Thermoplastic Pultrusion: A Review

Abstract

1. Introduction

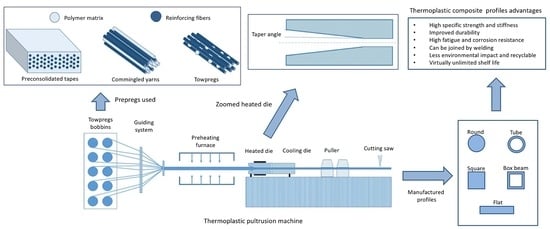

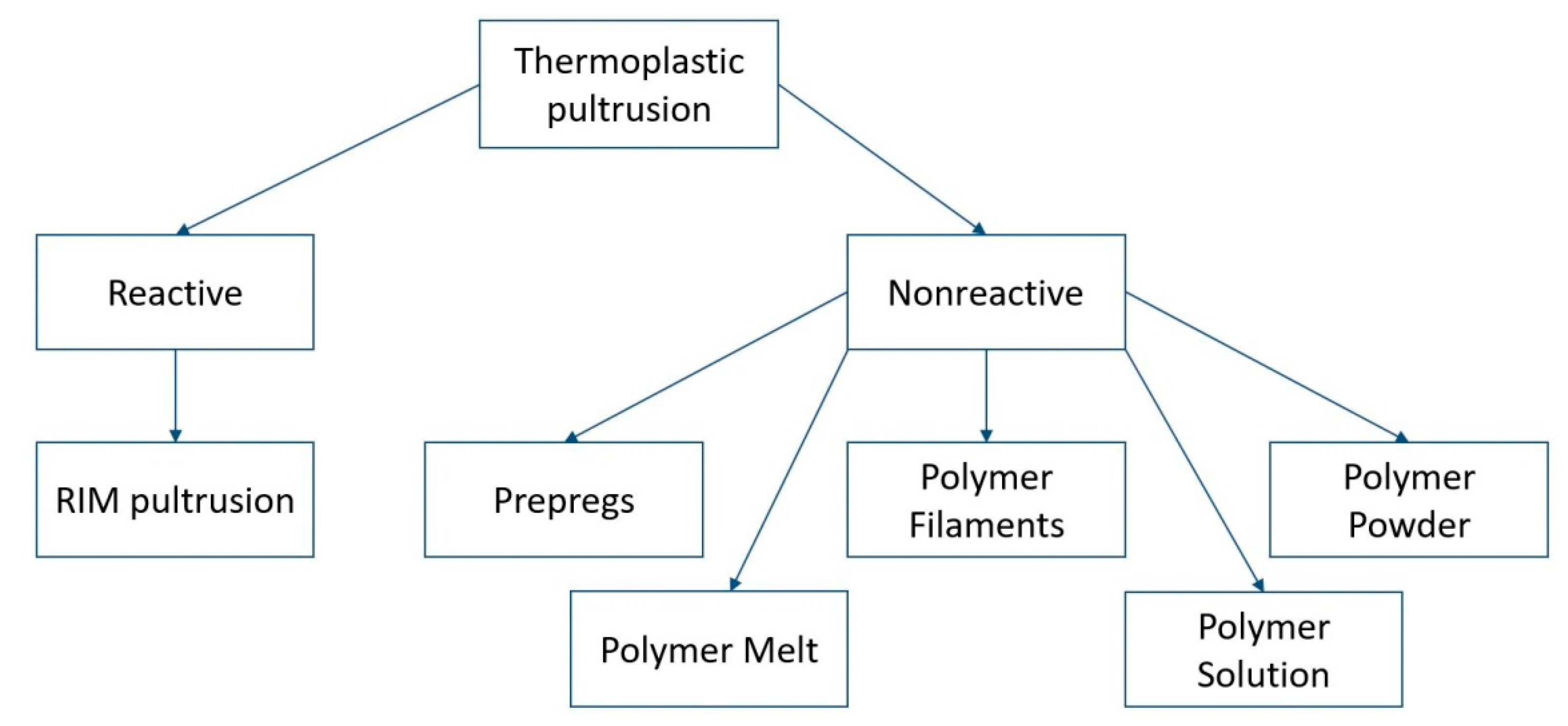

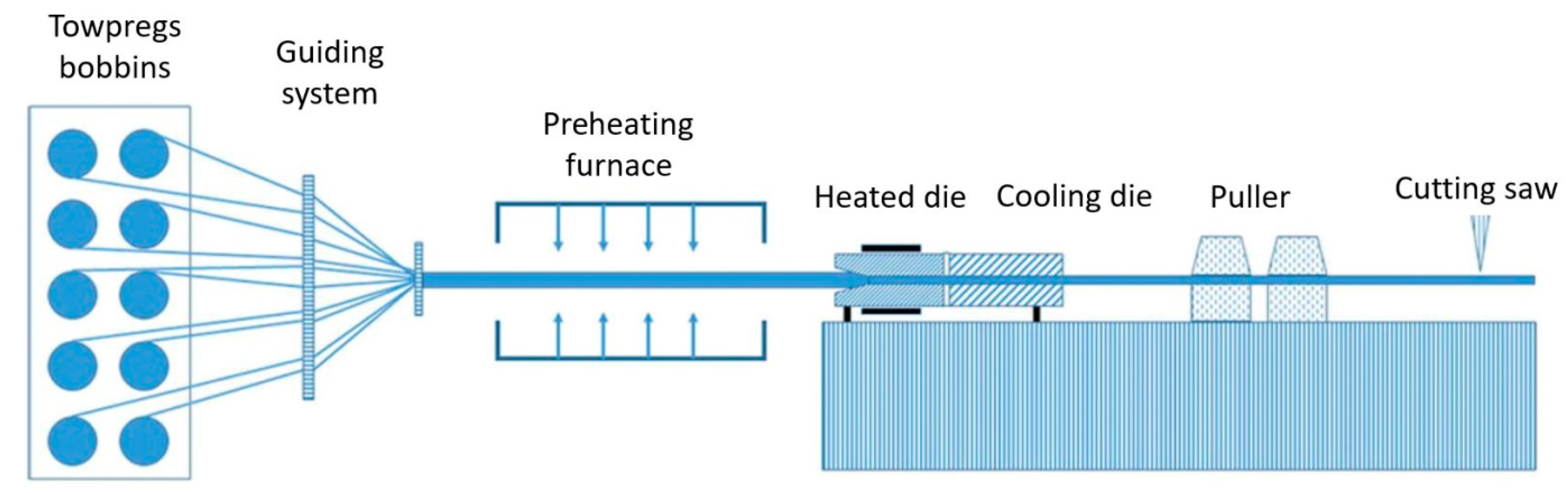

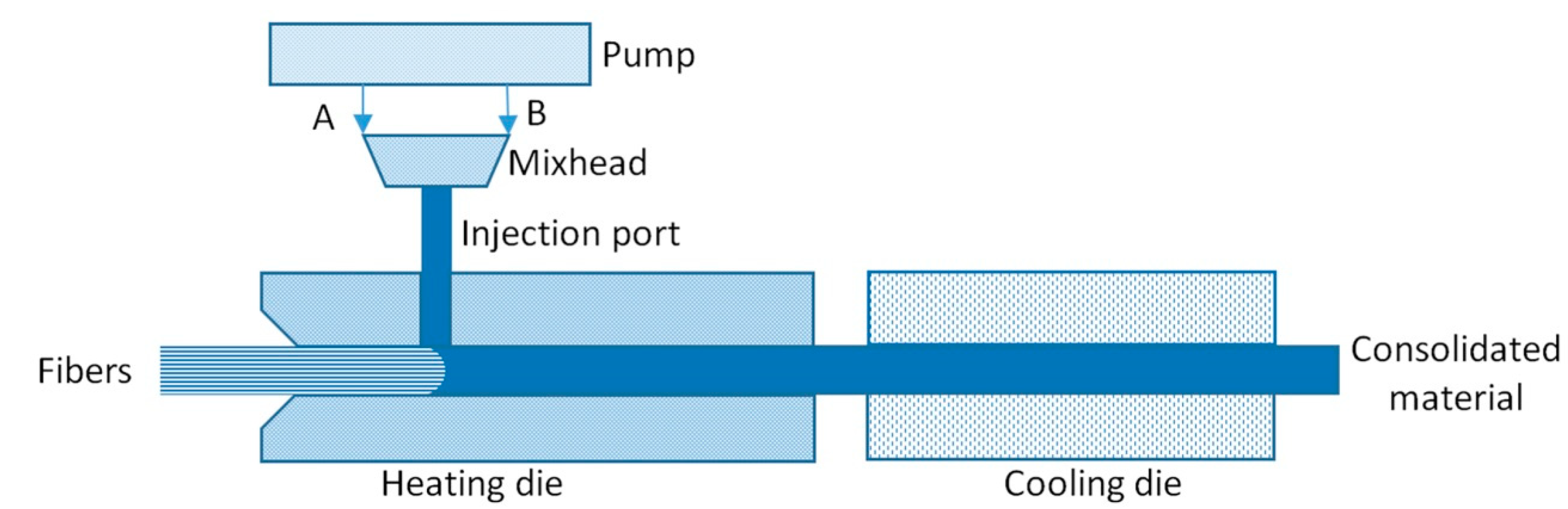

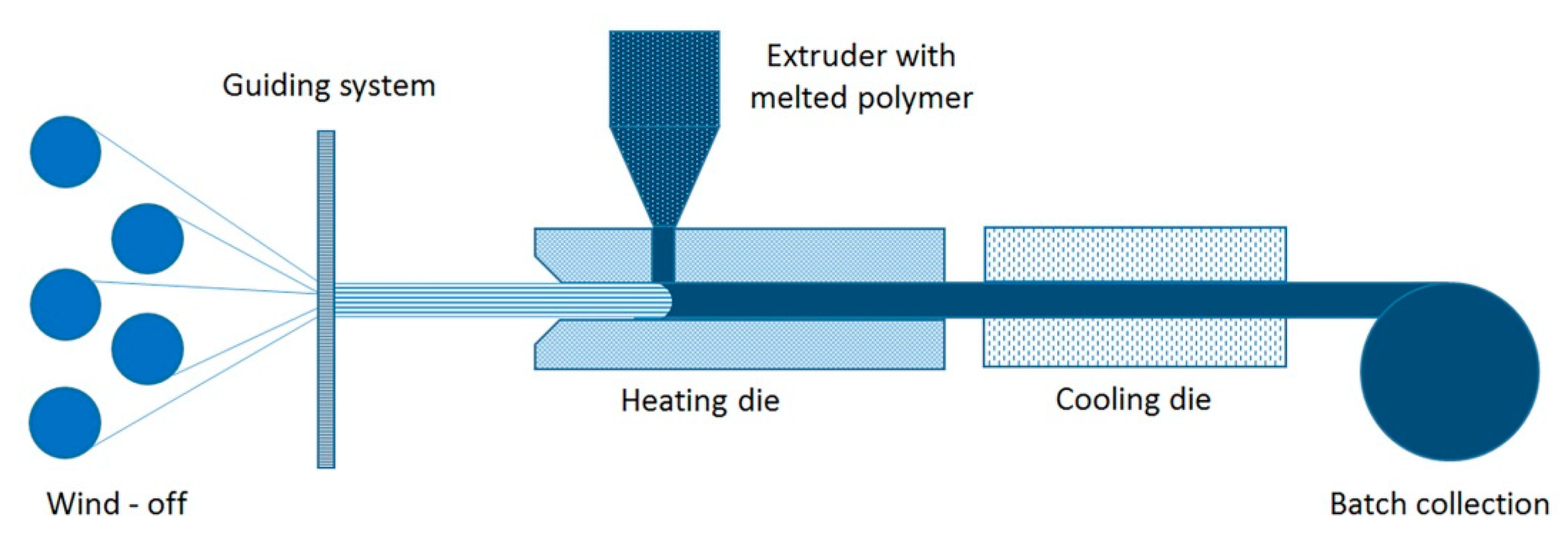

2. Thermoplastic Pultrusion and Process Parameters

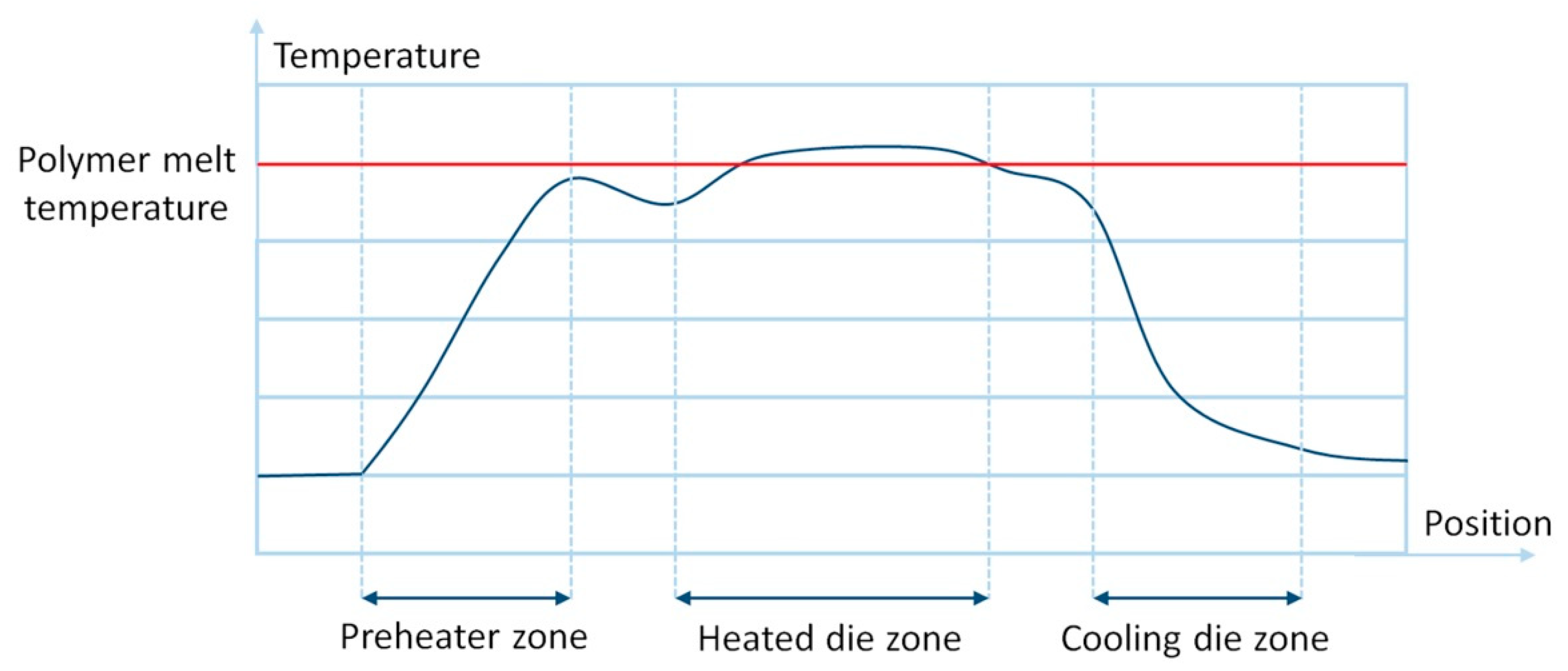

2.1. Preheater Temperature

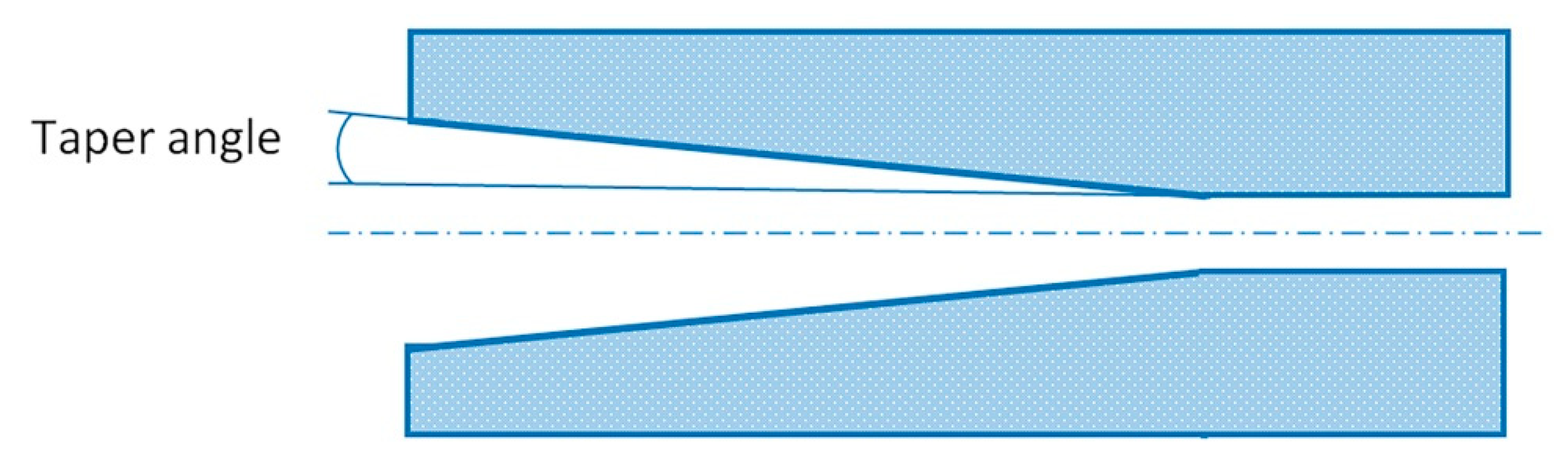

2.2. Temperature and Geometry of the Heated Die

2.3. Heated Die Pressure

2.4. Temperature of a Cooling Die

2.5. Pulling Speed

2.6. Pulling Force

2.7. Future Trends

3. Raw Materials and Properties of Obtained Composites

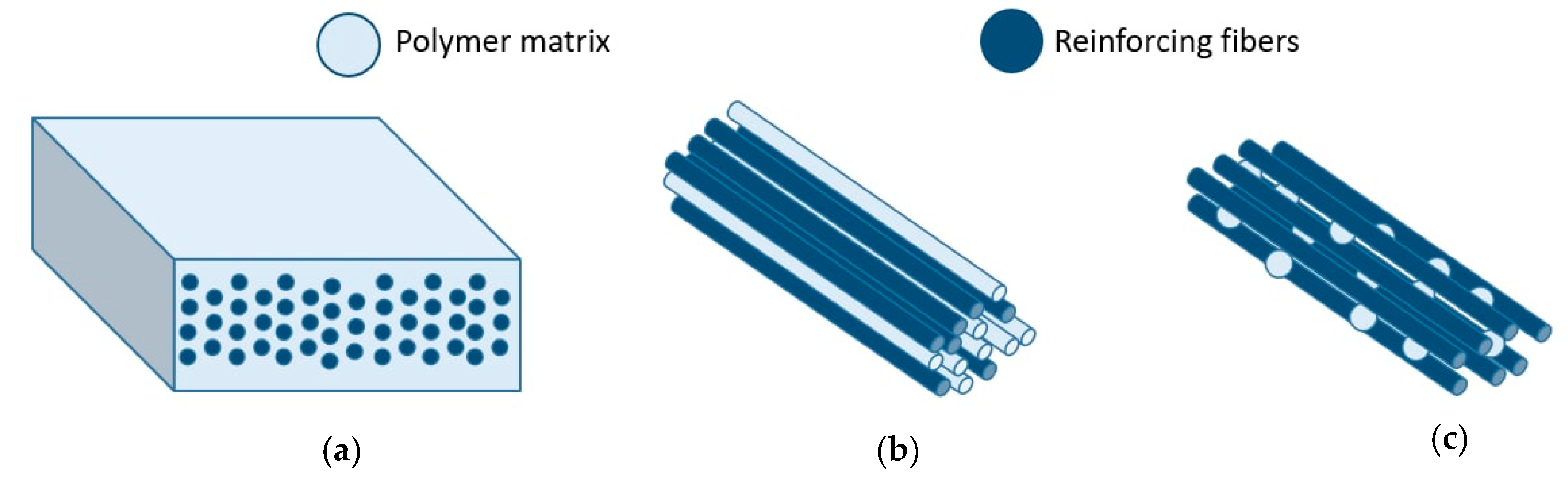

3.1. Preconsolidated Tape

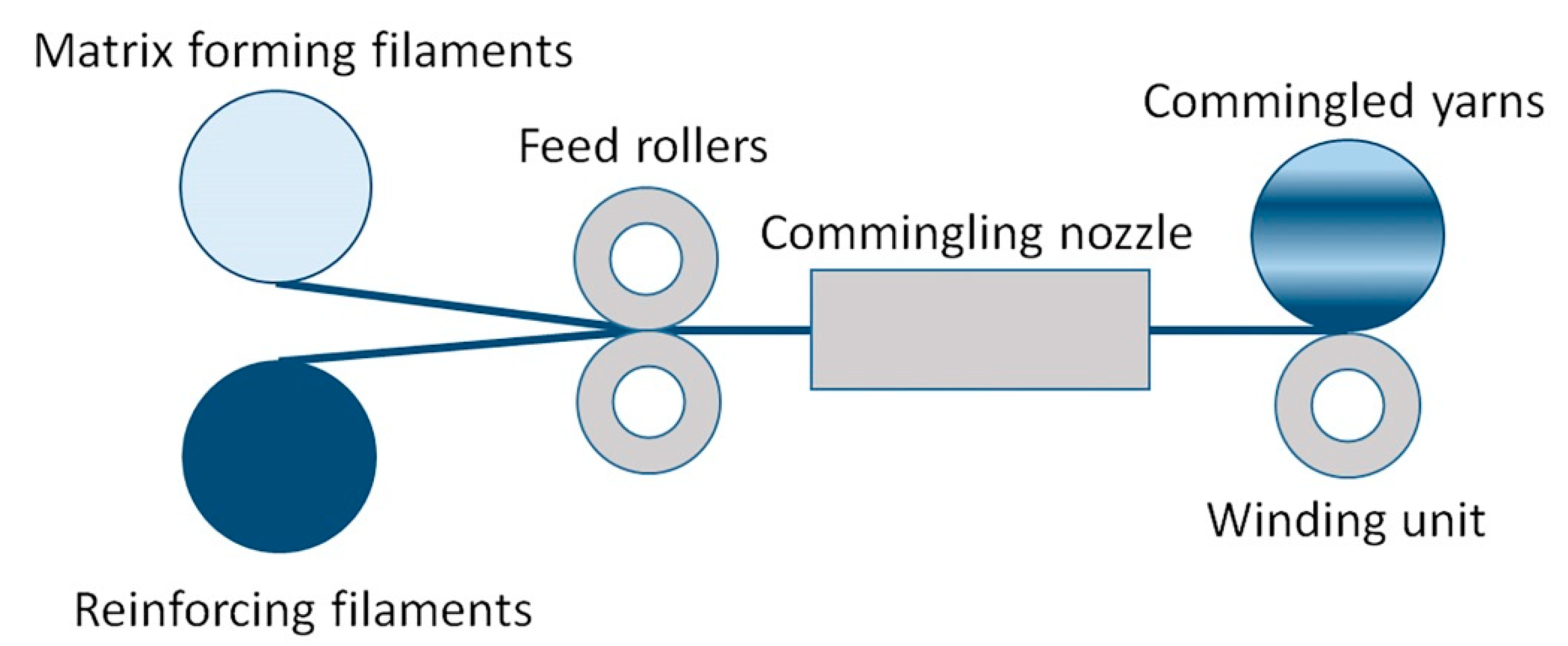

3.2. Commingled Yarns (CY)

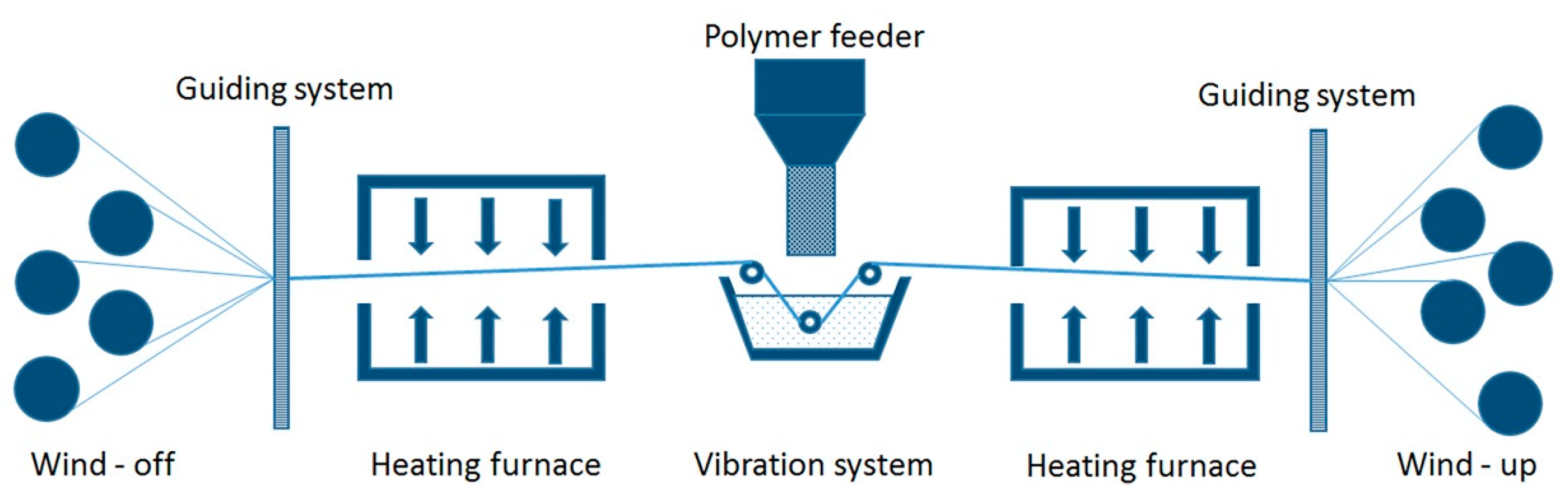

3.3. Towpregs

3.4. Mechanical Properties of Obtained Composites

3.5. Durability of Thermoplastic Pultruded Materials

3.6. Future Trends

4. Process Modeling

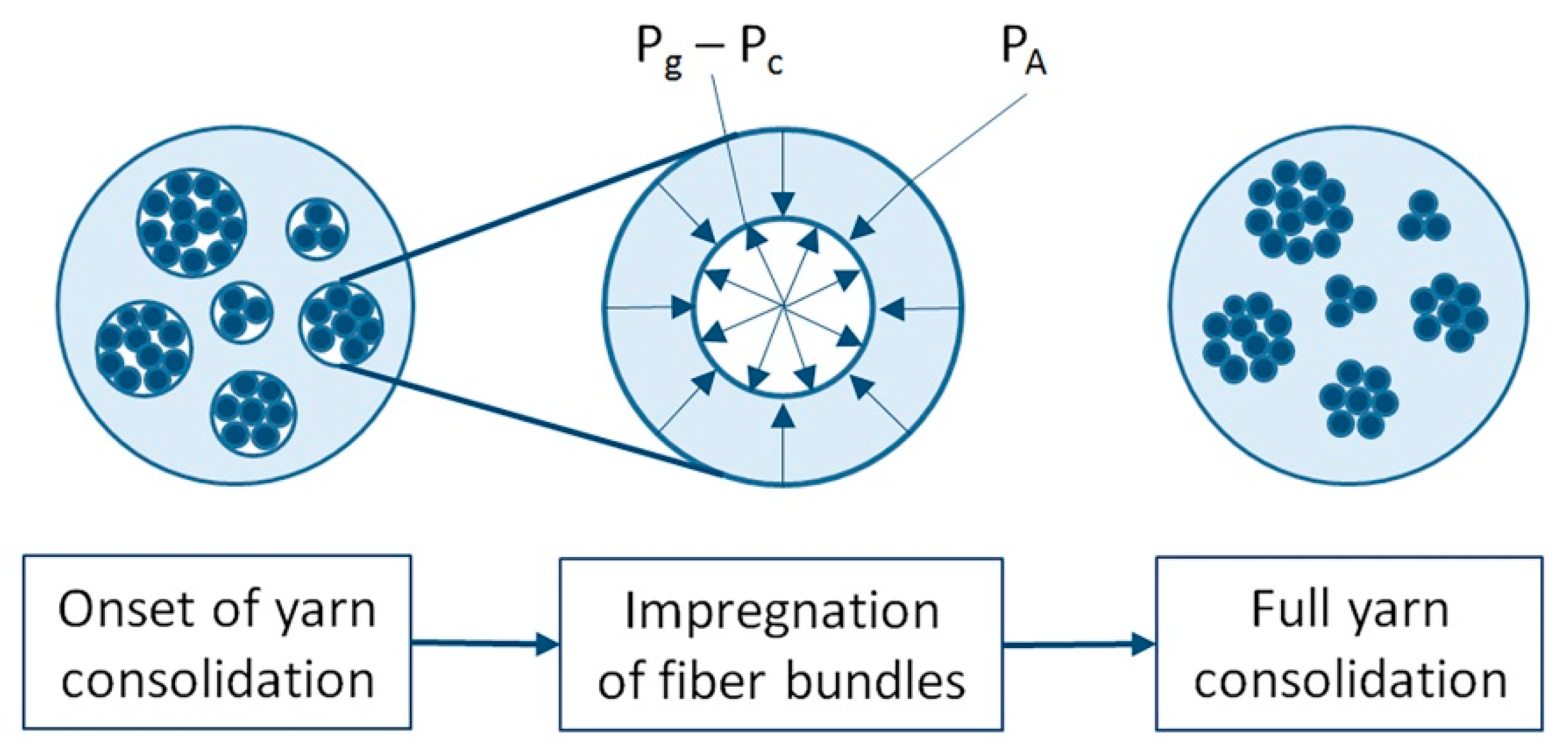

4.1. Impregnation

- Reinforcing fibers are represented by separate groups (agglomerations) in the thermoplastic melt (Figure 10);

- These groups have an elliptical or circular section;

- Fibers are impregnated uniformly over the bulk of the product on all sides.

4.2. Temperature Distribution

4.3. Pressure and Pulling Force

4.4. Future Trends

5. Application

5.1. Pultrusion Market

5.2. Patents

5.3. Current Applications of Thermoplastic Pultruded Profiles

5.4. Future Trends

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6. [Google Scholar] [CrossRef]

- Starr, T.F. Pultrusion for Engineers; Woodhead Publishing: Cambridge, UK, 2000; ISBN 9781855734258. [Google Scholar]

- Yuksel, O.; Sandberg, M.; Baran, I.; Ersoy, N.; Hattel, J.H.; Akkerman, R. Material characterization of a pultrusion specific and highly reactive polyurethane resin system: Elastic modulus, rheology, and reaction kinetics. Compos. Part B Eng. 2020, 108543. [Google Scholar] [CrossRef]

- Liu, T.; Feng, P.; Lu, X.; Yang, J.-Q.; Wu, Y. Flexural behavior of novel hybrid multicell GFRP-concrete beam. Compos. Struct. 2020, 250. [Google Scholar] [CrossRef]

- Budiyantoro, C.; Rochardjo, H.S.B.; Nugroho, G. Effects of processing variables of extrusion–pultrusion method on the impregnation quality of thermoplastic composite filaments. Polymers 2020, 12, 2833. [Google Scholar] [CrossRef]

- Uslu, E.; Gavgali, M.; Erdal, M.O.; Yazman, Ş.; Gemi, L. Determination of mechanical properties of polymer matrix composites reinforced with electrospinning N66, PAN, PVA and PVC nanofibers: A comparative study. Mater. Today Commun. 2021, 26. [Google Scholar] [CrossRef]

- Guo, Z.; Zhu, Y.; Chen, Y.; Zhao, Y. Test on residual ultimate strength of pultruded concrete-filled GFRP tubular short columns after lateral impact. Compos. Struct. 2020, 113520. [Google Scholar] [CrossRef]

- Madenci, E.; Onuralp Özkılıç, Y.; Gemi, L. Buckling and free vibration analyses of pultruded GFRP laminated composites: Experimental, numerical and analytical investigations. Compos. Struct. 2020, 254. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; AlAjarmeh, O.; Mohammed, A.A.; Salih, C.; Yu, P.; Mehrinejad Khotbehsara, M.; Schubel, P. Static behaviour of glass fibre reinforced novel composite sleepers for mainline railway track. Eng. Struct. 2021, 229. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Mechanical property evolution and life prediction of carbon fiber and pultruded carbon fiber reinforced polymer plate exposed to elevated temperatures. Polym. Compos. 2020, 41, 5143–5155. [Google Scholar] [CrossRef]

- Vedernikov, A.N.; Safonov, A.A.; Gusev, S.A.; Carlone, P.; Tucci, F.; Akhatov, I.S. Spring-in experimental evaluation of L-shaped pultruded profiles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 747, 012013. [Google Scholar] [CrossRef]

- Mukherji, A.; Njuguna, J. Shock Propagation Behaviour and Determination of Greisen State of Equation for Pultruded Polyester/Glass Fibre-Reinforced Composites. Compos. Struct. 2020, 113444. [Google Scholar] [CrossRef]

- Sirajudeen, R.S.; Sekar, R. Buckling Analysis of Pultruded Glass Fiber Reinforced Polymer (GFRP) Angle Sections. Polymers 2020, 12, 2532. [Google Scholar] [CrossRef] [PubMed]

- Ueda, M.; Ui, N.; Ohtani, A. Lightweight and anti-corrosive fiber reinforced thermoplastic rivet. Compos. Struct. 2018, 188, 356–362. [Google Scholar] [CrossRef]

- Ding, L.; Liu, L.; Wang, X.; Shen, H.; Wu, Z. Effects of connecting materials on the static and fatigue behavior of pultruded basalt fiber-reinforced polymer bolted joints. Constr. Build. Mater. 2020, 121683. [Google Scholar] [CrossRef]

- Haloi, J.; Kumar Mushahary, S.; Chandra Borsaikia, A.; Darunkumar Singh, K. Experimental investigation on the web crippling behaviour of pultruded GFRP wide-flange sections subjected to two-flange loading conditions. Compos. Struct. 2020, 113469. [Google Scholar] [CrossRef]

- Wang, Z.; Li, C.; Sui, L.; Xian, G. Effects of adhesive property and thickness on the bond performance between carbon fiber reinforced polymer laminate and steel. Thin-Walled Struct. 2021, 158. [Google Scholar] [CrossRef]

- Poulton, M.; Sebastian, W. Taxonomy of fibre mat misalignments in pultruded GFRP bridge decks. Compos. Part A Appl. Sci. Manuf. 2020, 106239. [Google Scholar] [CrossRef]

- Borsellino, C.; Urso, S.; Alderucci, T.; Chiappini, G.; Rossi, M.; Munafò, P. Temperature effects on failure mode of double lap glass-aluminum and glass-GFRP joints with epoxy and acrylic adhesive. Int. J. Adhes. Adhes. 2021, 105. [Google Scholar] [CrossRef]

- Kar, K.K. Composite Materials. Processing, Application, Characterization; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9783662495148. [Google Scholar]

- Advani, S.G.; Hsiao, K.T. Introduction to composites and manufacturing processes. In Manufacturing Techniques for Polymer Matrix Composites (PMCs): A Volume in Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2012. [Google Scholar]

- Vedernikov, A.; Tucci, F.; Safonov, A.; Carlone, P.; Gusev, S.; Akhatov, I. Investigation on the Shape Distortions of Pultruded Profiles at Different Pulling Speed. Procedia Manuf. 2020, 47, 1–5. [Google Scholar] [CrossRef]

- Sapanci, E.; Günay, G.E.; Aydoǧmuş, A.; Roketsan, A.S. Composite canister profile manufacturing by pultrusion process. In Proceedings of the International SAMPE Technical Conference, Seattle, CA, USA, 22–26 May 2017. [Google Scholar]

- Passos, A.; de Aguiar, R.; Costa, H.; Sampaio, E.; de Barros, S. Adherence of geopolymer and pultruded composite substrates: Influence of adhesive type and surface treatment. J. Adhes. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Sandberg, M.; Yuksel, O.; Baran, I.; Hattel, J.H.; Spangenberg, J. Numerical and experimental analysis of resin-flow, heat-transfer, and cure in a resin-injection pultrusion process. Compos. Part A Appl. Sci. Manuf. 2020, 106231. [Google Scholar] [CrossRef]

- Schäfer, J.; Gries, T.; Schuster, R.; Lammel, C. Continious production of fibre reinforced thermoplastic composites by braiding pultrusion. In Proceedings of the ICCM International Conferences on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; Volume 2015. [Google Scholar]

- Zou, X.; Lin, H.; Feng, P.; Bao, Y.; Wang, J. A review on FRP-concrete hybrid sections for bridge applications. Compos. Struct. 2020. [Google Scholar] [CrossRef]

- Safonov, A.A.; Carlone, P.; Akhatov, I. Mathematical simulation of pultrusion processes: A review. Compos. Struct. 2018, 184, 153–177. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ma, C.C.M.; Yn, M.S. Poly (ϵ-caprolactam)-poly (butadiene-co-acrylonitrile) block copolymers II. Processability and properties of pultruded glass-fiber-reinforced composites. Mater. Chem. Phys. 1995, 42. [Google Scholar] [CrossRef]

- Novo, P.J.; Silva, J.F.; Nunes, J.P.; Marques, A.T. Advances in thermoplastic pultruded composites. In Proceedings of the ICCM International Conferences on Composite Materials, Copenhagen, Denmark, 19 July 2015; Volume 2015. [Google Scholar]

- Pillay, S.; Thattaiparthasarathy, K.B.; Vaidya, U.K.; Husman, G. Development of pultrusion process and applications for thermoplastic composites. In Proceedings of the International SAMPE Symposium and Exhibition, Long Beach, CA, USA, 12–16 May 2007; Volume 52. [Google Scholar]

- Sumerak, J.E. Pultruded composites in impact and toughness driven applications achieve new performance levels with polyurethane resin. In Proceedings of the International SAMPE Symposium and Exhibition, Long Beach, CA, USA, 11–15 May 2003; Volume 48 II. [Google Scholar]

- Han, N.; Baran, I.; Zanjani, J.S.M.; Yuksel, O.; An, L.; Akkerman, R. Experimental and computational analysis of the polymerization overheating in thick glass/Elium® acrylic thermoplastic resin composites. Compos. Part B Eng. 2020, 202, 108430. [Google Scholar] [CrossRef]

- Bechtold, G.; Wiedmer, S.; Friedrich, K. Pultrusion of thermoplastic composites—New developments and modelling studies. J. Thermoplast. Compos. Mater. 2002, 15. [Google Scholar] [CrossRef]

- Miller, A.H.; Dodds, N.; Hale, J.M.; Gibson, A.G. High speed pultrusion of thermoplastic matrix composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 773–782. [Google Scholar] [CrossRef]

- Vaughan, J.G.; Dillard, T.W.; Seal, E. A Characterization of the Important Parameters for Graphite/PEEK Pultrusion. J. Thermoplast. Compos. Mater. 1990, 3. [Google Scholar] [CrossRef]

- Epple, S.; Bonten, C. Production of continuous fiber thermoplastic composites by in-situ pultrusion. AIP Conf. Proc. 2014, 1593, 454–457. [Google Scholar] [CrossRef]

- Udipi, K.; Dave, R.S.; Kruse, R.L.; Stebbins, L.R. Anionic Polymerization of Lactams: Some Industrial Applications. ACS Symp. Ser. 1998, 696. [Google Scholar] [CrossRef]

- Neise, E. Long-Fiber Reinforced Thermoplastics. Gummi Fasern Kunstst. 1986, 39, 282–287. [Google Scholar]

- Chauzu, F. Process for Producing a Rigid Composite Structure Obtained by welding Profiles and Rigid Frames Obtained Thereby. F.R. Patent 3037856A1, 29 June 2016. [Google Scholar]

- Wei, S.M. Application study of FRTP materials in the civil engineering products. In Proceedings of the Applied Mechanics and Materials, Anshan, China, 13–17 July 2013; Volume 395–396. [Google Scholar]

- Ben, G.; Hirabayashi, A.; Kawazoe, Y. Evaluation of quasi-isotropic plate and cylindrical shell fabricated with green composite sheets. Adv. Compos. Mater. 2013, 22. [Google Scholar] [CrossRef]

- Lebel, L.L.; Nakai, A. Design and manufacturing of an L-shaped thermoplastic composite beam by braid-trusion. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1717–1729. [Google Scholar] [CrossRef]

- Vincent, G.A.; de Bruijn, T.A.; Wijskamp, S.; van Drongelen, M.; Akkerman, R. Process- and material-induced heterogeneities in recycled thermoplastic composites. J. Thermoplast. Compos. Mater. 2020, 0892705720979347. [Google Scholar] [CrossRef]

- Erber, A.; Janetzko, S.; Spitko, S.; Brudzinski, P.V. Comparison of process chains for the production of thermoplastic UD-tapes and organic sheets. In Proceedings of the ECCM 2016—Proceeding of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Edwards, C. Thermoplastic pultrusion promises new synergies. Reinf. Plast. 2001, 45. [Google Scholar] [CrossRef]

- Ramani, K.; Borgaonkar, H.; Hoyle, C. Experiments on compression moulding and pultrusion of thermoplastic powder impregnated towpregs. Compos. Manuf. 1995, 6, 35–43. [Google Scholar] [CrossRef]

- Liu, M.; Yan, B.; Peng, X.; Peng, F.; Wang, L. Crashworthiness of Thermoplastic Woven Glass Fabric Reinforced Composite Tubes Manufactured by Pultrusion. Fibers Polym. 2020, 21, 416–427. [Google Scholar] [CrossRef]

- Suresh, S.; Senthil Kumar, V.S. Effects of fabric structure on the formability characteristics of thermoplastic composites under various process conditions. Trans. Can. Soc. Mech. Eng. 2018, 42, 298–308. [Google Scholar] [CrossRef]

- Choudhury, M.R.; Debnath, K. A review of the research and advances in electromagnetic joining of fiber-reinforced thermoplastic composites. Polym. Eng. Sci. 2019, 59, 1965–1985. [Google Scholar] [CrossRef]

- Ahmed, T.J.; Stavrov, D.; Bersee, H.E.N.; Beukers, A. Induction welding of thermoplastic composites-an overview. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1638–1651. [Google Scholar] [CrossRef]

- Bayerl, T.; Duhovic, M.; Mitschang, P.; Bhattacharyya, D. The heating of polymer composites by electromagnetic induction—A review. Compos. Part A Appl. Sci. Manuf. 2014, 57, 27–40. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I.P.S.; Penna, R.; Feo, L. Weldability of thermoplastic materials for friction stir welding- A state of art review and future applications. Compos. Part B Eng. 2018, 137, 1–15. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Barsotti, R.J. Ultrasonic welding of novel carbon/elium® thermoplastic composites with flat and integrated energy directors: Lap shear characterisation and fractographic investigation. Materials 2020, 13, 1634. [Google Scholar] [CrossRef]

- Belingardi, G.; Beyene, A.T.; Koricho, E.G.; Martorana, B. Lightweight Solutions for Vehicle Frontal Bumper: Crash Design and Manufacturing Issues; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2017; ISBN 9780081009024. [Google Scholar]

- Guillon, D.; Lemasçon, A.; Callens, C. QSP®: An innovative process based on tailored preforms for low cost and fast production of optimized thermoplastic composite parts. In Proceedings of the ECCM 2016—Proceeding of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Flores, R.; Fuller, D.; Green, S.; Ho, T.; Kajdan, T.; Lee, R.; McKelvy, M.; Sutton, T.; Traugott, T. Long glass fiber polyolefin systems for automotive applications requiring UV and thermal stability. In Proceedings of the Society of Petroleum Engineers International Conference on Polyolefins 2006: From Reserves to Retailers—The Changes Confronting the Polyolefins Business Worldwide, Houston, TX, USA, 26 February–1 March 2006; Volume 2. [Google Scholar]

- Bartus, S.D.; Vaidya, U.K.; Ulven, C.A. Design and development of a long fiber thermoplastic bus seat. J. Thermoplast. Compos. Mater. 2006, 19. [Google Scholar] [CrossRef]

- Mascarin, A.E.; Wzorek, J.F.; Rossi, G.; Brachos, V. Development of a manufacturing strategy for moderate volume production of a composite vehicle structure. In Proceedings of the SAE Technical Papers, Detroit, MI, USA, 29 September–1 October 1998. [Google Scholar]

- Crosby, J.M.; Drye, T.R. Fracture Studies of Discontinuous Fiber Reinforced Thermoplastic Composites. J. Reinf. Plast. Compos. 1987, 6. [Google Scholar] [CrossRef]

- Zoller, A.; Escalé, P.; Gérard, P. Pultrusion of Bendable Continuous Fibers Reinforced Composites with Reactive Acrylic Thermoplastic ELIUM® Resin. Front. Mater. 2019, 6, 1–9. [Google Scholar] [CrossRef]

- Fortier, V.; Brunel, J.-E.; Lebel, L. Fastening composite structures using braided thermoplastic composite rivets. J. Compos. Mater. 2019, 54, 002199831986737. [Google Scholar] [CrossRef]

- Offringa, A. Design and application of a pultrusion for multiple use in the Fokker 100. Compos. Struct. 1988, 10. [Google Scholar] [CrossRef]

- Nunes, J.P.; Siva, J.F. Production of thermoplastic matrix towpregs for highly demanding and cost-effective commercial applications. In Proceedings of the Materials Science Forum, Guimaraes, Portugal, 18–22 April 2013; Volume 730–732. [Google Scholar]

- Botelho, E.C.; Scherbakoff, N.; Rezende, M.C.; Kawamoto, A.M.; Sciamareli, J. Synthesis of polyamide 6/6 by interfacial polycondensation with the simultaneous impregnation of carbon fibers. Macromolecules 2001, 34. [Google Scholar] [CrossRef]

- Taylor, S.R. Industrial/commercial applications for pultruded thermoplastic composites. In Proceedings of the International SAMPE Technical Conference, 24th and International SAMPE Metals and Metals Processing Conference, Toronto, ON, Canada, 20–24 October 1992; Volume 24. [Google Scholar]

- Essiga, W.; Kreutzbruck, M. Development of an inline monitoring system for quality assurance of thermoplastic CFRP tape using air-coupled ultrasound. In Proceedings of the AIP Conference Proceedings, Cancun, Mexico, 10–14 December 2019; Volume 2139. [Google Scholar]

- Yu, Z.; Wang, X.; Wu, D. Mechanical properties, impact fracture behavior, and morphology of long-polyimide-fiber-reinforced poly(butylene terephthalate) composites. J. Compos. Mater. 2017, 51. [Google Scholar] [CrossRef]

- Peled, A.; Mobasher, B.; Cohen, Z. Mechanical properties of hybrid fabrics in pultruded cement composites. Cem. Concr. Compos. 2009, 31. [Google Scholar] [CrossRef]

- Gilby, J. Pultrusion provides roof solution. Reinf. Plast. 1998, 42. [Google Scholar] [CrossRef]

- Nunes, J.P.; Silva, J.F.; Ferreira, J.C.; Marques, A.T. New composite poles for electrical lighting, transport and distribution. In Proceedings of the ICCM International Conferences on Composite Materials, Edinburgh, Scotland, 27–31 July 2009. [Google Scholar]

- Alam, P.; Ansell, M.P.; Smedley, D. Mechanical repair of timber beams fractured in flexure using bonded-in reinforcements. Compos. Part B Eng. 2009, 40, 95–106. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Summerscales, J. Composites manufacturing for marine structures. In Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2016. [Google Scholar]

- Seymour, R.J.; Sloan, F.E. Pultrusion and thermoforming of a graphite-reinforced-thermoplastic marine cable. In Proceedings of the International SAMPE Symposium and Exhibition (Proceedings), San Diego, CA, USA, 15–18 April 1991; Volume 36. [Google Scholar]

- Chisholm, J.M.; Hahn, H.T.; Williams, J.G. Effect of seawater on the fracture toughness of pultruded rods. In Proceedings of the American Society of Mechanical Engineers, Applied Mechanics Division, AMD, Berkeley, CA, USA, 20–22 June 1988; Volume 92. [Google Scholar]

- Buck, M. Advanced thermoplastic composites processing. JEC Compos. Mag. 2005, 14, 54–56. [Google Scholar]

- Zhang, S.; Wang, X.; Wu, D. Design and fabrication of long-carbon-fiber-reinforced polyamide-6/nickel powder composites for electromagnetic interference shielding and high mechanical performance. Polym. Compos. 2016, 37, 2705–2718. [Google Scholar] [CrossRef]

- Kemmerer, J.; Ward, S. Effects of fiber length and orientation on the electrical conductivity of long carbon fiber reinforced thermoplastic molding compounds. In Proceedings of the International SAMPE Symposium and Exhibition (Proceedings), Los Angeles, CA, USA, 20–22 June 1989; Volume 3. [Google Scholar]

- Wood, K.; Skilton, R.W.; Wille, R.; Barré, T.; Hayes, J.; Harasin, S. High performance in the frame Waterborne finishes for PU pultrusion window profiles need no primer. Proc. Eur. Coat. J. 2013, 5, 18–22. [Google Scholar]

- Nakai, A.; Uozumi, T.; Ohtani, A.; Kanamori, T.; Nagoh, S. High-cycle molding of continuous fiber reinforced thermoplastic composites pipe. In Proceedings of the ICCM International Conferences on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; Volume 2015. [Google Scholar]

- Cervenka, A. Composite pipes based on thermoplastic matrices reinforced by continuous fibres. In Proceedings of the Mechanics of Composite Materials and Structures, Troia, Portugal, 12–24 July 1999. [Google Scholar]

- El-Tahan, M.; Galal, K.; Hoa, V.S. New thermoplastic CFRP bendable rebars for reinforcing structural concrete elements. Compos. Part B Eng. 2013, 45, 1207–1215. [Google Scholar] [CrossRef]

- Montsinger, L.V. MTI thermoplastic pultrusion process. J. Eng. Appl. Sci. 1996, 2, 2546–2551. [Google Scholar]

- Nakada, M.; Miyano, Y.; Morisawa, Y.; Nishida, H.; Hayashi, Y.; Uzawa, K. Prediction of statistical life time for unidirectional CFRTP under creep loading. J. Reinf. Plast. Compos. 2019, 38, 938–946. [Google Scholar] [CrossRef]

- Greco, A.; Romano, G.; Maffezzoli, A. Selective reinforcement of LLDPE components produced by rotational molding with thermoplastic matrix pultruded profiles. Compos. Part B Eng. 2014, 56. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, Z.; Zhang, Z.; Ou, J. Study on the fabricating process monitoring of thermoplastic based materials packaged OFBG and their sensing properties. In Proceedings of the Sensor Systems and Networks: Phenomena, Technology, and Applications for NDE and Health Monitoring, San Diego, CA, USA, 18–22 March 2007; Volume 6530. [Google Scholar]

- Cowen, G.; Measuria, U.; Turner, R.M. Section pultrusions of continuous fibre reinforced thermoplastics. In Proceedings of the I Mech E Conference Publications (Institution of Mechanical Engineers), Liverpool, UK, 8–10 April 1986. [Google Scholar]

- About Fiberline Building Profiles. Available online: https://fiberline.com/about-us/who-we-are/ (accessed on 18 December 2020).

- Luisier, A.; Bourban, P.E.; Månson, J.A.E. Reaction injection pultrusion of PA12 composites: Process and modelling. Compos. Part A Appl. Sci. Manuf. 2003, 34, 583–595. [Google Scholar] [CrossRef]

- Bechtold, G.; Wiedmer, S.; Friedrich, K. Composite Materials Pultrusion of Thermoplastic Composites—New Developments. J. Thermoplast. Compos. Mater. 2002, 15, 443–465. [Google Scholar] [CrossRef]

- Carlsson, A.; Tomas Åström, B. Experimental investigation of pultrusion of glass fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 585–593. [Google Scholar] [CrossRef]

- Carlsson, A.; Astrom, B.T. Modelling of heat transfer and crystallization kinetics in thermoplastic pultrusion. Int. SAMPE Symp. Exhib. 1996, 41, 1324–1334. [Google Scholar]

- Bates, P.; Ekhator, I. Continuous consolidation of commingled glass and polypropylene roving. J. Reinf. Plast. Compos. 2004, 23, 1409–1424. [Google Scholar] [CrossRef]

- Wiedmer, S.; Manolesos, M. An experimental study of the pultrusion of carbon fiber-polyamide 12 yarn. J. Thermoplast. Compos. Mater. 2006, 19, 97–112. [Google Scholar] [CrossRef]

- Linganiso, L.Z.; Bezerra, R.; Bhat, S.; John, M.; Braeuning, R.; Anandjiwala, R.D. Pultrusion of flax/poly(lactic acid) commingled yarns and nonwoven fabrics. J. Thermoplast. Compos. Mater. 2014, 27, 1553–1572. [Google Scholar] [CrossRef]

- Zhu A Thermoplastic-Composite-Material Pultrusion Technology. C.N. Patent 105599323A, 14 March 2016.

- Hatano, D.; Takagi, M.; Ohtani, A.; Nakai, A. Pultrusion system for continuous fiber reinforced thermoplastic composite with braiding technique. In Proceedings of the 26th Annual Technical Conference of the American Society for Composites 2011 and the 2nd Joint US-Canada Conference on Composites, Jeju, Korea, 21–26 August 2011; Volume 2. [Google Scholar]

- Takai, Y.; Nakai, A.; Hamada, H. Mechanical properties of thermoplastic pultrusion products with braiding technique. In Proceedings of the ICCM International Conferences on Composite Materials, Kyoto, Japan, 3–8 July 2007. [Google Scholar]

- Reese, E. Thermoplastic FRP Multi-Chamber Hollow Profile and Wicket Pultrusion Process and Braided Pultrusion Plant for Its Production. D.E. Patent 102011119245A1, 22 November 2011. [Google Scholar]

- Reese, E. Pultrusion Process for Producing a Thermoplastic FRP Hollow Profile. D.E. Patent 102016008192A1, 5 July 2016. [Google Scholar]

- Reese, E. Braiding Pultrusion Method for Manufacturing Thermoplastic Fiber Reinforced Plastics Hollow Profile in Pultrusion System, Involves Creating Multi-Layered Hollow Profile Braid of Multiple Hybrid Rovings Fiber Tapes. D.E. Patent 102011018420A1, 21 March 2011. [Google Scholar]

- Reese, E. Continuous Braiding Pultrusion Process for a Thermoplastic FRP Hollow Section and Braided Pultrusion Line. D.E. Patent 102011018422A1, 21 April 2011. [Google Scholar]

- Reese, E. Braid Pultrusion Method for Manufacturing Bent Thermoplastic or Fiber Reinforced Plastic-Hollow in Pultrusion System, Involves Generating Multi-Layer Hollow Profile Braid Made of Multiple Hybrid Rovings or Fiber Tapes. D.E. Patent 102011100546A1, 5 May 2011. [Google Scholar]

- Memon, A.; Nakai, A. Mechanical properties of jute spun Yarn/PLA tubular braided composite by pultrusion molding. Energy Procedia 2013, 34, 818–829. [Google Scholar] [CrossRef]

- Guan, Y.; Qu, X.; Shi, Y.; Qu, C. Fiber Reinforced Thermoplastic Composite Material Direct Online Pultrusion Moulding Device. C.N. Patent 102363363B, 25 October 2011. [Google Scholar]

- Cheng, Y.; Cheng, Z. Pultrusion Method and Equipment for Thermoplastic Composite Material of Continuous Fiber. C.N. Patent 101913255A, 13 September 2010. [Google Scholar]

- Kilian, B.; Bruening, D.; Remmel, J. Pultrusion Method for Producing Fibre-Reinforced Plastic Profiled Sections and Pultrusion Device. U.S. Patent 20200282674A1, 6 October 2017. [Google Scholar]

- Louis, L.L.; Mannot, P.; Oswald, A.; Lapointe, F. Pultruded Beam Reinforced With Natural Fibers, Pultrusion System and Method Therefor. U.S. Patent 20190193346A1, 22 June 2017. [Google Scholar]

- Johnson, D.W.; Garrett, S.A.; Moyers, S.G. Thermoplastic Pultrusion Die System and Method. U.S. Patent 8684722B1, 24 March 2009. [Google Scholar]

- Johnson, D.W.; Garrett, S.A.; Moyers, S.G. Thermoplastic Pultrusion die System and Method. U.S. Patent 8747098B1, 9 October 2013. [Google Scholar]

- Montsinger, L.V. Apparatus and Method for Forming Fiber Filled Thermoplastic Composite Materials. U.S. Patent 5176775A, 16 December 1991. [Google Scholar]

- Pilling, D.A.; Korzeniowski, G. Method for Pultruding Fiber-Reinforced, Thermoplastic Stock. U.S. Patent 5114516A, 5 October 1990. [Google Scholar]

- Pfeiffer, B.; Skaletz, D.; Heckel, H.; Texier, A.; Heydweiller, J. Production of Fiber-Reinforced Composites by Pultrusion with Thermoplastic Powder Pretreatment. U.S. Patent 5725710A, 28 July 1993. [Google Scholar]

- Ehleben, M.; Mertens, T.; Briesemann, S.; Fleischhauer, M. Process for Producing a Pultruded Fiber Composite Plastic Profile. D.E. Patent 102016206025A1, 12 April 2016. [Google Scholar]

- Hilakos, W.; Patterson, D.J. Pultrusion Apparatus and Method for Impregnating Continuous Lengths of Multi-Filament and Multi-fiber Structures. U.S. Patent 4907527A, 15 December 1987. [Google Scholar]

- James, E.; O’Connor Beever, W.H.; Dancer, J.W.; Beaulieu, W.B.; Selby, L.M.; Virgil, H.; Rhodes, J. Pultrusion Process and Apparatus. U.S. Patent 4883552A, 5 December 1986. [Google Scholar]

- Lambing, C.L.T.; Barbus, J.J.; Miller, D.C. Method for Pultruding Fiber-Reinforced Thermoplastic stock. U.S. Patent 5264060A, 22 January 1992. [Google Scholar]

- Hornung, S.; Weicker, S. Process for Producing a Fiber-Reinforced Plastic Profile and a Fiber-Reinforced Plastic Profile. D.E. Patent 102017219715A1, 7 November 2017. [Google Scholar]

- Taylor, S.R. Apparatus for Pultruding Thermoplastic Structures at Below Melt Temperatures. U.S. Patent 5091036A, 5 October 1989. [Google Scholar]

- Beever, W.H. Thermoplastic Re-Pultrusion. U.S. Patent 4992229A, 14 February 1991. [Google Scholar]

- O’Connor, J.E. Method for Making Variable Cross Section Pultruded Thermoplastic Composite Articles. U.S. Patent 5026447A, 10 February 1991. [Google Scholar]

- Chauzu, F. Method and Installation for Obtaining a Profile of a Section Variated by Pultrusion. F.R. Patent 3053915B1, 18 July 2019. [Google Scholar]

- Zhou, X.; Fang, L.; Guo, B.; Huang, S.; Lin, Q.; Fan, C. Production Equipment and Using Method for Thermoplastic Pultrusion Product. C.N. Patent 102615840A, 9 April 2012. [Google Scholar]

- Beever, W.H. Method and Apparatus for Pultruding Non-Linear Thermoplastic Composite articles. U.S. Patent 4892600A, 15 December 1990. [Google Scholar]

- Edwards, C.M.; D’Hooghe, E.L. Process for In-Line Forming of Pultruded Composites. U.S. Patent 6872343B2, 13 January 2005. [Google Scholar]

- Rubin, A.; Fox, J.; Wilkerson, R. Fabrication Process for Thermoplastic Composite Parts. U.S. Patent 8795457B2, 2 February 2014. [Google Scholar]

- Ishida, H.; Zimmerman, D.A. The development of an epoxy resin system for the injection molding of long-fiber epoxy composties. Polym. Compos. 1994, 15. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Karger-Kocsis, J. Polymers and related composites via anionic ring-opening polymerization of lactams: Recent developments and future trends. Polymers 2018, 10, 357. [Google Scholar] [CrossRef]

- Botelho, E.C.; Rezende, M.C. Reaction injection pultrusion: A potential technique to process polyamide 6,6/carbon fiber composites. J. Adv. Mater. 2004, 36, 49–53. [Google Scholar]

- Ning, X.; Ishida, H. RIM-pultrusion of nylon-6 and rubber-toughened nylon-6 composites. Polym. Eng. Sci. 1991, 31. [Google Scholar] [CrossRef]

- Ishida, H.; Rotter, G. RIM-pultrusion of thermoplastic matrix composites. In Proceedings of the Society of the Plastics Industry, Reinforced Plastics/Composites Institute, Annual Conference—Proceedings, Cincinnati, OH, USA, 1–5 February 1988. [Google Scholar]

- Chauzu, F. Method for Obtaining a Profiled Part Made of Thermoplastic Composite Material, and Device for Carrying out Said Method. E.P. Patent 3272506A1, 18 July 2016. [Google Scholar]

- Chen, J.H.; Kang, H.C.; Kang, C.J.; Wu, Y.D.; Laiw, R.F. Pultrusion Process for Long Fiber-Reinforced Nylon Composites. U.S. Patent 5424388A, 24 June 1993. [Google Scholar]

- Ageyeva, T.; Sibikin, I.; Kovács, J.G. Review of thermoplastic resin transfer molding: Process modeling and simulation. Polymers 2019, 11, 1555. [Google Scholar] [CrossRef]

- Cho, B.G.; Mccarthy, S.P.; Fanucci, J.P.; Nolet, S.C. Fiber reinforced nylon-6 composites produced by the reaction injection pultrusion process. Polym. Compos. 1996, 17, 673–681. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Bersee, H.E.N.; Jager, W.F.; Picken, S.J. Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic composites: Choice of activator and initiator. Compos. Part A Appl. Sci. Manuf. 2006, 37, 949–956. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Hua, S.; Xue, P. Optimization of initiator and activator for reactive thermoplastic pultrusion. J. Polym. Res. 2019, 26. [Google Scholar] [CrossRef]

- Yn, M.S.; Ma, C.C.M.; Lin, S.H.; Wu, Y.D. Pultrusion of poly(ε-caprolactam)/poly(butadiene-co-acrylonitrile) composites: I. Simulation and a mathematical model. Compos. Sci. Technol. 1995, 54, 123–131. [Google Scholar] [CrossRef]

- Åström, B.T.; Larsson, P.H.; Hepola, P.J.; Pipes, R.B. Flexural properties of pultruded carbon/PEEK composites as a function of processing history. Composites 1994, 25, 814–821. [Google Scholar] [CrossRef]

- Kerbiriou, V.; Friedrich, K. Pultrusion of Thermoplastic Composites-Process Optimization and Mathematical Modeling. J. Thermoplast. Compos. Mater. 1999, 12, 96–120. [Google Scholar] [CrossRef]

- Bechtold, G.; Sakaguchi, M.; Friedrich, K.; Hamada, H. Pultrusion of micro-braided GF/PA6 yarn. Adv. Compos. Lett. 1999, 8. [Google Scholar] [CrossRef]

- Evstatiev, M.; Angelov, I.; Friedrich, K. Structure and properties of microfibrillar-reinforced composites based on thermoplastic PET/LDPE blends after manufacturing by means of pultrusion. Polym. Eng. Sci. 2010, 50. [Google Scholar] [CrossRef]

- Michaeli, W.; Jürss, D. Thermoplastic pull-braiding: Pultrusion of profiles with braided fibre lay-up and thermoplastic matrix system (PP). Compos. Part A Appl. Sci. Manuf. 1996, 27, 3–7. [Google Scholar] [CrossRef]

- Nejhad, M.N.G. Thermal Analysis for Thermoplastic Composite Tow/Tape Preheating and Pultrusion. J. Thermoplast. Compos. Mater. 1997, 10, 504–523. [Google Scholar] [CrossRef]

- Lapointe, F.; Laberge Lebel, L. Fiber damage and impregnation during multi-die vacuum assisted pultrusion of carbon/PEEK hybrid yarns. Polym. Compos. 2019, 40, E1015–E1028. [Google Scholar] [CrossRef]

- Schäfer, J.; Gries, T. Alternative heating technology for the braiding pultrusion process. In Proceedings of the CAMX 2016—Composites and Advanced Materials Expo, Anaheim, CA, USA, 26–29 September 2016. [Google Scholar]

- Oswald, A.; Lapointe, F.L.; Laberge Lebel, L. Multi-die, vacuum assisted pultrusion of flax/PLA thermoplastic biocomposite rods. In Proceedings of the ECCM 2016—Proceeding of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Wongsriraksa, P.; Nakai, A. A study on the processing ability of carbon fiber reinforced thermoplastic epoxy resin composites by using pultrusion technique. In Proceedings of the ICCM International Conferences on Composite Materials, Xi’an, China, 20–25 August 2017; Volume 2017. [Google Scholar]

- Wongsriraksa, P.; Nakai, A. The Effect of Process Parameters on Impregnation Properties of Pultruded Carbon Fiber Reinforced Thermoplastic Epoxy Composites. ECS Trans. 2018, 88, 177–185. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Sun, H.; Xue, P. Thermoplastic reaction injection pultrusion for continuous glass fiber-reinforced polyamide-6 composites. Materials 2019, 12, 463. [Google Scholar] [CrossRef]

- Åström, B.T. Development and application of a process model for thermoplastic pultrusion. Compos. Manuf. 1992, 3, 189–197. [Google Scholar] [CrossRef]

- Glemet, M.; Causier, A.; Gourdon, B. Pultrusion Process. U.S. Patent 5084222A, 18 Febuary 1987. [Google Scholar]

- Hepola, P.J. Thermoplastic Pultrusion with On-Line Dry Powder Impregnation of Fibers. Ph.D. Thesis, University of Delaware, Newark, DE, USA, 1993. [Google Scholar]

- Tomas åström, B.; Larsson, P.H.; Byron Pipes, R. Development of a facility for pultrusion of thermoplastic-matrix composites. Compos. Manuf. 1991, 2. [Google Scholar] [CrossRef]

- Fanucci, J.P.; Nolet, S.C.; Koppernaes, C.; Kim, Y.R. Measurement of internal die pressure distributions during pultrusion of thermoplastic composites. Sampe 1990, 22, 50–64. [Google Scholar]

- Michaeli, W.; Blaurock, J. Pultrusion of endless fibre-reinforced profiles with thermoplastic matrix systems. Eng. Plast. 1996, 9, 282–292. [Google Scholar]

- Ghaedsharaf, M.; Brunel, J.-E.; Lebel, L. Thermoplastic composite rod manufacturing using biaxial braid-trusion. In Proceedings of the ECCM18–18th European Conference on Composite Materials, Athens, Greece, 24–28 June 2018. [Google Scholar]

- Devlin, B.J.; Williams, M.D.; Quinn, J.A.; Gibson, A.G. Pultrusion of unidirectional composites with thermoplastic matrices. Compos. Manuf. 1991, 2, 203–207. [Google Scholar] [CrossRef]

- Sala, G.; Cutolo, D. The pultrusion of powder-impregnated thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 1997, 28, 637–646. [Google Scholar] [CrossRef]

- Astroem, B.T.; Larsson, P.H.; Pipes, R.B. Experimental investigation of a thermoplastic pultrusion process. In Proceedings of the International SAMPE Symposium and Exhibition (Proceedings), San Diego, CA, USA, 15–18 April 1991; Volume 36. [Google Scholar]

- Squires, C.; Almaraz, J.; O’Toole, B. Experimental simulation of the thermoplastic pultrusion process. Int. SAMPE Symp. Exhib. 1996, 41. [Google Scholar]

- Azari, A.D. Influence of the pultrusion line speed on the mechanical properties of the thermoplastic rovings impregnated long fiber. J. Eng. Appl. Sci. 1996, 2, 2526–2530. [Google Scholar]

- Ozturk, O.; Das, P.; Stadler, M.; Pipes, R.B. Optimization of thermoplastic impregnation of glass fiber yarns with pultrusion. In Proceedings of the Annual Technical Conference—ANTEC, Conference Proceedings, Chicago, IL, USA, 16–20 May 2004; Volume 2. [Google Scholar]

- Nunes, J.P.; Silva, J.F.; Novo, P.J. Processing thermoplastic matrix towpregs by pultrusion. Adv. Polym. Technol. 2013, 32. [Google Scholar] [CrossRef]

- Åstroöm, B.T.; Pipes, R.B. A modeling approach to thermoplastic pultrusion. II: Verification of models. Polym. Compos. 1993, 14, 184–194. [Google Scholar] [CrossRef]

- Nakai, A.; Morino, K. Molding condition for shortening molding time during pultrusion molding of thermoplastic composites. In Proceedings of the ICCM International Conferences on Composite Materials, Xi’an, China, 20–25 August 2017; Volume 2017. [Google Scholar]

- Vedernikov, A.; Tucci, F.; Carlone, P.; Gusev, S.; Konev, S.; Firsov, D.; Akhatov, I.; Safonov, A. Effects of pulling speed on structural performance of L-shaped pultruded profiles. Compos. Struct. 2021, 255. [Google Scholar] [CrossRef]

- Svensson, N.; Shishoo, R.; Gilchrist, M. Manufacturing of thermoplastic composites from commingled yarns—A review. J. Thermoplast. Compos. Mater. 1998, 11, 22–56. [Google Scholar] [CrossRef]

- Longmuir, A.; Wilcox, J. Bridging the gap between pultrusions and extrusions. Mater. World 2000, 8, 18–20. [Google Scholar]

- Thomasset, J.; Carreau, P.J.; Sanschagrin, B.; Ausias, G. Rheological properties of long glass fiber filled polypropylene. J. Nonnewton. Fluid Mech. 2005, 125. [Google Scholar] [CrossRef]

- Broyles, N.S.; Verghese, K.N.E.; Davis, R.M.; Lesko, J.J.; Riffle, J.S. Pultruded carbon fiber/vinyl ester composites processed with different fiber sizing agents. Part I: Processing and static mechanical performance. J. Mater. Civ. Eng. 2005, 17, 320–333. [Google Scholar] [CrossRef]

- Verghese, K.N.; Broyles, N.S.; Lesko, J.J.; Davis, R.M.; Riffle, J.S. Pultruded Carbon Fiber/Vinyl Ester Composites Processed with Different Fiber Sizing Agents. Part II: Enviro-Mechanical Durability. J. Mater. Civ. Eng. 2005, 17. [Google Scholar] [CrossRef]

- Verghese, K.N.; Broyles, N.S.; Case, S.W.; Lesko, J.J.; Davis, R.M.; Riffle, J.S. Pultruded Carbon Fiber/Vinyl Ester Composites Processed with Different Fiber Sizing Agents. Part III: Theoretical Aspects. J. Mater. Civ. Eng. 2005, 17. [Google Scholar] [CrossRef]

- Roy, S.; Lu, H.; Narasimhan, K.; Hussain, F. Characterization and modeling of strength enhancement mechanisms in a polymer/clay nanocomposite. In Proceedings of the Collection of Technical Papers—AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, TX, USA, 18–21 April 2005; Volume 1. [Google Scholar]

- Roy, S.; Vengadassalam, K.; Hussain, F.; Lu, H. Compressive strength enhancement of pultruded thermoplastic composites using nanoclay reinforcement. In Proceedings of the International SAMPE Symposium and Exhibition (Proceedings), Long Beach, CA, USA, 16–20 May 2004; Volume 49. [Google Scholar]

- Fink, H.P.; Ganster, J. Novel thermoplastic composites from commodity polymers and man-made cellulose fibers. In Proceedings of the Macromolecular Symposia, Rio de Janeiro, Brazil, 16–21 July 2006; John Wiley & Sons Ltd.: Chichester, UK, 2006; Volume 244. [Google Scholar]

- Novo, P.J.; Silva, J.F.; Nunes, J.P.; Van Hattum, F.W.J.; Marques, A.T. Development of a new pultrusion equipment to manufacture thermoplastic matrix composite profiles. In Proceedings of the ECCM 2012—Composites at Venice, Proceedings of the 15th European Conference on Composite Materials; European Conference on Composite Materials, ECCM, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Tao, Z.; Wang, Y.; Li, J.; Wang, X.; Wu, D. Fabrication of long glass fiber reinforced polyacetal composites: Mechanical performance, microstructures, and isothermal crystallization kinetics. Polym. Compos. 2015, 36. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Wu, D. Mechanical and tribological enhancement of polyoxymethylene-based composites with long basalt fiber through melt pultrusion. Compos. Interfaces 2016, 23. [Google Scholar] [CrossRef]

- Kahl, C.; Feldmann, M.; Heim, H.P. Inline UV light irradiation of cellulose and glass fibers in pultrusion of thermoplastic composites. In Proceedings of the Annual Technical Conference—ANTEC, Conference Proceedings, Orlando, FL, USA, 7–10 May 2018; Volume 2018. [Google Scholar]

- Shayan Asenjan, M.; Sabet, A.R.; Nekoomanesh, M. Long fiber thermoplastic composites under high-velocity impact: Study of fiber length. J. Compos. Mater. 2019, 53, 353–360. [Google Scholar] [CrossRef]

- Saito, T.; Nakai, A.; Ohtani, A. Effects of fabrication method of composite yarn intermediate material and resin melt viscosity on the impregnation properties and mechanical properties of PA66 fiber and glass fiber composites. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Asensio, M.; Esfandiari, P.; Núñez, K.; Silva, J.F.; Marques, A.; Merino, J.C.; Pastor, J.M. Processing of pre-impregnated thermoplastic towpreg reinforced by continuous glass fibre and recycled PET by pultrusion. Compos. Part B Eng. 2020, 200, 108365. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Chawla, K.K. Processing of fibre reinforced thermoplastic composites. Int. Mater. Rev. 2008, 53, 185–218. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Thermoplastic pultrusion of natural fibre reinforced composites. Compos. Struct. 2001, 54, 355–360. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, X.; Wu, D. Preparation, microstructures, and properties of long-glass-fiber-reinforced thermoplastic composites based on polycarbonate/poly(butylene terephthalate) alloys. J. Reinf. Plast. Compos. 2015, 34, 1804–1820. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers; ChemTec Publishing: Ontario, ON, Canada, 2012. [Google Scholar]

- Novo, P.J.; Silva, J.F.; Nunes, J.P.; Marques, A.T. Pultrusion of fibre reinforced thermoplastic pre-impregnated materials. Compos. Part B Eng. 2016. [Google Scholar] [CrossRef]

- Wilson, M.L.; Buckley, J.D. The Potential for Low Cost Thermoplastic Pultrusion. J. Reinf. Plast. Compos. 1994, 13, 927–941. [Google Scholar] [CrossRef]

- Nunes, J.P.; Van Hattum, F.W.J.; Bernardo, C.A.; Silva, J.F.; Marques, A.T. Advances in thermoplastic matrix towpregs processing. J. Thermoplast. Compos. Mater. 2004, 17, 523–544. [Google Scholar] [CrossRef]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of Wood and Biodegradable Thermoplastics: A Review. Polym. Rev. 2018, 58, 444–494. [Google Scholar] [CrossRef]

- Wilson, M.L.; Buckley, J.D.; Dickerson, G.E.; Johnson, G.S.; Taylor, E.C.; Covington, E.W. Pultrusion Process Development of a Graphite Reinforced Polyetherimide Thermoplastic Composite. J. Thermoplast. Compos. Mater. 1989, 2, 230–246. [Google Scholar] [CrossRef]

- Larock, J.A.; Hahn, H.T.; Evans, D.J. Pultrusion Processes for Thermoplastic Composites. J. Thermoplast. Compos. Mater. 1989. [Google Scholar] [CrossRef]

- Hedayati Velis, H.; Golzar, M.; Yousefzade, O. Composites based on HDPE, jute fiber, wood, and thermoplastic starch in tubular pultrusion die: The correlation between mechanical performance and microstructure. Adv. Polym. Technol. 2018, 37, 3483–3491. [Google Scholar] [CrossRef]

- Ma, C.C.M.; Yn, M.S.; Chen, C.H.; Chiang, C.L. Processing and properties of pultruded thermoplastic composites (I). Compos. Manuf. 1990, 1, 191–196. [Google Scholar] [CrossRef]

- Kumar, A.; Srivastava, A. Preparation and Mechanical Properties of Jute Fiber Reinforced Epoxy Composites. Ind. Eng. Manag. 2017, 6, 4–7. [Google Scholar] [CrossRef]

- Qian, H.; Greenhalgh, E.S.; Shaffer, M.S.P.; Bismarck, A. Carbon nanotube-based hierarchical composites: A review. J. Mater. Chem. 2010, 20, 4751–4762. [Google Scholar] [CrossRef]

- Sattar, R.; Kausar, A.; Siddiq, M. Advances in thermoplastic polyurethane composites reinforced with carbon nanotubes and carbon nanofibers: A review. J. Plast. Film Sheeting 2015, 31, 186–224. [Google Scholar] [CrossRef]

- Markov, A.V. The effect of the manufacturing procedure on the electric properties of carbon-black-filled, fiberglass-reinforced thermoplastic composites. Polym. Sci. Ser. A 2007, 49. [Google Scholar] [CrossRef]

- Novo, P.J.; Nunes, J.P.; Silva, J.F.; Tinoco, V.; Marques, A.T. Production of thermoplastics matrix preimpregnated materials to manufacture composite pultruded profiles. Cienc. Tecnol. Mater. 2013, 25, 85–91. [Google Scholar] [CrossRef]

- Iftekhar, M.A. Effect of processing and material modifications on the viscosity of engineering thermoplastics at high temperatures. In Proceedings of the Annual Technical Conference—ANTEC, Conference Proceedings, Toronto, ON, Canada, 27 April–2 May 1997; Volume 2. [Google Scholar]

- Mariatti, M.; Nasir, M.; Ismail, H. Effect of prepreg geometry on the prepreg and plain weave composite properties. J. Reinf. Plast. Compos. 2002, 21. [Google Scholar] [CrossRef]

- Zhou, H. Production Technology of Continuous Fiber Reinforced Thermoplastic Composites (CFRTP) Pultruded Profiles. C.N. Patent 106626444A, 27 July 2016. [Google Scholar]

- Eastep, D.W.; Wesley, M.L.; Heydweiller, J.; Stiehm, R.; Littwitz, B.; Borgner, T.; Wagner, B.; Bernd, H. Method of Making Long Fiber-Reinforced Thermoplastic Composites Utilizing Hybrid or Commingled Yarn. W.O. Patent 2004080698A1, 6 March 2004. [Google Scholar]

- Ye, L.; Friedrich, K.; Kästel, J. Consolidation of GF/PP commingled yarn composites. Appl. Compos. Mater. 1994, 1, 415–429. [Google Scholar] [CrossRef]

- Van West, B.P.; Pipes, R.B.; Advani, S.G. The consolidation of commingled thermoplastic fabrics. Polym. Compos. 1991, 12, 417–427. [Google Scholar] [CrossRef]

- Klinkmüller, V.; Um, M.K.; Steffens, M.; Friedrich, K.; Kim, B.S. A new model for impregnation mechanisms in different GF/PP commingled yarns. Appl. Compos. Mater. 1994, 1, 351–371. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, W.I.; Friedrich, K. A model for a thermoplastic pultrusion process using commingled yarns. Compos. Sci. Technol. 2001, 61, 1065–1077. [Google Scholar] [CrossRef]

- Bernet, N.; Michaud, V.; Bourban, P.E.; Manson, J.A.E. Impregnation model for the consolidation of thermoplastic composites made from commingled yarns. J. Compos. Mater. 1999, 33, 751–772. [Google Scholar] [CrossRef]

- Mota, J.N.F.DA.; Nunes, J.P.L.G.; Pouzada, A.S.D. Pultrusion Head to Produce Long Fibre Reinforced Thermoplastic Matrix Profiles. W.O. Patent 2002006037A1, 14 July 2000. [Google Scholar]

- Novo, P.J.; Silva, J.F.; Nunes, J.P.; Marques, A.T. Optimizing the production and processing of fibre reinforced thermoplastic pre-impregnated materials. In Proceedings of the 16th European Conference on Composite Materials, ECCM, Seville, Spain, 22–26 June 2014. [Google Scholar]

- ASTM Standard ASTM D6641/D6641M-16e1. Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- EN ISO 527-5:2009. Plastics—Determination of Tensile Properties—Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites. Available online: https://www.iso.org/standard/52991.html (accessed on 21 December 2020).

- ASTM D790-03. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM D7078/D7078M-12. Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D2344/D2344M-16. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Ma, C.-C.M.; Chen, C. Pultruded fiber-reinforced poly(methyl methacrylate) composites. I. Effect of processing parameters on mechanical properties. J. Appl. Polym. Sci. 1992, 44, 807–817. [Google Scholar] [CrossRef]

- Dubé, M.G.; Batch, G.L.; Vogel, J.G.; Macosko, C.W. Reaction injection pultrusion of thermoplastic and thermoset composites. Polym. Compos. 1995, 16, 378–385. [Google Scholar] [CrossRef]

- Sousa, J.M.; Garrido, M.; Correia, J.R.; Cabral-Fonseca, S. Hygrothermal ageing of pultruded GFRP profiles: Comparative study of unsaturated polyester and vinyl ester resin matrices. Compos. Part A Appl. Sci. Manuf. 2021, 140. [Google Scholar] [CrossRef]

- Spaccini, R.; Todisco, D.; Drosos, M.; Nebbioso, A.; Piccolo, A. Decomposition of bio-degradable plastic polymer in a real on-farm composting process. Chem. Biol. Technol. Agric. 2016, 3, 1–12. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Leja, K.; Lewandowicz, G. Polymer biodegradation and biodegradable polymers—A review. Polish J. Environ. Stud. 2010, 19, 255–266. [Google Scholar]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2001, 99, 483. [Google Scholar] [CrossRef]

- Zobel, D.A. A New Class of Biodegradable Materials: Poly-3-hydroxy- butyrate/ Steam Exploded Straw Fiber Composites. 1. Thermal and Impact Behaviour. J. Appl. Polym. Sci. 1993, 88, 116. [Google Scholar] [CrossRef]

- Ishiaku, U.S.; Pang, K.W.; Lee, W.S.; Ishak, Z.A.M. Mechanical properties and enzymic degradation of thermoplastic and granular sago starch filled poly(ε-caprolactone). Eur. Polym. J. 2002, 38, 393–401. [Google Scholar] [CrossRef]

- Ratto, J.A.; Stenhouse, P.J.; Auerbach, M.; Mitchell, J.; Farrell, R. Processing, performance and biodegradability of a thermoplastic aliphatic polyester/starch system. Polymer 1999, 40, 6777–6788. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, M. Biodegradable polylactide and its nanocomposites: Opening a new dimension for plastics and composites. Macromol. Rapid Commun. 2003, 24, 815–840. [Google Scholar] [CrossRef]

- Leonor, I.B.; Ito, A.; Onuma, K.; Kanzaki, N.; Reis, R.L. In vitro bioactivity of starch thermoplastic/hydroxyapatite composite biomaterials: An in situ study using atomic force microscopy. Biomaterials 2003, 24, 579–585. [Google Scholar] [CrossRef]

- Shogren, R.L.; Doane, W.M.; Garlotta, D.; Lawton, J.W.; Willett, J.L. Biodegradation of starch/polylactic acid/poly(hydroxyester-ether) composite bars in soil. Polym. Degrad. Stab. 2003, 79, 405–411. [Google Scholar] [CrossRef]

- Iovino, R.; Zullo, R.; Rao, M.A.; Cassar, L.; Gianfreda, L. Biodegradation of poly(lactic acid)/starch/coir biocomposites under controlled composting conditions. Polym. Degrad. Stab. 2008, 93, 147–157. [Google Scholar] [CrossRef]

- Strömberg, E.; Karlsson, S. The effect of biodegradation on surface and bulk property changes of polypropylene, recycled polypropylene and polylactide biocomposites. Int. Biodeterior. Biodegrad. 2009, 63, 1045–1053. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A.; Kazemi Tabrizi, A. Characterization and biodegradability of polypropylene composites using agricultural residues and waste fish. Compos. Part B Eng. 2014, 56, 279–283. [Google Scholar] [CrossRef]

- Akonda, M.; Alimuzzaman, S.; Shah, D.U.; Rahman, A.N.M.M. Physico-mechanical, thermal and biodegradation performance of random flax/polylactic acid and unidirectional flax/polylactic acid biocomposites. Fibers 2018, 6, 98. [Google Scholar] [CrossRef]

- Ashori, A. Wood-plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Timar, M.C.; Pitman, A.; Mihai, M.D. Biological resistance of chemically modified aspen composites. Int. Biodeterior. Biodegrad. 1999, 43, 181–187. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Rong, M.Z.; Lu, X. Fully biodegradable natural fiber composites from renewable resources: All-plant fiber composites. Compos. Sci. Technol. 2005, 65, 2514–2525. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Wibowo, A.; Misra, M.; Drzal, L.T. Development of Renewable Resource-Based Cellulose Acetate Bioplastic: Effect of Process Engineering on the Performance of Cellulosic Plastics. Polym. Eng. Sci. 2003, 43, 1151–1161. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Hinrichsen, G. A review on pineapple leaf fibers, sisal fibers and their biocomposites. Macromol. Mater. Eng. 2004, 289, 955–974. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Gfeller Laban, B.; Lundquist, L.; Leterrier, Y.; Månson, J.A.E.; Jolliet, O. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Chen, S.; Wu, Z. Static and fatigue behavior of basalt fiber-reinforced thermoplastic epoxy composites. J. Compos. Mater. 2020, 54, 2389–2398. [Google Scholar] [CrossRef]

- Nikforooz, M.; Montesano, J.; Golzar, M.; Shokrieh, M.M. Assessment of failure toughening mechanisms in continuous glass fiber thermoplastic laminates subjected to cyclic loading. Compos. Part B Eng. 2019, 161, 344–356. [Google Scholar] [CrossRef]

- Ahlborn, K. Durability of carbon fibre reinforced plastics with thermoplastic matrices under cyclic mechanical and cyclic thermal loads at cryogenic temperatures. Cryogenics 1991, 31, 257–260. [Google Scholar] [CrossRef]

- D’Amore, A.; Caprino, G.; Nicolais, L.; Marino, G. Long-term behaviour of PEI and PEI-based composites subjected to physical aging. Compos. Sci. Technol. 1999, 59, 1993–2003. [Google Scholar] [CrossRef]

- Sergi, C.; Tirillò, J.; Seghini, M.C.; Sarasini, F.; Fiore, V.; Scalici, T. Durability of basalt/hemp hybrid thermoplastic composites. Polymers 2019, 11, 603. [Google Scholar] [CrossRef] [PubMed]

- Wolfrum, J.; Whitney, E.; Eibl, S. Approaches to understand and predict the influence of rapid heat-up on degradation and strength of carbon fibre polymer matrix composites. J. Compos. Mater. 2017, 51, 2435–2447. [Google Scholar] [CrossRef]

- Kim, J.; Lee, W.I. Modeling of mechanical property degradation by short-term aging at high temperatures. Key Eng. Mater. 2000, 33, 631–636. [Google Scholar] [CrossRef]

- Carpier, Y.; Vieille, B.; Coppalle, A.; Barbe, F. About the tensile mechanical behaviour of carbon fibers fabrics reinforced thermoplastic composites under very high temperature conditions. Compos. Part B Eng. 2020, 181, 107586. [Google Scholar] [CrossRef]

- Burcham, L.J.; Eduwee, R.F.; Gillespie, J.W. Investigation of the Microcracking Behavior of B ism alei m ide Com pos i t es During Thermal Aging. Polym. Compos. 1971, 16, 507–517. [Google Scholar] [CrossRef]

- Robert, M.; Roy, R.; Benmokrane, B. Environmental effects on glass fiber reinforced polypropylene thermoplastic composite laminate for structural applications. Polym. Compos. 2009, 16, 604–611. [Google Scholar] [CrossRef]

- Arhant, M.; Le Gac, P.Y.; Le Gall, M.; Burtin, C.; Briançon, C.; Davies, P. Effect of sea water and humidity on the tensile and compressive properties of carbon-polyamide 6 laminates. Compos. Part A Appl. Sci. Manuf. 2016, 91, 250–261. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Jiang, P.; Yan, F. Durability of fiber-reinforced polyoxymethylene composites under the high hydrostatic pressure in the deep sea. J. Appl. Polym. Sci. 2020, 137, 22–24. [Google Scholar] [CrossRef]

- Sang, L.; Wang, Y.; Wang, C.; Peng, X.; Hou, W.; Tong, L. Moisture diffusion and damage characteristics of carbon fabric reinforced polyamide 6 laminates under hydrothermal aging. Compos. Part A Appl. Sci. Manuf. 2019, 123, 242–252. [Google Scholar] [CrossRef]

- Davies, P.; Le Gac, P.Y.; Le Gall, M. Influence of Sea Water Aging on the Mechanical Behaviour of Acrylic Matrix Composites. Appl. Compos. Mater. 2017, 24, 97–111. [Google Scholar] [CrossRef]

- Ma, Y.; Jin, S.; Yokozeki, T.; Ueda, M.; Yang, Y.; Elbadry, E.A.; Hamada, H.; Sugahara, T. Effect of hot water on the mechanical performance of unidirectional carbon fiber-reinforced nylon 6 composites. Compos. Sci. Technol. 2020, 200, 108426. [Google Scholar] [CrossRef]

- Dandy, L.O.; Oliveux, G.; Wood, J.; Jenkins, M.J.; Leeke, G.A. Accelerated degradation of Polyetheretherketone (PEEK) composite materials for recycling applications. Polym. Degrad. Stab. 2015, 112, 52–62. [Google Scholar] [CrossRef]

- Parvatareddy, H.; Wang, J.Z.; Dillard, D.A.; Ward, T.C.; Rogalski, M.E. Environmental aging of high-performance polymeric composites: Effects on durability. Compos. Sci. Technol. 1995, 53, 399–409. [Google Scholar] [CrossRef]

- Kuruvilla, S.P.; Renukappa, N.M. Effects of nano- and micro-filler on water diffusion and leakage current of GRP composites. Lect. Notes Mech. Eng. 2019, 53–61. [Google Scholar] [CrossRef]

- Manjunath, M.; Renukappa, N.; Suresha, B. Influence of micro and nanofillers on mechanical properties of pultruded unidirectional glass fiber reinforced epoxy composite systems. J. Compos. Mater. 2016, 50, 1109–1121. [Google Scholar] [CrossRef]

- Roy, S.; Hussain, F.; Narasimhan, K. Characterization of mechanical properties of thermoplastic nanocomposites manufactured using pultrusion. In Proceedings of the 39th International SAMPE Technical Conference—From Art to Science: Advancing Materials and Process Engineering, Cincinnati, OH, USA, 29 October–1 November 2007. [Google Scholar]

- Alam, M.K.; Morosko, J.; Shin, D. Enhancement of conductivity of continuous fiber composite tapes using vapor grown nanofiber. In Proceedings of the 39th International SAMPE Technical Conference—From Art to Science: Advancing Materials and Process Engineering, Cincinnati, OH, USA, 29 October–1 November 2007. [Google Scholar]

- Akhtar, M.N.; Sulong, A.B.; Nazir, M.S.; Majeed, K.; Radzi, M.K.F.; Ismail, N.F.; Raza, M.R. Kenaf-biocomposites: Manufacturing, characterization, and applications. Green Energy Technol. 2017. [Google Scholar] [CrossRef]

- Lapointe, F.L.; Oswald, A.; Nakai, A.; Laberge Lebel, L. Manufacturing of carbon/polyamide beam by vacuum assisted pultrusion. In Proceedings of the ECCM 2016—Proceeding of the 17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Yang, Y.; Murakami, M.; Hamada, H. Molding Method, Thermal and Mechanical Properties of Jute/PLA Injection Molding. J. Polym. Environ. 2012, 20. [Google Scholar] [CrossRef]

- Nakamura, H.; Shikamoto, N.; Nakai, A.; Hamada, H. Application of continuous natural fiber reinforced biodegradable resin composites for structural member. In Proceedings of the 24th Annual Technical Conference of the American Society for Composites 2009 and 1st Joint Canadian-American Technical Conference on Composites, Newark, DE, USA, 15–17 September 2009; Volume 4. [Google Scholar]

- Ganster, J.; Fink, H.P. Novel cellulose fibre reinforced thermoplastic materials. Cellulose 2006, 13. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21. [Google Scholar] [CrossRef]

- Nunes, F.; Correia, J.R.; Silvestre, N. Structural behaviour of hybrid FRP pultruded columns. Part 1: Experimental study. Compos. Struct. 2016, 139, 291–303. [Google Scholar] [CrossRef]

- Advani, S.G.; Sozer, M. Process Modeling in Composites Manufacturing, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Baran, I.; Tutum, C.C.; Nielsen, M.W.; Hattel, J.H. Process induced residual stresses and distortions in pultrusion. Compos. Part B Eng. 2013, 51, 148–161. [Google Scholar] [CrossRef]

- Baran, I.; Akkerman, R.; Hattel, J.H. Modelling the pultrusion process of an industrial L-shaped composite profile. Compos. Struct. 2014, 118, 37–48. [Google Scholar] [CrossRef]

- Safonov, A.; Gusev, M.; Saratov, A.; Konstantinov, A.; Sergeichev, I.; Konev, S.; Gusev, S.; Akhatov, I. Modeling of cracking during pultrusion of large-size profiles. Compos. Struct. 2019, 111801. [Google Scholar] [CrossRef]

- Hamada, H.; Maekawa, Z.-I.; Ikegawa, N.; Matsuo, T.; Yamane, M. Influence of the impregnating property on mechanical properties of commingled yarn composites. Polym. Compos. 1993, 14, 308–313. [Google Scholar] [CrossRef]

- Ye, L.; Friedrich, K. Processing of thermoplastic composites from powder/sheath-fibre bundles. J. Mater. Process. Technol. 1995, 48, 317–324. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Morigaki, T.; Cai, Z. The Consolidation of Laminate Composites. J. Compos. Mater. 1987, 21, 172–188. [Google Scholar] [CrossRef]

- Koubaa, S.; Burtin, C.; Lecorre, S.; Poitou, A. Simple modelling of impregnation in pultrusion process of thermoplastic composites. Int. J. Microstruct. Mater. Prop. 2012, 7, 428–438. [Google Scholar] [CrossRef]

- Koubaa, S.; Le Corre, S.; Burtin, C. Thermoplastic pultrusion process: Modeling and optimal conditions for fibers impregnation. J. Reinf. Plast. Compos. 2013, 32, 1285–1294. [Google Scholar] [CrossRef]

- Gibson, A.G.; Miller, A. Impregnation techniques for thermoplastic matrix composites. Polym. Polym. Compos. 1996, 4, 459–481. [Google Scholar]

- Haffner, S.M.; Friedrich, K.; Hogg, P.J.; Busfield, J.J.C. Finite Element Assisted Modelling of the Microscopic Impregnation Process in Thermoplastic Preforms. Appl. Compos. Mater. 1998, 5. [Google Scholar] [CrossRef]

- Bechtold, G.; Kameo, K.; Langler, F.; Hamada, H.; Friedrich, K. Pultrusion of braided thermoplastic commingled yarn—simulation of the impregnation process. In Proceedings of the 5th International Conference on Flow Processes in Composite Materials, Plymouth, UK, 12–14 July 1999. [Google Scholar]

- Koubaa, S.; Burtin, C.; Le Corre, S. Investigation of capillary impregnation for permeability prediction of fibrous reinforcements. J. Compos. Mater. 2016, 50, 1417–1429. [Google Scholar] [CrossRef]

- Ngo, S.I.; Lim, Y.I.; Hahn, M.H.; Jung, J.; Bang, Y.H. Multi-scale computational fluid dynamics of impregnation die for thermoplastic carbon fiber prepreg production. Comput. Chem. Eng. 2017, 103. [Google Scholar] [CrossRef]

- Lee, W.I.; Springer, G.S.; Smith, F.N. Pultrusion of thermoplastics. Int. SAMPE Symp. Exhib. 1991, 36, 1309–1318. [Google Scholar]

- Åstroöm, B.T.; Pipes, R.B. A Modeling Approach to Thermoplastic Pultrusion. I: Formulation of Models. Polym. Compos. 1993, 14, 173–183. [Google Scholar] [CrossRef]

- Babeau, A.; Comas-Cardona, S.; Binetruy, C.; Orange, G. Modeling of heat transfer and unsaturated flow in woven fiber reinforcements during direct injection-pultrusion process of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2015, 77, 310–318. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Beghishev, V.P.; Keapin, I.A. Macrokinetics of polymer crystallization. Polymer 1983, 24, 81–84. [Google Scholar] [CrossRef]

- Haffner, S.M.; Friedrich, K.; Hogg, P.J.; Busfield, J.J.C. Finite-element-assisted modelling of a thermoplastic pultrusion process for powder-impregnated yarn. Compos. Sci. Technol. 1998, 58, 1371–1380. [Google Scholar] [CrossRef]

- Ruan, Y.; Liu, J.G.; Chesonis, D.C.; Carvell, L.A. Development of a two-dimensional thermal model for the steady state thermoplastic pultrusion process. In Proceedings of the International SAMPE Symposium and Exhibition, Anaheim, CA, USA, 9–12 March 1992; Volume 37. [Google Scholar]

- Carlsson, A.; Tomas Åström, B. Modeling of heat transfer and crystallization kinetics in thermoplastic composites manufacturing: Pultrusion. Polym. Compos. 1998, 19. [Google Scholar] [CrossRef]

- Ahmed, F.; Joshi, S.C.; Lam, Y.C. Three-dimensional FE-NCV modeling of thermoplastic composites pultrusion. J. Thermoplast. Compos. Mater. 2004, 17, 447–462. [Google Scholar] [CrossRef]

- Joshi, S.C.; Lam, Y.C. Integrated approach for modelling cure and crystallization kinetics of different polymers in 3D pultrusion simulation. J. Mater. Process. Technol. 2006, 174, 178–182. [Google Scholar] [CrossRef]

- Lee, W.I.; Springer, G.S.; Smith, F.N. Pultrusion of Thermoplastics—A Model. J. Compos. Mater. 1991, 25. [Google Scholar] [CrossRef]

- Astrom, B.T.; Pipes, R.B. Modeling of a thermoplastic pultrusion process. Q. Soc. of Aerosp. Mater. Process Eng. 1991, 22, 55–64. [Google Scholar]

- Parasnis, N.C.; Ramani, K.; Borgaonkar, H.M. Ribbonizing of electrostatic powder spray impregnated thermoplastic tows by pultrusion. Compos. Part A Appl. Sci. Manuf. 1996, 27, 567–574. [Google Scholar] [CrossRef]

- Blaurock, J.; Michaeli, W. Calculation of the pulling force in the thermoplastics pultrusion process. In Proceedings of the International SAMPE Symposium and Exhibition (Proceedings), Anaheim, CA, USA, 4–8 May 1997; Volume 42. [Google Scholar]

- Baran, I.; Tutum, C.C.; Hattel, J.H.; Akkerman, R. Pultrusion of a vertical axis wind turbine blade part-I: 3D thermo-chemical process simulation. Int. J. Mater. Form. 2015, 8, 379–389. [Google Scholar] [CrossRef]

- Baran, I.; Hattel, J.H.; Tutum, C.C.; Akkerman, R. Pultrusion of a vertical axis wind turbine blade part-II: Combining the manufacturing process simulation with a subsequent loading scenario. Int. J. Mater. Form. 2015, 8, 367–378. [Google Scholar] [CrossRef]

- Struzziero, G.; Teuwen, J.J.E.; Skordos, A.A. Numerical optimisation of thermoset composites manufacturing processes: A review. Compos. Part A Appl. Sci. Manuf. 2019, 124. [Google Scholar] [CrossRef]

- Coelho, R.M.L.; Calado, V.M.A. An optimization procedure for the pultrusion process based on a finite element formulation. Polym. Compos. 2002, 23, 329–341. [Google Scholar] [CrossRef]

- Santos, L.S.; Pagano, R.L.; Biscaia, E.C.; Calado, V.M.A. Optimum heating configuration of pultrusion process. Comput. Aided Chem. Eng. 2009, 27, 705–710. [Google Scholar] [CrossRef]

- Santos, L.S.; Pagano, R.L.; Calado, V.M.A.; Biscaia, E.C.J. Optimization of a pultrusion process using finite difference and particle swarm algorithms. Brazilian J. Chem. Eng. 2015, 32, 543–553. [Google Scholar] [CrossRef]

- Acquah, C.; Datskov, I.; Mawardi, A.; Zhang, F.; Achenie, L.E.K.; Pitchumani, R.; Santos, E. Optimization under uncertainty of a composite fabrication process using a deterministic one-stage approach. Comput. Chem. Eng. 2006, 30, 947–960. [Google Scholar] [CrossRef]

- Mawardi, A.; Pitchumani, R. Cure cycle design for thermosetting-matrix composites fabrication under uncertainty. Ann. Oper. Res. 2004, 132, 19–45. [Google Scholar] [CrossRef]

- Li, J.; Joshi, S.C.; Lam, Y.C. Curing optimization for pultruded composite sections. Compos. Sci. Technol. 2002, 62, 457–467. [Google Scholar] [CrossRef]

- Lam, Y.C.; Li, J.; Joshi, S.C. Simultaneous Optimization of Die-Heating and Pull-Speed in Pultrusion of Thermosetting Composites. Polym. Compos. 2003, 24, 199–209. [Google Scholar]

- Joshi, S.C.; Lam, Y.C.; Win Tun, U. Improved cure optimization in pultrusion with pre-heating and die-cooler temperature. Compos. Part A Appl. Sci. Manuf. 2003, 34, 1151–1159. [Google Scholar] [CrossRef]

- Carlone, P.; Palazzo, G.S.; Pasquino, R. Pultrusion manufacturing process development: Cure optimization by hybrid computational methods. Comput. Math. Appl. 2007, 53, 1464–1471. [Google Scholar] [CrossRef][Green Version]

- Costa Dias, R.D.C.; Santos, L.D.S.; Ouzia, H.; Schledjewski, R. Improving degree of cure in pultrusion process by optimizing die-temperature. Mater. Today Commun. 2018, 17, 362–370. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, B.; Zhou, Z. Optimization of CFRP pultrusion process with NSGA-II and ANN. Adv. Mater. Res. 2012, 538–541, 2705–2711. [Google Scholar] [CrossRef]

- Chen, X.; Xie, H.; Chen, H.; Zhang, F. Optimization for CFRP pultrusion process based on genetic algorithm-neural network. Int. J. Mater. Form. 2010, 3, 1391–1399. [Google Scholar] [CrossRef]

- Baran, I.; Tutum, C.C.; Hattel, J.H. Optimization of the thermosetting pultrusion process by using hybrid and mixed integer genetic algorithms. Appl. Compos. Mater. 2013, 20, 449–463. [Google Scholar] [CrossRef]

- Tutum, C.C.; Baran, I.; Hattel, J.H. Utilizing multiple objectives for the optimization of the pultrusion process based on a thermo-chemical simulation. Key Eng. Mater. 2013, 554–557, 2165–2174. [Google Scholar] [CrossRef]

- Tutum, C.C.; Baran, I.; Deb, K. Optimum design of pultrusion process via evolutionary multi-objective optimization. Int. J. Adv. Manuf. Technol. 2014, 72, 1205–1217. [Google Scholar] [CrossRef]

- Safonov, A.; Bondarchuk, D.; Saratov, A.; Ushakov, A.; Akhatov, I. Optimal process design for large-scale pultrusion structures. In Proceedings of the ICCM International Conferences on Composite Materials; International Committee on Composite Materials, Xi’an, China, 20–25 August 2017; Volume 2017. [Google Scholar]

- Safonov, A.A. 3D topology optimization of continuous fiber-reinforced structures via natural evolution method. Compos. Struct. 2019, 215, 289–297. [Google Scholar] [CrossRef]

- The European Pultrusion Technology Association: EPTA. Available online: https://pultruders.org (accessed on 21 December 2020).

- Global Thermoplastic Composites Market Report. Available online: https://www.researchandmarkets.com/reports/5136171/th-ermoplastic-composites-market-by-resin-type (accessed on 4 January 2021).

- Witten, E.; Mathes, V. The Market for Glass Fibre Reinforced Plastics (GRP) in 2020. Market Developments, Trends, Outlooks and Challenges; Federation of Reinforced Plastics: Frankfurt, Germany, 2020. [Google Scholar]

- Nelson, S.M.; Eastep, D.W.; Regan, T.A.; Wesley, M.L.; Stiehm, R. Structural Member Formed from a Solid Lineal Profile. U.S. Patent 9238347B2, 11 June 2016. [Google Scholar]

- Zhang, Y.; Zhang, R.; Jing, R.; Wang, Y.; Meng, Y.; Zhao, Y.; Wei, K.; Zhang, X. Production Device for Thermoplastic Composite Yarn Pultrusion Plates. C.N. Patent 209999713U, 27 February 2020. [Google Scholar]

- Bordellier, F.; Callens, C.; Masson, C.; Broek, G. Van Den Installation and Method for Pultrusion of Banded Composite Material. F.R. Patent 3068286A1, 30 June 2017. [Google Scholar]

- Zhu, Z.; Yang, C.; Luo, G.; Liu, F. Novel Wiper Elastic Sheet and Preparation Method Thereof. C.N. Patent 110654041A, 30 September 2020. [Google Scholar]

- Nelson, S.M.; Eastep, D.W.; Tibor, T.L.; Regan, T.A.; Wesley, M.L.; Stiehm, R. Continuous Fiber Reinforced Thermoplastic Rod and Pultrusion Method for Its Manufacture. U.S. Patent 20140106166A1, 12 March 2020. [Google Scholar]

- Nelson, S.M.; Eastep, D.W.; Tibor, T.L.; Regan, T.A.; Wesley, M.L. Continuous Fiber Reinforced Thermoplastic Rod and Pultrusion Method for Its Manufacture. U.S. Patent 10676845B2, 12 March 2011. [Google Scholar]

- Cui, C.; Wu, Y. Preparation Device for Fiber Reinforced Composite Material Anti-Eccentric Wearing Continuous Sucker rod. C.N. Patent 202965218U, 30 November 2012. [Google Scholar]

- Szaplonczay, P. Method and Instalation for Fabrication of Heat Resistant Transmission Line Having a Thermo Softening Core. H.U. Patent 228364B1, 24 March 2008. [Google Scholar]

- Zhu, B.; Cai, X.; Wang, C.; Cai, H. Composite Wire Core Bar with Thermoplastic Resin Substrate and Preparation Die and Process Thereof. C.N. Patent 102024518B, 1 November 2010. [Google Scholar]

- Yao, J.; Wei, J.; Xu, J.; Chen, T.; Zheng, Z.; Yu, H. A kind of Pulltrusion Device for Producing Thermoplastic Matrix Layer. C.N. Patent 206765399U, 17 March 2017. [Google Scholar]

- Hirotoshi, I.; Hirotoshi, I.; Takuya, T.; Takuya, T. Thin-Walled Tube Manufacturing Method, Tube Manufactured by the Manufacturing Method, and Multilayer Structure Tube. J.P. Patent 5655020B2, 28 February 2015. [Google Scholar]

- Liu, B.; Liu, B. A Kind of Fiberglass Pultrusion, the Preparation Process of the Duplexing Skill Compound Bellows of Winding. C.N. Patent 108006334A, 12 December 2017. [Google Scholar]

- Nelson, S.M.; Eastep, D.W.; Regan, T.A. Reinforced Hollow Profiles. E.P. Patent 2585278A2, 22 June 2010. [Google Scholar]

- Gusev, S.; Safonov, A.; Rubtsov, M.; Sergeichev, I.; Akhatov, I. Thermoplastic Reinforced Pultrusion Profile. R.U. Patent 2738606C1, 8 April 2020. [Google Scholar]

- Schmidt, S.; Fink, N.; Rhönisch, T.; Al-Sheyyab, A. Process for Producing a Thermoplastic Window or Door Hollow Chamber Profile. D.E. Patent 102016119766A1, 18 October 2016. [Google Scholar]

- Safonov, A.; Gusev, S.; Rubtsov, M.; Sergeichev, I.; Akhatov, I. Thermoplastic Pultrusion Reinforcement Insert in a Hollow Plastic Frame of a Window or Door Unit. R.U. Patent 2738062C1, 31 July 2020. [Google Scholar]

- Preisler, D.J.; Peash, D.A. Reinforced Composite Pallet Assembly of the Cellular Core Sandwich-Type. U.S. Patent 6655299B2, 30 October 2003. [Google Scholar]

- Preisler, D.J. Reinforced Composite Vehicle Load Floor of the Cellular Core Sandwich-Type. U.S. Patent 6843525B2, 30 October 2001. [Google Scholar]

- Gao, K.; Li, G.; Zhou, G.; Ma, S. A Kind of Composite Material Truck Fuel Tanks Bracket with Skeleton Enhancing. C.N. Patent 109050240A, 24 July 2018. [Google Scholar]

- Edward O’Connor, J.; Rocco Bonazza, B.; Thomas Webster, J. Method for Producing Reinforced Thermoplastic Composite-Metallic Foil Laminated Articles. E.P. Patent 0372505A2, 7 December 1989. [Google Scholar]

- Zhu, B.; Cao, W.; Wang, Y.; Qiao, K.; Zhang, M. A Kind of Pultrusion Composite Board. C.N. Patent 209700001U, 20 July 2018. [Google Scholar]

- Nelson, S.M.; Eastep, D.W.; Regan, T.A. Method for Forming Reinfoced Pultruded Profiles. U.S. Patent 20130149521A1, 22 June 2010. [Google Scholar]

- Guan, Y.; Qu, X.; Shi, Y.; Qu, C. Direct On-Line Pultrusion Process for Fiber Reinforced Thermoplastic Composite material. C.N. Patent 102336026B, 25 November 2011. [Google Scholar]

- Kang, K.; Wang, P.; Lei, Y. A Kind of Continuously Shaped Matrix Device of Intelligence Composite Material Thermoplastic and Method. C.N. Patent 109648891A, 14 December 2018. [Google Scholar]

- Nelson, S.M.; Eastep, D.W.; Regan, T.A. Method for Forming Reinforced Pultruded Profiles. U.S. Patent 9409347B2, 22 June 2011. [Google Scholar]

- Dufresne, R.P. Insulating Anti-Corrosive Rail Clamp Integrally Made of Polymeric Composition. U.S. Patent 20100044451A1, 5 January 2014. [Google Scholar]

- Chauzu, F. Process for Obtaining a Thermoplastic Composite Composite Curved Piece and Installation for Implementing said Method. F.R. Patent 3053912B1, 18 July 2016. [Google Scholar]

- Balazek, D.T.; Griffiths, T.J.; Pearson, D.E. Pultrusion/Extrusion Method. U.S. Patent 4938823A, 7 October 1988. [Google Scholar]

- Schmidt, S.; Pardos, S.; Goldstein, J.; Al-Sheyyab, A. Process for Producing a Thermoplastic Extruded Profile. D.E. Patent 102016119765A1, 18 October 2016. [Google Scholar]

- Offringa, A.R. Thermoplastic composites—Rapid processing applications. Compos. Part A Appl. Sci. Manuf. 1996, 27, 329–336. [Google Scholar] [CrossRef]

- Plastic Bumper Beam Produced by Curved Reactive Thermoplastic Pultrusion (CRTP). Available online: https://www.plastics.gl/automotive/plastic-bumper-beam-produced-by-curved-reactive-thermoplastic-pultrusion-crtp-2/ (accessed on 21 December 2020).

- David, K. Method for Manufacturing a Wheel Rim from Fibre Composite Material and Wheel Rim for a Motor Vehicle. European Patent EP2626218A1, 14 August 2013. [Google Scholar]

- Balaji Thattaiparthasarathy, K.; Pillay, S.; Ning, H.; Vaidya, U.K. Process simulation, design and manufacturing of a long fiber thermoplastic composite for mass transit application. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1512–1521. [Google Scholar] [CrossRef]

- Brøndsted, P.; Lilholt, H.; Lystrup, A. Composite materials for wind power turbine blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Davies, P.; Riou, L.; Mazeas, F.; Warnier, P. Thermoplastic composite cylinders for underwater applications. J. Thermoplast. Compos. Mater. 2005, 18, 417–443. [Google Scholar] [CrossRef]

- Shayan Asenjan, M.; Sabet, S.A.R.; Nekoomanesh, M. Mechanical and high velocity impact performance of a hybrid long carbon/glass fiber/polypropylene thermoplastic composite. Iran. Polym. J. 2020, 29, 301–307. [Google Scholar] [CrossRef]

- Kim, Y.; Park, O.O. Effect of Fiber Length on Mechanical Properties of Injection Molded Long-Fiber-Reinforced Thermoplastics. Macromol. Res. 2020, 28, 433–444. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Effect of compounding and injection molding on the mechanical properties of flax fiber polypropylene composites. J. Reinf. Plast. Compos. 2010, 29, 1366–1385. [Google Scholar] [CrossRef]

- Fujiura, T.; Okamoto, T.; Tanaka, T.; Imaida, Y. Improvement of mechanical properties of long jute fiber reinforced polylactide prepared by injection molding process. WIT Trans. Ecol. Environ. 2010, 138, 181–188. [Google Scholar] [CrossRef]

- Fujiura, T.; Sakamoto, K.; Tanaka, T.; Imaida, Y. A study on preparation and mechanical properties of long jute fiber reinforced polylactic acid by the injection molding process. In Proceedings of the WIT Transactions on the Built Environment, Algarve, Portugal, 13–15 May 2008; Volume 97, pp. 231–240. [Google Scholar]

- Takai, Y.; Kawai, N.; Nakai, A.; Hamada, H. Fabrication of long fiber reinforced thermoplastic composites with pultrusion technique. In Proceedings of the American Society for Composites—21st Technical Conference of the American Society for Composites, Dearborn, MI, USA, 17–20 September 2006; Volume 3, pp. 1649–1656. [Google Scholar]

- Truckenmüller, F.; Fritz, H.-G. Injection molding of long fiber-reinforced thermoplastics: A comparison of extruded and pultruded materials with direct addition of roving strands. Polym. Eng. Sci. 1991, 31, 1316–1329. [Google Scholar] [CrossRef]