1. Introduction

Pulp, paper and wood fibres, along with plant fibres, for instance, jute, flax and hemp, have attracted considerable attention in the past two decades. It has continually been appealing to utilise bio-based/natural fibres rather than synthetic ones, in particular glass fibres (GF) as the predominating reinforcing element [

1].

Regenerated cellulose (rayon) fibres have been demonstrated to present substantial promise as reinforcements for thermoplastics [

1,

2,

3]. Regenerated cellulose fibres possess unique characteristics in the sense that they offer the merit of both natural (NF) and synthetic fibres. These include on the one hand low density, CO

2 neutrality [

4], non-abrasiveness to processing equipment [

4] and the biodegradability [

5] of NFs, and on the other hand, the physical, mechanical and uniform morphological properties of synthetic ones. Rayon is manufactured by the regeneration of dissolved cellulose and is utilised in the textile yarn forms. Due to their high tenacity, which leads to good impact resistance, high specific strength and low density (~1.5 g/cm

3), rayon yarns have been utilised to reinforce car tires as tire cord [

6].

Several articles have been published on the topic, spanning a diversity of manufacturing routes and combinations of rayon fibre and matrices. Primarily, works have been performed to produce short-fibre thermoplastic composites using melt-mixing coupled with injection moulding, followed by solvent impregnation or pultrusion [

1,

3,

7] and compression moulding for continuous fibre composites. Polypropylene (PP) seems to have been the most attractive choice of polymer for regenerated cellulose fibre-reinforced composites thus far.

It was reported that short rayon fibre PP composites demonstrate comparable mechanical performance to those of GF PP materials at the same fibre mass fraction (30 wt%) [

1]. Although the tensile modulus was lower for regenerated cellulose PP composite (2.9 GPa) than for its GF counterpart (4.1 GPa), the strength was measured at 78.7 MPa, which showed a 40% increase compared to the GF PP composite. This proves the potential of this type of bio-based fibre as a reinforcement in composite systems. The resulting rayon PP composite was utilised in the production of door panels and dashboards by Faurecia interior systems and Cordenka [

7]. In the automotive industry, it was revealed that rayon-based composites offer excellent mechanical performance, reaching and partially surpassing the level of GF ones [

8,

9]. In comparison with NF counterparts, regenerated fibre composites display significant enhancement in strength and impact properties [

7], whilst stiffness can easily be improved by the incorporation of NFs at a good level [

10].

For semi-structural applications, these sorts of fibres can be used in the form of fabric, and the woven structure of the reinforcement can further enhance the properties of the developed composite. It is customary to use a type of liquid thermoset to develop a composite based on textile reinforcements. Thermosets, due to their high mechanical behaviour, are used in high-performance applications. On the other hand, thermoplastics are appealing to manufacturers as they provide high impact tolerance [

11], good vibration-dampening capacities [

12], recyclability [

11] and post-manufacturing formability [

13], and some have eco-friendly contents [

14]. A novel thermoplastic resin (Elium

®) has been developed by Arkema Chemicals, which enables the process of composites at room temperature (as a result, it is a less energy-intensive thermoplastic polymer relative to other ones) and offers similar mechanical properties as epoxy-based systems. This manufacturing condition contributes to preventing the degradation of the performance of the bio-based fibre, which is generally caused by the high processing temperature of thermoplastics. Resin infusion and resin transfer moulding (RTM) can be employed to polymerise the fibre-reinforced Elium

® part at ambient temperature. The incorporation of a peroxide curing agent into the monomer (methyl methacrylate (MMA)) initiates free radical polymerisation, which subsequently reacts to form a poly methyl methacrylate (PMMA) polymer [

15,

16]. It is worth noting that higher bio-based fibre mass fraction can be obtained in the composites when using hot compression or resin infusion methods compared to that which can be obtained from an injection moulding technique. This can be a crucial point that needs to be taken into account when the presence of maximum fibre content in the part is important [

17,

18,

19].

In this work, the reinforcing capabilities of rayon fabric in a liquid thermoplastic resin were investigated. The mechanical performance and glass transition temperature of the resulting composite were compared with those of other bio-based and NF (jute and ramie) thermoset/thermoplastic composite systems. Very few studies reported the tensile, flexural and viscoelastic behaviour of rayon fabric Elium® composite (the combination of a regenerated cellulose fabric and Elium®) and were found to show the potential of this type of bio-based fabric composite for secondary applications. Scanning electron microscope (SEM) analysis was performed to investigate the mode of fracture after the tensile test. Rayon fabric Elium ® composite produced using the resin infusion (RI) method, which is typically employed in fabric-reinforced thermoset composites. Rayon and Elium® were used for the first time to make a bio-based fabric thermoplastic composite using the RI method, to the best of the authors’ knowledge. A finite element (FE) model was developed, and the model was indicated to be capable of predicting the structural performance of the regenerated cellulose Elium® composite panel. The bending performance of the bio-based composite was modelled with a polynomial function, and the materials model was applied to the FE (ABAQUS) software for the calibration and validation of the bent rectangular sample. Subsequently, the same materials model was assigned to a door car (interior) panel, and then the bending deformation, deflection and reaction forces were predicted. This kind of simulation has not been extensively carried out for bio-based composites.

3. Results and Discussion

Tensile tests were performed to study the strength, modulus and elongation at break of the rayon Elium® composite and to compare the respective results with the available natural fibre (NF) composite counterparts.

The incorporation of rayon instead of NF was seen to enhance the strength and toughness of the composites compared to that of natural fibre composites, as the breaking point elongated to a much higher value (

Table 1) using the same manufacturing technique, as conducted by the authors [

17,

20]. It was shown that rayon fibre has higher elongation and lower modulus than flax fibre [

21].

ANOVA analysis for the tensile strength of the above-mentioned composites is displayed in

Table 2, which includes the variance of the tensile strength, i.e., between groups (BG) and within group (WG). SS refers to the sum of square, and df stands for degree of freedom. The F is the ratio of the BG mean square (MS) to the WG mean square. For all three composites, 5 samples were considered; therefore, there were 15 samples in total. If the

p-value of the F-test is less than 0.05, as reported here, the difference between the average tensile strength from one type of composite to another at a 95% confidence level is statistically significant.

Table 3 shows the ANOVA analysis of the tensile modulus; similarly, the P-value was calculated to be less than 0.05, indicating a statistically significant difference between the average tensile modulus from one composite to another at the confidence level of 95%.

It was detected that the rayon fibre treatments with acetylation, 3-methacryloxypropyltrimethoxy silane (MPS) and 3-aminopropyltriethoxy silane (APS) were found to reduce the tensile strength by 2.1–35% and modulus by 2–24% of the resulting composites; however, the elongation slightly increased only for MPS-treated rayon fibre unsaturated polyester composite, as measured by one of the authors before [

22]. The transfer of stresses goes from matrix to fibre; thus, the fibre–matrix interface is very important but was not achieved in these investigations. As the tensile properties were more fibre-dependent, this explains the ineffectiveness of rayon fibre chemical modifications.

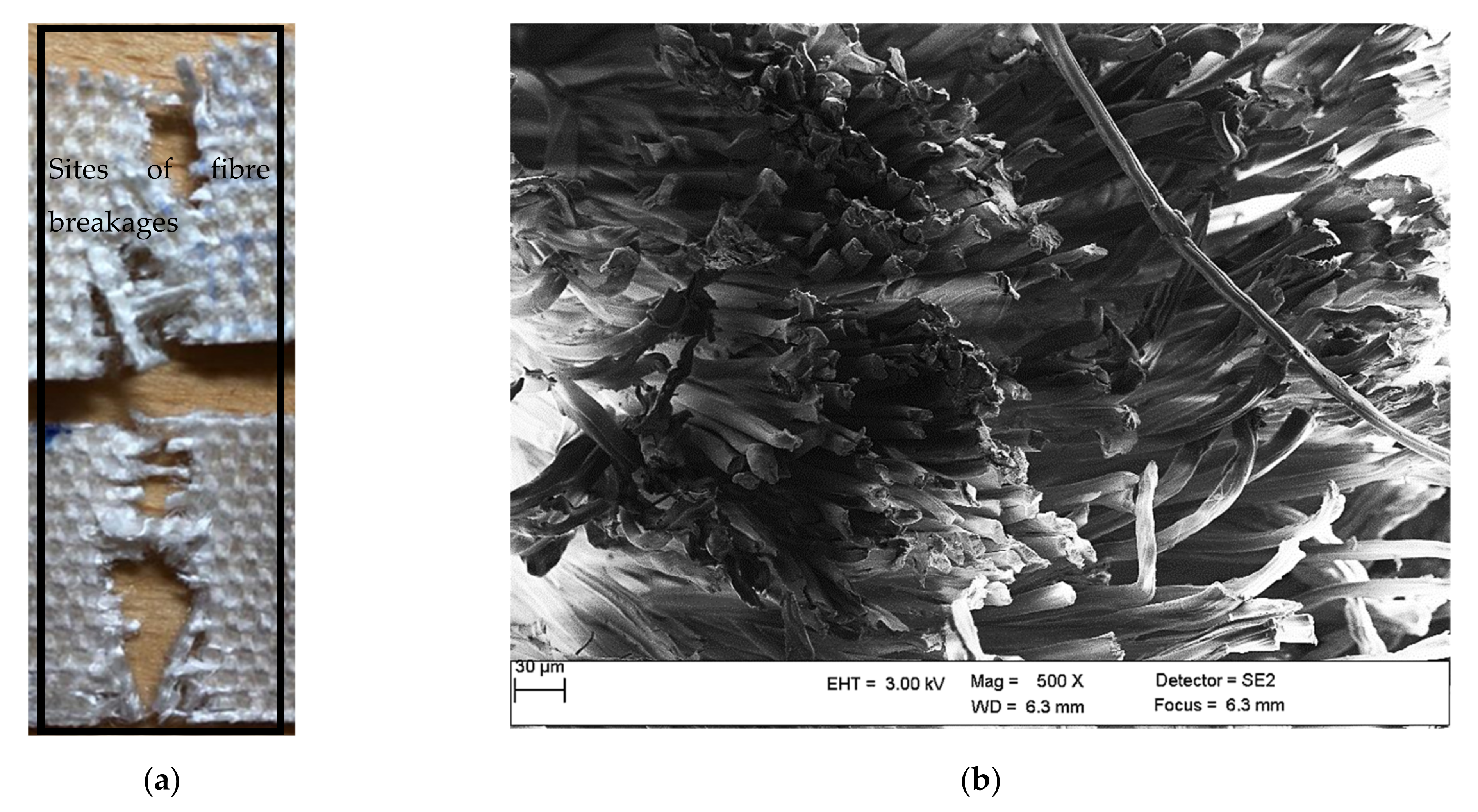

As illustrated in

Figure 1, no indication of fabric delamination was detected in the cross-sectional image, and the mode of fracture was fibre breakage. The sites of fractures are shown in

Figure 1a and fibres broke along the tension direction are displayed in

Figure 1b. Good interfacial adhesion was observed between the rayon fibres and the Elium

® matrix.

The three-point bending strength and modulus of rayon fibre-reinforced Elium

® composite samples were measured in order to evaluate the properties and compare them with those of natural (ramie and jute) fibre Elium

® composite systems, as well as rayon fibre epoxy composites, fabricated via the same production method. The stress–strain curves of rayon fibre-reinforced Elium

® composite samples are displayed in

Figure 2, and the average flexural strength and modulus are tabulated (

Table 4). The values are 93.5 MPa and 5.6 GPa for strength and modulus, respectively, which are in the same range as rayon fibre epoxy composite (as described in the previous work) [

23]. Moreover, 0&90 woven jute fabric Elium

® was found to show lower strength (7%) and modulus [

20].

It was shown that the chemical treatment of rayon fibres did not lead to the enhancement of the flexural properties of their respective composites. For instance, γ-aminopropyltriethoxysilane (APTES) was used to modify the rayon fibre surface, and, in some composites, a silane-coupling agent was used for incorporation into the epoxy system; however, no improvement was recorded for the flexural performance of the developed rayon epoxy composites [

23]. In another investigation by the author [

22], 3-methacryloxypropyltrimethoxy silane (MPS) and acetic anhydride were employed for silane and acetylation treatments of the rayon surface to produce treated rayon unsaturated polyester composites, which did not provide positive results for bending modulus and strength.

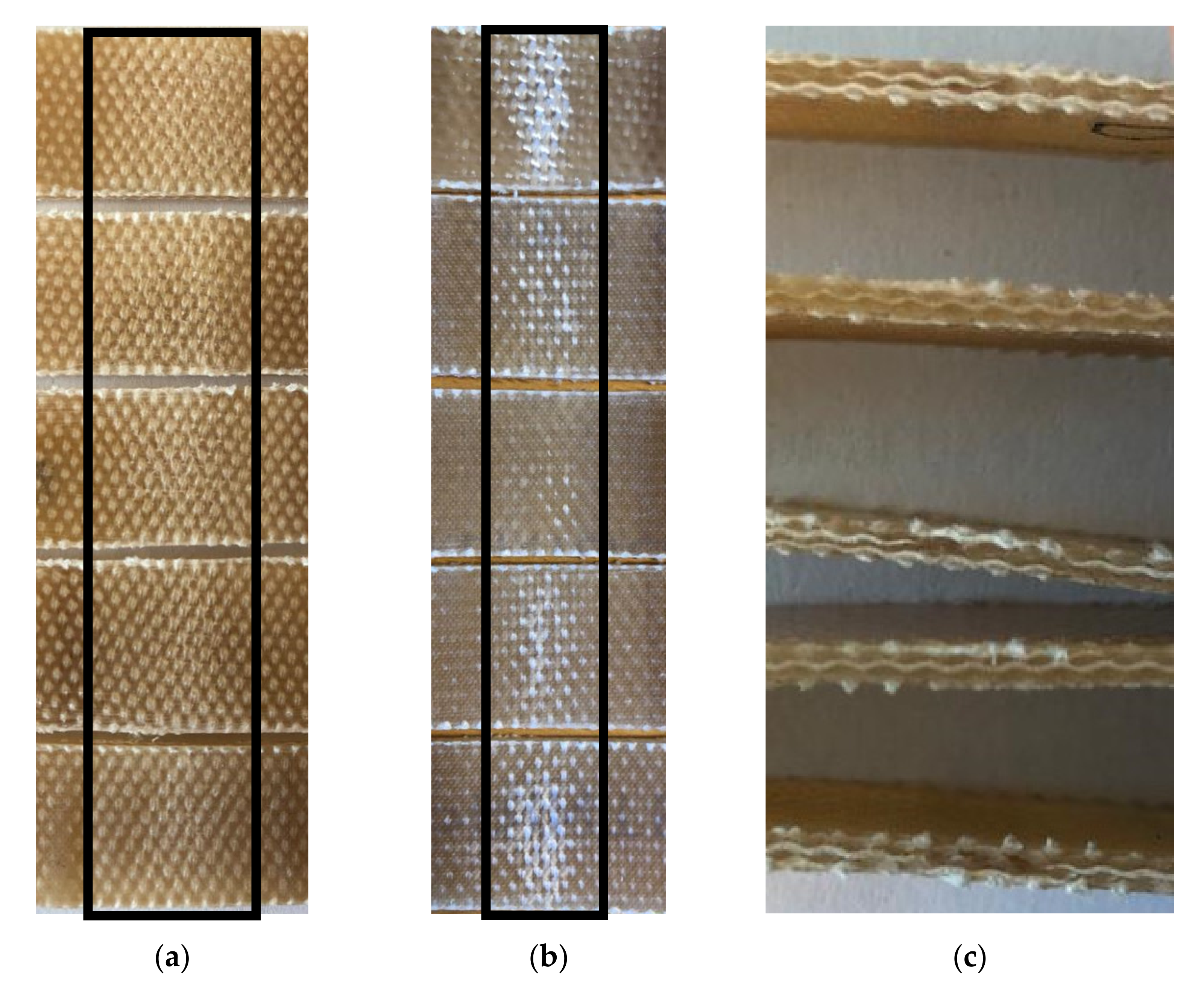

It was observed that the bending samples did not fracture even after 7% bending strain; instead, very tiny cracks were observed on the tensile and compressive sides of the samples. On the tension and compression surfaces of the bent samples, the matrix became whiter and less transparent due to the breakage of polymer chains (

Figure 3a,b). The cross-sectional views of the bent samples were detected to illustrate no signs of delamination or breakage, as depicted in

Figure 3c.

Tabulated ANOVA analysis (

Table 5 and

Table 6) shows the variance of flexural properties for the rayon Elium

® and jute Elium

® composites. The variance of flexural strength calculated between the groups and within groups (each group contains the result of five samples) demonstrated that the

p-value equals 0.05. This implies that the difference between the flexural strength of these two composites was relatively significant, at slightly less than a 95% confidence level. This value could be explained by the fact that the bending test is more matrix-dependent, and, as the same matrix was used to make these two composites, the results can partly overlap. However, a

p-value of less than 0.05 was obtained from the F-test of the modulus values, which indicates a statistically significant difference between the average flexural modulus of these two composites at a confidence level of 95%.

Besides, in order to have a better understanding of the performance of the bio-based composite in an actual part, first finite element (FE) simulation of the bending scenario was calibrated and validated with the experiment, and subsequently, the materials model was applied to a car door panel for predicting the behavior of the component under flexural loading.

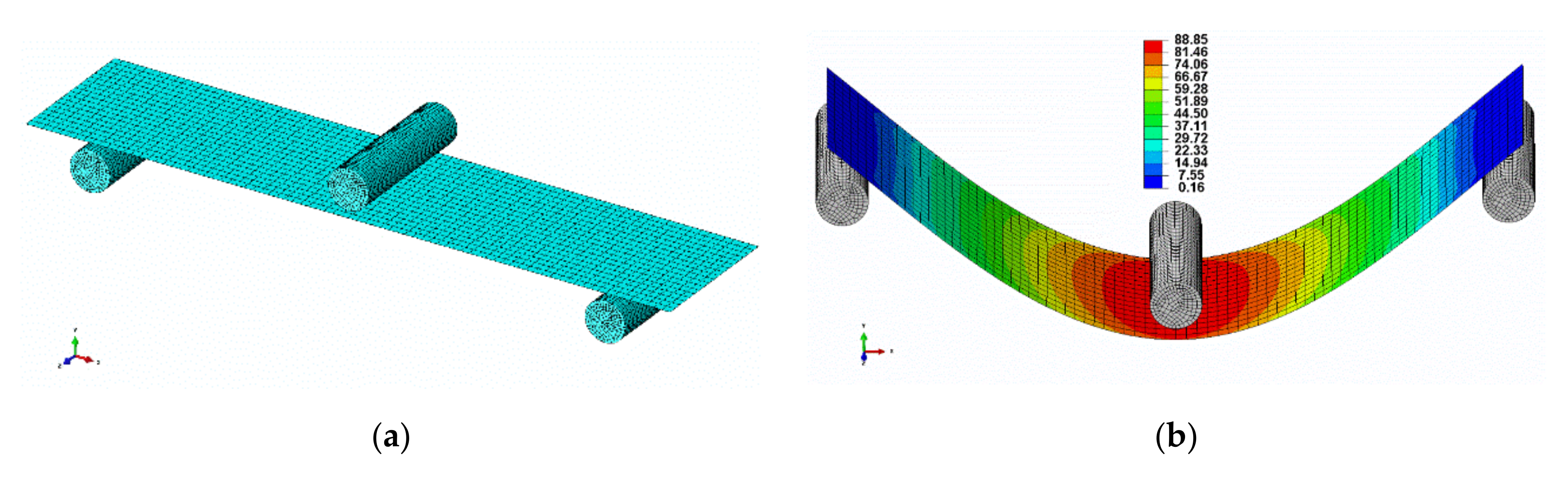

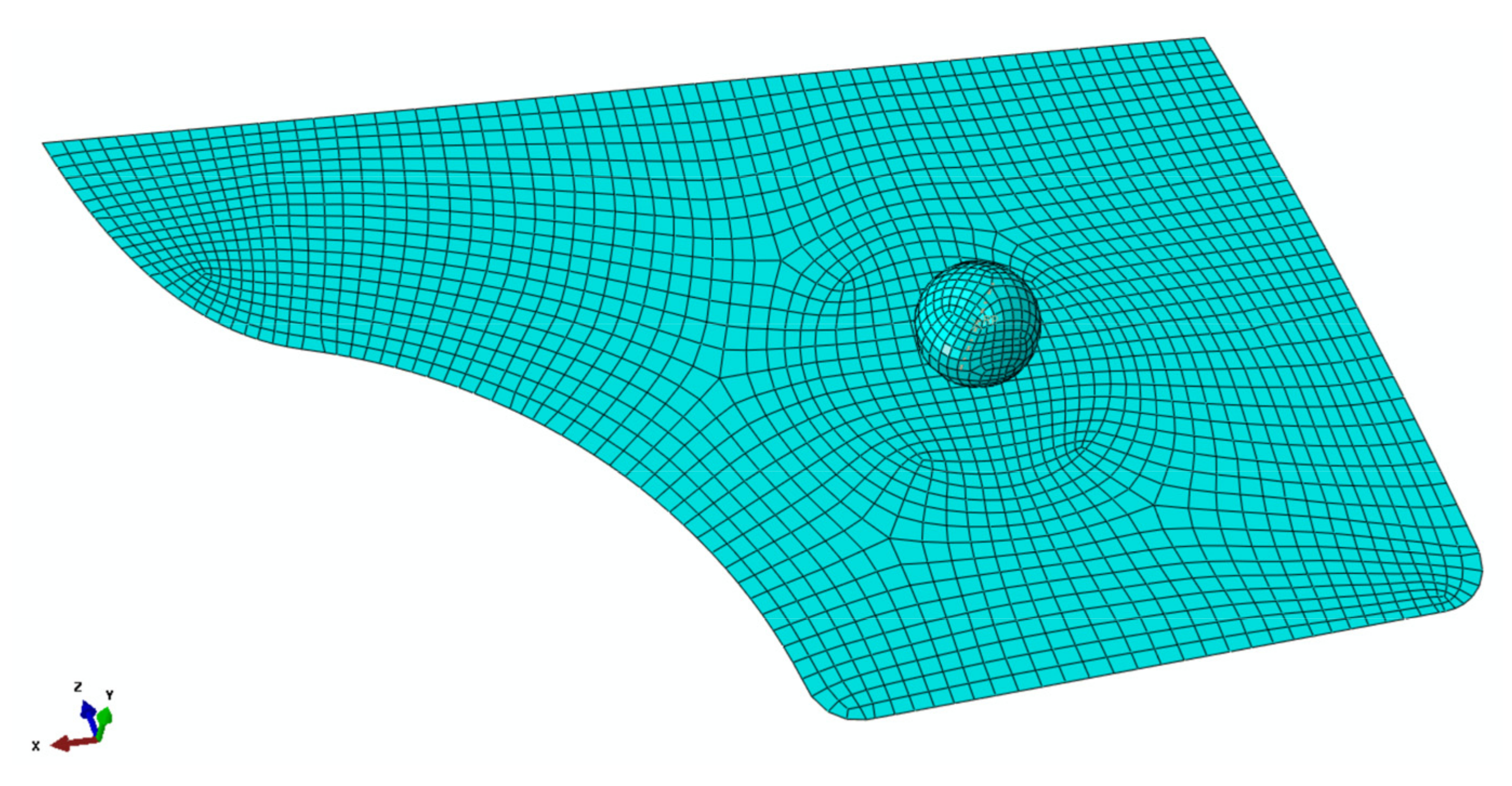

The whole flexural setup was designed according to the experiment, as shown in

Figure 4, and a materials model was adopted as per the experiment test result. The width, length and span of the sample were 20 mm, 80 mm and 64 mm, respectively, and it was modelled as a homogeneous shell. The supports and the load, which are presented as a cylinder with a diameter of 5 mm, were modelled as rigid. The modulus was obtained from the experiment and density, and Poisson’s ratios were 1.29 g/cm

3 and 0.37 [

24,

25], respectively. Coulomb friction was used to model the friction between surfaces with a coefficient equal to 0.2 [

26]. Polynomial materials modelling was assumed to model the plastic constitutive behavior. The bottom cylinders were fixed in all directions and rotations, whereas the top cylinder was fixed in the

x and

z directions and could only move downwards (along the

y direction). The mesh type of the sample was a 2D shell quad with an element size of 1 mm, and the number of elements was 1440. The parameters above were found to be optimal in terms of computational time and accuracy convergence after performing some preliminary investigations of the element size. The FE model with the mesh and the color representation of the von Mises stress subjected to the bending load is displayed in

Figure 4a,b and a vertical displacement of 18 mm was registered in the center of the sample.

A polynomial function of degree two was used to estimate the plastic deformation of the sample and is obtained as

where

σ is the stress (in MPa);

x is the instantaneous strain;

ak is the strain amplitude, and

k is the strain exponent. Polynomial expression fitted the experimental results by using the strain amplitudes of

a2,

a1 and

a0, which were employed as approximately 8, 54 and 10, respectively, and the strain exponent of

k = 2. All of these parameters were extracted with a coefficient of determination (R2) of 99%.

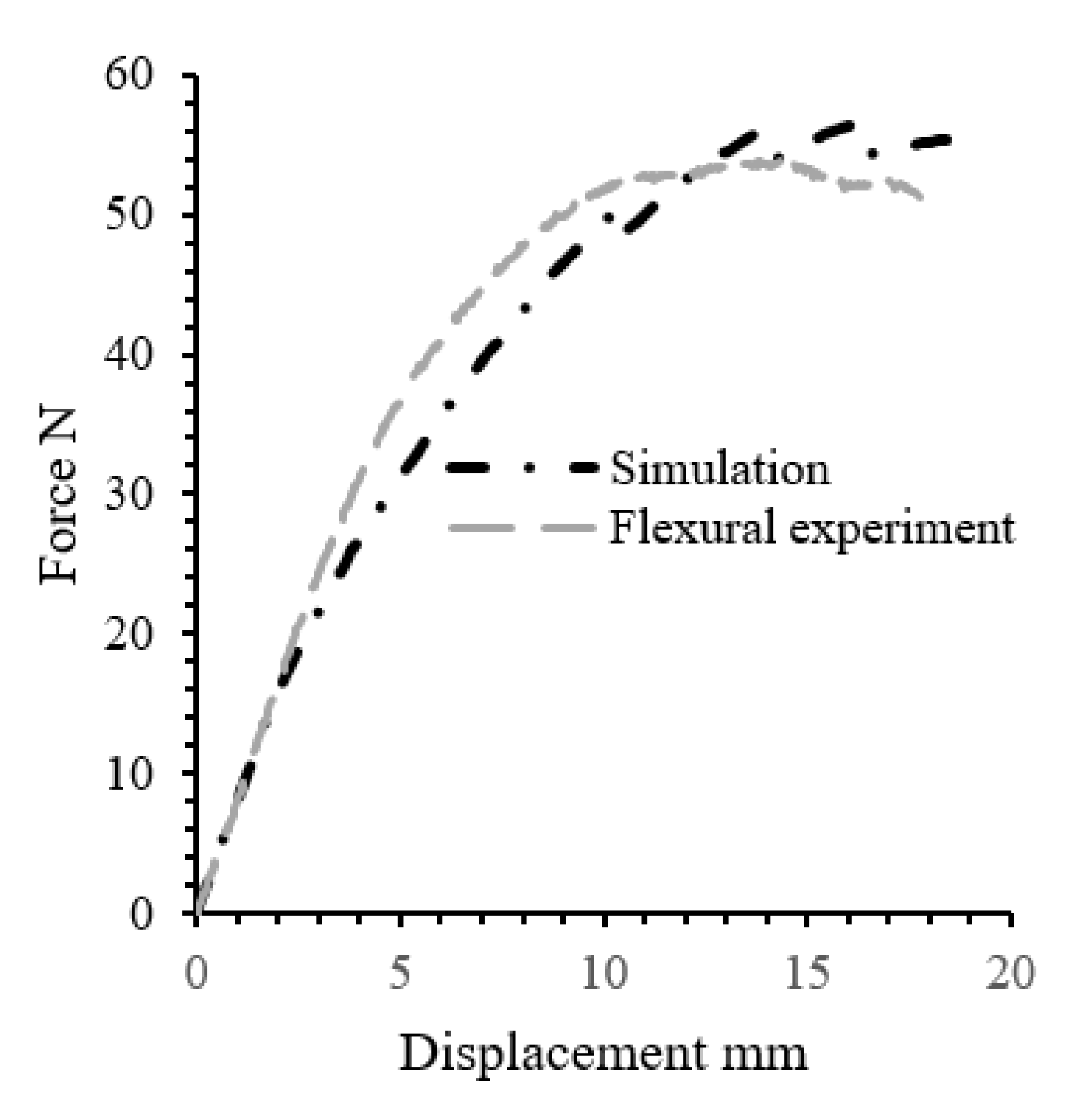

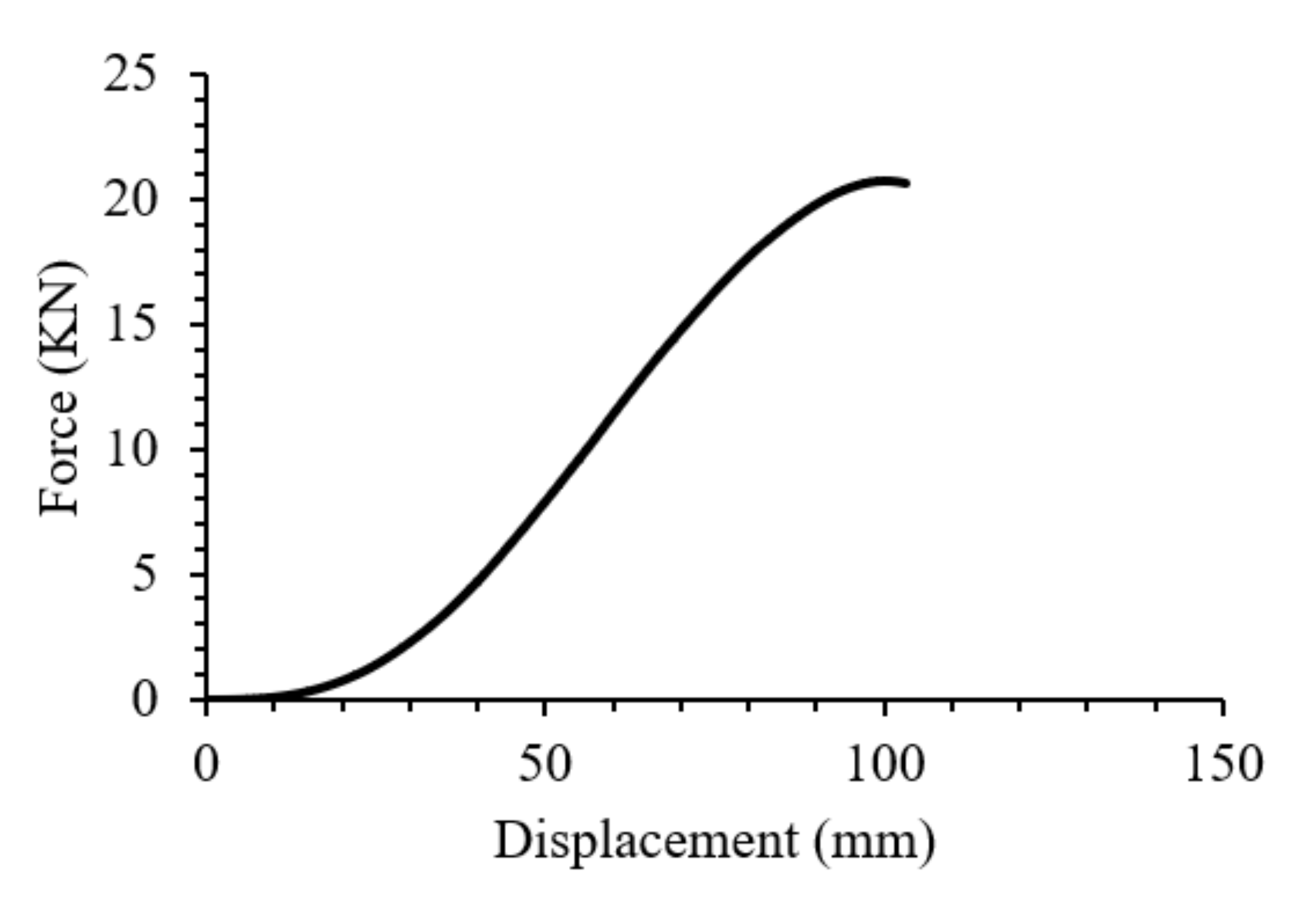

A comparison between FE model results in terms of force-displacement and the experimental measurements is depicted in

Figure 5. Generally, a good agreement was obtained between the experimental result and the FE simulation. The small deviation in the plastic region is due to the fact that the average Poisson’s ratio used for this simulation was the value obtained from the literature, which could not demonstrate the precise amount. This validated the developed model and enabled its utilisation for the prediction of the bending performance of the real-life component.

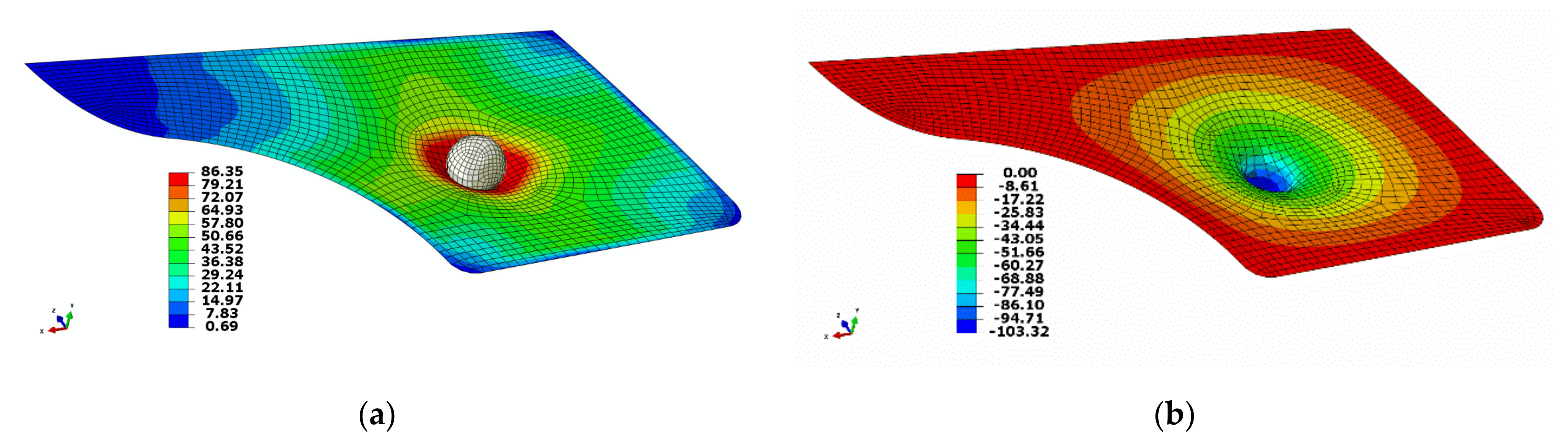

The simulation enabled the assessment of the displacement-force performance and the deformation of the car door panel made of the same developed material in a bending scenario.

The swift car door panel [

27] was used to simulate the bending of the part, which was modelled with the same materials model used for the bending test validation, under a flexural load in the shape of a sphere measuring 100 mm diameter. A friction coefficient of 0.2 was applied for the interaction between surfaces. The sphere placed in such a way to bend the middle of the door panel and its position from the bottom right corner of the door panel was 337 mm and 284 mm in the x and z directions, respectively. The dimension and mesh of the door interior are depicted in

Figure 6. The FE model of the whole assembly, i.e., the sphere and the door panel is also shown in

Figure 7. All the parameters were adjusted in accordance with the materials model developed in the flexural test experiment. The door panel was fixed from all the edges and the displacement to the

Y direction was enabled in the assembly. When the sphere went down into the middle of the component, the maximum load was obtained at the deflection of around 100 mm (

Figure 8b). However, the deflection could be much lower if the panel was supported by the door exterior. It is worth mentioning that the von Mises stress obtained (~86 MPa) was close to that of the bending test scenario (

Figure 8a). Eventually, the prediction of the deflection-force behavior of the car door panel bent by the ball is shown in

Figure 9. At around 102 mm deflection, a maximum load of approximately 20 kN could be recorded. This sort of materials modelling and structural simulation could contribute to the prediction of the performance and deformation of the automotive interior components, which can be fabricated using bio-based composites.

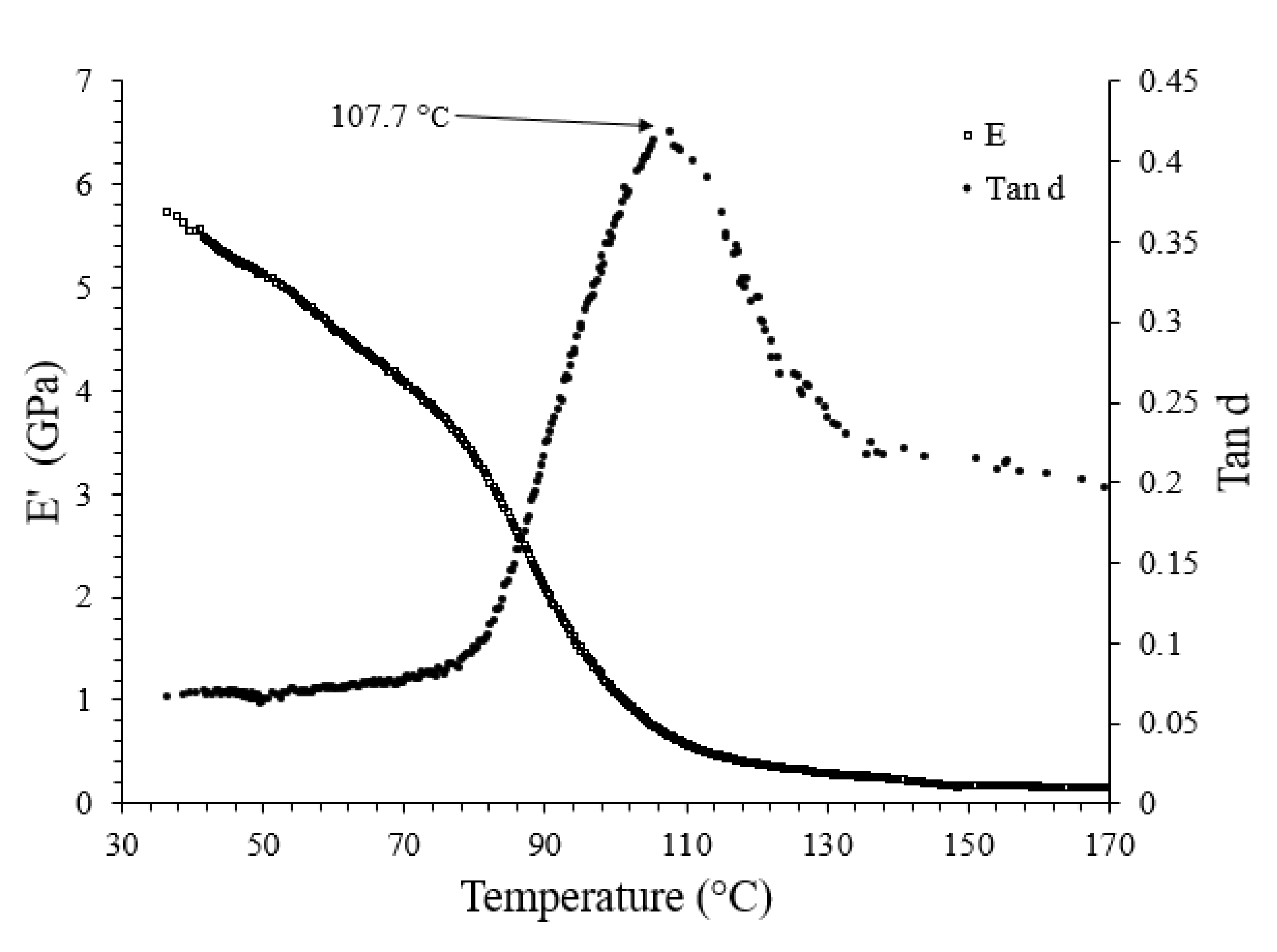

The DMA test was also performed to investigate the viscoelastic properties of rayon fibre Elium composite and to compare them with those of NF polymeric composites investigated by the authors, as shown in

Figure 10.

The storage modulus (E′) was measured at 5.8 GPa at 30 °C, which is in good agreement with the flexural modulus as obtained from the three-point bending test at room temperature. The glassy state region lasted until 80 °C wherein glass transition phase was initiated, as illustrated in the E′ curve. The glass transition zone continued until about 100 °C, with a swift continuous drop in E′.

It can be discovered that the glass transition temperature of rayon fibre-reinforced Elium

® composite (107.7 °C), as obtained from the loss factor peak (tan (d)), is higher or comparable with that of rayon epoxy systems and other natural fibre Elium

® counterparts. The standard deviation of the T

g value for the composite is shown in parentheses in

Table 7.

The whole mechanical results and viscoelastic analysis demonstrate the great potential of the developed bio-based composite for the interior applications, and structural simulation can be performed to initially predict the mode of deformation and expected force in the component.