Hollow Fiber Polyimide Membranes Prepared in a Triple Orifice Spinneret: Effect of a Reduced Water Activity in the Bore Fluid on the Gas Separation Performance

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Spinning Protocol

2.3. SEM Analyses

2.4. Gas Permeation Tests

3. Results and Discussion

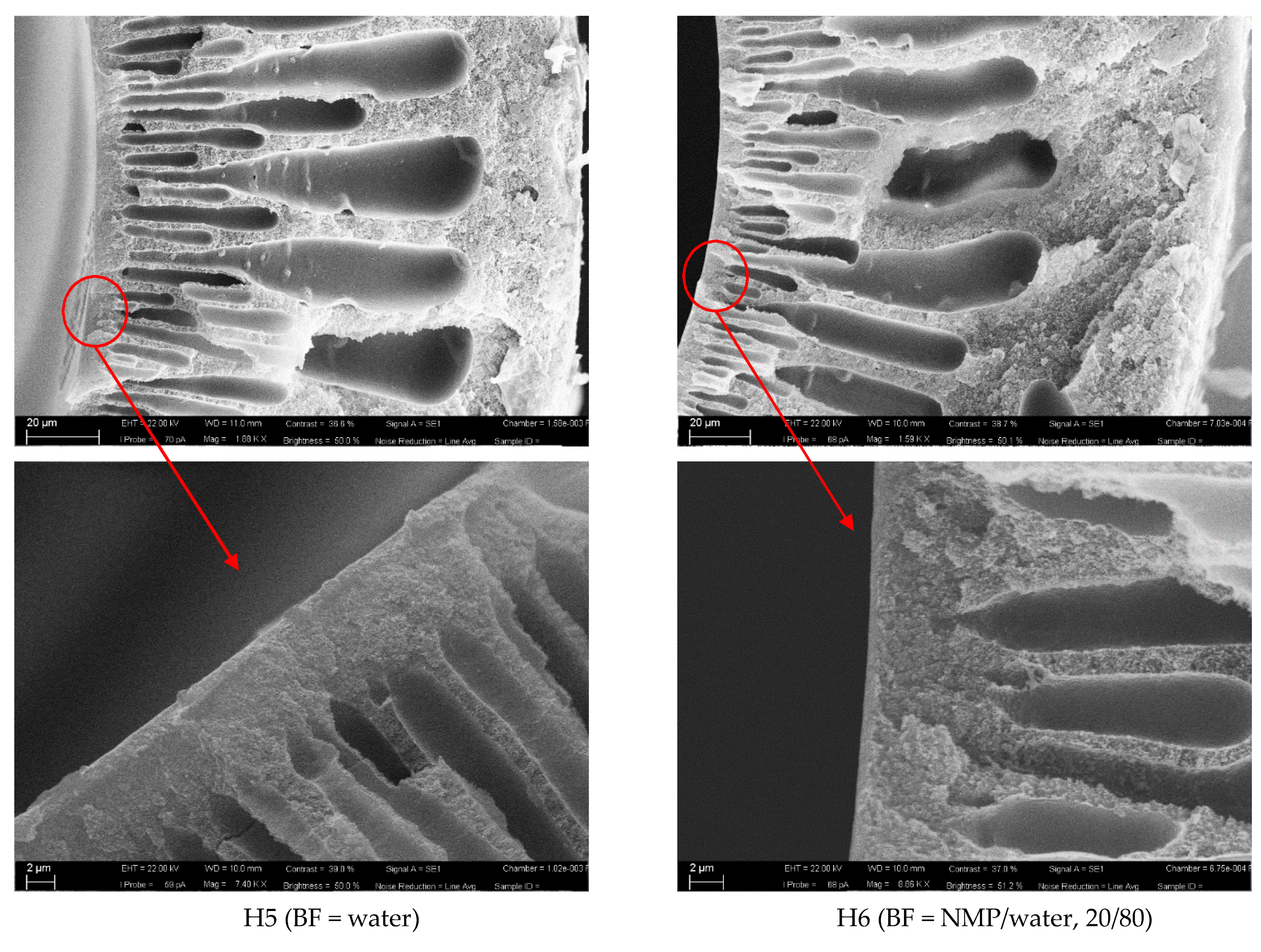

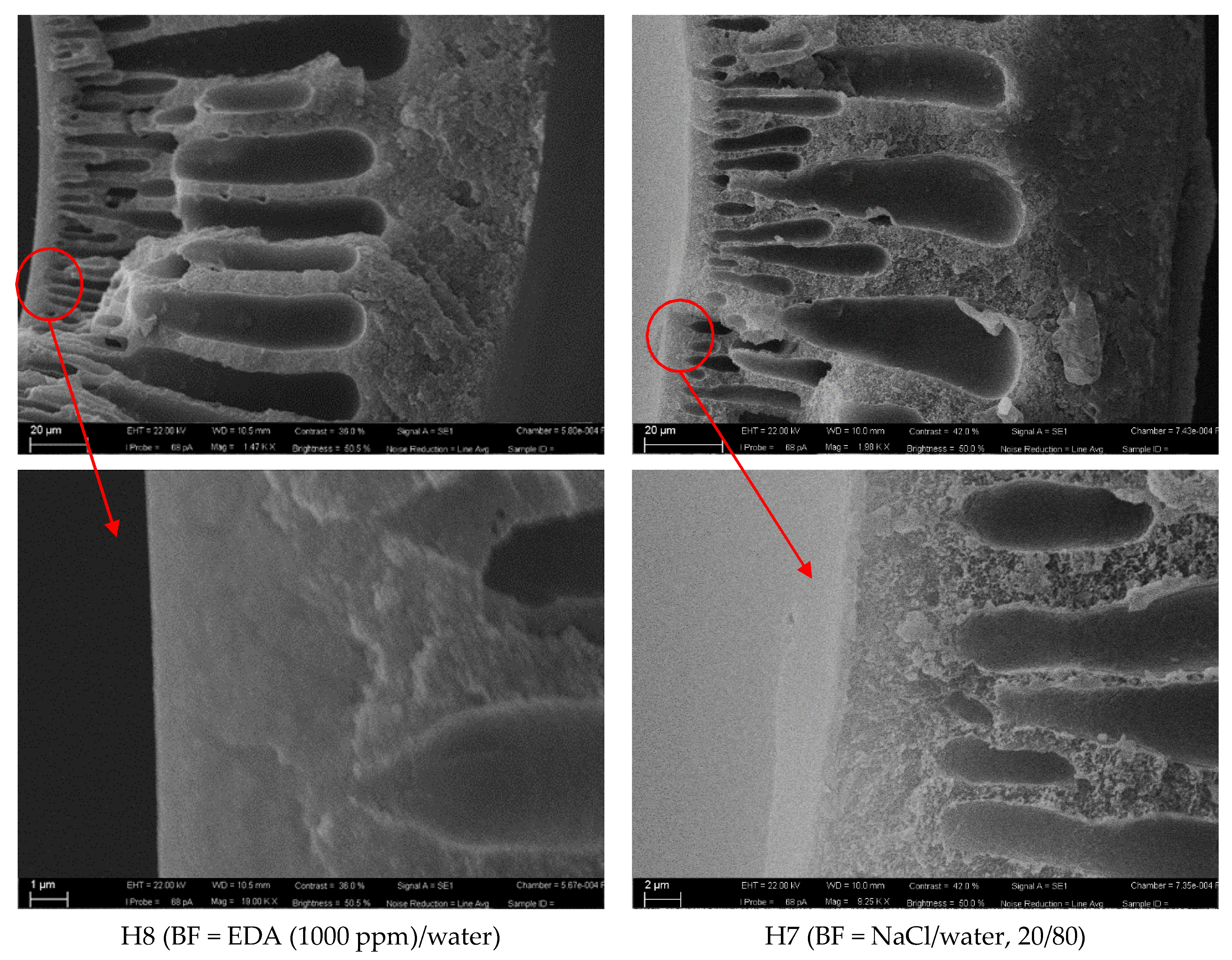

3.1. Morphological Analysis

3.2. Gas Permeation

3.2.1. Effect of the Dope Flow-Rate

3.2.2. Effect of the Bore Fluid Composition

| Material | HSP (MPa)0.5 | GP (J/m3) | |||

|---|---|---|---|---|---|

| δD | δP | δH | δt | ||

| Matrimid® | 18.7 | 9.5 | 6.7 | 22.0 [31] | 1.5 a |

| NMP | 18.0 | 12.3 | 7.2 | 22.96 [32] | 0.89 [32] |

| Water | 15.5 | 16.0 | 42.3 | 47.8 [32] | 2.77 [32] |

| NaCl | 168.0 b | ||||

| NMP/water (20/80 wt/wt) | 16.0 | 15.3 | 35.3 | 42.8 c | 2.39 c |

| NMP/water (30/70 wt/wt) | 16.2 | 14.9 | 31.8 | 40.3 | |

| NMP/water (60/40 wt/wt) | 17.0 | 13.8 | 21.2 | 32.9 | |

| NMP/water (95/5 wt/wt) | 17.9 | 12.5 | 9.0 | 24.2 | |

| NaCl/water (20/80 wt/wt) | 71.84 c | 4.32 d | |||

3.2.3. Long Term Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baker, R.W. Future directions of membrane gas-separation technology. Ind. Eng. Chem. Res. 2002, 41, 1393–1411. [Google Scholar] [CrossRef]

- Bakeri, G.; Ismail, A.F.; Shariaty-Niassar, M.; Matsuura, T. Effect of polymer concentration on the structure and performance of polyetherimide hollow fiber membranes. J. Membr. Sci. 2010, 363, 103–111. [Google Scholar] [CrossRef]

- Yao, M.; Ren, J.; Akthera, N.; Woo, Y.C.; Tijing, L.D.; Kim, S.-H.; Shon, H.K. Improving membrane distillation performance: Morphology optimization of hollow fiber membranes with selected non-solvent in dope solution. Chemosphere 2019, 230, 117–126. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.U.; Othman, M.H.D.; Ismail, A.F.; Matsuura, T.; Hashim, H.; Nordin, N.A.H.M.; Rahman, M.A.; Jaafar, J.; Jilaniaf, A. Status and improvement of dual-layer hollow fiber membranes via co-extrusion process for gas separation: A review. J. Nat. Gas Sci. Eng. 2018, 52, 215–234. [Google Scholar] [CrossRef]

- Jung, J.T.; Wang, H.H.; Kim, J.F.; Lee, J.; Kim, J.S.; Drioli, E.; Lee, Y.M. Tailoring nonsolvent-thermally induced phase separation (N-TIPS) effect using triple spinneret to fabricate high performance PVDF hollow fiber membranes. J. Membr. Sci. 2018, 559, 117–126. [Google Scholar] [CrossRef]

- Fang, C.; Liu, W.; Zhang, P.; Rajabzadeh, S.; Kato, N.; Sasaki, Y.; Shon, H.K.; Matsuyama, H. Hollow fiber membranes with hierarchical spherulite surface structure developed by thermally induced phase separation using triple-orifice spinneret for membrane distillation. J. Membr. Sci. 2021, 618, 118586. [Google Scholar] [CrossRef]

- Bernardo, P.; Prete, S.; Clarizia, G.; Tasselli, F. Effect of external fluid and inline crosslinking on the performance of polyimide hollow fibres prepared by using a triple–orifice spinneret. J. Membr. Sci. 2019, 570, 410–417. [Google Scholar] [CrossRef]

- Bernardo, P.; Tasselli, F.; Chiappetta, G.; Clarizia, G. Effect of the post-spinning solvent exchange on the performance of asymmetric polyimide hollow fibers prepared by using a triple orifice spinneret. Materials 2019, 12, 3632. [Google Scholar] [CrossRef] [Green Version]

- Clarizia, G.; Tasselli, F.; Bernardo, P. Effect of Physical aging on gas transport in asymmetric polyimide hollow fibers prepared by triple orifice spinneret. Polymers 2020, 12, 441. [Google Scholar] [CrossRef] [Green Version]

- Pesek, S.C.; Koros, W.J. Aqueous quenched asymmetric polysulfone hollow fibers prepared by dry/wet phase separation. J. Membr. Sci. 1994, 88, 1–19. [Google Scholar] [CrossRef]

- Ismail, A.F.; Shilton, S.J.; Dunkin, I.R.; Gallivan, S.L. Direct measurement of rheologically induced molecular orientation in gas separation hollow fiber membranes and effects on selectivity. J. Membr. Sci. 1997, 126, 133–137. [Google Scholar] [CrossRef]

- Ismail, A.F.; Dunkin, R.; Gallivan, S.L.; Shilton, S.J. Production of super selective polysulfone hollow fiber membranes for gas separation. Polymer 1999, 40, 6499–6506. [Google Scholar] [CrossRef]

- Wang, H.H.; Jung, J.T.; Kim, J.F.; Kim, S.; Drioli, E.; Lee, Y.M. A novel green solvent alternative for polymeric membrane preparation via nonsolvent-induced phase separation (NIPS). J. Membr. Sci. 2019, 574, 44–54. [Google Scholar] [CrossRef]

- Nunes, S.P.; Culfaz-Emecen, P.Z.; Ramon, G.Z.; Visser, T.; Koops, G.H.; Jin, W.; Ulbricht, M. Thinking the future of membranes: Perspectives for advanced and new membrane materials and manufacturing processes. J. Membr. Sci. 2020, 598, 117761. [Google Scholar] [CrossRef]

- Reig, M.; Casas, S.; Aladjem, C.; Valderrama, C.; Gibert, O.; Valero, F.; Centeno, C.M.; Larrotch, E.; Cortina, J.L. Concentration of NaCl from seawater reverse osmosis brines for the chlor-alkali industry by electrodialysis. Desalination 2014, 342, 107–117. [Google Scholar] [CrossRef]

- Tasselli, F.; Drioli, E. Tuning of hollow fiber membrane properties using different bore fluids. J. Membr. Sci. 2007, 301, 11–18. [Google Scholar] [CrossRef]

- Clarizia, G.; Bernardo, P.; Gorrasi, G.; Zampino, D.; Carroccio, S.C. Influence of the preparation method and photo-oxidation treatment on the thermal and gas transport properties of dense films based on a poly(ether-block-amide) copolymer. Materials 2018, 11, 1326. [Google Scholar] [CrossRef] [Green Version]

- Yong, W.F.; Li, F.Y.; Xiao, Y.C.; Chung, T.S.; Tong, Y.W. High performance PIM-1/Matrimid hollow fiber membranes for CO2/CH4, O2/N2 and CO2/N2 separation. J. Membr. Sci. 2013, 443, 156–169. [Google Scholar] [CrossRef]

- Pesek, S.C.; Koros, W.J. Aqueous quenched asymmetric polysulfone membranes prepared by dry/wet phase separation. J. Memb. Sci. 1993, 81, 71–88. [Google Scholar] [CrossRef]

- Roman, I.C. Membranes for Nitrogen Generation: Recent Advances and Impact on Other Gas Separations. In Ecological Applications of Innovative Membrane Technology in the Chemical Industry; IRMERC-CNR and United Nations Economic Commission for Europe: Cetraro, Italy, 1996. [Google Scholar]

- Clausi, D.T.; Koros, W.J. Formation of defect-free polyimide hollow fiber membranes for gas separations. J. Membr. Sci. 2000, 167, 79–89. [Google Scholar] [CrossRef]

- Huang, Y.; Paul, D.R. Effect of film thickness on the gas-permeation characteristics of glassy polymer membranes. Ind. Eng. Chem. Res. 2007, 46, 2342–2347. [Google Scholar] [CrossRef]

- Ismail, A.F.; Ibrahim, S.M.; Nasri, N.S. Effects of dope extrusion rate on the morphology and gas separation performance of asymmetric polysulfone hollow fiber membranes for O2/N2 separation. Songklanakarin J. Sci. Technol. 2003, 24, 833–842. [Google Scholar]

- Hansen, C.M. Hansen Solubility Parameters: A User’s Book, 2nd ed.; CRC Press: New York, NY, USA, 2007. [Google Scholar]

- Hildebrand, J.H.; Prausnitz, J.M.; Scott, R.L. Regular and Related Solutions: The Solubility of Gases, Liquids, and Solids, 1st ed.; Van Nostrand Reinhold: New York, NY, USA, 1970. [Google Scholar]

- Reichardt, C.; Welton, T. Solvents and Solvent Effects in Organic Chemistry, 4th ed.; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Kittel, C. Introduction to Solid State Physics, 5th ed.; Wiley: New York, NY, USA, 1976. [Google Scholar]

- Gordon, J.E. The Organic Chemistry of Electrolyte Solutions; John Wiley and Sons: New York, NY, USA, 1975. [Google Scholar]

- Girifalco, L.A.; Good, R.J. A Theory for the Estimation of Surface and Interfacial Energies. I. Derivation and Application to Interfacial Tension. J. Phys. Chem. 1957, 61, 904–909. [Google Scholar] [CrossRef]

- Fatyeyeva, K.; Dahi, A.; Chappey, C.; Langevin, D.; Valleton, J.-M.; Poncin-Epaillard, F.; Marais, S. Effect of cold plasma treatment on surface properties and gas permeability of polyimide films. RSC Adv. 2014, 4, 31036–31046. [Google Scholar] [CrossRef]

- Dong, G.; Li, H.; Chen, V. Factors affect defect-free Matrimid® hollow fiber gas separation performance in natural gas purification. J. Membr. Sci. 2010, 353, 17–27. [Google Scholar] [CrossRef]

- Jalili, R.; Aboutalebi, S.; Esrafilzadeh, D.; Konstantinov, K.K.; Moulton, S.E.; Razal, J.M.; Wallace, G.G. Organic solvent based graphene oxide liquid crystals: A facile route toward the next generation of self-assembled layer-by-layer multifunctional 3D architectures. ACS Nano 2013, 7, 3981–3990. [Google Scholar] [CrossRef] [Green Version]

- Singh, M. Quantitative analysis of cohesive energy density: A Gordon parameter of 1:1 aqueous sodium salts solutions. Int. J. Phys. Sci. 2011, 6, 5716–5719. [Google Scholar]

- Lovelock, K.R.J. Quantifying intermolecular interactions of ionic liquids using cohesive energy densities. R. Soc. Open Sci. 2017, 4, 171223. [Google Scholar] [CrossRef] [Green Version]

- Henni, A.; Hromek, J.J.; Tontiwachwuthikul, P.; Chakma, A. Volumetric Properties and Viscosities for Aqueous N-Methyl-2-pyrrolidone Solutions from 25 °C to 70 °C. J. Chem. Eng. Data 2004, 49, 231–234. [Google Scholar] [CrossRef]

- MacDonald, D.D.; Dunay, D.; Hanlon, G.; Hyne, J.B. Properties of the n-methyl-2-pyrrolidinone-water system. Can. J. Chem. Eng. 1971, 49, 420–423. [Google Scholar] [CrossRef]

- Kitic, D.; Jardim, D.C.P.; Favetto, G.J.; Resnik, S.L.; Chirife, J. Theoretical Prediction of the Water Activity of Standard Saturated Salt Solutions at Various Temperatures. J. Food Sci. 1986, 51, 1037–1041. [Google Scholar] [CrossRef]

- Ismail, A.F.; Yean, L.P. Review on the Development of Defect-Free and Ultrathin Skinned Asymmetric Membranes for Gas Separation through Manipulation of Phase Inversion and Rheological Factors. J. Appl. Polym. Sci. 2003, 88, 442–451. [Google Scholar] [CrossRef]

- Rowe, B.W.; Freeman, B.D.; Paul, D.R. Physical aging of ultrathin glassy polymer films tracked by gas permeability. Polymer 2009, 50, 5565–5575. [Google Scholar] [CrossRef]

| Dope Flow-Rate (g min−1) | 3.6 or 5.0 |

|---|---|

| BF flow-rate (g min−1) | 3 |

| EF flow-rate (g min−1) | 3 |

| Air gap (cm) | 60 |

| T dope (°C) | 50 |

| T coagulation bath (°C) | 18 |

| HF Code | QDOPE = g min−1 | BF Composition (wt/wt) | EF Composition (wt/wt) |

|---|---|---|---|

| H0 | 5.0 | water | - |

| H1 | 5.0 | water | NMP/water (95/5) |

| H5 | 3.6 | ||

| H2 | 5.0 | NMP/water (20/80) | NMP/water (95/5) |

| H6 | 3.6 | ||

| H3 | 5.0 | NMP/water (30/70) | NMP/water (95/5) |

| H4 | 5.0 | NMP/water (60/40) | NMP/water (95/5) |

| H7 | 3.6 | NaCl/water (20/80) | NMP/water (95/5) |

| H8 | 3.6 | EDA/water (1000 ppm) | NMP/water (95/5) |

| HF Code | Thickness (nm) | BF Composition (wt/wt) | EF Composition (wt/wt) |

|---|---|---|---|

| H0 | ca. 800 | water | - |

| H1 | ca. 800 | water | NMP/water (95/5) |

| H2 | ca. 700 | NMP/water (20/80) | NMP/water (95/5) |

| H3 | ca. 400 | NMP/water (30/70) | NMP/water (95/5) |

| H4 | ca. 250 | NMP/water (60/40) | NMP/water (95/5) |

| H5 | ca. 900 | water | NMP/water (95/5) |

| H6 | ca. 600 | NMP/water (20/80) | NMP/water (95/5) |

| H7 | ca. 700 | NaCl/water (20/80) | NMP/water (95/5) |

| H8 | ca. 3400 | EDA/water | NMP/water (95/5) |

| HF Code | BF | EF | Permeance (GPU) | Selectivity (-) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2 | He | CO2 | O2 | CH4 | N2 | O2/N2 | CO2/N2 | H2/N2 | |||

| H0 | water | - | 42.3 | 36.3 | 13.9 | 3.52 | 0.50 | 0.62 | 5.68 | 22.4 | 68.2 |

| H1 | water | NMP/water (95/5) | 46.4 | 39.7 | 21.5 | 4.03 | 0.54 | 0.645 | 6.25 | 33.3 | 71.9 |

| H2 | NMP/water (20/80) | NMP/water (95/5) | 31.5 | 29.3 | 10.4 | 1.94 | 0.31 | 0.33 | 5.88 | 31.5 | 95.5 |

| H3 | NMP/water (30/70) | NMP/water (95/5) | 45.7 | 38.9 | 21.0 | 3.83 | 0.59 | 0.70 | 5.47 | 30.0 | 65.3 |

| H4 | NMP/water (60/40) | NMP/water (95/5) | 148 | 127 | 63.3 | 12.6 | 2.17 | 2.34 | 5.38 | 27.1 | 63.3 |

| 1 GPU = 10−6 cm3 cm−2 s−1 cmHg−1 | |||||||||||

| HF Code | BF | EF | Permeance (GPU) | Selectivity (-) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2 | He | CO2 | O2 | CH4 | N2 | O2/N2 | CO2/N2 | H2/N2 | |||

| H5 | water | NMP/water (95/5) | 41.1 | 36.5 | 18.2 | 3.53 | 0.51 | 0.58 | 6.10 | 31.4 | 71.4 |

| H6 | NMP/water (20/80) | NMP/water (95/5) | 34.4 | 31.4 | 10.6 | 2.0 | 0.284 | 0.353 | 5.67 | 30.0 | 97.5 |

| H7 | NaCl/water (20/80) | NMP/water (95/5) | 47.2 | 42.1 | 17.1 | 3.2 | 0.44 | 0.485 | 6.49 | 34.7 | 97.3 |

| H8 | EDA/water 1000 ppm | NMP/water (95/5) | 17.0 | 16.1 | 5.2 | 1.05 | 0.12 | 0.156 | 6.73 | 33.3 | 109 |

| 1 GPU = 10−6 cm3 cm−2 s−1 cmHg−1 | |||||||||||

| HF Code | BF | EF | Testing | Permeance (GPU) | Selectivity (-) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H2 | He | CO2 | O2 | CH4 | N2 | O2/N2 | CO2/N2 | H2/N2 | ||||

| H0 | water | - | As-spun | 42.3 | 36.3 | 13.9 | 3.52 | 0.50 | 0.62 | 5.68 | 22.4 | 68.2 |

| Aged | 20.0 | 19.3 | 4.94 | 1.24 | 0.16 | 0.21 | 5.90 | 23.5 | 95.2 | |||

| H1 | water | NMP/water (95/5) | As-spun | 46.4 | 39.7 | 21.5 | 4.03 | 0.54 | 0.645 | 6.25 | 33.3 | 71.9 |

| Aged | 23.9 | 23.6 | 8.03 | 1.68 | 0.212 | 0.25 | 6.72 | 32.1 | 95.6 | |||

| H2 | NMP/water (20/80) | NMP/water (95/5) | As-spun | 31.5 | 29.3 | 10.4 | 1.94 | 0.31 | 0.33 | 5.88 | 31.5 | 95.5 |

| Aged | 24.4 | 24.3 | 8.51 | 1.7 | 0.199 | 0.254 | 6.69 | 33.5 | 96.1 | |||

| H5 | water | NMP/water (95/5) | As-spun | 41.1 | 36.5 | 18.2 | 3.53 | 0.51 | 0.58 | 6.10 | 31.4 | 71.4 |

| Aged | 21.6 | 21.3 | 7.84 | 1.56 | 0.198 | 0.24 | 6.50 | 32.7 | 90.0 | |||

| H6 | NMP/water (20/80) | NMP/water (95/5) | As-spun | 34.4 | 31.4 | 10.6 | 2.0 | 0.284 | 0.353 | 5.67 | 30.0 | 97.5 |

| Aged | 23.6 | 22.9 | 7.37 | 1.51 | 0.183 | 0.242 | 6.24 | 30.5 | 97.5 | |||

| H7 | NaCl/water (20/80) | NMP/water (95/5) | As-spun | 47.2 | 42.1 | 17.1 | 3.2 | 0.44 | 0.485 | 6.49 | 34.7 | 97.3 |

| Aged | 31.5 | 30.7 | 9.22 | 1.88 | 0.252 | 0.27 | 6.96 | 34.1 | 117 | |||

| H8 | EDA/water (1000 ppm) | NMP/water (95/5) | As-spun | 17 | 16.1 | 5.2 | 1.05 | 0.12 | 0.156 | 6.73 | 33.3 | 109 |

| Aged | 10.6 | 10.0 | 2.83 | 0.586 | 0.071 | 0.085 | 6.89 | 33.3 | 125 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernardo, P.; Tasselli, F.; Clarizia, G. Hollow Fiber Polyimide Membranes Prepared in a Triple Orifice Spinneret: Effect of a Reduced Water Activity in the Bore Fluid on the Gas Separation Performance. Polymers 2021, 13, 2211. https://doi.org/10.3390/polym13132211

Bernardo P, Tasselli F, Clarizia G. Hollow Fiber Polyimide Membranes Prepared in a Triple Orifice Spinneret: Effect of a Reduced Water Activity in the Bore Fluid on the Gas Separation Performance. Polymers. 2021; 13(13):2211. https://doi.org/10.3390/polym13132211

Chicago/Turabian StyleBernardo, Paola, Franco Tasselli, and Gabriele Clarizia. 2021. "Hollow Fiber Polyimide Membranes Prepared in a Triple Orifice Spinneret: Effect of a Reduced Water Activity in the Bore Fluid on the Gas Separation Performance" Polymers 13, no. 13: 2211. https://doi.org/10.3390/polym13132211

APA StyleBernardo, P., Tasselli, F., & Clarizia, G. (2021). Hollow Fiber Polyimide Membranes Prepared in a Triple Orifice Spinneret: Effect of a Reduced Water Activity in the Bore Fluid on the Gas Separation Performance. Polymers, 13(13), 2211. https://doi.org/10.3390/polym13132211