Microstructure-Forming Mechanism of Optical Sheet Based on Polymer State Transition in Injection-Rolling Process

Abstract

1. Introduction

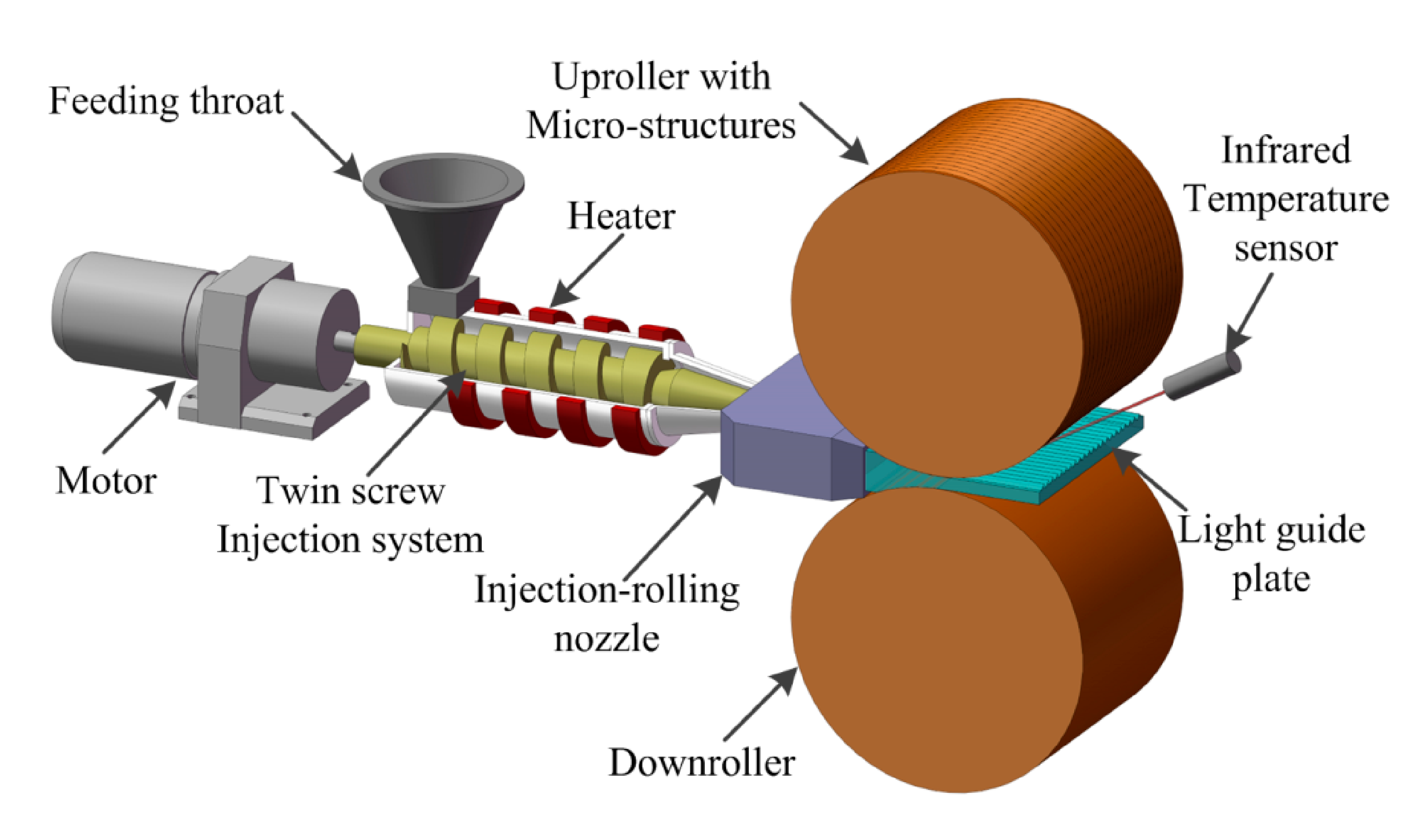

2. Experimental Method and Simulation

2.1. Setup and Process Parameters

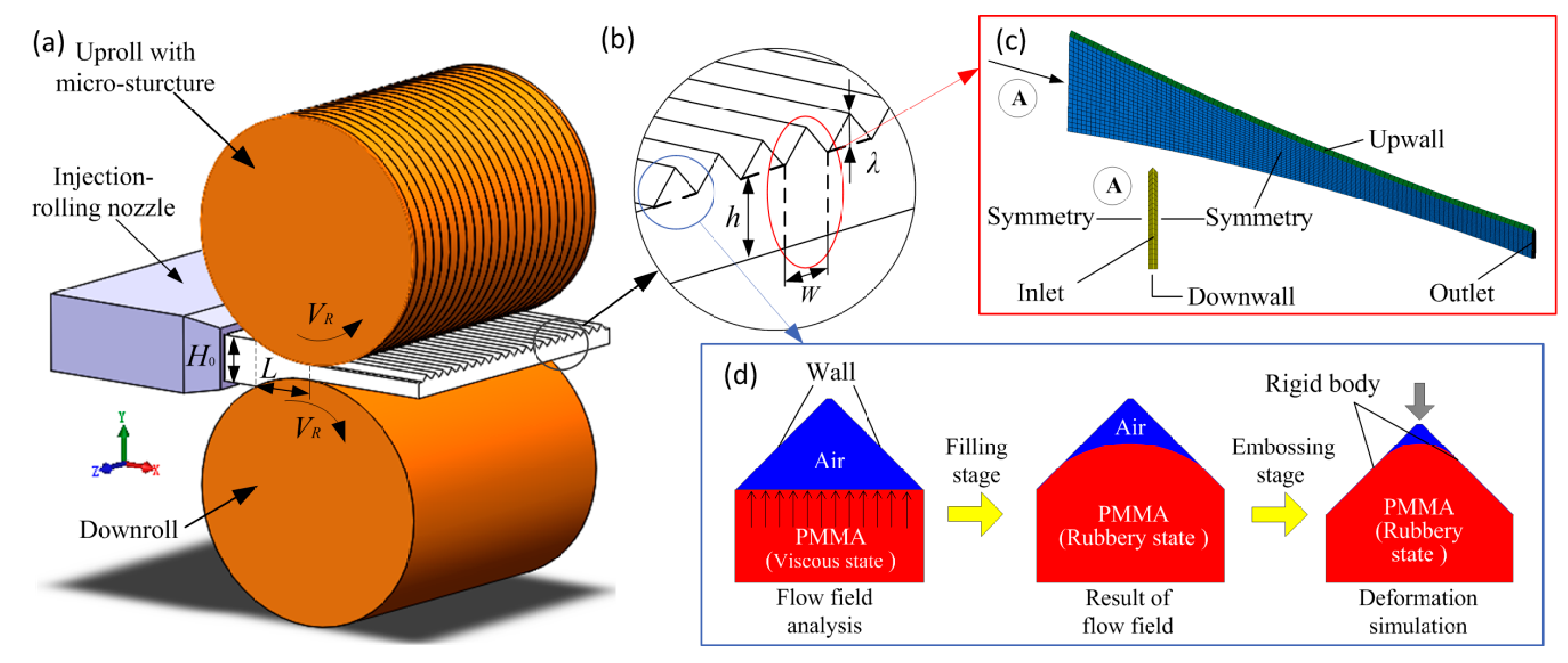

2.2. Finite Element Modeling

2.2.1. Mathematical Models and Boundary Conditions

2.2.2. Material Property

3. Results and Discussion

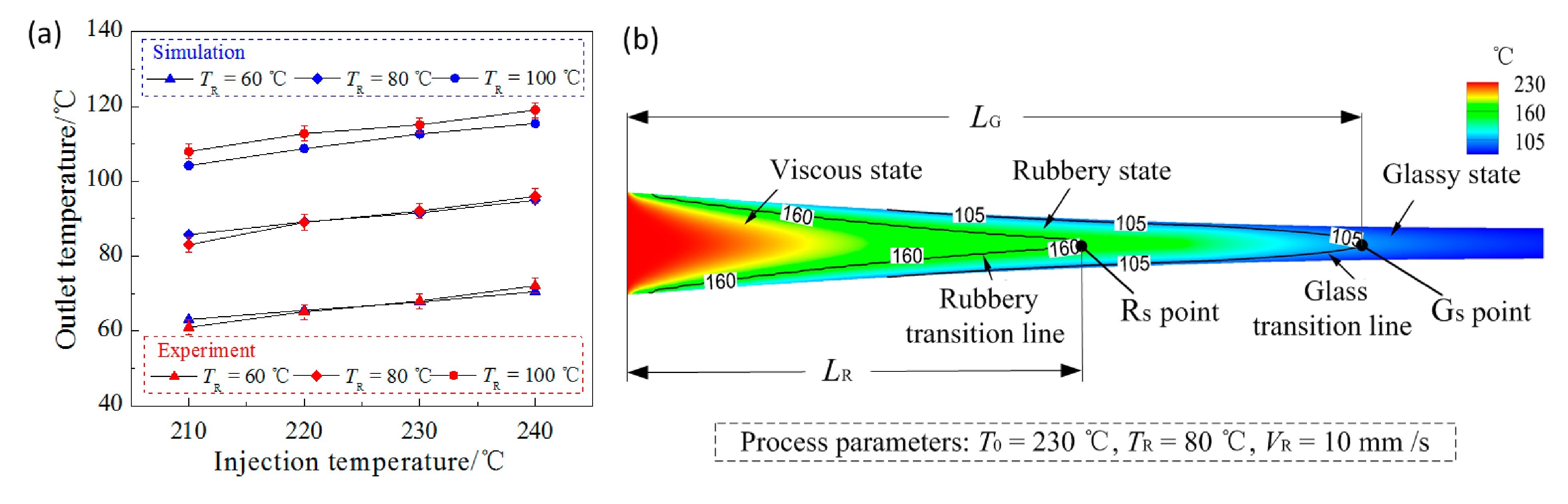

3.1. Simulation Results and Experimental Verification

3.1.1. Results and Verification of Injection-Rolling Zone Model

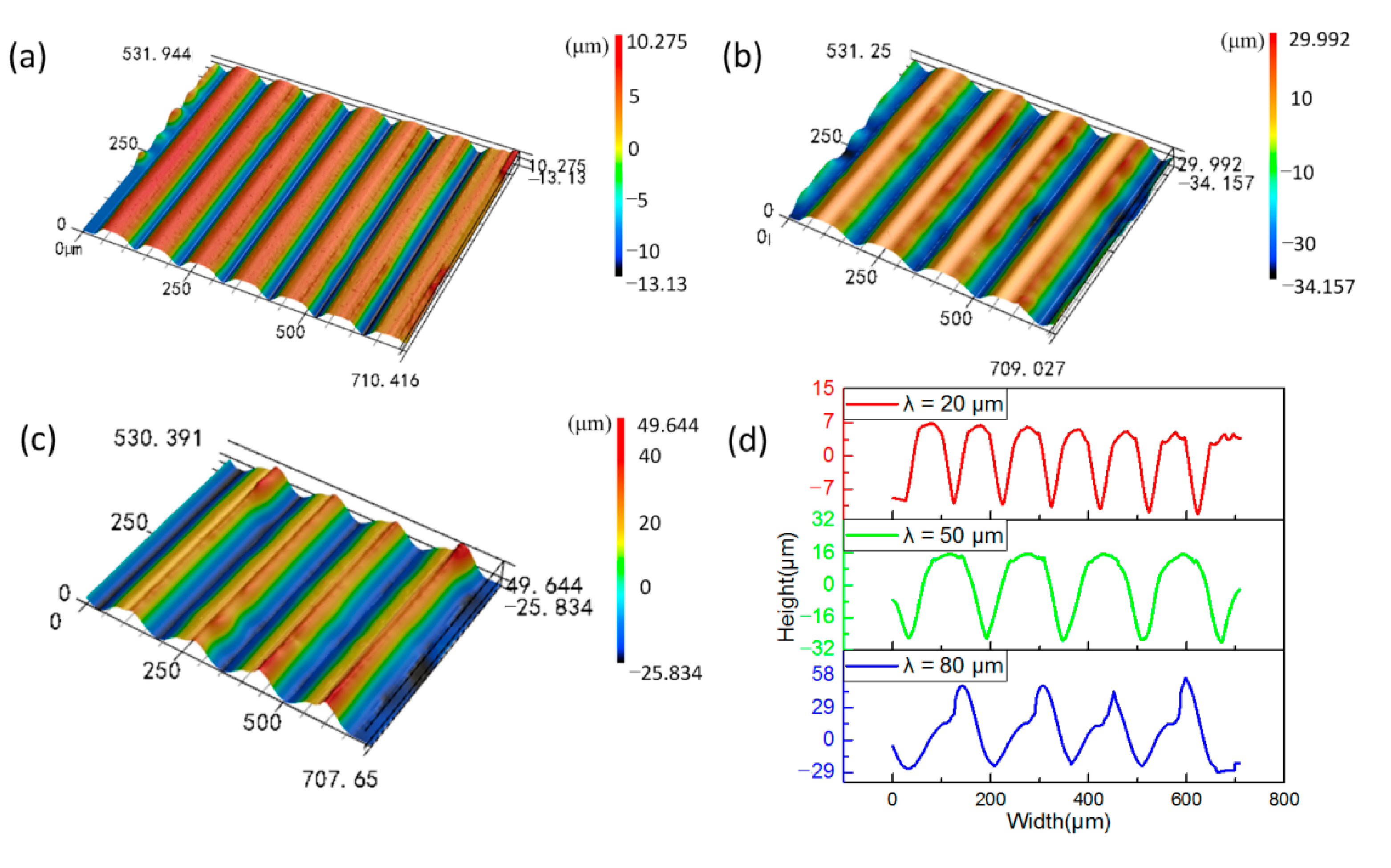

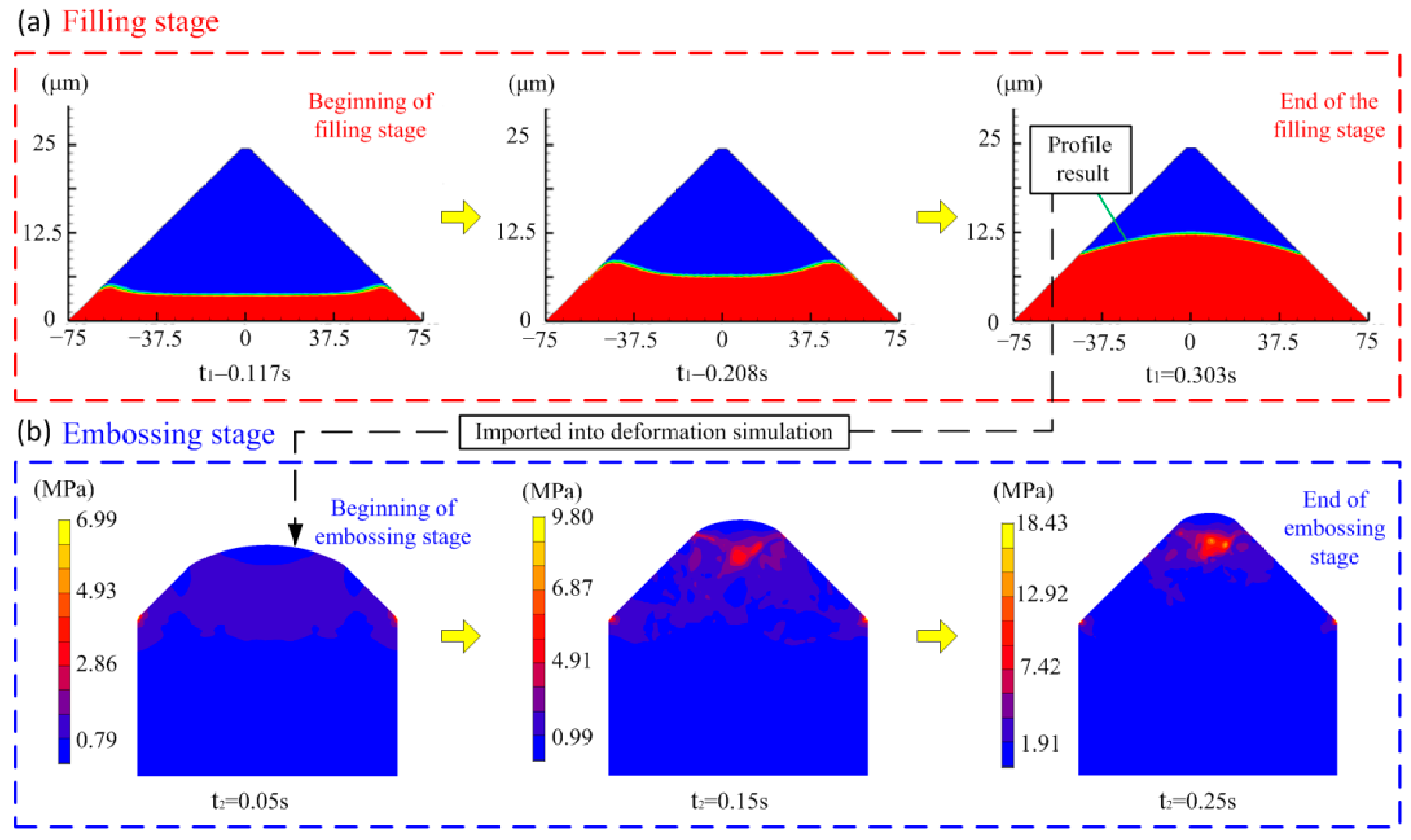

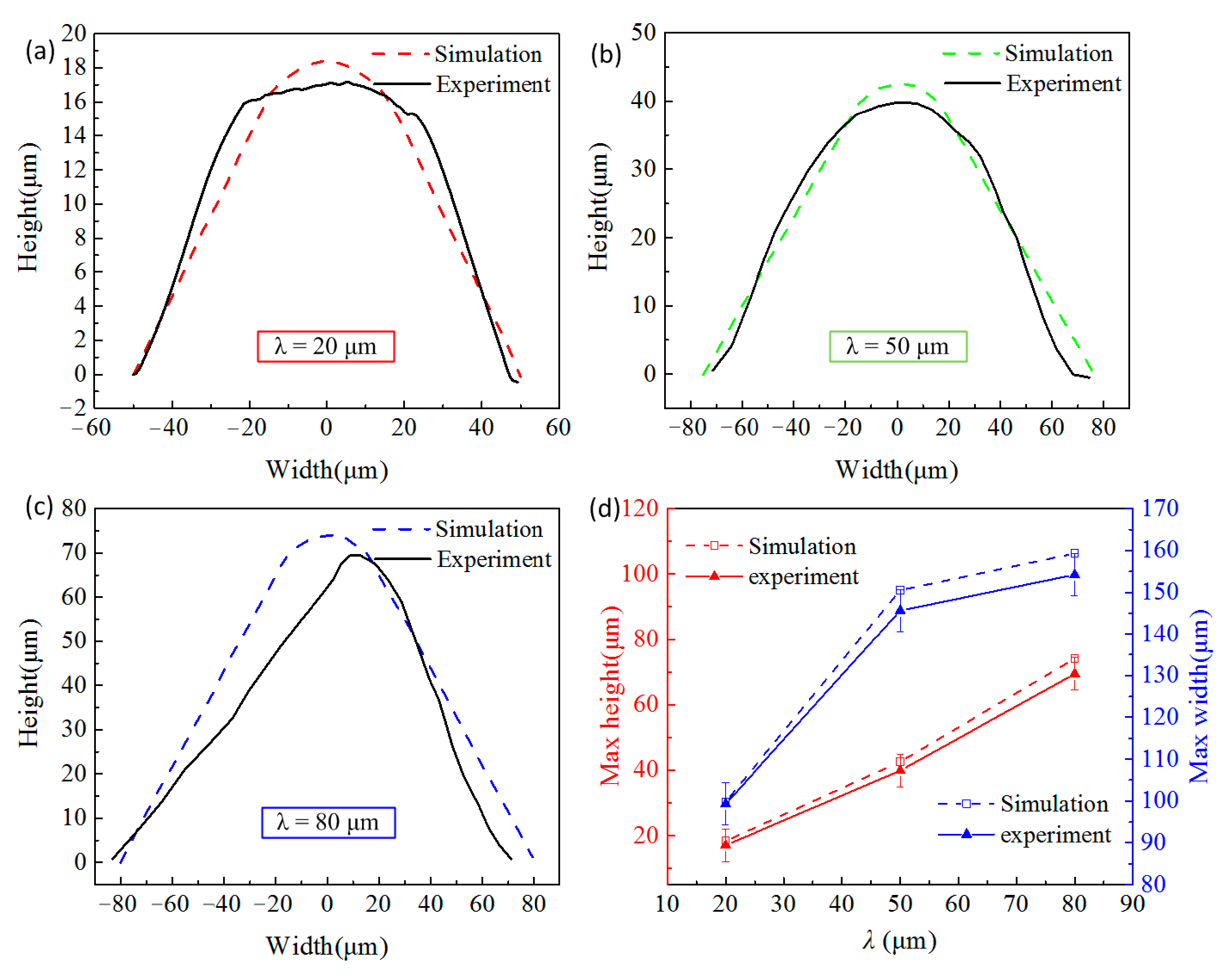

3.1.2. Verification of Microstructure-Forming Model

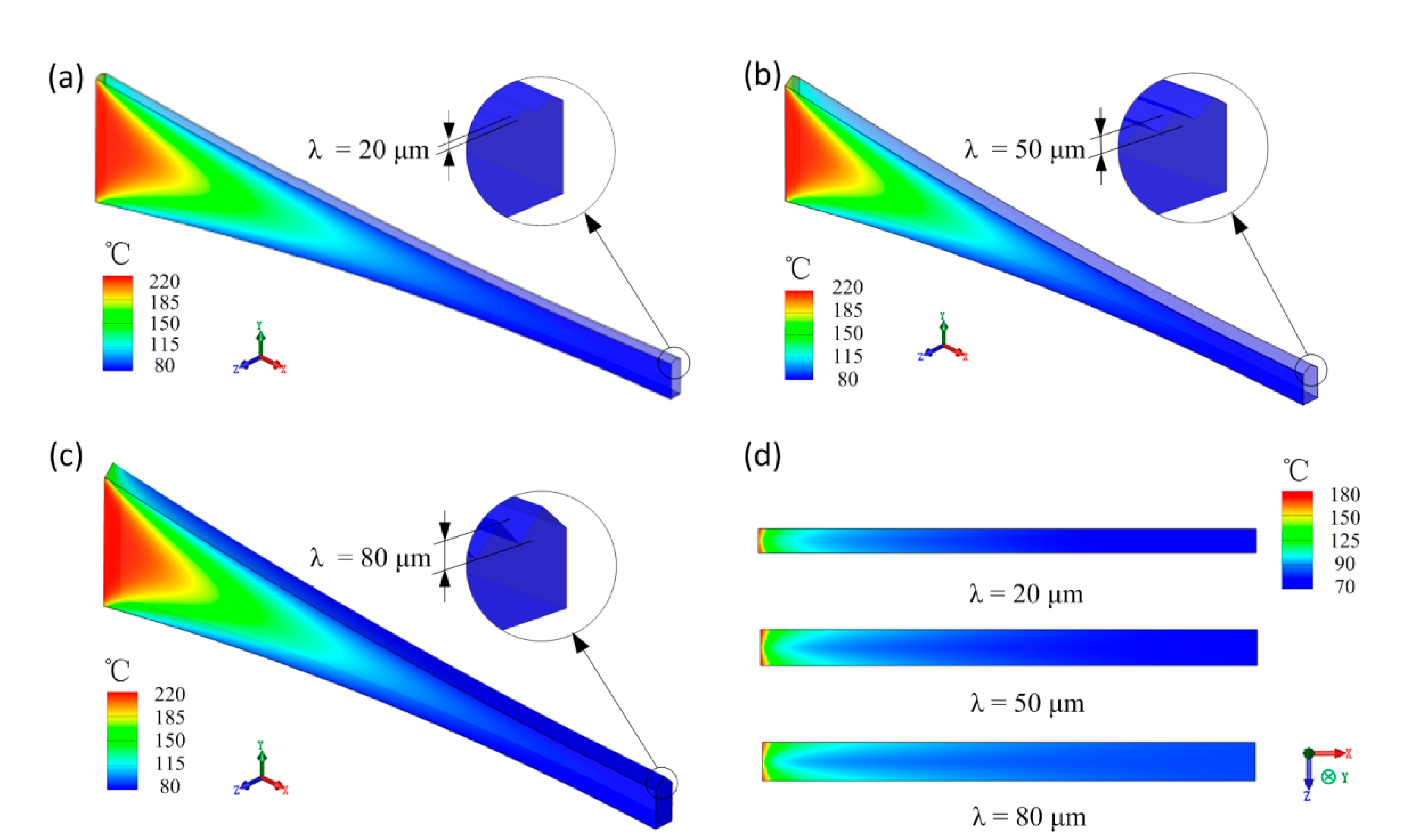

3.2. Effect of Microstructure Depth on Temperature Field in Injection-Rolling Zone

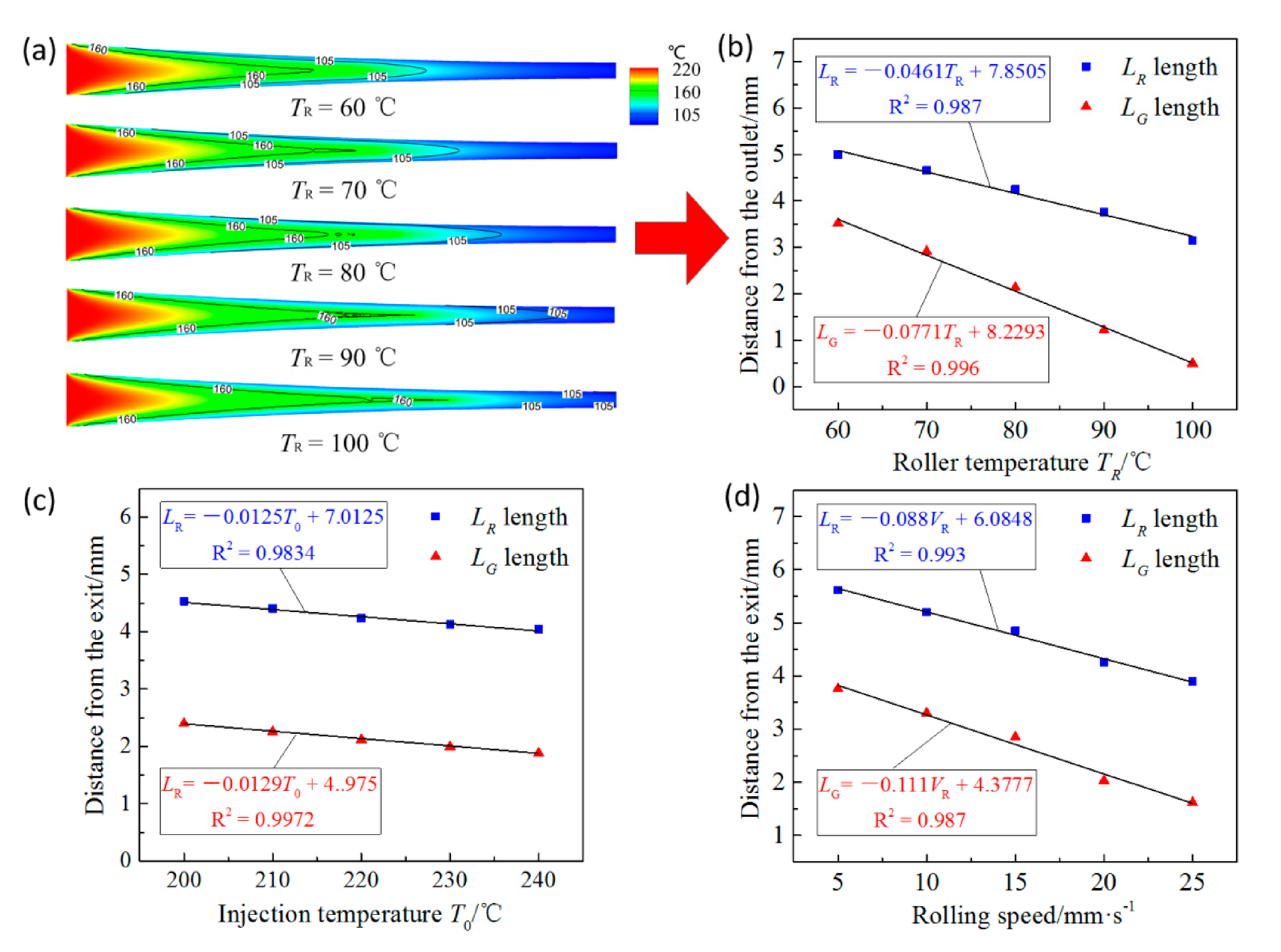

3.3. Effect of Parameters on Horizontal Positions of Rs and Gs

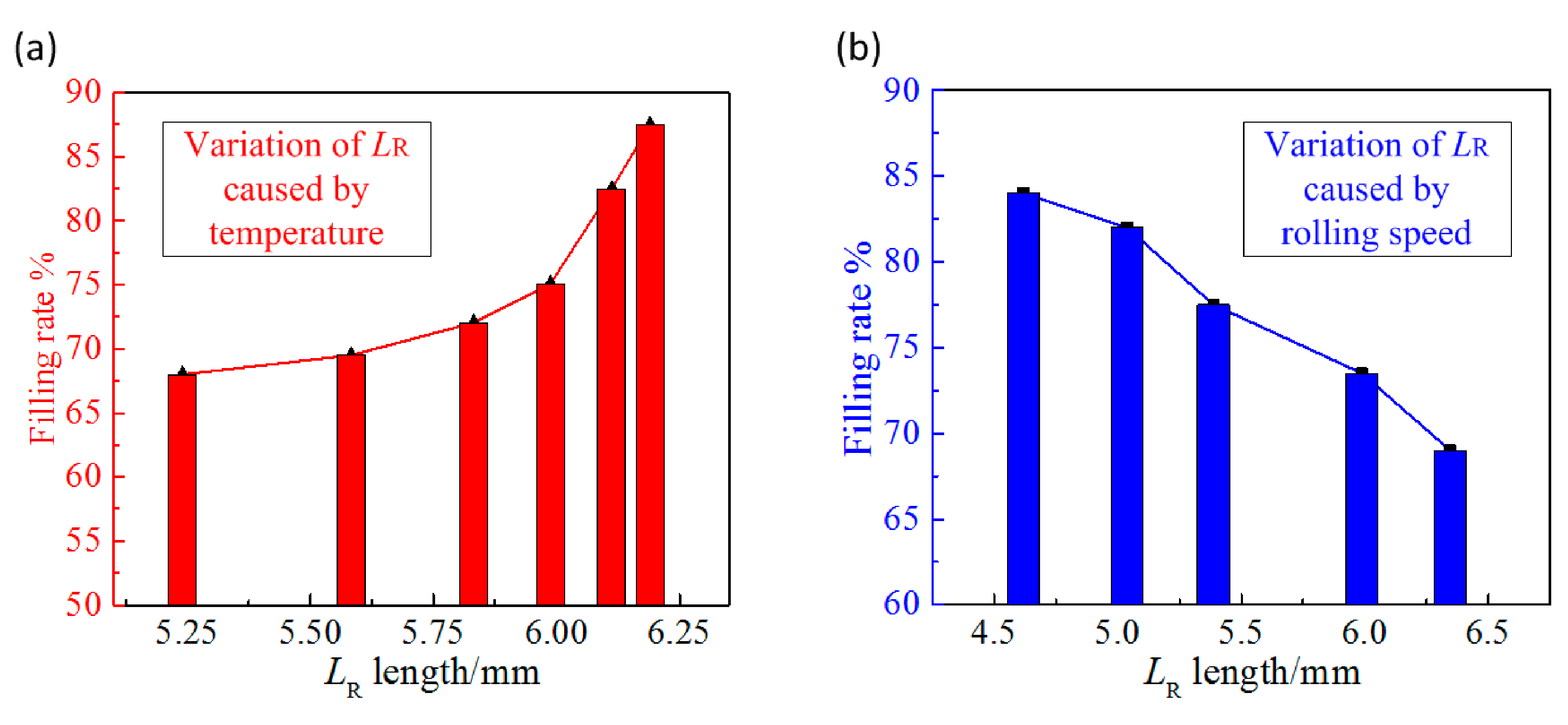

3.4. Effect of State Transition Interface on Microstructure Filling Rate

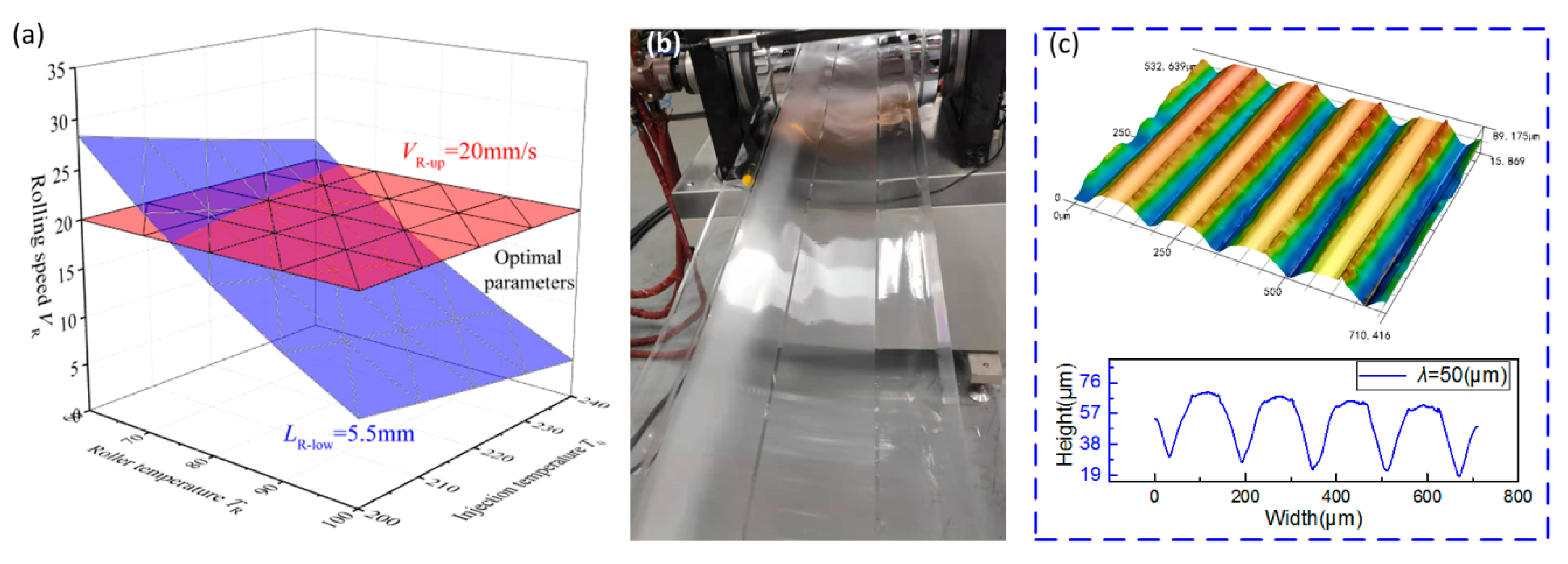

3.5. Optimal Process Parameters for the Injection-Rolling Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, D.; Jin, G.; Yan, Y.; Fan, S. High quality light guide plates that can control the illumination angle based on microprism structures. Appl. Phys. Lett. 2004, 85, 6016–6018. [Google Scholar] [CrossRef]

- Holthusen, A.K.; Riemer, O.; Schmuetz, J.; Meier, A. Mold machining and injection molding of diffractive microstructures. J. Manuf. Process 2017, 26, 290–294. [Google Scholar] [CrossRef]

- Lin, Y.H.; Huang, C.F.; Cheng, H.C.; Lin, Y. Flatness and microstructure of a light guide plate fabricated by microinjection molding. Polym. Eng. Sci. 2013, 53, 212–218. [Google Scholar] [CrossRef]

- Lim, H.C.; Kim, H.; Jang, K.; Kim, J.Y.; Baek, J.H.; Yang, S.J.; Jeong, S.H.; Park, J.R. Design and fabrication of light-guiding plate for a photobioreactor that utilizes sunlight. Opt. Rev. 2015, 2, 779–785. [Google Scholar] [CrossRef]

- Gao, S.; Qiu, Z.J.; Ouyang, J.H. The Improvement Effect and Mechanism of Longitudinal Ultrasonic Vibration on the Injection Molding Quality of a Polymeric Micro-Needle Array. Polymers 2019, 11, 151. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Xu, H.; Cheng, J.Y.; Zhao, N.; Chen, S.C. Flexure-based roll-to-roll platform: A practical solution for realizing large-area microcontact printing. Sci. Rep. 2015, 5, 10402. [Google Scholar] [CrossRef]

- Sun, H.W. Recent progress in low temperature nanoimprint lithography. Microsyst. Technol. 2015, 21, 1–7. [Google Scholar] [CrossRef]

- Cheng, G.; Sahli, M.; Gelin, J.C.; Barriere, T. Physical modelling, numerical simulation and experimental investigation of microfluidic devices with amorphous thermoplastic polymers using a hot embossing process. J. Mater. Process. Technol. 2016, 229, 36–53. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef]

- Wu, D.; Sun, J.; Liu, Y.; Yang, Z.; Xu, H.; Zheng, X.; Gou, P. Rapid fabrication of microstructure on PMMA substrate by the plate to plate Transition-Spanning isothermal hot embossing method nearby glass transition temperature. Polym. Eng. Sci. 2017, 57, 268–274. [Google Scholar] [CrossRef]

- Kolli, V.; Woidt, C.; Hillmer, H. Residual-layer-free 3D nanoimprint using hybrid softtemplates. Microelectron. Eng. 2016, 149, 159–165. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Zhang, W.; Guo, L.J.; Zhuang, L. Sub-10 nm imprint lithography and applications. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1997, 15, 2897–2904. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. High-speed roll-to-roll nanoimprint lithography on flexible plastic substrates. Adv. Mater. 2008, 20, 2044–2049. [Google Scholar] [CrossRef]

- Lim, H.; Choi, K.B.; Kim, G.; Lee, S.; Park, H.; Ryu, J.; Jung, S.; Lee, J. Roll-to-roll nanoimprint lithography for patterning on a large-area substrate roll. Microelectron. Eng. 2014, 123, 18–22. [Google Scholar] [CrossRef]

- Lou, Y.; Wu, G.; Li, J.; Wang, H.; Bai, C. Development of a continuous injection direct rolling imprint system for microstructure thin-plate. Microsyst. Technol. 2017, 23, 2509–2519. [Google Scholar] [CrossRef]

- Wang, H.; Lv, Y.; Lou, Y.; Li, J.; Cheung, C.F. Continuous injection direct rolling for optical elements with microstructures. Int. J. Adv. Manuf. Technol. 2016, 85, 2247–2255. [Google Scholar] [CrossRef]

- Feng, Y.; Lou, Y.; Lei, Q. Theoretical and experimental investigation of an ultrathin optical polymer light guide plate during continuous injection direct rolling. Int. J. Adv. Manuf. Technol. 2021, in press. [Google Scholar]

- Shan, X.C.; Liu, Y.C. LamStudies of polymer deformation and recovery in micro hot embossing. Microsyst. Technol. 2008, 14, 1055–1060. [Google Scholar] [CrossRef]

- Jin, P.; Gao, Y.; Liu, T. Simulation and experimental study on recovery of polymer during hot embossing. Jpn. J. Appl. Phys. 2009, 48, 1–6. [Google Scholar] [CrossRef]

- Hong, S.; Kang, J.; Yoon, K. Correlation between thermal contact resistance and filling behavior of a polymer melt into multiscale cavities in injection molding. Int. J. Heat Mass Transf. 2015, 87, 222–236. [Google Scholar] [CrossRef]

- Pignon, B.; Sobotka, V.; Boyard, N.; Delaunay, D. Improvement of heat transfer analytical models for thermoplastic injection molding and comparison with experiments. Int. J. Heat Mass Transf. 2017, 118, 14–26. [Google Scholar] [CrossRef]

- Liu, Y.; Gehde, M. Evaluation of heat transfer coefficient between polymer and cavity wall for improving cooling and crystallinity results in injection molding simulation. Appl. Therm. Eng. 2015, 80, 238–246. [Google Scholar] [CrossRef]

- Pawar, E. A review article on acrylic PMMA. IOSR J. Mech. Civil Eng. 2016, 13, 1–4. [Google Scholar]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A review of the properties and applications of poly (methyl methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Lou, Y.; Lei, Q.A.; Wu, G. Research on Polymer Viscous Flow Activation Energy and Non-Newtonian Index Model Based on Feature Size. Adv. Polym. Technol. 2019, 1, 1–11. [Google Scholar] [CrossRef]

- Ce, J.; Huang, H.; Sun, J. Process window prediction of solid-liquid cast-rolling bonding (SLCRB) process through numerical analysis to fabricate bimetallic clad pipes. Int. J. Heat Mass Transf. 2018, 120, 1305–1314. [Google Scholar]

| Parameters | Unit | Value |

|---|---|---|

| Roll diameter, R | mm | 300 |

| Initial thickness H0/Outlet thickness, h | mm | 1/0.3 |

| Microstructure height, λ/width, W | μm | 20/100, 50/150, 80/160 |

| Initial temperature, T0 | °C | 200, 210, 220, 230, 240 |

| Roll temperature, TR | °C | 60, 70, 80, 90, 100 |

| Rolling speed, VR | mm/s | 10, 15, 20, 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Lou, Y.; Shen, J. Microstructure-Forming Mechanism of Optical Sheet Based on Polymer State Transition in Injection-Rolling Process. Polymers 2021, 13, 181. https://doi.org/10.3390/polym13020181

Feng Y, Lou Y, Shen J. Microstructure-Forming Mechanism of Optical Sheet Based on Polymer State Transition in Injection-Rolling Process. Polymers. 2021; 13(2):181. https://doi.org/10.3390/polym13020181

Chicago/Turabian StyleFeng, Yanfeng, Yan Lou, and Jun Shen. 2021. "Microstructure-Forming Mechanism of Optical Sheet Based on Polymer State Transition in Injection-Rolling Process" Polymers 13, no. 2: 181. https://doi.org/10.3390/polym13020181

APA StyleFeng, Y., Lou, Y., & Shen, J. (2021). Microstructure-Forming Mechanism of Optical Sheet Based on Polymer State Transition in Injection-Rolling Process. Polymers, 13(2), 181. https://doi.org/10.3390/polym13020181