1. Introduction

Currently, the issues of energy consumption and carbon emissions have become the focus of international concern, and there is an increasing need for a low-carbon and high-efficiency technology upgrade, especially in the chemical industry [

1,

2,

3]. An extruder is a typical piece of chemical equipment, and its plasticizing and melting performance is an important part of polymer extrusion process control, divided into plasticizing efficiency and plasticizing uniformity, which is accompanied by high energy consumption. In polymer processing, the energy consumed by melting accounts for 70% to 80% of the total input energy. The efficiency of the melting process directly determines the entire process, and the melting process largely determines the stability and quality of the subsequent process. However, due to the phase transition and solid–liquid two-phase transport, the flow and heat transfer process is quite complex. Accordingly, it is very important to study the fluid ductile flow behavior to enhance melting and heat transfer in the melting zone for low-carbon, energy-saving and improving the quality of products. Screw structure optimization is an important research and development direction.

The extrusion process generally involves three processes: solid particle compaction, melt plasticization and melt homogenization. Due to the high viscosity, non-Newtonian and other special physical properties of polymer melt, it is difficult to plasticize uniformly, so the homogenization process needs to be extended by using screws with a large length-diameter ratio to make up for the uneven plasticization, which greatly reduces processing efficiency and increases energy consumption. Wang et al. [

4] denoted that improving the processing efficiency and plasticizing uniformity essentially requires effective control of the flow field and temperature field in the extrusion process, such as the introduction of elongational flow in the extrusion system.

In fact, in terms of melting efficiency and power consumption, the elongational flow is far superior to the shear-type flow found in most mixing systems. In this connection, many scholars and researchers have made great efforts. Qu et al. [

5] proposed and studied a vane extruder based on the volumetric tensile deformation of polymers. Results indicated that the vane plasticizing and conveying units caused mandatory deformation of particles, resulting in plastic energy dissipation to accelerate the solid particle melting and shorten the thermo-mechanical history. Wu et al. [

6] further studied the formation mechanism of the elongational flow field in the vane extruder according to the basic structural and flow patterns of vane plasticizing and conveying units. Wen et al. [

7] designed an eccentric rotor extruder based on continuous elongational flow. Results showed that mechanical energy was dissipated into heat via the deformation of particles due to the eccentricity, which increased the melting efficiency and decreased the energy consumption. Rauwendaal et al. [

8] developed various screw configurations based on elongational rheology, such as CRD (Chris Rauwendaal Dispersive)mixing section, CRD barrier screw and CRD separation-type screw. The main structural feature of the CRD mixing section is that the flank of screw flights is inclined and conical grooves are set in the screw flights; the main structural feature of the CRD barrier screw is that a slanted part is added to the top of the barrier flights and the main structural feature of the CRD separation-type screw is that a slope is set at the top of the secondary screw flights, all of which causes elongational flow by setting converging wedge channels. The extensional flow created in the wedge-shaped zone reduces the viscous dissipation and power consumption and enhances the stress of the melt, so the melting and mixing are more efficient.

Furthermore, chaos theory is applied to polymer processing by some scholars. For example, Xu et al. [

9] developed a chaos screw by employing a reciprocating baffle. Through inserting a periodic barrier element into the screw, the steady flow field is disturbed, and chaotic flow is generated in the channel, thereby improving the efficiency of mixing and melting. Furthermore, Xu et al. [

10] studied the influence of geometric ratio and height of baffles on the chaotic mixing and achieved an optimal geometric ratio. Zeng and Qu [

11] introduced the vibration to obtain chaos control in the melting process of polymer. Results indicated that the addition of the vibration force field to the melting process can enhance the polymer plasticization. Zeng et al. [

12] analyzed the polymer plasticization in the developed electromagnetic dynamic extruder by establishing a mathematical-physical model. The results showed that the processing temperature and energy consumption were reduced, and the plasticizing rate was increased over 60% by adding a vibration force field.

A significant amount of experience has been gained over decades of active research on rheology and energy dissipation to accelerate the melting rate of polymers. However, heat transfer through a barrel is also an important heat resource to melt the polymer, and there are only a few reports on the heat transfer enhancement in the screw extrusion. Due to the poor thermal conductivity of polymer, the convective heat transfer effect inside the melt and between the polymer and external heater is insufficient, so improving the convective heat transfer is also an important direction to accelerate melting. Rauwendaal [

13] simulated the melt flow and temperature evolution in a single screw extruder (SSE) by using the finite element method (FEM), considering the influence of geometry parameters of screws. Furthermore, Rauwendaal [

14] developed an analytical theory to predicate the melt temperature profiles in the extrusion process by analyzing the flow and heat transfer behavior of both single and twin screw extruders. Teixeira et al. [

15] presented a plasticizing model for co-rotating the twin screw extruder to predicate the evolution of temperature and mechanical power consumption. All of the above researchers made a preliminary analysis of heat transfer; however, their focus is on temperature distribution without considering heat transfer efficiency. In order to improve the cooling capacity in polystyrene foam extrusion, Rauwendaal [

16] fabricated a high heat transfer (HHT) screw and achieved effective mass transfer from the center region to the outside region in the screw channel. In our previous work, Jian et al. [

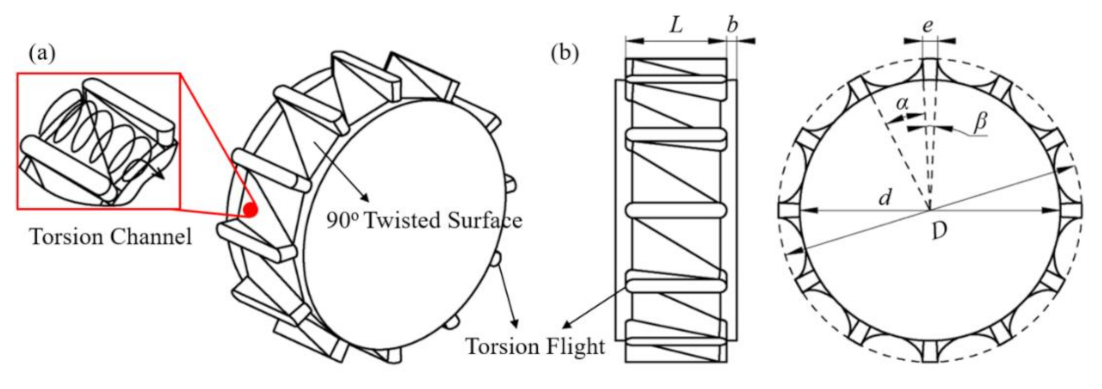

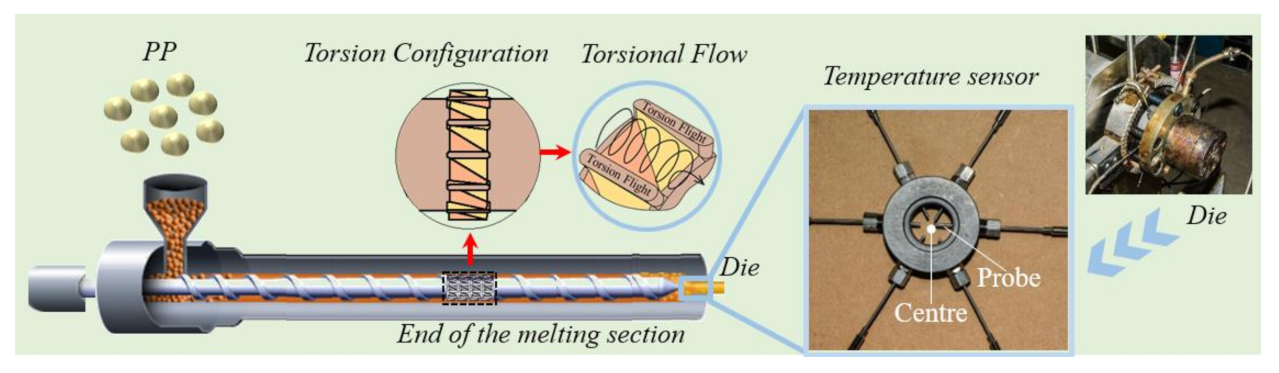

17,

18] developed a torsion extrusion technology based on multi-field synergy, inducing torsional spiral flow in the screw channel to improve phase-to-phase molecular and thermal mobility, achieving effective mass transfer from the top region to the bottom region in the screw channel. Then, Jian et al. [

19,

20] studied the heat transfer and mixing capability of a torsion screw compared with three typical geometric forms commonly employed in practical application: conventional screw, Maddock screw and Pin screw. The result indicated that the torsion screw by setting twisted channels displayed superior mixing and heat transfer properties through the self-twisting mass transfer of particles, avoiding over-shear and overheating. This multi-field synergy theory of polymer focuses on the heat transfer enhancement through the barrel and the mass and thermal transfer efficiency inside of the polymer itself, especially in the radial direction, offering a novel perspective to optimize and design the screw.

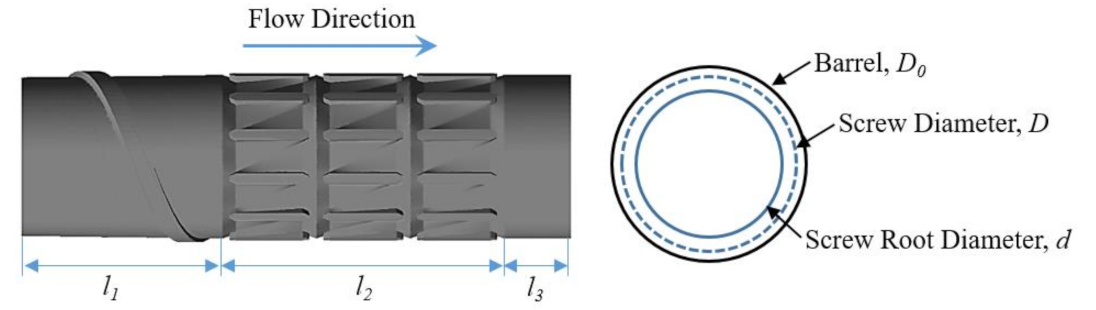

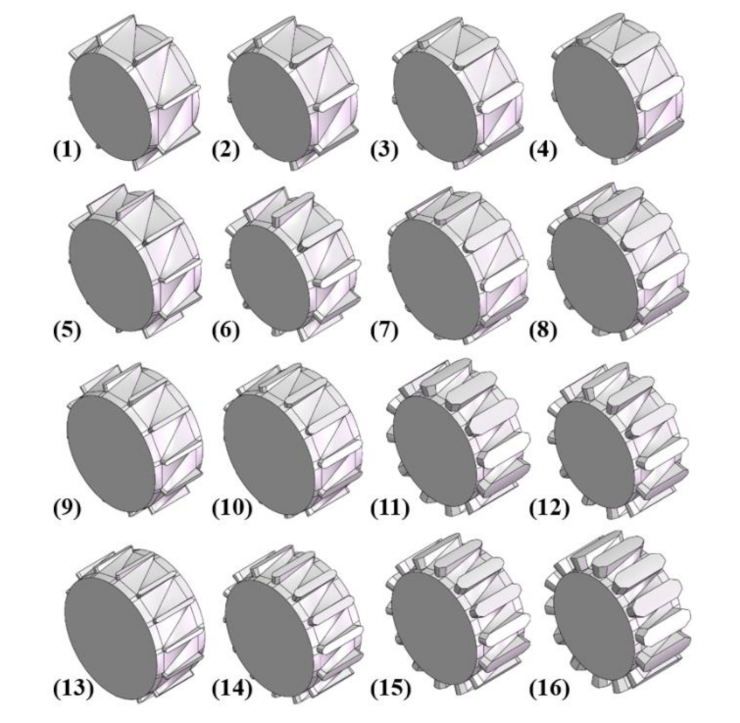

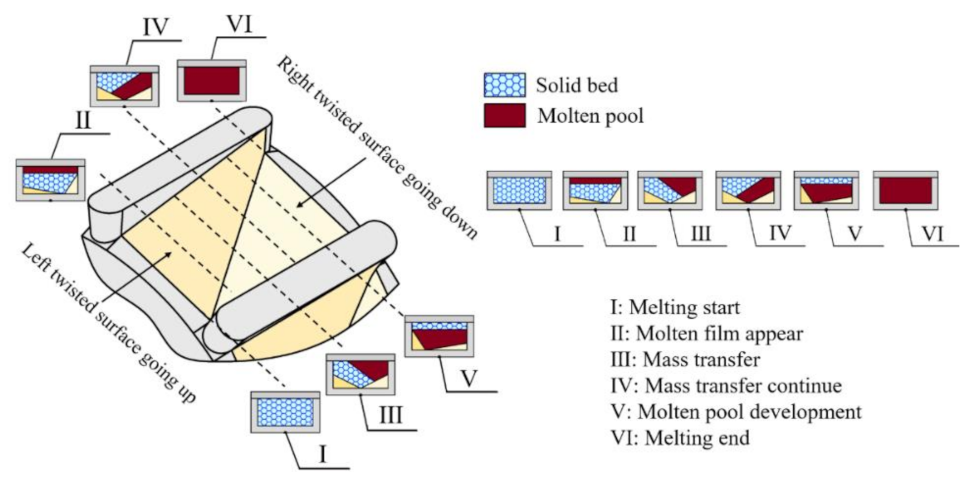

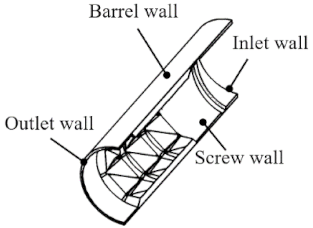

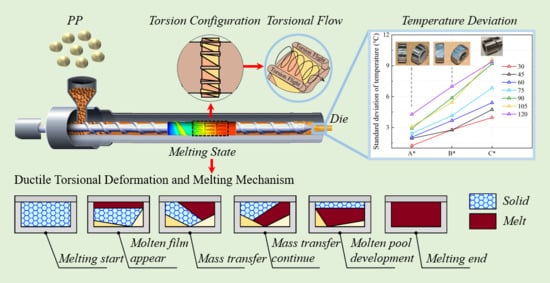

The torsion configuration is designed to achieve an effective exchange of material from the top region to the bottom region and vice versa, thereby improving the heat transfer and melting efficiency. Considering the torsion configuration has good heat transfer and melting capability, it is necessary to further investigate the influence of structural parameters on performance. Therefore, the authors conducted research on the plasticizing and melting capability by changing parameters of torsion configuration, including the number of flights, the width of flight, and the height of the channel based on the orthogonal test, ascertaining complex ductile deformation behavior and plasticizing properties in the solid–melt transition process.

4. Conclusions

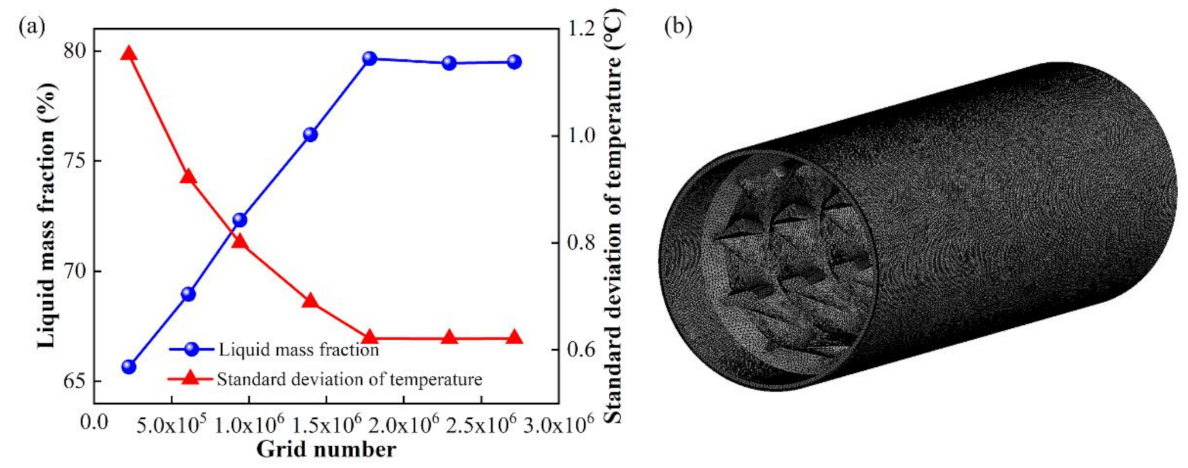

In the study, ductile behavior of torsion configurations was numerically studied by adopting CFD technology and orthogonal analysis. The velocity and temperature distribution inside the screw channel was recorded, and the ductile formation mechanism of the torsion configuration was discussed. The main factors affecting the plasticizing and melting capability of torsion configurations and the optimal group of factors and levels were obtained by range analysis, together with the weight matrix analysis of the orthogonal test. The specific conclusions are as follows:

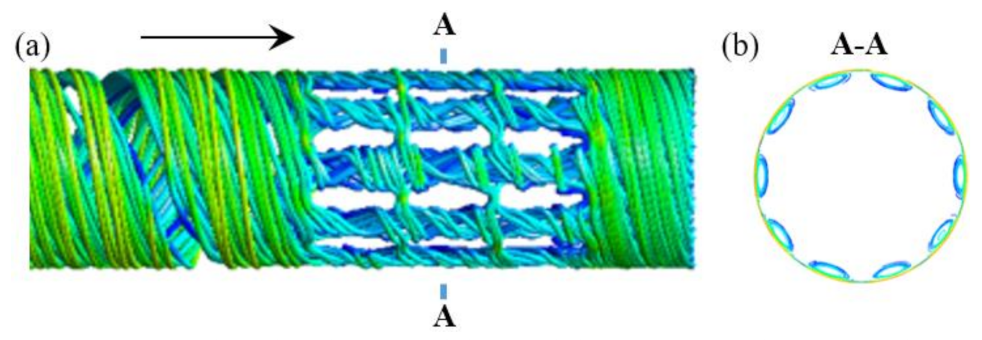

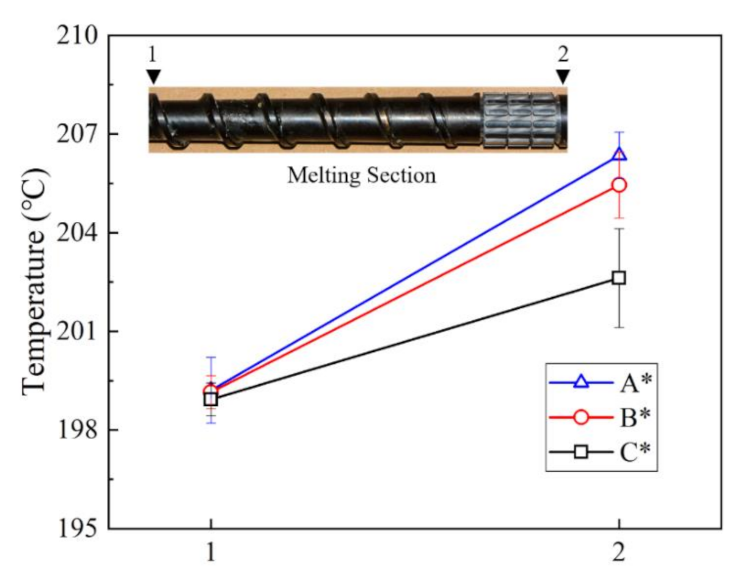

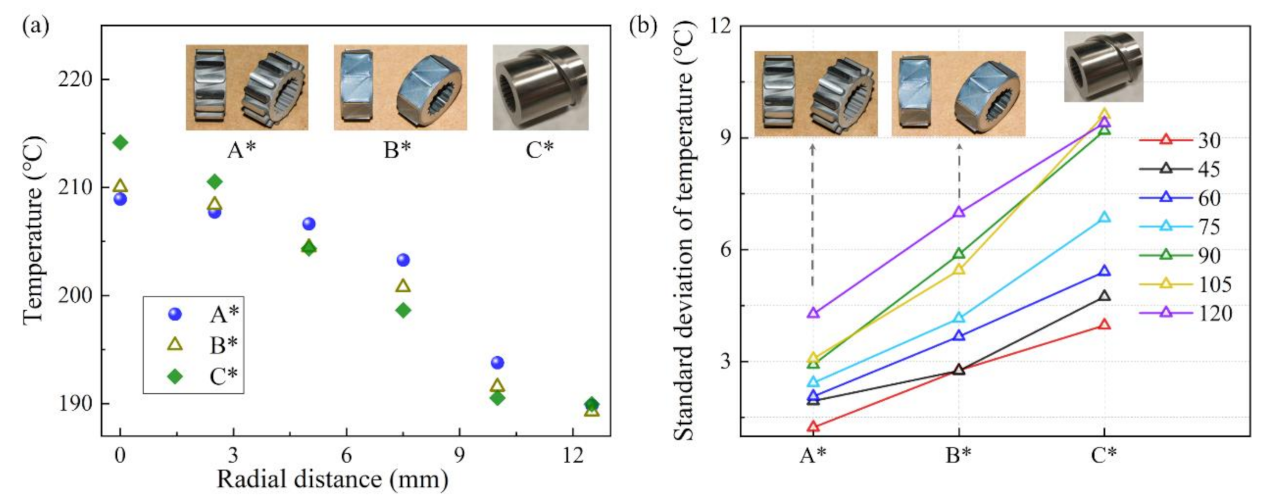

(1) From the flow and thermal conditions inside the screw channel, we found that the torsion spiral flow patterns occur in the torsion channel, inducing a ductile deformation of polymer in the form of a spiral, which in turn enhances the radial convection, resulting in a good plasticizing and melting capability. In addition, the characteristic parameters of torsion configuration have a significant influence on the plasticizing and melting capability of polymer.

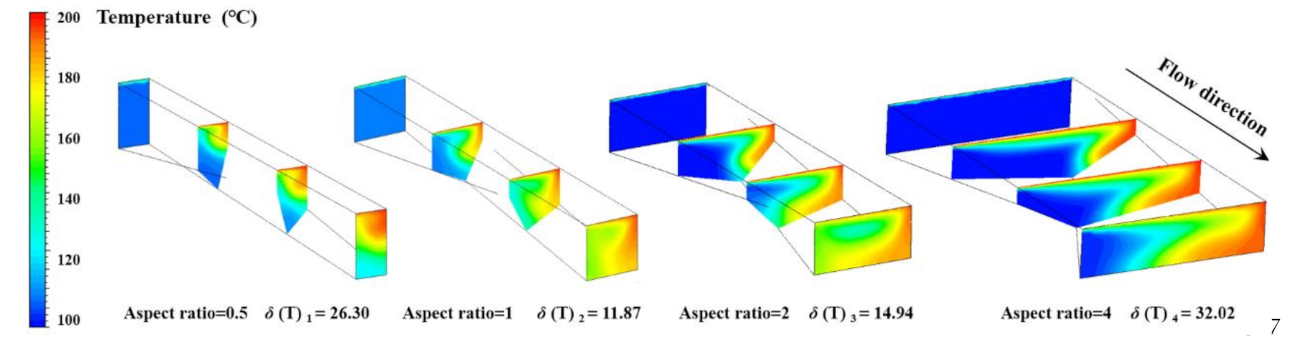

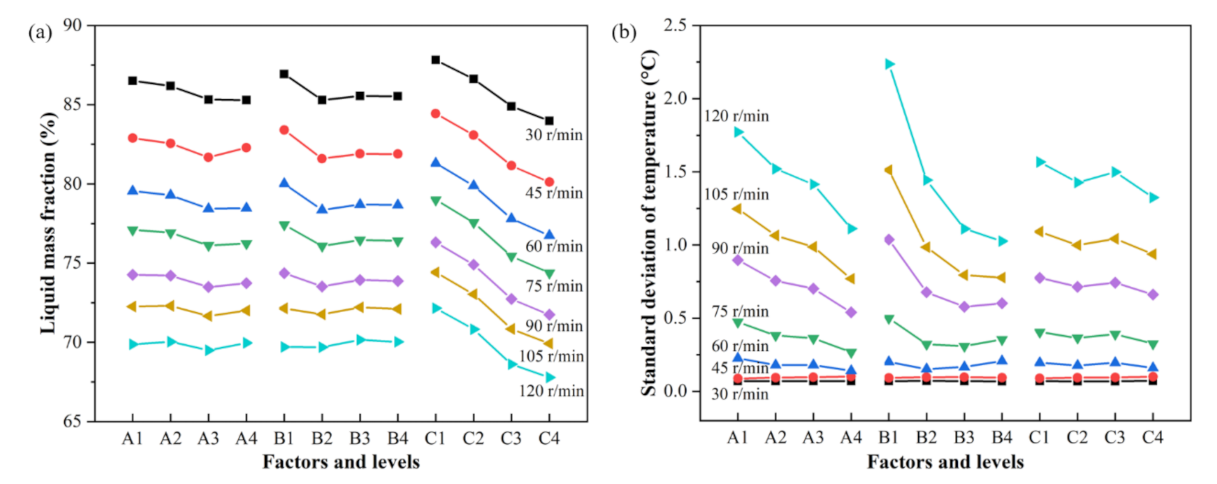

(2) The range analysis of the orthogonal experiment shows that the orders of the influence degree of factors on the liquid mass fraction (LMF), the Nusselt number (Nu) and the shear stress (τ) are: the height of the channel > the width of flight ≒ the number of flights (C > B ≒ A), whereas the order of the standard deviation of temperature (TSD) is: the number of flights ≒ the width of flight > the height of the channel (A ≒ B > C), respectively. The results indicated that the influence of characteristic parameters of torsion configuration on different indicators is different, which should be considered comprehensively.

(3) The weight matrix method of the orthogonal experiment shows that the influence weights of different factors on the liquid mass fraction (LMF) are A = 0.1413, B = 0.1930, C = 0.6657, whereas the weights for the standard deviation of temperature (TSD) are A = 0.4348, B = 0.4131, C = 0.1521. Results indicated the height of the channel is the main factor to determine the liquid mass fraction (LMF), and combinations of the number of flights and the width of flight, reflecting the width of the torsion channel, are the main factors to jointly determine the standard deviation of temperature (TSD).

(4) Combining the range analysis and weight matrix analysis, we found that the optimal combination is A4B3C1; in other words, when the number of flights is 14, the width of flight is 3 mm, and the height of the channel is 3mm, i.e., the aspect ratio of the torsion channel is almost equal to 1, the plasticizing and melting capability of the polymer is the best, which was validated by the extrusion experiment in practice. Thereby, it can offer a reference for the design and optimization of torsion configurations and provide an example for energy-efficient plasticization of polymers.

(5) Although the torsion configuration performs good radial convection and heat transfer enhancement, it does not have positive displacement transport characteristics compared with a helically grooved screw because its torsion flights are parallel to the screw axis. By redesigning the torsion flights to the helical type, it is expected to improve the positive displacement transport of the torsion configuration, which is one of our ongoing studies.