionic modifier on the LDH slowed the curing reaction, whereas the organic modifiers on MMT accelerated it. This could be seen in the lower CRI of the modified LDH composites. Both the modified and unmodified LDH decreased the TS of the rubber while the organically modified MMT increased the TS. The poor TS of the LDH composites may be due to the formation of agglomerates and poor interaction with the rubber. All the clays decreased EB because the clays themselves and the increased crosslink density increased the stiffness of the rubber. The organically modified LDH also reduced abrasion resistance due to poor dispersion in the polymer matrix. These results show that both the nature of the clay and the organic modifier play a role in how the properties of the rubber are affected.

The same group that worked on using ILs in XNBR cured with LDH also compared the effect of ILs on the properties of NR composites containing Mg-Al LDH, cellulose and silica [

95]. The focus of this discussion will be on the composites containing LDH. They compared 1-butyl-3-methylimidazolium bromide (BmiBr) and 1-butyl-1-methylpyrrolidinium bromide (BmpyrBr) at the same concentrations. FTIR showed that the LDH formed filler–filler and polymer–filler interactions and that the addition of the ILs did not affect these interactions. In comparison to neat NR, adding LDH lowered the t

and adding BmiBr to the LDH composite further decreased it, whereas adding BmpyrBr increased the t

to a value similar to neat NBR. The scorch time was lowered slightly in the LDH composites compared to neat NR and both ILs decreased it further to a small extent. The maximum torque was increased by adding ILs which may have been due to an increase in crosslink density. In comparison to when silica was used as filler, the effect of the LDH was less pronounced. The cellulose results were similar to that of the LDH composites. Swelling tests showed that, compared to neat NR, LDH caused a significant increase in crosslink density. This may have been due to the LDH participating in the crosslinking by acting as an activator, similarly to ZnO, by providing metal ions. The authors suggested that the alkaline nature of LDH may also have played a role, since sulphur vulcanisation favours alkaline conditions. The other two fillers are both hydrophilic and as such were not compatible with the NR and did not increase the crosslink density as much. Adding the ILs further increased the crosslink density regardless of filler type. BmiBr increased the crosslink densities more than BmpyrBr did. The increase in crosslink density when ILs were added was due to the improved dispersion of the crosslinking additives in the rubber matrix, improving the efficiency of the crosslinking process. The T

was not affected by the three fillers or by the ILs. The authors reported that the differences in T

were within the range of experimental error and as such the influence of these additives was not significant. Adding LDH to the NR increased the modulus and TS and decreased the EB. The ILs, in combination with LDH, further increased the modulus and TS, with BmiBr increasing it the most. The ILs also further decreased the EB, with BmiBr decreasing it the most. This corresponds to the changes in crosslink density of the composites containing LDH. In comparison to the other fillers, LDH had the greatest reinforcing effect as well as the highest crosslink density, which resulted in these composites having the highest TSs. The EB of the filled composites was decreased due to the increased stiffness caused by the presence of the fillers and the increased crosslink density. The fillers decreased the tan(

) peak due to the increased stiffness that reduced chain mobility. LDH influenced the tan(

) peak the least and silica the most. The ILs did not affect the tan(

) values. Addition of ILs decreased the thermal stability of all the composites, with BmpyrBr decreasing it the most. Silica and cellulose increased the onset decomposition temperature whereas LDH decreased it. The NR composites remained thermally stable up to 300

C regardless of filler type. This work showed that ILs can enhance the mechanical properties of NR composites containing these three fillers and help to increase the stiffness of the rubber composites.

Table 5 summarises the effect of LDH on the properties of NR. In the first entry, the only comparison available was between modified and unmodified LDH and the percentage change is therefore from unmodified LDH to modified LDH rather than from neat NR to NR containing LDH like the other entries.

5.6. Silicone Rubber (SR)

SR contains polar Si-O groups in the backbone, making it unique in having both organic and inorganic properties. SR can be crosslinked using organic and metal peroxide crosslinking or via electron beam crosslinking [

47,

96]. The Si-O groups in this rubber give it very good heat, cold, abrasion and ozone resistance, chemical stability, weatherability and electrical insulation properties, making SRs useful in many fields, such as the automotive, construction, electronic and food industries [

97].

There are four articles on the effect of LDH on the mechanical properties of SR. They were published in 2011, 2012, 2014 and 2020. The LDHs used in SR were Mg-Al LDH, Li-Al LDH and Co-Al LDH, and the modifiers used were dodecyl sulphate and stearate, although unmodified LDHs were also used.

Inorganic nanofillers such as LDH can be used to improve the properties of SR. Pradhan et al. [

98] modified Mg-Al LDH with dodecyl sulphate (DS-LDH) and found that compared to neat SR, addition of DS-LDH improved the TS and EB, toughness, thermal stability and solvent uptake resistance, although the properties decreased at higher loadings due to agglomeration of the DS-LDH particles. The DS-LDH particles were exfoliated in the SR, which may have been in part due to hydrogen bonding between the LDH hydroxyl groups and the SR. At low loadings the DS-LDH was well dispersed. The increase in mechanical properties was due to the interactions between the rubber and LDH as well as the exfoliation and good dispersion of the LDH. The platelet orientation and chain slippage of DS-LDH in the rubber matrix helped increase the EB. The particles improved the mechanical properties because they could absorb energy during deformation and interrupted crack propagation. The strong interaction between the DS-LDH and SR could also be seen in the increase in T

at low LDH loadings. Agglomeration decreased the T

at higher LDH loadings. The crystallinity of the SR was increased due to the DS-LDH particles acting as nucleating agents, though agglomeration at higher DS-LDH loadings decreased the crystallinity.

Pradhan et al. [

99] also added stearate-modified Mg-Al LDH (St-LDH) to SR. At low concentrations the LDH was uniformly dispersed and exfoliated. At higher loadings agglomeration started to occur. There was also evidence of hydrogen bonding between St-LDH and SR. The thermal stability of SR was increased by adding St-LDH because the exfoliated layers of LDH acted as a barrier to volatile degradation products. As the LDH loading was increased the thermal stability decreased. This was most likely due to the formation of agglomerates and decreased exfoliation, as well as the decomposition of the organic modifier and the particles acting as heat source domains. St-LDH had a nucleating effect in SR and the T

increased with increasing LDH content. The T

increased, reached a maximum and then decreased with increasing St-LDH content. The increase in T

may have been due to the interaction between the hydroxyl groups of the LDH and the SR restricting chain movement. TS, modulus and EB of SR were also increased by the St-LDH, with a maximum increase at 3 wt %. Agglomeration reduced the mechanical properties at higher loadings of St-LDH. The TS and storage modulus were increased by the large aspect ratio of St-LDH particles and the polymer–filler interaction. Chain slippage and platelet orientation increased the EB. The stearate modifier had a plasticising effect in the SR and lowered the T

.

Organically modified LDH has been successfully incorporated into SR. Another filler of interest in rubber is CNT [

84]. Pradhan and Srivastava [

83] prepared multiwalled carbon nanotube (MWCNT) hybrids with unmodified Li-Al LDH, Mg-Al LDH and Co-Al LDH by dry grinding them together. The Li-LDH-MWCNT was not homogeneously dispersed in SR but Mg-LDH-MWCNT and Co-LDH-MWCNT were better dispersed. Mg-LDH-MWCNT was dispersed best. The LDH/MWCNT hybrids formed a three-dimensional network inside the SR. Mg-LDH-MWCNT had the largest surface area and Li-LDH-MWCNT had the smallest surface area. The larger surface area could have assisted in dispersing the MWCNT in the SR. The hybrid fillers all increased the TS and EB of the SR and the improvement reached a maximum before decreasing again due to agglomeration. Mg-LDH-MWCNT was well dispersed and had a large surface area, which resulted in strong interaction and good stress transfer between it and the rubber. This caused the Mg-LDH-MWCNT to increase the TS more than the other fillers. The increase in EB was due to the entanglement of SR chains, chain slippage, platelet orientation and the deformation of MWCNT. In comparison to neat LDH and neat MWCNT, the improvement in mechanical properties was better when the hybrids were used. This showed that LDH and the MWCNT had a synergistic effect in SR. Surface fracture morphology showed that Mg-LDH-MWCNT had the strongest interaction with SR and Li-LDH-MWCNT had the weakest interaction since the Li-LDH-MWCNT particles were pulled out of the rubber matrix and Mg-LDH-MWCNT particles were not. The hybrid fillers also increased T

and T

by restricting the movement of polymer chains. T

was increased as well, which indicated that the hybrid fillers acted as nucleating agents. The neat LDHs and MWCNT did not have the same effect on T

, T

and T

, which again shows the synergy between the LDH and MWCNT. Mg-LDH-MWCNT increased the thermal stability and crosslink density of SR the most due to its good dispersion and interaction with SR. The synergy between LDH and MWCNT can prove useful in the reinforcement of rubber.

Anti-tracking agents are added to SR to reduce tracking and erosion failure but are incompatible with SR and require high loadings to be effective, thus reducing the mechanical properties of SR. In their previous work, Wu et al. [

100] found that silane-containing additives improved tracking and erosion resistance of SR [

101,

102] so they added vinyltriethoxysilane (ViTES) and Mg-Al LDH to high temperature vulcanised SR and found that ViTES and LDH have a synergistic effect in SR. The ViTES ethoxy groups hydrolysed into hydroxyl groups and condensed with the LDH hydroxyl groups, forming chemical bonds. This improved dispersion of the LDH. The ViTES acted as a bridge between the LDH and SR and participated in the crosslinking reaction. When both ViTES and LDH were added to SR the TS, EB and tear strength were improved but when they were added separately the properties deteriorated. This showed that the combination improved interfacial bonding with SR and thus improved stress transfer. Individually, ViTES and LDH did not improve tracking, but together they improved tracking and erosion resistance.

Table 6 summarises the effect of various types of LDH and modifiers on the properties of SR.

5.7. Nitrile Butadiene Rubber (NBR)

NBR is an acrylonitrile and butadiene copolymer, and as such has double bonds in the backbone chain. Due to these unsaturated bonds, NBR can undergo sulphur vulcanisation [

103] and peroxide vulcanisation [

104]. It is resistant to oil absorption, but oxidises very easily, so aging resistance can be a concern [

3].

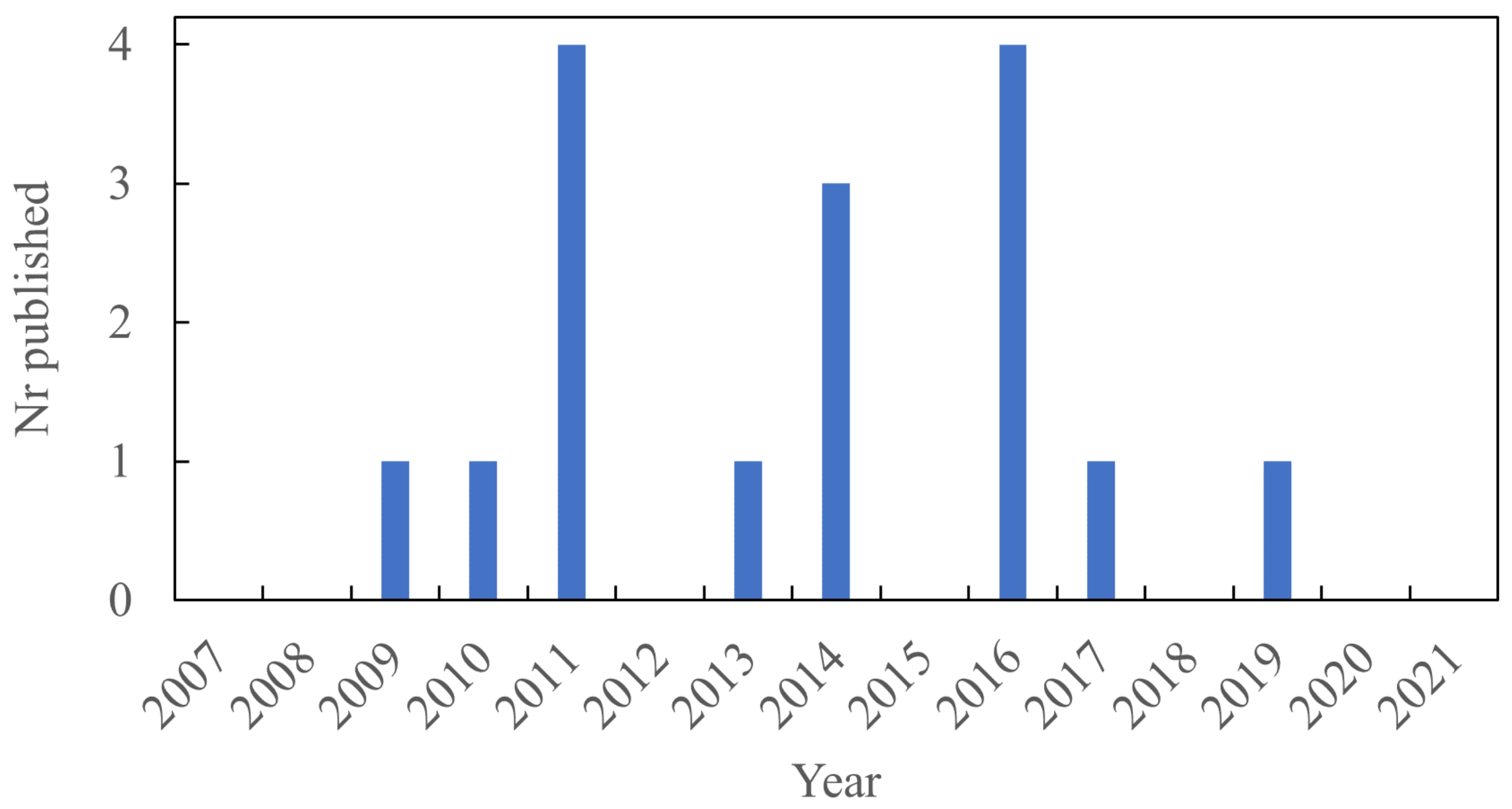

There are 15 studies in which NBR was used, as shown in

Figure 10, although four of these articles were on PU/NBR blends and were discussed in the section on PU.

The first study that used NBR was conducted by Kotal et al. [

41] where Mg-Al LDH modified with dodecyl sulphate was used in a 50:50 wt % PU/NBR blend, as discussed in the PU section.

While stearic acid can be used to modify LDH simply to increase the interlayer spacing and compatibilise the LDH with the rubber matrix, it is also a component of sulphur cure systems. Another important component of the sulphur cure system is ZnO. In recent years, there has been growing concern over the effect that ZnO has on aquatic life and an effort has been made to reduce the levels of ZnO in rubber [

105,

106,

107]. Das et al. [

16] synthesised Mg-Zn-Al LDH modified with stearic acid and added it to NBR to determine whether it can replace the stearic acid and ZnO used in the sulphur cure system. Other elastomers, SSBR, CR, NR and XNBR, were also tested but the focus of the article was on NBR. They compared the ZnO and stearic acid free composites to a control sample with stearic acid and ZnO as well as one that also contained carbon black. They found that partial intercalation and exfoliation took place in the NBR. Due to this exfoliation, the LDH had a large surface area so more of the Zn ions were available to participate in the crosslinking process. In comparison, most of the ZnO ions are in the bulk crystal and cannot participate in the crosslinking reaction. This means less Zn is needed when the LDH is used instead of ZnO to obtain the same results. The LDH cure was also more efficient than the conventional cure system despite having ten times less Zn than the conventional cure system. The TS of the LDH-cured composite was comparable to the ZnO and stearic acid-cured composite, but the EB was lower. This was most likely due to the increase in crosslink density of the LDH-cured composite. When NBR containing carbon black was cured with the LDH, the mechanical properties were not significantly affected. The LDH-cured composite also retained its properties better after aging than the conventionally cured NBR. This may be due to the LDH layers acting as a barrier to oxygen, slowing down oxidative cleavage. Interestingly, the LDH composite was transparent. This shows that LDH has the potential to act as a functional filler that can be used to reduce the amount of ZnO used to cure rubber.

Feng et al. [

108] investigated the effect of two different organically modified LDHs, styrene sulphonate-modified LDH (SS-LDH) and dodecyl benzenesulphonate-modified LDH (DBS-LDH), on the properties of NBR and compared it to unmodified LDH. Some polymer chain intercalation occurred in SS-LDH but not in DBS-LDH, which in fact saw a decrease in basal spacing and was poorly dispersed. Unmodified LDH also did not have any polymer chains intercalated due to the small interlayer spacing and the poor interaction between the LDH and the rubber. This also caused agglomeration and poor dispersion of the LDH. The NBR was peroxide-cured. The SS-LDH delayed the curing process which was most likely due to the fact that the modifier had a double bond that participated in the curing reaction. This caused the crosslink density of the SS-LDH composite to be higher than the other composites despite the slower cure and was also the reason that SS-LDH had better interaction with NBR than the other LDHs. DBS-LDH and LDH decreased the cure times compared to neat NBR. The basic nature of the LDH could be favourable to the homolytic cleavage of peroxide, which could then accelerate the cure. The good interaction between SS-LDH and NBR led to this composite having the highest TS. The EB was slightly decreased but not significantly. Both organic modifiers caused an increase in T

due to improved interaction with the rubber. Unmodified LDH had a very small increase in T

. This study shows that the nature of the organic modifier plays a role in how effective the LDH is as a reinforcing filler in NBR.

The effect of using the surfactant Pluronic F-127 on the dispersion of Mg-Al LDH in NBR latex was investigated by Braga et al. [

109]. The LDH adsorbed the hydrophilic groups of the surfactant through hydrogen bonding and the hydrophobic groups of the surfactant then acted as a barrier between LDH particles. This improved their dispersion in NBR and reduced agglomeration in comparison to when no surfactant was used. NBR chains were also intercalated into the LDH layers.

The same research group that used lignin-modified LDH in SBR [

110] also investigated the effect of using lignosulphonate, a byproduct of the pulping industry, as a modifier for Mg-Al LDH in NBR [

111]. Compared to neat LDH, the lignosulphonate-modified LDH (LS-LDH) was better dispersed in NBR and did not form agglomerates. This translated to a larger increase in TS and tear strength, although EB was lower than for the unmodified LDH composite. Contrary to what has been observed in most other studies, the T

was decreased by unmodified LDH as well as LS-LDH, although the LS-LDH decreased the T

less, showing that LS-LDH had better interaction with NBR.

Previous work showed that LDH containing Zn could be used to replace ZnO in rubber [

16]. Stearate-modified Zn-Al LDH was used as a replacement for ZnO in NBR in a sulphur cure and a peroxide cure system by Eshwaran et al. [

112]. The acrylonitrile (ACN) content of the NBR was also varied. The LDH was partially exfoliated in the rubber and some of the rubber chains intercalated into the LDH. Despite having a lower concentration of Zn ions in the LDH sulphur cure system than the conventional system with ZnO, the cure was still efficient. At low ACN content, the LDH sulphur cure system performed better than conventional sulphur and peroxide cures. At high ACN content, and therefore high polarity, the LDH peroxide cure was the most efficient. In general, however, the optimum cure time for the peroxide and the curing reactions were not affected by the LDH. The NBR composites containing LDH had higher moduli and TS values at all ACN content levels than the conventionally cured composites while the EB values were lower. After aging, the LDH-cured composites also retained their mechanical properties better. This may be due to the LDH acting as a barrier to oxygen diffusion which slowed down degradation. This shows that ZnO can be replaced by Zn-Al LDH in a sulphur cure system and that Zn-Al LDH can also be added to peroxide cured composites without negatively impacting the cure system and can, in fact, be used to improve the properties of the composites.

Eshwaran et al. [

113] investigated the effect of stearate modification of Zn-Mg-Al LDH (St-LDH) on the properties of NBR where unmodified LDH and St-LDH was used to replace ZnO and stearic acid in the curing system. A commercial unmodified LDH, a commercial stearate-modified Zn-Al LDH and a lab synthesised stearate-modified Zn-LDH were used and compared to a stearic acid and ZnO cure system with Zn levels equivalent to that of the LDHs. Despite there being no stearic acid present when the unmodified LDH was used, the NBR still cured but the scorch time was decreased due to the absence of stearate groups. The cure rate of the lab synthesised St-LDH was the highest. The excess stearate anions made the formation of zinc stearate coordination complexes more effective. The crosslink density was reduced by the modified LDHs compared to unmodified LDH but the crosslink densities of these composites were still higher than the ZnO and stearic acid-cured composite. A higher stearate content decreased the crosslink density. Unmodified LDH increased the mechanical properties the most. The stearate groups may have acted as internal lubricants and this effect dominated over the reinforcing effect caused by polymer chain intercalation and the platelets themselves, decreasing the mechanical properties. A larger number of stearate groups caused a greater reduction in mechanical properties. The LDH platelets may also have collapsed as the Zn and stearate groups participated in the curing process, reducing the reinforcing effect of the LDH. The modified LDHs still outperformed the ZnO and stearic acid-cured composite. The modified lab synthesised LDH reduced T

due to the lubricating effect of the stearate chains. At equivalent levels of Zn, the Zn-AL LDHs performed better as part of the vulcanisation process but the stearate groups negatively impacted the mechanical properties due to their lubricating effect.

Three studies were conducted with 50:50 wt % PU/NBR blends where Mg-Al LDH together with organically modified CNT [

85], Zn-Al LDH together with CNT and CNF [

86] and Mg-Al LDH with CNF [

87] were used, as discussed in the PU section.

He et al. [

114] modified Mg-Al LDH with sodium p-styrenesulphonate hydrate (SSS-LDH) and investigated the effect of this LDH on the aging behaviour of NBR. SSS-LDH was compared to unmodified LDH. Unlike in most work performed previously, carbon black was also added to all the formulations. The composites with unmodified LDH had higher TS than the composites containing SSS-LDH. In both cases TS decreased with increasing LDH content. The unmodified LDH still improved the TS compared to the LDH free composite but the SSS-LDH decreased the TS to values below that of the LDH free composite. The authors mention that the unmodified LDH may have acted as an accelerator in the sulphur vulcanisation while the SSS-LDH acted as a suppressant. A similar trend was observed for the EB. After aging, however, the SSS-LDH composite had the highest TS and EB. This may be because the vulcanisation process continued during aging. The additional interactions between SSS-LDH and NBR then increased the strength of the interfacial interaction. The saturation of NBR was also increased, which reduced chain scission during aging. The accelerating effect of unmodified LDH, however, caused the vulcanisation to reach saturation before aging and could have caused over-vulcanisation. There was also little interaction between the LDH and NBR, which allowed microvoids to form around the LDH particles. This could have allowed more oxygen to penetrate into the rubber and cause a reduction in mechanical properties.

Wang et al. [

115] used Mg-Al LDH surface modified with polyvinylpyrrolidone (PVP) to improve the gas barrier properties of NBR and used layer-by-layer assembly to incorporate the LDH into the NBR. LDHs have good gas barrier properties due to the large aspect ratios of the platelets. They found that the oxygen permeability was decreased by the LDH and that the LDH improved the thermal stability and TS compared to neat NBR and slightly reduced EB.

LDHs have proven to be useful in improving the mechanical properties of NBR and can also be used to improve the aging resistance. Li et al. [

116] modified Mg-Al LDH with 4 amino-benzenesulphonic acid monosodium salt (SAS-LDH) and used it to improve the aging resistance of NBR. During mixing, and even after aging, some NBR chains were intercalated into the SAS-LDH and the SAS-LDH was exfoliated. This did not happen when unmodified LDH was used. Both LDHs increased EB and TS compared to neat NBR. Before aging the unmodified LDH composite had better mechanical properties because the LDH accelerated the vulcanisation process. However, in comparison to unmodified LDH and unfilled NBR, the SAS-LDH composite had a smaller decrease in TS and EB after aging and therefore had the best mechanical properties after aging. The unmodified LDH composite may have aged faster due to the poor interaction between the LDH and polymer causing microvoids to form around the LDH particles, allowing more oxygen to penetrate into the NBR. The microvoids also decreased the mechanical properties. The modified NBR composites did not form any microvoids due to better interaction between the LDH and NBR. SAS-LDH also increased the thermal stability, T

and storage modulus due to the strong interaction between NBR and SAS-LDH.

The dispersion of LDH and the interaction between the LDH and rubber both affect the mechanical properties of the composites. Maciejewska and Sowińska [

117] used ILs (BMpyrrolBF4, BMpyrBF4 and BMpipBF4) to improve the dispersion of Mg-Al LDH in NBR. They compared the composites containing LDH and IL with one containing carbon black and one containing silica. The LDH composite had the lowest thermal stability compared to when carbon black or silica was used as filler because LDH starts decomposing above 100

C. Adding ILs decreased the thermal stability for all three composite types. NBR containing LDH had the lowest onset temperature of vulcanisation. The authors stated that this may be because LDH is alkaline and sulphur vulcanisation prefers alkaline conditions. The nature of the IL also determined how the LDH affected vulcanisation. BMpyrrolBF4 and BMpipBF4 did not affect the onset temperature but did reduce the enthalpy of vulcanisation. BMpyrBF4 increased the vulcanisation temperature. All three ILs lowered the temperature at which the post-curing reactions took place. BMpyrBF4 also made the crosslink distribution in the LDH composite more homogeneous but did not affect the crosslink density. This may be because the BMpyrBF4 improved the dispersion of LDH and crosslinking agents in the rubber matrix. The effect of LDH on the storage modulus was not changed by the ILs. All three filler types increased the storage modulus, with silica increasing it the most. Carbon black and LDH increased the T

similarly and the ILs did not affect the T

significantly.

Previous work had shown that modifying LDH with SSS or SAS improved the aging resistance of NBR [

114,

116]. The same research group then also focused on synthesising a multi-modified LDH to improve the aging resistance of NBR [