Phlogopite-Reinforced Natural Rubber (NR)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer

Abstract

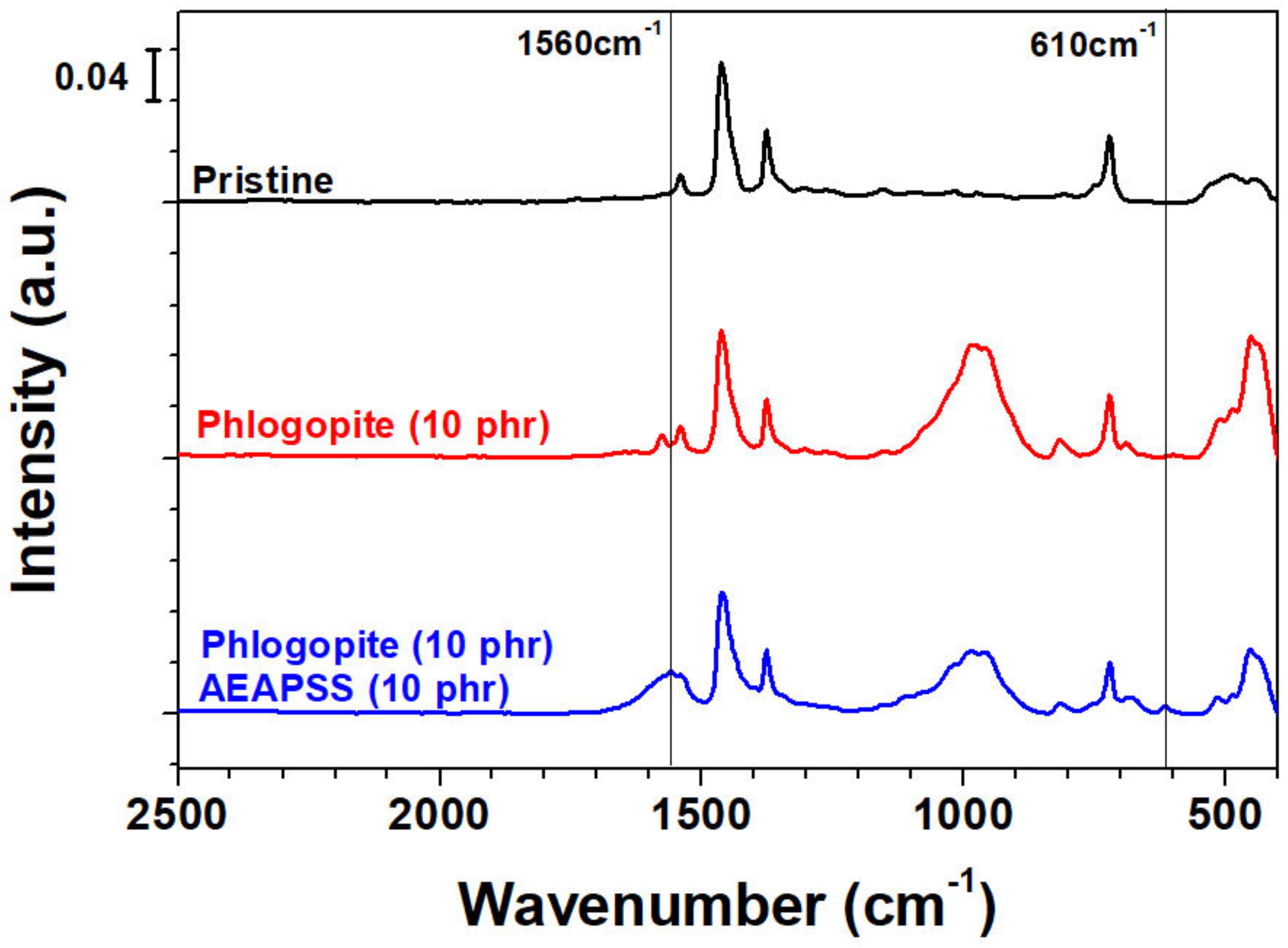

:1. Introduction

2. Experiment

2.1. Materials

2.2. Rubber Compounding

2.3. Curing Characteristic

2.3.1. Cure Time (T90)

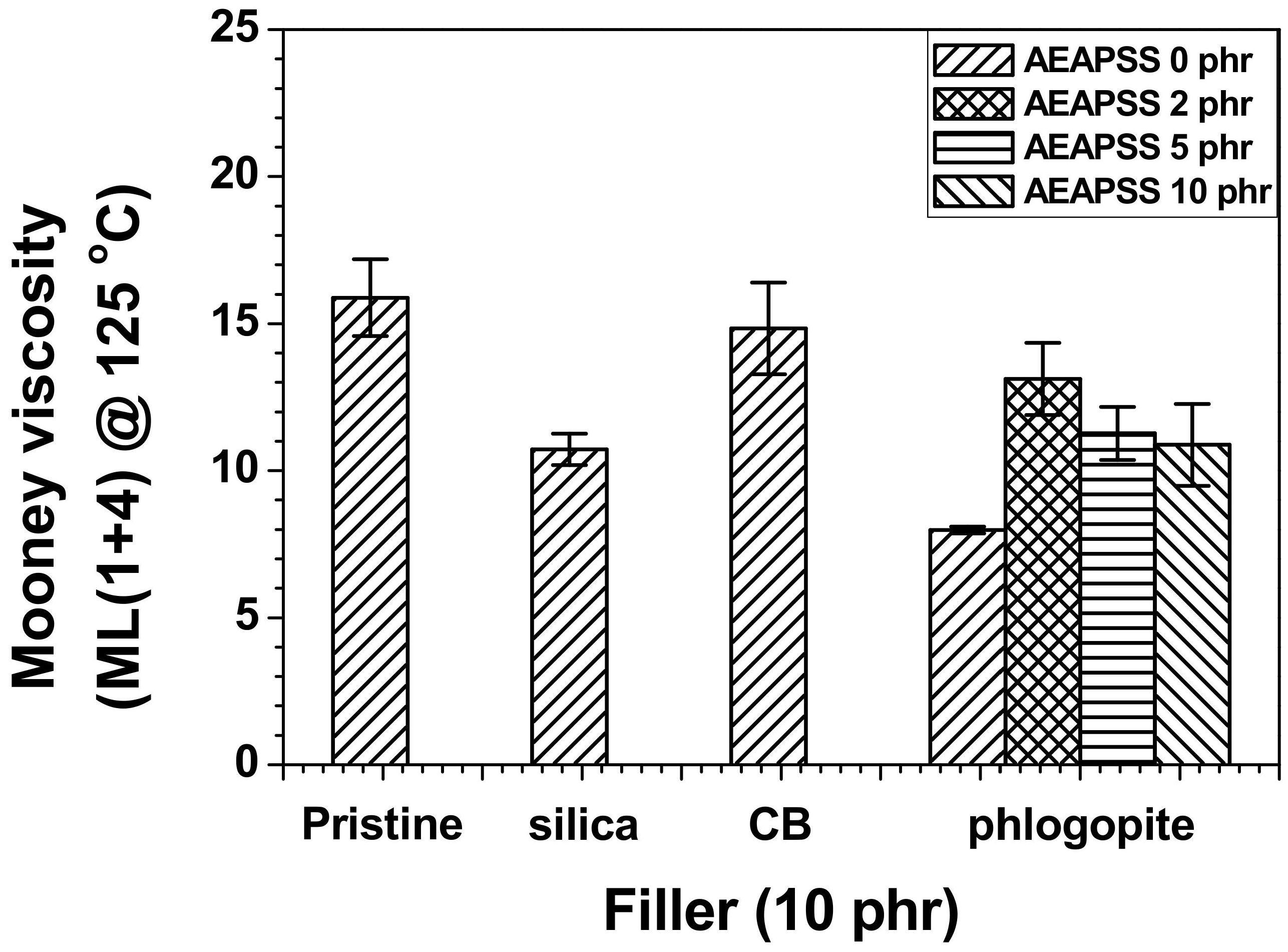

2.3.2. Mooney Viscosity

2.4. Mechanical Properties

2.4.1. Tensile Properties

2.4.2. Hardness

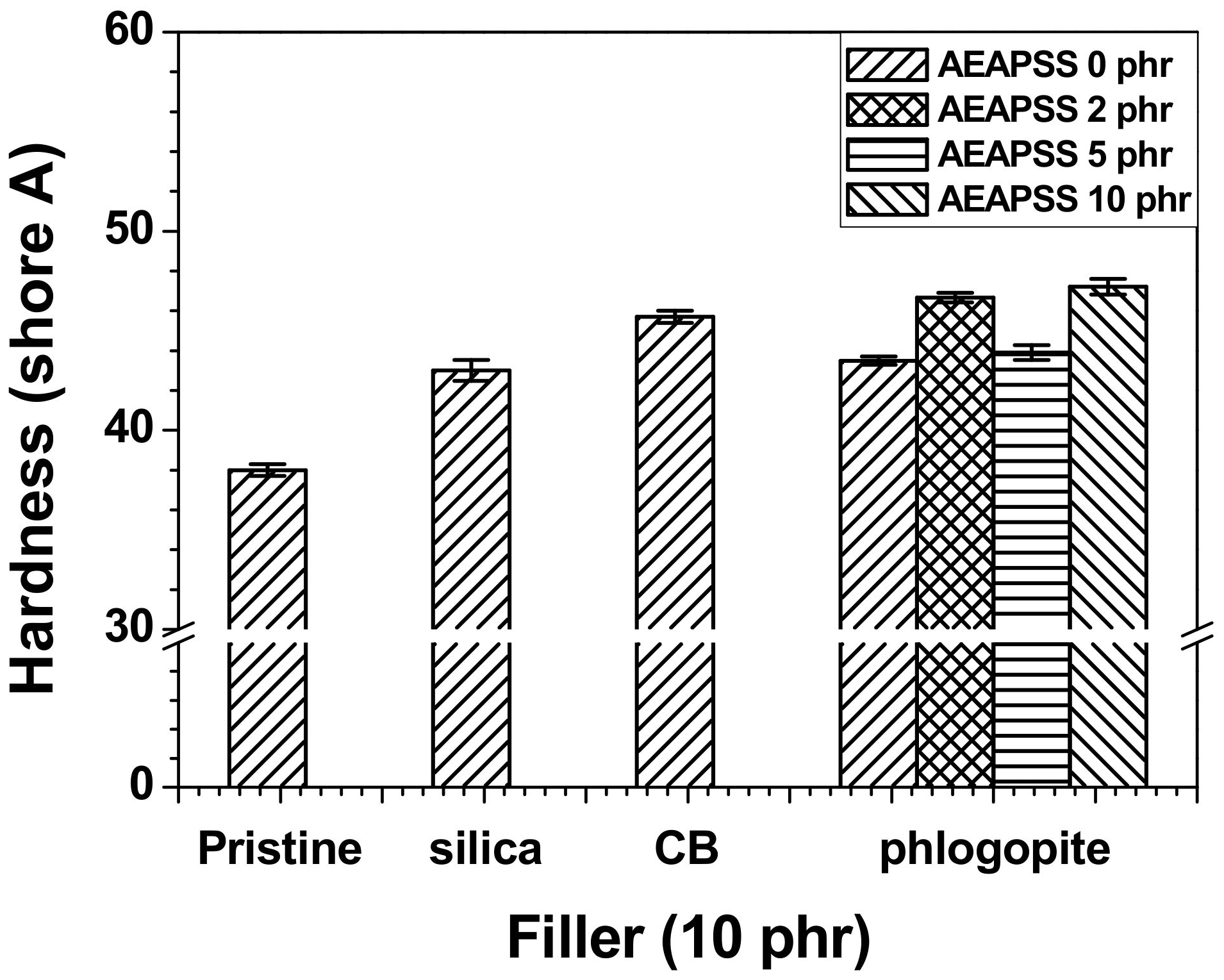

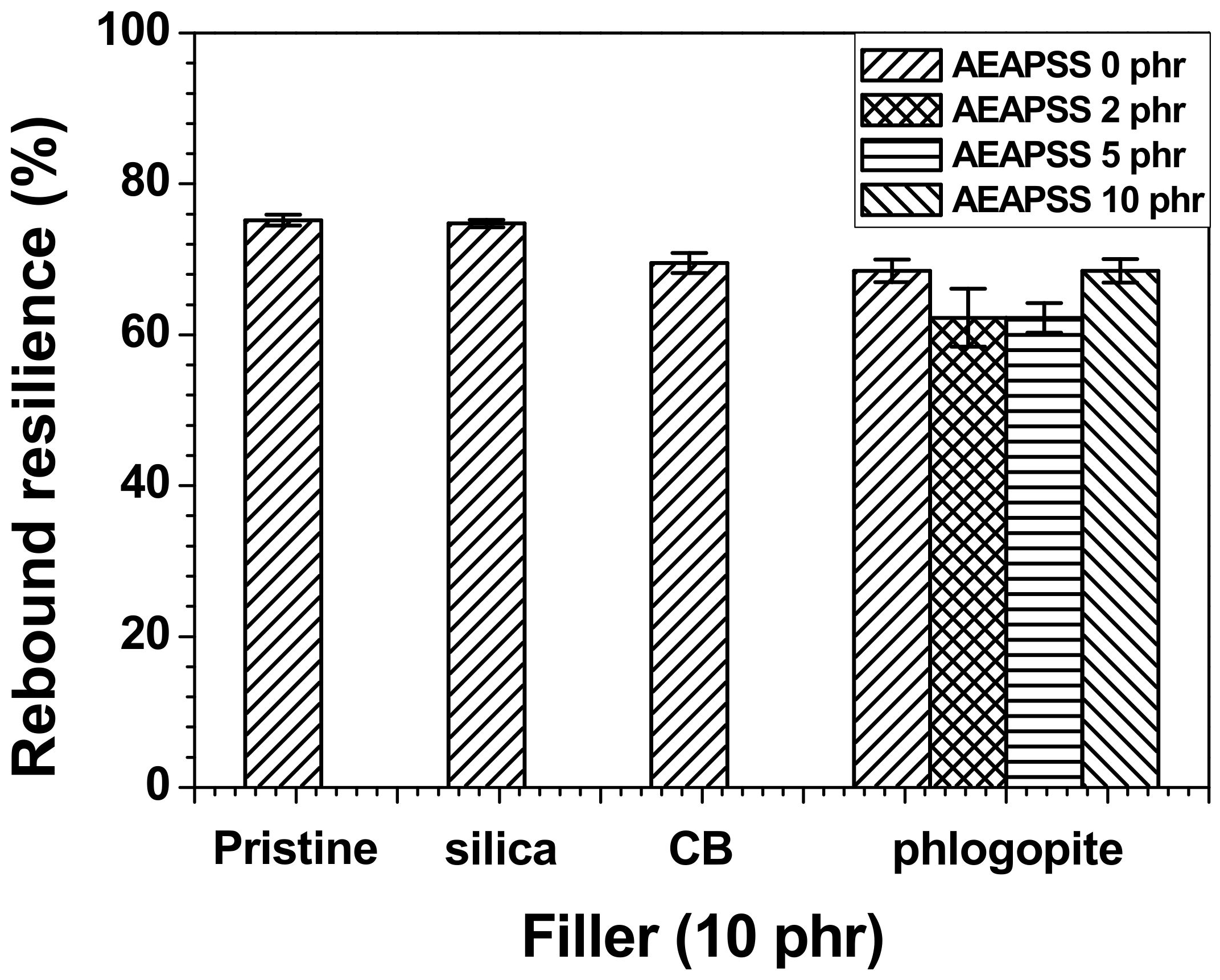

2.4.3. Rebound Resilience

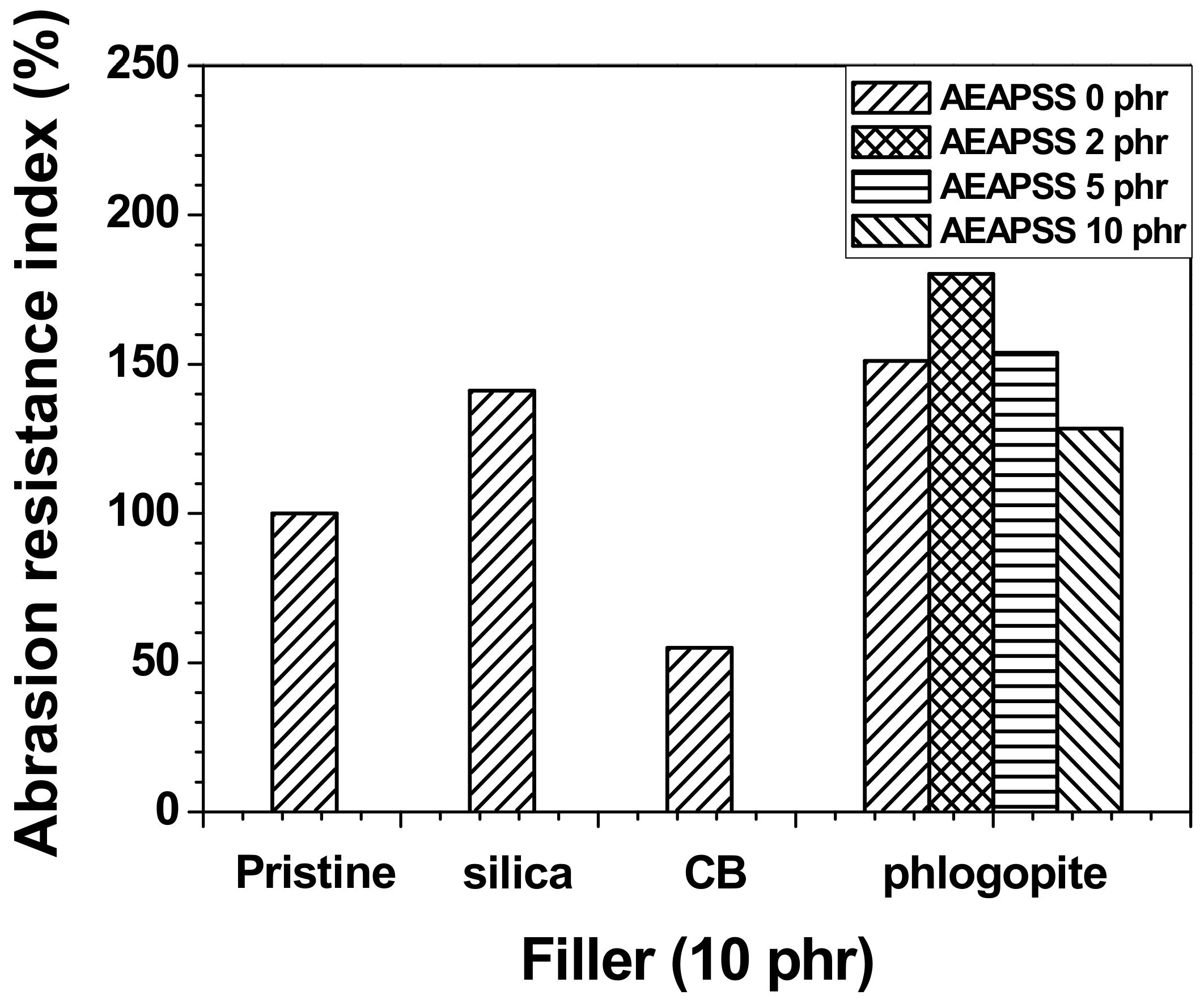

2.4.4. Abrasion Resistance

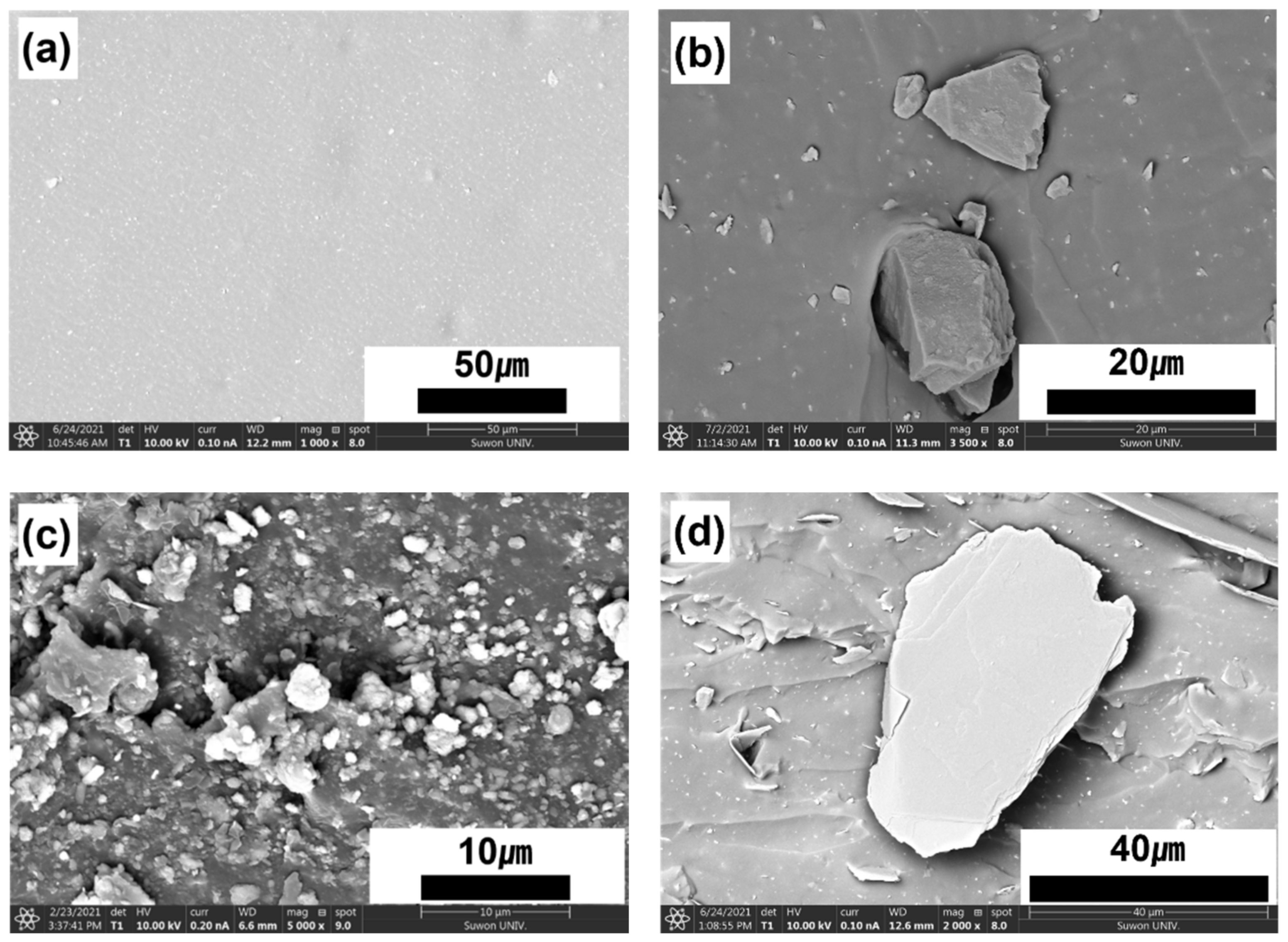

2.4.5. Morphology

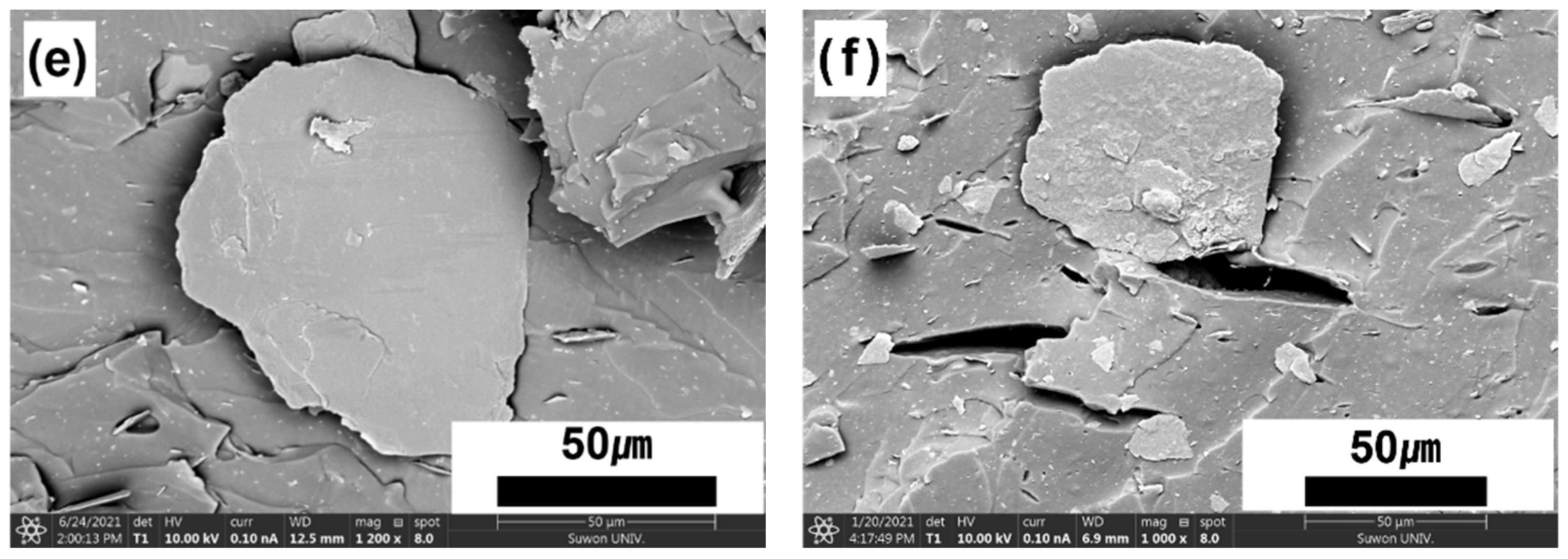

2.4.6. FTIR-ATR

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Rattanasom, N.; Poonsuk, A.; Makmoon, T. Effect of Curing System on the Mechanical Properties and Heat Aging Resistance of Natural Rubber/Tire Tread Reclaimed Rubber Blends. Polym. Test. 2005, 24, 728–732. [Google Scholar] [CrossRef]

- Okamoto, Y. Thermal Aging Study of Carboxyl-Terminated Polybutadiene and Poly(Butadiene-Acrylonitrile)-Reactive Liquid Polymers. Polym. Eng. Sci. 1983, 23, 222–225. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, J.; Yang, R.; Iervolino, R.; Barbera, S. Effect of Lubricating Oil on Thermal Aging of Nitrile Rubber. Polym. Degrad. Stab. 2018, 151, 136–143. [Google Scholar] [CrossRef]

- He, S.; Bai, F.; Liu, S.; Ma, H.; Hu, J.; Chen, L.; Lin, J.; Wei, G.; Du, X. Aging Properties of Styrene-Butadiene Rubber Nanocomposites Filled with Carbon Black and Rectorite. Polym. Test. 2017, 64, 92–100. [Google Scholar] [CrossRef]

- Yip, E.; Cacioli, P. The Manufacture of Gloves from Natural Rubber Latex. J. Allergy Clin. Immunol. 2002, 110, S3–S14. [Google Scholar] [CrossRef]

- Idris, R.; Glasse, M.D.; Latham, R.J.; Linford, R.G.; Schlindwein, W.S. Polymer Electrolytes Based on Modified Natural Rubber for Use in Rechargeable Lithium Batteries. J. Power Sources 2001, 94, 206–211. [Google Scholar] [CrossRef]

- Molnar, W.; Varga, M.; Braun, P.; Adam, K.; Badisch, E. Correlation of Rubber Based Conveyor Belt Properties and Abrasive Wear Rates under 2- and 3-Body Conditions. Wear 2014, 320, 1–6. [Google Scholar] [CrossRef]

- Mott, P.H.; Roland, C.M. Elasticity of Natural Rubber Networks. Macromolecules 1996, 29, 6941–6945. [Google Scholar] [CrossRef] [Green Version]

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Sustainability of Natural Rubber Processing Can Be Improved: A Case Study with Crepe Rubber Manufacturing in Sri Lanka. Resour. Conserv. Recycl. 2018, 133, 417–427. [Google Scholar] [CrossRef]

- Obata, Y.; Kawabata, S.; Kawai, H. Mechanical Properties of Natural Rubber Vulcanizates in Finite Deformation. J. Polym. Sci. Part 2 Polym. Phys. 1970, 8, 903–919. [Google Scholar] [CrossRef]

- Sandberg, O.; Bäckström, G. Thermal Properties of Natural Rubber versus Temperature and Pressure. J. Appl. Phys. 1979, 50, 4720–4724. [Google Scholar] [CrossRef]

- Vinod, V.S.; Varghese, S.; Kuriakose, B. Degradation Behaviour of Natural Rubber–Aluminium Powder Composites: Effect of Heat, Ozone and High Energy Radiation. Polym. Degrad. Stab. 2002, 75, 405–412. [Google Scholar] [CrossRef]

- Zheng, T.; Zheng, X.; Zhan, S.; Zhou, J.; Liao, S. Study on the Ozone Aging Mechanism of Natural Rubber. Polym. Degrad. Stab. 2021, 186, 109514. [Google Scholar] [CrossRef]

- Seentrakoon, B.; Junhasavasdikul, B.; Chavasiri, W. Enhanced UV-Protection and Antibacterial Properties of Natural Rubber/Rutile-TiO2 Nanocomposites. Polym. Degrad. Stab. 2013, 98, 566–578. [Google Scholar] [CrossRef]

- El-Sabbagh, S.H. Compatibility Study of Natural Rubber and Ethylene–Propylene Diene Rubber Blends. Polym. Test. 2003, 22, 93–100. [Google Scholar] [CrossRef]

- Chang, Y.-W.; Shin, Y.-S.; Chun, H.; Nah, C. Effects of Trans-Polyoctylene Rubber (TOR) on the Properties of NR/EPDM Blends. J. Appl. Polym. Sci. 1999, 73, 749–756. [Google Scholar] [CrossRef]

- Kumar, A.; Dipak, G.; Basu, K. Natural Rubber–Ethylene-Propylene-Diene Rubber Covulcanization: Effect of Reinforcing Fillers. J. Appl. Polym. Sci. 2002, 84, 1001–1010. [Google Scholar] [CrossRef]

- Delor-Jestin, F.; Lacoste, J.; Barrois-Oudin, N.; Cardinet, C.; Lemaire, J. Photo-, Thermal and Natural Ageing of Ethylene–Propylene–Diene Monomer (EPDM) Rubber Used in Automotive Applications. Influence of Carbon Black, Crosslinking and Stabilizing Agents. Polym. Degrad. Stab. 2000, 67, 469–477. [Google Scholar] [CrossRef]

- Zaharescu, T.; Meltzer, V.; Vîlcu, R. DSC Studies on Specific Heat Capacity of Irradiated Ethylene-Propylene Elastomers—II. EPDM. Polym. Degrad. Stab. 1998, 61, 383–387. [Google Scholar] [CrossRef]

- Arayapranee, W.; Rempel, G.L. A Comparative Study of the Cure Characteristics, Processability, Mechanical Properties, Ageing, and Morphology of Rice Husk Ash, Silica and Carbon Black Filled 75: 25 NR/EPDM Blends. J. Appl. Polym. Sci. 2008, 109, 932–941. [Google Scholar] [CrossRef]

- Alipour, A.; Naderi, G.; Bakhshandeh, G.R.; Vali, H.; Shokoohi, S. Elastomer Nanocomposites Based on NR/EPDM/Organoclay: Morphology and Properties. Int. Polym. Process. 2011, 26, 48–55. [Google Scholar] [CrossRef]

- Zaharescu, T.; Meltzer, V.; Vîlcu, R. Thermal Properties of EPDM/NR Blends. Polym. Degrad. Stab. 2000, 70, 341–345. [Google Scholar] [CrossRef]

- Cook, S. Compounding NR/EPDM blends for tyre sidewalls. In Blends of Natural Rubber: Novel Techniques for Blending with Speciality Polymers; Tinker, A.J., Jones, K.P., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 1998; pp. 184–208. ISBN 978-94-011-4922-8. [Google Scholar]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Thapthong, P. Influence of Accelerator Type on Properties of NR/EPDM Blends. Polym. Test. 2007, 26, 1062–1067. [Google Scholar] [CrossRef]

- Lewis, C.; Bunyung, S.; Kiatkamjornwong, S. Rheological Properties and Compatibility of NR/EPDM and NR/Brominated EPDM Blends. J. Appl. Polym. Sci. 2003, 89, 837–847. [Google Scholar] [CrossRef]

- Sirqueira, A.S.; Soares, B.G. The Effect of Mercapto- and Thioacetate-Modified EPDM on the Curing Parameters and Mechanical Properties of Natural Rubber/EPDM Blends. Eur. Polym. J. 2003, 39, 2283–2290. [Google Scholar] [CrossRef]

- Hopper, R.J. Improved Cocure of EPDM-Polydiene Blends by Conversion of EPDM into Macromolecular Cure Retarder. Rubber Chem. Technol. 1976, 49, 341–352. [Google Scholar] [CrossRef]

- Azizli, M.J.; Barghamadi, M.; Rezaeeparto, K.; Mokhtary, M.; Parham, S. Compatibility, Mechanical and Rheological Properties of Hybrid Rubber NR/EPDM-g-MA/EPDM/Graphene Oxide Nanocomposites: Theoretical and Experimental Analyses. Compos. Commun. 2020, 22, 100442. [Google Scholar] [CrossRef]

- Chattopadhyay, S. Compatibility Studies on Solution of Polymer Blends by Viscometric and Phase-Separation Technique. J. Appl. Polym. Sci. 2000, 77, 880–889. [Google Scholar] [CrossRef]

- Suma, N.; Joseph, R.; George, K.E. Improved Mechanical Properties of NR/EPDM and NR/ Butyl Blends by Precuring EPDM and Butyl. J. Appl. Polym. Sci. 1993, 49, 549–557. [Google Scholar] [CrossRef]

- Sahakaro, K.; Naskar, N.; Datta, R.N.; Noordermeer, J.W.M. Blending of NR/BR/EPDM by Reactive Processing for Tire Sidewall Applications. I. Preparation, Cure Characteristics and Mechanical Properties. J. Appl. Polym. Sci. 2007, 103, 2538–2546. [Google Scholar] [CrossRef]

- Jang, K.-S. Probing Toughness of Polycarbonate (PC: Ductile and Brittle)/Polypropylene (PP) Blends and Talc-Triggered PC/PP Brittle Composites with Diverse Impact Fracture Parameters. J. Appl. Polym. Sci. 2019, 136, 47110. [Google Scholar] [CrossRef]

- Jang, K.-S. Mechanics and Rheology of Basalt Fiber-Reinforced Polycarbonate Composites. Polymer 2018, 147, 133–141. [Google Scholar] [CrossRef]

- Jang, K.-S. Mineral Filler Effect on the Mechanics and Flame Retardancy of Polycarbonate Composites: Talc and Kaolin. E-Polymers 2016, 16, 379–386. [Google Scholar] [CrossRef]

- Ram, R.; Soni, V.; Khastgir, D. Electrical and Thermal Conductivity of Polyvinylidene Fluoride (PVDF) – Conducting Carbon Black (CCB) Composites: Validation of Various Theoretical Models. Compos. Part B Eng. 2020, 185, 107748. [Google Scholar] [CrossRef]

- Bueche, F. Mullins Effect and Rubber–Filler Interaction. J. Appl. Polym. Sci. 1961, 5, 271–281. [Google Scholar] [CrossRef]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.-D. The Effect of Filler–Filler and Filler–Elastomer Interaction on Rubber Reinforcement. Compos. Part Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Ayala, J.A.; Hess, W.M.; Kistler, F.D.; Joyce, G.A. Carbon-Black-Elastomer Interaction. Rubber Chem. Technol. 1991, 64, 19–39. [Google Scholar] [CrossRef]

- Jong, L. Influence of Protein Hydrolysis on the Mechanical Properties of Natural Rubber Composites Reinforced with Soy Protein Particles. Ind. Crops Prod. 2015, 65, 102–109. [Google Scholar] [CrossRef]

- Arroyo, M.; López-Manchado, M.A.; Herrero, B. Organo-Montmorillonite as Substitute of Carbon Black in Natural Rubber Compounds. Polymer 2003, 44, 2447–2453. [Google Scholar] [CrossRef]

- Visakh, P.M.; Thomas, S.; Oksman, K.; Mathew, A.P. Crosslinked Natural Rubber Nanocomposites Reinforced with Cellulose Whiskers Isolated from Bamboo Waste: Processing and Mechanical/Thermal Properties. Compos. Part Appl. Sci. Manuf. 2012, 43, 735–741. [Google Scholar] [CrossRef]

- Pasquini, D.; Teixeira, E.d.M.; Curvelo, A.A.d.S.; Belgacem, M.N.; Dufresne, A. Extraction of Cellulose Whiskers from Cassava Bagasse and Their Applications as Reinforcing Agent in Natural Rubber. Ind. Crops Prod. 2010, 32, 486–490. [Google Scholar] [CrossRef]

- Peterson, S.C. Utilization of Low-Ash Biochar to Partially Replace Carbon Black in Styrene–Butadiene Rubber Composites. J. Elastomers Plast. 2013, 45, 487–497. [Google Scholar] [CrossRef]

- Castro, D.F.; Suarez, J.C.M.; Nunes, R.C.R.; Visconte, L.L.Y. Effect of Mica Addition on the Properties of Natural Rubber and Polybutadiene Rubber Vulcanizates. J. Appl. Polym. Sci. 2003, 90, 2156–2162. [Google Scholar] [CrossRef]

- Escócio, V.A.; Visconte, L.L.Y.; Nunes, R.C.R.; Oliveira, M.G. Rheology and Processability of Natural Rubber Composites with Mica. Int. J. Polym. Mater. Polym. Biomater. 2008, 57, 374–382. [Google Scholar] [CrossRef]

- Roshanaei, H.; Khodkar, F.; Alimardani, M. Contribution of Filler–Filler Interaction and Filler Aspect Ratio in Rubber Reinforcement by Silica and Mica. Iran. Polym. J. 2020, 29, 901–909. [Google Scholar] [CrossRef]

- Ünalan, F.; Gürbüz, Ö.; Nihan, N.; Bilgin, P.; Sermet, B. Effect of Mica as Filler on Wear of Denture Teeth Polymethylmethacrylate (PMMA) Resin. Balk. J. Stomatol. 2007, 11, 133–137. [Google Scholar]

- Verbeek, C.J.R. Highly Filled Polyethylene/Phlogopite Composites. Mater. Lett. 2002, 52, 453–457. [Google Scholar] [CrossRef]

- Cai, L.; Dou, Q. Effect of Filler Treatments on the Crystallization, Mechanical Properties, Morphologies and Heat Resistance of Polypropylene/Phlogopite Composites. Polym. Compos. 2019, 40, E795–E810. [Google Scholar] [CrossRef]

- Verbeek, C.J.R. Effect of Preparation Variables on the Mechanical Properties of Compression-Moulded Phlogopite/LLDPE Composites. Mater. Lett. 2002, 56, 226–231. [Google Scholar] [CrossRef]

- Debnath, S.; De, S.K.; Khastgir, D. Effects of Silane Coupling Agents on Mica-Filled Styrene-Butadiene Rubber. J. Appl. Polym. Sci. 1989, 37, 1449–1464. [Google Scholar] [CrossRef]

- Ohta, S.-I. Synthetic Mica and Its Applications. Clay Sci. 2006, 12, 119–124. [Google Scholar] [CrossRef]

- Magaraphan, R.; Thaijaroen, W.; Lim-ochakun, R. Structure and Properties of Natural Rubber and Modified Montmorillonite Nanocomposites. Rubber Chem. Technol. 2003, 76, 406–418. [Google Scholar] [CrossRef]

- López-Manchado, M.A.; Arroyo, M.; Herrero, B.; Biagiotti, J. Vulcanization Kinetics of Natural Rubber–Organoclay Nanocomposites. J. Appl. Polym. Sci. 2003, 89, 1–15. [Google Scholar] [CrossRef]

- Jenkins, D.M. Empirical Study of the Infrared Lattice Vibrations (1100–350 Cm-1) of Phlogopite. Phys. Chem. Miner. 1989, 16, 408–414. [Google Scholar] [CrossRef]

- Johansson, U.; Holmgren, A.; Forsling, W.; Frost, R.L. Adsorption of Silane Coupling Agents onto Kaolinite Surfaces. Clay Miner. 1999, 34, 239–246. [Google Scholar] [CrossRef]

- Luo, D.; Geng, R.; Wang, W.; Ding, Z.; Qiang, S.; Liang, J.; Li, P.; Zhang, Y.; Fan, Q. Trichoderma Viride Involvement in the Sorption of Pb(II) on Muscovite, Biotite and Phlogopite: Batch and Spectroscopic Studies. J. Hazard. Mater. 2021, 401, 123249. [Google Scholar] [CrossRef] [PubMed]

- Rao Darmakkolla, S.; Tran, H.; Gupta, A.B.; Rananavare, S. A Method to Derivatize Surface Silanol Groups to Si-Alkyl Groups in Carbon-Doped Silicon Oxides. RSC Adv. 2016, 6, 93219–93230. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Park, S.-Y.; Chung, K.-H.; Jang, K.-S. Phlogopite-Reinforced Natural Rubber (NR)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer. Polymers 2021, 13, 2318. https://doi.org/10.3390/polym13142318

Lee S-H, Park S-Y, Chung K-H, Jang K-S. Phlogopite-Reinforced Natural Rubber (NR)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer. Polymers. 2021; 13(14):2318. https://doi.org/10.3390/polym13142318

Chicago/Turabian StyleLee, Sung-Hun, Su-Yeol Park, Kyung-Ho Chung, and Keon-Soo Jang. 2021. "Phlogopite-Reinforced Natural Rubber (NR)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer" Polymers 13, no. 14: 2318. https://doi.org/10.3390/polym13142318

APA StyleLee, S.-H., Park, S.-Y., Chung, K.-H., & Jang, K.-S. (2021). Phlogopite-Reinforced Natural Rubber (NR)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer. Polymers, 13(14), 2318. https://doi.org/10.3390/polym13142318