Bionanocarbon Functional Material Characterisation and Enhancement Properties in Nonwoven Kenaf Fibre Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bionanocarbon from OPS

2.3. Characterisation of Activated Bio Nanocarbon and Nonwoven Kenaf Fibre

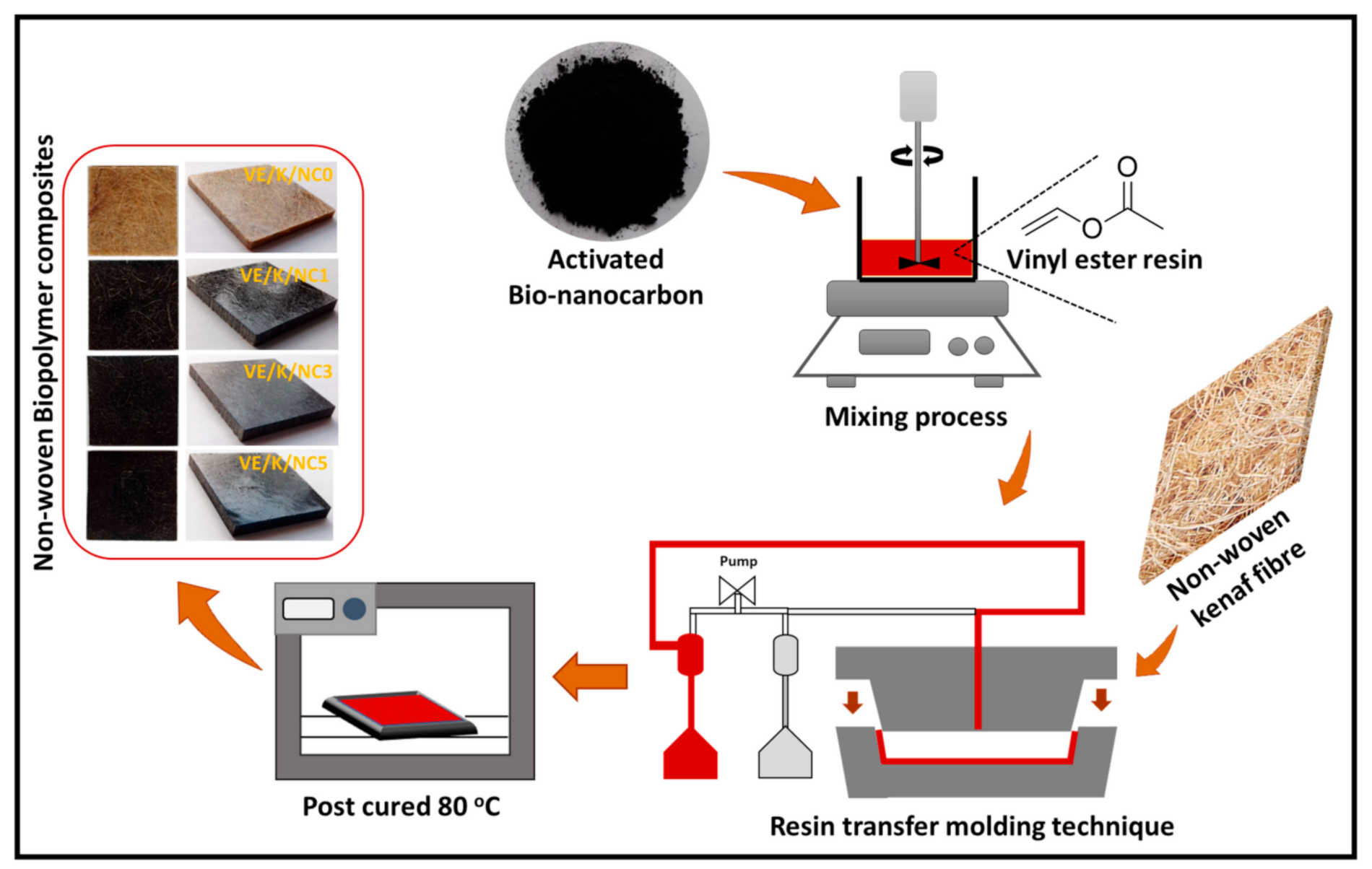

2.4. Preparation of Nanocomposites

2.5. Characterisation of Bionanocomposites

3. Results and Discussion

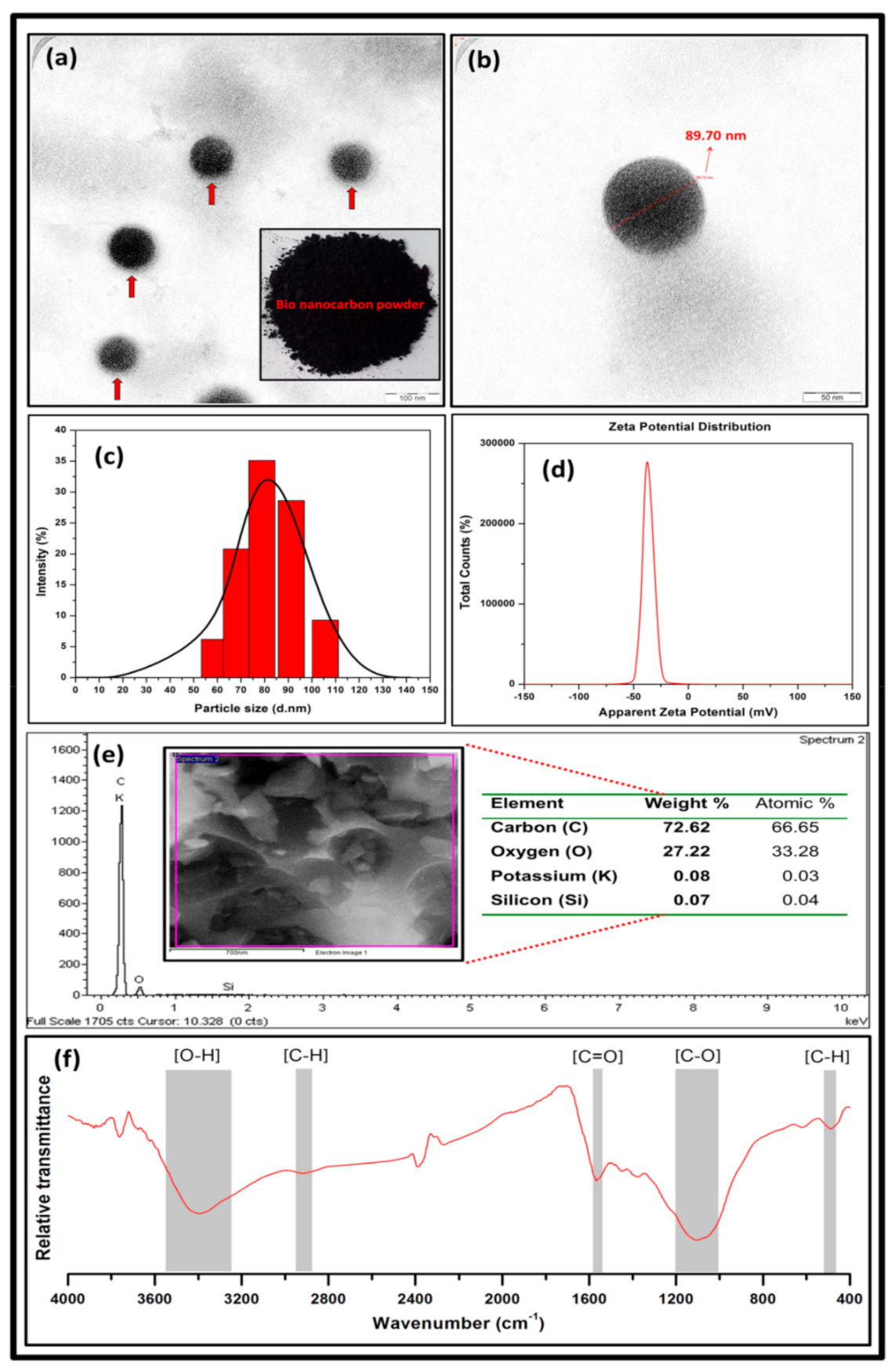

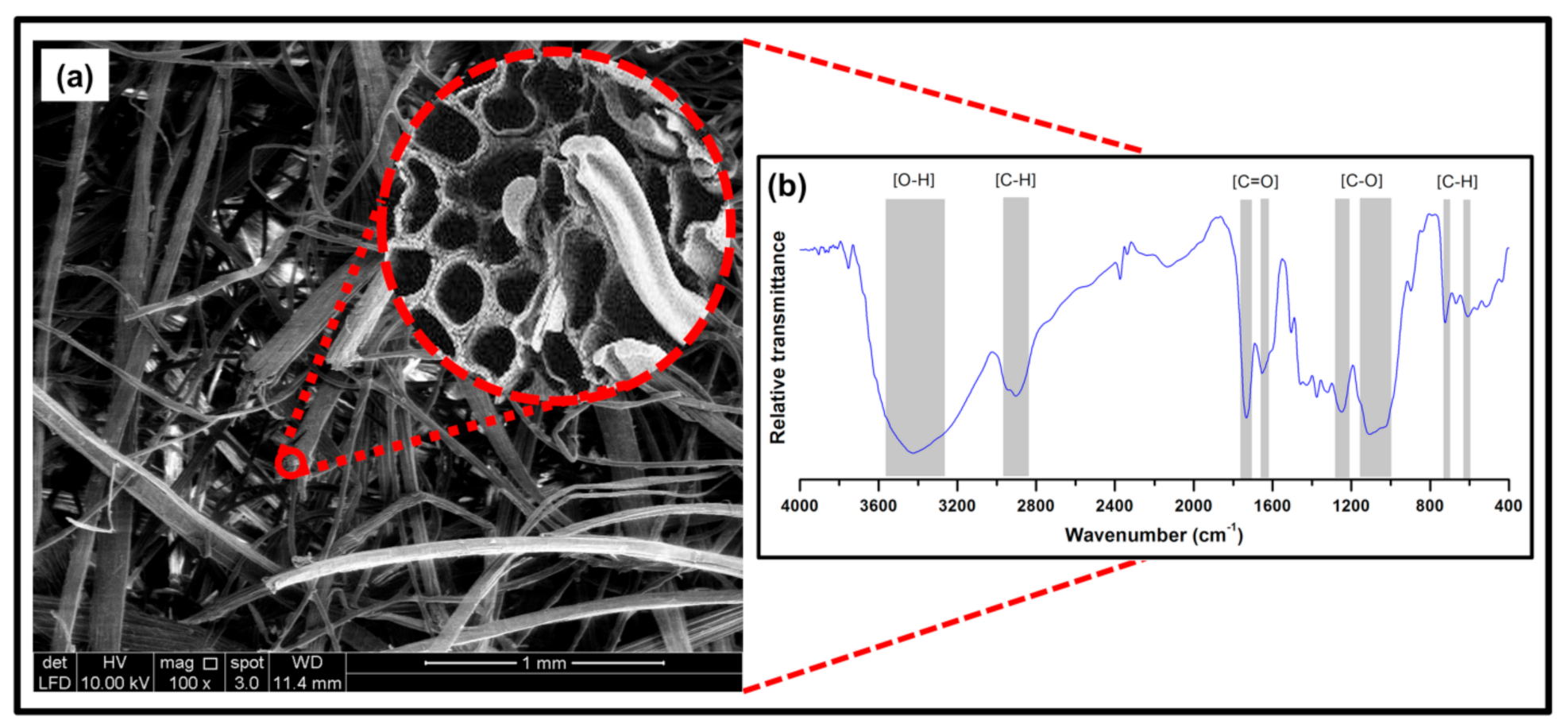

3.1. Properties of Bio Nanocarbon and Kenaf Fibre

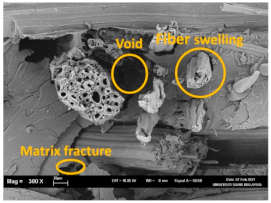

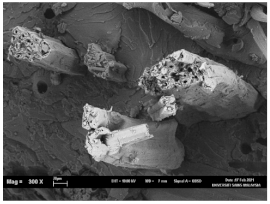

3.2. Characterisation of Bionanocarbon/Kenaf Fibre/Vinyl Ester Composites

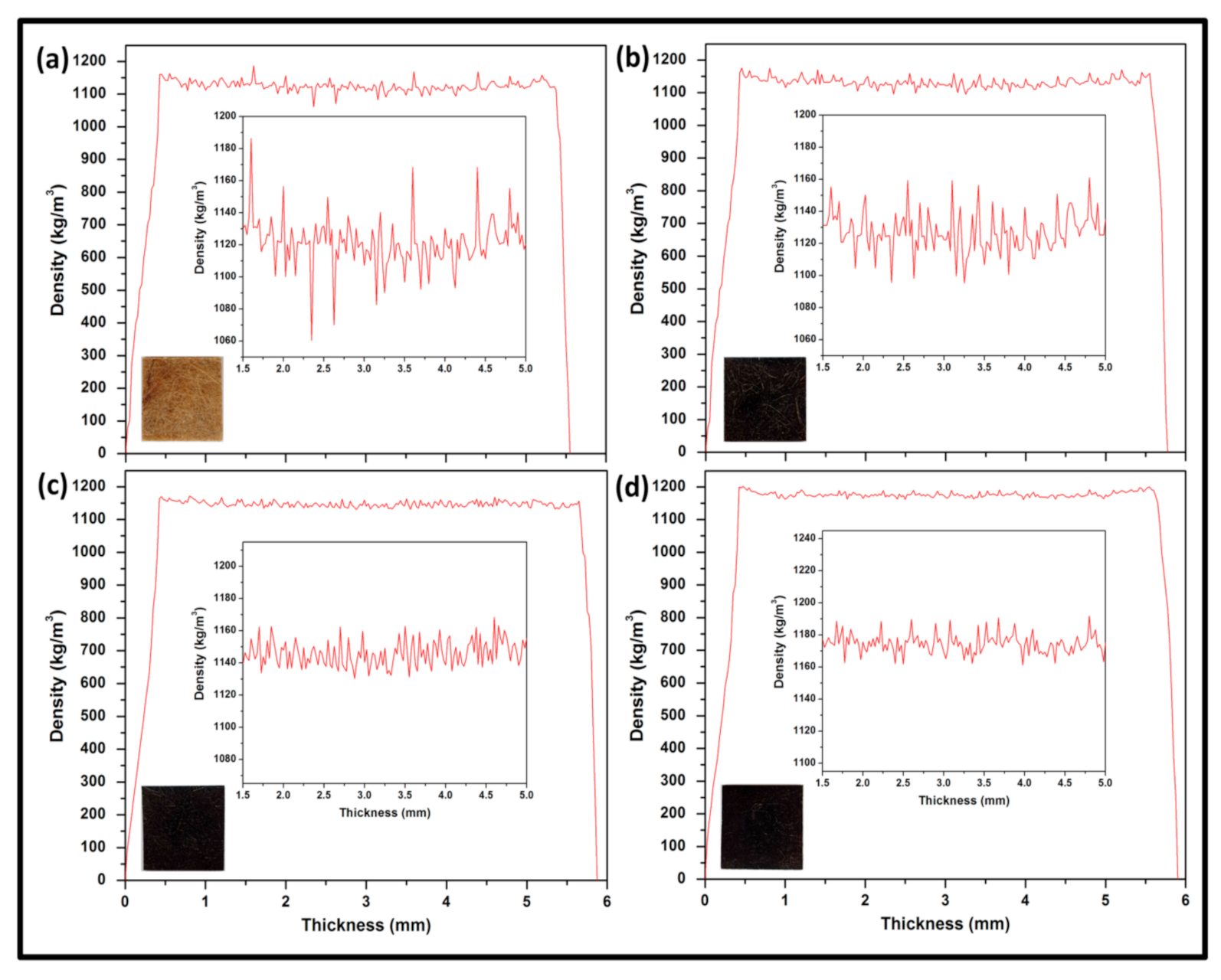

3.2.1. Physical Properties

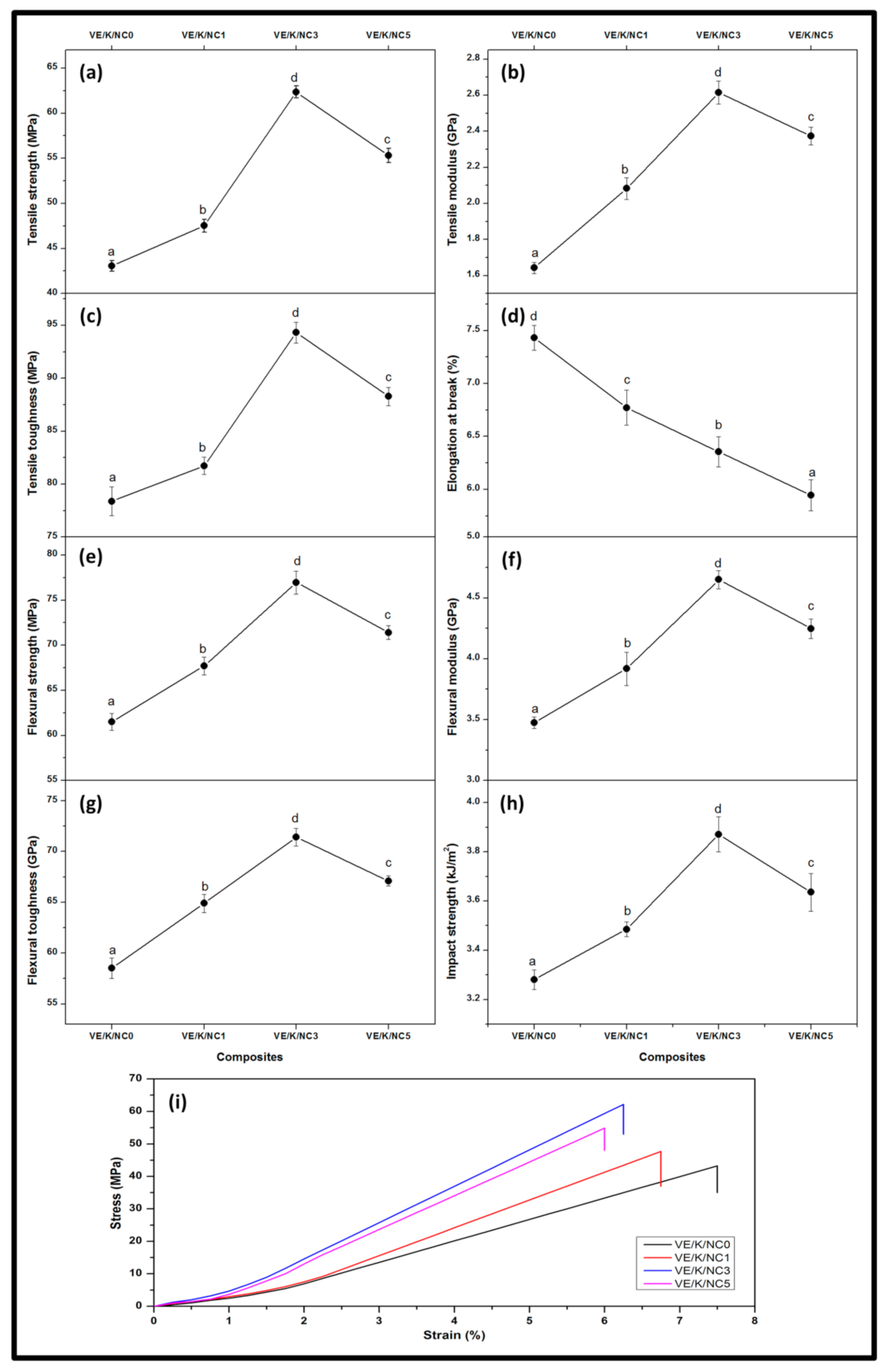

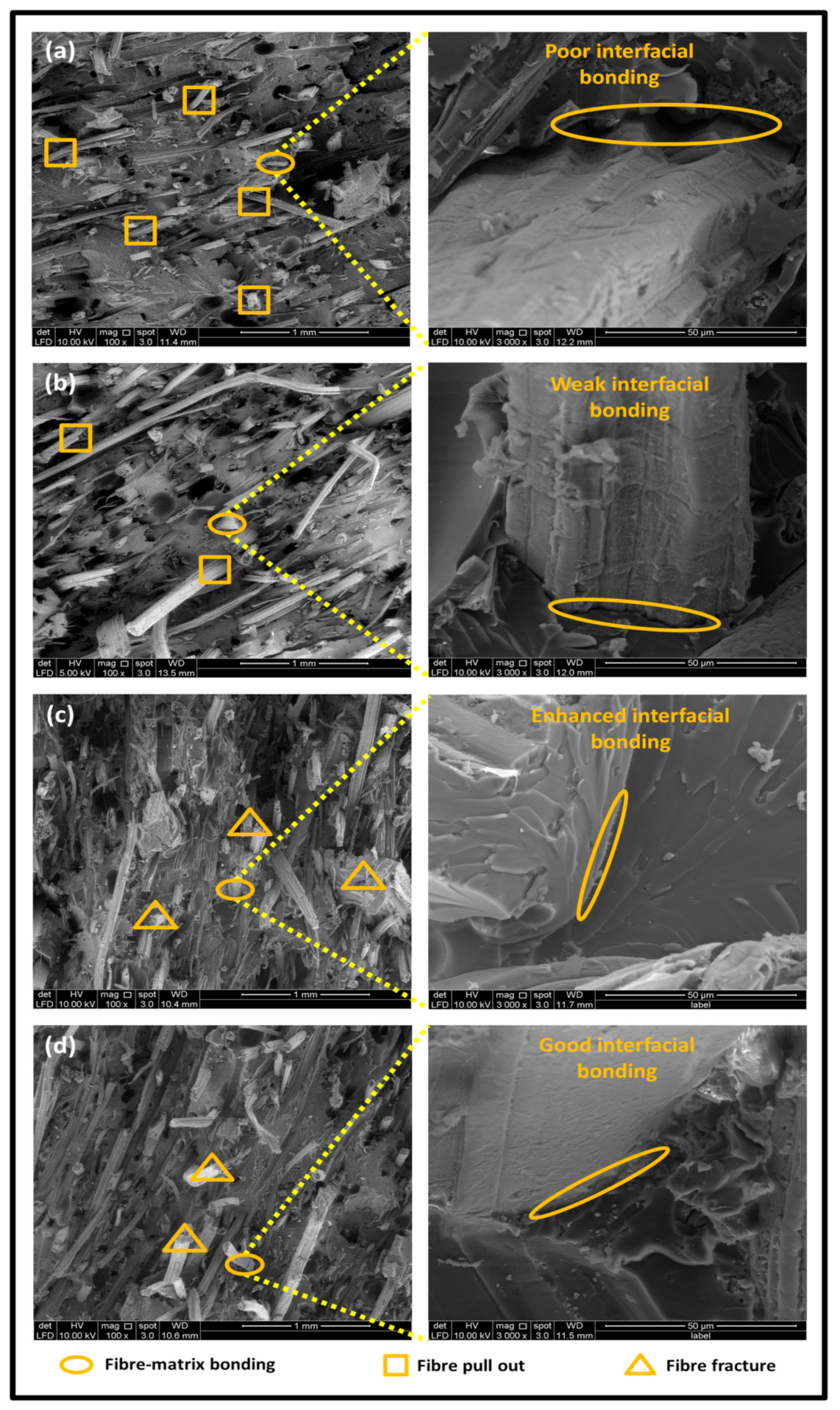

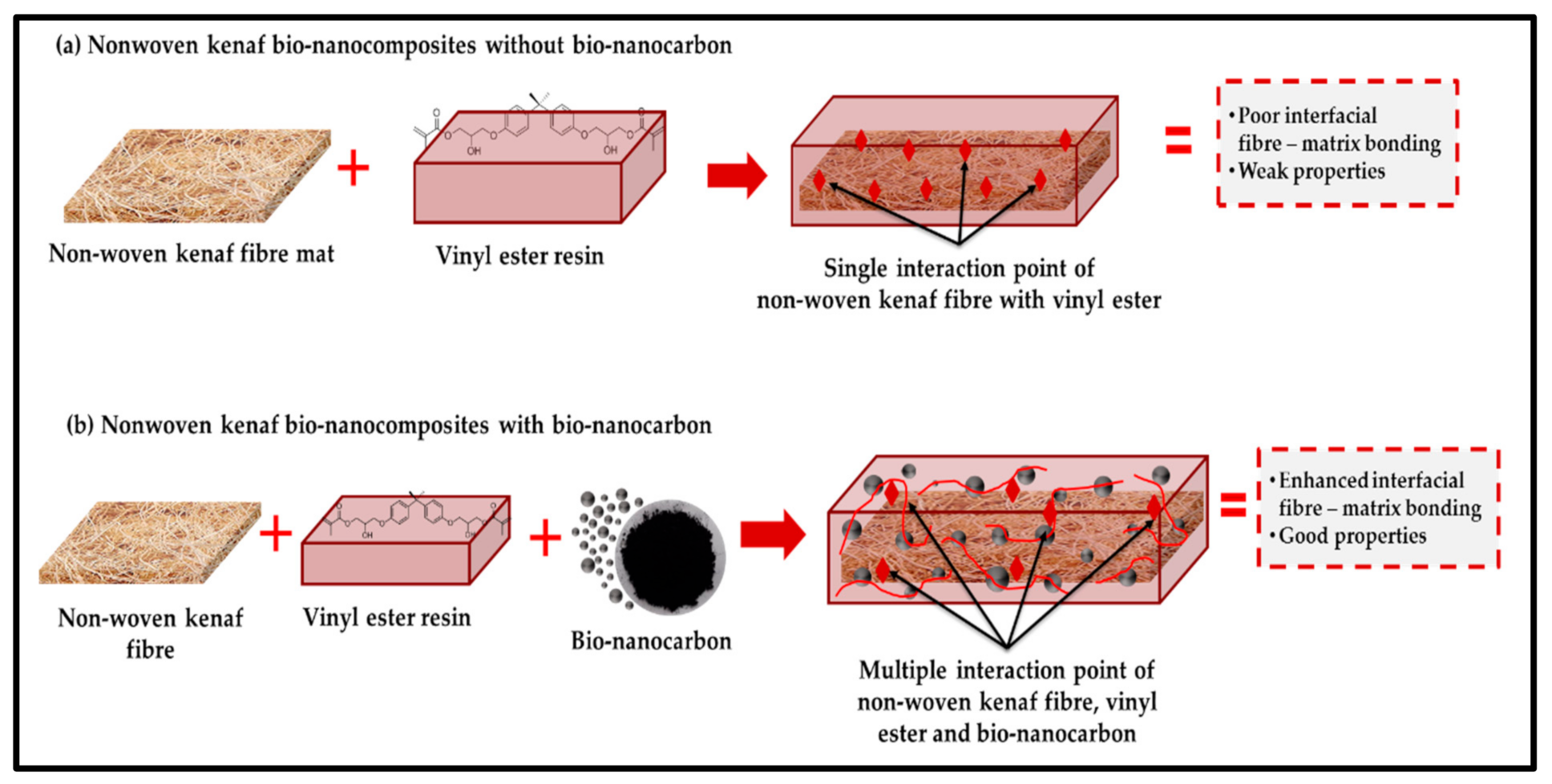

3.2.2. Mechanical Properties

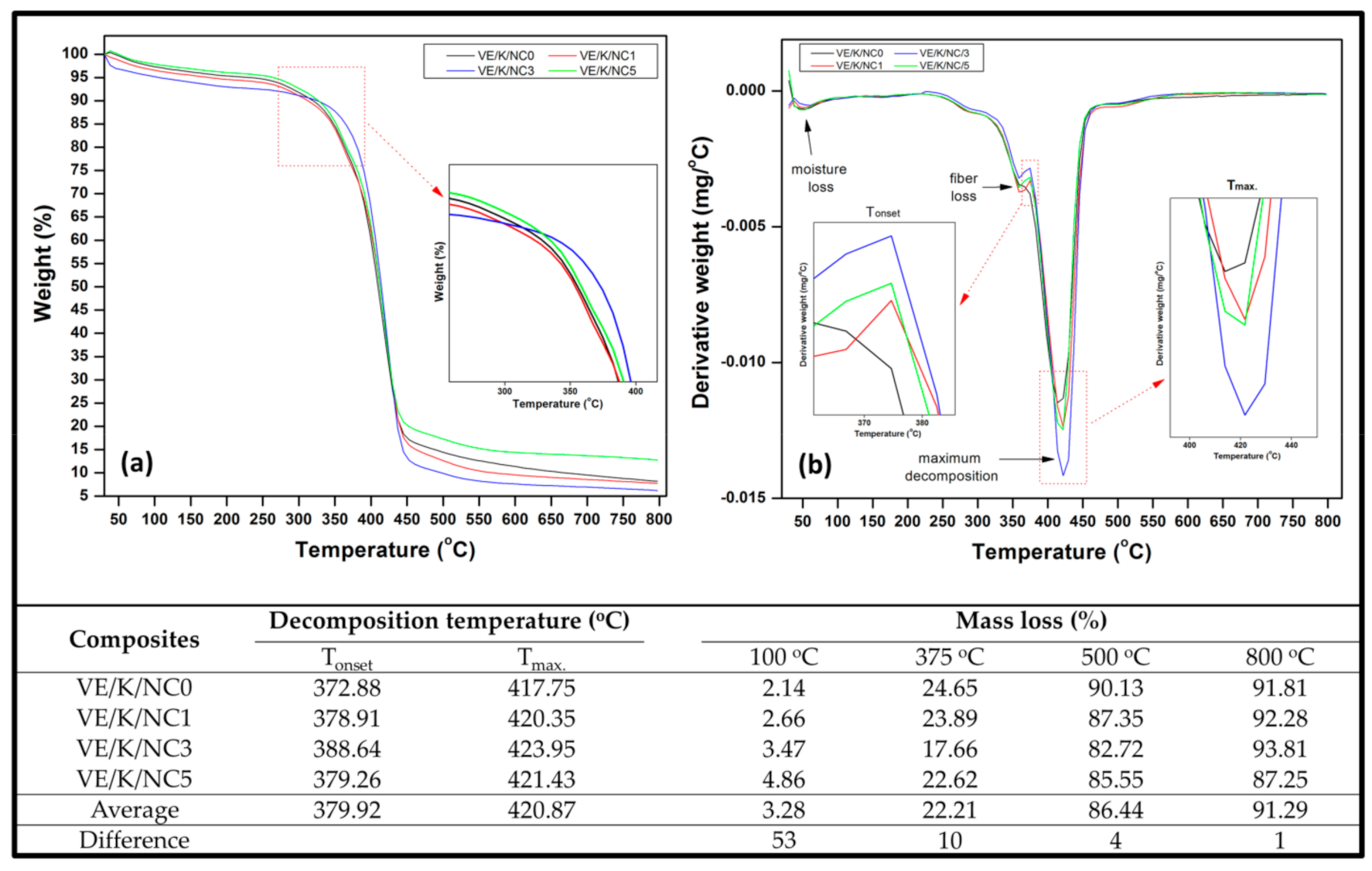

3.2.3. Structural and Thermal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khezami, L.; Chetouani, A.; Taouk, B.; Capart, R. Production and characterisation of activated carbon from wood components in powder: Cellulose, lignin, xylan. Powder Technol. 2005, 157, 48–56. [Google Scholar] [CrossRef]

- Wang, T.; Tan, S.; Liang, C. Preparation and characterization of activated carbon from wood via microwave-induced ZnCl2 activation. Carbon 2009, 47, 1880–1883. [Google Scholar] [CrossRef]

- Januszewicz, K.; Kazimierski, P.; Klein, M.; Kardaś, D.; Łuczak, J. Activated carbon produced by pyrolysis of waste wood and straw for potential wastewater adsorption. Materials 2020, 13, 2047. [Google Scholar] [CrossRef] [PubMed]

- Jain, A.; Balasubramanian, R.; Srinivasan, M. Hydrothermal conversion of biomass waste to activated carbon with high porosity: A review. Chem. Eng. J. 2016, 283, 789–805. [Google Scholar] [CrossRef]

- Jjagwe, J.; Olupot, P.W.; Menya, E.; Kalibbala, H.M. Synthesis and application of Granular activated carbon from biomass waste materials for water treatment: A review. J. Bioresour. Bioprod. 2021, 1–31. [Google Scholar] [CrossRef]

- Kawano, T.; Kubota, M.; Onyango, M.S.; Watanabe, F.; Matsuda, H. Preparation of activated carbon from petroleum coke by KOH chemical activation for adsorption heat pump. Appl. Therm. Eng. 2008, 28, 865–871. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Yusup, S. Co-valorization of delayed petroleum coke–palm kernel shell for activated carbon production. J. Hazard. Mater. 2021, 403, 123876. [Google Scholar] [CrossRef] [PubMed]

- Umerah, C.O.; Kodali, D.; Head, S.; Jeelani, S.; Rangari, V.K. Synthesis of carbon from waste coconutshell and their application as filler in bioplast polymer filaments for 3D printing. Compos. Part B Eng. 2020, 202, 108428. [Google Scholar] [CrossRef]

- Liu, S.-H.; Tang, Y.-H. Hierarchically porous biocarbons prepared by microwave-aided carbonization and activation for capacitive deionization. J. Electroanal. Chem. 2020, 878, 114587. [Google Scholar] [CrossRef]

- Yahya, M.A.; Al-Qodah, Z.; Ngah, C.Z. Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: A review. Renew. Sustain. Energy Rev. 2015, 46, 218–235. [Google Scholar] [CrossRef]

- Oginni, O.; Singh, K.; Oporto, G.; Dawson-Andoh, B.; McDonald, L.; Sabolsky, E. Effect of one-step and two-step H3PO4 activation on activated carbon characteristics. Bioresour. Technol. Rep. 2019, 8, 100307. [Google Scholar] [CrossRef]

- Oginni, O.; Singh, K.; Oporto, G.; Dawson-Andoh, B.; McDonald, L.; Sabolsky, E. Influence of one-step and two-step KOH activation on activated carbon characteristics. Bioresour. Technol. Rep. 2019, 7, 100266. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Marliana, M.M.; Issam, A.M.; Bakare, I.O. Exploring isolated lignin material from oil palm biomass waste in green composites. Mater. Des. 2011, 32, 2604–2610. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Abdul Khalil, H.P.S. Effect of fiber treatments on mechanical properties of coir or oil palm fiber reinforced polyester composites. J. Appl. Polym. Sci. 2000, 78, 1685–1697. [Google Scholar] [CrossRef]

- Wu, Y.; Cai, L.; Mei, C.; Lam, S.S.; Sonne, C.; Shi, S.Q.; Xia, C. Development and evaluation of zinc oxide-blended kenaf fiber biocomposite for automotive applications. Mater. Today Commun. 2020, 24, 101008. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Yusra, A.F.I.; Bhat, A.H.; Jawaid, M. Cell wall ultrastructure, anatomy, lignin distribution, and chemical composition of Malaysian cultivated kenaf fiber. Ind. Crop. Prod. 2010, 31, 113–121. [Google Scholar] [CrossRef]

- Pang, A.L.; Ismail, H.; Abu Bakar, A. Eco-friendly coupling agent-treated kenaf/linear low-density polyethylene/poly (vinyl alcohol) composites. Iran. Polym. J. 2018, 27, 87–96. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Jawaid, M.; Midani, M.; Khan, A. Tensile and flexural properties of silica nanoparticles modified unidirectional kenaf and hybrid glass/kenaf epoxy composites. Polymers 2020, 12, 2733. [Google Scholar] [CrossRef]

- Yorseng, K.; Rangappa, S.M.; Pulikkalparambil, H.; Siengchin, S.; Parameswaranpillai, J. Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: Morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr. Build. Mater. 2020, 235, 117464. [Google Scholar] [CrossRef]

- Atiqah, M.; Gopakumar, D.A.; FAT, O.; Pottathara, Y.B.; Rizal, S.; Aprilia, N.; Hermawan, D.; Paridah, M.; Thomas, S.; HPS, A.K. Extraction of Cellulose Nanofibers via Eco-friendly Supercritical Carbon Dioxide Treatment Followed by Mild Acid Hydrolysis and the Fabrication of Cellulose Nanopapers. Polymers 2019, 11, 1813. [Google Scholar] [CrossRef] [Green Version]

- Yadav, S.K.; Schmalbach, K.M.; Kinaci, E.; Stanzione III, J.F.; Palmese, G.R. Recent advances in plant-based vinyl ester resins and reactive diluents. Eur. Polym. J. 2018, 98, 199–215. [Google Scholar] [CrossRef]

- Shah, P.N.; Dev, S.; Lee, Y.; Hansen, C.J. Processing and mechanical properties of bio-derived vinyl ester resin-based composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Shaker, K.; Nawab, Y.; Saouab, A. Influence of silica fillers on failure modes of glass/vinyl ester composites under different mechanical loadings. Eng. Fract. Mech. 2019, 218, 106605. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.; Matsko, N.B. “True” biocomposites with biopolyesters and date seed powder: Mechanical, thermal, and degradation properties. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- El Assami, Y.; Drissi Habti, M.; Raman, V. Stiffening offshore composite wind-blades bonding joints by carbon nanotubes reinforced resin–a new concept. J. Struct. Integr. Maint. 2020, 5, 87–103. [Google Scholar] [CrossRef]

- Drissi-Habti, M.; El Assami, Y.; Raman, V. Multiscale Toughening of Composites with Carbon Nanotubes—Continuous Multiscale Reinforcement New Concept. J. Compos. Sci. 2021, 5, 135. [Google Scholar] [CrossRef]

- Zhang, D.; Cai, J.; Xu, W.; Dong, Q.; Li, Y.; Liu, G.; Wang, Z. Synthesis, characterization and adsorption property of cellulose nanofiber-based hydrogels. J. For. Eng. 2019, 4, 92–98. [Google Scholar]

- Abdullah, C.; Ismail, I.; Nurul Fazita, M.; Olaiya, N.; Nasution, H.; Oyekanmi, A.; Nuryawan, A.; HPS, A.K. Properties and Interfacial Bonding Enhancement of Oil Palm Bio-Ash Nanoparticles Biocomposites. Polymers 2021, 13, 1615. [Google Scholar] [CrossRef]

- Nuryawan, A.; Abdullah, C.; Hazwan, C.M.; Olaiya, N.; Yahya, E.B.; Risnasari, I.; Masruchin, N.; Baharudin, M.; Khalid, H.; Abdul Khalil, H.P.S. Enhancement of Oil Palm Waste Nanoparticles on the Properties and Characterization of Hybrid Plywood Biocomposites. Polymers 2020, 12, 1007. [Google Scholar] [CrossRef]

- Louisy, E.; Samyn, F.; Bourbigot, S.; Fontaine, G.; Bonnet, F. Preparation of glass fabric/poly (L-lactide) composites by Thermoplastic Resin Transfer Molding. Polymers 2019, 11, 339. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Hu, Y.P.; Hu, C.J.; Yu, Y.H. Microstructures and mechanical properties of natural fibers. Adv. Mater. Res. 2008, 33–37, 553–558l. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.; Ariffin, A.H.; Shah, A.U. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Song, Y.; Han, G.; Jiang, W. Comparison of the performance of kenaf fiber using different reagents presoak combined with steam explosion treatment. J. Text. Inst. 2017, 108, 1762–1767. [Google Scholar] [CrossRef]

- Samaei, S.E.; Mahabadi, H.A.; Mousavi, S.M.; Khavanin, A.; Faridan, M.; Taban, E. The influence of alkaline treatment on acoustical, morphological, tensile and thermal properties of Kenaf natural fibers. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Sani, N.; Manaf, M.; Ahsan, Q.; Osman, E.; Doan, V. Electrical resistivity and characterization of indium doped zinc oxide coated kenaf fiber. J. Adv. Manuf. Technol. JAMT 2020, 14. Available online: https://jamt.utem.edu.my/jamt/article/view/5861 (accessed on 10 July 2021).

- Asmal Rani, M.S.; Rudhziah, S.; Ahmad, A.; Mohamed, N.S. Biopolymer Electrolyte Based on Derivatives of Cellulose from Kenaf Bast Fiber. Polymers 2014, 6, 2371–2385. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Aprilia, N.S.; Khalil, H.A.; Bhat, A.; Dungani, R.; Hossain, M.S. Exploring material properties of vinyl ester biocomposites filled carbonized jatropha seed shell. BioResources 2014, 9, 4888–4898. [Google Scholar] [CrossRef] [Green Version]

- Chandramohan, D.; Murali, B.; Vasantha-Srinivasan, P.; Kumar, S.D. Mechanical, moisture absorption, and abrasion resistance properties of bamboo–jute–glass fiber composites. J. Bio Tribo Corros. 2019, 5, 66. [Google Scholar] [CrossRef]

- Raj, M.; Joshi, S.; Savaliya, R.; Raj, L. Studies on reactive blending of LDPE and cenosphere. J. Macromol. Sci. Part A 2019, 56, 115–126. [Google Scholar] [CrossRef]

- King, J.A.; Klimek, D.R.; Miskioglu, I.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/epoxy composites. J. Appl. Polym. Sci. 2013, 128, 4217–4223. [Google Scholar] [CrossRef]

- Singh, S.; Deepak, D.; Aggarwal, L.; Gupta, V. Tensile and flexural behavior of hemp fiber reinforced virgin-recycled HDPE matrix composites. Procedia Mater. Sci. 2014, 6, 1696–1702. [Google Scholar] [CrossRef] [Green Version]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- do Amaral Montanheiro, T.L.; Cristóvan, F.H.; Machado, J.P.B.; Tada, D.B.; Durán, N.; Lemes, A.P. Effect of MWCNT functionalization on thermal and electrical properties of PHBV/MWCNT nanocomposites. J. Mater. Res. 2015, 30, 55–65. [Google Scholar] [CrossRef]

- Park, C.H.; Tocci, E.; Fontananova, E.; Bahattab, M.A.; Aljlil, S.A.; Drioli, E. Mixed matrix membranes containing functionalized multiwalled carbon nanotubes: Mesoscale simulation and experimental approach for optimizing dispersion. J. Membr. Sci. 2016, 514, 195–209. [Google Scholar] [CrossRef]

- Zhang, P.; Xu, P.; Fan, H.; Zhang, Z.; Chen, Y. Phosphorus-nitrogen Flame Retardant Waterborne Polyurethane/Graphene Nanocomposite for Leather Retanning. J. Am. Leather Chem. Assoc. 2018, 113. [Google Scholar]

- Cesano, F.; Cravanzola, S.; Brunella, V.; Scarano, D. Porous carbon spheres from poly(4-ethylstyrene-co-divinylbenzene: Role of ZnCl2 and KOH agents in affecting porosity, surface area and mechanical properties. Microporous Mesoporous Mater. 2019, 288, 109605. [Google Scholar] [CrossRef]

- Samira, S.; Mojtaba, H. Evaluation of CO2 and CH4 adsorption using a novel amine modified MIL-101-derived nanoporous carbon/polysaccharides nanocomposites: Isotherms and thermodynamics. Chem. Eng. J. 2021, 410, 128315. [Google Scholar]

- Chen, R.; Han, N.; Li, L.; Wang, S.; Ma, X.; Wang, C.; Li, H.; Li, H.; Zeng, L. Fundamental understanding of oxygen content in activated carbon on acetone adsorption desorption. Appl. Surf. Sci. 2020, 145211. [Google Scholar] [CrossRef]

- Lendzion-Bieluń, Z.; Czekajło, Ł.; Sibera, D.; Moszyński, D.; Sreńscek-Nazzal, J.; Morawski, A.W.; Wrobel, R.J.; Michalkiewicz, B.; Arabczyk, W.; Narkiewicz, U. Surface characteristics of KOH-treated commercial carbons applied for CO2 adsorption. Adsorpt. Sci. Technol. 2018, 36, 478–492. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Kim, J.S.; Lee, S.-Y.; Mahajan, R.L.; Kim, Y.-T. Exploration of hybrid nanocarbon composite with polylactic acid for packaging applications. Int. J. Biol. Macromol. 2020, 144, 135–142. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polym. Test. 2018, 68, 34–38. [Google Scholar] [CrossRef]

- Qin, J.; Wang, C.; Lu, R.; Su, S.; Yao, Z.; Zheng, L.; Gao, Q.; Wang, Y.; Wang, Q.; Wei, H. Uniform growth of carbon nanotubes on carbon fiber cloth after surface oxidation treatment to enhance interfacial strength of composites. Compos. Sci. Technol. 2020, 195, 108198. [Google Scholar] [CrossRef]

- Pati, S.; Manomaisantiphap, S.; Goto, T.; Takahashi, T.; Yokozeki, T. Development of CFRP with Polyaniline-based Resin using Curable Dopants Employing Storage Stable Prepregs. Appl. Compos. Mater. 2021, 28, 381–394. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Effect of water absorption on the mechanical properties of nano-filler reinforced epoxy nanocomposites. Mater. Des. 2012, 42, 214–222. [Google Scholar] [CrossRef] [Green Version]

- Zorah, M.; Mustapa, I.R.; Daud, N.; Jumah, N.; Sudin, N.A.S.; Majhool, A.; Mahmoudi, E. Thermomechanical Study and Thermal Behavior of Plasticized Poly (Lactic Acid) Nanocomposites. Solid State Phenom. 2021, 317, 333–340. [Google Scholar] [CrossRef]

- Michael, F.M.; Ratnam, C.T.; Khalid, M.; Ramarad, S.; Walvekar, R. Surface modification of nanohydroxyapatite and its loading effect on polylactic acid properties for load bearing implants. Polym. Compos. 2018, 39, 2880–2888. [Google Scholar] [CrossRef]

- Mandal, S.; Roy, D.; Prasad, N.E.; Joshi, M. Interfacial interactions and properties of cellular structured polyurethane nanocomposite based on carbonaceous nano-fillers. J. Appl. Polym. Sci. 2021, 138, 49775. [Google Scholar] [CrossRef]

- Subramanian, N.; Rai, A.; Chattopadhyay, A. Atomistically derived cohesive behavior of interphases in carbon fiber reinforced CNT nanocomposites. Carbon 2017, 117, 55–64. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Xia, J.; Zhou, W.; Zhou, L.; Hussain, G.; Li, Q.; Ostrikov, K.K. Adhesion and cohesion of epoxy-based industrial composite coatings. Compos. Part B Eng. 2020, 193, 108035. [Google Scholar] [CrossRef]

- Zhao, F.; Huang, Y.; Liu, L.; Bai, Y.; Xu, L. Formation of a carbon fiber/polyhedral oligomeric silsesquioxane/carbon nanotube hybrid reinforcement and its effect on the interfacial properties of carbon fiber/epoxy composites. Carbon 2011, 49, 2624–2632. [Google Scholar] [CrossRef]

- Bisht, A.; Dasgupta, K.; Lahiri, D. Investigating the role of 3D network of carbon nanofillers in improving the mechanical properties of carbon fiber epoxy laminated composite. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105601. [Google Scholar] [CrossRef]

- Li, L.-X.; Li, F. The effect of carbonyl, carboxyl and hydroxyl groups on the capacitance of carbon nanotubes. New Carbon Mater. 2011, 26, 224–228. [Google Scholar] [CrossRef]

- Subasinghe, A.; Das, R.; Bhattacharyya, D. Study of thermal, flammability and mechanical properties of intumescent flame retardant PP/kenaf nanocomposites. Int. J. Smart Nano Mater. 2016, 7, 202–220. [Google Scholar] [CrossRef] [Green Version]

| Property | Unit | Value |

|---|---|---|

| Kenaf fibre | ||

| Microstructure [32] | ||

| Number of the cells | - | 21 |

| Area | µm2 | 3678 |

| Perimeter | µm | 228.5 |

| Major diameter | µm | 89.03 |

| Minor diameter | µm | 56.7 |

| Mechanical [33] | ||

| Density | g/cm3 | 1.50 |

| Tensile strength | MPa | 930 |

| Tensile modulus | GPa | 53 |

| Elongation | % | 1.6 |

| Chemical [34] | ||

| Cellulose | % | 56.45 ± 1.36 |

| Hemicellulose | % | 25.26 ± 0.65 |

| Lignin | % | 16.76 ± 1.56 |

| Thermal [35] | ||

| Initial degradation temperature | °C | 338 |

| Maximum degradation temperature | °C | 346 |

| Electrical [36,37] | ||

| Surface resistivity | Ω/sq | 1.2 × 1010 |

| Conductivity | S/cm | 7.51 × 10−5 |

| Vinyl ester | ||

| Appearance | - | Yellowish liquid |

| Viscosity [Brookfield @ 25 °C; Spindle #3 at 60 rpm] | cps | 400–600 |

| Acid value | - | <10 |

| Styrene monomer content | % | 42–45 |

| Gelation time [Co 6%, 0.3%, MEKPO 55%, 1% at 30 °C] | minute | 30–35 |

| Composites | Water Absorption (%) | Thickness Swelling (%) | Before Immersion | After Immersion |

|---|---|---|---|---|

| VE/K/NC0 | 3.82 (±0.10) a | 1.39 (±0.07) a |  |  |

| VE/K/NC1 | 3.23 (±0.11) b | 1.16 (±0.05) b |  |  |

| VE/K/NC3 | 2.64 (±0.12) d | 0.62 (±0.04) d |  |  |

| VE/K/NC5 | 2.87 (±0.09) c | 0.88 (±0.03) c |  |  |

| Weight Gain (+)/Loss (−) (%) | ||||

|---|---|---|---|---|

| Chemicals | VE/K/NC0 | VE/K/NC1 | VE/K/NC3 | VE/K/NC5 |

| C6H6 | 4.06 ± 0.17 a | 2.75 ± 0.08 b | 0.38 ± 0.02 d | 1.43 ± 0.06 c |

| C7H8 | 3.81 ± 0.12 a | 2.79 ± 0.06 b | 0.32 ± 0.01 d | 1.70 ± 0.08 c |

| CCL4 | 3.97 ± 0.14 a | 2.48 ± 0.09 b | 0.29 ± 0.01 d | 1.61 ± 0.07 c |

| HCl | 9.64 ± 0.39 a | 7.03 ± 0.27 b | 1.47 ± 0.09 d | 3.85 ± 0.18 c |

| HNO3 (40%) | 8.30 ± 0.33 a | 6.57 ± 0.21 b | 1.28 ± 0.07 d | 3.48 ± 0.11 c |

| CH3COOH (5%) | 14.17 ± 0.58 a | 11.64 ± 0.35 b | 2.53 ± 0.08 d | 5.73 ± 0.25 c |

| NaOH (10%) | 11.85 ± 0.46 a | 7.97 ± 0.24 b | 3.46 ± 0.14 d | 6.14 ± 0.30 c |

| Na2CO3 (20%) | 8.92 ± 0.22 a | 6.10 ± 0.16 b | 0.71 ± 0.04 d | 1.82 ± 0.13 c |

| NH4OH (10%) | 16.43 ± 0.63 a | 10.85 ± 0.38 b | 3.19 ± 0.12 d | 5.67 ± 0.24 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizal, S.; Mistar, E.M.; Rahman, A.A.; H.P.S., A.K.; Oyekanmi, A.A.; Olaiya, N.G.; Abdullah, C.K.; Alfatah, T. Bionanocarbon Functional Material Characterisation and Enhancement Properties in Nonwoven Kenaf Fibre Nanocomposites. Polymers 2021, 13, 2303. https://doi.org/10.3390/polym13142303

Rizal S, Mistar EM, Rahman AA, H.P.S. AK, Oyekanmi AA, Olaiya NG, Abdullah CK, Alfatah T. Bionanocarbon Functional Material Characterisation and Enhancement Properties in Nonwoven Kenaf Fibre Nanocomposites. Polymers. 2021; 13(14):2303. https://doi.org/10.3390/polym13142303

Chicago/Turabian StyleRizal, Samsul, E. M. Mistar, A. A. Rahman, Abdul Khalil H.P.S., A. A. Oyekanmi, N. G. Olaiya, C. K. Abdullah, and Tata Alfatah. 2021. "Bionanocarbon Functional Material Characterisation and Enhancement Properties in Nonwoven Kenaf Fibre Nanocomposites" Polymers 13, no. 14: 2303. https://doi.org/10.3390/polym13142303

APA StyleRizal, S., Mistar, E. M., Rahman, A. A., H.P.S., A. K., Oyekanmi, A. A., Olaiya, N. G., Abdullah, C. K., & Alfatah, T. (2021). Bionanocarbon Functional Material Characterisation and Enhancement Properties in Nonwoven Kenaf Fibre Nanocomposites. Polymers, 13(14), 2303. https://doi.org/10.3390/polym13142303