1. Introduction

In order to influence the biodistribution of drug-loaded micro- and nanoparticles in pharmaceutics and the targeting, release profile, and bioavailability of the drug, the ability to precisely manipulate size, shape, and surface properties of the particles is important [

1,

2]. Similarly, the composition, size and shape of a metallic nanoparticle dictate the resonant frequency of the electron oscillation in localized surface plasmonics. This phenomenon is used in detecting analytes bound to molecules immobilized on the metallic particle, which is applied in biosensors, immunoassays, and spectroscopy [

3,

4]. Thus, novel applications in drug delivery, tissue engineering, and biosensing are pushing towards novel fabrication techniques. These techniques can produce specifically designed particles, with additional functionalities and sensitive cargos such as drugs or biomolecules [

5,

6].

Non-spherical microparticles with precisely controlled physical and chemical properties have been conventionally fabricated by using.

Microelectromechanical systems (MEMS) and semiconductor technologies such as photolithography and dry etching [

7,

8]. However, these processes are expensive, have low throughput, and can sometimes degrade the cargo in the particle susceptible to UV light or high processing temperatures. Soft lithography is an alternative approach for non-spherical microparticle fabrication [

9]. It is an umbrella term for various prototyping methods such as microcontact printing, replica molding, microtransfer molding, micromolding in capillary (MIMIC), solvent-assisted Micromolding, and more recently particle replication in non-wetting template (PRINT) [

10,

11]. The common feature for all the aforementioned processes is the application of a “soft” deformable mold made of materials such as polydimethylsiloxane (PDMS) for printing, embossing, or molding of the microparticle material. However, such a mold is susceptible to damage already after a few runs of processing. In order to address this limitation for microparticle fabrication, hot punching was developed [

12]. In this method, the particle material was prepared on a deformable substrate and patterned by a durable Ni mold instead of a deformable mold [

12]. This allowed for large-scale fabrication of high aspect ratio reservoir-based particles for oral drug delivery, declared as microcontainers, in biodegradable and biocompatible polymers [

13,

14]. However, the application of heat during hot punching of microparticles for drug delivery can lead to degradation of sensitive cargo included in the microparticles such as biomolecule drugs. Furthermore, heating typically implies longer processing time and requires more advanced microfabrication equipment.

Another common feature of soft lithography and hot punching methods is the manipulation of some form of ink or liquid/semi-liquid precursor solution as material for microparticle fabrication. Alternatively, the microparticle material can be a solid sheet that can be deformed and cut to fabricate microparticles with desired structures and dimensions. This new perspective of handling the microparticle layer as a deformable sheet is inspired by a high throughput macromanufacturing technique called punching or blanking that has been used for metal sheet forming for hundreds of years. Blanking and punching are shearing processes in which a punch and die are used to modify webs [

15].

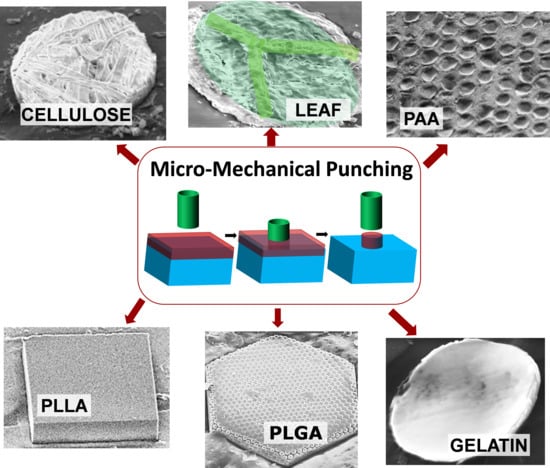

Inspired by the punching process, we introduce Micromechanical Punching (MMP) as a simple, benign, and fast process for fabrication of microparticles. Here, we demonstrate the concept and potential of MMP by fabrication of a variety of microparticles with different materials that can potentially be used for a wide array of applications. Finally, as an illustrative example, we show the application of MMP to produce poly(lactic-co-glycolic acid) (PLGA) microparticles loaded with Furosemide (Furo) for oral drug delivery.

2. Materials and Methods

2.1. Materials

Dichloromethane (DCM) (anhydrous >99.8%), Poly-ɛ-caprolactone (PCL) pellets (average Mw~100,000), Poly(acrylic acid) (PAA) solution (average Mw~100,000, 35 wt.% in H2O), Acetone (>99.5% purity), and gelatin powder were obtained from Sigma-Aldrich (Copenhagen, Denmark). Phosphate buffer saline (PBS) tablets and Furosemide (≥98% purity) acquired from Sigma-Aldrich (St. Louis, MO, USA). Milli-Q water was obtained from MilliQ Integral Water Purication System for Ultrapure Water, manufactured by Merck Millipore (Burlington, MA, USA). Poly(Lactic-co-glycolic acid) (PLGA) 50:50 (acid end cap, Mn 85,000–100,000 g/mol) was obtained from Akina, IN, US. Poly(L-lactic acid) (PLLA) 2003D grade is purchased from Natureworks (Minnetonka, MN, USA), with Mw = 126,000 Da, determined by size exclusion chromatography measurements. Polytetrafluoroethylene sheets (PTFE sheet of Fluoroplast, opaque) were bought from RS Components A/S. Cellulose weighing paper was acquired from VWR European. Co-extruded polyethylene (PE) and polypropylene (PP) films were obtained by Inmold A/S.

2.2. Scanning Electron Microscopy and Stylus Profilometry

A TM3030Plus (Hitachi, Japan) tabletop SEM was used for scanning electron microscopy (SEM). The micrographs were obtained at an operating voltage of 15 KV in charge reduction mode using mixed secondary electrons (SE) and backscattered electron (BSE) detector signal.

The thicknesses of the PLGA-Furo films were measured using KLA-Tencor Alpha Step IQ stylus profilometer (Milpitas, CA, USA). The thickness of the film was measured by mechanically removing a part of the coated area to expose the substrate beneath. Then the thickness was measured by doing step height analysis. An average of five thickness measurements on the PLGA-Furo film is reported here.

2.3. Film Production Using Blade Coating

For blade coating, first, a homogenous solution of polymer or polymer–drug was prepared. The homogenous solution of biocompatible and biodegradable polymers like PCL, PLLA, and PLGA was prepared as 10 wt.% in DCM solvent. The water soluble polymers like gelatin and PAA were dissolved as 5 wt.% concentration solutions. These solutions were dispensed on an Erichson blade coating machine, and the blade height was adjusted as per the thickness required. PCL, PLLA, and PLGA solutions were coated with blade height ≈ 0.5 mm, while gelatin and PAA solutions were coated with blade height ≈ 0.1 mm. The blade was then moved at a slow speed of 0.5 m/min. The film was left overnight for solvent evaporation. The films were either directly prepared on the deformable substrate or were coated on a PTFE sheet and peeled later.

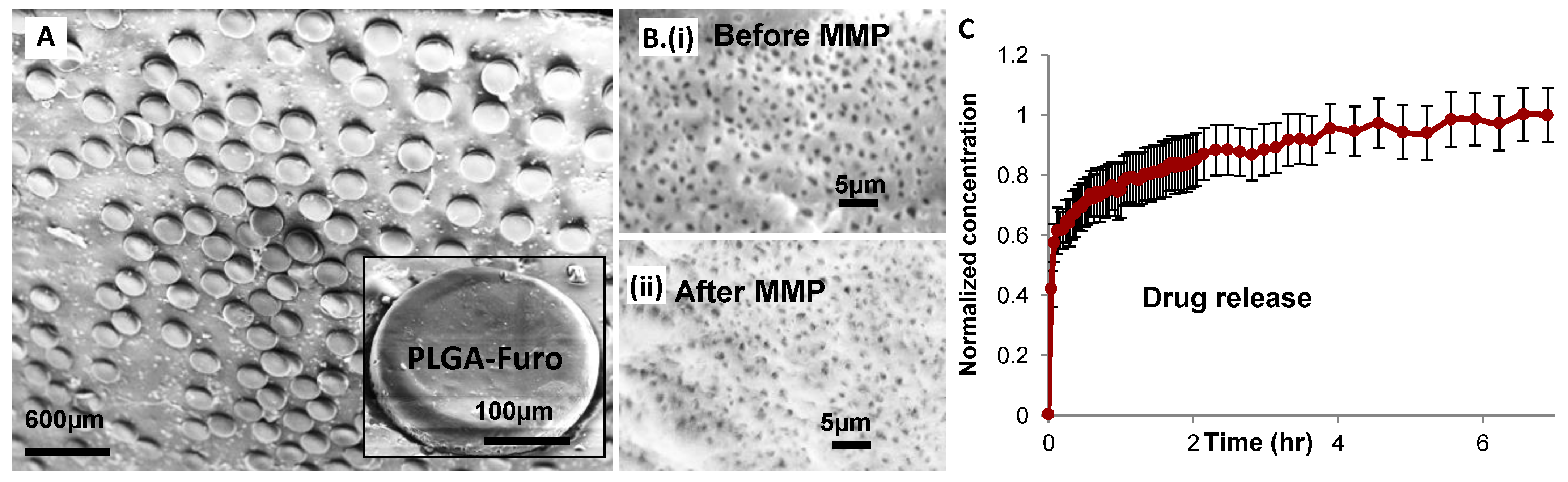

In order to prepare PLGA-Furo films for the in vitro release of Furosemide from PLGA, a homogenous solution of 10 wt.%, consisting of 1:5 Furosemide to PLGA in acetone and DCM, was prepared. The solution was blade coated on a PTFE sheet and left overnight at room temperature for solvent evaporation. This resulted in a 40 ± 4 µm thick PLGA-Furo film. The film was peeled from the PTFE sheet and transferred to a PP sheet.

2.4. Preparation of Formulation: Capsule Loading

First the lid of the rat capsule is weighed without any microparticles. Then, the cap of the capsule is taken off and the capless capsule is placed in a capsule holder. The particles lying on the deformable substrate were scraped off by a lab knife and gently nudged in a funnel that sits on the top of a stainless steel holder. The holder is specifically designed for the capsule in terms of shape and size. A funnel is then placed on this holder and then the microparticles are scraped off the deformable substrate with the help of a lab knife. The scraped microparticles are allowed to fall on the funnel in order to fill the capsule. Sometimes the microparticles clogging the funnel hole are gently nudged in the capsule by a piston. During and after the filling of the capsule, it is weighed with the cap on. Approximately 0.5 mg of particles was weighed in the capsules for the in vitro release studies.

2.5. In Vitro Release of Furosemide from PLGA Matrix

In vitro drug release was measured in dissolution studies performed with a microdissolution profiler [

16]. The PLGA-Furo particles were filled in the rat gelatin capsules and placed in the glass vials filled with 10 mL of phosphate buffer (pH 7.5) solution (PBS). The gelatin capsules are predominantly dissolved within few seconds of being placed in the PBS media. Experiments were performed at 37 °C using a stirring rate of 200 rpm. The path length of UV probes was chosen as 20 mm on the µDiss profiler (Pion, United Kingdom). Standard curve for the calibration of the channels was performed prior to the release experiments. For the standard curve, Furosemide in milliQ (pH = 10) stock solution was prepared. A fixed amount of this solution was added to 10 mL of PBS. The defined concentration was measured by detecting the UV absorbance from the added analyte in the stock solution. After the calibration of the channels, the actual experiment was performed with the capsules by scanning the samples by the in situ UV probes every 30 s with a run time of 7 h. The release experiments are expressed as normalized (to the maximum drug released after 7 h) drug release over time. The experiments were performed in 6 replicates from 3 independent productions within a week of film and particle formation.

2.6. Micromechanical Punching (MMP)

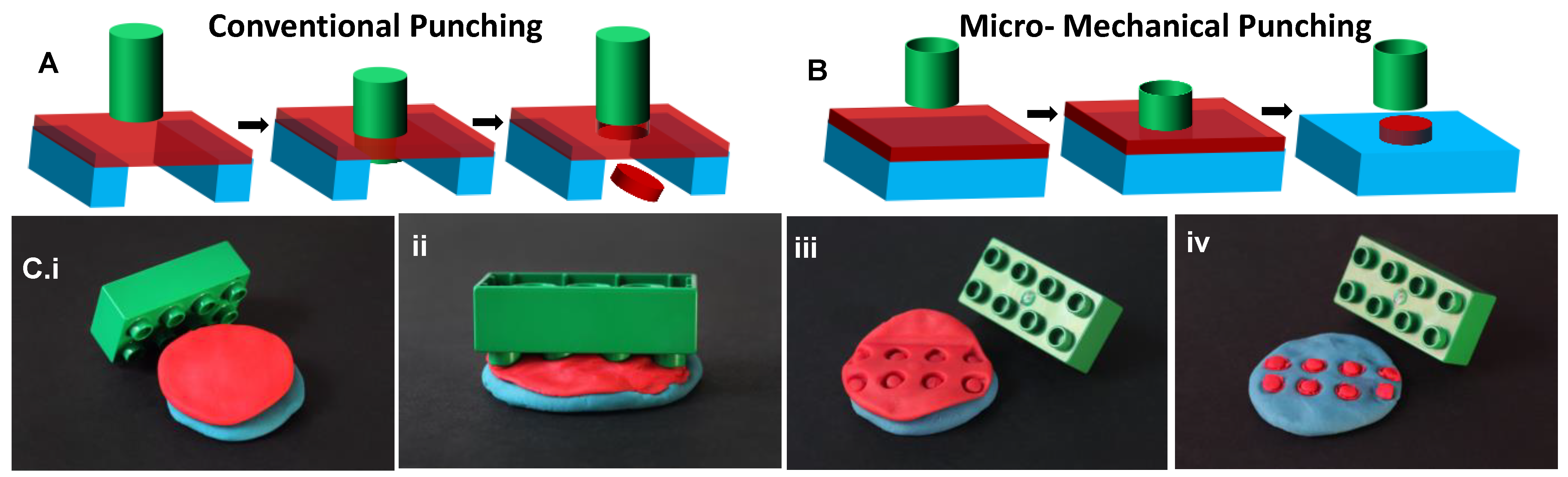

The conventional punching or blanking process includes three basic steps illustrated in

Figure 1A: (1) A metal sheet is positioned on an inflexible die. (2) The punch and the metal sheet are brought into contact by the application of a high force. The penetration of the punch into the voids of the die results in build-up of stresses in the metal sheet with the maximum stress located at the edges of the punch. When the maximum stress exceeds the ultimate tensile strength of the metal, the metal sheet below the punch is cut free from the surrounding metal. (3) Finally, the punch and the die are separated [

15].

The two significant differences of the proposed MMP process compared to the conventional punching technique are the utilization of a deformable substrate and a hollow punch. In MMP, the microparticle layer is placed on a deformable substrate in the form of a solid material sheet. This flexible stack of the substrate and the microparticle layer is punched by a hard but hollow punch or mold. During MMP, the cutting or indentation of the microparticle layer by the hollow mold and the final punching of the microparticle layer occur in a single step, leading to the fabrication of microparticles of controlled shapes, sizes, and surface topography (

Figure 1B,C).

The MMP process starts with the preparation of the deformable substrate, the microparticle layer, and the hard mold (

Figure 1(Ci)). For the deformable substrate, compression molded or extruded polymer sheets, solution-casted cross-linked PDMS layers, commercially available aluminum (Al) sheets, or polymer films prepared from solutions by spin coating, blade coating, or spray coating are suitable [

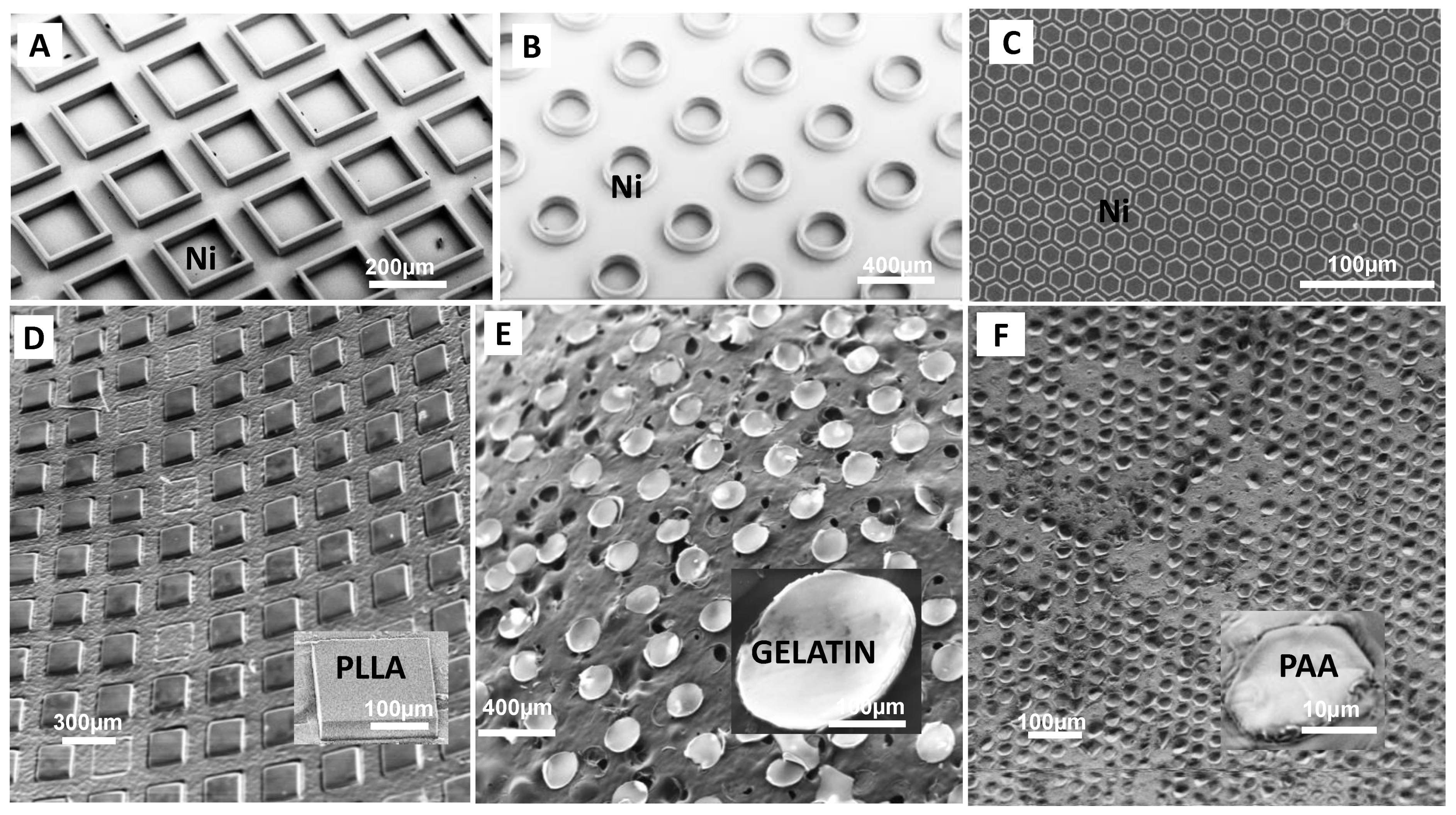

17]. As high pressure is applied during mechanical punching, a robust deformable substrate is important. For example, a PDMS substrate succumbs under 5 bars platen pressure while a polyethylene (PE) substrate can tolerate platen pressures >20 bars. The microparticle layer can be materials, ranging from polymers and gels to metals. At room temperature any material which is not too ductile as poly-ε-caprolactone and too brittle as ceramics can be mechanically punched. However, in principle, ductile materials can be frozen and brittle materials can be processed at elevated temperatures for successful punching. The microparticle layer can be directly deposited on the deformable substrate by above mentioned coating techniques or prepared separately and then transferred to the deformable substrate before MMP. Finally, MMP requires a robust mold that does not succumb under the pressure applied. The mold consists of large arrays of protruding walls around a cavity of desired size and shape, as shown in

Figure 1(B,Ci). In general, the mold material should have a higher hardness than the other materials in the stack. Molds with sharp protrusions are required for easy punching, while mold features with low roughness and slightly positive sidewall angles are necessary for easy demolding after the MMP process. The mold protrusions should be higher than the thickness of the material layer to allow for complete punching.

After preparation of the mold, the material layer and the deformable substrate are prepared. The complete stack is placed in a parallel plate (P2P) embosser. High pressure is applied on the stack in order to punch the microparticle layer (

Figure 1(Cii)). After the punching process, the mold is separated from the microparticle layer (

Figure 1(Ciii)). The leftover film in between the punched particles is peeled from the substrate (

Figure 1(Ciii)) and the microparticles either remain on the deformable substrate (

Figure 1(Civ,D)) or are transferred to the mold. In the latter case, another step of bonding or particle transfer to a desired substrate is performed. The micromechanical punching was performed using the hot embosser (Collin

® Press, Ebersberg, Germany, 300 SV). The particles were generally punched at pressures >20 bars for 1 min.

4. Conclusions

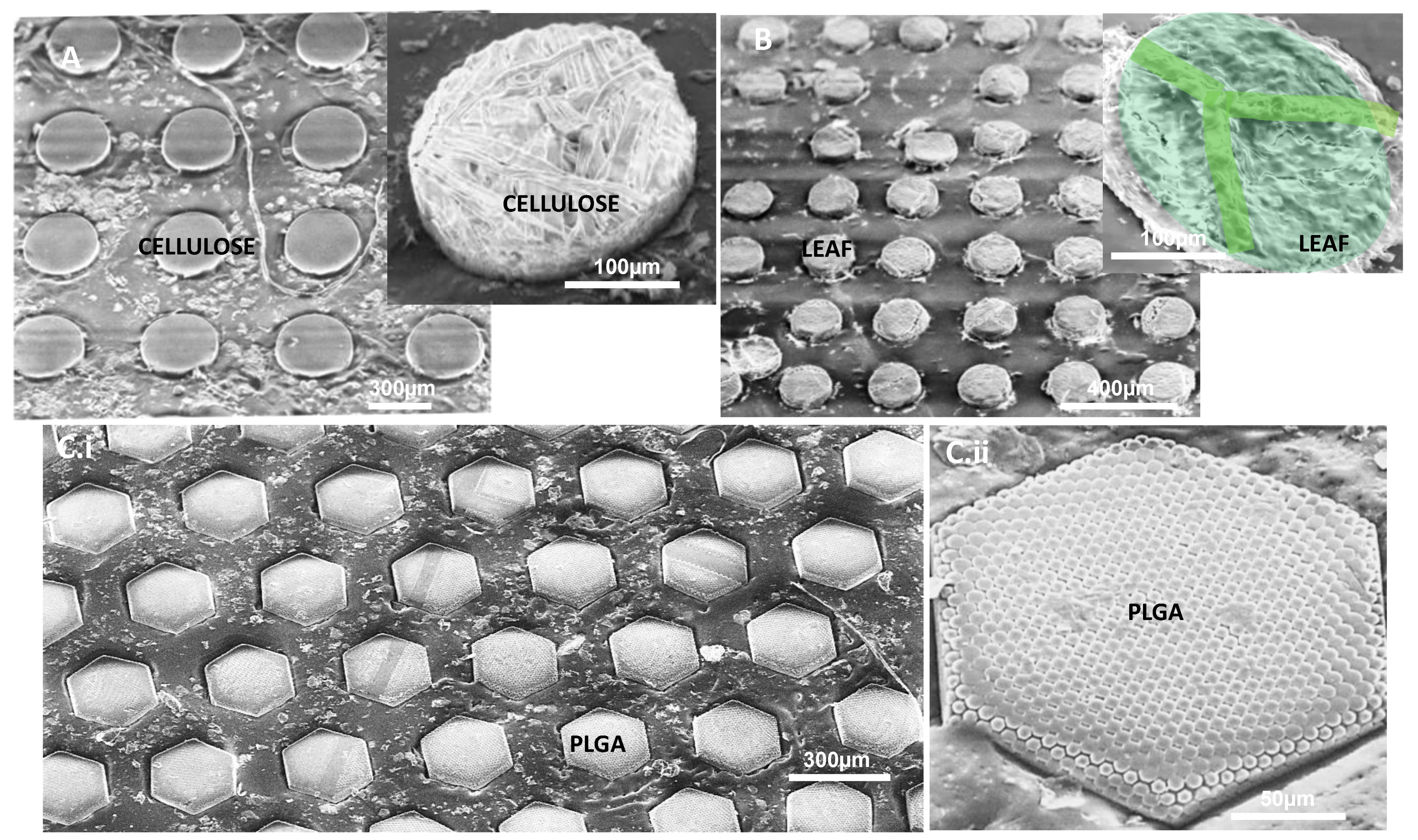

In this paper, the Micromechanical Punching (MMP) process is introduced for the fabrication of microparticles. Microparticles of various shapes and sizes, made up of biodegradable and biocompatible polymers like PCL, PLGA, and PLLA and water-soluble polymers like gelatin and PAA, have been successfully fabricated using MMP. It is also demonstrated that MMP can be used for punching prepatterned, fibrous or porous films to successfully fabricate hierarchal/patterned, fibrous, or porous microparticles, respectively. Some of the examples shown in the paper are punching of fibrous cellulose sheet, Fagus sylvatica leaf and hexagon- patterned PLGA films. Finally, using MMP, Furosemide (Furo)-containing PLGA microparticles are fabricated with uniform size and shape. In vitro release studies are conducted on these PLGA-Furo particles. Successful release of Furosemide from PLGA matrix is shown depicting the viability of using MMP for drug delivery applications.

MMP is a low cost, single-step process that can be scaled up to roll-to-roll production, which in principle can be completely solvent-free. In future, it would be interesting to develop this technology to fabricate nanoparticles that can be applied for future applications in biotechnology and photonics. Investigation into the effect of pressure on thin film materials, 2D materials, and sensitive cargos embedded in the films will be interesting as well as required for applications like drug delivery and tissue engineering. Micromechanical Punching has potential to obtain widespread application in academic laboratories and industrial scale manufacturing around the world due to the simplicity of its execution on practically any conceivable material that can be acquired as a sheet or can be applied on a substrate film.