Natural Rubber-TiO2 Nanocomposite Film for Triboelectric Nanogenerator Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of NR-TiO2 Composite Films

2.2. Material Characterizations

2.3. TENG Output Measurement

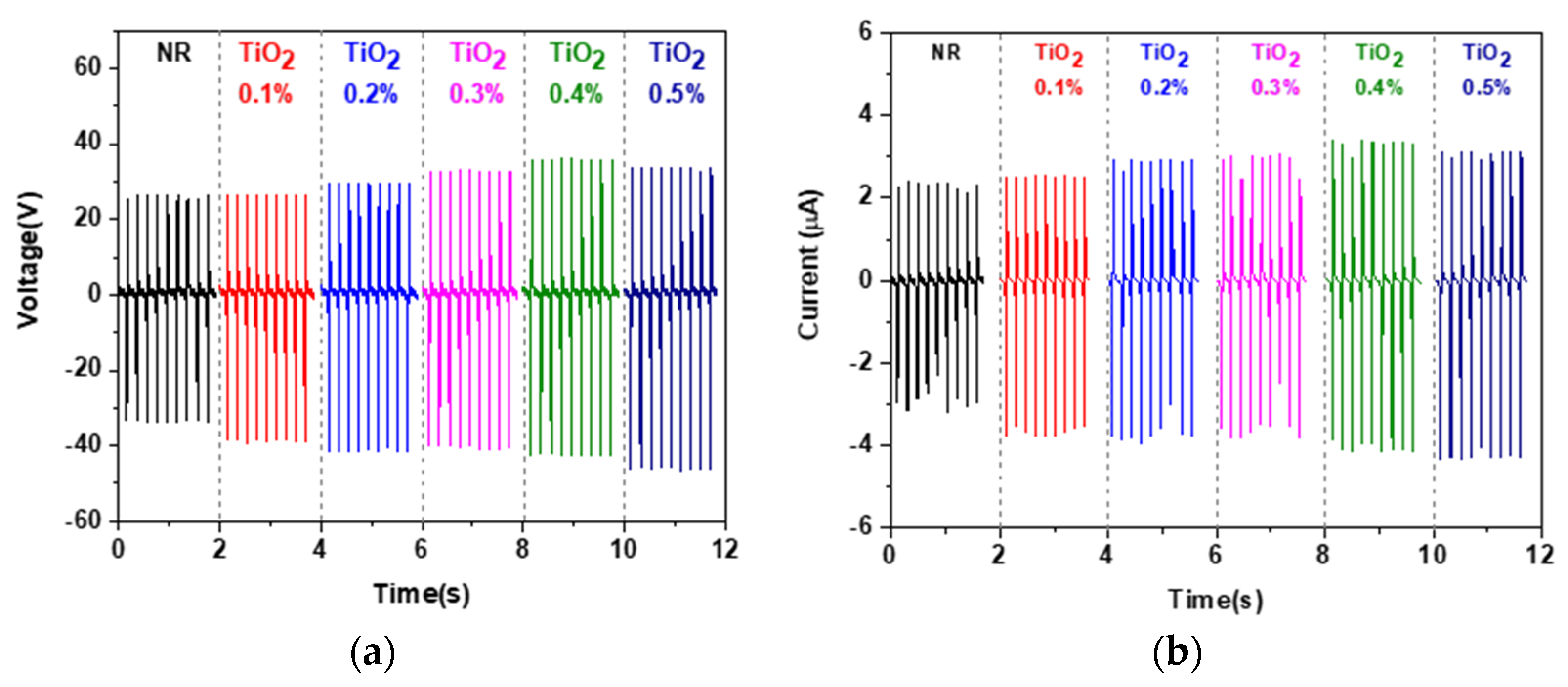

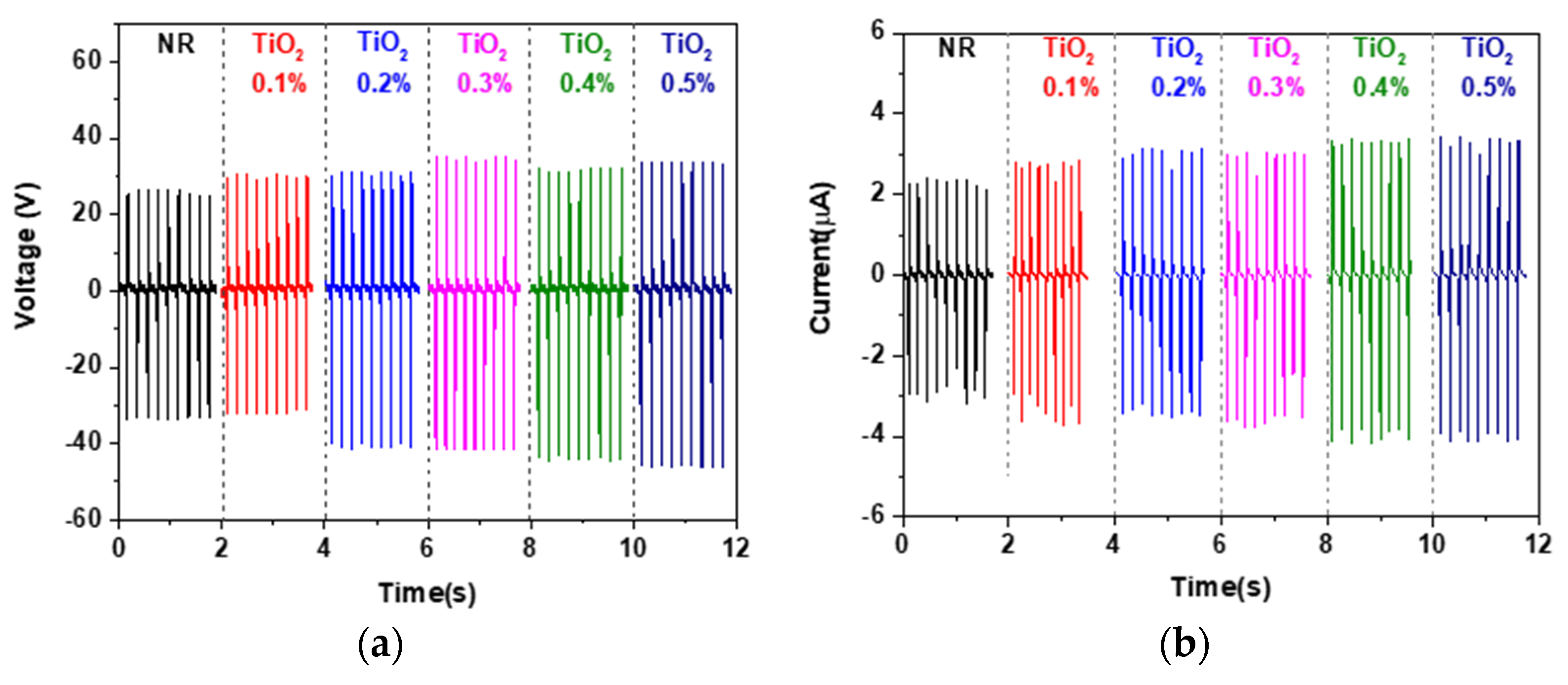

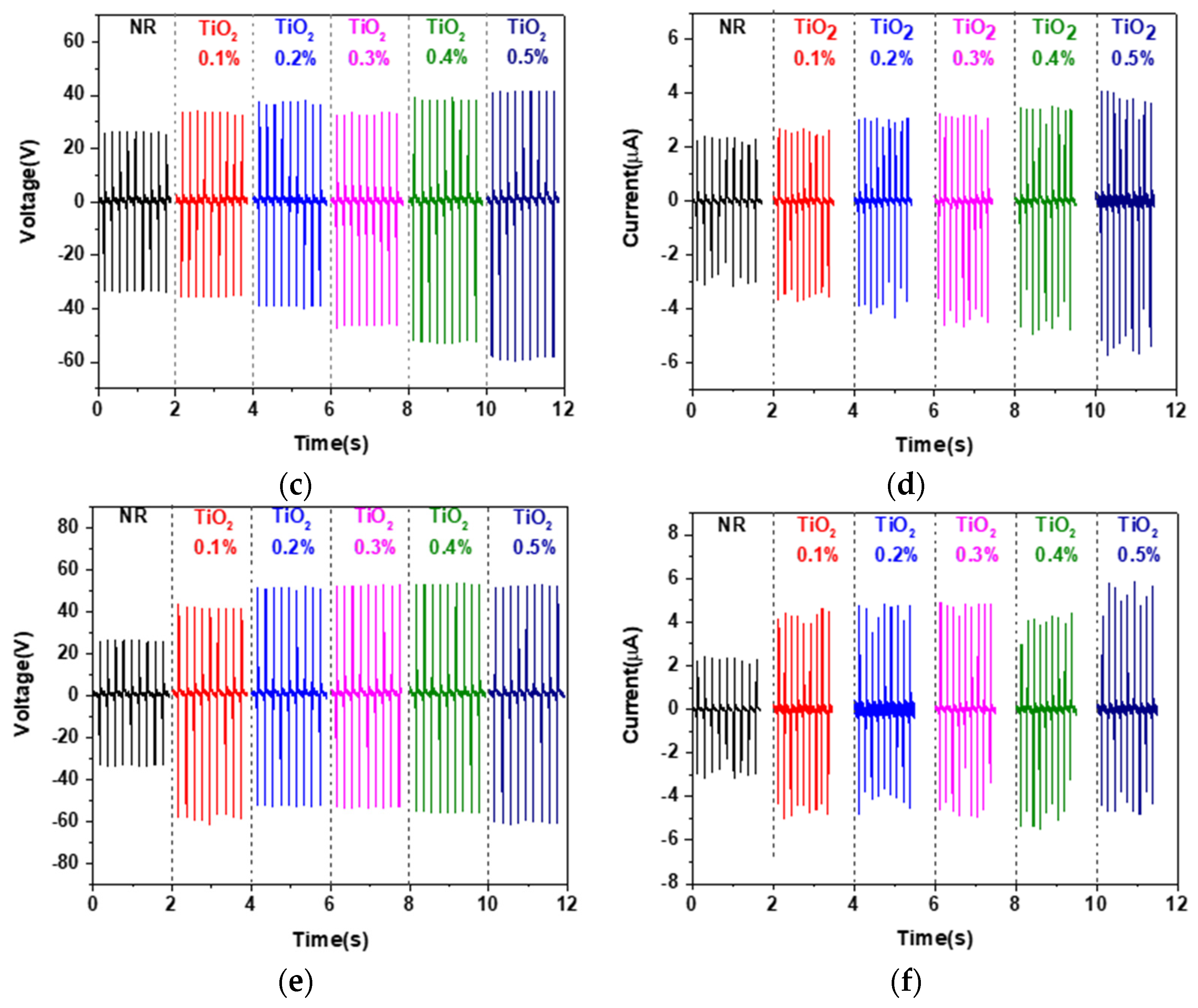

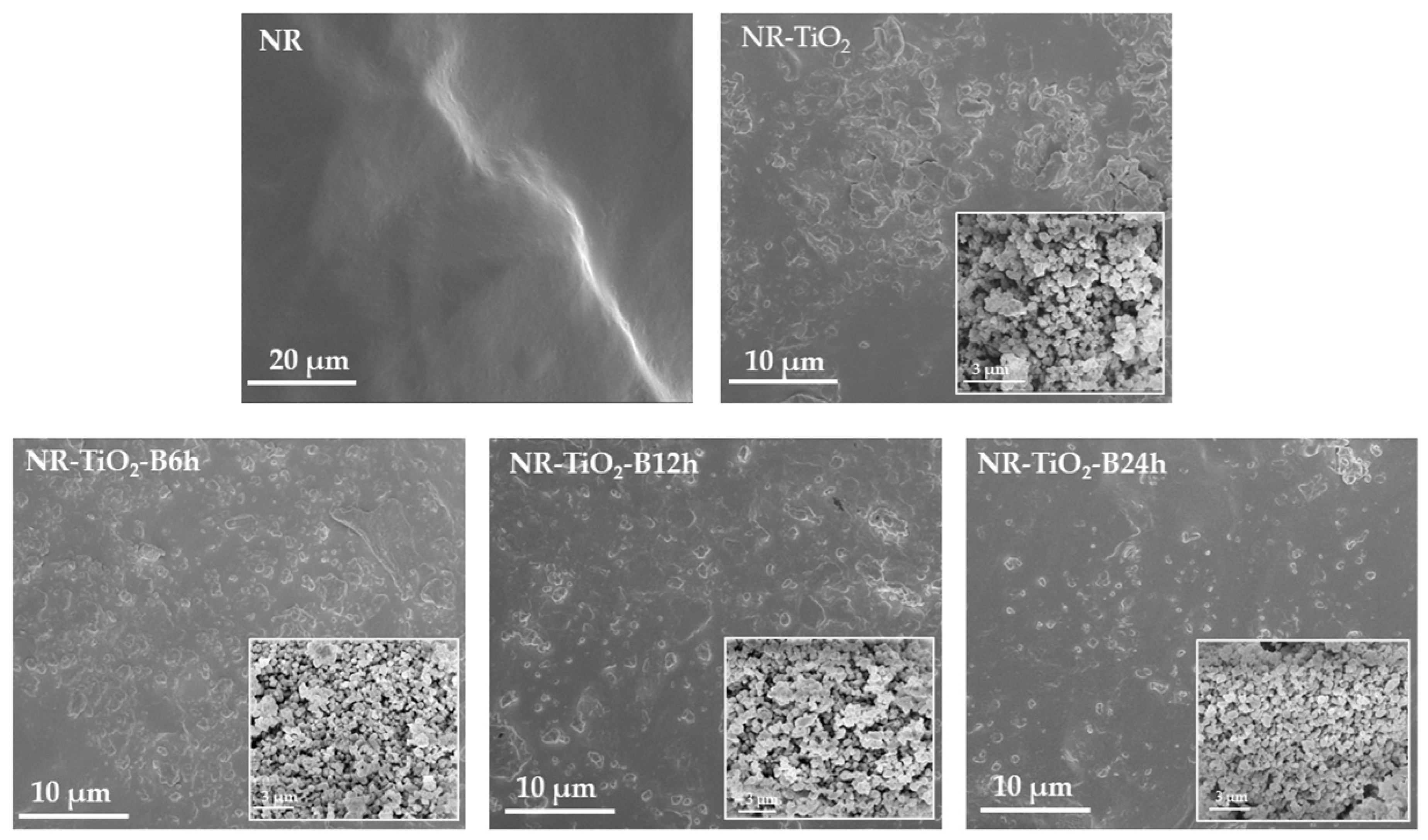

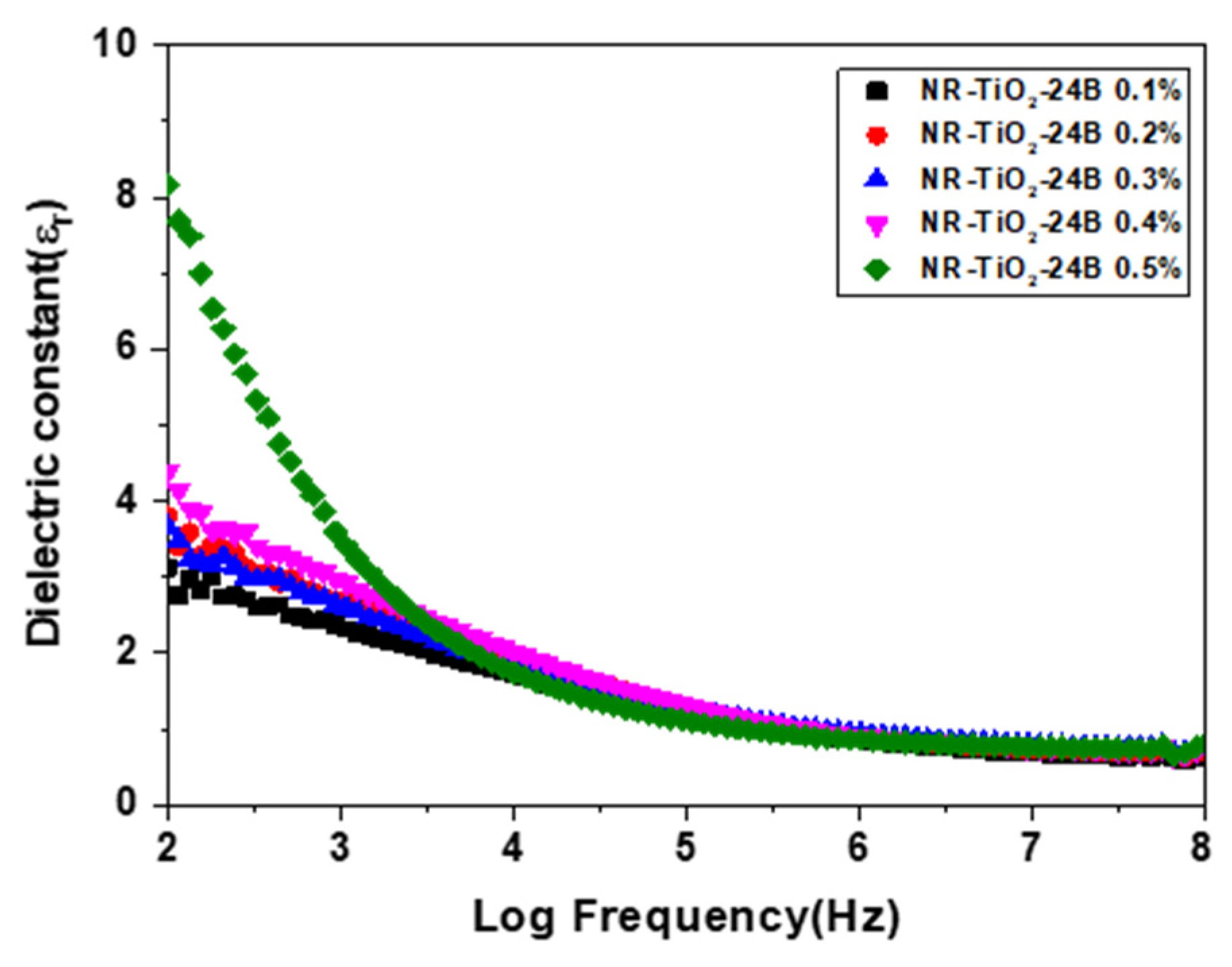

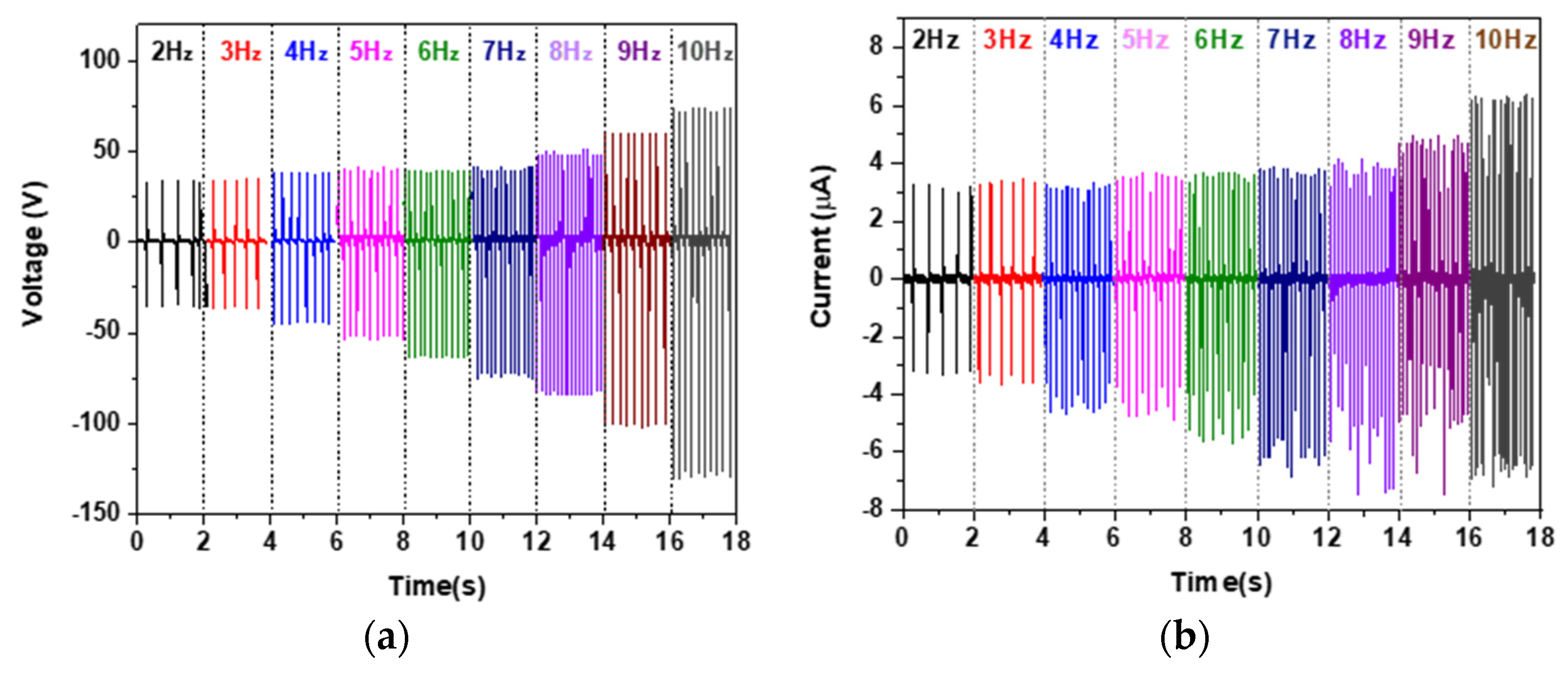

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Ding, W.; Wu, C.; Zi, Y.; Zou, H.; Wang, J.; Cheng, J.; Wang, A.C.; Wang, Z.L. Self-powered wireless optical transmission of mechanical agitation signals. Nano Energy 2018, 47, 566–572. [Google Scholar] [CrossRef]

- Yao, G.; Xu, L.; Cheng, X.; Li, Y.; Huang, X.; Guo, W.; Liu, S.; Wang, Z.L.; Wu, H. Bioinspired triboelectric nanogenerators as self-powered electronic skin for robotic tactile sensing. Adv. Funct. Mater. 2020, 30, 1907312. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Lin, Z.-H.; Liu, Y.; Chen, J.; Lin, Z.; Zhou, Y.S.; Wong, C.P.; Wang, Z.L. A hybrid energy cell for self-powered water splitting. Energy Environ. Sci. 2013, 6, 2429–2434. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, M.; Shi, Q.; Wen, F.; Liu, L.; Dong, B.; Haroun, A.; Yang, Y.; Vachon, P.; Guo, X.; et al. Progress in teng technology—A journey from energy harvesting to nanoenergy and nanosystem. EcoMat 2020, 2, e12058. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, N.; Tang, Y.; Zhang, H.; Ning, C.; Tian, L.; Li, W.; Zhang, J.; Mao, Y.; Liang, E. Single-electrode triboelectric nanogenerators based on sponge-like porous ptfe thin films for mechanical energy harvesting and self-powered electronics. J. Mater. Chem. A 2017, 5, 12252–12257. [Google Scholar] [CrossRef]

- Liu, D.; Yin, X.; Guo, H.; Zhou, L.; Li, X.; Zhang, C.; Wang, J.; Wang, Z.L. A constant current triboelectric nanogenerator arising from electrostatic breakdown. Sci. Adv. 2019, 5, eaav6437. [Google Scholar] [CrossRef] [PubMed]

- Ko, Y.H.; Nagaraju, G.; Lee, S.H.; Yu, J.S. Pdms-based triboelectric and transparent nanogenerators with zno nanorod arrays. ACS Appl. Mater. Interfaces 2014, 6, 6631–6637. [Google Scholar] [CrossRef]

- Harnchana, V.; Ngoc, H.V.; He, W.; Rasheed, A.; Park, H.; Amornkitbamrung, V.; Kang, D.J. Enhanced power output of a triboelectric nanogenerator using poly(dimethylsiloxane) modified with graphene oxide and sodium dodecyl sulfate. ACS Appl. Mater. Interfaces 2018, 10, 25263–25272. [Google Scholar] [CrossRef]

- Lee, J.P.; Lee, J.W.; Baik, J.M. The progress of pvdf as a functional material for triboelectric nanogenerators and self-powered sensors. Micromachines 2018, 9, 532. [Google Scholar] [CrossRef] [PubMed]

- Shaikh, M.O.; Huang, Y.-B.; Wang, C.-C.; Chuang, C.-H. Wearable woven triboelectric nanogenerator utilizing electrospun pvdf nanofibers for mechanical energy harvesting. Micromachines 2019, 10, 672. [Google Scholar] [CrossRef]

- Jian, G.; Meng, Q.; Jiao, Y.; Meng, F.; Cao, Y.; Wu, M. Enhanced performances of triboelectric nanogenerators by filling hierarchical flower-like TiO2 particles into polymethyl methacrylate film. Nanoscale 2020, 12, 14160–14170. [Google Scholar] [CrossRef] [PubMed]

- Busolo, T.; Ura, D.P.; Kim, S.K.; Marzec, M.M.; Bernasik, A.; Stachewicz, U.; Kar-Narayan, S. Surface potential tailoring of pmma fibers by electrospinning for enhanced triboelectric performance. Nano Energy 2019, 57, 500–506. [Google Scholar] [CrossRef]

- Candau, N.; Chazeau, L.; Chenal, J.-M.; Gauthier, C.; Munch, E. A comparison of the abilities of natural rubber (nr) and synthetic polyisoprene cis-1,4 rubber (ir) to crystallize under strain at high strain rates. Phys. Chem. Chem. Phys. 2016, 18, 3472–3481. [Google Scholar] [CrossRef] [PubMed]

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef]

- He, X.; Guo, H.; Yue, X.; Gao, J.; Xi, Y.; Hu, C. Improving energy conversion efficiency for triboelectric nanogenerator with capacitor structure by maximizing surface charge density. Nanoscale 2015, 7, 1896–1903. [Google Scholar] [CrossRef]

- Kim, D.; Jeon, S.-B.; Kim, J.Y.; Seol, M.-L.; Kim, S.O.; Choi, Y.-K. High-performance nanopattern triboelectric generator by block copolymer lithography. Nano Energy 2015, 12, 331–338. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, J.; Chen, K.; Chen, J. Advances in nanostructures for high-performance triboelectric nanogenerators. Adv. Mater. Technol. 2021, 6, 2000916. [Google Scholar] [CrossRef]

- Fang, Z.; Chan, K.H.; Lu, X.; Tan, C.F.; Ho, G.W. Surface texturing and dielectric property tuning toward boosting of triboelectric nanogenerator performance. J. Mater. Chem. A 2018, 6, 52–57. [Google Scholar] [CrossRef]

- Kim, Y.J.; Lee, J.; Park, S.; Park, C.; Park, C.; Choi, H.-J. Effect of the relative permittivity of oxides on the performance of triboelectric nanogenerators. RSC Adv. 2017, 7, 49368–49373. [Google Scholar] [CrossRef]

- Chen, J.; Guo, H.; He, X.; Liu, G.; Xi, Y.; Shi, H.; Hu, C. Enhancing performance of triboelectric nanogenerator by filling high dielectric nanoparticles into sponge pdms film. ACS Appl. Mater. Interfaces 2016, 8, 736–744. [Google Scholar] [CrossRef] [PubMed]

- Shi, K.; Zou, H.; Sun, B.; Jiang, P.; He, J.; Huang, X. Dielectric modulated cellulose paper/pdms-based triboelectric nanogenerators for wireless transmission and electropolymerization applications. Adv. Funct. Mater. 2020, 30, 1904536. [Google Scholar] [CrossRef]

- Zhu, T.; Gao, S.-P. The stability, electronic structure, and optical property of tio2 polymorphs. J. Phys. Chem. C 2014, 118, 11385–11396. [Google Scholar] [CrossRef]

- Schneider, J.; Matsuoka, M.; Takeuchi, M.; Zhang, J.; Horiuchi, Y.; Anpo, M.; Bahnemann, D.W. Understanding TiO2 photocatalysis: Mechanisms and materials. Chem. Rev. 2014, 114, 9919–9986. [Google Scholar] [CrossRef]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Wypych, A.; Bobowska, I.; Tracz, M.; Opasinska, A.; Kadlubowski, S.; Krzywania-Kaliszewska, A.; Grobelny, J.; Wojciechowski, P. Dielectric properties and characterisation of titanium dioxide obtained by different chemistry methods. J. Nanomater. 2014, 2014, 124814. [Google Scholar] [CrossRef]

- Ali, I.; Suhail, M.; Alothman, Z.A.; Alwarthan, A. Recent advances in syntheses, properties and applications of TiO2 nanostructures. RSC Adv. 2018, 8, 30125–30147. [Google Scholar] [CrossRef]

- Longseng, R.; Khaokong, C. Hexamethylene diamine-modified epoxidized natural rubber and its effect on cure characteristics and properties of natural rubber blends. Iran. Polym. J. 2020, 29, 1113–1121. [Google Scholar] [CrossRef]

- Tanaka, Y. Structural characterization of natural polyisoprenes: Solve the mystery of natural rubber based on structural study. Rubber Chem. Technol. 2001, 74, 355–375. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Zheng, Q.; Shi, B.; Fan, F.; Wang, X.; Yan, L.; Yuan, W.; Wang, S.; Liu, H.; Li, Z.; Wang, Z.L. In vivo powering of pacemaker by breathing-driven implanted triboelectric nanogenerator. Adv. Mater. 2014, 26, 5851–5856. [Google Scholar] [CrossRef]

- Liu, J.; Gu, L.; Cui, N.; Bai, S.; Liu, S.; Xu, Q.; Qin, Y.; Yang, R.; Zhou, F. Core-shell fiber-based 2D woven triboelectric nanogenerator for effective motion energy harvesting. Nanoscale Res. Lett. 2019, 14, 311. [Google Scholar] [CrossRef] [PubMed]

- Roh, H.; Yu, J.; Kim, I.; Chae, Y.; Kim, D. Dynamic analysis to enhance the performance of a rotating-disk-based triboelectric nanogenerator by injected gas. ACS Appl. Mater. Interfaces 2019, 11, 25170–25178. [Google Scholar] [CrossRef] [PubMed]

- Suphasorn, P.; Appamato, I.; Harnchana, V.; Thongbai, P.; Chanthad, C.; Siriwong, C.; Amornkitbamrung, V. Ag nanoparticle-incorporated natural rubber for mechanical energy harvesting application. Molecules 2021, 26, 388. [Google Scholar] [CrossRef] [PubMed]

- Kao, K.C. 2. Electric polarization and relaxation. In Dielectric Phenomena in Solids; Kao, K.C., Ed.; Academic Press: San Diego, CA, USA, 2004; pp. 41–114. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bunriw, W.; Harnchana, V.; Chanthad, C.; Huynh, V.N. Natural Rubber-TiO2 Nanocomposite Film for Triboelectric Nanogenerator Application. Polymers 2021, 13, 2213. https://doi.org/10.3390/polym13132213

Bunriw W, Harnchana V, Chanthad C, Huynh VN. Natural Rubber-TiO2 Nanocomposite Film for Triboelectric Nanogenerator Application. Polymers. 2021; 13(13):2213. https://doi.org/10.3390/polym13132213

Chicago/Turabian StyleBunriw, Weeraya, Viyada Harnchana, Chalathorn Chanthad, and Van Ngoc Huynh. 2021. "Natural Rubber-TiO2 Nanocomposite Film for Triboelectric Nanogenerator Application" Polymers 13, no. 13: 2213. https://doi.org/10.3390/polym13132213