1. Introduction

Traditional reinforced concrete (RC) structures exhibit aging problems related to the corrosion of the steel reinforcement, and there have been many recent studies into strengthening and retrofitting these structures using composite materials.

Recently, the FRP–concrete concept was used in manufacturing hybrid slab [

1], column repairing [

2] and a wall system [

3]. Some of the advantages of these hybrid elements are good flexural stiffness, a high load-bearing capacity and excellent corrosion resistance.

There are two main typologies of FRP–concrete hybrid structures. In the first type, FRP is used as a tubular or box envelope for concrete, whereas in the second and more studied type, FRP is presented as a girder or a pultruded profile connected to a top concrete section to aid bending resistance. Regarding the first approach, several researchers have studied the bending resistance design of hybrid structures based on the box system. Yang et al. [

4] performed tests over longitudinal pultruded GFRP box-profile and transverse steel stirrups. Some GFRP shear connectors (rib and bolted) enhanced the bonding between the GFRP profile and the concrete portion. In addition, Zhang et al. [

5] experimentally studied a box-type profile using wet bonding (WB) and FRP shear key (SK) connections. Moreover, Liu et al. [

6] tested pultruded GFRP three-cell box-section and concrete slabs for pedestrian bridges, while Dagher et al. [

7] worked on solutions with tubular FRP filled with concrete for the same application.

Far more research can be found regarding the second hybrid FRP–concrete typology, which is based on connecting FRP pultruded profiles to upper concrete sections to generate hybrid beams. One of the pioneering works on hybrid composite single beams is by Hulatt et al. [

8], in which manufactured hollow beams of GFRP webs, concrete heads and carbon FRP (CFRP) plies in the bottom flange were studied. Along the same lines, T-shaped beams combining GFRP and steel reinforcement for girders were tested by Wu et al. [

9]. Zhang et al. [

10] tested I-shaped pultruded GFRP profiles with the web strengthened by externally bonded CFRP sheets, comparing both common concrete and ultra-high concrete (UHPC) cases. Nordin et al. [

11] considered GFRP I-beams reinforced with CFRP in the bottom flange connected to a concrete head, while Zou et al. [

12] investigated the shear behavior of FRP–concrete composite sections using bending tests.

Regarding more specific tests on the connection between FRP profiles and concrete parts, Gonilha et al. (2014) [

13] performed several push-out tests and simulations of hybrid systems for a girder with I-shaped GFRP beams and concrete. Six specimens connected with steel bolts and/or bonding were considered in Koaik et al. [

14], and I-shaped pultruded GFRP bolt-connected profiles with partial interaction can be found in Neagoe et al. [

15]. The specific performance of FRP–concrete sections was also experimentally analyzed by Zou et al. [

16]. These authors developed an experimental study of bolted hybrid FRP–ultra-high-performance concrete (UHPC). They performed 14 push-out tests with varying parameters, such as bolt strength, bolt diameter and bolt-embedding length. Similarly, Etim et al. [

17] developed several push-out tests to investigate the shear transmission between normal concrete and GFRP profiles. However, analytical methods have not yet been fully developed enough to precisely predict the shear capacity of the composite sections due to the complexity of the FRP–concrete connection. A specific attempt at GFRP and concrete hybrid beams can be found in Neagoe and Gil [

18]. To complement the modeling branch, there are some numerical approaches, such as Gong et al. [

19], who evaluated the composite action of a hybrid beam of FRP and fiber-reinforced polymer–concrete. These authors assumed that only shear connectors provide composite action between the FRP and concrete components. A more applied numerical study, as the one presented in Muc et al., was aimed at the design of a GFRP bridge girder combined with concrete [

20]. Real applications of this type of FRP beam and concrete hybrid structures can be found in Jurkiewiez et al. [

21], who tested a GFRP and concrete footbridge until failure. In this case, the connection between the slab and the GFRP profiles was a mixed bonded/bolted connection. Along the same lines, a real-size bridge with a hybrid solution of GFRP and CFRP with a concrete slab and a span of 21 m was tested in Siwowski et al. [

22], and the details of a girder are in [

23].

As can be observed from the literature review, most of the developments in hybrid FRP–concrete structures have been oriented toward implementing beam-like solutions. There are few contributions to research on plane slab typology, in which FRP can even be used as formwork. On this topic, the work by Gai et al. [

24] has to be highlighted as it investigated the use of GFRP formwork for concrete floor slabs. The concept of using FRP as formwork was presented by one of the pioneering studies in Hall and Mottram [

25] in which a combination of pultruded GFRP profiles as permanent formwork for concrete was studied. Therefore, there is a comparative lack of research in the area of hybrid FRP–concrete slabs that needs to be covered.

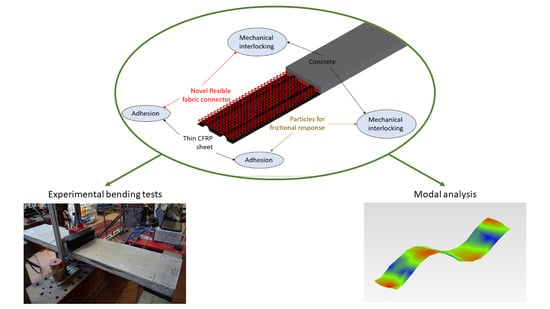

In addition, it can be seen that the connection systems between FRP and concrete always rely on epoxy-bonded solutions for previously cast concrete, or on mechanical punctual connectors for cast-in-place concrete. Accordingly, a novel connection system based on embedding a flexible fiber fabric bonded to FRP and mechanically interlocking it with concrete is proposed, tested and analyzed. This is an entirely new technology, to the best of our knowledge, with the closest research considering fiber fabrics together with FRP profiles being found in the work by Sutter et al. [

26], who tested hollow TRC beams reinforced with CFRP and embedded in concrete and mathematically analyzed them [

27].

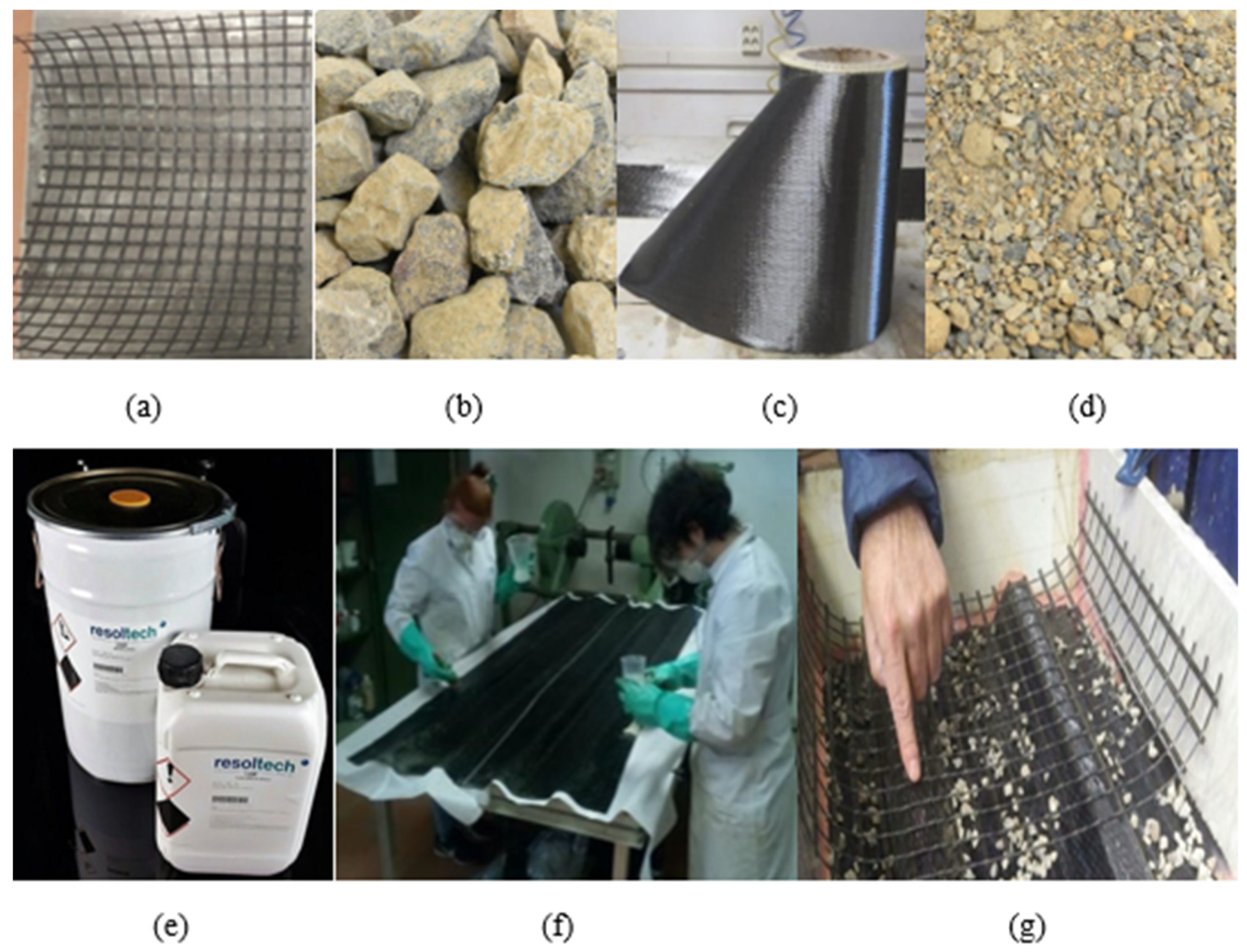

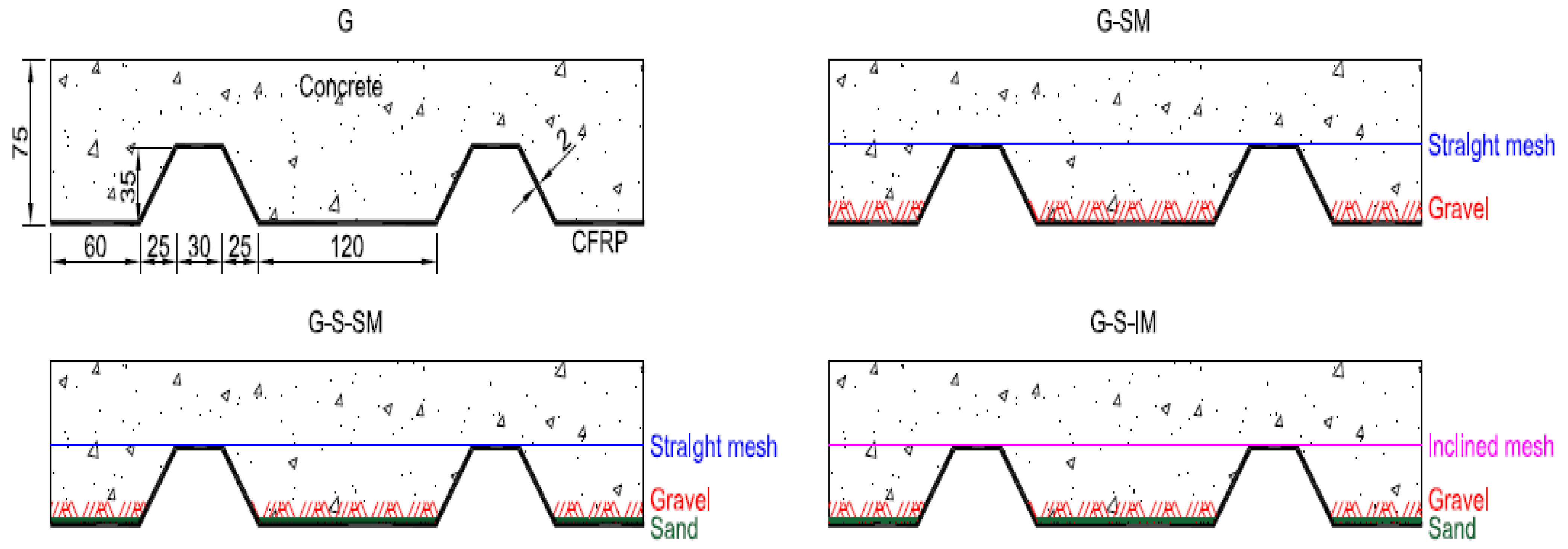

The current work focuses on the description and mechanical characterization of the structural response of a novel hybrid slab system made with a thin CFRP sheet, which is also the formwork, and a concrete block that is connected through a flexible fiber fabric. An additional connection using particle-based frictional enhancement is also considered and compared. Among the mechanical characterization tasks, the experimental modal analysis is aimed at qualitatively relating the vibrational response with the particular studied typologies of FRP–concrete connection systems. In addition, three-point bending tests are presented to analyze the load-bearing capacity, strain distribution, evolution of the position of the neutral axis and the dissipated energy, among other parameters.

The study presented herein analyses, for the first time, the effect of a flexible fabric mesh as a connector between CFRP sheet and concrete, for producing hybrid structures aimed to support bending efforts. The potential benefits of this study include (i) opening the possibility of replacing thin steel sheets with FRP sheets, avoiding the corrosion problems typical of aggressive environments; (ii) characterizing a connection technology based on distributing the load-transferring mechanism to be more compatible with FRP materials whose mechanical connection is always controversial; and (iii) providing the order of magnitude of the load-bearing capacity of thin slabs produced with this novel connection based on flexible fiber fabric.

5. Calculations, Comparison and Discussion

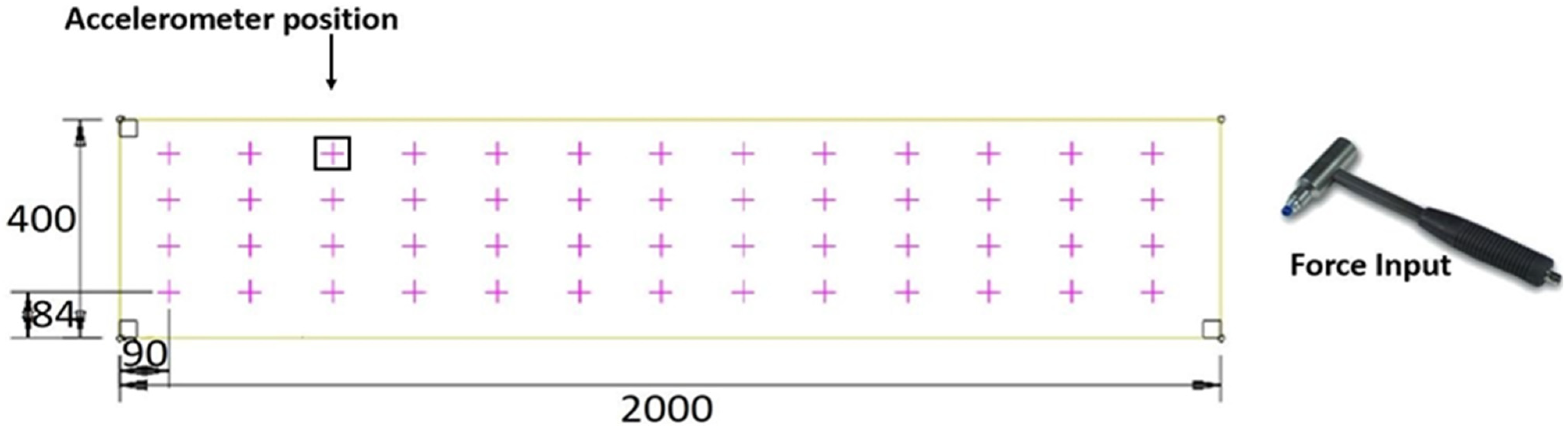

5.1. Modal Analysis

Initially, it should be noted that the vibrational response of mechanical systems is influenced by the supports. As all the tested specimens had the same support, the results obtained from the experimental modal analysis (

Section 4.1) can be used as comparative results. Thus, the results in

Table 2 are not intended to produce an absolute vibration frequency value for the slabs, but can merely be used as a relative tool to find patterns that relate vibrational results with connection systems.

First, it is observed (see

Table 2) that the G-S-SM-1 specimen showed an abnormally low vibration frequency (269 Hz) in comparison with the rest of the specimens, and its damping ratio was higher (4.93%) than the values for all other tests (between 1.2% and 2.5%). According to the results of the concrete compression tests (see

Table 1), the strength of the concrete in this specimen was very low (16.4 MPa) in comparison with the other specimens (averaging 20 MPa). Therefore, it is surmised that there was an error in the concrete pouring process (some voids in the concrete were observed after a destructive test) that resulted in the concrete of this specimen being so different that it could not be used in a dynamic response comparison. From this point on, this specimen was rejected and was not considered for the remaining study of the modal analysis results.

Non-destructive experimental modal analysis tests showed that there was a certain correlation between the dynamical response and the connection system. The inclusion of a connection mesh led to an increase in the natural frequency (

Table 2). The G samples had lower frequency values compared with G-SM (19.5%), G-S-SM (5.2%) and G-S-IM (8.1%). Results seem to indicate that adding sand to the gravel in the frictional mechanism was not beneficial (comparing G-S-SM with G-SM), but inclining the connection mesh had positive effects (comparing G-S-SM with G-S-IM). These non-destructive qualitative results are completely aligned with the destructive bending test results (see

Section 5.2), proving that there is a certain relationship that requires further research to confirm the ability of the experimental modal analysis to relate the natural vibration frequency and particular connection systems in a quantitative way. In fact, general observations from the modal analysis indicate that this technique is highly dependent on the performance of individual materials. Thus, the connection system should not dramatically affect the results because the low excitation energy of this test results in a response in the elastic range, where the connection system is not very influential. It is not possible to see any pattern from the damping ratio.

In conclusion, including small-size particles for the roughness improvement of the CFRP–concrete contact surface (G-SM vs. G-S-SM) reduced the dynamic stiffness of the specimens and it was translated in a 12% lower frequency of vibration of the third bending mode. Thus, it is clear that small-size particles affect CFRP–concrete connection. In contrast, adding a straight mesh caused an increase of 20% of the vibration frequency (comparing G-SM and G cases), proving that the inclusion or not of this connection element may be comparatively assessed by experimental modal analysis. Finally, inclining the mesh has little effect (2.8% of the vibration frequency increase) supporting the idea that the orientation of the mesh has no effect in the lineal elastic response and only plays an important role at failure stage.

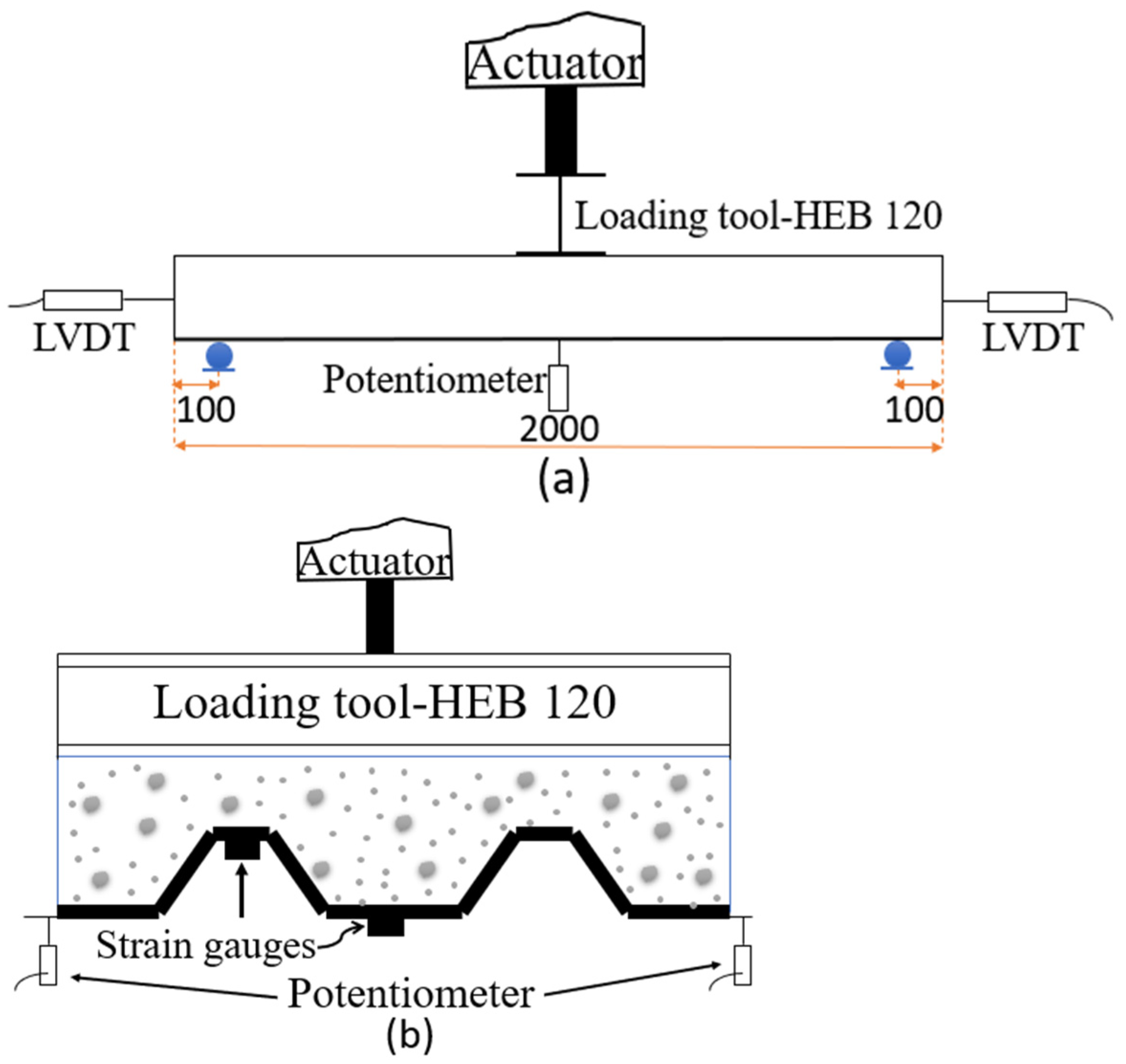

5.2. Bending Tests

It should be observed that the obtained results show clear trends, despite the significant variability. The differences between sample results are related to the uncertainty of hand manufacture and the complexity of the interaction in the interfaces for shear transmission. This could present a problem for practitioners that pretend to use it at work, and it means that quality control must be mandatory to produce homogeneous specimens. Therefore, the analysis of the impact of the different connection techniques between the CFRP sheets and concrete is mostly qualitative.

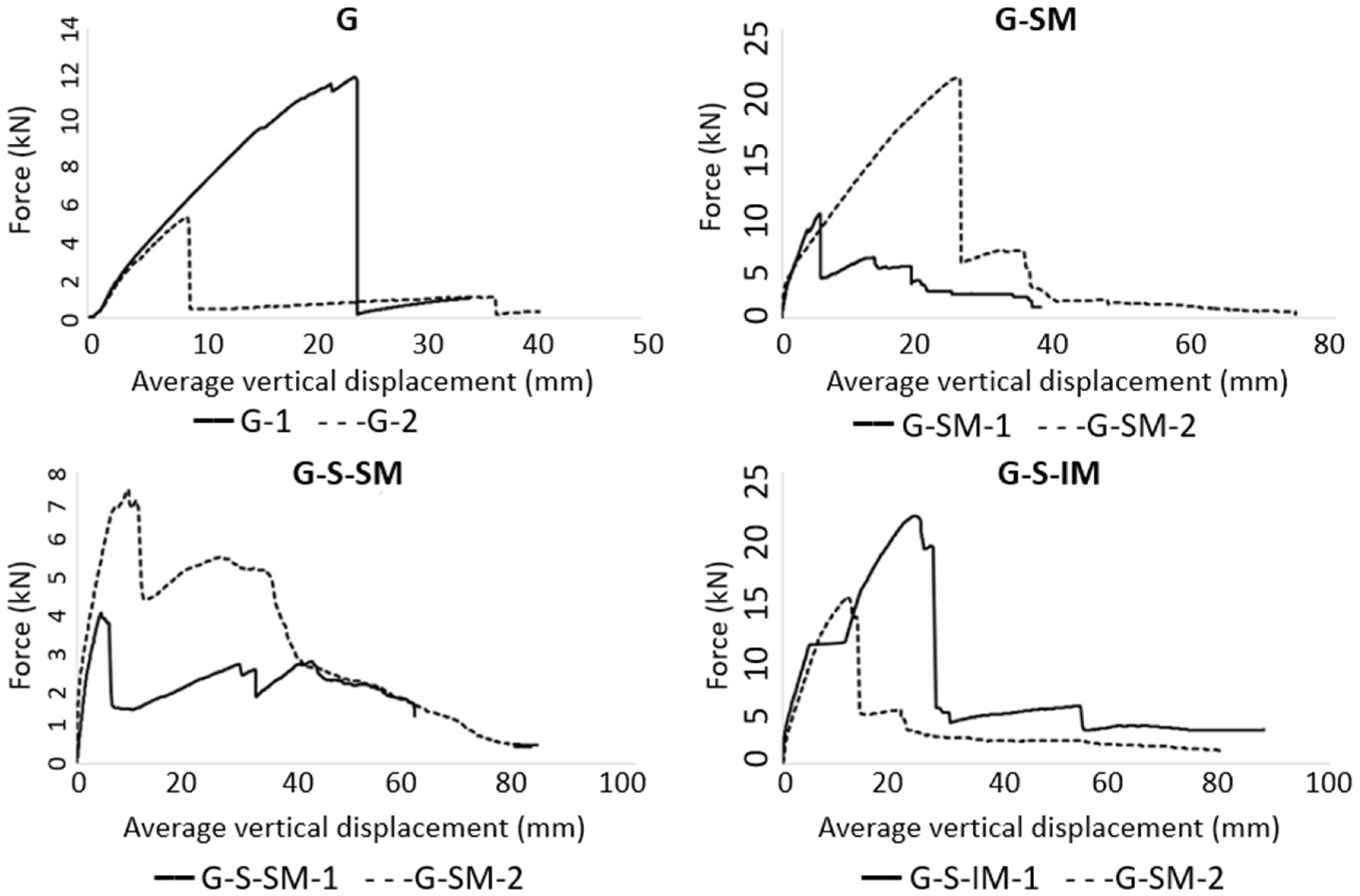

Focusing on the overall comparison of the maximum load-bearing capacity, it can be observed that including the mesh connection (G-SM, G-S-SM and G-S-IM vs. G specimens) causes an average increase in the maximum load of approximately 60%. It can also be seen that placing sand, theoretically intended to increase the frictional response, provides the opposite result, reaching lower load-bearing capacities in comparison with the G-S-SM and G-SM specimens. This result is consistent with the observation from experimental modal analysis.

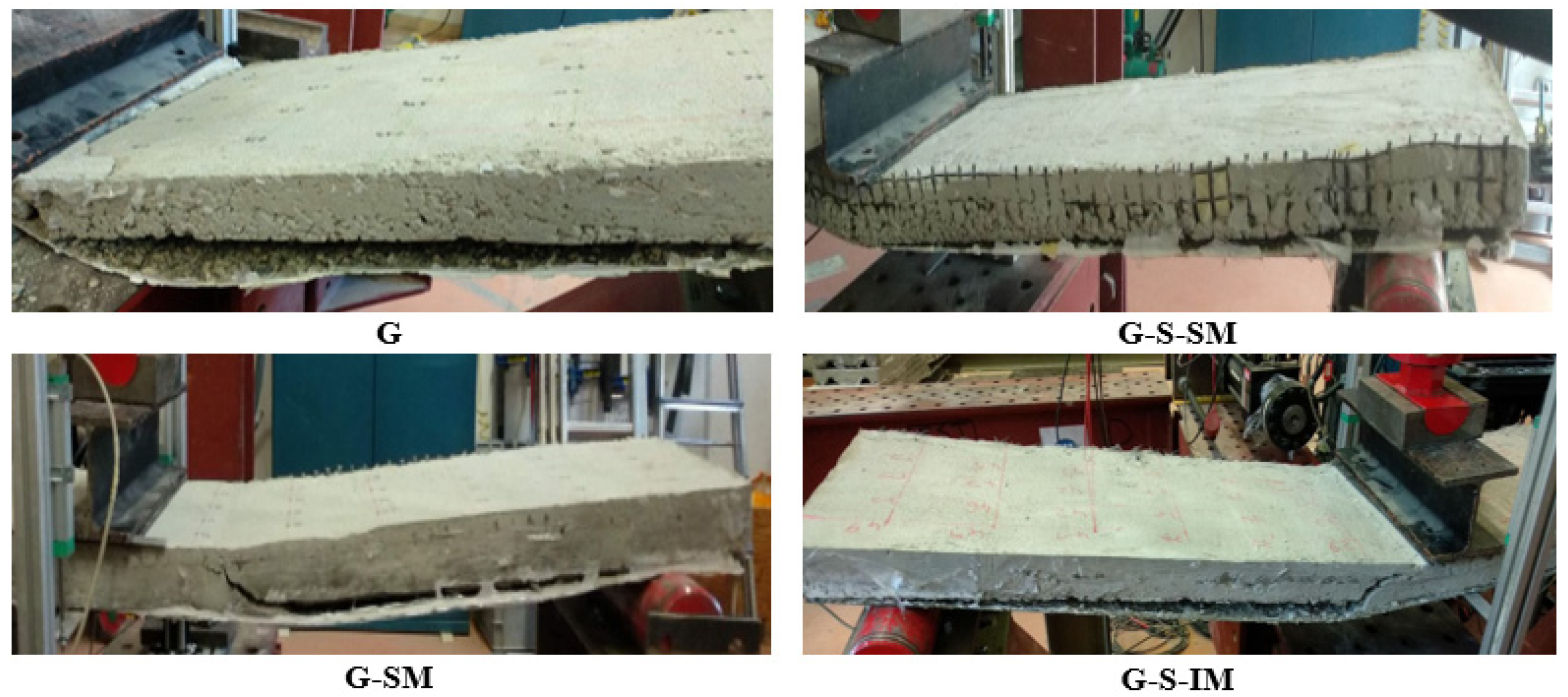

Regarding the applied load, it is clear that incorporating a mesh (G-SM, G-S-SM and G-S-IM vs. G) allowed the slabs to withstand a residual strength after reaching the maximum peak and the corresponding load drop (see

Figure 6). Hence, the novel connection proposal of including a flexible mesh had a positive effect, providing CFRP–concrete partial interlocking, even after a connection failure. This residual strength was greater for G-S-IM specimens (between 3 kN and 5 kN), supporting the idea that inclined mesh configuration brought more quantity of fibers to simultaneously collaborate even after the global failure of the structure. This fact translates to the practical implication of providing additional post-failure strength, so increased safety margin. Regarding the sand particles, it can be observed from the modal analysis (see

Table 2) that incorporating them caused a decrease in the load-bearing capacity (G-S-SM vs. G-SM) that was also translated into a lower vibration frequency. However, it must be noted that, in the G-S-SM case, the slope of the force–displacement curve after the peak load was slightly positive, thus showing a weak hardening behavior and a partial recovering of the supported load. Moreover, the load drop in the G-S-SM case was less significant than in G-SM, which was approximately a 70% slighter drop. In summary, it seems that the inclusion of sand caused a premature partial failure of the connection, which remained with enough capacity to increase the withstand load again. In comparison, other connection types using mesh (G-SM and G-S-IM), in which the breaking damage was more extensive when occurring, showed a greater load drop and avoided the possibility of increasing the resisted load when increasing the displacement after the maximum load.

Regarding the inclination of the mesh, it seems to have a positive effect on the load-bearing capacity of the proposed hybrid slabs (G-S-IM vs. G-S-SM). In addition, this case showed a better connection that translated to less bending cracks developing during tests and the failure mechanism that simultaneously mobilized almost all CFRP–concrete contact surfaces of one half of the slab. However, this case (G-S-IM) showed the second greatest load drop due to connection failure after no mesh (G) cases. Therefore, inclining the mesh helps to distribute the connection mechanism reaching higher loads, but also making the whole system more fragile, as the failure involves the full interface.

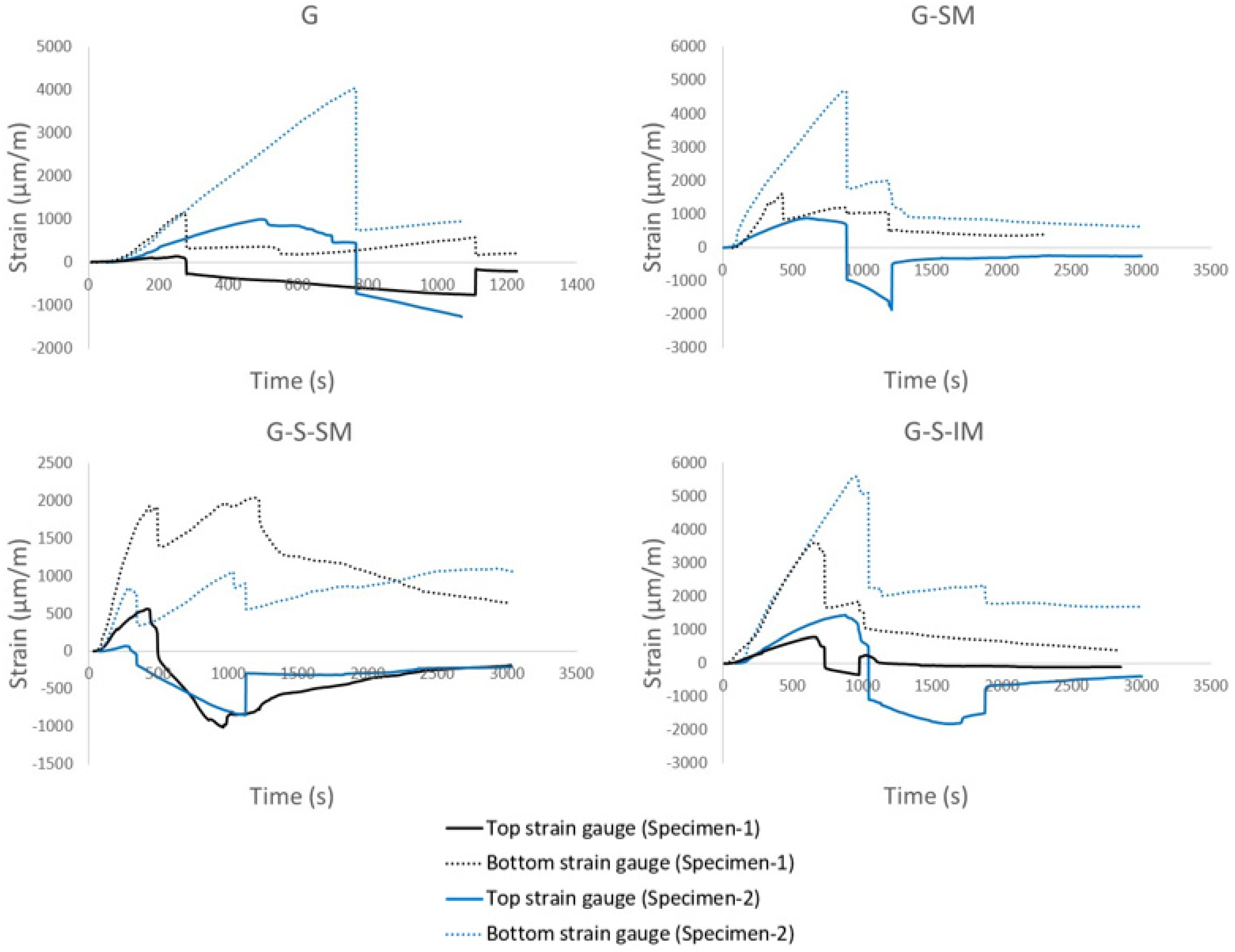

Strain–time plots (see

Figure 7) showed that the inclined mesh specimens (G-S-IM) achieved the greatest strain in CFRP, with a mean value of 5000 μm/m compared to 3500 μm/m for G-SM, and double that of the G specimens. The G-S-IM plots showed that the bonding of both materials performed as a single cross-section during the bending test for longer compared with the other specimens. Moreover, CFRP in G-S-IM performed for higher levels of load under tensile stresses than the rest of specimens, which means that the loss of adherence with concrete was more difficult. For all cases, when the connection was lost (maximum load), the top part of the CFRP suddenly started to work under compression. From this point on, the bending movement was no longer distributed according to Navier’s hypothesis. Overall, it can be ascertained that inclined mesh helps to uniformly distribute the connection between concrete and CFRP over a wider contact area than the other solutions. Thus, it is the preferred connection system from among the newly presented ones, including flexible mesh.

Summarizing the effect of the key parameters on the direct results of the bending tests, it can be stated that including a flexible fabric connector (G-SM vs. G) increased the load-bearing capacity and brought residual strength. In contrast, including small-size particles in the CFRP–concrete contact (G-SM vs. G-S-SM) reduced the load-bearing capacity but allowed some post-peak strength because of higher frictional effect after contact failure. Finally, inclining the connection mesh (G-S_MS vs. G-S-IM) increased the load-bearing capacity and increased the residual strength but made the failure process more fragile. All these effects are related with the largest quantity of fibers simultaneously contributing (and simultaneously failing) to the connection strength of G-S-IM cases.

5.2.1. Evolution of the Position of the Neutral Axis

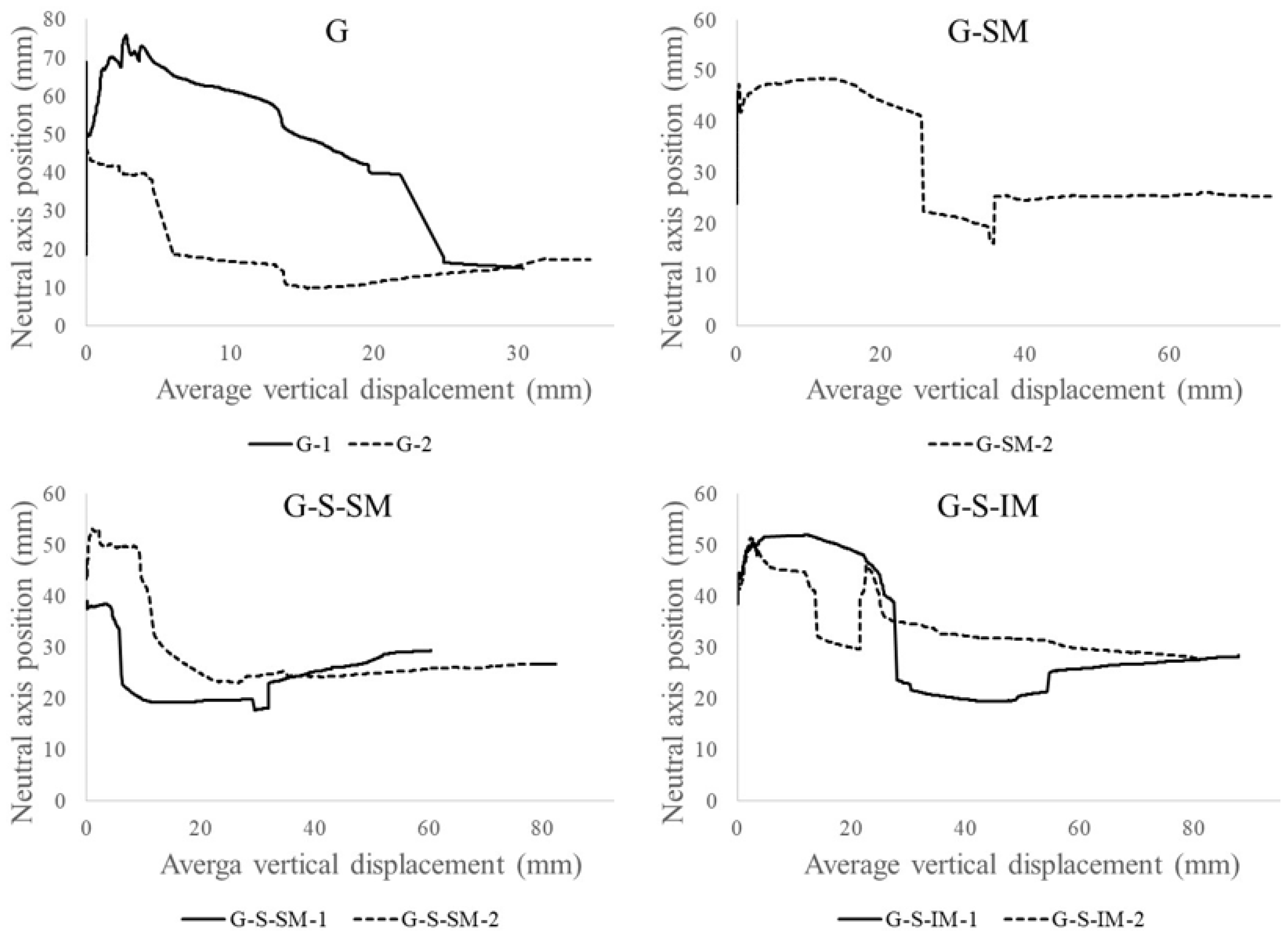

Figure 8 includes the neutral axis vs. vertical displacement at mid-span plots. As per the previous section, the vertical displacement was calculated with the average data from both external potentiometers. The position of the neutral axis was calculated from the measurements of the two strain gauges and by imposing the hypothesis of strain compatibility to the section. As previously indicated, the top strain gauge of the G-SM-1 specimen had no useful values, and it was not possible to calculate the position of the neutral axis for this case.

The neutral axis is referenced from the bottom part of the cross-section. When the neutral axis position was over 35 mm, the CFRP sheet was subjected to tensile stresses, and the concrete below the axis was supposed to be cracked. Conversely, when the axis was below 35 mm, the CFRP sheet was partially compressed. This is shown in

Figure 7 which looks at the change in the signs of top strain measurements.

The corresponding positions of the neutral axis during the linear-elastic branch (under 2 kN in

Figure 6) are in a span of values between 40 mm and 70 mm. Thus, all the CFRP material and the mesh connection were subjected to normal tensile stresses at this moment. This position moved upwards at the first loading steps, but with the beginning of the non-linear load, the decrease was associated with the progressive cracking of the concrete (see

Figure 6). The neutral axis position started to move downwards until reaching the maximum load, when the neutral axis position dropped down from a value over 35 mm to a value below this threshold (see

Figure 8). Thus, the connection failure correlates in time with the sudden movement of the neutral axis that left the top part of the CFRP and the connection mesh subjected to normal compression stresses. Therefore, the CFRP–concrete connection was assured while the neutral axis was over 35 mm and it was subjected to tensile stresses. When the CFRP sheet became compressed, local buckling failure was possible due to the narrow thickness of the sheet. This phenomenon was clearly observed in the G specimens due to the total disconnection between the CFRP and concrete (

Figure 5).

The post-maximum load response, after the neutral axis drop, was characterized by an almost constant position value of the neutral axis (between 20 mm and 30 mm). This means that after the failure of the interface, a residual friction between the CFRP, the cracked concrete and the mesh still contributed a little, as was shown in

Figure 6.

Analyzing the effect of the studied parameters, it was observed that including the mesh (G vs. G-SM) allowed to stabilize the position of the neutral axis between 40 mm and 50 mm for a long period of the test up to the maximum load, whereas the cases without mesh showed a clear downward movement of the position of the neutral axis from the very beginning. Among the cases with meshes, no clear tendency is observed, so the response of the position of the neutral axis seems not to depend on the inclination of the mesh.

5.2.2. CFRP–Concrete Equivalent Shear Stress

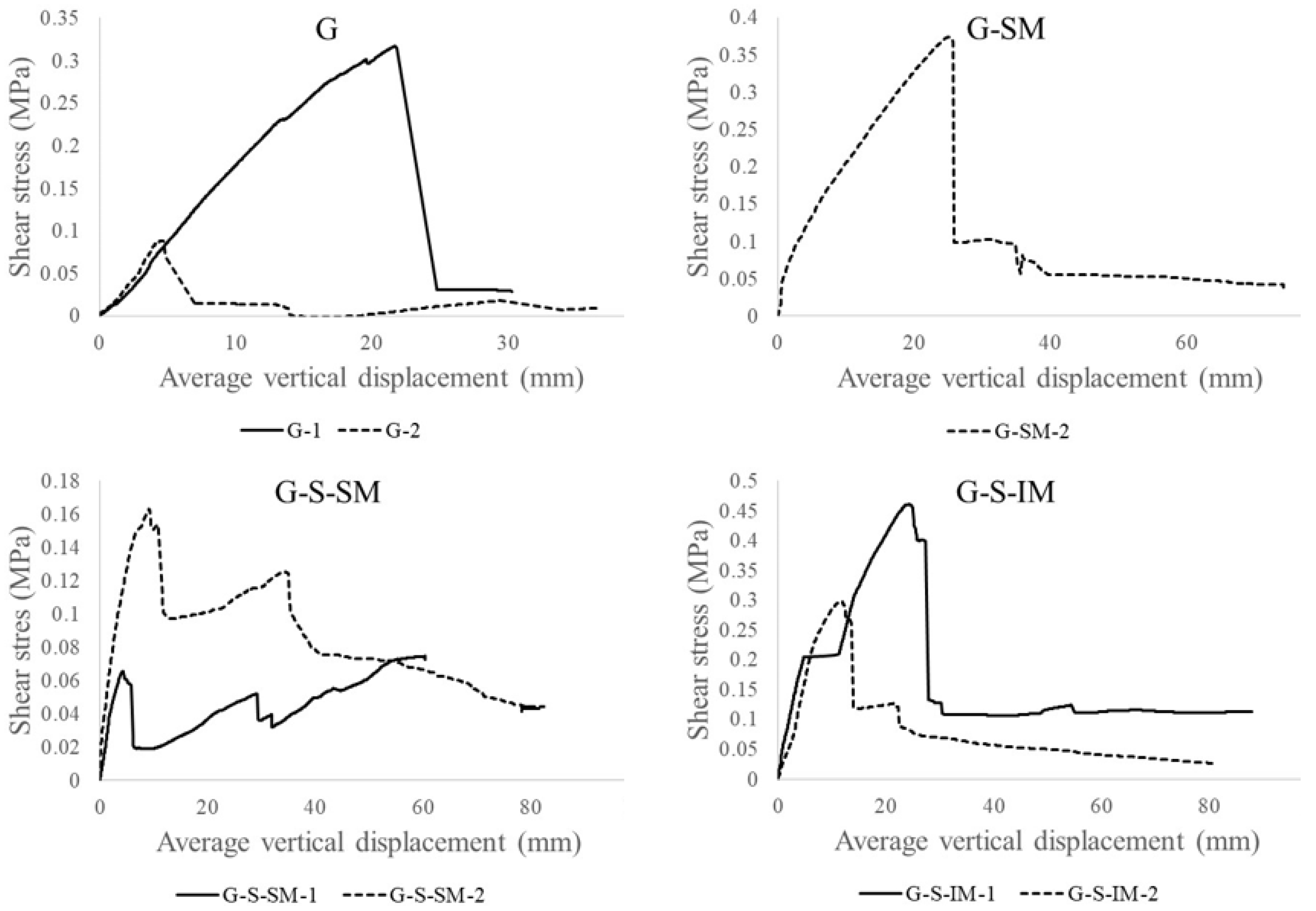

Figure 9 shows the CFRP–concrete connection shear stress vs. vertical displacement plots. As per the previous sections, vertical displacement was calculated by averaging the data from the external potentiometers. The CFRP–concrete shear stress assumed an equivalent uniform distribution of the compressive/tensile force to be transmitted between the bottom and top parts of the section. This was calculated by dividing the normal total compressive or tensile force in the mid-span section by the CFRP–concrete idealized contact surface in half of the length of the slab (length × width = 1 m × 0.4 m = 0.4 m

2). This total compressive/tensile force was calculated from the strain distribution and the corresponding force equilibrium.

The overall shape of the plots in

Figure 9 was similar to those in

Figure 6. Nevertheless, they show more clearly the interface performance of both materials. For example, it can be seen that after reaching the maximum shear stress, the diagram goes down almost to a value of 0 for the G cases, indicating that no connection mechanism remained after reaching the maximum load-bearing capacity. In contrast, for the G-S-IM and G-SM cases, low frictional stress (between 0.05 and 0.10 MPa) from the rough surfaces of the materials kept an almost constant small value. Finally, the G-S-SM case showed that the level of shear stress was very low from the beginning of the test (maximum value of 0.16 MPa for G-S-SM-2 specimen), showing a weak bond between the concrete and the CFRP with the addition of sand particles.

The particular analysis of the study variables showed that including a flexible fabric connector (G vs. G-SM) increased the residual shear strength (from 30 kPa to 50 kPa). The same effect is observed when inclining the connection mesh (G-S-SM vs. G-S-IM) that doubled the residual shear strength. Finally, adding small-size particles to the CFRP–concrete interface (G-SM vs. G-S-SM) clearly reduced the shear strength (from 0.37 MPa to 0.11 MPa in average) although slightly increased the residual shear strength (from 40 kPa to 65 kPa as average value).

5.2.3. External Energy

Table 3 presents the accumulated external energy at peak load, that maximum accumulated external energy and the increment of the later respect to the former one for every specimen. Last column shows the increment of the total accumulated energy respect to the G cases taken as reference. External energy was calculated from the force and vertical displacement at the loaded section (mid-span). Results showed that a significant amount of energy can still be dissipated after reaching the peak load for the cases including flexible fabric connector (G-SM, G-S-SM and G-S-IM) due to the progressive breaking of the fibers. In addition, considering that the connection area of the cases with inclined mesh is greater than for the straight mesh ones (see

Section 4.2.1), it is confirmed that more relative energy dissipation was possible for the cases with straight mesh due to the progressive breaking of transversal fabric tows. In the case of inclined mesh, a greater amount of fabric is simultaneously contributing, so at failure, there was little amount of unloaded fabric to dissipate more energy after reaching the maximum load. Nevertheless, this simultaneous contribution of G-S-IM cases justifies this is the connection system that more external energy dissipates (350% more than G cases and double of the comparable cases with straight mesh). Dissipated energy is an indirect measure of the damage capacity and resilience of the structure. In this regard, the inclusion of the flexible mesh connector enables more energy to dissipate (approximately 3-fold more), and the performance is better still if the mesh is inclined with respect to the direction of the nerves.

6. Conclusions

After performing an experimental modal analysis and eight bending tests on CFRP sheet–concrete hybrid slabs with four different connection alternatives, including the novel approach of embedding a flexible fiber mesh, the following conclusions were reached:

The structural bending response of this type of slab showed three stages. For small loads (approximately 2 kN in these tests), the specimens performed according Navier’s hypothesis with a linear elastic response of the cross-section. For higher loads, the concrete started to crack and the load–displacement response tended to be non-linear. The existence of interlocking elements (gravel, sand and mesh) helped to keep the complex shear transmission mechanisms between materials. Finally, a peak load was reached, and a sudden failure occurred due to the loss of the connection between the concrete and CFRP sheet. The load dropped down and both materials were separated leaving a residual shear mechanism from the friction of the rough surfaces. Thus, the structural response of this novel connection system between thin FRP sheets and concrete is qualitatively described.

Gravel particles bonded to the CFRP sheet surface provided a superficial connection with concrete. The performance of this connection was fragile and presented the lowest values of load-bearing capacity. This connection system as a stand-alone is not recommended for practical applications.

The novel inclusion of a flexible glass-fiber mesh directly bonded onto the CFRP, as a connector between the composite sheet and the concrete, allowed an increase in the load-bearing capacity of the slabs, produced residual strength after connection failure and increased the stiffness of the vibrational response of the slab specimens.

A qualitative relationship between the vibrational response obtained from the experimental modal analysis and the load-bearing capacity was observed, although further research is required to confirm this fact and to progress its quantification.

The inclusion of sand particles bonded to the inner bottom surface of the CFRP had the unexpected effect of reducing the load-bearing capacity and the cohesion between the concrete and the CFRP sheet, although the post-peak residual strength was slightly increased.

The inclination of the mesh clearly contributed to uniformly distributing the shear forces in the interface of the materials. This is likely to be because more fibers were oriented in a direction closer to the shear effort to be resisted, compared to the case of a straight position. Therefore, the inclined mesh seems to be the best choice of the two orientations of this novel connection strategy.

All CFRP sheet–concrete hybrid slabs failed when the neutral axis moved into the CFRP area (under 35 mm) causing the top part of the CFRP and the connection of the glass fiber mesh, when existing, to be compressed and to definitively separate from the concrete. Even thin CFRP can suffer buckling, as was observed.

The amount of cumulative energy corresponds with a qualitative estimation of the capacity of the slabs to dissipate energy and resist damage. The inclined mesh solution was confirmed to be the most competitive one.

In conclusion, the main design lines of thin hybrid FRP–concrete slabs based on flexible fiber fabric connectors are provided as results of this study. Two of them have to be highlighted: using aggregates larger than 5 mm to provide roughness to the inner FRP surface and positioning the fiber fabric in an inclined orientation to distribute the load-transfer mechanism after reaching maximum load along a greater area. Finally, this study opens the door to a wide research field on the characterization of the structural response of these type of structures (or other ones based on the novel proposed flexible distributed connectors), including the study of different materials, geometries or adhesives. These results also put the basis for the development of analytical and numerical models of these systems.