Electrical Supply Circuit for a Cold Plasma Source at Atmospheric Pressure Based on a Voltage Multiplier

Abstract

:1. Introduction

2. Materials and Methods

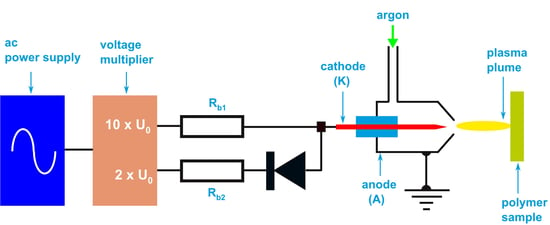

2.1. Mechanical Layout of the Plasma Source

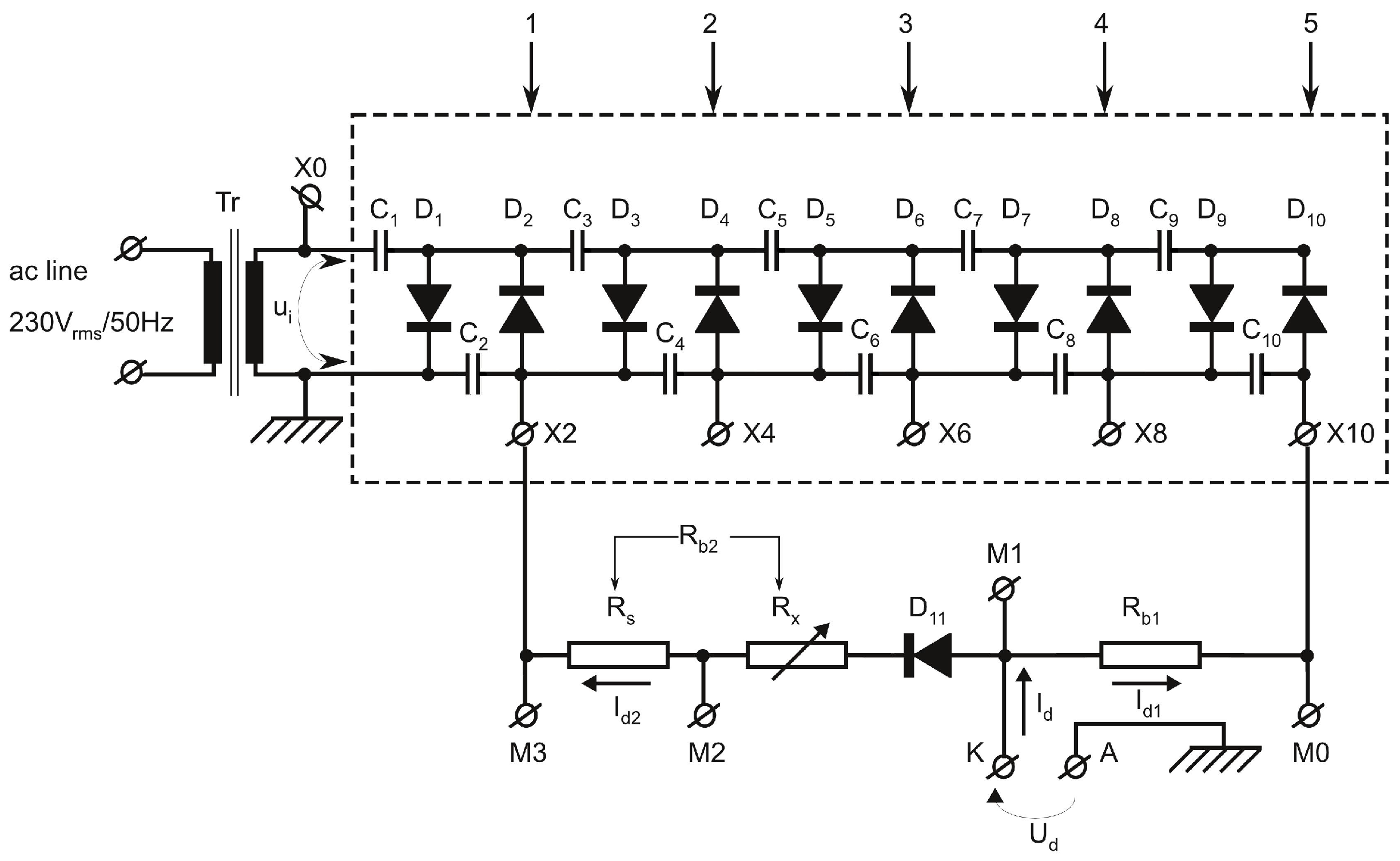

2.2. Electrical Supply Circuit

2.3. Operating Principle

3. Results

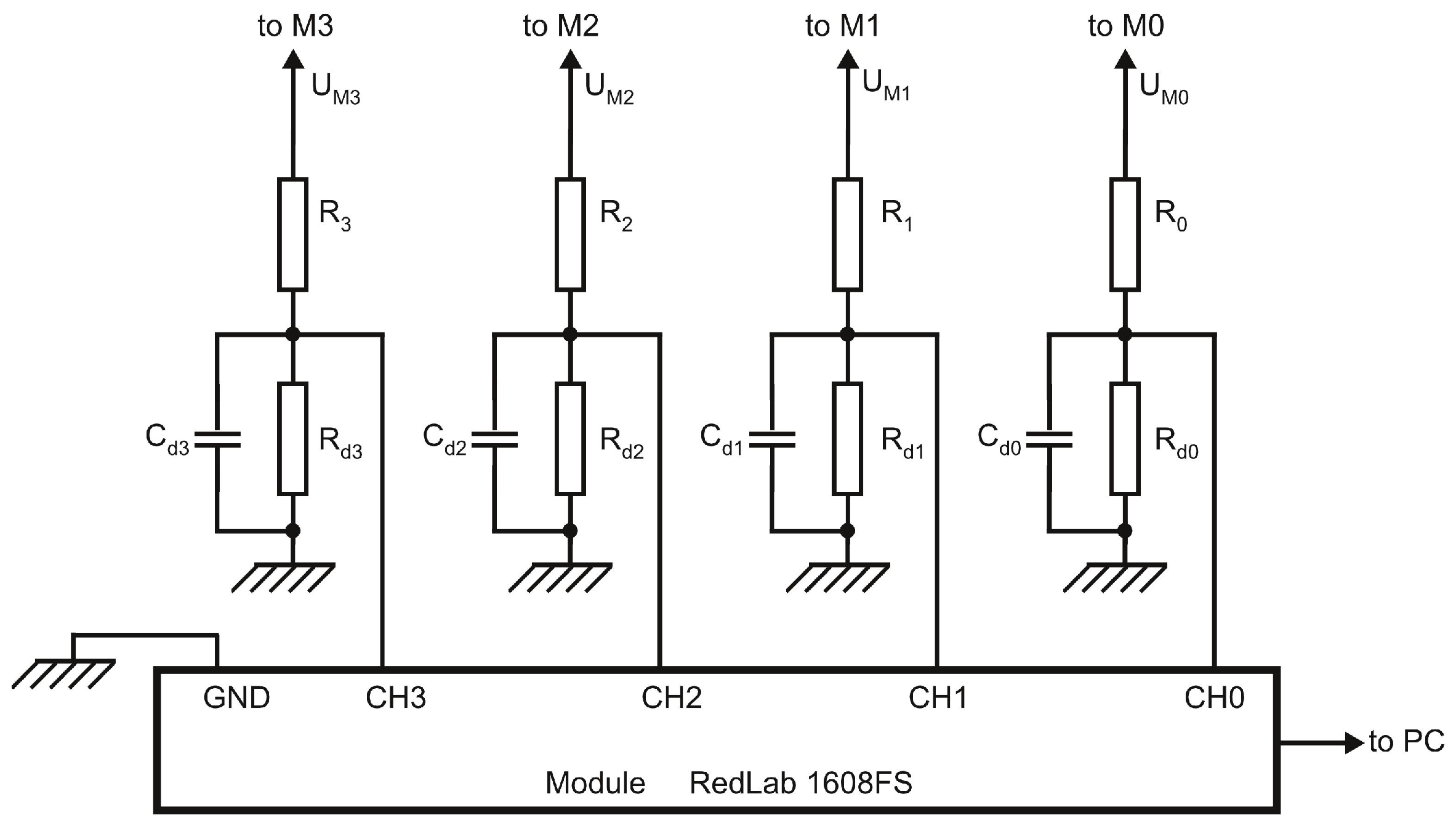

3.1. Measurement Setup

- -

- Discharge voltage representing the dc voltage applied to the cathode = ;

- -

- Voltage multiplier X10 terminal voltage equal to ;

- -

- Voltage multiplier X2 terminal voltage equal to ;

- -

- Current drawn from terminal X10 by the electrical discharge calculated as:

- -

- Current drawn from terminal X2 by the electrical discharge, calculated as:by neglecting the current through the voltage divider R–R (<0.03 mA).

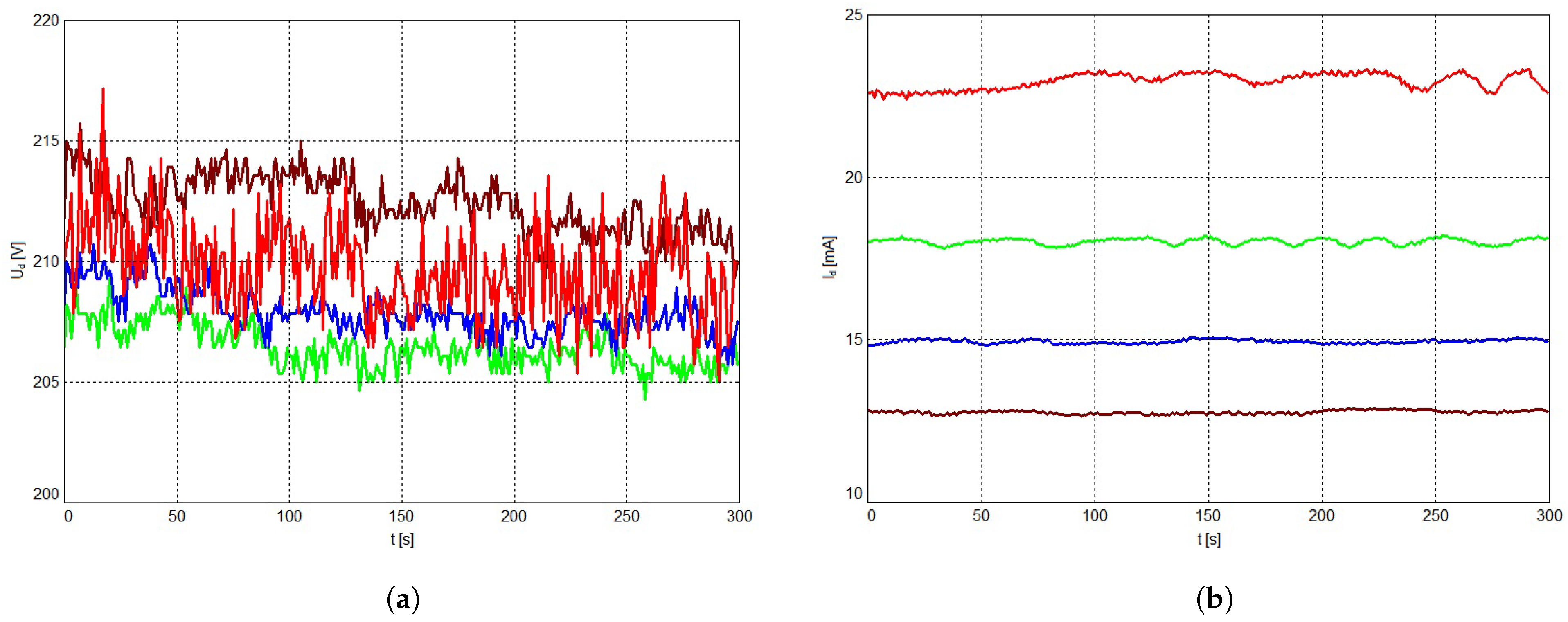

3.2. Measurement Results during a Normal Operation Regime

4. Discussion and Conclusions

- -

- The plasma generation is based on a pure dc electrical discharge. This characteristic combined with a stable regime mode allows to minimize the rf perturbations emission. Technical issues related to the matching circuits required by rf or microwave generators do not exist.

- -

- A very simple electrical supply circuit. The two dc voltage sources switch “naturally”, running simultaneously or separately, as a function of plasma electrical parameters.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Winter, J.; Brandenburg, R.; Weltmann, K.-D. Atmospheric pressure plasma jets: An overview of devices and new directions. Plasma Sources Sci. Technol. 2015, 24, 064001. [Google Scholar] [CrossRef]

- Tabares, F.L.; Junkar, I. Cold Plasma Systems and their Application in Surface Treatments for Medicine. Molecules 2021, 26, 1903. [Google Scholar] [CrossRef] [PubMed]

- Bruggeman, P.J.; Kushner, M.J.; Locke, B.R.; Gardeniers, J.G.E.; Graham, W.G.; Graves, D.B.; Hofman-Caris, R.C.H.M.; Maric, D.; Reid, J.P.; Ceriani, E.; et al. Plasma–liquid interactions: A review and roadmap. Plasma Sources Sci. Technol. 2016, 25, 053002. [Google Scholar] [CrossRef]

- Bruggeman, P.J.; Iza, F.; Brandenburg, R. Foundations of atmospheric pressure non-equilibrium plasmas. Plasma Sources Sci. Technol. 2017, 26, 123002. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, F.; Vanraes, P.; Nikiforov, A.; Morent, R.; De Geyter, N. Applications of Plasma-Liquid Systems: A Review. Materials 2019, 12, 2751. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Penkov, O.V.; Khadem, M.; Lim, W.-S.; Kim, D.-E. A review of recent applications of atmospheric pressure plasma jets for materials processing. J. Coat. Technol. Res. 2015, 12, 225–235. [Google Scholar] [CrossRef]

- Weltmann, K.-D.; Kolb, J.F.; Holub, M.; Uhrlandt, D.; Šimek, M.; Ostrikov, K.; Hamaguchi, S.; Cvelbar, U.; Černák, M.; Locke, B.; et al. The future for plasma science and technology. Plasma Process Polym. 2019, 16, e1800118. [Google Scholar] [CrossRef] [Green Version]

- Yanling, C.; Yingkuan, W.; Chen, P.; Deng, S.; Ruan, R. Non-thermal plasma assisted polymer surface modification and synthesis: A review. Int. J. Agric. Biol. Eng. 2014, 7, 1–9. [Google Scholar] [CrossRef]

- Kuettner, L.A. Use of Atmospheric-Pressure Plasma Jet for Polymer Surface Modification: An Overview. In Los Alamos National Laboratory Report LA-UR-17-22230; 2017. Available online: https://permalink.lanl.gov/object/tr?what=info:lanl-repo/lareport/LA-UR-17-22230 (accessed on 20 June 2021).

- Popelka, A.; Novák, I.; Lehocký, M.; Chodák, I.; Sedliačik, J.; Gajtanska, M.; Sedliačiková, M.; Vesel, A.; Junkar, I.; Kleinová, A.; et al. Anti-bacterial Treatment of Polyethylene by Cold Plasma for Medical Purposes. Molecules 2012, 17, 762–785. [Google Scholar] [CrossRef] [Green Version]

- Fricke, K.; Tresp, H.; Bussiahn, R.; Schröder, K.; von Woedtke, T.; Weltmann, K.-D. On the Use of Atmospheric Pressure Plasma for the Bio-Decontamination of Polymers and Its Impact on Their Chemical and Morphological Surface Properties. Plasma Chem. Plasma Process. 2012, 32, 801–816. [Google Scholar] [CrossRef]

- Pankaj, S.K.; Bueno-Ferrer, C.; Misra, N.N.; Milosavljević, V.; O’Donnell, C.P.; Bourke, P.; Keener, K.M.; Cullen, P.J. Applications of cold plasma technology in food packaging. Trends Food Sci. Technol. 2014, 35, 5–17. [Google Scholar] [CrossRef]

- Honarvar, Z.; Farhoodi, M.; Khani, M.R.; Mohammadi, A.; Shokri, B.; Ferdowsi, R.; Shojaee-Aliabad, S. Application of cold plasma to develop carboxymethyl cellulose-coated polypropylene films containing essential oil. Carbohydr. Polym. 2017, 176, 1–10. [Google Scholar] [CrossRef]

- Cheng, C.; Liye, Z.; Zhan, R.-J. Surface modification of polymer fibre by the new atmospheric pressure cold plasma jet. Surf. Coat. Technol. 2006, 200, 6659–6665. [Google Scholar] [CrossRef]

- Vishnuvarthanan, M.; Rajeswari, N. Effect of mechanical, barrier and adhesion properties on oxygen plasma surface modified PP. Innov. Food Sci. Emerg. Technol. 2015, 30, 119–126. [Google Scholar] [CrossRef]

- Zille, A.; Oliveira, F.R.; Souto, A.P. Plasma Treatment in Textile Industry. Plasma Process. Polym. 2015, 12, 98–131. [Google Scholar] [CrossRef] [Green Version]

- Wiącek, A.E.; Terpiłowski, K.; Jurak, M.; Worzakowska, M. Low-temperature air plasma modification of chitosan-coated PEEK biomaterials. Polym. Test. 2016, 50, 325–334. [Google Scholar] [CrossRef]

- Ma, C.; Wang, L.; Nikiforov, A.; Onyshchenko, Y.; Cools, P.; Ostrikov, K.; De Geyter, N.; Morent, R. Atmospheric-pressure plasma assisted engineering of polymer surfaces: From high hydrophobicity to superhydrophilicity. Appl. Surf. Sci. 2021, 535, 147032. [Google Scholar] [CrossRef]

- Dowling, D.P.; O’Neill, F.T.; Langlais, S.J.; Law, V.J. Influence of dc Pulsed Atmospheric Pressure Plasma Jet Processing Conditions on Polymer Activation. Plasma Process. Polym. 2011, 8, 718–727. [Google Scholar] [CrossRef] [Green Version]

- Abourayana, H.; Dobbyn, P.; Dowling, D. Enhancing the mechanical performance of additive manufactured polymer components using atmospheric plasma pre-treatments. Plasma Process Polym. 2018, 15, e1700141. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Verschuren, J.; De Clerck, K.; Kiekens, P.; Leys, C. Non-thermal plasma treatment of textiles. Surf. Coatings Technol. 2008, 202, 3427–3449. [Google Scholar] [CrossRef]

- Schütze, A.; Jeong, J.Y.; Babayan, S.E.; Park, J.; Selwyn, G.S.; Hicks, R.F. The Atmospheric-Pressure Plasma Jet: A Review and Comparison to Other Plasma Sources. IEEE Plasma Sci. 1998, 26, 1685–1694. [Google Scholar] [CrossRef] [Green Version]

- Bárdos, L.; Baránková, H. Plasma processes at atmospheric and low pressures. Vacuum 2009, 83, 522–527. [Google Scholar] [CrossRef]

- BY4…BY16 Datasheet. Available online: https://diotec.com/tl_files/diotec/files/pdf/datasheets/by4.pdf (accessed on 23 May 2021).

- Kuffel, E.; Zaengl, W.S.; Kuffel, J. High Voltage Engineering. Fundamentals, 2nd ed.; Butterworth-Heinemann: Woburn, MA, USA, 2000; pp. 13–21. ISBN 0 7506 3634 3. [Google Scholar]

- Iqbal, S.; Besar, R. A Bipolar Cockcroft-Walton Voltage Multiplier for Gas Lasers. Am. J. Appl. Sci. 2007, 4, 795–801. [Google Scholar] [CrossRef] [Green Version]

- Ruzbehani, M. A Comparative Study of Symmetrical Cockcroft-Walton Voltage Multipliers. J. Electr. Comput. Eng. 2017, 2017, 4805268. [Google Scholar] [CrossRef]

- Stoican, O.S. High voltage pulses circuit for generating a plasma plume at atmospheric pressure. Rom. Rep. Phys. 2019, 71, 406. [Google Scholar]

- Weltmann, K.D.; Kindel, E.; von Woedtke, T.; Hähnel, M.; Stieber, M.; Brandenburg, R. Atmospheric-pressure plasma sources: Prospective tools for plasma medicine. Pure Appl. Chem. 2010, 82, 1223–1237. [Google Scholar] [CrossRef]

- Tanaka, H.; Ishikawa, K.; Mizuno, M.; Toyokuni, S.; Kajiyama, H.; Kikkawa, F.; Metelmann, H.-R.; Hori, M. State of the art in medical applications using non-thermal atmospheric pressure plasma. Rev. Mod. Plasma Phys. 2017, 1. [Google Scholar] [CrossRef]

- Maximum Continuous Service Temperature—Plastic Properties. Available online: https://omnexus.specialchem.com/polymer-properties/properties/max-continuous-service-temperature (accessed on 20 June 2021).

- Vartiainen, J.; Rättö, M.; Tapper, U.; Paulussen, S.; Hurme, E. Surface modification of atmospheric plasma activated BOPP by immobilizing chitosan. Polym. Bull. 2005, 54, 343–352. [Google Scholar] [CrossRef]

- Szymańska, E.; Winnicka, K. Stability of Chitosan—A Challenge for Pharmaceutical and Biomedical Applications. Mar. Drugs 2015, 13, 1819–1846. [Google Scholar] [CrossRef] [PubMed]

- Dreghici, D.B.; Butoi, B.; Predoi, D.; Iconaru, S.L.; Stoican, O.; Groza, A. Chitosan–Hydroxyapatite Composite Layers Generated in Radio Frequency Magnetron Sputtering Discharge: From Plasma to Structural and Morphological Analysis of Layers. Polymers 2020, 12, 3065. [Google Scholar] [CrossRef] [PubMed]

- Nikitin, D.; Lipatova, I.; Naumova, I.; Sirotkin, N.; Pleskunov, P.; Krakovský, I.; Khalakhan, I.; Choukourov, A.; Titov, V.; Agafonov, A. Immobilization of Chitosan Onto Polypropylene Foil via Air/ Solution Atmospheric Pressure Plasma Afterglow Treatment. Plasma Chem. Plasma Process. 2020, 40, 207–220. [Google Scholar] [CrossRef]

- Nedelchev, I.Y. Stability of the Indirect Plasmatron in the Plasma Spray Coating Process. TEM J. 2016, 5, 15–20. [Google Scholar] [CrossRef]

- Schoenbach, K.H.; Becker, K. 20 years of microplasma research: A status report. Eur. Phys. J. D 2016, 70, 29. [Google Scholar] [CrossRef]

| Terminal | X2 | X10 |

|---|---|---|

| Multiple of ac input peak voltage [kV] | −1.13 | −5.66 |

| Measured voltage [kV] | ||

| Voltage dividers connected to M0 and M4. | ||

| Diode D and resistor R are disconnected. | −1.13 | −5.36 |

| Parameter Description | Symbol | Units | ||||

|---|---|---|---|---|---|---|

| 40 kΩ | 30 kΩ | 20 kΩ | 10 kΩ | |||

| Voltage at cathode (discharge voltage) | kV | −0.212 | −0.208 | −0.206 | −0.210 | |

| Voltage at terminal X10 | kV | −3.01 | −2.76 | −2.40 | −1.84 | |

| Current drawn by electrical discharge from terminal X10 | mA | 0.28 | 0.26 | 0.22 | 0.16 | |

| Voltage at terminal X2 | kV | −0.71 | −0.65 | −0.57 | −0.44 | |

| Current drawn by electrical discharge from terminal X2 (discharge current) | mA | 12.77 | 14.95 | 18.03 | 22.97 | |

| [kΩ] | [°C] | [W] |

|---|---|---|

| 10 | 96 | 4.8 |

| 20 | 78 | 3.7 |

| 30 | 68 | 3.1 |

| 40 | 58 | 2.7 |

| Relative Deviation | ||||

|---|---|---|---|---|

| 40 kΩ | 30 kΩ | 20 kΩ | 10 kΩ | |

| 1.6 | 1.4 | 1.4 | 3.6 | |

| 1.0 | 0.9 | 1.3 | 2.5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoican, O.S. Electrical Supply Circuit for a Cold Plasma Source at Atmospheric Pressure Based on a Voltage Multiplier. Polymers 2021, 13, 2132. https://doi.org/10.3390/polym13132132

Stoican OS. Electrical Supply Circuit for a Cold Plasma Source at Atmospheric Pressure Based on a Voltage Multiplier. Polymers. 2021; 13(13):2132. https://doi.org/10.3390/polym13132132

Chicago/Turabian StyleStoican, Ovidiu S. 2021. "Electrical Supply Circuit for a Cold Plasma Source at Atmospheric Pressure Based on a Voltage Multiplier" Polymers 13, no. 13: 2132. https://doi.org/10.3390/polym13132132

APA StyleStoican, O. S. (2021). Electrical Supply Circuit for a Cold Plasma Source at Atmospheric Pressure Based on a Voltage Multiplier. Polymers, 13(13), 2132. https://doi.org/10.3390/polym13132132