Quasi-Static Compression Properties of Bamboo and PVC Tube Reinforced Polymer Foam Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

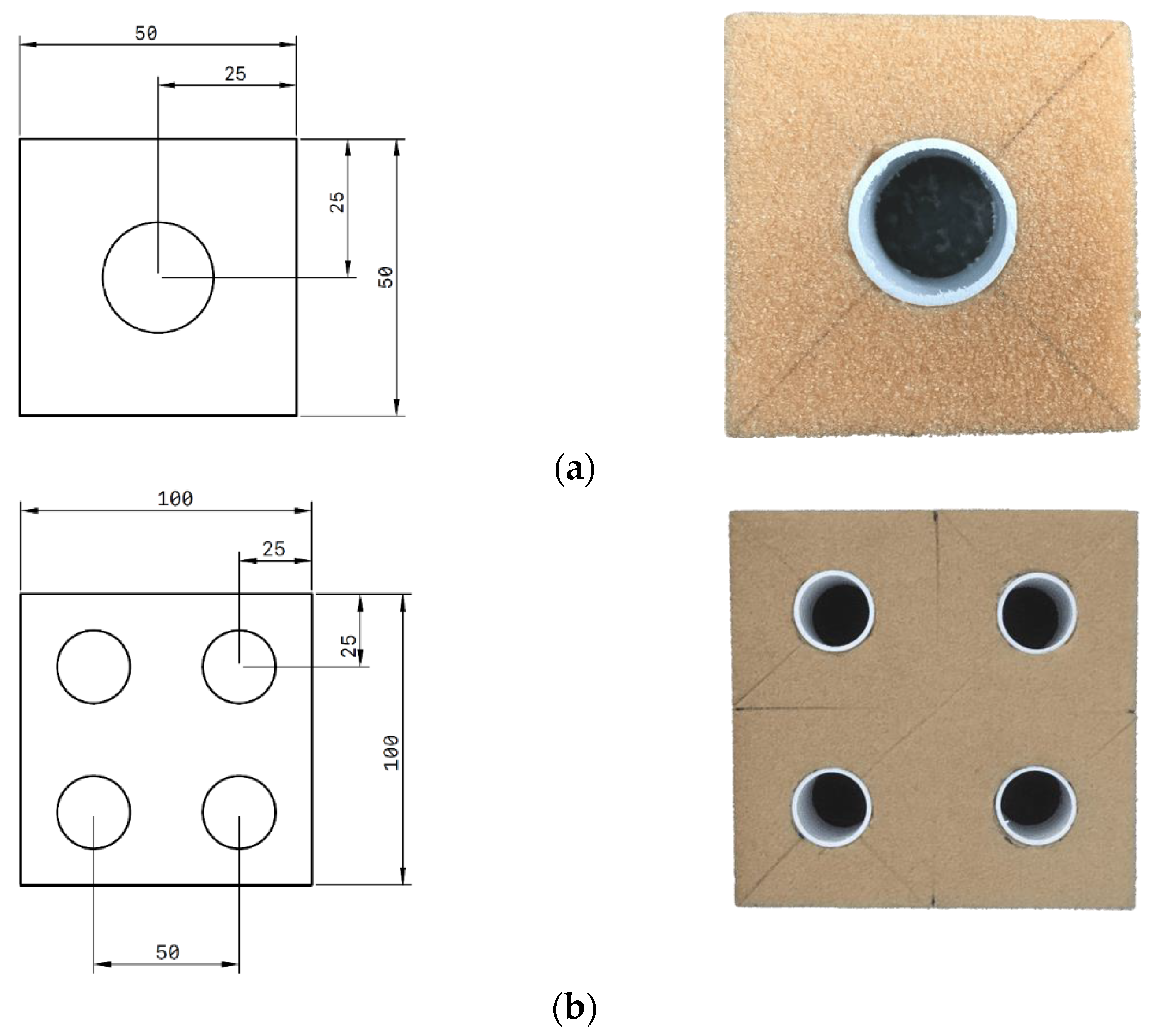

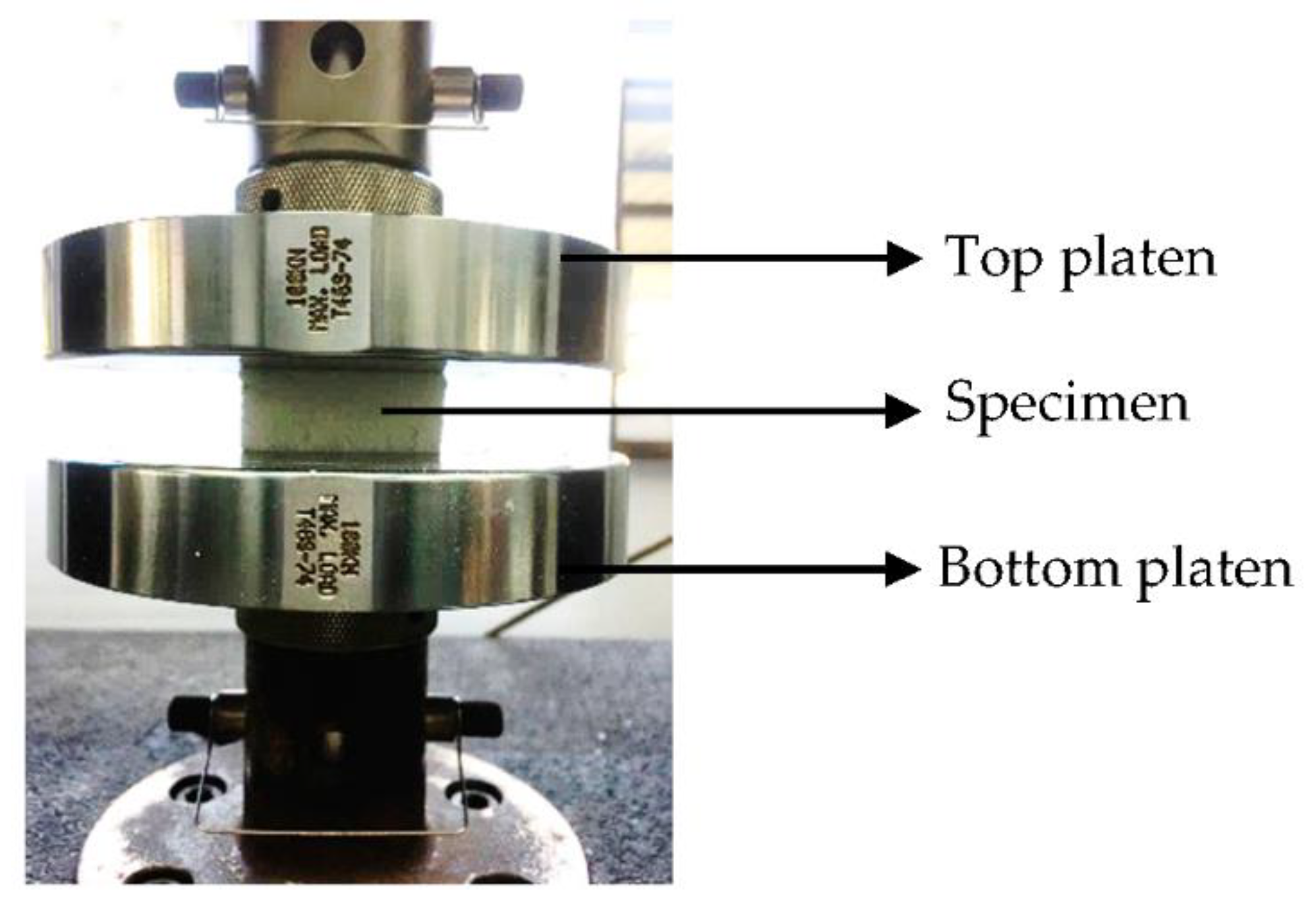

2.2. Fabrication and Mechanical Testing

3. Results and Discussion

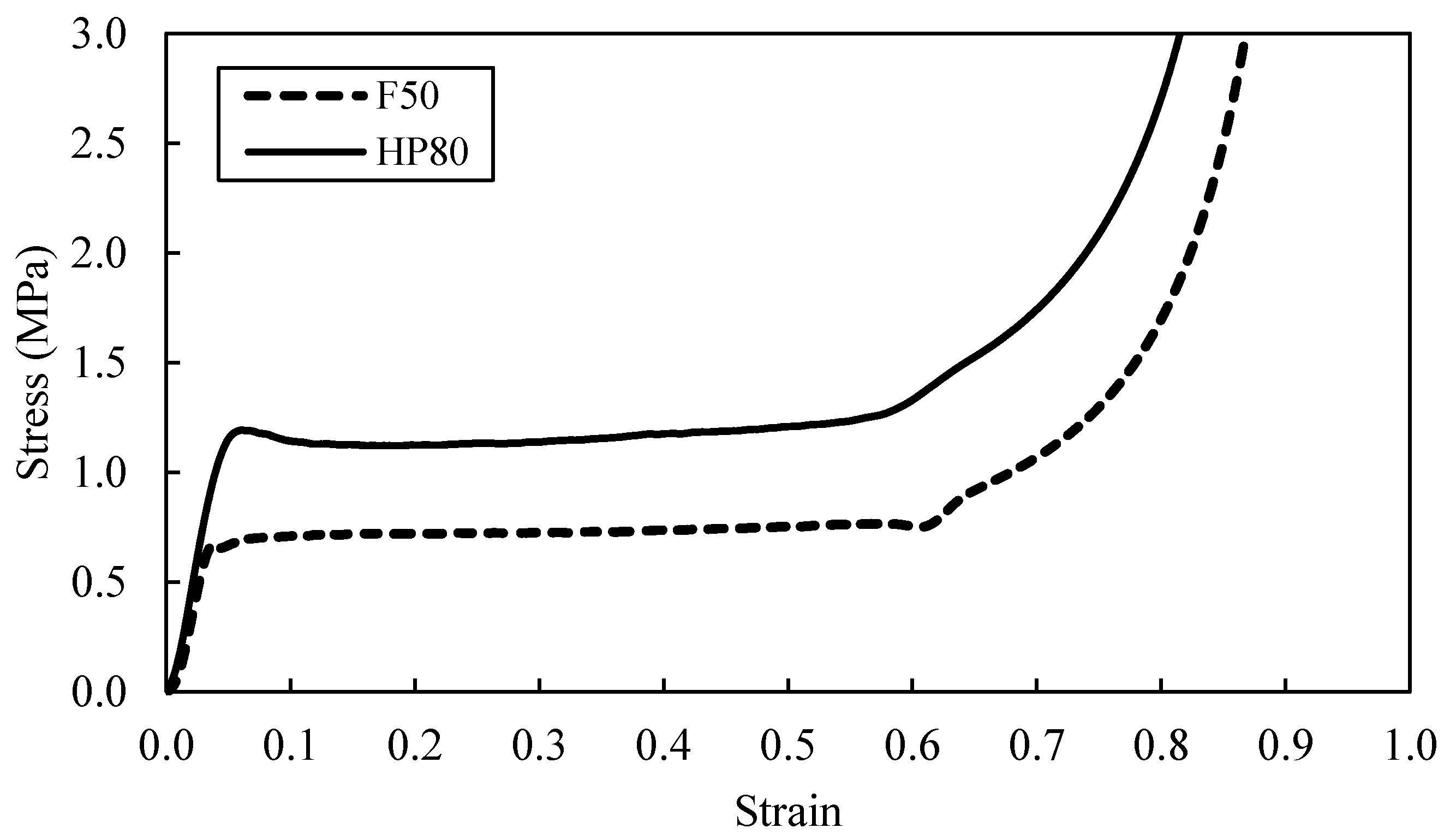

3.1. Compressive Behaviour of Foam Material

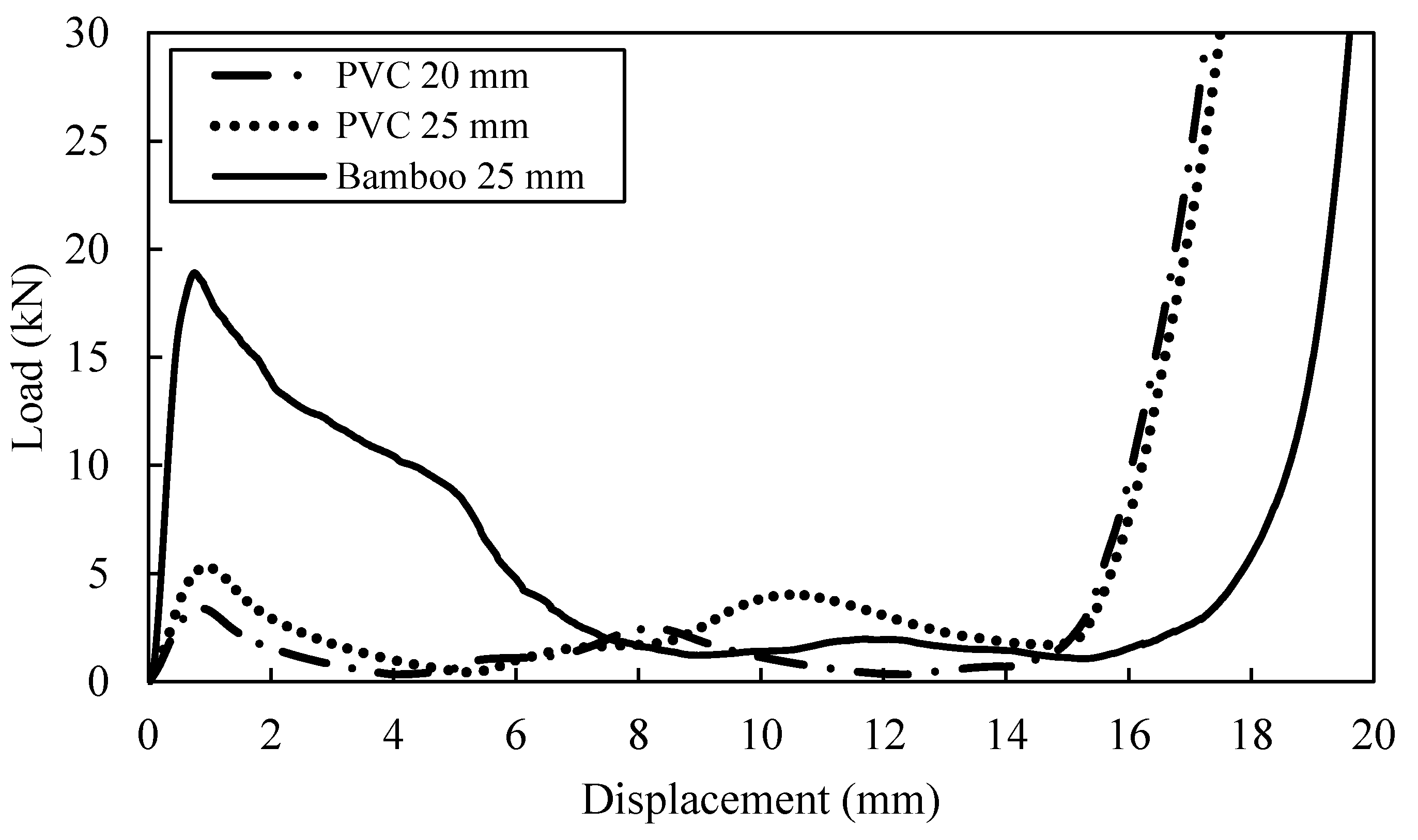

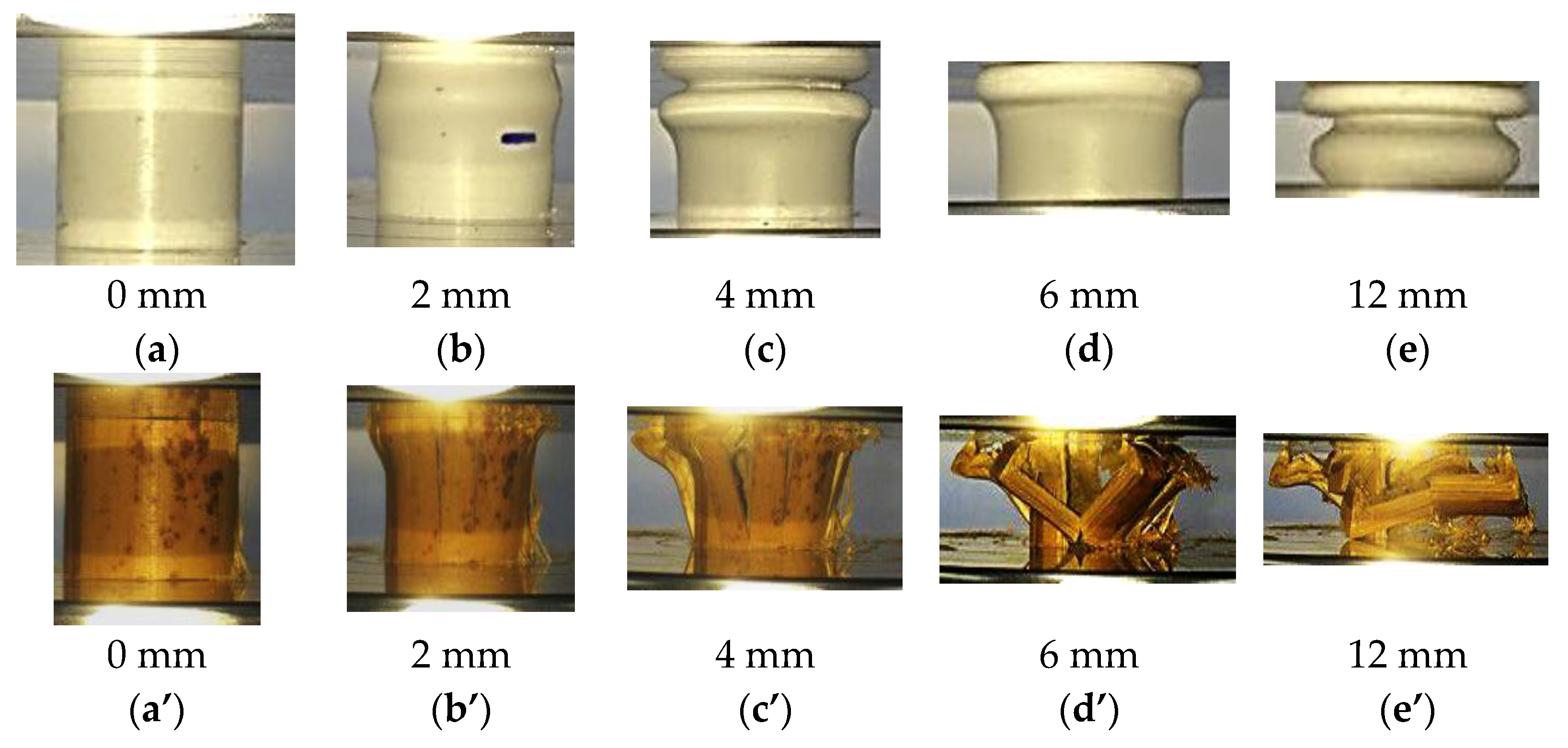

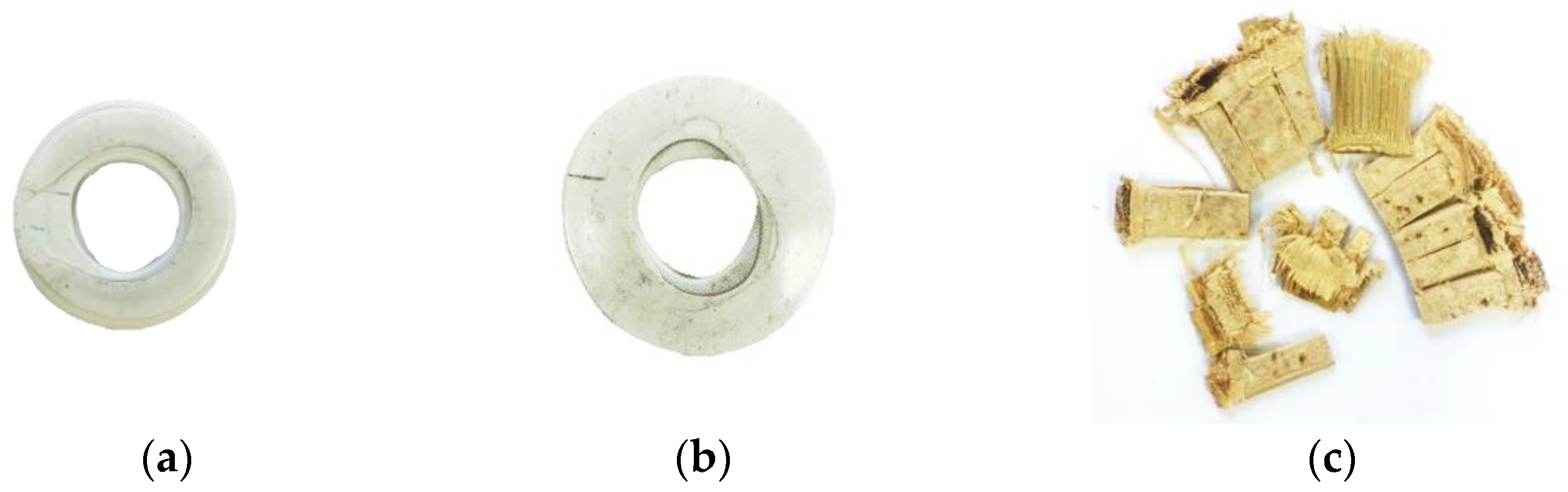

3.2. Compression Behaviour of Single Tube

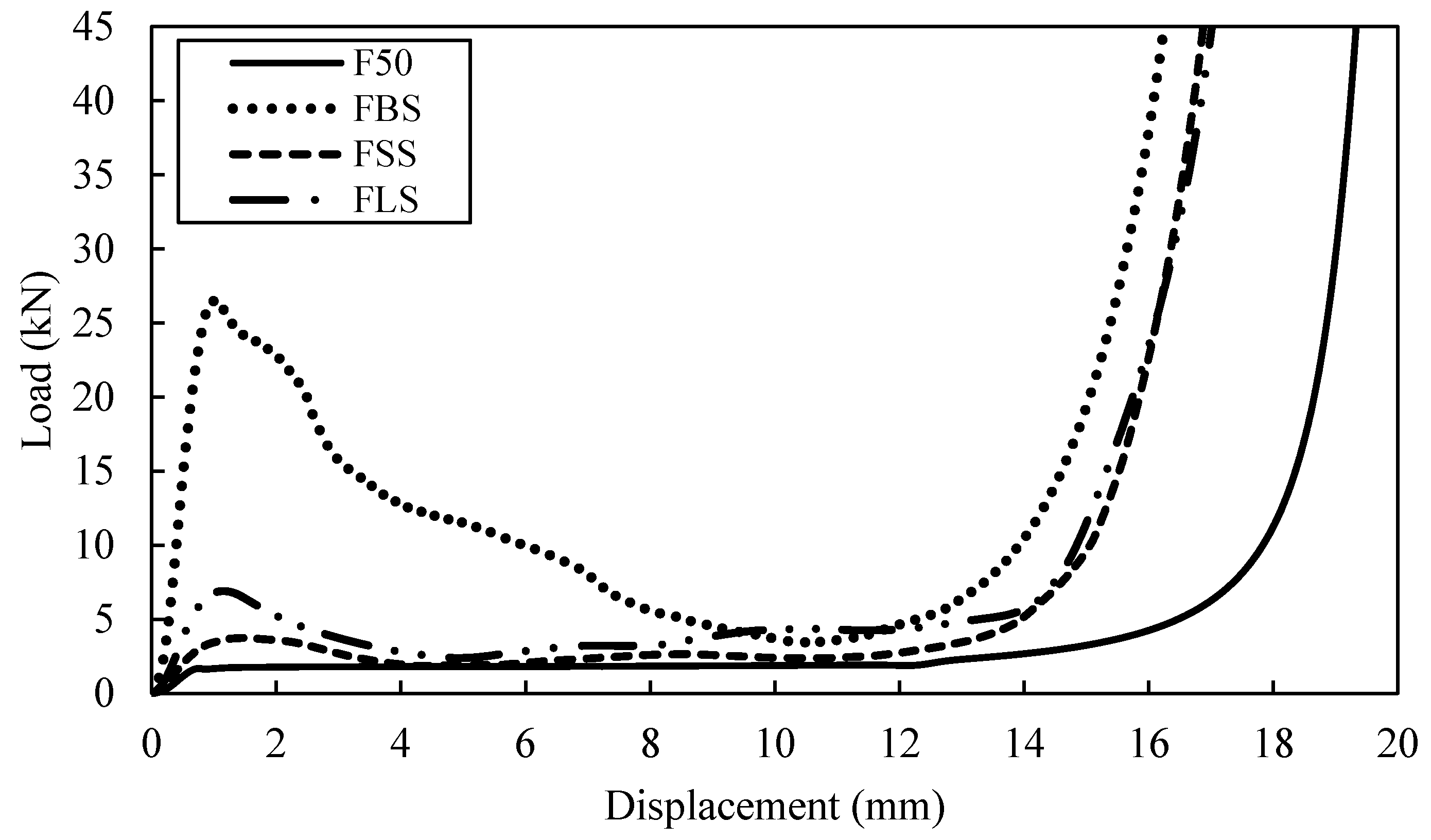

3.3. Single Tube Reinforced Foam Structures

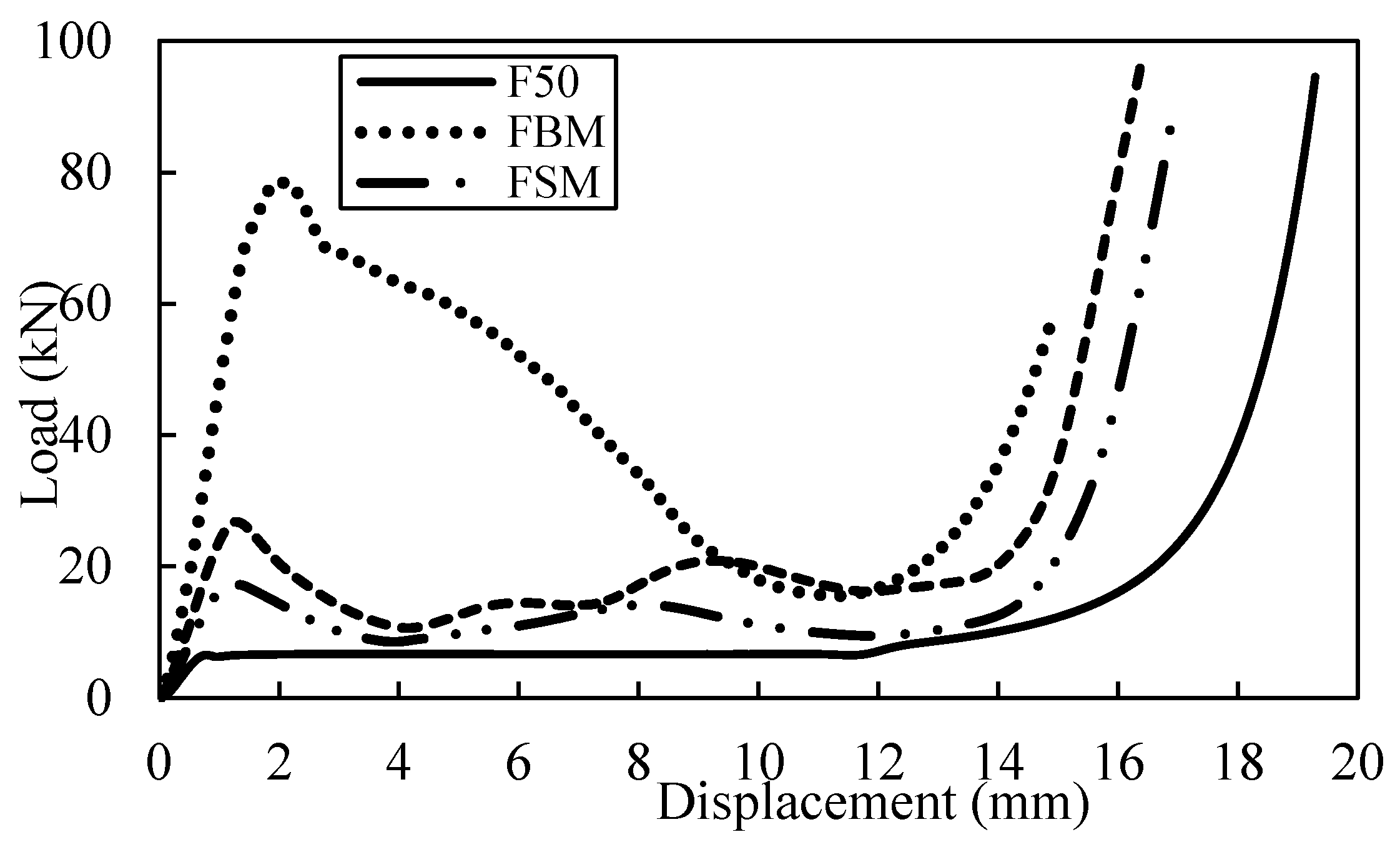

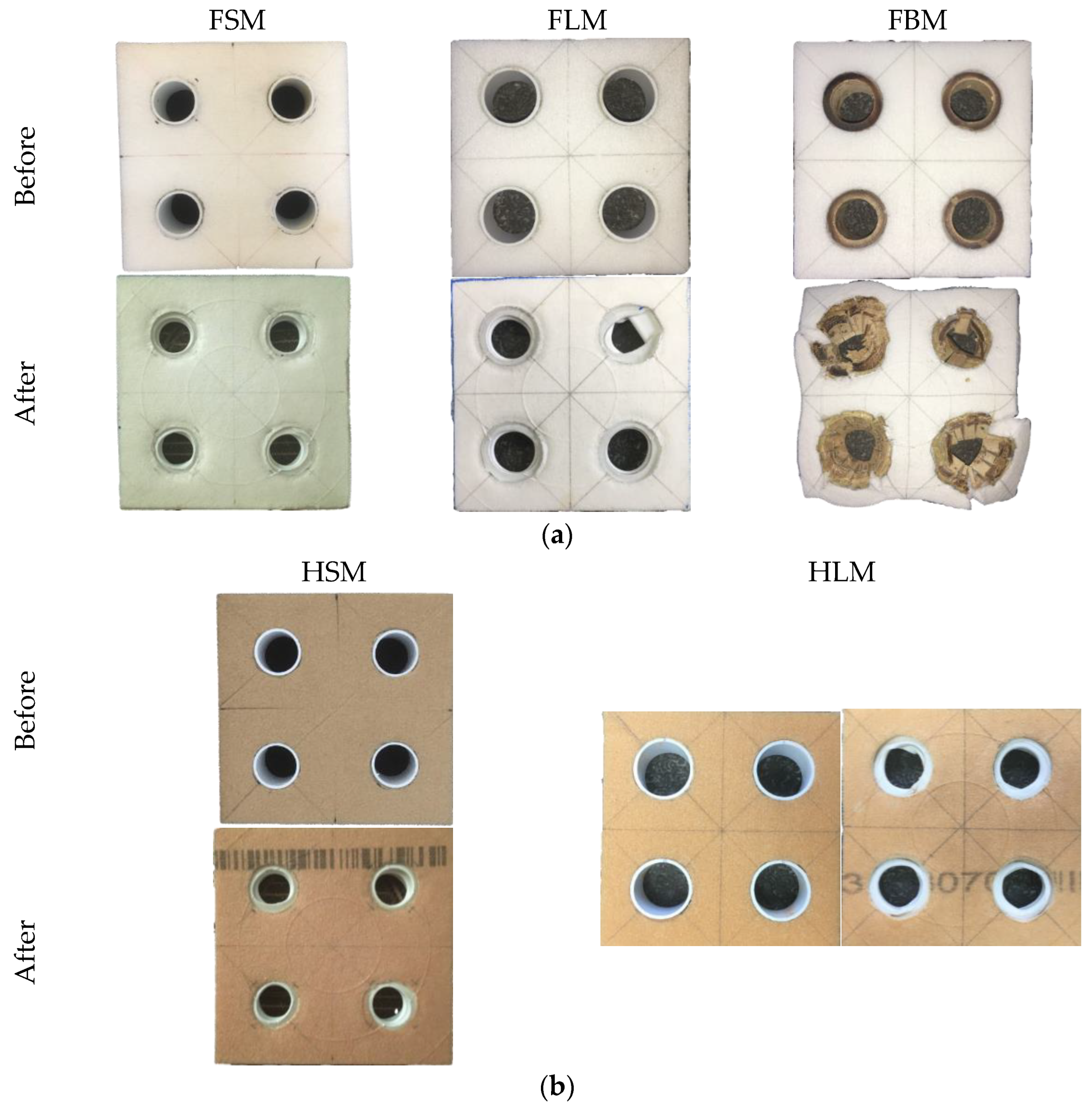

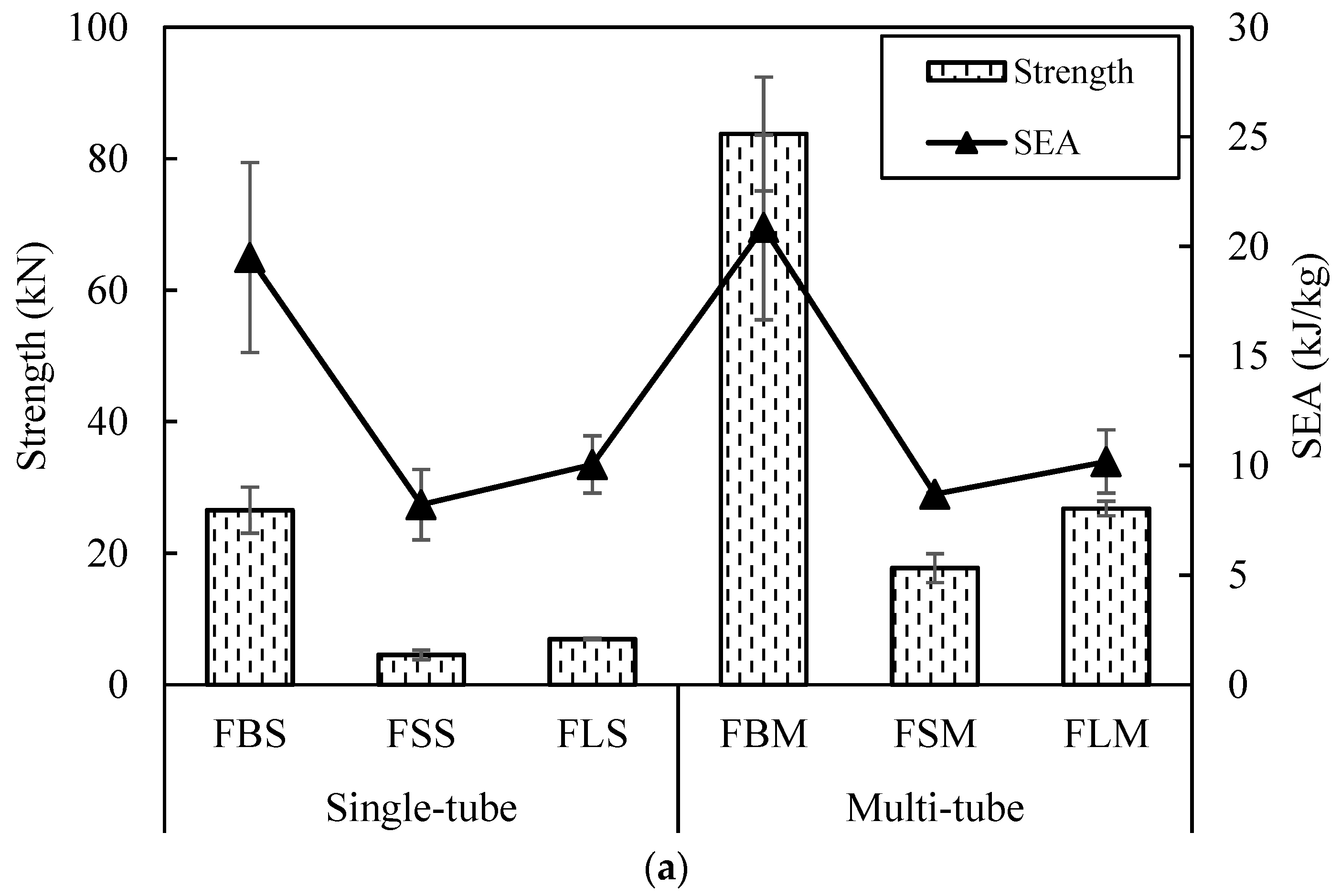

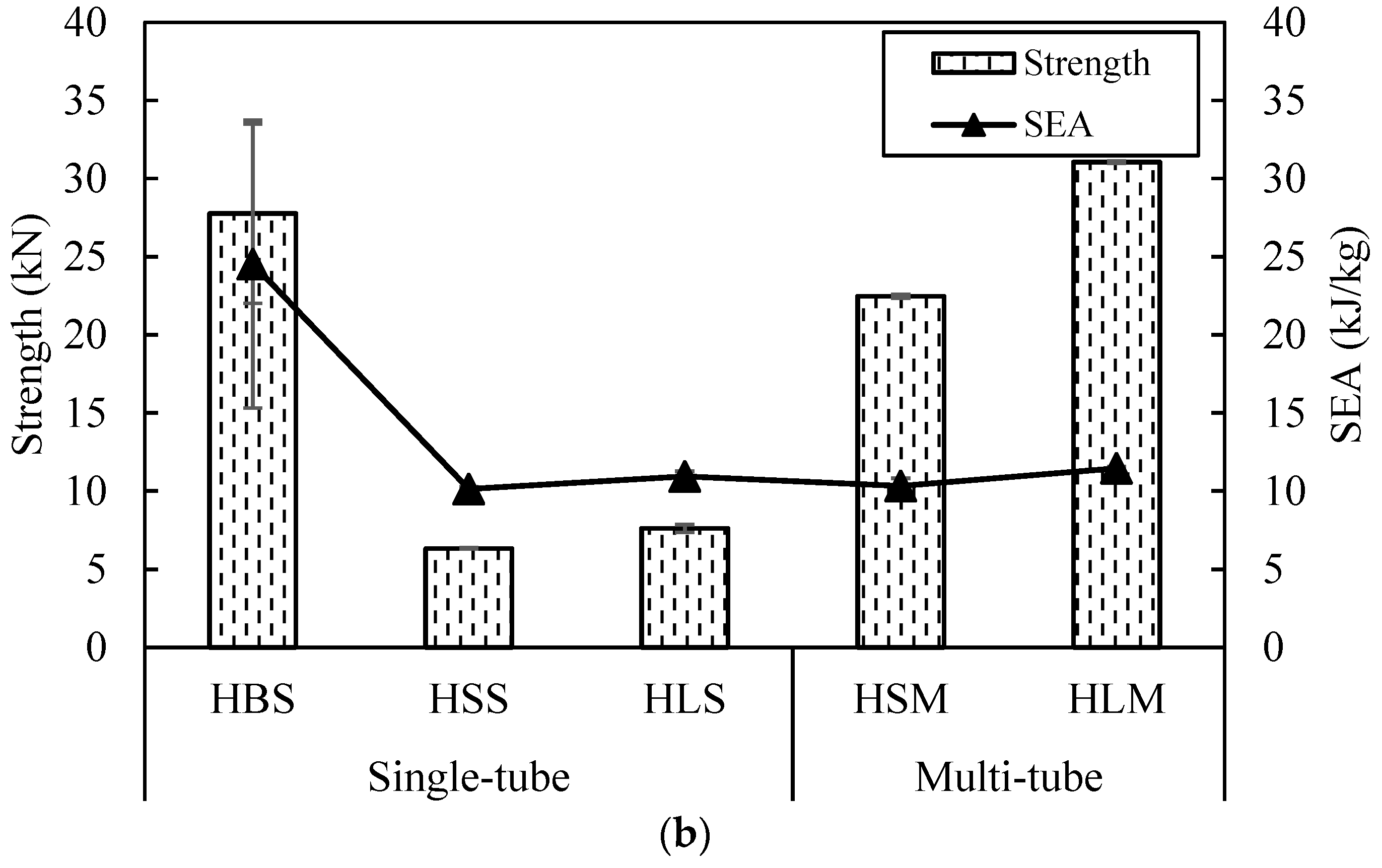

3.4. Multi Tube Reinforced Foam Structures

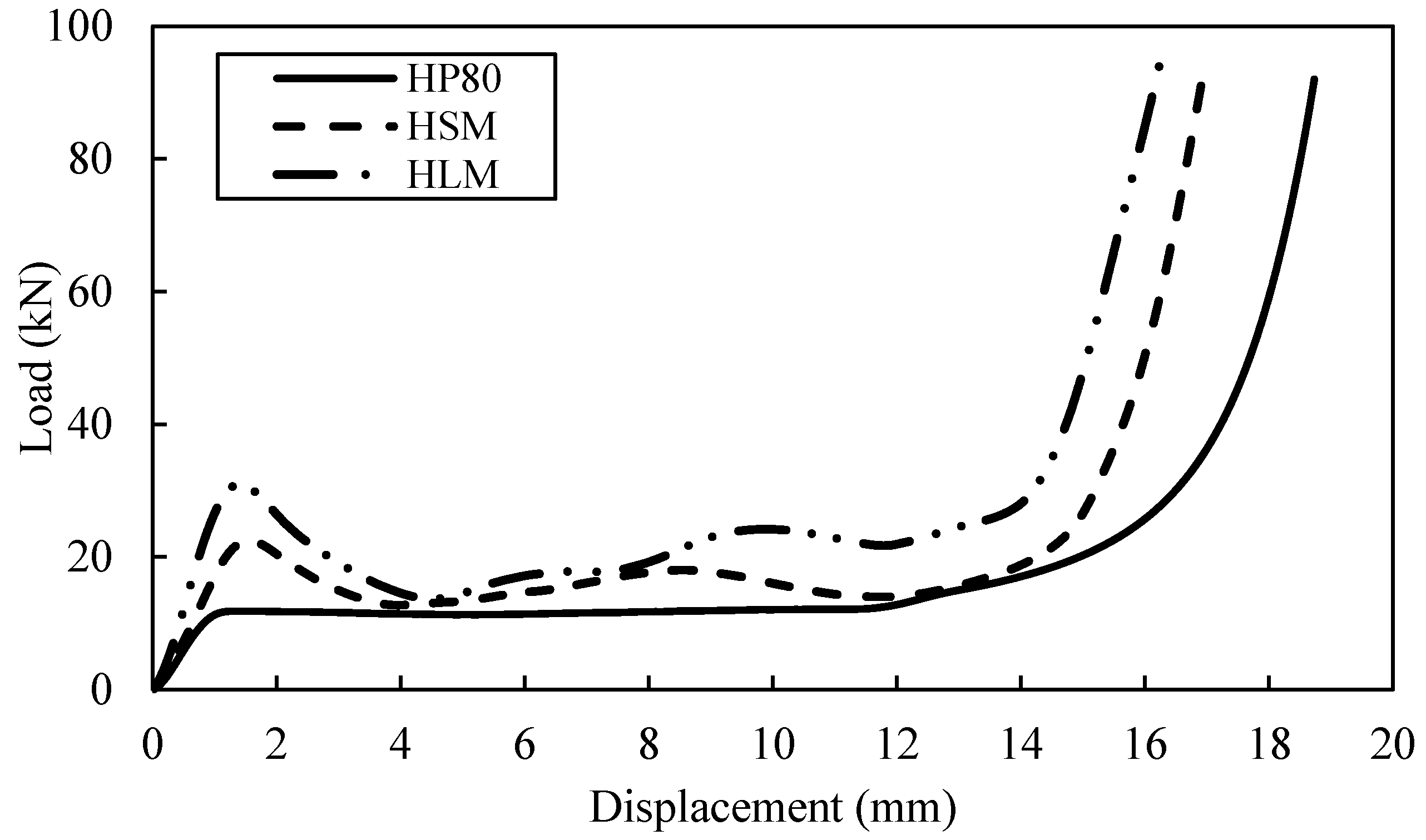

3.5. Influence of Crosshead Speed on Multiple Tube Reinforced Foam Structures

4. Conclusions

- Single bamboo tube reinforced foam structure offers highest value in specific energy absorption and compression strength. By increasing the foam density, it will increase the specific energy absorption and compressive strength value. A larger size of diameter of tube can enhance the specific energy absorption and compressive strength.

- The compressive strength increases significantly when several tubes are introduced inside the foam. In contrast, the specific energy absorption does not change significantly for multiple tube reinforced foam structure. The multiple bamboo tube reinforced F50 foam structure offers better value of compression properties. In addition, the multiple PVC tube reinforced foam structure with a diameter of 25 mm gives the highest energy absorbing capability in HP80 foam.

- The specific energy absorption does not vary significantly under the different crosshead speed below 20 mm/min. However, an increase in crosshead speed during testing can leads a slightly higher value of specific energy absorption. Therefore, the structures are believed to have a strain-rate effect when a higher speed is applied.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alia, R.A. The Energy-Absorbing Characteristics of Novel Tube-Reinforced Sandwich Structures. Ph.D. Thesis, University of Liverpool, Liverpool, UK, 2015. [Google Scholar]

- Cinar, K. Evaluation of sandwich panels with composite tube-reinforced foam core under bending and flatwise compression. J. Sandw. Struct. Mater. 2020, 22, 480–493. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Colloca, M.; Dorogokupets, G.; Gupta, N.; Porfiri, M. Mechanical properties and failure mechanisms of closed-cell PVC foams. Int. J. Crashworthiness 2012, 17, 327–336. [Google Scholar] [CrossRef]

- Shinde, R.B.; Mali, K.D. An Overview on Impact Behaviour and Energy Absorption of Collapsible Metallic and Non-Metallic Energy Absorbers used in Automotive Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 346, 2018. [Google Scholar] [CrossRef]

- Khan, R.A.; Mahdi, E.; Cabibihan, J.J. Effect of fibre orientation on the quasi-static axial crushing behaviour of glass fibre reinforced polyvinyl chloride composite tubes. Materials 2021, 14, 2235. [Google Scholar] [CrossRef] [PubMed]

- Zuhri, M.Y.M.; Liao, Y.; Wang, Q.Y.; Guan, Z.W. The energy absorbing properties of bamboo-based structures. J. Sandw. Struct. Mater. 2019, 21, 1032–1054. [Google Scholar] [CrossRef]

- Zhou, J.; Guan, Z.; Cantwell, W.J. The energy-absorbing behaviour of composite tube-reinforced foams. Compos. Part B Eng. 2018, 139, 227–237. [Google Scholar] [CrossRef]

- Alhawamdeh, M.; Alajarmeh, O.; Aravinthan, T.; Shelley, T.; Schubel, P.; Kemp, M.; Zeng, X. Modelling hollow pultruded FRP profiles under axial compression: Local buckling and progressive failure. Compos. Struct. 2021, 262, 113650. [Google Scholar] [CrossRef]

- Alia, R.A.; Cantwell, W.J.; Langdon, G.S.; Yuen, S.C.K.; Nurick, G.N. The energy-absorbing characteristics of composite tube-reinforced foam structures. Compos. Part B Eng. 2014, 61, 127–135. [Google Scholar] [CrossRef]

- Molari, L.; Mentrasti, L.; Fabiani, M. Mechanical characterization of five species of Italian bamboo. Structures 2020, 24, 59–72. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Flatwise Compressive Properties of Sandwich Cores 1. Am. Soc. Test. Mater. 2003, 2–4. [Google Scholar] [CrossRef]

- Li, Q.M.; Magkiriadis, I.; Harrigan, J.J. Compressive strain at the onset of densification of cellular solids. J. Cell. Plast. 2006, 42, 371–392. [Google Scholar] [CrossRef]

- Rajput, M.S.; Burman, M.; Köll, J.; Hallström, S. Compression of structural foam materials—Experimental and numerical assessment of test procedure and specimen size effects. J. Sandw. Struct. Mater. 2019, 21, 260–288. [Google Scholar] [CrossRef] [Green Version]

- Umer, R.; Balawi, S.; Raja, P.; Cantwell, W.J. The energy-absorbing characteristics of polymer foams reinforced with bamboo tubes. J. Sandw. Struct. Mater. 2014, 16, 108–122. [Google Scholar] [CrossRef]

- Alantali, A.; Alia, R.A.; Umer, R.; Cantwell, W.J. Energy absorption in aluminium honeycomb cores reinforced with carbon fibre reinforced plastic tubes. J. Sandw. Struct. Mater. 2019, 21, 2801–2815. [Google Scholar] [CrossRef]

- Wei, Y.; Zhou, M.; Zhao, K.; Zhao, K.; Li, G. Stress–strain relationship model of glulam bamboo under axial loading. Adv. Compos. Lett. 2020, 29, 1–11. [Google Scholar] [CrossRef]

- Xiang, C.; Xiao, Z.; Ding, H.; Wang, Z. Compressive Properties and Energy Absorption Characteristics of Extruded Mg-Al-Ca-Mn Alloy at Various High Strain Rates. Materials 2020, 14, 87. [Google Scholar] [CrossRef] [PubMed]

| Tube | Outer Diameter, Do (mm) | Inner Diameter, Di (mm) | Thickness (mm) | Di/t Ratio |

|---|---|---|---|---|

| PVC 20 | 20 | 17 | 1.5 | 11.3 |

| PVC 25 | 25 | 21 | 2.0 | 10.5 |

| Bamboo | 25 | 18 | 3.5 | 5.1 |

| Type of Specimen | Code | ||

|---|---|---|---|

| Foam | Tube | Single | Multiple |

| F50 | Bamboo Ø 25 mm | FBS | FBM |

| F50 | PVC Ø 20 mm | FSS | FSM |

| F50 | PVC Ø 25 mm | FLS | FLM |

| HP80 | Bamboo Ø 25 mm | HBS | HBM |

| HP80 | PVC Ø 20 mm | HSS | HSM |

| HP80 | PVC Ø 25 mm | HLS | HLM |

| Foam | Density (kg/m3) | Compressive Load (kN) | Compressive Strength (MPa) | Compressive Modulus (MPa) | SEA (kJ/kg) |

|---|---|---|---|---|---|

| F50 | 50 | 1.76 | 0.70 | 26.45 | 7.89 |

| HP80 | 80 | 2.99 | 1.20 | 29.66 | 9.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amelia, J.J.N.; Zuhri, M.Y.M.; Leman, Z.; Zahari, N.I.; As’arry, A.; Ilyas, R.A. Quasi-Static Compression Properties of Bamboo and PVC Tube Reinforced Polymer Foam Structures. Polymers 2021, 13, 3603. https://doi.org/10.3390/polym13203603

Amelia JJN, Zuhri MYM, Leman Z, Zahari NI, As’arry A, Ilyas RA. Quasi-Static Compression Properties of Bamboo and PVC Tube Reinforced Polymer Foam Structures. Polymers. 2021; 13(20):3603. https://doi.org/10.3390/polym13203603

Chicago/Turabian StyleAmelia, J. J. N., M. Y. M. Zuhri, Z. Leman, N. I. Zahari, A. As’arry, and R. A. Ilyas. 2021. "Quasi-Static Compression Properties of Bamboo and PVC Tube Reinforced Polymer Foam Structures" Polymers 13, no. 20: 3603. https://doi.org/10.3390/polym13203603

APA StyleAmelia, J. J. N., Zuhri, M. Y. M., Leman, Z., Zahari, N. I., As’arry, A., & Ilyas, R. A. (2021). Quasi-Static Compression Properties of Bamboo and PVC Tube Reinforced Polymer Foam Structures. Polymers, 13(20), 3603. https://doi.org/10.3390/polym13203603