Investigation of Roughness Correlation in Polymer Brushes via X-ray Scattering

Abstract

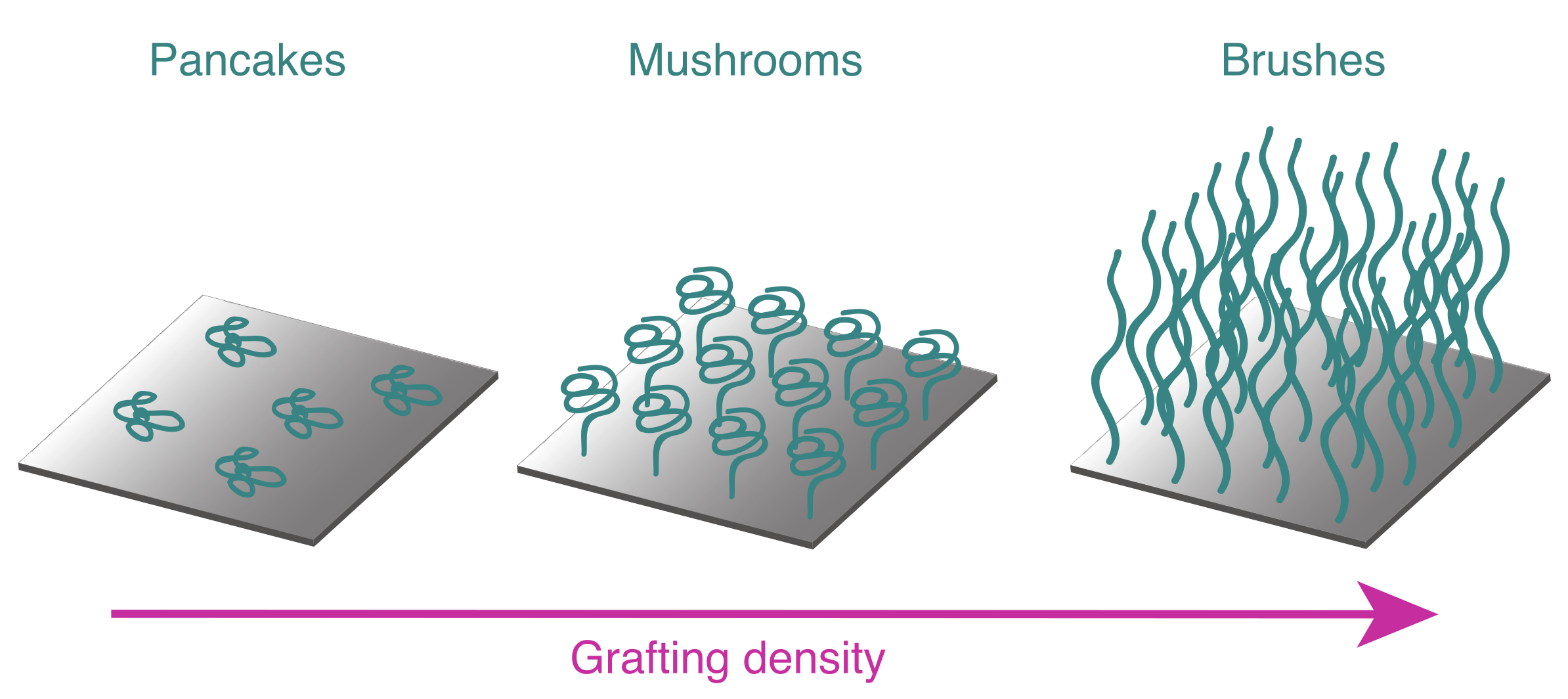

1. Introduction

2. Materials and Methods

2.1. Immobilization of APDMES on Silicon Wafer

2.2. Synthesis of 2-Bromo-2-methyl-N-[3-(dimethylsilylethoxy)propyl] on Silicon Substrates

2.3. Synthesis of PMMA Brushes

2.4. Synthesis of PS Brushes and PMMA-b-PS Brushes

2.5. Spin-Coating Procedure for Polymer Thin Films

2.6. Film Thickness Determination with Ellipsometry

2.7. AFM Characterization

2.8. XRR Measurements

2.9. GISAXS Measurements

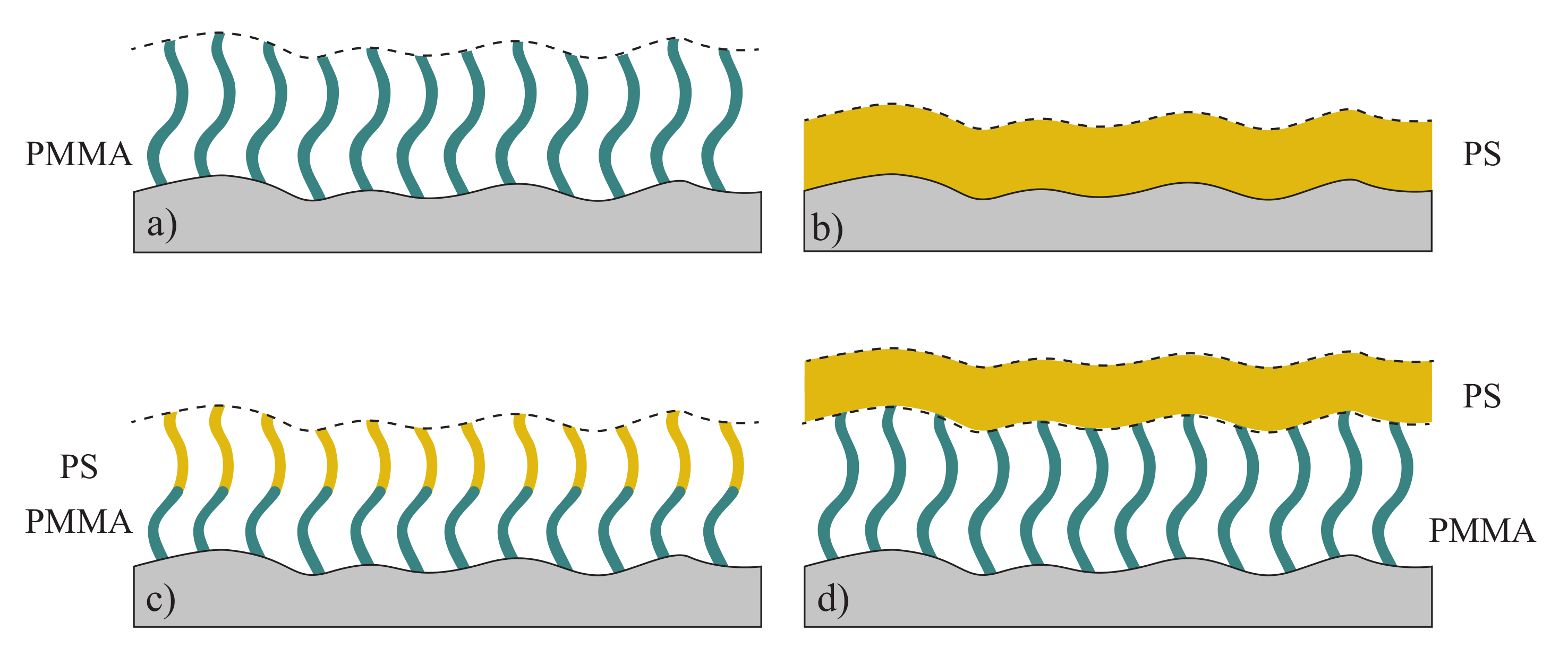

3. Results and Discussion

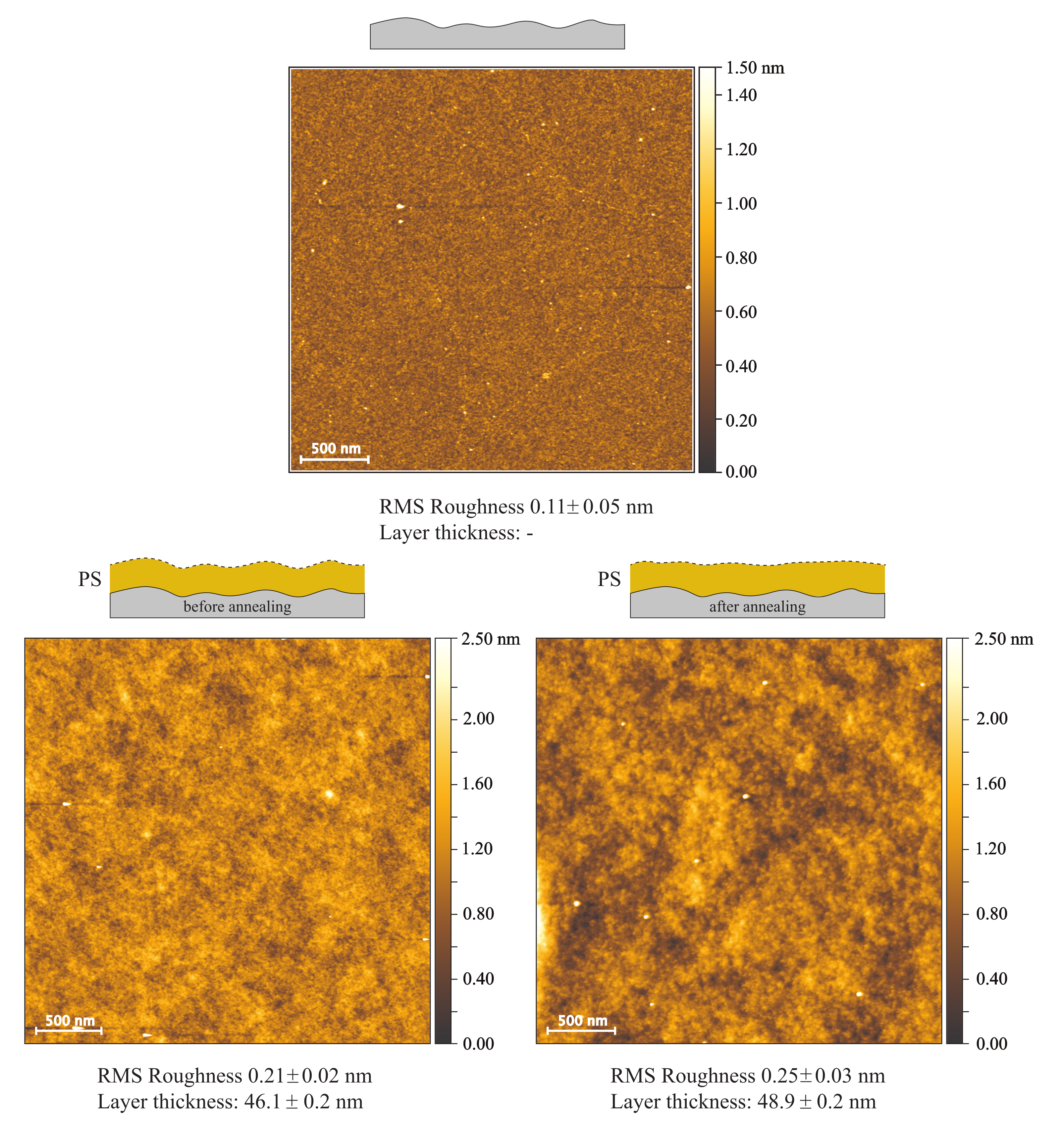

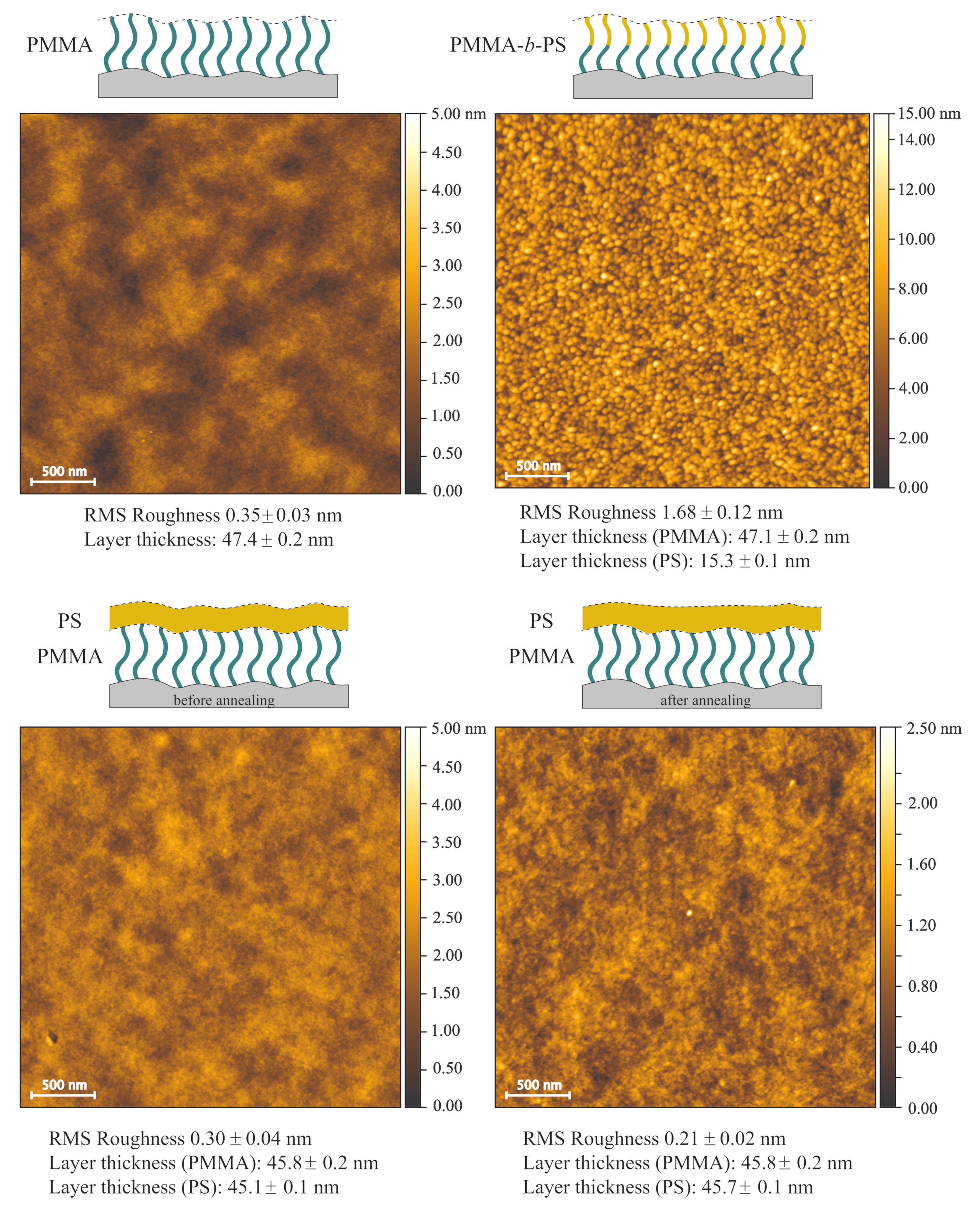

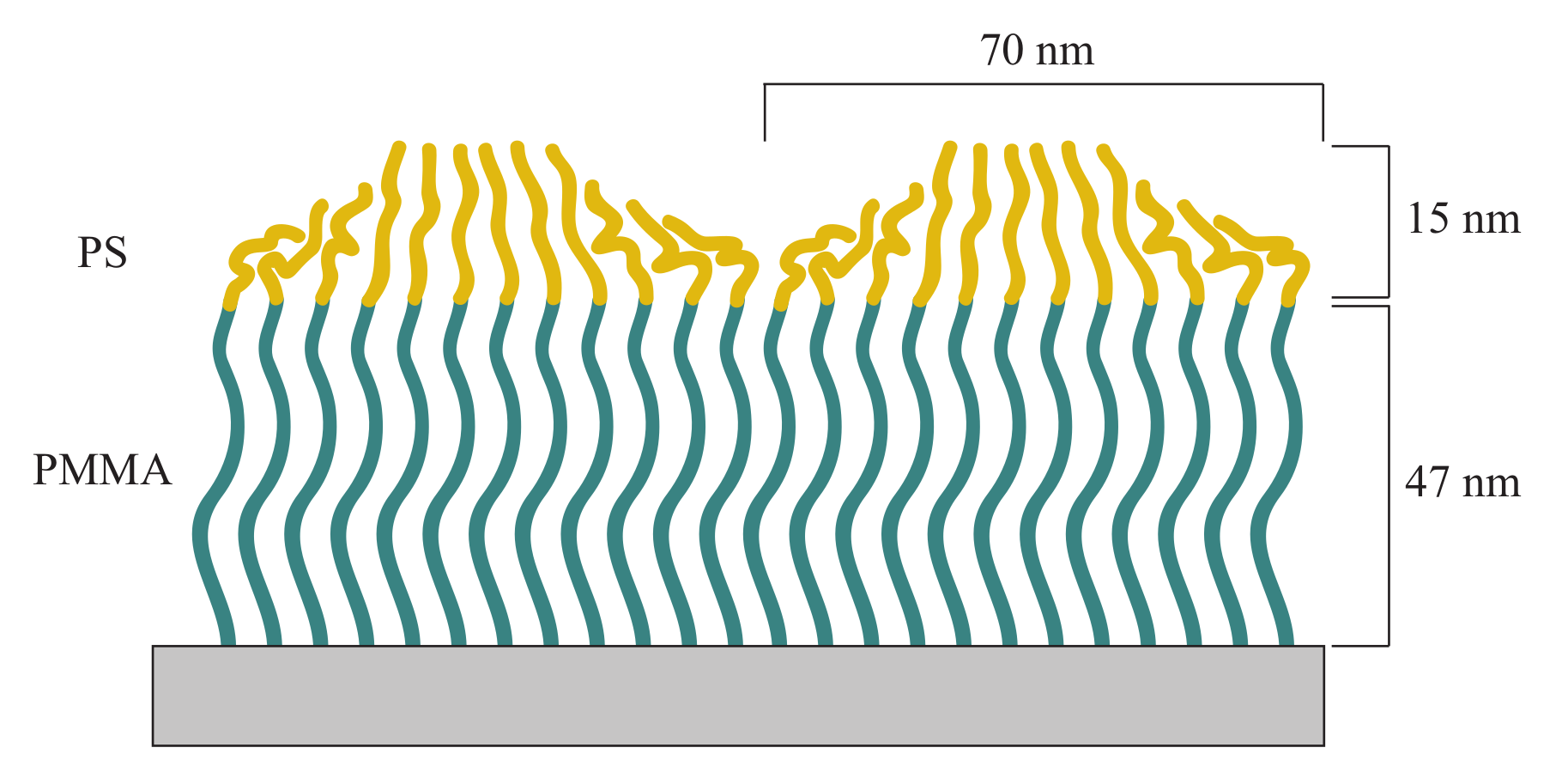

3.1. AFM Analysis of the Surface Structure

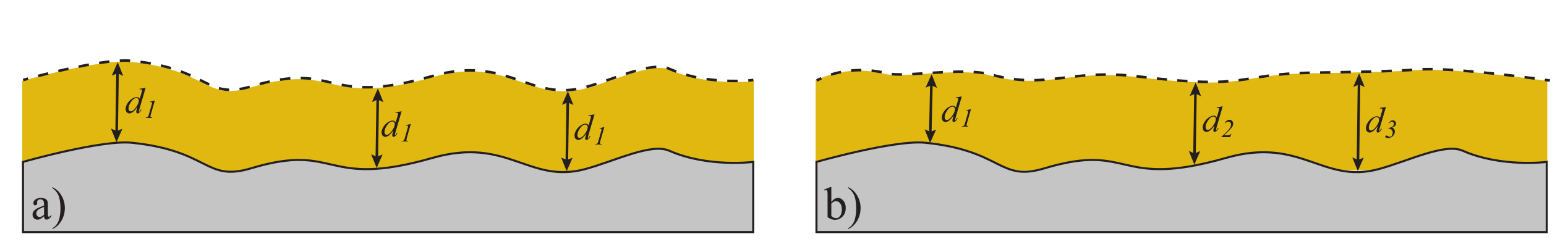

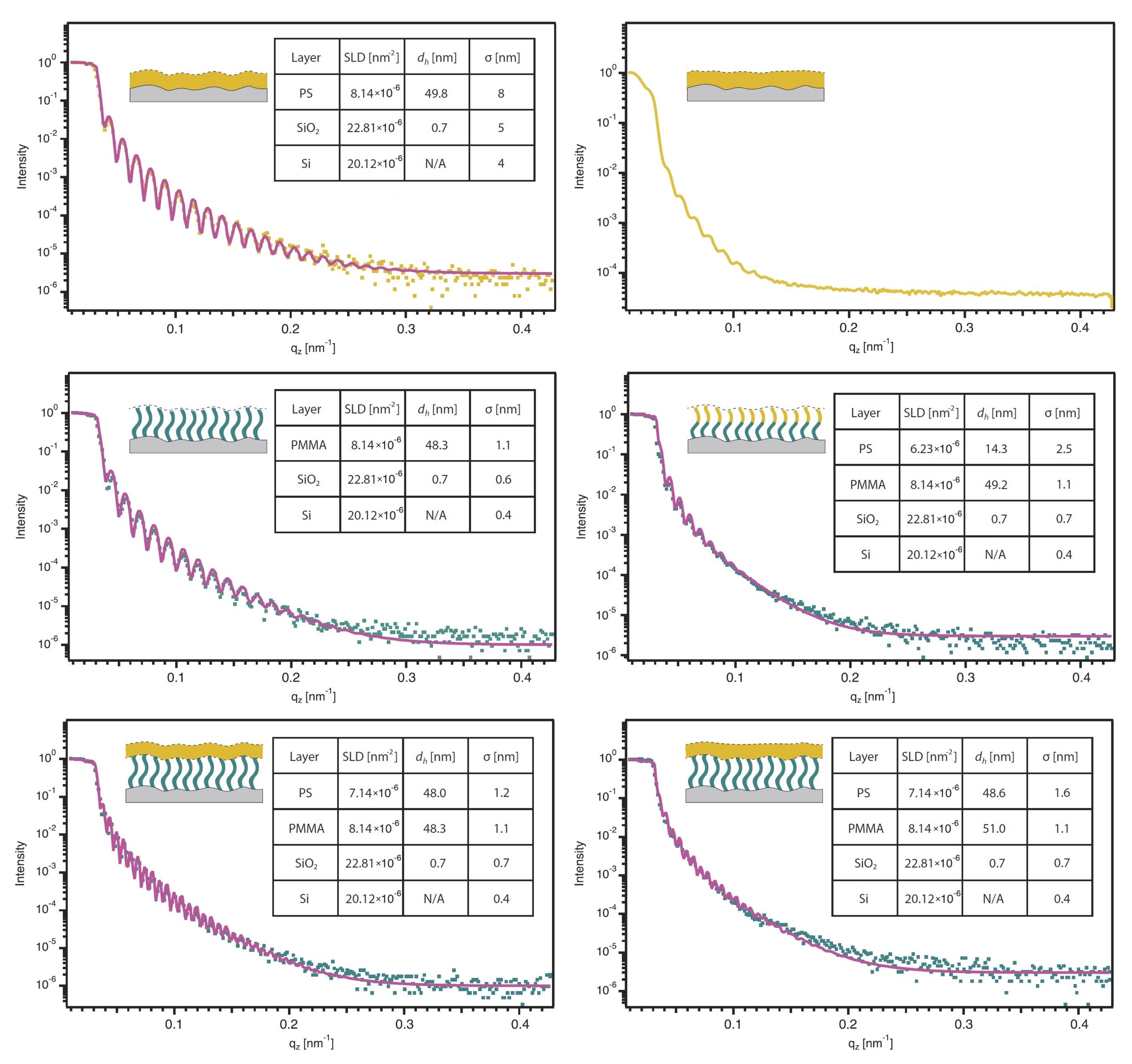

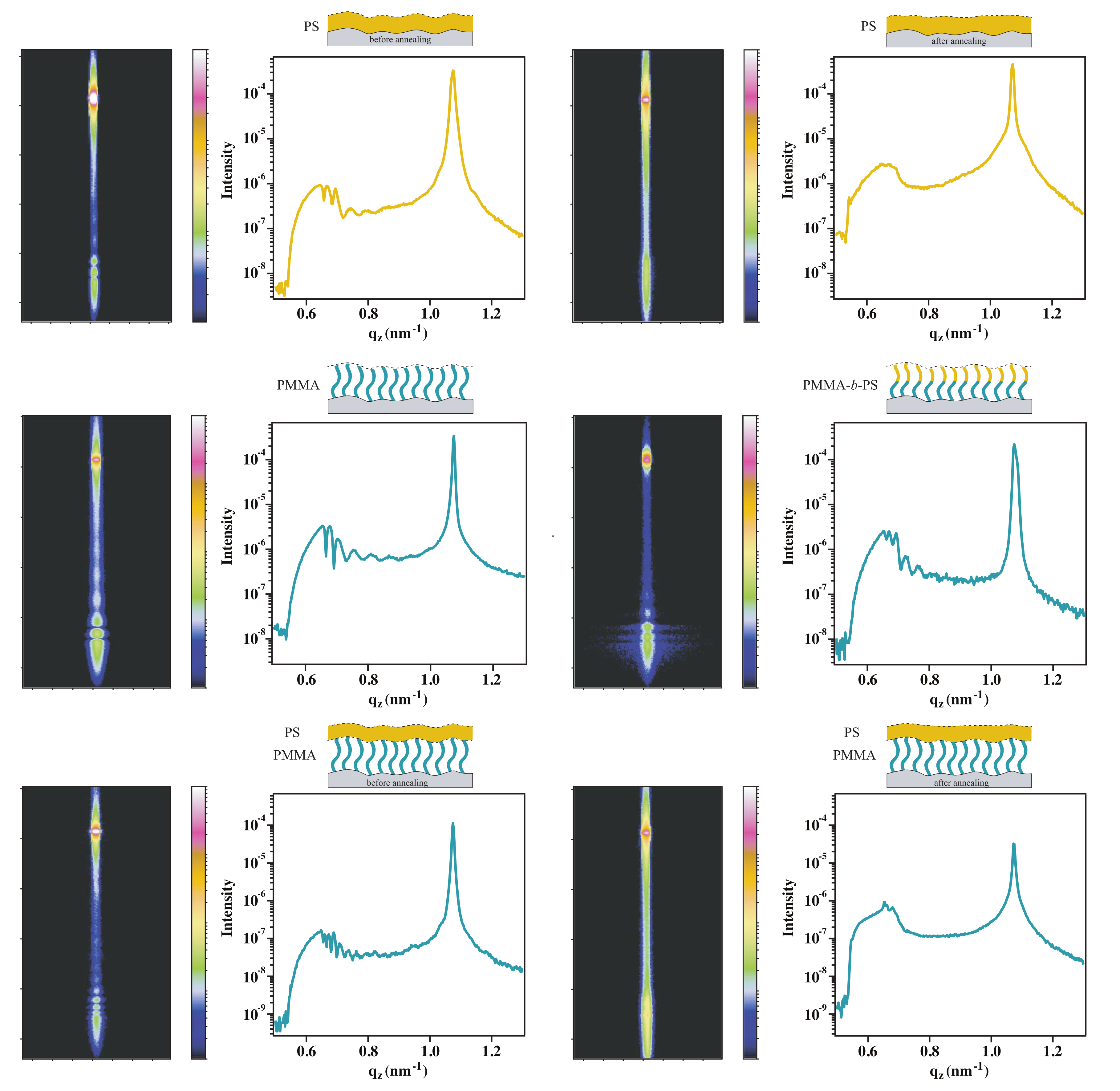

3.2. XRR Experiments on Polymer Thin Films

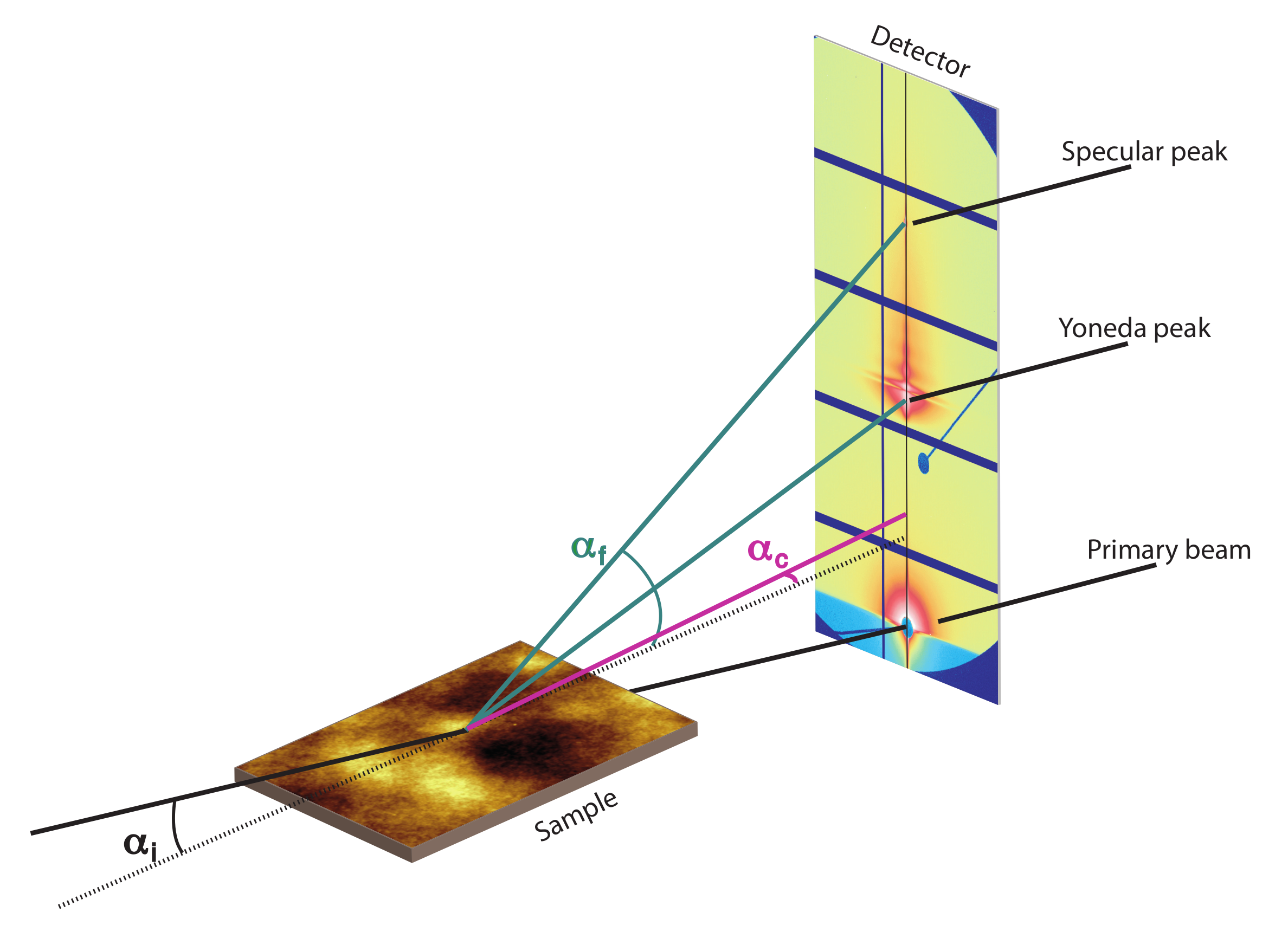

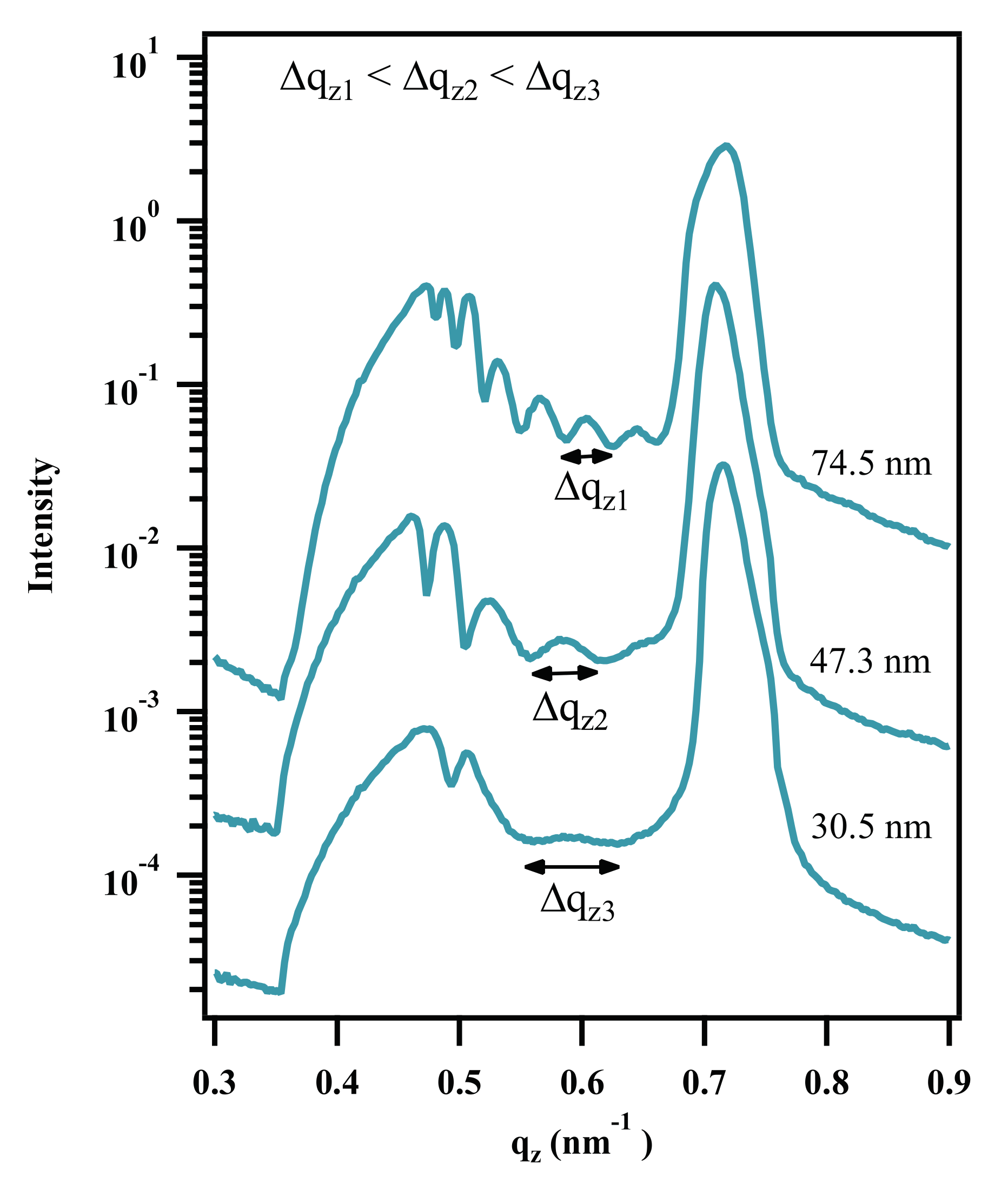

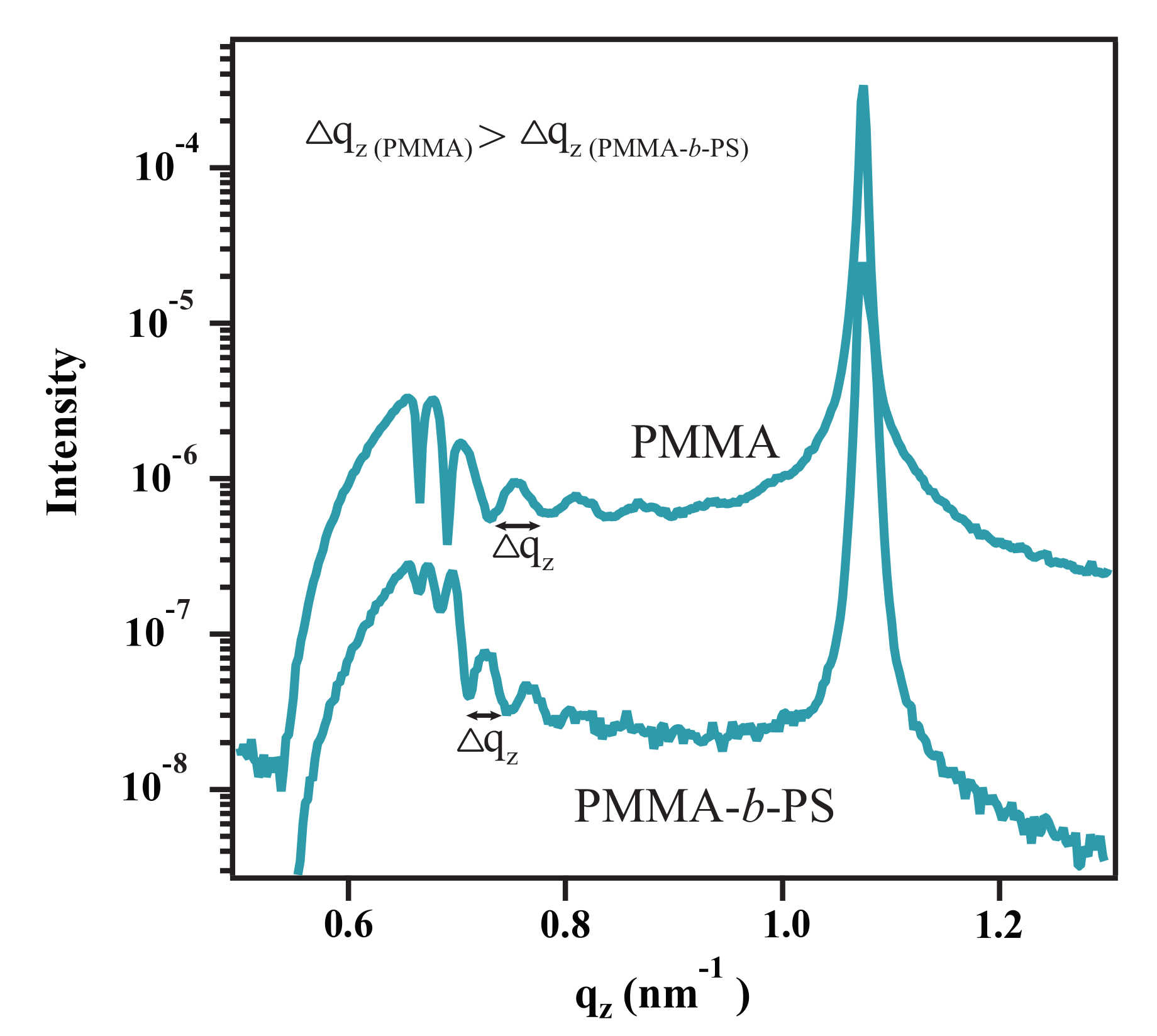

3.3. GISAXS Studies on Polymer Thin Films

4. Summary

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barbey, R.; Lavanant, L.; Paripovic, D.; Schüwer, N.; Sugnaux, C.; Tugulu, S.; Klok, H.A. Polymer Brushes via Surface Initiated Controlled Radical Polymerization: Synthesis, Characterization, Properties, and Applications. Chem. Rev. 2009, 109, 5437–5527. [Google Scholar] [CrossRef] [PubMed]

- Zoppe, J.O.; Ataman, N.C.; Mocny, P.; Wang, J.; Moraes, J.; Klok, H.-A. Surface-Initiated Controlled Radical Polymerization: State-of-the-Art, Opportunities, and Challenges in Surface and Interface Engineering with Polymer Brushes. Chem. Rev. 2017, 117, 1105–1318. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.; Xu, J.; Buchanan, R.C. Surface roughness: A review of its measurement at micro-/nano-scale. Phys. Sci. Rev. 2018, 3, 20170057. [Google Scholar] [CrossRef]

- Gibaud, A. Specular Reflectivity from Smooth and Rough Surfaces. In X-ray and Neutron Reflectivity; Daillant, J., Gibaud, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 85–131. [Google Scholar]

- Vancso, G.J.; Schönherr, H. Scanning Force Microscopy of Polymers; Vancso, G.J., Schönherr, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Russell, T. On the reflectivity of polymers: Neutrons and X-rays. Phys. B Condens. Matter 1996, 221, 267–283. [Google Scholar] [CrossRef]

- Tidswell, I.M.; Rabedeau, T.A.; Pershan, P.S.; Kosowsky, S.D. Complete wetting of a rough surface: An X-ray study. Phys. Rev. Lett. 1991, 66, 2108–2111. [Google Scholar] [CrossRef]

- Smilgies, D.; Müller-Buschbaum, P.; Papadakis, C.M.; Posselt, D. Characterization of polymer thin films with small-angle X-ray scattering under grazing incidence (GISAXS). Synchrotron Radiat. News 2002, 15, 35–42. [Google Scholar] [CrossRef]

- Holy, V.; Baumbach, T.; Bessiere, M. Interface roughness in surface-sensitive X-ray methods. J. Phys. D Appl. Phys. 1995, 28, A220–A226. [Google Scholar] [CrossRef]

- Holy, V.; Baumbach, T. Nonspecular x-ray reflection from rough multilayers. Phys. Rev. B 1994, 49, 10668–10676. [Google Scholar] [CrossRef]

- Baumbach, G.; Holy, V.; Pietsch, U.; Gailhanou, M. The influence of specular interface reflection on grazing incidence X-ray diffraction and diffuse scattering from superlattices. Phys. B Condens. Matter 1994, 198, 249–252. [Google Scholar] [CrossRef]

- Hexemer, A.; Müller-Buschbaum, P. Advanced grazing incidence techniques for modern soft matter materials analysis. IUCrJ 2015, 1, 106–125. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P. Grazing incidence small-angle X-ray scattering: An advanced scattering technique for the investigation of nanostructured polymer films. Anal. Bioanal. Chem. 2003, 376, 3–10. [Google Scholar] [CrossRef]

- Yoneda, Y. Anomalous Surface Reflection of X Rays. Phys. Rev. 1963, 131, 2010–2013. [Google Scholar] [CrossRef]

- Gutmann, J.S.; Müller-Buschbaum, P.; Schubert, D.; Stribeck, N.; Smilgies, D.; Stamm, M. Roughness correlations in ultra-thin polymer blend films. Phys. B Condens. Matter 2000, 283, 40–44. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Gutmann, J.S.; Lorenz-Haas, C.; Mahltig, B.; Stamm, M.; Petry, W. Early Stages of Film Creation in Thin Diblock Copolymer Films. Macromolecules 2001, 34, 7463–7470. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Gutmann, J.S.; Stamm, M. Dewetting of confined polymer films: An X-ray and neutron scattering study. Chem. Rev. 1999, 1, 3857–3863. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Gutmann, J.S.; Lorenz, C.; Schmitt, T.; Stamm, M. Decay of Interface Correlation in Thin Polymer Films. Macromolecules 1998, 31, 9265–9272. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Stamm, M. Correlated Roughness, Long-Range Correlations, and Dewetting of Thin Polymer Films. Macromolecules 1998, 31, 3686–3692. [Google Scholar] [CrossRef]

- Alexander, S. Adsorption of chain molecules with a polar head a scaling description. J. Phys. 1977, 38, 983–987. [Google Scholar] [CrossRef]

- De Gennes, P.G. Conformation of a polymer chain in certain mixed solvents. J. Phys. Lett. 1976, 37, 59–61. [Google Scholar] [CrossRef][Green Version]

- De Gennes, P.G. Conformations of Polymers Attached to an Interface. Macromolecules 1980, 13, 1069–1075. [Google Scholar] [CrossRef]

- De Gennes, P.G. Scaling Concepts in Polymer Physics; Cornell University Press: Ithaca, NY, USA, 1979; p. 324. [Google Scholar]

- De Gennes, P.G. Scaling theory of polymer adsorption. J. Phys. France 1976, 37, 1445–1452. [Google Scholar] [CrossRef]

- Milner, S.T.; Witten, T.A.; Cates, M.E. Theory of the grafted polymer brush. Macromolecules 1988, 21, 2610–2619. [Google Scholar] [CrossRef]

- Milner, S.T. Polymer Brushes. Science 1991, 251, 905–914. [Google Scholar] [CrossRef] [PubMed]

- Milner, S.T.; Witten, T.A.; Cates, M.E. A Parabolic Density Profile For Grafted Polymers. Europhys. Lett. 1988, 5, 413–418. [Google Scholar] [CrossRef]

- Matyjaszewski, K.; Miller, P.J.; Shukla, N.; Immaraporn, B.; Gelman, A.; Luokala, B.B.; Siclovan, T.M.; Kickelbick, G.; Vallant, T.; Hoffmann, H.; et al. Polymers at Interfaces, Using Atom Transfer Radical Polymerization in the Controlled Growth of Homopolymers and Block Copolymers from Silicon Surfaces in the Absence of Untethered Sacrificial Initiator. Macromolecules 1999, 32, 8716–8724. [Google Scholar] [CrossRef]

- Akgun, B.; Brittain, W.J.; Li, X.; Wang, J.; Foster, M.D. Interface Roughness Correlation in Diblock Copolymer Brushes Synthesized by Atom Transfer Radical Polymerization. Macromolecules 2005, 38, 8614–8616. [Google Scholar] [CrossRef]

- Kim, H.; Foster, M.; Müller-Buschbaum, P.; Zhang, H.; Prucker, O.; Rühe, J.; Pfütze, G.; Cunis, S.; Gehrke, R. Roughness Correlation of Polymer Brushes. In HASYLAB Annual Report; Deutsches Elektronen Synchrotron (DESY): Hamburg, Germany, 2001. [Google Scholar]

- Schubert, D.W. Spin coating as a method for polymer molecular weight determination. Polym. Bull. 1997, 38, 177–184. [Google Scholar] [CrossRef]

- Parratt, L.G. Surface Studies of Solids by Total Reflection of X-rays. Phys. Rev. 1954, 95, 359–369. [Google Scholar] [CrossRef]

- Jülich Centre for Neutron Science. GALAXI: Gallium anode low-angle x-ray instrument. J. Large-Scale Res. Facil. 2016, 2, A61. [Google Scholar] [CrossRef]

- Ochsmann, J. Stress and Structure of thin Polymer Brush Films. PhD Thesis, Johannes Gutenberg Universiät Mainz, Mainz, Germany, 2012. [Google Scholar]

- Zhao, B.A. Combinatorial Approach to Study Solvent-Induced Self-Assembly of Mixed Poly(methyl methacrylate)/Polystyrene Brushes on Planar Silica Substrates: Effect of Relative Grafting Density. Langmuir 2004, 20, 11748–11755. [Google Scholar] [CrossRef]

- Flory, P.J. Thermodynamics of High Polymer Solutions. J. Chem. Phys. 1942, 10, 51–61. [Google Scholar] [CrossRef]

- Huggins, M.L. Theory of Solutions of High Polymers. J. Am. Chem. Soc. 1942, 64, 1712–1719. [Google Scholar] [CrossRef]

- Russell, T.P.; Hjelm, R.P.; Seeger, P.A. Temperature dependence of the interaction parameter of polystyrene and poly(methyl methacrylate). Macromolecules 1990, 23, 890–893. [Google Scholar] [CrossRef]

- Shull, K.R. Mean-field theory of block copolymers: Bulk melts, surfaces and thin films. Macromolecules 1992, 25, 2122–2133. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hildebrandt, M.; Shin, E.-y.; Yang, S.; Ali, W.; Altinpinar, S.; Gutmann, J.S. Investigation of Roughness Correlation in Polymer Brushes via X-ray Scattering. Polymers 2020, 12, 2101. https://doi.org/10.3390/polym12092101

Hildebrandt M, Shin E-y, Yang S, Ali W, Altinpinar S, Gutmann JS. Investigation of Roughness Correlation in Polymer Brushes via X-ray Scattering. Polymers. 2020; 12(9):2101. https://doi.org/10.3390/polym12092101

Chicago/Turabian StyleHildebrandt, Marcus, Eui-young Shin, Suan Yang, Wael Ali, Sedakat Altinpinar, and Jochen S. Gutmann. 2020. "Investigation of Roughness Correlation in Polymer Brushes via X-ray Scattering" Polymers 12, no. 9: 2101. https://doi.org/10.3390/polym12092101

APA StyleHildebrandt, M., Shin, E.-y., Yang, S., Ali, W., Altinpinar, S., & Gutmann, J. S. (2020). Investigation of Roughness Correlation in Polymer Brushes via X-ray Scattering. Polymers, 12(9), 2101. https://doi.org/10.3390/polym12092101